Page 1

EXES-6000

For

INTERCOM SYSTEM

Fully Electronic Exchange

EX-610/620/630

INSTALLATION HAND BOOK

EX-610/620/630

Page 2

WARNING: (For U.S.A. only)

This equipment generates, uses, and can radiate radio frequency energy

and if not installed and used in accordance with the instructions manual,

may cause interference to radio communications. It has been tested and

found

to

comply

with

the

limits

for a

Class A computing

device

pursuant to Subpart J of Part 15 of FCC Rules, which are designed to

provide reasonable protection such interference when operated in a

commercial environment.

Operation of this equipment in a residential area is likely to cause

interference in which case the user at his own expense will be required

to take whatever measures may be required to correct the interference.

Page 3

CONTENTS

INTRODUCTION TO THE INSTALLATION MANUAL FOR EXES-6000

— P AR T 1. OUTLINES OF EXES-6000 SYSTEM AND RELATED EQUIPMENT —

1. Description and Features

1-1 System

1-2 Exchanges (EX-610/620/630)

1-3 Stations

1-4 Terminal Boards (BX-610/620)

1-5 Junction Cables (YR-810/801)

2. Example of Exchange Mounted on Intercom Cabinet Rack

3. Recommendable Example of Exchange Mounted on Amplifier Cabinet Rack

4. Specifications Related to Installation

5. Functions of Units Mounted on Exchanges EX-610/620/630

5-1 CP (Central Processing Unit)

5-2 OC (Output Control Unit) .

5-3 HC (Highway Control Unit)

5-4 SG (Signal Generating & Distributing Unit)

5-5 DL (Duplex Link Unit) . .

5-6 CL (Conference Link Unit)

5-7 LM (Line MODEM Unit) .

5-8 SI (Speech Interface Unit)

5-9 PI (Paging Interface Unit)

5-10 SA (Station Paging Assignment Unit]

5-11 Tl (Tie-line Interface Unit)

5-12 DS (Power Supply Unit) . .

5-13 BC (Battery Case) . . . . .

page

1

2

2

2

2

2

3

5

5

6

6

6

7

8

8

8

8

8

8

8

8

8

— PART 2. INSTALLATION OF EXES-6000 SYSTEM —

6. Installation of the EXES-6000 System

6-1 Exchanges

6-2 Stations . .

6-3 Accessories

7. Cable Installation

7-1 Type of Cables

7-2 Core Diameter versus Transmission Distance

7-3 Wiring

1. General Information

2. Spacing

3. Piping .

8. Connection of Equipments

8-1 Connection of Power Supply

8-2 Connection between the Exchange and the Terminal Board (BX-610 or BX-620) . .

8-3 Connection of the Terminal Board (BX-610 or BX-620) to the Main Terminal Board

8-4 Connection of the Station Plug to the Exchange Jack

8-5 Connection of Stations

9. Connection and Adjustment of Equipment

9-1 Connection of the Speaker Station (Simplified Paging)

9-2 Paging Connection

1. PA Paging

2.1 Station Paging (for EX-610/620)

2.2 Station Paging (for EX-630) .

9-3 Calling Tone Modifications. .....

9-4 Caution for Conference Unit Usage

9-5 Remarks on Indication and Control

9-6 Connection of Station for Emergency Paging . . .

9-7 Method to Establish Press-to-talk Control Function

9-8 Connection of PI-62 to call a pager receiver

9-9 BGM equipment connection

10. Inspection

10-1 Check when Power is Switched On

10-2 Speech and Function Tests

10-3 System Check Flow Chart

10-4 Simple troubleshooting

9

9

9

9

10

10

11

11

11

12

16

18

19

20

21

22

23

27

29

29

29

29

29

29

30

31

31

32

33

Page 4

INTRODUCTION TO THE INSTALLATION MANUAL FOR EXES-6000

This manual forms part of the Installation Manual for INTERCOM SYSTEM EXES-6000.

The EXES-6000 permits various functions besides normal speech by programming or con-

necting optional equipment according to your specific needs. Correct operation of these

additional functions is not performed by simply connecting the additional equipments/

devices. Provision of such additional function requires the following:

(1) Connection of the additional equipment, as required.

(2) Selection of functions which satisfy your needs and setting up these functions in the

respective equipment.

This "Installation Handbook of Exchanges EX-610/620/630 for EXES-6000 System"

contains technical instructions as to connection of exchange, etc, mentioned in the above

Paragraph (1). In addition to this, the proper installation of the system necessitates the

other installation manuals dealing with the selection of the function and its programming

referred to in the above Paragraph (2).

– 1 –

Page 5

PART1. OUTLINES OF EXES-6000 SYSTEM AND RELATED EQUIPMENT

1. Description and Features

1-1 System

Since the EXES-6000 System is a fully electronic intercom

system, it has the following features that surpass conventional

mechanical systems.

1. All components of the exchange are designed according to the

modular concept. This results in a sizable reduction in the

number of procedures required to install the system.

2. The exchange and terminal boards (BX-610/620) are designed

as separate units, allowing independent inspection of the wiring

and the exchange.

3. The wiring for each station is a non-polar 2-wire system which

uses a minimum

number

of

connecting

to

ease

wiring.

1-2 Exchanges EX-610 (64 stations)/EX-620 (128

stations)/EX-630 (256 stations)

The features of the exchange of the Toa EXES-6000 Intercom

Syste m are as follows:

1. All exchange are of modulor constructions. This results in a great

increase in ease and speed of system installation.

2. Extensive incorporation of ICs makes each exchange efficient

and space-saving as well as allows quieter operation than conventional intercom system.

1-3 Stations

The stations of the Toa Intercom EXES-6000 have the following

features:

1.

Each

station

is

connection to cables.

provided

2. Wiring from the exchange to each station is the non-polar 2-wire

system. The fact that only 2 wires are necessary makes installation easier, and with a 2-Pin jack (YC-601 or YC-603) at the end

of each cable, connection can be quickly made with a screwdriver.

3. There are eleven types of stations available for selection: desk-

top type, flush-mount type and desk/surface-mount type, etc.

with a 2-Pin

plug

(YC-602)

for

easy

1-4 Terminal Boards (BX-610/620)

The terminal boards BX-610/620 connect the line between the

exchange and the station. Compact and easy to connect, this

terminal board saves space and ensures simple disconnection of any

station line from the exchange when inspection is necessary. One

terminal board BX-610 or BX-620 can connect a maximum of 64

stations (EX-610) or 128 stations (EX-620) to the exchange all-call

plus 15 paging zones and 8 tie-line links. The exchange and the

terminal board are connected by junction cable YR-810 (2-wire)

for stations and YR-801 (4-wire) for paging and tie-line links.

To connect the station line to the terminal board, clip terminals are

provided which allow ensure simple connection without soldering.

For future system expansion or modification, the collective terminal

board to be described later on. (See page 12) This terminal is part of

the exchange.

1-5 Junction Cables ( Y R -810/801)

The YR-810 or YR-801 junction cable connects the exchange to

the terminal board BX-610 or BX-620. A single line of this junction

cable is capable of connecting the exchange to 8 stations (YR-81 0)

or to 8 paging zones (YR-801) or to 8 tie-line links (YR-801)

through the terminal board BX-610 or BX-620. Both cable ends are

equipped with multi-pole connectors which can easily plugged into

the exchange or the terminal board BX-610 or 620. Refer to the

drawing which appears in the Cable Installation and Connection

seciton of this manual for the right direction and order of cable

connections.

– 2 –

Page 6

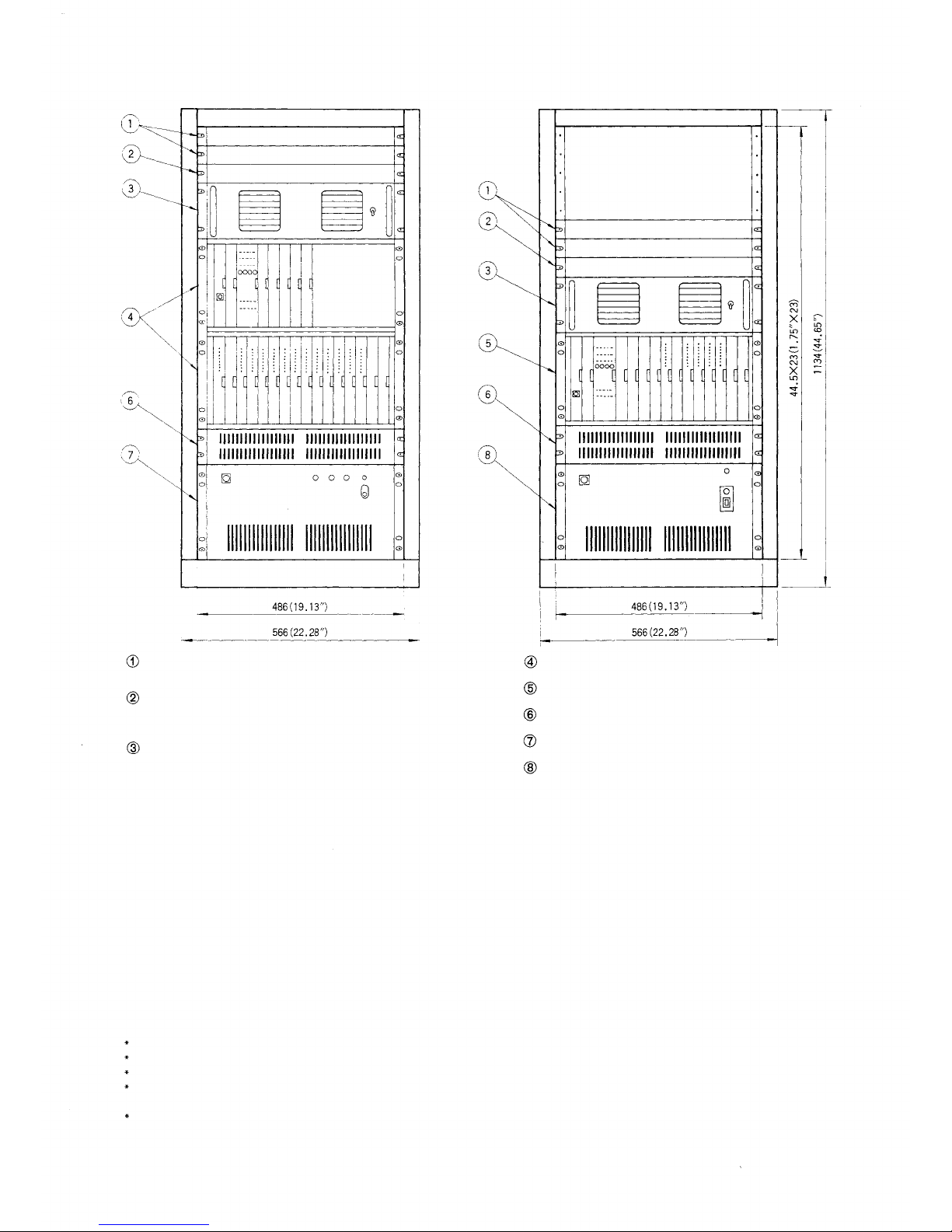

2. Example of Exchange Mounted on Intercom Cabinet Rack

(Including All-Call Paging and 15 Individual Zone Paging units and one Data Transmitting unit)

Exchange EX-620 (for 128 stations)

Exchange EX-610 (for 64 stations)

Central Processing Unit CP-66.

