Page 1

INSTALLATION MANUAL

BASIC INSTALLATION

RACK-MOUNTED EMERGENCY PA SYSTEM

MODEL NUMBERS : FS-971

FS-972

FS-973

FS-970 SERIES

Installation Precautions (For Sales Shops and Installers)

• When inspecting the speaker line insulation, disconnect the speaker lines from the PA system.

• If the system's fire alarm (EL) and fire confirmation signal (EF) terminals are connected during a

dielectric strength test of the relay contact of a fire alarm system or other external systems, this

can cause damage to the PA system.

Page 2

2

1. SAFETY PRECAUTIONS

.............................................................................................................

4

2. SUPPLIED MANUALS

..................................................................................................................

6

3. BEFORE STARTING INSTALLATION

3.1. System Summary ...........................................................................................................................

7

3.2. About the Emergency Power Supply

3.2.1. Selection of the emergency power supply panel and battery ..............................................

8

3.2.2. DC power supply panel expansion ......................................................................................

8

4. NI-CD BATTERY REPLACEMENT

...........................................................................................

9

5. INSTALLATION PROCEDURES

................................................................................................

10

6. EQUIPMENT RACK ASSEMBLY AND INSTALLATION

6.1. Poor Installation Locations ..............................................................................................................

11

6.2. Rack Assembly ...............................................................................................................................

11

6.3. Rack Installation .............................................................................................................................

12

6.4. Securing the Rack CR-272 or CR-412 to the Floor ........................................................................

12

6.5. Securing the Rack CR-412-6 to the Floor ......................................................................................

13

6.6. Securing the Rack to the Wall (for Prevention of the Fall) ..............................................................

13

6.7. Rack Suspension using Eyebolts ...................................................................................................

14

6.8. Fine Height Adjustment of the Installed Rack .................................................................................

14

6.9. Grounding .......................................................................................................................................

14

7. BEFORE MOUNTING THE COMPONENTS IN THE RACK

7.1. Integrated Control Panel EP-0510 ..................................................................................................

15

7.2. Pre-amplifier Panel PP-025B ..........................................................................................................

16

8. COMPONENT INSTALLATION

8.1. Integrated Control Panel .................................................................................................................

18

8.2. Junction Panel ................................................................................................................................

18

8.3. Emergency Power Supply Panel ....................................................................................................

19

8.4. DC Power Supply Panel .................................................................................................................

19

8.5. Power Amplifier Panel Mounting Position .......................................................................................

20

TABLE OF CONTENTS

Page 3

3

9. RACK INTER-PANEL CONNECTION

9.1. FS-971 System Panel Connection Diagram ...................................................................................

21

9.2. Pre-amplifier Panel PP-025B Connection .......................................................................................

22

9.3. Power Amplifier Panel Connection .................................................................................................

23

9.4. Emergency Power Supply Panel DS-029B Connection

9.4.1. Battery connection ...............................................................................................................

24

9.4.2. About the Emergency Power Supply Panel's (DS-029B's) terminals ..................................

24

9.4.3. About the operation of the Emergency Power Supply Panel DS-029B ...............................

25

9.4.4. Connections .........................................................................................................................

27

9.4.5. Connecting a single emergency power supply panel to power amplifiers ...........................

31

9.5. Junction Panel JP-0410 Connection

9.5.1. Connecting the Junction Panel's rear-mounted terminal block ............................................

32

9.5.2. Connecting the AC power supply of the Junction Panel JP-0410 .......................................

33

9.6. DC Power Supply Panel Connection

9.6.1. When the DC power supply panel is not required

(i.e. when you can do with the junction panel's internal power supply).... ...........................

34

9.6.2. When expanding the power supply for external equipment .................................................

35

9.6.3. When expanding the power supply for internal equipment ..................................................

35

9.6.4. Connection between DC power supply panel and Expansion Operation Panel EP-029 .....

36

9.6.5. Connection between DC power supply panel and Expansion Junction Panel JP-039 ........

37

10. SETTING OF THE INTEGRATED CONTROL PANEL EP-0510

......................................

38

11. EXPANSION PANEL ADDRESS SETTING

11.1. Expansion Operation Panel EP-029 .............................................................................................

41

11.2. Expansion Junction Panel JP-039 ................................................................................................

41

12. CONNECTING THE RACK-MOUNTED COMPONENTS TO EXTERNAL LINES

12.1. Names of the Front-Mounted Terminal of the Junction Panel JP-0410 ........................................

42

12.2. AC Power Supply Connections .....................................................................................................

42

12.3. Speaker Connections ...................................................................................................................

43

12.4. Connections to the Automatic Fire Alarm Systems ......................................................................

44

13. CONNECTION INSPECTION

13.1. Inspection of Connections and Wiring ..........................................................................................

45

13.2. Adjustment and Measurement of Power Circuitry

13.2.1. AC line insulation measurement (using megger) ...............................................................

45

13.2.2. Power voltage measurement (using tester) .......................................................................

45

13.3. Speaker Line Adjustment and Measurement

13.3.1. Speaker line impedance measurement (using impedance meter) ....................................

46

13.3.2. Speaker line insulation resistance measurement (Measuring instrument: Megger) ..........

47

13.4. Speaker Sound Pressure Level Measurement .............................................................................

48

14. POWER-ON AND INSPECTION

................................................................................................

48

15. SPECIFICATIONS OF THE MAIN RACK COMPONENTS

................................................

49

Page 4

4

When Installing the Unit

• Do not expose the unit to rain or an environment

where it may be splashed by water or other liquids,

as doing so may result in fire or electric shock.

• Use the unit only with the voltage specified on the

unit. Using a voltage higher than that which is

specified may result in fire or electric shock.

• Do not cut, kink, otherwise damage nor modify the

power supply cord. In addition, avoid using the

power cord in close proximity to heaters, and never

place heavy objects -- including the unit itself -- on

the power cord, as doing so may result in fire or

electric shock.

• Ensure that the voltage selector is properly set to

the local power voltage. Wrong settings may cause

a fire or electric shock.

When the Unit is in Use

• Should the following irregularity be found during

use, immediately switch off the AC breaker and

contact your nearest TOA dealer. Make no further

attempt to operate the unit in this condition as this

may cause fire or electric shock.

· If you detect smoke or a strange smell coming

from the unit.

· If water or any metallic object gets into the unit

· If the unit falls, or the unit case breaks

· If the power supply cord is damaged (exposure of

the core, disconnection, etc.)

· If it is malfunctioning (no tone sounds.)

• To prevent a fire or electric shock, never open nor

remove the unit case as there are high voltage

components inside the unit. Refer all servicing to

your nearest TOA dealer.

• Do not place cups, bowls, or other containers of

liquid on top of the rack. If they accidentally spill

into the mounted units, this may cause a fire or

electric shock.

• Do not insert nor drop metallic objects or

flammable materials in the ventilation slots of the

unit's cover, as this may result in fire or electric

shock.

1. SAFETY PRECAUTIONS

• Be sure to read the instructions in this section carefully before use.

• Make sure to observe the instructions in this manual as the conventions of safety symbols and messages

regarded as very important precautions are included.

• We also recommend you keep this instruction manual handy for future reference.

Safety Symbol and Message Conventions

Safety symbols and messages described below are used in this manual to prevent bodily injury and property

damage which could result from mishandling. Before operating your product, read this manual first and

understand the safety symbols and messages so you are thoroughly aware of the potential safety hazards.

WARNING

Indicates a potentially hazardous situation which, if mishandled, could

result in death or serious personal injury.

Indicates a potentially hazardous situation which, if mishandled, could

result in moderate or minor personal injury, and/or property damage.

WARNING

CAUTION

Page 5

5

When Installing the Unit

• Never plug in nor remove the power supply plug

with wet hands, as doing so may cause electric

shock.

• Do not block the upper panel ventilation slots in the

unit's cover. Doing so may cause heat to build up

inside the unit and result in fire.

• Avoid installing the unit in humid or dusty locations,

in locations exposed to the direct sunlight, near the

heaters, or in locations generating sooty smoke or

steam as doing otherwise may result in fire or

electric shock.

When the Unit is in Use

• Make sure to observe the following handling

precautions so that a fire or personal injury does

not result from leakage or explosion of the battery.

· Do not short, disassemble, heat nor put the

battery into a fire.

· Do not solder a battery directly.

· Be sure to use the specified type of batteries.

· Note correct polarity (positive and negative

orientation) when installing a battery in the unit.

· Avoid locations exposed to the direct sunlight,

high temperature and high humidity when storing

batteries.

CAUTION

Page 6

6

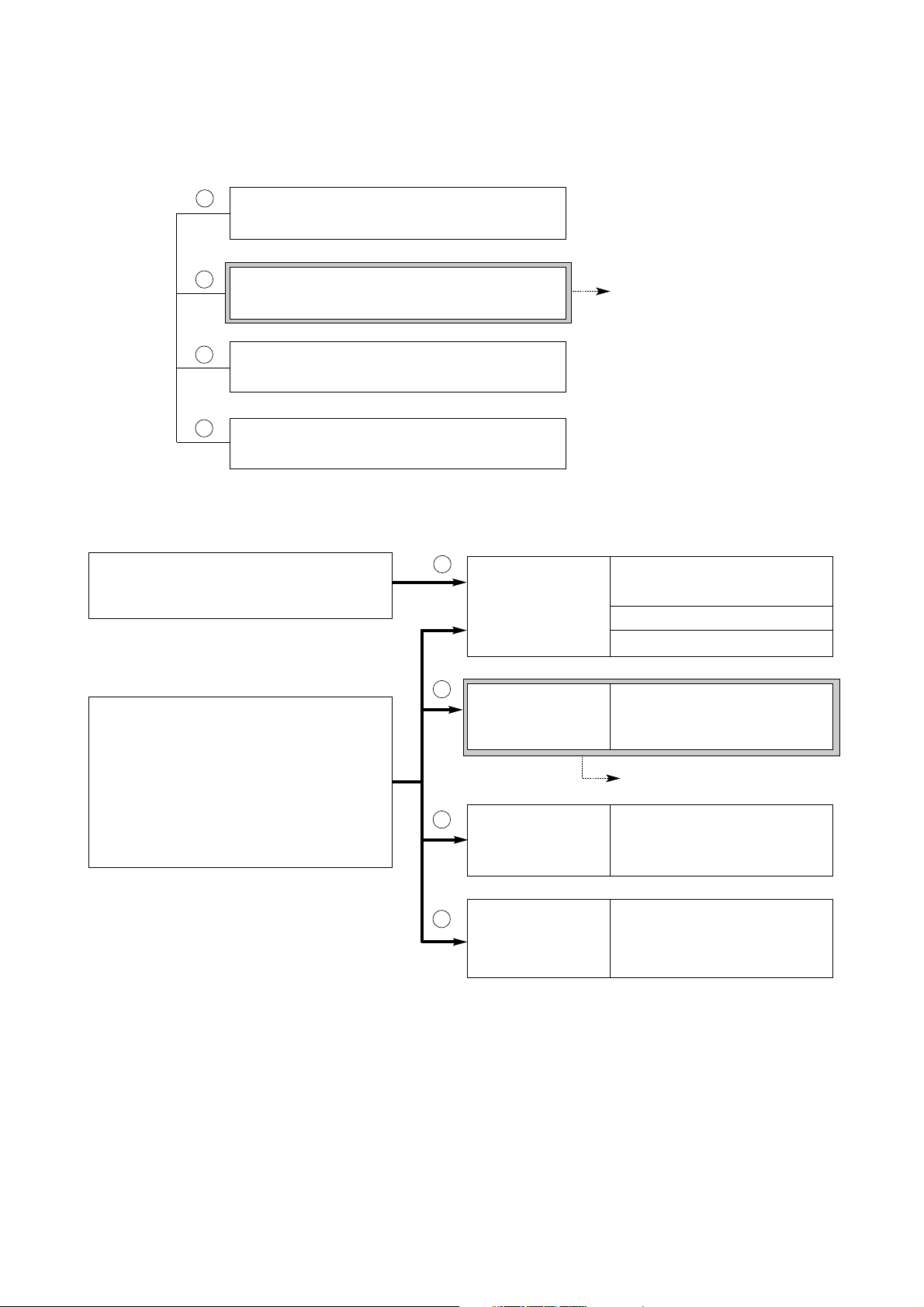

2. SUPPLIED MANUALS

The following manuals are supplied with the emergency PA system.

Emergency PA System FS-970 Series

Installation Manual

Emergency PA System FS-970 Series

Installation Manual - Basic Installation

The book you are reading now

• Read only the manuals that are suited for your purpose.