Output Control Unit OC-62

Highway Control Unit HC-62

Signal Generating and Distributing Unit SG-62

Conference Link Unit CL-62A (In this location, DL-62A is

also mountable.)

Duplex Link Unit DL-62A (CL-62A may be inserted into these

positions instead of DL-62A.).

Line Modem Unit LM-62B (LM-65, Line Modem Unit with

BGM function, may be inserted into these positions instead of

LM-62B).

Paging Interface Unit PI-62 (Type 2) (In t his location, LM-62B

or Tie-line unit TI-62 is also mountable.) (Zone 8~15 without

All-Call Paging)

Paging Interface Unit PI -62 (Typ e 1) (In this location, LM-62B

is also mountable.) (Zone 1~7 wit h All-Call Paging)

Perforated Panel PF-023A*

Data Transmitting Unit DT-E60 ( In the standard system, Perforated Panel PF-013A should come in this position.)* Junction

Cable YR-80 6 (Cable length: 1000mm) (YR-802 Cable length:

400mm) is not available.)

Note.*

The Exchange Cabinet Rack CR-610 or CR-620 includes

Perforated Panels PF-013A and PF-023A.

Power Supply Unit DS-620

Power Switch

AC Fuse 3A(110V/120V), 1.5A(220V/240V)

DC Fuse 20A(for use of 65 ~ 128 stations)

Battery Fuse 5A

Exchange Cabinet Rac k CR-620

Exchange Frame FR-620A

Power Supply Unit DS-610

Power Indication Lamp

Battery Power Indication Lamp

Buzzer Stop Switch

Exchange Cabinet Rac k CR-610

Exchange Frame FR-610A

Speech Interface Unit SI-62 (LM-62B may be

inserted into this position instead.).

– 3 –

Page 7

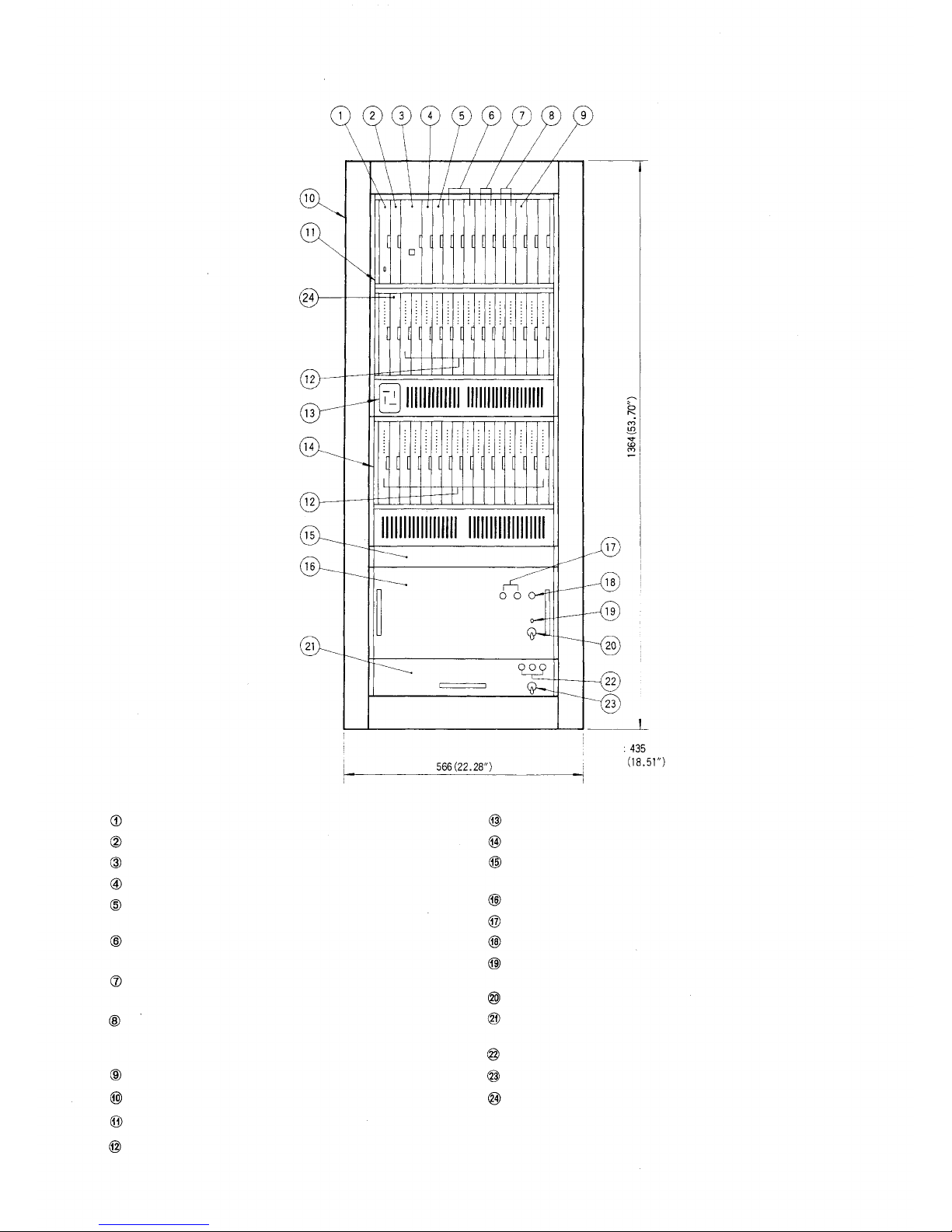

Exchange EX-630 (for 256 stations)

Central Processing Unit CP-66.

Output Contro l Unit OC-62

Highway Control Unit HC-64

Signal Generating and Distributing Unit SG-62

Conference Link Unit CL-62A (In this location, DL-62A is

also mountable.)

Duplex Link Unit DL-62A (CL-62A may be inserted into thes e

positions instead of DL-62A.)

Paging Interface Unit PI-62 (Type 1 in the left position, type 2

in the right position).

Tie-line Interface Unit TI-62 (In this location, Pl-62's are also

mountable. Type 3 in the left position, type 4 in the right

position)

Station Paging Assignment Unit SA-64

Cabinet Rack CR-271

Exchange Frame FR-630A

Line Modern Unit LM-62B (LM-65, Line Modem Unit with

BGM function, may be inserted into these positions instead of

LM-62B.)

Depth

Jack for Programming Station

Extention Frame FR-631A

Data Transmitting Unit DT-E60 (When this unit is not used,

mount Perforated Panel PF-013A in this place.)

Power Supply Unit DS-630

DC Fuse 20A (for use of 129 ~ 256 stations)

AC Fuse 10A (110V/120V), 5A (220V/240V)

Power Indication LED lamp (green for AC operation,

red for battery operation)

Power Switch

Battery

Case

BC-630

(When

this

unit

is not

used,

the Perforated Panel PF-023A in th is place.)

Battery Fuse 10A

Battery Power Switch

mount

Speech Interface Unit SI-62 (LM-62B may be inserted into this

position instead.)

– 4 –

Page 8

3. Recommendable Example of Exchange Mounted on Amplifier Cabinet Ra c k

Exchange EX-620 (for 128 stations)

Exchange EX-610 (for 64 stations)

Data Transmitting Unit DT-E60

Junction Cable YR-803 (for additional DT-E60)

Data Transmitting Unit DT-E60

Junction Cable YR-802 (Cable length: 400mm) or YR-806

(Cable length: 1000mm)

Blower Panel BP-031A (Do not substitute perforated panel for

this)

4. Specifications Related to Installation

4-1 Exchange

1) Wiring

Non-polar one twisted pair

Loop

Resistance:

Impedance: 600 ohms , balanced

Cable length: max. 1.0km (0.4mm dia.)

2) Power Sources (DS-610/620/630)

AC Mains (110, 120, 220, 240V) ± 10% 50/60Hz 24V DC

3) Rated Power Consumption

EX-610 130W (No link occupied) 300W (Max.)

EX-620 210W (No link occupied) 500W (Max.)

EX-630 410W (No link occupied) 1kw (Max.)

4) Battery for System Back-up on AC Power Failure (Option)

Type Sealed type Ni-Cd battery NDC-2435

Voltage 24V

Capacity 3500mAh

Charge System

Service Hours

EX-610: Approx. 2 hrs.

(2 x NDC-2435 necessary per system)

EX-620: Approx. 1.5 hrs.

(3 x NDC-2435 necessary per system)

EX-630: Approx. 1.5 hrs.

300

ohms,

or

less

max. 2.5km (0.65mm dia.)

max. 3.5km (0.9mm dia.)

Trickle Charging, approx. 1/40CA (20°C)

(3 x NDC-2460 necessary per system)

Exchange EX-620 (Frame FR-620A and necessary Units)

Exchange EX-610 (Frame FR-610A and necessary Units)

Perforated Panel PF-023A

Power Supply Unit DS-620

Power Supply Unit DS-610

5) Ambient Temperature

0~40°C(+32° ~+104°F)

6) Dimensions EX-610: 510(W) x 656(H) x 325(D)mm

(20.08" x 25.83" x 12.80")

EX-620: 510(W) x 878(H) x 325(D)mm

(20.08" x 34.57" x 12.80")

EX-630: 566(W) x 1364(H) x 435(D)mm

(22.28" x 53.70" x 17.13")

7) Weight EX-610: 45kg (99.1 IDS.) without battery

EX-620 : 57k g (125.63 Ibs.) without battery

EX-630: 109kg (240.30 Ibs.) without battery

Caution. Both top and side panels are perforated for ventiation

(EX-610/620). Do not place things on the top panel or

close to the side panels. (Intercom cabinet rack)

For maintenance works, allow much space between the

wal l and th e cabinet rack.

4-2 Station

Ambient Temperature

: 0° ~ +60° C (+32° ~ +140°F) (Except HF-640S)

: -10° ~ +60°C (+14° ~ +140°F) (Door Station HF-640S)

Permissible Loop Resistance: 300 ohms

Input/Output Impedance : 600 ohms (balanced)

Note. For details such as functions, dimensions and specifications,

refer to Spec. Sheet f or each equipment.

– 5 –

Page 9

5. Functions of Units Mounted on Exchanges EX-610/EX-620/EX-630

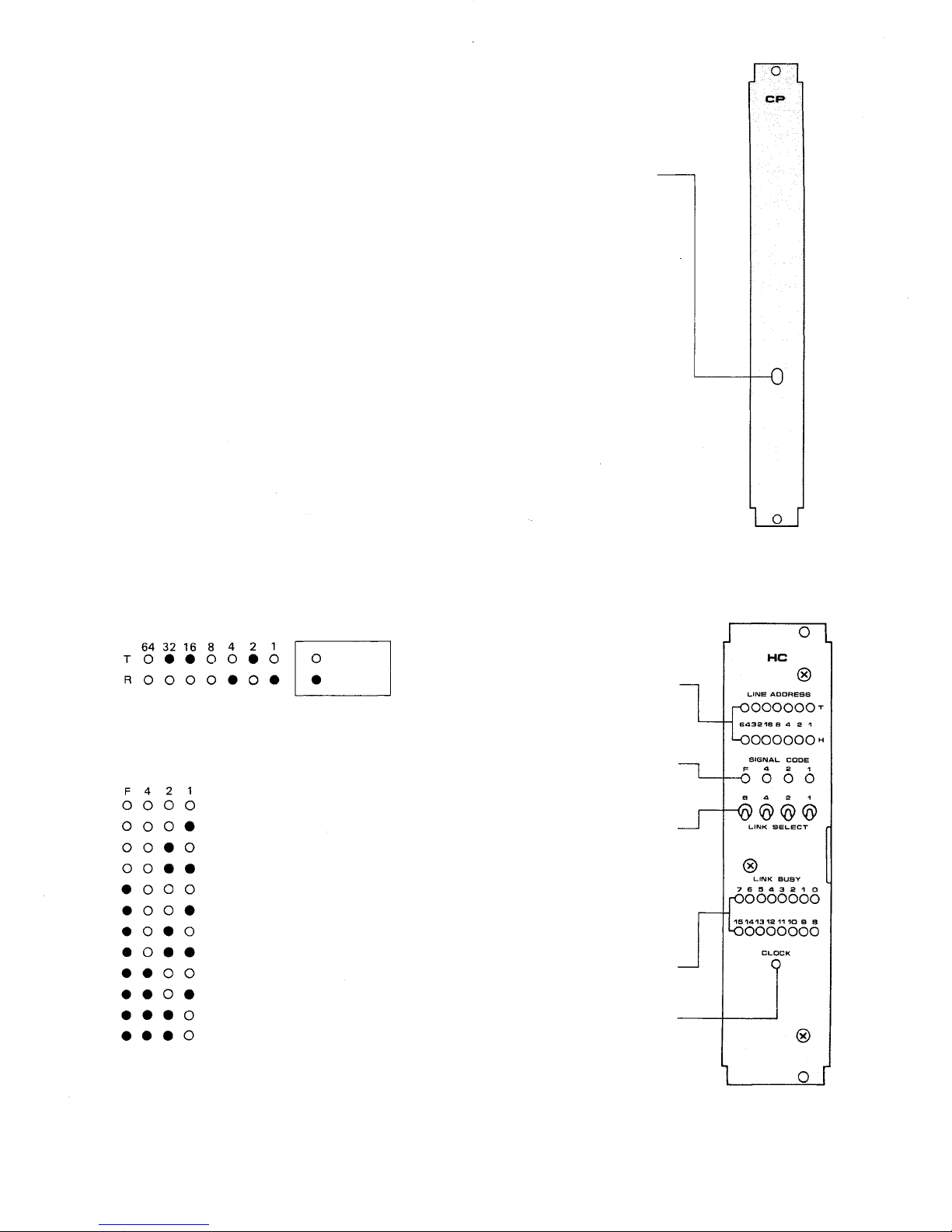

5-1 CP (Central Processing Unit)

Function: Reads out the exchange procedures written into the

5-2 OC (Output Cont rol Unit)

Function: Stores temporarily the output data from the CP unit

5-3 HC (Highway Control Unit HC-62

..... EX-610/620; HC-64..... EX-630)

Function: Turns on and off the time sharing switches at the LM,

memory ( ROM) and collates the data from stations for

traffic processing.

and distributes them to each unit.

DLand SG units according to instructions received from

the CP unit. The link busy indicator lamps on the front

panel dis pla y th e number of th e l in ks in us e.

PROGRAM SWITCH for #200

Programming

Set this to "ON" position only

at time of initial programming

of the exchange and registration

of functions. In this case,

station No.200 is "programming

station" but becomes a normal

station when switch is placed in

"OFF" position.

PROGRAM

ON

OFF

CP unit

(Example for HC-62)

LINE ADDRESS

Calling Station (T): No. 250

(200+32+16+2 = 250)

Called Station (R ) : No. 205

(200+4+1 = 205)

SIGNAL CODE

During Conversation

Press-to-talk (R -» T)

Press-to-talk (T-> R)

OFF duration on T & R

Calling

Privacy/Disconnected

Busy

Dialing

Zone paging

All call

Priority/Executive priority

Registration/Call holding/Mic-off

TONE AND

SPEECH MODE

Off

Bright

LINE ADDRESS Lamp

These lamps display the station

numbers (Binary number) using the

selected link (T: Calling station, R:

Called station)

SIGNAL CODE Lamp

These lamps display the code of

signal tone being used in the

selected link.

LINK SELECT Switch

The switch position is to be selected

in accordance with the number of

links in use. The line address and

the signal code of the link in use

are then displayed by the lamps.

Note: Operate these switches using

the binary notation.

LINK BUSY Lamp

These lamps display the number of

the links in use.

CLOCK Lamp

This lamp, when on, indicates

that the control signal for the

time sharing switch is being

transmitted normally.

HC uni t (HC-62)

– 6 –

Page 10

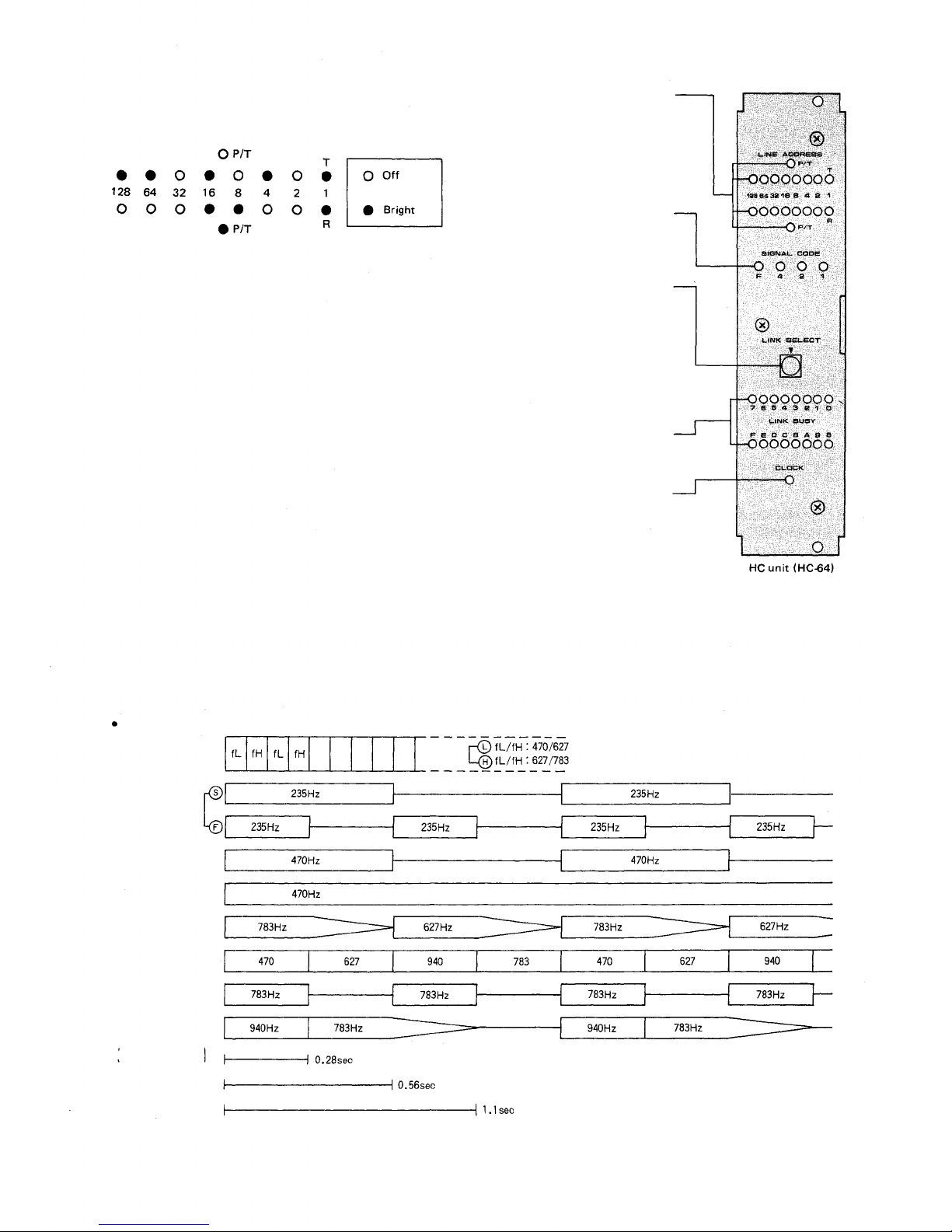

(Example for HC-64)

LIN E ADDRESS

LINE ADDRESS Lamp

These lamps display the station

numbers (Binary number) using the

selected link (T: Calling station,

R: Called station). The P/T lamps

when a paging or tie-line call is

made.