· Those who operate the PA system to

make both emergency and general

broadcasts

Instruction Manual

· Function

· Operation

· Routine inspection

· Overall inspection

Installation manual

(Basic installation)

· Installation

· The basics of installation

and its inspection

Installation manual

(Writing)

· Initialization

· Registration setting

· Setting registration chart

· Those who install the emergency PA

system

· Those who settle on a plan of use,

such as broadcast zone assignment,

and write (register) data

· Those who check system operations

Emergency PA System FS-970 Series

Installation Manual - Applied Installation

Installation manual

(Applied installation)

· Associated equipment

connections

· Reference items

Emergency PA System FS-970 Series

Installation Manual - Writing

The book you are reading now

1

12233

4

4

Page 7

7

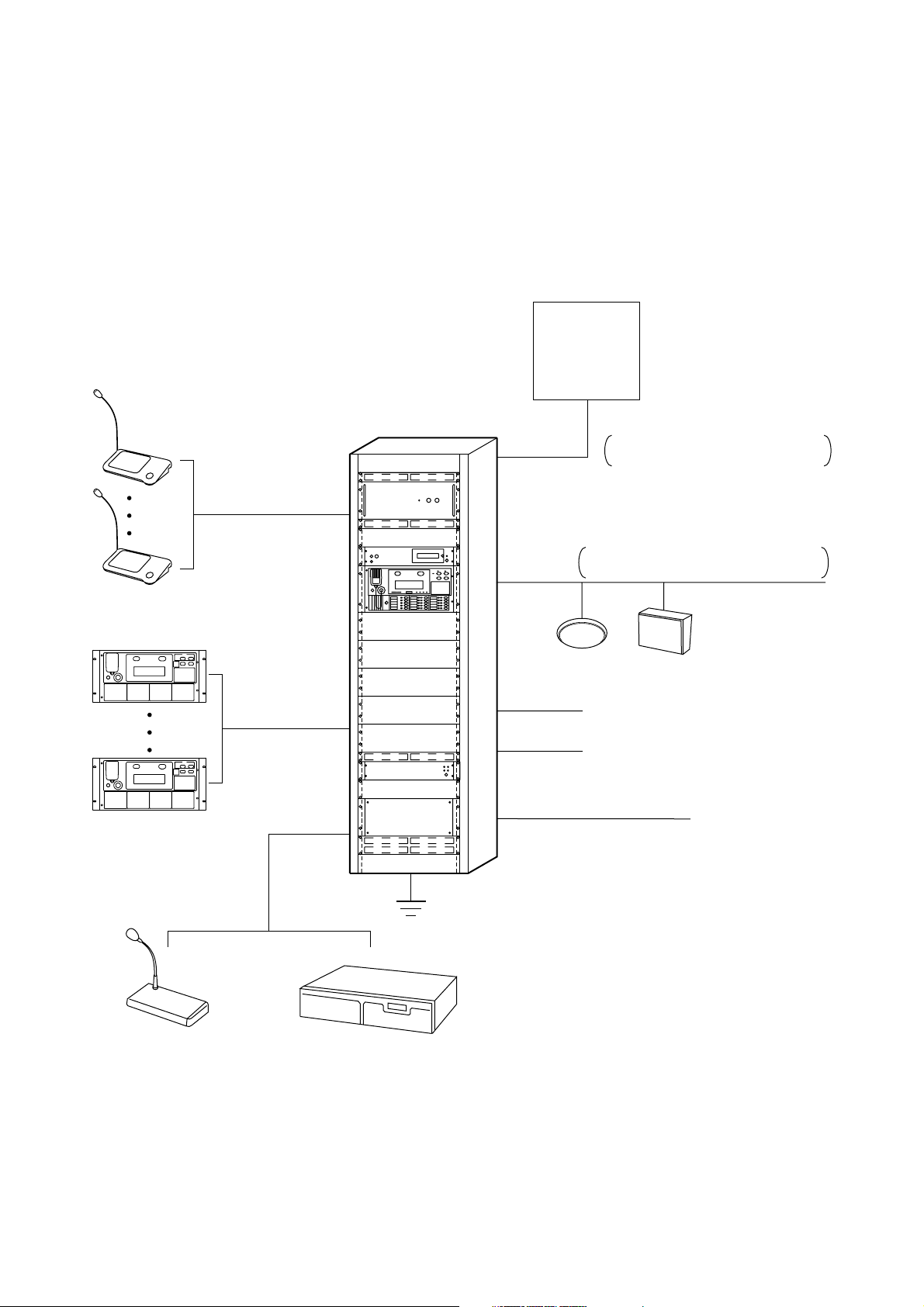

3. BEFORE STARTING INSTALLATION

3.1. System Summary

• The FS-971 and FS-973 permit system expansion of up to 330 lines and up to 330 emergency zones.

• The FS-972 permits system expansion of up to 50 lines and up to 50 emergency zones.

• Each of the FS-971, FS-972 and FS-973 permits connection of eight emergency remote control units and

eight general remote control units.

Fire alarm system

No. of emergency zones

FS-971/FS-973 types: Up to 330 zones

FS-972 type : Up to 50 zones

General remote control unit

(RM-1200)

Up to 8 units

Emergency remote

control unit

(RM-971)

Up to 8 units

AUX control terminal

(15 terminals)

Grounding

Speaker line

Power cable

(Power supply solely intended

for emergency PA systems)

FS-971 and FS-973 types: Up to 330 lines

FS-972 type : Up to 50 lines

Emergency power supply control unit

Speaker controller

110/220 VAC (50/60 Hz)

Remote Microphone

Music playing machine

Page 8

8

3.2. About the Emergency Power Supply

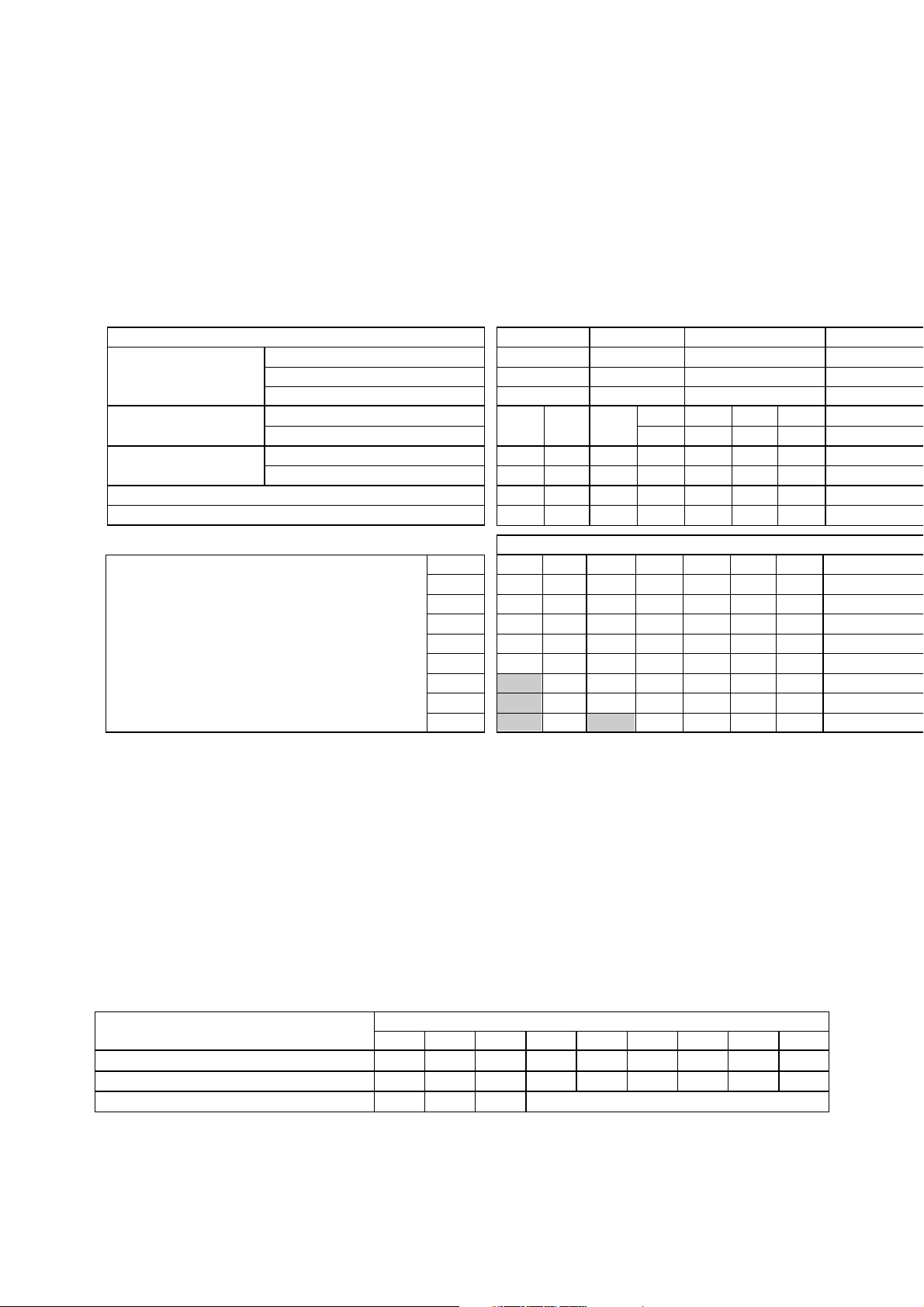

3.2.1. Selection of the emergency power supply panel and battery

The emergency PA system is designed to operate on both the main power supply and emergency power

supply. Because the emergency system needs to be operated for ten minutes or more during a power failure,

the emergency power supply suited to the system scale is required. The FS-970 series systems require the

emergency power supply panel DS-029B and Ni-Cd battery NDC-2435 or NDC-2460. The following table

provides guidelines on the number of emergency power supply panels and Ni-Cd batteries necessary for the

system.

Expansion power supply

AD-011

AD-031B

None (JP-0410's internal power supply only)

Rated output

No. of connected emergency remote control units

PA-1230B

PA-2440B

PA-3640B

0

1

2

3

4

5

6

7

8

Power amplifier panel

composition

Operation section/control section

Power amplifier panel

Battery composition

Quick reference table for emergency battery composition

No. of zones of the main rack and emergency remote control unit

NDC-2435

NDC-2460

Battery

No. of emergency power supply panels DS-029B

50

30

30

20

10

10

120

90

70

60

50

40

30

30

30

60

40

30

30

20

10

10

10

180

150

120

100

90

70

60

50

50

330

270

220

190

160

140

130

110

100

330

310

260

220

190

170

150

140

120

330

330

330

330

330

310

280

250

230

3.5AH

1

1

a

1

1

a

6AH

120W

1

6AH

1

1

a

3.5AH

3.5AH

2

1

b

6AH

6AH

2

1

b

7AH

6AH

2

1

2

c

12AH

6AH

3

2

c

240W

1

360W

1

Notes

• This table assumes that the main rack system and emergency remote control unit are identical in the

number of broadcast zones. It is also assumed that no other components are connected other than the EP029, EP-0510, EP-059R, JP-039, and JP-0410, and that any component is not connected to the emergency

power-off output or emergency output. In some systems, the number of zones may be less than those

shown in the above table.

• Refer to the connection examples on p. 27-30 for connection methods a-d of the Emergency Power Supply

Panel DS-029B.

3.2.2. DC power supply panel expansion

When multiple operation sections or emergency remote control units are connected to the main rack, the DC

power supply panel is required in addition to the Emergency Power Supply Panel DS-029B. For its

connection, refer to "DC Power Supply Panel Connection" on p. 34.

0 unit

70

160

30

Maximum zone Nos. vs. connected remote control unit Nos.

1 unit

50

130

20

2 unit

40

100

10

3 unit

30

80

4 unit

30

70

5 unit

20

60

6 unit

10

50

7 unit

10

50

8 unit

10

40

Note

Depending upon the connection method of the JP-0410's internal power supply/ expansion power supply to

expansion equipment (EP-029, EP-059R, JP-039, etc.), the number of zones may lower those shown in the

above table. When using other combinations not shown in the table, contact the shop from where you

purchased the unit.

Expansion power supply is required.