These lamps display the code of

signal tone being used in the select-

Calling Station ( T ): No. 413

(200+ 128 + 64+ 16 + 4 + 1 = 41 3)

Called Station ( R ) : paging No. 25

(16 + 8 + 1 = 25)

ed link.

The switch position is to be selected

in accordance with the number of

links in use. The line address and

the signal code of the link in use

are then displayed by the lamps.

Note: Operate this switch using the

hexadecimal notation.

These lamps display the number of

the links in use.

Indicates that the control signal for

the time sharing switch is being

transmitted normally.

5-4 SG (Signal Generating and Distributing Unit)

Function: Composed of 8 kinds of signal generators (calling, privacy/disconnected,

Tone of SG Unit

busy, dialing, zone paging, all call, priority/executive priority, registration

confirmation/call holding/mic-off) and distributors.

This unit distributes under HC control the required signal tones to each

individual link.

SIG NA L CODE Lamp

LINK SELECT Switch

LINK BUSY Lamp

CLOCK Lamp

Calling tone

Privacy tone

Busy tone

Dialing tone

Zone Paging

All-Call Paging

Priority tone

Holding tone

Registration

confirmation

(

tone

)

– 7 –

Page 11

5-5 DL (Duplex Link Unit)

Function: Operates under the control of the HC unit to connect or disconnect the

individual links for conversation between two stations, changing over

from the hands-free conversation to the full duplex conversation mode,

or

vice

versa.

be mounted in t he EX-610 and up to 4 in the EX-620/630.

One DL

unit

is

provided

with 4 links.

Up to 3 DL

units

can

5-6 CL (Conference Link Unit)

Function: Operates under the control of the HC unit to connect or disconnect the

links for conversation among up to 4 parties and conversation between 2

parties. One CL u n it i s provided with 1 conference link and 2 speech links.

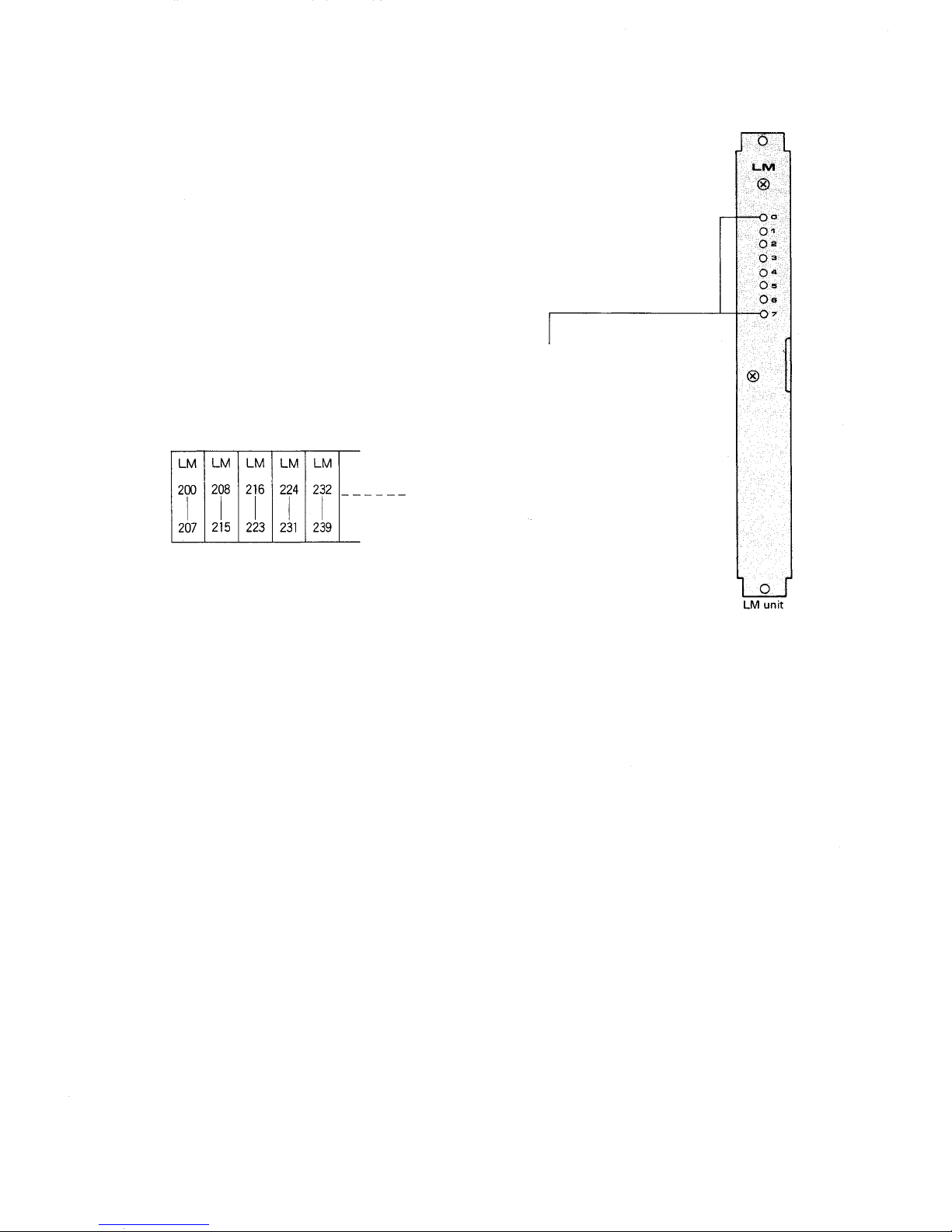

5-7 LM (Line MODEM Uni t)

Function: Is composed of a modulator to transmit signals from

the station to the speech link, a demodulator to send

out signals from the speech link to the station, a dial

receiver and a scanning circuit that scans the station

"Privacy ON/OFF" conditions and "Handset ON/ O FF "

conditions. Up to 8 stations can be connected per LM

Unit.

Station number lamp

Each lamp varies its brightness to in-

dicate the condition of the station. The

relation between brightness and line

status is as follows:

Bright: Exchange and station are con-

Off: Exchange and station are not

Extremely bright (yellow):

nected properly.

connected.

Short circuited between paired

lines.

Arrangement of the LMs with individual ranges for the

station numbers covered (from left to right) is shown here.

5-8 SI (Speech Interface Unit)

Function: Connects to the SM-600 Speech Message Device to

send or receive a voice signal.

5-9 PI (Paging Interface Unit)

Function: Provides PA paging and stati on paging. It sends out both

paging voice signals and relay make signals for power

remote control of the PA amplifier. It also delivers the

serial output for radio pagers. The PA paging si gna l goes

out through the assigned YR-801 cable to terminal P1

or P2 of the BX-610/620 terminal boards.

5- 1 0 SA (Station Paging Assignment Unit)

Function: Distributes each of paging outputs to each LM unit.

This unit cannot be used for EX-610/620.

5-11 T l (Tie-line Interface Unit)

Function: When 2 or 3 exchanges are tie-line connected, this units

transmits and receives the audio signals and dial data

between the exchanges.

5-12 DS (Power Supply Unit)

1. DS-610 (for 64 stations)

An exclusive power supply unit for the EX-610 exchange.

This unit cannot be used in the system for more than 64 stations.

2. DS-620 (for 128 stations)

An exclusive power supply unit for the EX-620 exchange and can

also be used for the EX-610 exchange.

3. DS-630 (for 256 stations)

An exclusive power supply unit for EX-630 exchange.

5-13 BC (Battery Case)

An exclusive battery case for EX-630.

Accomodates three of Ni-Cd batteries (Sealed type, NDC-2460).

The charger circuit is incorporated in DS-630.

– 8 –

Page 12

PART2. INSTALLATION OF EXES-6000 SYSTEM

6. Installation of the EXES-6000 System

6-1 Exchanges

Pay particular attention to the following points du ring installation

of the exchange:

The layout should allow easy servicing and inspection.

The exchange is compact and lightweight; however it is important to ascertain the strength of the floor or wall on which it will

be placed.

The exchange should be grounded. When it is used in combination with other systems, for example, a PA system, the exchange

should be connected to the other components for common

grounding.

Choose a low "source noise" AC power supply f or th e exchange.

Line noise can downgrade speech quality.

Be sure to provide a power outlet for the exchange and have its

capacity checked. A capacity of 500 watts is su fficient.

Plan the layout so that the terminal board BX-610 or BX-620

can be installed near the exchange.

System should include a surge protector.

This high performance exchange is compact as well as quiet, and can

be easily installed almost anywhere. Areas described below, however,

should be strictly avoided.

An area where it will obstruct traffic, for example, an indoor

hallway or near the entrance or exit of a room.

An area where it will be exposed to fire, heat or direct sunlight

(suitable ambient temperature is 0° ~ +40°C (+32° ~ +104°F)).

A dusty area (where there is metal dust or dirt).

Near a storage place for chemicals, oil, etc.

An area susceptible to vibration.

Near high-voltage equipment.

In a strong electric field.

Near equipment vulnerable to the influence of an electric field.

6-3 Accessories

The terminal board BX-610 or BX-620, which is to be connected to

the exchange by junction cable YR-810 or YR-801, can be mounted

on a wall near the exchange if the cable length 2.5m (8.2 feets) and

cable routing is adequate. The exchange should also be installed so

that it can easily be connected to the station line.

Junction cable YR-810 or YR-801, which connects the exchange

and the terminal board, should not be bent at a sharp angle. The

terminal board should be installed so that the cable can be connected with a reasonable amount of slack in it.

6-2 Stations

Particular attention should be given to the following points during

installation.

Choose a desk-top type, flush-mount type or desk/surface

mount typ e station according to the user's need.

If the PA paging function is adopted, precautions should be

taken to ensure against feed-back due to interference between

the station (microphone) and the paging speaker; that is, they

should be installed facing different directions or separated from

each other as far as possible.

The "para-branching" operation or the connection of more than

one station to one circuit is not possible.

Stations are compact for each installation almost anywhere. However, areas described below should be strictly avoided.

An area where it can be exposed to fire, heat or direct sunlight

(suitable ambient temperature is 0° ~ +60° C (+32° ~ +140°F)

(except HF-640S) or -10° ~ +60°C (+14° ~ +140°F) (Door

Station HF-640S)).

A dusty area (where there is metal dust or dirt).

Near a storage place for chemicals, oil, etc.

An area subject to vibration.

Near high-voltage equipment.

In a strong electric field.

SCR type light dimmers.