Connection of emergency power supply panel DS-029B

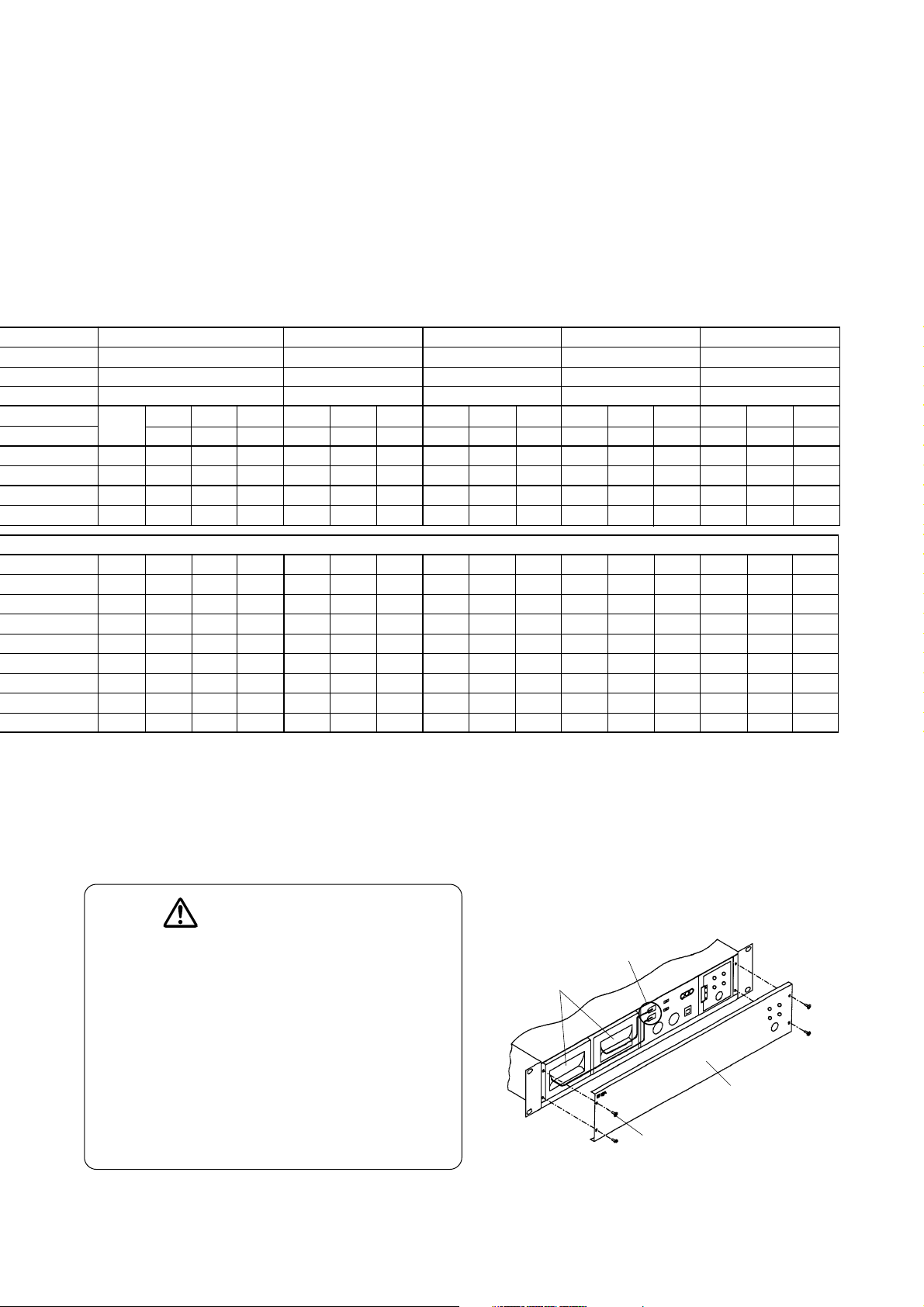

Page 9

9

330

270

220

190

160

140

130

110

100

330

310

260

220

190

170

150

140

120

330

330

330

330

330

310

280

250

230

330

270

220

190

160

140

130

110

100

330

310

260

220

190

170

150

140

120

330

330

330

330

330

310

280

250

230

330

270

220

190

160

140

130

110

100

330

310

260

220

190

170

150

140

120

330

330

330

330

330

310

280

250

230

330

270

220

190

160

140

130

110

100

330

310

260

220

190

170

150

140

120

330

330

330

330

330

310

280

250

230

330

270

220

190

160

140

130

110

100

330

310

260

220

190

170

150

140

120

330

330

330

330

330

310

280

250

230

No. of zones of the main rack and emergency remote control unit

140

110

90

70

60

50

40

40

30

6AH

7AH

2

1

2

c

7AH

7AH

4

2

c

12AH

7AH

2

2

2

c

6AH

12AH

3

2

c

7AH

12AH

2

2

2

c

12AH

12AH

4

2

c

6AH

18AH

4

2

d

7AH

18AH

2

3

3

c

12AH

18AH

6

3

c

2

1

b

6AH

24AH

5

3

c

7AH

24AH

2

4

3

c

12AH

24AH

6

3

c

6AH

30AH

6

3

d

12AH

30AH

7

4

c

7AH

30AH

2

5

4

c

480W

2

720W

2

1080W

3

1440W

4

1800W

5

12AH

4. NI-CD BATTERY REPLACEMENT

Emergency Power Supply Panel DS-029B

Ni-Cd battery

Connector

Front panel mounting screw

Front panel

1. Remove battery connectors.

2. Take the batteries out of the battery compartment.

CAUTION

• Do not short-circuit or disassemble the Ni-Cd

battery. Also, do not expose it to excessive heat

or throw it into a fire.

• To prevent short-circuiting of removed Ni-Cd

batteries, wrap electrical tape around their

terminals.

• Do not use the Ni-Cd batteries in combination

with dry batteries or other types of battery.

• When replacing the Ni-Cd battery, only use the

type designated in the section "About the

Emergency Power Supply" on p. 8.

Page 10

10

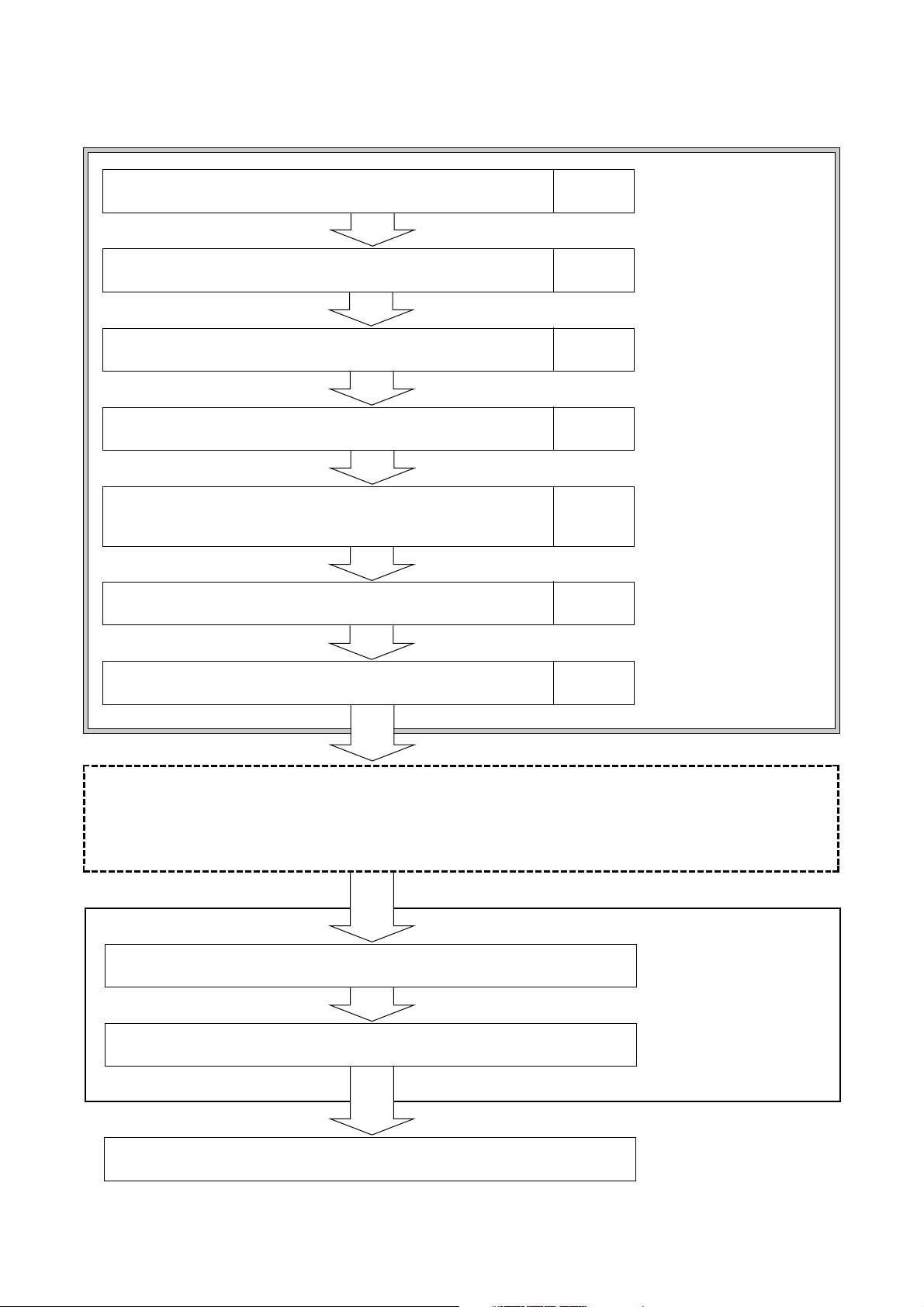

End

"Basic Installation Manual"

you are reading now

Separate book

"Writing"

• Finish construction work explained in the separate book "Applied

Installation" together with construction work explained in the

"Installation Manual-Basic Installation.

• When there is no applicable construction work, advance to writing.

Separate book

"Applied Installation"

2. Writing

1. Data Initialization

1. Equipment rack assembly and installation Page 11

2. Before installing rack components in the rack Page 15

3. Rack component mounting Page 18

4. Rack inter-component connections Page 21

5. Operation/expansion panel address setting and connection

to external lines

6. Connection inspection Page 45

7. Power on and check Page 48

5. INSTALLATION PROCEDURES

Page 38

Page 11

11

6. EQUIPMENT RACK ASSEMBLY AND INSTALLATION

6.1. Poor Installation Locations

Avoid installing the rack in the following locations.

• Locations that may be exposed to fire, heat or direct sunlight (ambient temperature should be between 0°C

and 40°C).

• Locations that may be exposed to rainwater, steam or high humidity.

• Locations exposed to vibration.

• Locations offering limited space at the rear of the rack for inspection.

• Locations where particles of metal or dust accumulate, or near chemicals or oil.

• Locations near high-voltage equipment or equipment sensitive to electro-magnetic fields.