– 9 –

Page 13

7. Cable Installation

7-1 The Ty pe of Cables

Wire type, number of wi re pairs and number of individual wires are

to be determined for individual sections of the wiring system according to the guidelines set out below.

Twisted paired cables (such as those used for key telephones)

are to be used for wiring between the station and the intermediate

or indoor terminal board.

As a rule, private branch cables are to be used f or wiring between

indoor terminal boards, intermediate terminal boards, main

terminal boards, e tc.

Exchanges

(EX-610/620)

YR-810

YR-801

Terminal

Boards

(BX-610/620)

Main

Terminal

Boards

Indoors, the number of cab les that can be run through a conduit

is, as a

rule,

less

than

200

Outdoor wires should be used where wiring passes through inaccessible areas such as in ceilings or under floors. Indoor wires may

also be used, however, in cases where there is no risk of deterioration due to exposure to heat, etc.

The number o f cable pairs laid should be determined considering

the possibility of future expansion of the system.

The following chart is provided to give an actual example of the

wiring plan within an installed system.

Intermediate

Terminal

Boards

pairs.

Secondary

Terminal

Boards

Stations

(HF-600M

etc.)

Speaker

Station

Amplifier (s) for Paging

1. Junction Cable (2-wire, for stations)

2. Junction Cable (4-wire, for paging)

3. Private Branch Cable ( Multi-core cable)

Make sure to connect quad pairing when using a

multi-core cable.

4. 2-Wire Cable

Never use a cable of 4 cores or more which is not

paired or quad-paired for connection to stations.

Note: Since hardware to connect the cable to the terminal board BX-610 or BX-620 is

provided, there is a limit to the diameter of cables that can be used to connect the

terminal board BX-610 or BX-620 and the main terminal board, and this limit

must be taken into consideration when planning wiring of the system. The diameter must be between 0.41mm (0.016") and 0.79mm (0.031").

7-2 C o r e Diameter versus Transmission Distance

Use appropriate cables according to the following table that shows

the relationships between core diameter and transmission distance.

Core

Diameter

mm (mils.)

1.02

18

20

22

24

(40.30)

0.81

(31.96)

0.64

(25.35)

0.51

(20.10)

Service

Distance

km

(ft)

4.6

(15,000)

3.5

(10,000)

2.5

(8,200)

1.5

(4,900)

-10-

Page 14

7-3 Wiring

1. General Information

Wiring should be done independently of public telephone lines.

Otherwise the EXES-6000's line (+30 dBm) can cause cross-talk in

the telephone line.

Wiring conduit is often installed underground or embedded in

building structures such as walls and floors, so care must be taken

to draw up a wiring plan that has ample reserve for future extension of the system and that can be adapted to future remodelling

or expansion of the building it is housed in. Wiring systems must

be planned with ample wires and conduit and with provision for

additions to the system.

Do not connect an unused cable to a connection cable between

the exchange and the station.

Exchange

Station

3. Piping

Where wiring is to be passed through a wall or the like, it should

be protected by a hard P VC or metal tube.

If the number of connecting wires between an indoor terminal

board and a station is small and the station's site is fixed so that

it wil l not be moved frequently, install a box at that site and pull

wiring through a metal or hard PVC tube as required by job or

ordinance.

Use a fl o o r duct if the number of connecting wires is large and th e

stations are likely to be moved frequently.

Station wiring which must be laid-across open areas of floor

should be protected by plastic or metal shields. (See drawing

below)

EXAMPLE:

Not allowed

When a multi-pair cable is used for connection, it must not be used

as a power cable or data transmitting cable for facsimile, etc.

2. Spacing

Since the working voltage of this system is low and the current

passing throug h it is small, there is no major safety problem involved

in the wiring.

However, since interference due to contact with other indoor wiring

can cause wire damage, leakage, and other problems, spacing should

be given close consideration when the small-current wiring of this

system is laid close to other indoor wiring, particularly AC wiring.

The following chart lists spacing standards to be followed in respect

to typical causes of interference.

Minimum

spacing

Cause of Interference

Heating Pipe

Water Pipe

Radio transmitting

coaxial cables (CB and

other).

Telephone wire.

Radio/TV Antenna

coaxial cables & twi n

lead. Ground cable.

acceptable

without

extra

protection

15cm (6")

10cm (4 ")

30cm (12")

Remarks

This minimum spacing

requirement should be

observed, since intercom

cable is vulnerable

to heat.

More spacing is required

where there is a risk of

induction.

Wall

Metal or hard PVC tube

2-Pin Jack

& Plug

Wire

Box

protector

Floor duct

Wire protector

Plastic or

Aluminum

4 inches

Desk

Floor

Floor

Station wirings

Protected Heating

and Cooling Pipes.

10cm (4 " )

– 11 –

Page 15

8. Connection of Equipments

8-1 Connection of Power Supply

1. DS-610 (for EX-610)

The connection on the terminals of the power section is illustrated

below.

When batteries are to be connected, connect the connector after

plugging into the AC power source. Connect to the AC power

source, as illustrated below, after setting the system.

Check

if the

unit

40 hours after power is switched o n.

operates

Fuse

Use a proper ty pe of fu s e according to the number o f the stations to

be connected. See the table below.

Number of Stations

0 ~ 30

31 ~ 64

on

battery

without

Fuse Capacity

DC 5A

DC 8A

any

problem

in

about

Important! To facilitate maintenance works of the fuses and bat-

teries, allow much space between the wall and the

cabinet rack.

Batteries

(24V

3.5 Ah)

AC Power Switch

EX-610

Put the Power supply

unit into the bottom

part of the exchange

Power

Cord

Put batteries in the

bottom compartment

of the Power supply

unit

Set the voltage selector in conformity with

the source voltage to be used.

Power Supply Unit (DS-610) (Rear view of the unit without the panel)

– 12 –

Page 16

2. DS-620 (for EX-620)

The following procedures should be followed for connection of the

power supply unit. (Refer to illustrations.)

1. Turn off a power switch on the front panel.

2. Connect cables coming from the rear frame of the exchange to

the terminal board of the power supply unit, confirming the

colour of cables and the voltage specification marked on the

cables.

3. Take out the front panel by removing 6 screws and connect 3

Ni-Cd batteries to 3 battery connection cables.

4. Set the voltage selector in conformity with the source voltage

to be used.

5. Make connections for AC power supply and grounding.

6. Switch power on, and both the AC power and th e battery circuits are activated.

7. Confirm the colour of Power indication lamp.

AC operation: Green

Battery operation: Red

8. Check if the unit operates on battery without any problem

about 40 hours after power is switched on.

Fuse

Use a proper ty p e o f f u s e ac c or d in g to t h e number of t h e stations to

be connected. S e e the table below.

EX-620

Put the Power supply

unit into the bottom

part of the exchange

Number of Stations

0-30

31 ~ 64

65 ~ 128

Fuse Capacity

DC 5A

DC 8A

DC20A

Voltage selector

Power code

Power Supply Unit ( DS-620)

(Rear view of the unit without the panel.)

Power switch

(AC/Battery)

Power Supply Unit (DS-620)

(Front view of the unit without the panel.)

– 13 –

Batter ies NDC-2435 x 3 (24V 3.5Ah)

Page 17

3. DS-630 (for EX-630)

Use following steps f o r connection of the power supply unit referring

to illustrations.

1. Turn off a power switch on the front panel.

2. Connect cables coming from the mother boards on the rear

frame of the exchange to the terminal boards of the power

supply

unit,

markings on the cables.

confirming

3. Prior to the connection in this step, be sure to place the battery

the

colours

of

cables

and

voltage

power switch of BC-630 in OFF position. Connect the battery

input terminal of the power supply unit to the battery output

terminal

of the

battery

case

(BC-630)

using

cables

supplied

with

BC-630.

4. Make connections for AC power supply and grounding.

5. Remove 5 screws on the front panel of the battery case, and pull

the panel toward you holding its handles.

Then connect 3 Ni-Cd batteries to 3 battery connection cables.

6. Turn on the power switch of the power supply unit, and the AC

power circuit is activated.

EX-630

AC MAIN

Power Supply Unit (DS-630)

(Rear view)

Battery Case (BC-630)

(Rear view)

– 14 –

Page 18

7. Turn on the battery power switch of the battery case, and the

battery circuit is activated.

8. Confirm the colour of power indication lamp.

AC operation: Green

Battery operation: Red

9. Conduct a battery operation test about 60 hours after power

is switched on since sufficient time is necessary f or the batteries

to charge fully.

Battery compartment

(NDC-2560x3)

BC-630

Pull toward you after removing

5 screws on the front panel.

Battery power switch

Batteries NDC-2460 x 3

(24V 6Ah)

– 15 –

Page 19

8-2 Connection between the Exchange and the Terminal Board (BX-610 or BX-620)

The terminal boards BX-610 for a maximum of 64 stations

and BX-620 for a maximum of 128 stations are available in the

EXES-6000 system. Use the YR-810 cable (2-wire and fo r 8 stations)

or the YR-801 cable (4-w ire and fo r 8 paging zones and 8 links of

tie-line system) for connection between the exchange and the

terminal board. It is also possible to utilize the BOX-08 terminal

board with cable (4-wire and for 8 stations, 8 zones and 8 links).

1. Wiring Example when Exchange EX-610 is used

1. For LM units: Connect J1 through J8 of the exchange to L1

through L8 of the terminal board w ith the YR 810 cable.

2. For PI units: Connect J8 (zones 1 ~ 7 plus All-call) of the exchange to P1 of the terminal board, and J7

(zones 8 ~ 15) to P2 with the YR-801 cable.

Exchange EX-610 without the rear panel.

Junction Cable (YR-810)

for Stations

Junction Cable (Y R-801 )

for Paging

3. For Tl unit: Connect J7 of the exchange to T1 of the terminal

4. For SI unit: Connect the SI unit to L2 of J2 terminal board

Terminal Board (BX-610)

without the cover.

Amplifier

board with the YR-8 01 cable.

of an exchange by means of the YR-810 cable.

Station

Speaker

2. Wiring Example when Exchange EX-620 is used

1. For LM units: Connect J1 through JI6 of the exchange to L1

through L16 of the terminal board with the YR-

810 cable.

2. For PI units: Connect J16 (zone 1-7 plus All-call) of the exchange to P1 of the terminal board, and J15

(zone 8-15) to P2 with the YR-801 cable.