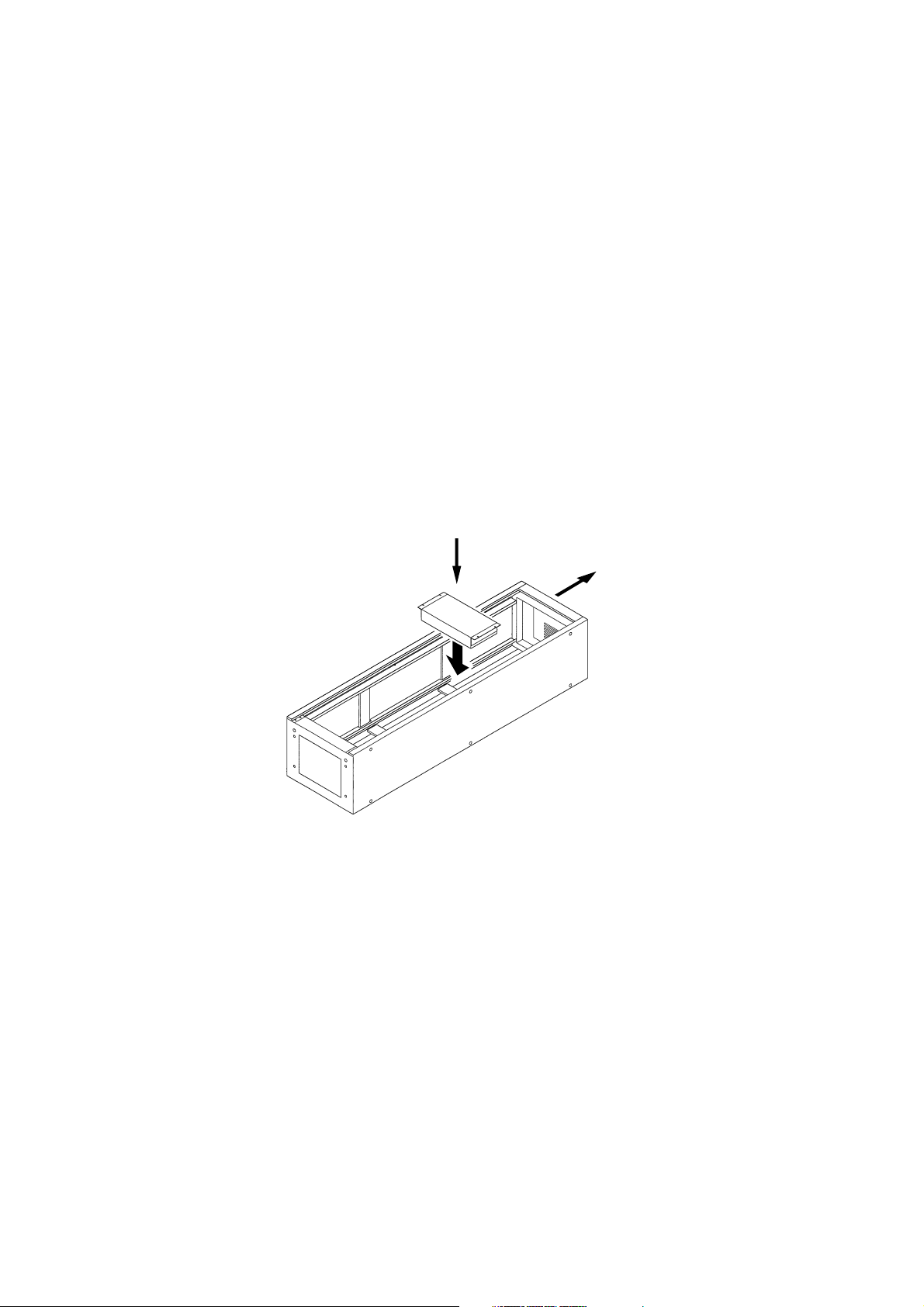

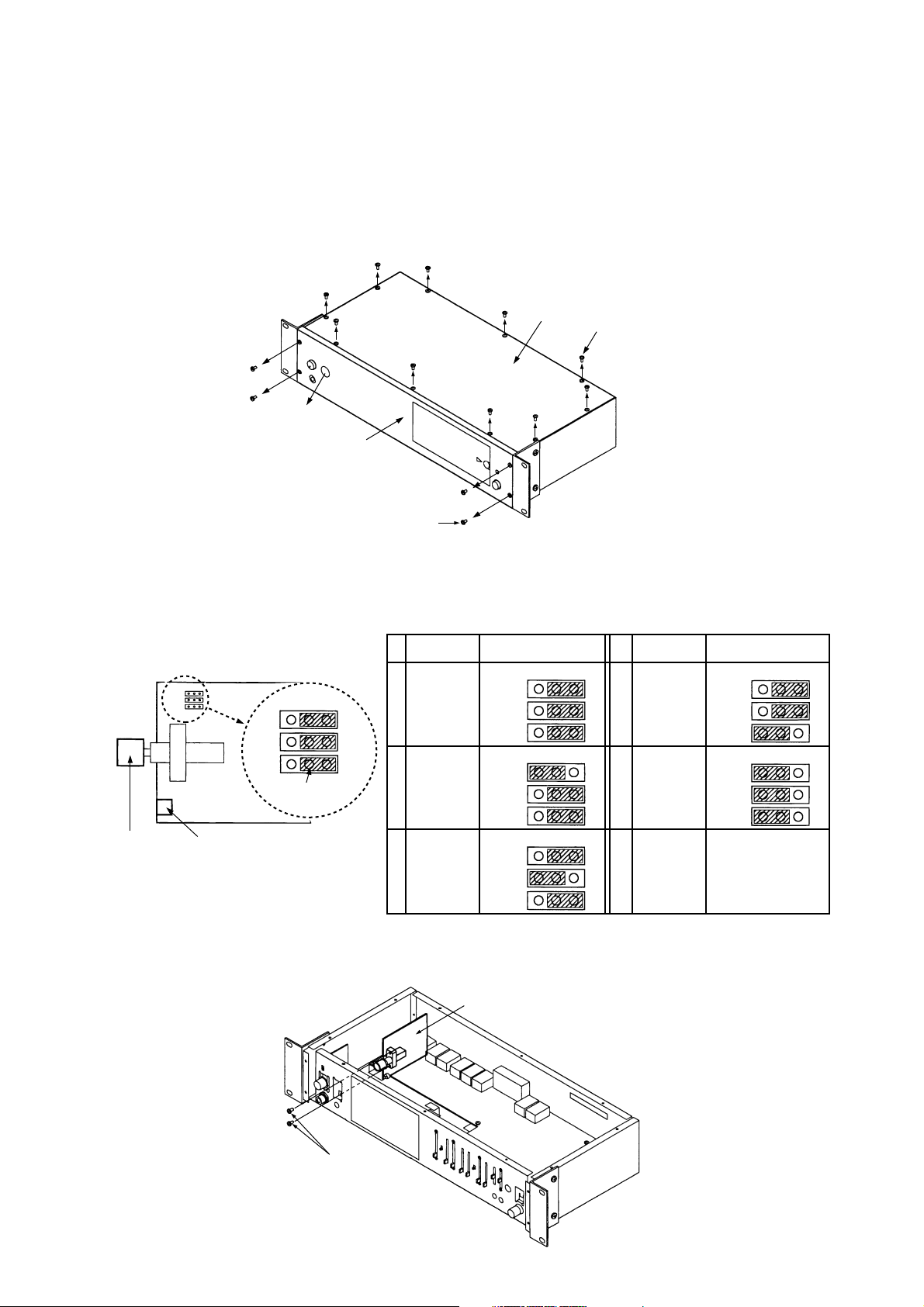

6.2. Rack Assembly

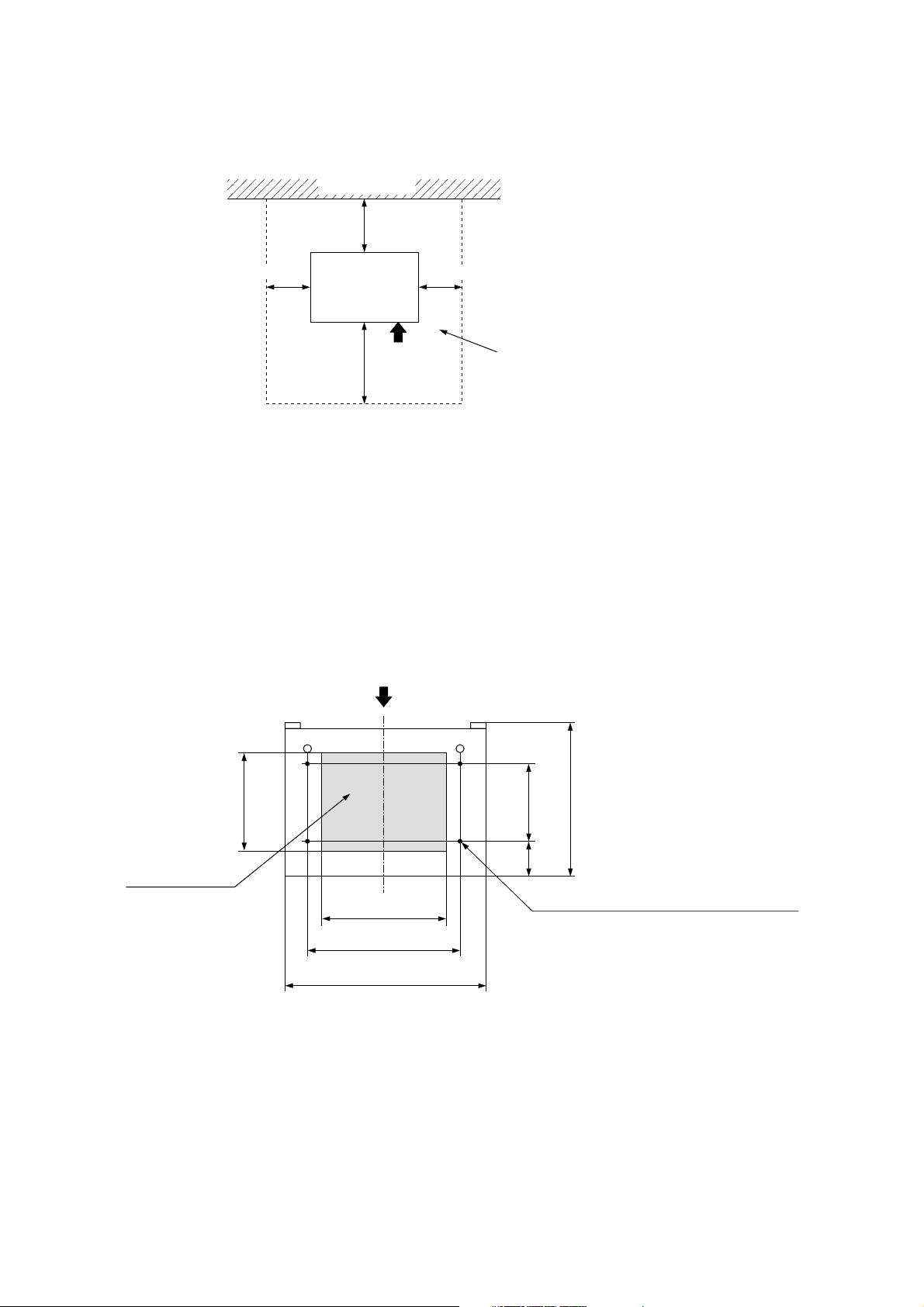

• Follow the instructions in the manual attached to the rack to assemble.

• When installing the rack components, lay the rack down face-up as shown in the figure to facilitate work and

ensure safety. (For component installation, refer to Component Installation on p. 18.)

• Install the Blower Unit BU-412 after rack assembly completion but before installing each rack component.

Note

Some components require their functions to be readjusted before they are installed in the rack. In such cases,

install the components after readjustment completion. (Refer to p. 15.)

Front

Ceiling

Page 12

12

6.3. Rack Installation

The emergency rack system must be installed as shown in the figure below.

• To prevent the equipment rack from falling down due to an earthquake, etc., secure the rack to the floor with

anchor bolts and to the wall with brackets.

• When installing the general rack system, also allow for the above spacing to facilitate maintenance.

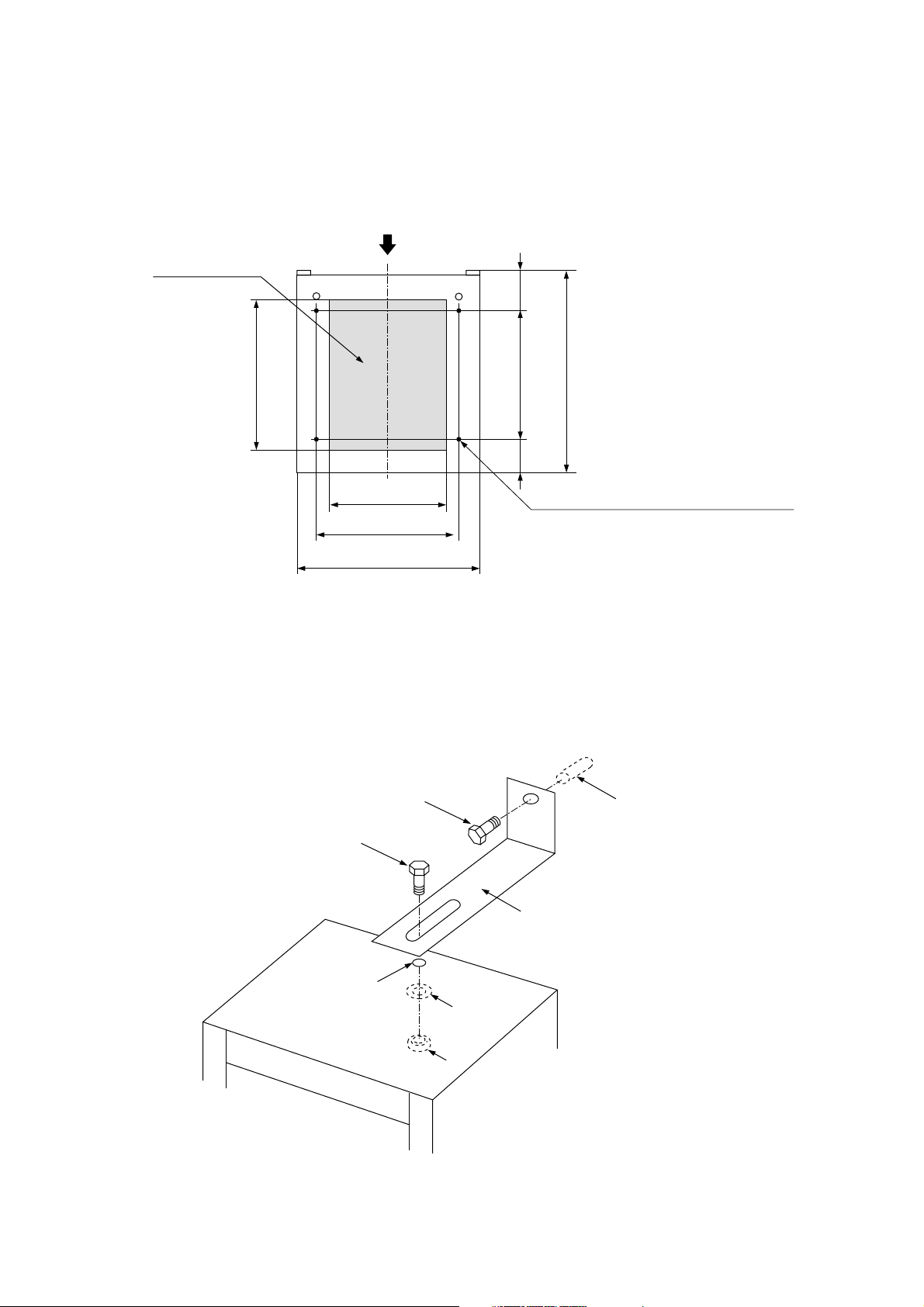

6.4. Securing the Rack CR-272 or CR-412 to the Floor

Four anchor bolt mounting holes (ø15 mm) are provided in the rack bottom surface to secure the rack to the

floor. Referring to the figure below, make holes in the floor, then secure the rack to the floor using four M10M12 anchor bolts.

Wall surface, etc.

Over 0.6 m

Front

Over 0.5 m

Space for inspection and operation

Over 0.5 m

Over 2 m

CR-272

CR-412

CR-412-6

Front

Cable entry opening

280

360

440

566

220100

435

Anchor bolt mounting hole (ø15 mm, 4 places)

Page 13

13

6.5. Securing the Rack CR-412-6 to the Floor

Four anchor bolt mounting holes (ø15 mm) are provided in the rack bottom surface to secure the rack to the

floor. Referring to the figure below, make holes in the floor, then secure the rack to the floor using four M10M12 anchor bolts.

Front

460

400

615

(115)

100

360

440

566

Anchor bolt mounting hole (ø15 mm, 4 places)

Cable entry opening

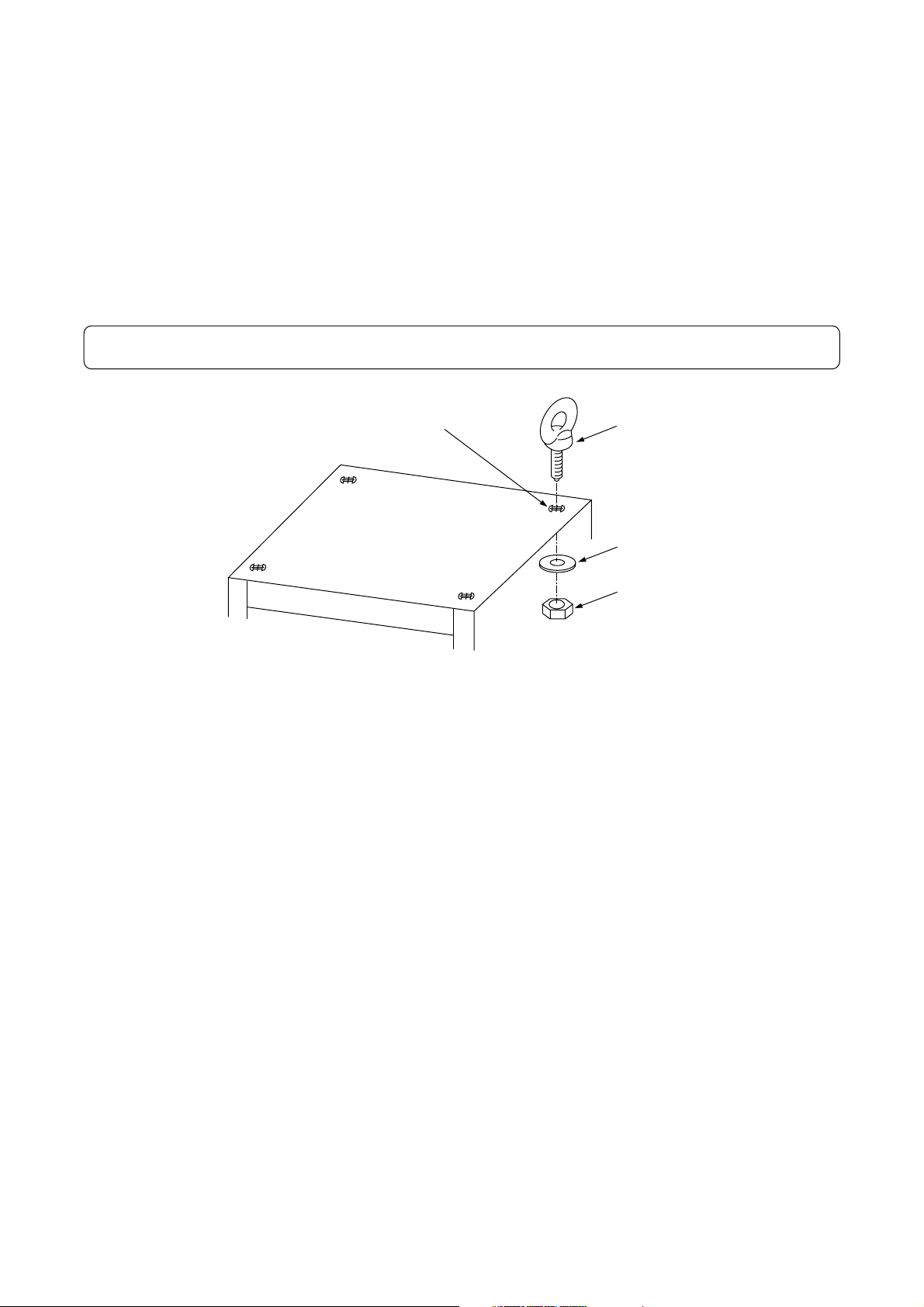

6.6. Securing the Rack to the Wall (for Prevention of the Fall)

A knock-out hole (ø6.5 mm) is provided on the rack top panel. Break this hole with a screwdriver, and secure

the rack to the wall by installing a bracket in the exposed hole. (Note the bracket is not supplied with the

system. Purchase it separately in the market.)

Washer

Knock-out hole

Nut

Bracket

M6 bolt

Anchor

Bolt

[Installation example]

Page 14

14

6.7. Rack Suspension using Eyebolts

Eyebolts for suspension can be mounted to the rack top panel.

• Purchase the following parts separately in the market.

Eyebolts M16 ............... 4 pieces

Nut M16 ....................... 4 pieces

Plain washer M16 ........ 4 pieces

Remove four rubber hole covers provided on the top panel, and install eyebolts (4 places) in the exposed

holes as shown in the figure.

Important: The maximum rack system weight for 4-point suspension is 300 kg.

6.8. Fine Height Adjustment of the Installed Rack

When the rack installed on the floor is unstable and shaky, make fine adjustment of its height by turning

clockwise the height adjustment screw located in the front of the bottom rack base. Use the standard

screwdriver for adjustment.

6.9. Grounding

Provide grounding terminals using three grounding terminal screws (M5) located at the rear of the bottom rack

base. Three female screws (M5) are located in the front of the base. Use these screws as required.

Remove this rubber hole cover.

Top panel of the CR-272,

CR-412 and CR-412-6

Eyebolt

Plain washer

Nut

Page 15

15

7. BEFORE MOUNTING THE COMPONENTS IN THE RACK

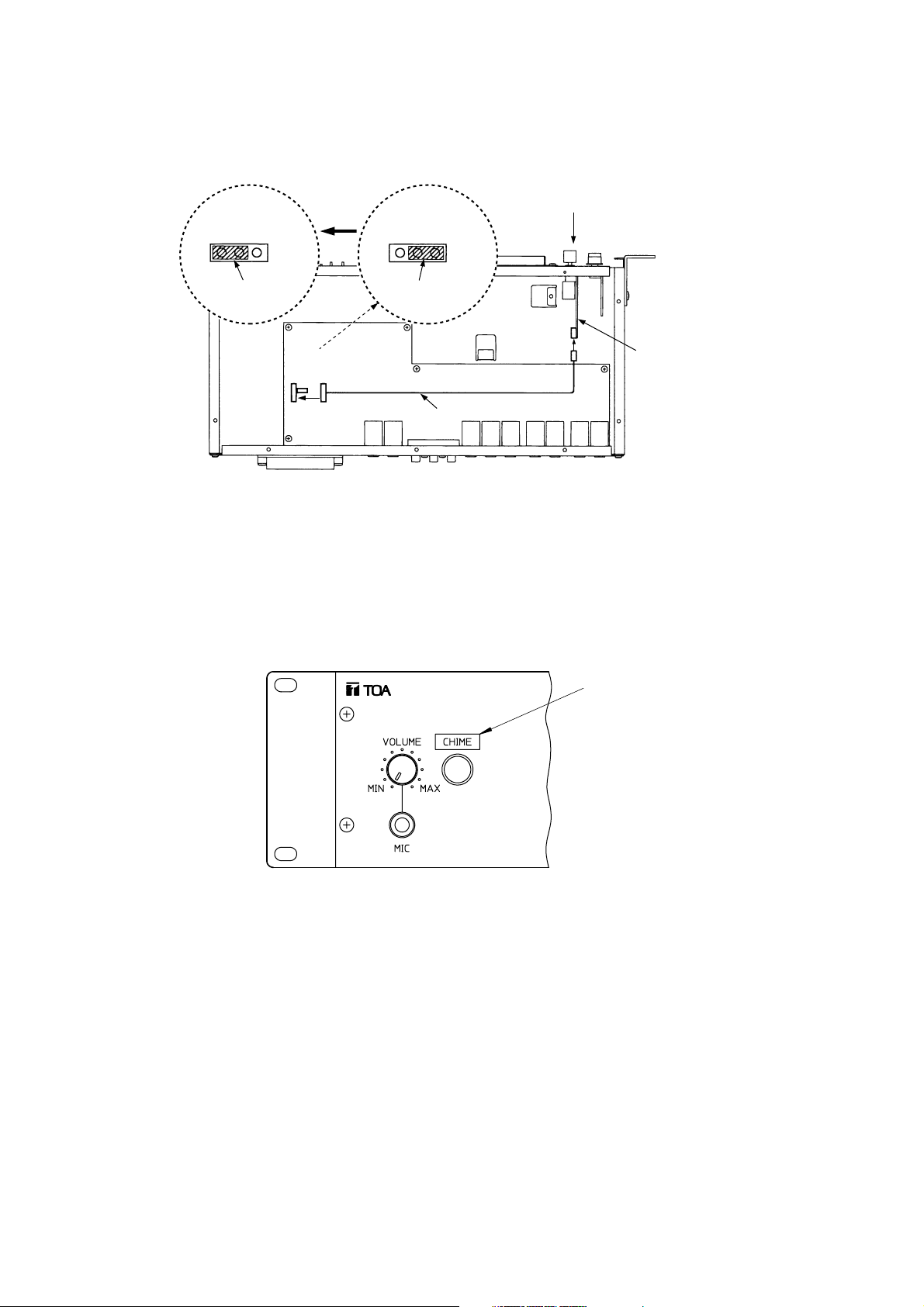

7.1. Integrated Control Panel EP-0510

• Chime Switch Installation

To activate the external chime device or the CK-025 Chime Unit built in the PP-025B Pre-amplifier, install the

chime switch (supplied with the EP-0510) as shown below. You may skip the following installation procedures

if the chime does not need to be activated from the EP-0510.

Supplied label

1. Push to break the chime switch hole on the

Operation Panel.

2. Remove two screws on the right of the

Operation Panel and open the panel.

3. Mount the chime switch to the inside of the

front panel using the supplied screws (3x6).

4. Connect the chime switch connector to CN8

on the control circuit board.

5. Attach the supplied label to the Operation

Panel.

Chime switch

Screw (3x6)

Mount from the back of the panel.

CN8

Control circuit board

Page 16

16

Screw (M3x6)

Chime Unit CK-025

7.2. Pre-amplifier Panel PP-025B

• Chime Unit (CK-025) Installation

Note: Install the Chime Unit in the Pre-amplifier Panel before mounting the Pre-amplifier Panel in the rack.

1. Remove the front panel, top panel and rubber hole cover on the front panel.

2. Select the chime tone type for the Chime Unit to install by changing the jumper connector position on JP1

through JP3 on the Chime Unit's circuit board.

3. Mount the Chime Unit and secure it using two screws (M3x6) supplied with the Chime Unit.

Hole cover

Front panel

Screw (M3x6)

Top panel

Screw (M3x6)

Jumper connector

position

21

JP 1

JP 2

JP 3

21

JP 1

JP 2

JP 3

21

JP 1

JP 2

JP 3

Chime switch Chime volume control

21

JP 1

JP 2

JP 3

Jumper connector

Chime tone Chime tone

1

Ascending

4-tone chime

2

Two tone

chime

3

Gong

Jumper connector

position

21

JP 1

JP 2

JP 3

21

JP 1

JP 2

JP 3

21

JP 1

JP 2

JP 3

4

Single tone

chime

5

Descending

4-tone chime

Page 17

17

4. Connect one end of the connector cable supplied with the Chime Unit to the Chime Unit' s connector, and

the other end to connector CN17 on the PP-025B's internal circuit board.

JP1

CHIME SET

USE NO USE

Jumper connector

JP1

CHIME SET

USE NO USE

Jumper connector

Front

JP1

CHIME

SET

CN17

CHIME

Connector cable supplied with

the CK-025

Chime Unit CK-025

Chime Unit is used.

(USE position)

Chime Unit is not used.

(NO USE position)

5. Remove JP1 jumper connector on the PP-025B's internal circuit board and reset it to the USE position.

6. Replace both the front and top panels, and attach "CHIME" label (included in the supplied input indication

labels) to the position above the chime switch.

"Chime" label

Page 18

18

8. COMPONENT INSTALLATION

This section describes the points of installation you need to bear in mind when mounting the following main

components in the rack.

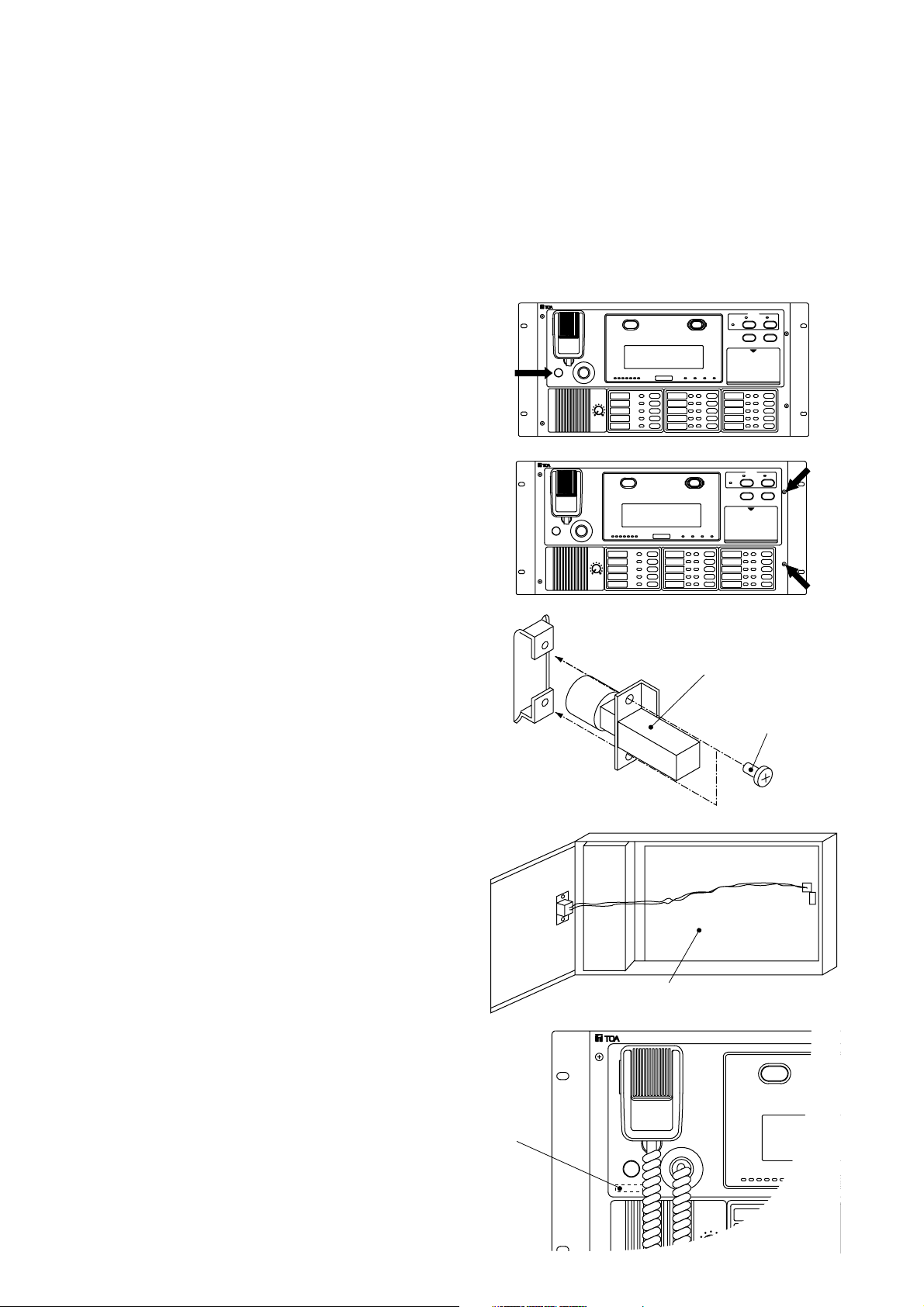

8.1. Integrated Control Panel

It is highly recommended that all the switches on the emergency operation panel be positioned at the height of

0.8 to 1.5 m from the floor. Therefore, the Integrated Control Panel EP-0510 and the Expansion Operation

Panels EP-029-10 and EP-029-20 must be positioned at the height shown below. When exceeding such

height ranges, install them in multiple racks and arrange those racks side by side.