Exchange EX-620 without t he rear panel

Junction Cable (YR-810)

for stations

Junction Cable (YR-801)

for Paging

3. For TI unit: Connect J15 of the exchange to T1 of the

4. For SI unit: Connect the SI unit t o L2 of J2 terminal board of

Terminal Board (BX-620)

without the cover.

Amplifier

terminal board with the YR-801 cable.

an exchange by means of the YR-810 cable.

Station

Speaker

– 16 –

Page 20

3. Wiring Example when EX-630 is used

1. For LM units: Connect K1 through K16 of th e exchange to L1

through L16 of the terminal board (A), and L1

through L16 of the exchange to L1 through L16

of the terminal board (B).

Use YR-810 cable for this connection.

2. For PI units: Connect PI1 (J9, zone 1-7 plus All-call) and PI2

(J10, zone 8-15) of the exchange to P1 and P2 of

the terminal board ( A ) , respectively.

Similarly, connect PIS (J11, zone 16-23) and PI 4

(J12, zone 24-31) to P1 and P2 of the terminal

Exchange EX-630 without the rear panel

Junction Cable

(YR-801)

for Paging

Junction

Cable

(YR-810)

for Stations

board (B ), respectively.

UseYR-801 cable f or this connection.

3. For TI units: Connect TI1 (J11, in th e place of PI3) and TI2

(J12, in the place of PI4) of the exchange to each

T1 of the terminal boards (A) and (B), respectively, with YR-801 cable.

4. For SI unit: Connect K2 or an exchange to L2 of a terminal

board (A ) .

Station

(A)

Terminal Board (BX-620)

without the cover.

Amplifier

Speaker

Junction Cable (YR-810)

for Stations

Junction Cable (YR-801)

for Paging

(B)

Terminal Board (BX-620)

without the cover.

Amplifier

Station

Speaker

– 17 –

Page 21

8-3 Connection of the Terminal Board (BX-610

or BX-620) to the Main Terminal Board

Route cables from the main terminal board to the terminal board

(BX-610 or BX-620) and connect them to the individual clip

terminals using clipping tool YC-105 (Optional accessory).

See Fig. 1 and 2 f or the diagram of the interior of the terminal

boards (BX-610/620).

Internal connections have been made for the corresponding numbers

between the connector and clip terminal (for example, L1 ~ L1 and

L2 ~ L2 . . . )

Connecting diagram of clip terminals is shown on the back surface

of the front door panel of the case.

Connect cables to the clip terminals according to the following

procedure:

Strip a cable insulative jacket (1.5 times the length of the clip

terminal) to expose inner cables.

Fix the cable at the cable clamping part.

Fit the exposed inner cable in a slot of the clip terminal, without

stripping an insulative jacket of the inner cable.

Push down on the cable with the YC-105 clipping tool

(optional), and the cable is cut of f . A t thi s point, the connection

is finished.

Fig. 1 BX-610

(for 64 stations)

Fig. 2 BX-620

(for 128 stations)

Terminal Board Side

Junction Cable Y R-810

(YR-801 is also the same dimension)

Yellow

Exchange Side

Cliping Tool

YC-105

Gray

Connector Clip Terminal

L1 ~ L8 L1 ~ L8

P1,P2,T1 P1,P2,T1

Connector Clip Terminal

L1 ~ L16 L1 ~ L16

P1,P2,T1 P1,P2,T1

Fig. 3 Terminal Board BX-610 Appearances

Knock-out

Junction Cable YR-801, 810

Optional Accessary

Push down

Cross-Section

ClipTeminal

Note

Connect the cables in order, starting with the

top terminal. When using the clipping tool,

take care about the cutting edge.

Specifications of the Clip Terminals

1. Connectable wire (Solid wire)

size range:

1) Insulated wire

Core diameter 0.4-0.8mm (1/ 64"-1/32")

2) Bared wire

Core diameter 1.0mm (max.) (0.04")

2. Insertion force

Approximately 3 kg (6.6 Lbs.) on a copper

wire wi th a core diameter of 0.5mm (0.02")

Case

Junction Cable Connector

Clip terminal

– 18 –

Page 22

Fig. 4 Terminal Board BX-620 Appearances

Case

Junction Cable Connector

Clip terminal

Junction Cable YR-801, 810

Optional Accessary

Knock-out

8-4 Connection of the Station Plug to the Exchange Jack

Clip Teminal of

Teminal Boards

(BX-610/620)

To Exchange

To other station

Note: 1.Use 4" x 2" Switch-Box for YC-603

(2-Pin Jack for flush-mount)

2. Terminals No.1 and No.2 inside the

jack have no polarity.

Station

2-Pin Plug

YC-602

Cover

2-Pin Jack

YC-601

– 19 –

Page 23

8-5 Connection o f the station

For station installation, refer to the instruction manual of the

station. When installing the desk-top/wall-mounted station, use the

YC-601 or YC-603 station jack for connection. The maximum distance between the station and the station jack is 3 meters since the

station cable is 3 meters in length.

Station jack YC-601 (Wall-mounted type)

Mount it on a wall or pillar or desk. Utilize either top/bottom

knock-out holes of the case or a cable entry hole provided in the

base for connecting the cables to the exchange.

Knock-out hole

(provided on the top and bottom)

Screw

for base

Base

Screw

Case

Cable entry hole

Station jack YC-603 (Flush-mounted type)

First mount the switch box in the wall and then make piping

and wiring arrangements before the station jack is installed.

Wall

Base

Plate

Screw

for plate

Case

Screw

for case

Screw

for box

Cable en tr y h ole

Switch box

– 20 –

Page 24

9. Connection and Adjustment of Equipment

9-1 Connection of the Speaker Station (Simplified Paging)

In the EXES-6000, instead of using a station, a speaker for one-way

conversa tion can be installed using a jumper in the LM-62B.

This is possible at each station position on th e LM-62B.

1. Cutting off the jumper wires of the LM units.

<For the LM-62A unit>

Cut off the jumper wires (JP101-

JP801) corresponding to the line con-

nected for "Speaker station" function.

<For the LM-62B/LM-62C/LM-65/

LM-65C units>

Cut off the jumper wires (JP104JP804) corresponding to the line connected for "Speaker station" function.

Side view of the LM-62A unit with parts

mounted

Side view of the LM-62B/LM-65 units wit h

parts mounted

2. Speaker Volume Adjustment

1. Speakers with an impedance of 600 ohms or more may be

used without a transformer.

If it is desired to use lower impedance speakers, a transformer

should be used to assure proper impedance matching.

2. Volume may be controlled only when:

(a) a matching transformer is used.

Non-polar capacitor

To exchange

(b) a resistor is connected.

Non-polar capacitor

To exchange

Side view of the LM-62C/LM-65C units

with parts mounted

low volume

high volume

approx. 1W

The Rs value should be decided in accordance with the speaker

impedance so that the volume is on a suitable level.

– 21 –

Page 25

9-2 Paging Connection

1. PA Paging

The audio signal line and control line from the PI unit are connected

to clip terminal P1 or P2 inside the terminal board. Fig. 1 shows

how to make connections between the terminal board (BX-610 or

BX-620) and external PA amplifier.

Audio signal

To speakers

Specifications of each output line

1. Audio signal line

Impedance: 600 ohms, balanced

Output level: —10dBm

2. Control line

Relay contact capacity: 30V DC, 0.5A

If the distance between the terminal board (BX-610 or BX-620)

and external PA amplifier is over 33 feet (10m), use the balanced

type to avoid external noise such as hum. Care should be taken in

selecting a relay for power control of the external PA amplifier

due to the small line contact capacity (30V, DC 0.5A). Refer to

Fig.1.

Two differrent types of PI Unit, Type 1 (Standard) and Type 2

(modified version of Type 1), are necessary to employ the "All-

call plus 15 or more indiv idual paging zones" function.

1. PI-62 Type 1 (PI1 ) is different from PI-62 Type 2 (P I2-P I4) in

the foll ow in g parts being used in each unit.

Table 1

PI-62 Type 1 (PI1)

Type

All-call + 7 Paging

Parts

Jumper Wi r e ( J W)

R100(200k⍀)

Ref er to Fig.3 for t he modification.

Zones (No. 1-7)

Connected

Not mounted

PI-62 Type 2 (PI2-

PI4) 8 Zones (No.

8-15,16-23,24-31)

without All-call

Disconnected

Mounted

Fig.

Power control relay

PA Amplifier

1

AC Power

a.PI-62 Type 1 (PI1)

b. PI-62 Type 2 (PI2-PI4)

2. For Ex-610 and Ex-620, "Station paging assignment plug" needs

to be modified. Refer to the following instructions for the

modifications.

Solder the electrolytic capacitor (33 µ F ) to the terminals, and

"PO" and "No. 319" (paired with No. 312) for EX-620, "PO"

and "No. 255" (paired with No. 248) for EX-610 of "Station

Paging Assignment" on the rear of exchange frame. Do not

connect No. 319 (255) to GND.

Polarity of capacitor ... PO : - , No. 319 (255): +

For EX-610

Fig. 2

For EX-620

Fig. 3

– 22 –

Page 26

2-1 Station Paging (for EX-610/620)

(1) The paging outputs of the PI unit must be connected to the

assigned lines of the LM unit via the station paging assignment plug provided at the back of the exchange. Follow t he

procedures below to make th e required connections.

<For the LM-62A unit>

1. A fter determining the zone allocation, record it in the Station

Paging Table, part of Initial Checking Sheet for the system (CP62/63/64). Refer to tables 1 and 2.

2. Perform the wiring of the station paging assignment plug by

soldering according to the zone allocation determined. Refer to

Fig. 1 and Table 1.

3. Cut off unnecessary jumper wires (JP3 ~ JP8) and resistor

(R126 ~ R826) of the LM unit according to the zone allocation.

4. If the exchange is the EX-610, both No. 256 and No. 263 pins

of the assignment plug must not be connected to the GND pin.

Fig. 2 LM-62A unit

To another

LM unit

Fig.1

Station Paging

Assignment Plug

Table 1 Wiring of Station Paging Assignment Plug

Table 2 Station Paging Connection (LM Unit)

Fig. 3 PI unit

Bottom

Note: Mark the disconnected jumper wire or resistor with "X".

-23-

Page 27

<For the LM-62B/62C/65/65C units>

1. After determining the zone allocation, record it in the Station

Paging Table, part of Initial Checking Sheet for th e system (CP-

66). Refer to tables 3 and 4.