Installation

height range

Under

10-unit size

Over

17-unit size

27-unit size

CR-272 rack

Capacity: 50 emergency broadcast zones

Installation

height range

Under

15-unit size

Over

17-unit size

Over 9-unit size

41-unit size

Over 0.8 m

Under 1.5 m

CR-412/-412-6 rack

Capacity: 110 emergency broadcast zones

One integrated control panel (5U) and

up to 2 expansion operation panels

(2U) are mountable.

One integrated control panel (5U) and

up to 5 expansion operation panels

(2U) are mountable.

The above figures show that the racks are installed directly on the floor. When using a channel base, ensure

that all the switches on the emergency operation panel are positioned at the height of 0.8 to 1.5 m from the

floor.

8.2. Junction Panel

• It is preferable to mount the perforated panel, such as the PF-023B, in the lowermost position of the rack,

and mount the Junction Panel JP-0410 above it. This facilitates connection of external wires.

• When mounting the Expansion Junction Panel JP-039-10 or JP-039-20 in the rack, mount it below the JP-

0410.

Page 19

19

8.3. Emergency Power Supply Panel

You need to mount the perforated panel (PF-013B, etc.) above and below each Emergency Power Supply

Panel DS-029B. However, up to two Emergency Power Supply Panels may be stacked without the perforated

panel between them.

Equipment rack

Emergency Power Supply Panel

Perforated Panel

Equipment rack

Emergency Power Supply Panel

Perforated Panel

8.4. DC Power Supply Panel

• The above-mentioned basic installation method of the Emergency Power Supply Panel also applies to the

installation of the DC Power Supply Panels AD-011 and AD-031B.

• The Rack Supporting Runner YA-706 is attached to the AD-031B. When installing it, follow the instructions

in the equipment rack installation manual.

Page 20

20

8.5. Power Amplifier Panel Mounting Position

• You need to mount the perforated panel (PF-013B, etc.) above and below each power amplifier panel.

However, up to two power amplifier panels may be stacked without the perforated panel between them

provided each amplifier output power is less than 120 W.

• Mounting examples

1. Power amplifier panel rated at 120 W or less (PA-1230B)

Equipment rack

Power amplifier panel

Perforated panel

2. Power amplifier panel rated at 240 W or more (PA-2440B and PA-3640B)

Equipment rack

Power amplifier panel

Perforated panel

• Rack Supporting Runner for the power amplifier panel

When installing the power amplifier panel PA-1230B, PA-2440B or PA-3640B, be sure to follow the

instructions in the Equipment Rack Installation Manual and attach the optional guide rail YA-706 to the rack.

Page 21

Supplied Connection Cables

Power cord, parallel vinyl covered cable, dual phone plug balanced cable

Dual phone plug balanced cable

Dual phone plug balanced cable, PP-JP control/power connector cable

EP-EP control connector cable, EP-EP power connector cable

Power cord, parallel vinyl covered cable (long cable x 1, short cable x 3), junction connector cable

JP-EP control connector cable, JP-EP power connector cable

JP-JP control connector cable, JP-JP power connector cable

21

9. RACK INTER-PANEL CONNECTION

9.1. FS-971 System Panel Connection Diagram

Component Model No.

PA-3640B

PP-025B

EP-0510

EP-029-20

DS-029B

JP-0410

JP-039-20

<Parallel vinyl covered cable>

Supplied with DS-029B.

Supplied with PA-3640B.

<JP-JP power

connector cable>

Supplied with

JP-039.

<Junction connector cable>

Supplied with DS-029B.

<Power cord>

Supplied with

DS-029B.

<EP-EP power connector

cable> Supplied with

EP-029.

<Power cord> Supplied with PA-3640B.

<PP-JP control/power connector cable> Supplied with EP-0510E.

<Parallel vinyl covered cable> Supplied with PA-3640B.

<Parallel vinyl covered cable> Supplied with DS-029B.

<Dual phone plug cable>

Supplied with PP-025B.

<JP-EP power connector cable> Supplied with JP-0410.

<EP-EP control connector

cable> Supplied with EP-029.

<Dual phone plug balanced cable>

Supplied with EP-0510.

<JP-EP control connector cable>

Supplied with JP-0410.

PA-3640B

PP-025B

EP-0510

EP-029-20

DS-029B

JP-0410

JP-039-20

<JP-JP control

connector cable>

Supplied with JP-039.

FS-971-36NA

Page 22

22

9.2. Pre-amplifier Panel PP-025B Connection

• You can install the Chime Unit in the Pre-amplifier Panel. (Refer to p. 16.)

• Input 1-A jack is located on both the front and rear panels. When both jacks are simultaneously used, the

broadcast from the front panel is allowed to go through.

• Input 1 takes precedence over Inputs 2 and 3, while Input 2 takes precedence over Input 3. Connect a BGM

player to Input 3, and the microphone and chime to Input 1 or 2 depending on the degree of their

importance. Use the muting volume control located in the front panel to adjust attenuation levels. Priority is

controlled by the external control signal from the control connector or by an input signal level. Should the

latter be the case, when the volume of the input signal is low, control may not be performed effectively. In

such a case, use the external control. Refer to the separate "Installation Manual - Writing" for the method by

external control.

• Line Output 2 is a dedicated output terminal for Input 3. Use this output to make multi-origination broadcast

by separating BGM zones from microphone announcement zones.

Supplied with PP-025B.

EP-0510 rear panel

PRE-AMP IN

JP-0410 rear panel

PP-025B power

PP-025B control

Supplied with EP-0510E.

Page 23

23

9.3. Power Amplifier Panel Connection

• Use the same output line voltage when connecting power amplifier panels for parallel operation. You can

connect up to three power amplifier panels of the same kind in parallel.

Important: Make connection so that the total of speaker rated input power is less than 1 kW for a group of

five consecutive speaker lines (i.e. lines 1-5, 6-10, etc.).

• Do not use the 4 Ωoutput terminal for the rack PA system.

• Refer to p. 24 "Emergency Power Supply Panel DS-029B Connection" for details of the connection to the

emergency power supply panel.

• The junction panel's C1 and H1 are input terminals for speaker lines 1-5, and C2 and H2 are for speaker

lines 6-10. When the panel is supplied from the factory, the input terminals are short-circuited between C1

and C2 and between H1 and H2 by means of a jumper wire. Also, because the monitor circuit is connected

to between C1 and H1, the monitor panel is additionally required for monitoring speaker lines 6-10 when

using the input terminals by separating C1 and H1 from C2 and H2.

Supplied with power

amplifier panel.

Supplied with power amplifier panel.

Supplied with power amplifier panel.

Supplied with power amplifier panel.

Supplied with EP-0510.

Supplied with DS-029B.

Supplied with DS-029B.

Power amplifier panel rear panel

Power amplifier panel rear panel

EP-0510 rear panel

DS-029B rear panel

JP-0410 rear panel

Page 24

24

9.4. Emergency Power Supply Panel DS-029B Connection

9.4.1. Battery connection

Internal Ni-Cd batteries are optional. Depending upon the output and number of power amplifier panels to use,

and the number of connected emergency remote control units, select the proper type of battery. After installing

the selected battery in the DS-029B, make connections. For battery selection, refer to p. 8 "About the

Emergency Power Supply".

After battery installation, connect the battery connector and set the battery using the battery selector switch

located on the right of the battery connector.

When using the NDC-2435, set the switch to the "3500 mAh" position.

When using the NDC-2460, set the switch to the "6000 mAh" position.

When not connecting any battery, set the switch to the OFF position.

OFF3500 mAh 6000 mAh

CHARGE CURRENT

Important

• The emergency PA system automatically checks the battery voltage every 24 hours. Therefore, if you set the

switch to the "3500 mAh" or "6000 mAh" position without connecting the battery, a warning tone is sounded

simultaneously with the battery error indication.

• Note that pressing the DS-029B's check key immediately after the system has been installed and the power

supplied may display the battery error indication.

• To check the battery manually, charge the battery for 24 hours or more before checking.

9.4.2. About the Emergency Power Supply Panel's (DS-029B's) terminals

REMOTE (left) (+, –) terminals

• These terminals supply power for making emergency broadcast when the activation of the fire alarm terminal

or the depression of the emergency key is detected while the system is in standby mode due to a power

failure. They also supply power to the operation/control section in emergency broadcast mode.

• 24 VDC is output when the supply of AC power stops. It is not output while the AC power is supplied.

(Outputs from two batteries 1 and 2 installed in the DS-029B are combined into one 24 VDC output through

a diode.)

• These terminals are connected to both the [EMG DS CTRL (+)] and [GND] terminals of the terminal block on

the rear panel of the Junction Panel JP-0410.

OUTPUT (+, –) terminals

• Output 24 VDC when there is a 24 VDC input to the [REMOTE (right) (+, –)] terminal while the supply of AC

power stops. Note that the 24 VDC power is not output while the AC power is supplied or the system is in

standby mode due to a power failure.

• Outputs 1 and 2 provide 24 VDC from Battery 1, and Outputs 3 and 4 provide it from Battery 2.

• The OUTPUT terminals connect to the power amplifier panel's [24 VDC INPUT (+, –)] terminals.

REMOTE (right) (+, –) terminals

• When these terminals receive 24 VDC while the supply of AC power stops, 24 VDC is output from output

terminals 1-4. Note that the 24 VDC power is not output from output terminals 1-4 even if the 24 VDC power

is input when the AC power is supplied.

• REMOTE (right) terminals connect to the [EMG DS ACTI (+)] and [GND] terminals of the terminal block on

the JP-0410's rear panel.

Page 25

25

9.4.3. About the operation of the Emergency Power Supply Panel DS-029B

When the AC power is supplied and the Emergency Activation terminal is not shorted (standby

status)....

Current flows in coils D and E, and contact points d and e are as shown below. 24 VDC is not sent to

REMOTE (left) or outputs 1-4.

AC power

D

E

DS-029B

Charging

circuit

Battery 1

Battery 2

b

c

e

Output 1

Output 2

Output 3

Output 4

REMOTE (left)

REMOTE (right)

EMG ACTI

EMG DS ACTI

EMG DS CTRL

JP-0410

f

F

d

C

B

When the AC power is cut off (power failure)....

Because no current flows in coils D and E, contact points d and e switch as shown below. 24 VDC is output

from Batteries 1 and 2 via a diode. The 24 VDC power is not sent to outputs 1-4.

AC power

D

E

b

c

e

JP-0410

f

F

d

C

B

DS-029B

Charging

circuit

Battery 1

Battery 2

Output 1

Output 2

Output 3

Output 4

REMOTE (left)

REMOTE (right)

EMG ACTI

EMG DS ACTI

EMG DS CTRL

Page 26

26

When the emergency function is operated while the AC power is cut off (power failure)....

Current flows in Coil F in the Junction Panel JP-0410 and contact point f switches, thereby causing the 24

VDC power output from REMOTE (left) of the Emergency Power Supply Panel DS-029B to return to the DS029B's REMOTE (right). As a result, the current flows in Coils B and C and contact points b and c switch as

shown below, transmitting 24 VDC to outputs 1-4.

D

E

b

c

e

f

d

C

B

JP-0410

F

AC power

DS-029B

Charging

circuit

Battery 1

Battery 2

Output 1

Output 2

Output 3

Output 4

REMOTE (left)

REMOTE (right)

EMG ACTI

EMG DS ACTI

EMG DS CTRL

Page 27

27

9.4.4. Connections

Connections of the Emergency Power Supply Panel DS-029B are classified into four methods a, b, c, and d

depending on the composition selected in the section "About the Emergency Supply Panel" on p. 8. Because

the operation and control sections are fundamental to the emergency broadcast system, any failure in their

operation will disable the function of the entire system. When two or more DS-029Bs are incorporated into the

system (connection methods c and d), the system's operating time can be extended by connecting all the

positive (+) and negative (–) REMOTE (left) terminals on all DS-029Bs in parallel. This permits all connected

batteries to be used as a backup power source for the operation and control sections.

Important: Be sure to connect the DS-029B's power source to the "UNSWITCHED" AC outlet located on the

JP-0410's rear panel.

Connection method a for the DS-029B

In this method, one battery (one DS-029B unit) is connected to supply power to both the operation/control

section and power amplifier panel.

PA-1230B's rear panel

DS-029B's rear panel

JP-0410's rear panel

Battery 1

NDC-2460

[Connection Example]

Rated output: 120 W

Battery composition: 6 Ah power is supplied to both operation/control section and power amplifier panel

Page 28

28

Connection method b for the DS-029B

In this method, two batteries (one DS-029B unit) are connected to supply power to the operation/control

sections and power amplifier panel separately.

PA-3640B's rear panel

DS-029B's rear panel

JP-0410's rear panel

[Connection Example]

Rated output: 360 W

Battery composition: Operation/control section 6 Ah, Power amplifier panel 6 Ah

Battery 1

NDC-2460

Battery 2

NDC-2460

In the above connection example, power is supplied to the power amplifier panel from Battery 2, and to the

operation/control section from both Batteries 1 and 2 (mainly from Battery 1).

In the case of another example of "Output: 480 W, Battery Composition: Common to both the

operation/control section and power amplifier panel for 12 Ah", connect the first PA-2440B power amplifier

panel to the Emergency Power Supply Panel's (DS-029B') Output 1, and the second PA-2440B unit to Output

3. Power is supplied to the first PA-2440B unit from Battery 1, and to the second unit from Battery 2. The

operation/control section receives the power from both Batteries 1 and 2.

Page 29

29

Connection method c for the DS-029B

In this method, three or more batteries (multiple DS-029B connection) are connected to supply power to the

operation/control section and power amplifier panel separately.

Battery 1

NDC-2460

Battery 3

NDC-2460

Battery 2

NDC-2460

Battery 4

NDC-2460

Second PA-3640B unit

Rear panel

First PA-3640B unit

Rear panel

Second DS-029B

Rear panel

First DS-029B

Rear panel

JP-0410

Rear panel

[Connection Example]

Rated output: 720 W

Battery composition: Operation/control section 12 Ah, Power amplifier panel 12 Ah

In the above connection example, power is supplied to the first power amplifier panel PA-3640B from Battery

3, and to the second power amplifier panel from Battery 4. The operation/control section receives power

mainly from both Batteries 1 and 2.

Page 30

30

Connection method d for the DS-029B

In this method, three or more batteries (multiple DS-029B connection) are connected. A single DS-029B unit

contains two batteries: one to supply power to the operation/control section and one to supply power to the

power amplifier panel.

In the above connection example, power is supplied to the first power amplifier panel PA-3640B from Battery

2, to the second power amplifier panel from Battery 3, and to the third power amplifier panel from Battery 4.

The operation/control section receives power mainly from Battery 1.

Third PA-3640B unit

Rear panel

Second PA-3640B unit

Rear panel

First PA-3640B unit

Rear panel

Battery 3

NDC-2460

Battery 4

NDC-2460

Second

DS-029B

Rear panel

Battery 1

NDC-2460

Battery 2

NDC-2460

First DS-029B

Rear panel

JP-0410

Rear panel

[Connection Example]

Rated output: 1080 W

Battery composition: Operation/control section 6 Ah, Power amplifier panel 18 Ah

Page 31

31

9.4.5. Connecting a single emergency power supply panel to power amplifiers

The figure below shows the method of connecting the Emergency Power Supply Panel DS-029B to the power

amplifier panel. Refer to the figure when expanding power amplifier panels or designing the power amplifier

rack.

• Only a single power amplifier panel (up to 120 W) can be connected per output terminal of the emergency

power supply panel.

• When using the 240 W power amplifier panel, connect it to parallel-connected outputs 1 and 2 (or 3 and 4) of

the emergency power supply panel.

• When using the 360 W power amplifier panel, connect the emergency power supply panel's outputs 1 and 2

(or 3 and 4) separately to individual power amplifier panels.

When using the PA-1230B (120 W)

First PA-1230B unit

Second PA-1230 unit

Third PA-1230B unit

Fourth PA-1230B unit

Power amplifier panel's

rear-mounted terminal block

Emergency power supply

panel's (DS-029B)

rear-mounted terminal block

When using the PA-2440B (240 W)

First PA-2440B unit Second PA-2440 unit

Power amplifier panel's

rear-mounted terminal block

Emergency power supply

panel's (DS-029B)

rear-mounted terminal block

When using the PA-3640B (360 W)

First PA-3640B unit

Second PA-3640B unit

Power amplifier panel's

rear-mounted terminal block

Emergency power supply

panel's (DS-029B)

rear-mounted terminal block

Page 32

32

9.5. Junction Panel JP-0410 Connection

9.5.1. Connecting the Junction Panel's rear-mounted terminal block

1. 24V IN/OUT terminals

• The power capacity of the JP-0410's

built-in power supply is 2 A. Use the 24V

IN/OUT terminals when the power

capacity is insufficient because of an

increase in the number of zones or

remote controls. (Refer to p. 35.)

• The junction panel is shorted between

IN and OUT terminals using a jumper

wire at the factory. Remove this jumper

and connect an expansion power supply

when using the expansion power

supply. (Refer to the figure on the right.)

2. EMG (Emergency) 24V terminal

• 24 VDC is output when emergency broadcast is made. (Maximum usable current: 100 mA.)

• Used to control external equipment.

3. EMG (Emergency) DS, GEN (General) DS, BATTERY FAULT/ CHECK terminals

• Connect to the DS-029B's rear-mounted terminal block.

4. TIMER 2 terminal

• Connects to the music playing machine's BUSY terminal activated by timer.

• Preset broadcast zones are automatically selected at the designated time, and the time signal (such as

Westminster Chime) is provided to the preset zones.

5. CHIME OUT terminal

• Connect this terminal to play the music playing machine's 4-tone chime without installing a chime device in

the pre-amplifier.

• Pressing the chime button on the main rack, general remote control unit or emergency remote control unit

currently making broadcast outputs an activation signal from this terminal.

6. Power amplifier panel connection terminals

• Connect to the power amplifier panel's speaker output terminals. There are two pairs of terminals (C1-H1

and C2-H2), and the relationship of each terminal to output speaker line is as shown below.

C1/H1: Speaker lines 1-5

C2/H2: Speaker lines 6-10

• These terminals are shorted with a jumper wire between C1 and C2 and between H1 and H2 at the factory.

Remove the jumper wire and connect these terminals to individual power amplifier panels when avoiding the

parallel operation of power amplifier panels or when making different broadcasts to each of five-zone

groups. Note that if the jumper wire has been removed, the output of the second power amplifier panel and

its subsequent panels cannot be monitored without the Monitor Panel MP-011.

DC power supply panel

OUT

IN

Built-in power supply

Built-in circuit

Emergency power supply

Emergency remote control unit

General remote control unit

Emergency cutoff 24 V

Page 33

Power Consumption

303 W

572 W

700 W

33

9.5.2. Connecting the AC power supply of the Junction Panel JP-0410

• The Junction Panel JP-0410 supplies the AC power to each component mounted in the rack.

• AC power is always supplied to the UNSWITCHED AC outlets. Be sure to connect the Emergency Power

Supply Panel to the UNSWITCHED outlet to keep its internal batteries fully charged. Make sure that the DC

Power Supply Panels AD-011 and AD-031B are also connected to the UNSWITCHED outlet.

• AC power is supplied to the SWITCHED AC outlets when the pre-amplifier's power switch is set to the ON

position or when the broadcast zone is selected from any connected component or when the Emergency

Activation terminal is shorted. Power amplifier panels are mainly connected to the SWITCHED outlets.

Note: The "H" version is equipped with terminal blocks instead of the AC outlets.

Note: Up to a total of 450 VA for six UNSWITCHED AC outlets

(five on the rear panel and one on the front panel).

Up to a total of 450 VA for all two outlets

JP-0410's (L version) rear panel

JP-0410's (H version) rear panel

• Power consumption of the power amplifier panel

The following table shows the power consumption of each power amplifier panel, providing guidelines on the

maximum connectable power for the SWITCHED AC outlets.

Model No.

PA-1230B

PA-2440B

PA-3640B

Component Name

120 W power amplifier panel

240 W power amplifier panel

360 W power amplifier panel

Page 34

34

9.6. DC Power Supply Panel Connection

9.6.1. When the DC power supply panel is not required (i.e. when you can do with the junction panel's

internal power supply)....

The power capacity of the Junction Panel's (JP-0410) internal power supply is 2 A in maximum output current.

Note the total current of connected components and external equipment. If their total current exceeds 2 A, the

power supply must be expanded. If not exceeding 2 A, use the junction panel with a jumper wire connected

between 24V IN and OUT terminals. (The jumper wire is connected at the factory.)

JP-0410's rear-mounted

terminal block

Jumper wire

Jumper wire

Rack mounted components

(Operation on 24 VDC)

Emergency power supply

DS-029B

OUT

IN

Internal circuit

Internal power supply

JP-0410

Emergency remote control unit

General remote control unit

Emergency cutoff 24 V

External equipment

Rack-mounted components (operation on 24 VDC)

Rack-connected external equipment (operation on 24 VDC)

Current Consumption

0.45 A

0.4 A

0.65 A

0.6 A

0.1 A

0.18 A

0.2 A

0.4 A

Model No.

JP-0410 (internal circuit)

JP-039-10

JP-039-20

EP-0510

EP-029-10

EP-029-20

PP-025B

MP-011

Component Name

Junction Panel

10-zone Expansion Junction Panel

20-zone Expansion Junction Panel

Integrated Control Panel

10-zone Expansion Operation Panel

20-zone Expansion Operation Panel

Pre-amplifier Panel

Monitor Panel

Current Consumption

0.3 A

0.1 A

0.18 A

0.13 A

0.13 A

Model No.

EP-059R

EP-029-10

EP-029-20

RM-1100

RM-1200

Component Name

Integrated Emergency Remote Control Panel

10-zone Expansion Operation Panel

20-zone Expansion Operation Panel

10-zone Remote Microphone

20-zone Remote Microphone

Page 35

35

9.6.2. When expanding the power supply for external equipment

Let us assume that one expansion power supply is added to the system solely to cover the shortage of power

to be supplied to external equipment as the result of connecting many external equipment or mounting many

components in the rack.

Note: Remove the jumper wire placed between the 24V IN and OUT terminals of the terminal block located on

the rear panel of the Junction Panel JP-0410.

Rack mounted components

(Operation on 24 VDC)

DS-029B

OUT

IN

Internal circuit

Internal power supply

Emergency power supply

Expansion power supply

JP-0410

Emergency remote control unit

General remote control unit

Emergency cutoff 24 V

External equipment

<DC power supply panel>

Two types of expansion power supplies (DC power supply panels) are made available depending on the

current capacity.

9.6.3. When expanding the power supply for internal equipment

When many components are mounted in the rack, the power supply system needs to be divided using an

expansion power supply.

Memo

• Leave a jumper wire connected between 24V IN and OUT terminals of the terminal block located on the rear

panel of the Junction Panel JP-0410.

• Supply power to the Integrated Control Panel EP-0510 from the JP-0410.

• Connect the output terminal of the Emergency Power Supply Panel DS-029B to the DC input terminal of the

expansion power supply.

Rack mounted components

(Operation on 24 VDC)

Rack mounted

components

(Operation

on 24 VDC)

DS-029B

OUT

IN

Internal circuit

Internal power supply

Emergency

power supply

Expansion

power supply

JP-0410

Emergency remote control unit

General remote control unit

Emergency cutoff 24V

<DC power supply panel>

External equipment

24 VDC OUT 24 VDC IN

AD-011: Maximum current 2.5 A

AD-011's rear-mounted terminal block

Connects to DC24 V IN terminal of JP-0410's rearmounted terminal block.

Connects to GND terminal of JP-0410's rear-mounted

terminal block.

DC24V DC24V Main power supply

IN OUT MAX10A

AD-031B: Maximum current 10 A

GND GND GND

AD-031B's rear-mounted

terminal block

Connects to DC24V IN terminal of JP-0410's rearmounted terminal block.

Connects to GND terminal of JP-0410's rear-mounted

terminal block.

Page 36

36

9.6.4. Connection between DC power supply panel and Expansion Operation Panel EP-029

Make connections using the optional expansion power cable YR-931. Note the polarity when connecting. The

red cord is for 24 VDC (+), while the black cord is for 24 VDC (–).

YR-931

EP-EP cord

Integrated Control Panel

EP-0510

Use this cord to

disconnect the

power supply.

Supplied with EP-029.

YR-931

EP-AD cord

Use this cord to connect

the power supply.

Black

Red

EP power supply

EP power supply

24 VDC OUT 24 VDC IN

Red

Black

AD-011's rear-mounted

terminal block

DS-029's

rear-mounted

terminal block

Expansion Operation

Panel

EP-029

DC Power Supply

Panel

AD-011

Emergency Power

Supply Panel

DS-029B

Page 37

37

9.6.5. Connection between DC power supply panel and Expansion Junction Panel JP-039

Use the optional expansion power cable YR-931 for connection. Note the polarity when connecting. The red

cord is for 24 VDC (+), while the black cord is for 24 VDC (–).

k

Junction Panel

JP-0410

Expansion Junction Panel

JP-039

DC Power Supply Panel

AD-011

Emergency Power

Supply Panel

DS-029B

24 VDC OUT 24 VDC IN

Black Red

AD-011's rear-mounted

terminal block

DS-029B's

rear-mounted

terminal block

YR-931

JP-JP cord

Use this cord to

disconnect power.