2. Perform the wiring of the station paging assignment plug by

soldering according to the zone allocation determined. Refer to

Fig. 1 and Table 1.

3. Cut off unnecessary jumper wires (JP200 ~ JP800, JP201 ~

JP801, JP105 ~ JP805) of the LM unit according to the zone

allocation.

4. If the exchange is the EX-610, both No. 256 and No. 263 pins

of the assignment plug mu st not be connected to the GND pin.

To another

LM unit

Fig.4

Station Paging

Assignment Plug

Fig. 5 LM-62B/65 units

Fig. 6 PI unit

Bottom

Top

Bottom

– 24 –

Page 28

To another

LM unit

Fig.7

Station Paging

Assignment Plug

Fig. 8 LM-62C/65C units

Bottom

Top

Table 3 Wiring of Station Paging Assignment Plug

Table 4 Station Paging Connection (LM Unit)

Fig. 9 PI unit

Bottom

Note: Mark the disconnected jumper wire or resistor with "X".

-25-

Page 29

(2) Connection example

1. If the station paging zones are to be assigned as shown in Table

1, each individual LM unit is divided as shown in Fig. 4.

2. Cut off the following the jumper wires of the LM unit to allocate stations of each group.

©

<For

the

LM-62A

unit>

Refer

to

Table

LM1

(No.

200 ~

207):

LM3

(No.

(2) <For the LM-62B/62C/65/65C units> Refer to Table 4.

LM1 (No. 200 ~ 207): JP700 - JP701

LM3 (No. 216 ~ 223): JP600/JP601 and JP800/JP801

216 ~

223):

JP8

JP7 and JP9

2.

3. Stations of each group must have the consecutive station numbers. The station included in the group but not requiring the

station paging function can be disconnected by cutting off t he

corresponding resistor wires or the jumper wires of stations.

© <For the LM-62A unit>

R126 ~ R826 Refer to Table 2 and Fig. 2.

(2) <For t he LM-62B/62C/65/65C units>

JP105 ~ JP805 Refer to Table 4, Fig. 5 and 8.

4. Perform the wiring of the station paging assignment plug for

connection between the LM and PI units. (See Fig. 1, 4 and 5.)

The plug can be detached by inserting a screwdriver into be-

tween the plug and its socket after removing the rear panel of

the exchange. (When inserting the screwdriver, take care that

pins are not damaged.)

5. Paging output lines of the PI unit have been connected to pins

No . PO through P 7 of the plug. For station output lines of the

plug, the pin corresponding to the first station number of each

LM unit has been connected to a connector 46B of each LM

unit, with the pin corresponding to the last station number of

each LM unit having been connected to a connector 46A of each

LM unit.

EX-610: LM1 - LM7 (Station No.200 ~ N o.25 5)

EX-620: LM1 ~ LM15 (Station No.200 ~ No.319)

6. Use solder to connect each PI output pin (PO through P7) of the

plug to the input pin of the first or last station number of the

corresponding paging zone. (Refer to Fig. 1)

7. If the paging zone involves 2 or more LM units, connect between

two pins (of the plug) corresponding to the last station number

of one LM unit and to the first station number of another LM

unit. If there is the LM unit not used for paging, be sure to

connect its corresponding two input pin s of the plug to the G ND

pin. Failure to do this can cause crosstalk.

8. After finishing these connections, insert the plug into its 40-pin

socket.

Fig. 4 Assignment of Station Paging

Important! To give easy access to the station paging assignment

plug, provide sufficient space between the wall and the

rack.

Output

Paging zone

P 1 (No 200-No 205)

terminal

of plug

No 200

No 207

No 208

P 2 (No 206—No 220)

P 3 (No223-No231)

P 4 (No232—No239)

Fig. 5 Connection of Station Paging Assignment Plug

No 215

No 216

No 223

No 224

No 232

Input

terminal

of plug

P 1

P 2

P 3

P 4

– 26 –

Insert

Fig.

6

Page 30

2.2 Station Paging (for EX-630)

(1)The paging outputs of the PI units must be connected to the

assigned lines of the LM unit via the SA unit. Follow the procedures below to make the required connections.

1. After determining of the zone allocation, record it in the Station Paging Table of "Initial Checking Sheet for the System

(CP-64/66)". Refer to Table 1 and Fig. 2.

2. Perform the wiring of the SA unit using solder according to the

zone allocation determined. (Table 1.)

3. Cut off unnecessary jumper wires of the LM unit (JP200 ~

JP800, JP201 ~ JP801, JP105 ~ JP805). Re fer to Table 2 and

Fig.

2.

(2) Connection example

1. If the station paging zones are to be assigned as shown in Table

1, e a c h indiv i dual LM un it is divided as shown in Fig. 1.

2. Cut off the following the jumper wires of the LM unit to allo-

cate sta tions of each group.

<For

the

LM-62A

unit>

Refer

to

Table

LM1

LM3

(No.

(No.

200 ~

216 ~

207):

223):

JP7 and JP9

JP8

2.

<For the LM-62B/62C/65/65C units> Refer to Table 3.

LM1 (No. 200 ~ 207): JP700 ~ JP701

LM3 (No. 216 ~ 223): JP600/JP601 and JP800/JP801

Stations of each group must have the consecutive station num-

bers. The station included in the group but not requiring the

station paging function can be disconnected by cutting off the

corresponding resistor wires or the jumper wires of stations.

<For the LM-62A unit>

R126 ~ R826 Refer to Table 2.

<For the LM-62B/62C/65/65C units>

JP105 ~ JP805 Refer to Table 3.

4. Perform the wiring of the SA unit for connection between the

LM and PI units. The paging lines of the PI unit have been

factory wires to pins No. P1 through P31 of the SA unit and

the paging input lines of the LM unit have been connected to

pins No.1 through No.32 for th e LM unit. Use solder to connect

each paging zone to the first station number or last station

number of LM. (Refer to Fig. 2.)

5. If one paging zone involves 2 or more LM units, connect between two pins (of the SA unit) corresponding to the last

station number of one LM and to the first station number of

another LM unit.

6. In the SA unit, all the paging input lines of the LM are. short-

circuited to ground via jumper wires. Be sure to cut off the

jumper wires corresponding to the LM unit used for paging.

Refer to Fig. 2.

Table 1 Wiring of SA Unit

Zone

1

2

3

4

First station No.

200

206

223

232

29

30

31

Last station No.

205

230

231

239

Fig. 1 Assignment of Station Paging

– 27 –

Page 31

Table 2 Station Paging Connection (LM-62A Unit)

Note: Mark the disconnected jumper wire or resistor with "X ".

Table 3 Station Paging Connection (LM-62B/62C/65/65C Units)

Paging Zone

Note: Mark the disconnected jumper wire or resistor w ith "X".

Fig. 2 Wiring on SA unit

LM No.

Station

No.

Paging distribution line

LM

Unrequired paging line

Paging Zone

Unrequired paging line

Paging distribution line

LM

Station

No.

LM No.

– 28 –

Page 32

9-3 Calling Tone Modifications

1. The EXES-6000 system permits you to select any one of the

following calling tones ((a) ~ (c))by connecting or cutting the

jumper wires and a resistor on the SG -6 2 unit.

(a)

627Hz/783Hz

(b) 470Hz/627Hz trill tone

(c) 627Hz single tone

2. Modifications necessary for selection of desired calling tone.

trill

tone

(factory-wired

to

this

tone)

Type of Calling tone

627Hz/783Hz Trill tone

(a)

(factory -wired to this tone)

470Hz/627Hz Trill tone

(b)

627Hz Single tone

(c)

3. Notes

Select calling tone (a) or (b) when the station needs to be called

by a continuous calling tone.

Even when (a) or (b) tone is selected, by selecting the DIP

switches of the CP-unit, the calling tone of the hands-free

station alone can be made a Single note tone 470Hz (0.2 second).

JP-4

Connect

Cut

Leave this

intact

9- 4 Precautions in using conference unit

The Conference Unit CL-62A is required for holding the interco m

conference. Build this unit in all exchanges connected by tie-line.

It is not possible to orginate the conference from a station connected to the exchange without the CL unit but possible to participate in the conference from that station.

9-5 Indication and control

Use the DT-E60 data transmitting unit or the DR-B61 data receiving unit for indication and control.

DT-E60: One (1) DT-E60 unit can be mounted in the rack type

DR-B61: Such devices as indicator, control unit etc. can be made

exchange. Use the YR-806 cable (1000 mm in length).

When using 2 or more DT-E60 units, mount the m in an

equipment rack. Use the YR-802 cable (400 mm in

length) for connection between the exchange and the

DT-E60, and the YR-803 extension cable f o r the DT-E60.

by using this unit and 24V DC power supply.

JP-5

Cut

Connect

Leave this

intact

JP-6

Connect

Connect

Cut

R32

Connect

Connect

(68k

Cut

SG-62

9-6 Connecting the station f or emergency paging

Connect the station to pin No.247 (147). An emergency paging

call can be placed by lifting a handset of the handset type station

or by shifting back the Privacy switch of the handsfree station from

ON to

OFF.

9-7 Press-to-talk control

The PI -62 paging interface is required.

1. Be sure to use the PI-62 T ype 2, a modified version of Type 1.

2. Insert the Type 2 into the PI2 slot (Z one No.8 ~ No.15) when

the EX-610 or EX-620 exchange is used, and into the PI4 slot

(Zone No.24 ~ No.31) when the EX-630 exchange is used.

3. Call the station No.200 (No.100) ~ No.207 (No.107). Pressing

the PTT bar causes the relay corresponding to No.0 to No.7 of

the PI unit to be connected, and releasing it disconnects the

relay.

4. The press-to-talk control function can be used for door lock

release, switch control of signal transmission/reception to and

from radio equipment via an interface, etc.

– 29 –

9-8 Connection of PI-62 to call a pager receiver

It is possible to call a pager receiver by connecting the PI-62 to a

pager transmitter having an interface of serial input (dial speed:

10

pps).

[Connection diagram]

Note. Cut of f a j umper wire (JP1) shown in Fig. 3 page 23, Fig. 6

page 24 and Fig. 9 page 25.

[Specifications]

Contact capacity: 12.5 VA (30VDC 1 A)

Dial speed: 10 pps

Page 33

9-9 BGM equipment connection

By connecting both the LM-65/65C and BOX-08 to a BGM player, a

time signal machine or a chime generator, background music, tim e

signal or chime may be heard from the station.