YR-931

JP-AD cord

Blac

Red

Use this cord to

connect power.

Page 38

38

10. SETTING OF THE INTEGRATED CONTROL PANEL EP-0510

Use switches SW1-SW4 on the EP-0510's control circuit board for setting.

Set the following items using the switches SW1-SW4.

• [Warning Announcement Interlock] or [Warning Announcement Non-Interlock] mode (SW4-1)

Use SW4-1 switch to set either mode.

• [Warning Announcement] or [Evacuation Announcement] mode (SW4-2)

Use SW4-2 switch to select either announcement.

• Manual operation interlock (SW4-3)

Set whether to select interlocking zones or individual zones when the selector key is pressed to make

emergency broadcast.

SW4

ON

OFF

1

Interlock

Non-interlock

SW4

Warning announcement non-interlock

ON

12345678

SW4

ON

12345678

ON

OFF

2

Warning Announcement

Evacuation Announcement

SW4

Warning/Evacuation Announcement selection

SW4

ON

OFF

3

Individual zone

Interlocking zone

SW4

Manual operation interlock

when making emergency broadcast

ON

12345678

ON

12345678

ON ON ON

12345678 12345678 12345678

SW2 SW3 SW4

SW1

Page 39

39

• Evacuation Announcement interval (SW4-4 through SW4-8)

Time intervals can be set for 30 seconds to 15 minutes 30 seconds in 30 seconds units.

• All-zone announcement interval (SW2-3 through SW2-8)

Time intervals can be set for "OFF", "0 second" or "30 seconds to 15 minutes 30 seconds" in 30 seconds

units.

• Warning Announcement (SW3-2 through SW3-8)

Set "repeat yes or no", "number of repeats", "repeat intervals", and "repeat mode" for the Warning

Announcement.

SW4

ON

OFF

4

0

8 minutes

5

0

4 minutes

6

0

2 minutes

7

0

1 minute

8

0

30 seconds

SW4

Evacuation Announcement interval

ON

12345678

SW2

ON

OFF

3

Off

On

4

0

8 minutes

5

0

4 minutes

6

0

2 minutes

7

0

1 minute

8

0

30 seconds

SW2

All-zone announcement interval

ON

12345678

SW3

ON

OFF

2

Termination

Resumption

SW3

Repeat mode No. of repeats Repeat intervalRepetition

ON

12345678

3

+0

+2

4

+0

+1

5

No

Yes

6

0 minute

1 minute

7

0 second

30 seconds

8

0 second

15 seconds

Memo

• "Resumption": Warning Announcement interrupted by a PA microphone announcement is resumed after

microphone announcement completion.

• "Termination": Warning Announcement is terminated when a PA microphone announcement is made. (It is

not resumed even when the microphone announcement is completed.)

• Number of repeats: Warning Announcement is repeated twice when the SW3-3 and SW3-4 switches are

both set to OFF. If, for example, the SW3-3 switch (+2) is set to ON, the number of repeats increases by

two, causing the Warning Announcement to be repeated four times.

Page 40

40

Set equipment that can initiate Main Rack BGM. Both switches are set to OFF at the factory so as to allow the

Main Rack BGM to be played from the [Main rack system and all emergency remote control units].

SW1

Equipment that can initiate Main Rack BGM

Main rack system and all emergency remote control units

Main rack system only

All emergency remote control units

Emergency remote control unit of address 0 only

1

OFF

OFF

OFF

2

ON

ON

ON ON

OFF

SW1

ON

12345678

Note

When equipment is not registered as the "equipment that can initiate Main Rack BGM", even if you press its

group selector key or individual zone selector key, which are both registered for [BGM], you cannot select the

Main Rack BGM.

SW1

ON

OFF

8

Normal

Zone lamp line indication

Line

SW1

ON

12345678

When neither emergency broadcast nor general

broadcast is made, the line operation status screen on

the right is displayed.

Displaying line status.

Return the test switch to OFF

after checking line status.

Note

If the SW1-8 switch (zone lamp line indication) is left ON (line check mode), the fire floor lamp does not light

when emergency broadcast is made. Therefore, shift the switch back to OFF (normal mode) and ensure that

the line operation status display is turned off after completing the check of lines in use.

• Main Rack BGM broadcast (SW1-1 and SW1-2)

Set the switch to ON (line check mode) to check to see which speaker line is currently in use by lighting the

zone lamp.

• Zone lamp line indication (SW1-8)

Page 41

41

11. EXPANSION PANEL ADDRESS SETTING

11.1. Expansion Operation Panel EP-029

When your system contains the 10-Zone Expansion Operation Panel EP-029-10 or 20-Zone Expansion

Operation Panel EP-029-20, the address number needs to be assigned to each expansion unit.

• Use consecutive numbers starting with 0 to set the address.

First unit : Address 0

Second unit : Address 1

Third unit : Address 2

Fourth unit : Address 3

Eleventh unit : Address A

Sixteenth unit: Address F

11.2. Expansion Junction Panel JP-039

• Systems incorporating the 10-Zone Expansion Junction Panel JP-039-10 or 20-Zone Expansion Junction

Panel JP-039-20 require that the address number be assigned to each expansion unit, as with the

expansion operation panel.

• As with the Expansion Operation Panel, assign the address using consecutive numbers starting with 0.

First unit : Address 0

Second unit : Address 1

Third unit : Address 2

Fourth unit : Address 3

Eleventh unit : Address A

Sixteenth unit: Address F

• The address switch is located

behind the zone name label at the

lower right. Set the switch using a

screwdriver for watch repair.

Expansion Operation Panel

Expansion Operation Panel

EP-029-20

EP-029-10

1

0

2

F

3

E

4

5

6

(Address setting to 1)

D

C

7

B

8

A

9

Address switch

(Address setting to 1)

0

1

F

2

E

3

D

C

4

5

6

B

7

A

8

9

Address switch

Expansion Junction Panel

JP-039-20

Expansion Junction Panel

JP-039-10

Page 42

42

12. CONNECTING THE RACK-MOUNTED COMPONENTS TO EXTERNAL

LINES

12.1. Names of the Front-Mounted Terminal of the Junction Panel JP-0410

12.2. AC Power Supply Connections

The power supply circuit of an emergency broadcast system must be a dedicated circuit, and the circuit

breaker after a branch point must be marked with the indication of the dedicated power supply.

Memo

About ZNR GND. (This memo also applies to the Expansion Junction Panel JP-039.)

ZNR GND is a dedicated grounding terminal for the speaker line surge absorber. By placing a shorting piece,

the surge absorber is grounded. Do not move the shorting piece except when conducting dielectric strength

and insulation resistance tests (p. 45).

BB

B

Low-voltage indoor

AC trunk line

Dedicated power

supply for emergency

broadcast system

Power supply for

general applications

BB

B

Low-voltage indoor

AC trunk line

Dedicated power

supply for emergency

broadcast system

Power supply for

general applications

JP-0410 (L version) JP-0410 (H version)

Service outlet

AC power is always supplied.

(Up to 100 VA)

Shorting piece

for ZNR GND

Shorting piece

for ZNR GND

front panel front panel

Page 43

Total speaker line wattage

Under 24 W

25-40 W

41-80 W

81-120 W

121-160 W

161-200 W

43

12.3. Speaker Connections

Connect speaker cables to terminals R,N, and C, as shown below. (The R wire may be omitted when no

attenuator is used.) When Expansion Junction Panel JP-039 is additionally used, make connections in like

manner.

Notes

• The maximum connectable speaker wattage per line is 200 W. When exceeding 200 W, divide the line into

two or more groups.

• Connect speaker cables so that the total of rated inputs of every five speaker lines (1-5, 6-10, etc.) is less

than 1 kW.

The junction panel is fitted at the factory with 0.5 A fuses for speaker line protection. Depending upon the

speaker line wattage to be used, these may have to be replaced with other values of optionally available

fuses. When replacing, be sure to use a specified type fuse set (10 fuses per set, option).

Fuse current capacity

0.3A

0.5A

1.0A

1.5A

2.0A

2.5A

Fuse set model No.

F-0.3A10

F-0.5A10

F-1A10

F-1.5A10

F-2A10

F-2.5A10

• Connections between speaker and attenuator

Speaker line No. 1

Speaker line No. 10

N1

R1

C1

N10

R10

C10

JP-0410 front panel

N R COM

Attenuator

C

H

N R COM

Attenuator

C

H

To other speakers

Normal (N)

Emergency (R)

Common (C)

Black

Red

White

No attenuator Attenuator used Attenuated speaker

Page 44

44

12.4. Connections to the Automatic Fire Alarm Systems

By connecting the emergency PA system to an automatic fire alarm system, voice alarms can be

automatically provided as soon as the PA system receives a fire signal from a fire detector. It must be seen to

that the floor signal lines (EL) are connected to the junction panel terminals of their corresponding floors.

Because fire confirmation signals (EF) are also important to automatic broadcast, connect their cables

properly.

When sounding a zone sound device ("zone bell" herein) simultaneously with the activation of the automatic

fire alarm system, connect the zone bell stop signal (EB1) lines to both the fire alarm system and PA system

in order to stop the zone bell during voice alarm broadcast (except the second signal) or microphone

announcement. Also, when using emergency guidance panels of the type that sounds a guidance tone,

connect the EB terminal (EB2) so that the guidance tone is disabled during voice alarm broadcast or

microphone announcement.

Only the floor signal lines are connected to the Expansion Junction Panel JP-039.

Notes

• Each contact of the automatic fire alarm system must be a no-voltage make contact with a contact capacity

of 30 VDC/200 mA or more.

• EB1 and EB2 are independent contacts and are exactly the same in operation timing.

• The line resistance of wiring between automatic fire alarm system and amplifier must be less than 50 Ω.

EF

confirmation

Guidance panel with

guidance tone device,

etc.

EC

EL1

EL2

EL3

EL4

EL5

EL6

EL7

EL8

EL9

EL10

EF

EB

EB

Automatic fire alarm system

Fire floor signal

Fire confirmation

signal

Zone bell stop

JP-0410 front panel

EB1

EB2

EL (automatic fire alarm system)

Page 45

45

13. CONNECTION INSPECTION

13.1. Inspection of Connections and Wiring

• After all connections are completed, inspect the connections and wiring again before turning on the AC

breaker of Junction Panel JP-0410.

• Ensure that cables are correctly connected between components. Also, check external wiring for connection

errors and wiring omissions.

13.2. Adjustment and Measurement of Power Circuitry

13.2.1. AC line insulation measurement (using megger)

Disconnect the power cable connection to measure the insulation between the following items.

(1) Between the ground and one line (Between G and L1) : Over 0.1 MΩ

(2) Between ground and another line (Between G and L2) : Over 0.1 MΩ

(3) Between lines (Between L1 and L2) : Over 0.1 MΩ

When lowering 0.1 MΩ, check for flaws on cable sheath, defective taping in the joint box, and any leakage into

pipes. If such problems are found, repair immediately.

13.2.2. Power voltage measurement (using tester)

Measure voltage between lines. Normally, it must be within the range between –5% and +10% of nominal

voltage.

• When lowering –5% of nominal voltage, the power capacity is insufficient. Inspect and adjust the receiving

system.

• When exceeding +10% of nominal voltage, adjust the receiving facilities to prevent equipment burning.

Page 46

46

13.3. Speaker Line Adjustment and Measurement

13.3.1. Speaker line impedance measurement (using impedance meter)

Measure the impedance of each speaker line, then measure the total impedance of all lines. Record the

planned impedance and measured impedance for future maintenance and inspection. If the planned

impedance is notably different from the total impedance, inspect individual lines again to find and remove the

cause.

Impedance of arbitrary wattage can be calculated using the formula below.

Z = E

2

/P (Ω)

where E = Rated line voltage (100 V)

P = Speaker wattage (per line)

Note: Disconnect each speaker line from the terminal block inside the main rack, and measure the impedance

of each line.

When the speaker lines are connected to the terminal block inside the main rack, remove the terminal block

by loosening two screws indicated by the arrow in the figure below, and disconnect the speaker lines from the

main rack.

Measure the impedance between C and N and between C and R of the speaker line using an impedance

meter (ZM-104, etc.).

JP-0410 front panel

Page 47

47

13.3.2. Speaker line insulation resistance measurement (Measuring instrument: Megger)

Measure between the ground and the cable for each line. Do not measure between cables, as this can

damage both the speaker and matching transformer. It is recommended that wiring be performed so that the

following resistance values are obtained.

• New line : 10 MΩ minimum

• Existing line : 5 MΩ minimum

• New line total resistance : 3 MΩ minimum

• Existing line total resistance : 1 MΩ minimum

Note: Do not measure the insulation resistance with the speaker line connected to the terminal block inside

the main rack.

When the speaker lines are already connected to the terminal block inside the main rack, remove the terminal

block by loosening two screws indicated by the arrow in the figure below, then disconnect the speaker lines

from the main rack.

Measure the insulation resistance between the ground and each speaker line using the megger.

When the measure insulation value is much lower than the specified value, this can be caused by shorts

inside the pipe or joint box, defective taping, incorrect wiring, play of the speaker, or contact of a lead with wall

surface. To ensure effective inspection, divide lines into lots when inspecting them.