[Connection diagram]

8-station terminal

box BOX-08

-20—

-10dBm

Station

Exchange without rear

panel EX-610/620/630

BX-610/620

Alarm or timer

input signal

Timer or alarm

starting signal input

Station No. 0

BGM player No.1

Station No.1

BGM player No.2

BGM player No.3

Station No.2

Station No.3

Timer signal input

[Sound volume adjustment]

<For the LM-65 unit>

The BGM volume of each individual station may be decreased by cutting off the corresponding jumper wires

(JP103-JP803, JP102-JP802).

See the figure below.

1. Cutting off the jumper wire having the greatest number

of the two (JP103-JP803) decreases the volume by 6

dB.

2. Cutting o ff the both of the paired jumper wires (JP103JP803, JP102-JP802) decreases the volume by 12 d B.

[BOX-08]

YR-810/801

Station No.4

BGM player No.4

BGM player No.5

Station No.5

BGM player No.6

BGM player No.7

Statio n No.6

Stat ion No.7

<For the LM65C unit>

The BGM volume of each individual station may be adjusted by setting the corresponding switches (SW101SW801).

See the figure below.

1. Setting the switches having the greatest number of the

two (SW101-SW801) to the center position decreases

the volume by 6 dB.

2. Setting the switches (SW101-SW801) to the MIN posi-

tion decreases the volume by 12 dB.

Note: Switch is preset to the MAX position when unit is

shipped from factory.

Alarm starting

signal input

Timer starting

signal input

Station

Station

– 30 –

Page 34

10. Preformance test

10-1 Check when Power is Switched On

Before turning on the power switch, check if the power cord is plugged in and th e fuse is in place. Also, check for damage to the printed

circuit board, connectors a n d power section. Make sure that the connections of exchange and stations are co mpleted.

Turn on the Power switch o f th e exchange.

The front-mounted AC indicator of the exchange comes on. If it does not come on, set the power switch to OFF and check both the

cor d a n d fuse.

Connect batteries after confirming that the system operates on AC mains. Use 2 batteries for the EX-610 and 3 batteries for the EX-620/

630: voltage; 24V, capacity; 3.5 Ah per battery for EX-610/620, 6A per battery for EX-630.

With batteries connected, system unit automatically switches to battery operation when AC power source is cut off . In the event of the

DS-610, DC indicator lamp will be on being accompanied by buzzer. To stop the buzzer, push the buzzer reset switch.

In the event of the DS-620/630, an operation indicator lamp changes from green to red.

10-2 Speech and Function Tests

After completion of wiring, exchange checks and power supplying,

perform operation and function tests from each station. Record the

test

results

in

"Initial

Checking

1. Speech Te st

Under the normal condition, make conversation using the

stations connected to the exchange and check the sound volume

and sound quality.

According to the operation environment (surrounding noise,

echo, installed location, etc.), the microphone sensitivity or

speaker volume needs to be adjusted for hands-free conversation.

When the paging function is employed, adjust the gain of the

paging amplifier or change the installed location of the speakers

and stations to minimize f eed-back.

<Method of Speech test>

Sheet

for

CP-66".

Noisy area

Station A Station B

Voice from stat ion B is

interrupted.

Quiet area

Background noise level

at station A is high.

(Voice from station B is

almost impossible to

hear.)

(1) Hands-free conversation

1. Call the other station.

2. Start conversation about 50 cm away fr o m each s ta tio n to check

the sound quality and its volume.

3. Confirm that the automatic voice switching allows for smooth

conversation.

4. When the other station is in a very noisy area, the voice switches

are liable to fail to work properly, causing the voic e from the

station in a quiet area to be interrupted. In this case, adjust

microphone sensitivity and speaker sound volume according to

the operating instructions contained in a package of each s ta tio n.

(2) Conversation between a handset station and handsfree station

1. Call the other station.

2. Start conversation and check the sound quality and sound

volume. Also confirm that simu lt aneous conversation is possible.

3. When feedback occurs, adjust the microphone sensitivity or

speaker volume of t he hands-free station.

(3) Handset conversation

1. Call the other station.

2. Start conversation and check the sound quality and sound

volume. Also confirm that simultaneous conversation is possible.

2. Function Test

Confirm that each function works properly by performing tests

according to operation manual.

Press key to talk

and release it to listen.

Speak loudly or

press key to talk.

-31-

Page 35

10-3 System Check Flow Chart

START

DIP switch on CP

correctly set ?

Mini-jumper for battery

back-up (JP1) ON ?

Program switch on CP

OFF ?

Set power switch to on.

Proper voltages at

each output power

terminal ? (Table 1)

CLOCK lamp on HC lights

blight ?

Other lamps on HC OFF ?

Station No. lamp on LM

corresponding to connected

station lights up ?

EXES-6000 SYSTEM CHECK FLOW CHART

Set DIP switch

according to each CP Inst.

Set JP1 to ON

Program switch OFF

Disconnect DC power

connection and check

Replace HC

Replace HC

Check wiring to the station

Replace the station

LM

CP

0C

Table 1

Fig. 1

Fig. 2

If +24V or + 18V is not

in the range, check

power supply (DS-610/620/630).

If

+12V

or +5V is not

in the range, replace

DC/DC converter.

ON

OFF

ON

OFF

Clear all No. 200 programmings

according to each CP Inst.

Dial 2 at any M-station

One of LINK BU SY lamps on

HC lights bright ?

Station number is indicated with LINE

ADDRESS-T lamp of HC ?

On dialling 2, dial tone

heard ?

Call from any station

to any station

Station number is properly indicated

with LINE ADDRESS-T/R lamp

of HC ? SIG CODE lamp lights

up as shown in Fig. 2 ?

Callin g tone heard ?

Two way conversation OK ?

Replace Station

Dial • , SIG. CORD lamps

on HC light up as shown in

Fig.1 ?

In other links, dial

tone and lamps OK ?

Replace Station- LM — CP —HC

Replace SG—check wing between

station and exchange, wiring

Other links are normal ?

LM

Replace HC

HC

CP

0C

OC

CP

Replace

Replace

Replace CL or DL concerned

Replace Station

All other links OK ?

Conversation possible

with all stations ?

END

Replace CL or DL

concerned

Program No.200 functions

– 32 –

Page 36

10-4 Simple troubleshooting

Delimitative point f or system check

A system is checked for the following delimited portions.

Exchange

BX-610/620

Line

Station

YC-601/603

Exchange check

An exchange is checked for the following delimited portions.

(1) Speech path section SG-62, DL-62A, LM-62B, PI-62, CL-62A,

TI-62,andSA-64

(2) Speech path control section CP-66, OC-62, HC-62, and HC-64

(3) Power supply section DS-610, DS-620 and DS-630

Line Check

Line faults are checked with the LED lamps of the LM. The LED

lamps light orange in an normal condition.

(1) Symptom — No LED lights up.

Cause — L1 and L2 have broken in most cases.

(2 ) Sym p t o m — Wh e n a call is made, two speech links ar e connected

at a time.

Cause — L1 or L2 is connected to the other station.

(3) Symptom — The lamps of the LM are lighting yellow .

Cause — L1 and L2 are short-circuited.

(4) Disconnect the lines from both the exchange and station and

only check the lines for the following.

Between the BX-610/620 and YC-601/603

Ground to station insulation (Over 1Mi7)

Insulation between lines (Over 1Mft)

Resistance (Below 100S7 for 1km wi th 0.65mm thick cable)

Station

A station can be divided into the following portions.

(1) Microphone circuit and amplifier

(2) Keyboard and dial signal transmitter

(3) Speaker

(4) Power supply

To find cause of failures, check for the following symptoms first

because the failures, for the most part, show such symptoms. When

there is a failure, however, first replace the station with one which

works normally. If the symptom remains unchanged, then the

trouble lies in the station or in the line. If the station replacement

causes the state to return to normal, then the trouble lies in the

station.

(1) Symptom

Cause —

In-use lamp does not come on when dialled.

LED i s faulty

Power supply section is faulty

Dialling is possible.

No dialling is

possible.

(2) Symptom

Cause —

M5 (HB 1 C) i s faulty

No dial tone is audible when dialled.

Speaker wires are broken .. . No tone.

Transformer wires are broken.

Dialing is possible

Hum noise is provided.

(3) Symptom

Two stations are connected, but calling party's

voice does not reach called party.

Cause —

1C of M2 is faulty ... No dialling is possible.

Unless replacement of printed circuit board

remedies situation, microphone is faulty.

(4) Symptom

Cause —

No dialling is possible.

If no signal is transmitted when dialled, M5 (HB

1C) is

faulty.

If only specific keys can be dialled and replace-

ment of printed circuit board does not remedy

situation, trouble is in keyboard matrix.

(5) Symptom

No fully-duplex (simultaneous) conversation is

made when handset is lifted. (HF-200M and TL-

600).

Cause —

Hook switch in printed circuit board is faulty if

state remains the same despite replacement of

station printed ci rcui t board.

Forty Hertz (40Hz) oscillator is faulty . . . Both

conversation and dialling are possible.

Whole system check

(1) Confirmation of numbering schedule

Points to check for numbering schedule

Are sta tions of the same paging group numbered consecutively?

Is the maximum number of paging groups two f or the same LM

unit?

Confirm if stations are grouped correct ly f or calling party indication.

Confirm if the station indicated on the in/out annunciation

board by the personal number is in the correct place (office).

Confirm if the station is connected to the corresponding termi-

nal of the terminal box.

(2) Confirmation of power fuse current capacity (DS-610/620/630)

(3) Confirm if the CP DIP switches are properly set fo r each func-

tion.

(4) Confirm if a memory backup jumper of the CP is set to ON.

(5) Confirm if the exchange is wired properly as planned in the

station paging group numbering schedule.

(6) Confirm wiring of the paging assignment unit.

(7) Confirm the channel number of the DT-E60.

(8) Confirm if both t he YR-810 and YR-801 cables are used proper-

ly.

(9) Confirm that setting the power switch to ON causes all link busy

indicators on the HC to go out.

(10) Set the front-mounted program s wit ch of the CP to ON.

(11) Make the exchange initial setting. (Turn off the program switch

after setting.)

(12) Perform link tests.

(13) Perform speech tests by calling other stations from the station

No. 200.

(14) Turn on the CP program switch.

(15) Program each function into the exchange from the station No.

200.

(16) Perform function tests.

(17) Check battery connection.

– 33 –

Page 37

Printed in USA 4-92

133-21-117-1B-ABC

Loading...

Loading...