Page 1

INSTALLATION MANUAL

DIGITAL MIXER D-2000 Series

(Version 4)

D-2008SP

D-2012C/

2012AS

Thank you for purchasing TOA's Digital Mixer.

Please carefully follow the instructions in this manual to ensure long, trouble-free use of your equipment.

Page 2

2

TABLE OF CONTENTS

1. HANDLING PRECAUTIONS ........................................................................... 5

2. NOMENCLATURE AND FUNCTIONS

2.1. D-2008SP Digital Mixing Processor Unit ............................................................ 6

2.2. D-2012C Remote Console Unit ........................................................................ 10

2.3. D-911 VCA Fader Unit ..................................................................................... 16

2.4. Optional Modules

2.4.1. D-921F Microphone/Line Input Module .................................................. 18

2.4.2. D-921E Microphone/Line Input Module ................................................. 18

2.4.3. D-922F Microphone/Line Input Module .................................................. 19

2.4.4. D-922E Microphone/Line Input Module ................................................. 19

2.4.5. D-2000AD1 Microphone/Line Input Module ........................................... 20

2.4.6. D-936R Stereo Input Module ................................................................. 21

2.4.7. D-923AE Digital Input Module ................................................................ 21

2.4.8. D-937SP Digital Input Module ................................................................ 21

2.4.9. D-971M Line Output Module .................................................................. 22

2.4.10. D-971E Line Output Module ................................................................ 22

2.4.11. D-971R Line Output Module ................................................................ 22

2.4.12. D-2000DA1 Line Output Module .......................................................... 23

2.4.13. D-972AE Digital Output Module ........................................................... 24

2.4.14. D-961SP Digital Output Module ........................................................... 24

2.4.15. D-981 Remote Control Module ............................................................ 24

2.4.16. D-983 Remote Control Module ............................................................ 25

2.4.17. D-984VC VCA Control Module ............................................................ 25

2.4.18. D-2000CB CobraNet Interface Module ................................................ 26

3. INSTALLATION

3.1. Inserting the D-2000CB .................................................................................... 27

3.2. Rack Mounting

3.2.1. D-2008SP .............................................................................................. 29

3.2.2. D-2012C ................................................................................................. 30

3.2.3. D-911 ..................................................................................................... 30

3.3. When Installing the D-2012C on a Desk

3.3.1. Components of the D-2012AS Console Case ....................................... 31

3.3.2. Attaching the D-2012AS Console Case ................................................. 31

4. CONNECTION

4.1. Connection Example 1 ..................................................................................... 33

4.2. Connection Example 2 ..................................................................................... 34

4.3. Removable Terminal Plug Connection ............................................................. 35

4.4. Connecting the Monitor Bus Terminal of the D-2008SP and D-2012C ............ 36

4.5. Audio Monitor Line Connection When Multiple Units Are Connected .............. 37

4.6. D-2012C's AC Power Cord Connection ........................................................... 38

4.7. D-911 Connection ............................................................................................ 38

4.8. D-984VC Specifications

4.8.1. Connection cable and pin arrangements of each terminal ..................... 39

4.8.2. Input and output channel VCA controls (1) – (4) .................................... 39

4.8.3. Contact controls (5) – (8) ....................................................................... 40

4.9. Ferrite Cable Clamp Attachment (For D-972AE only) ...................................... 41

4.10. System Expansion Using CobraNet Connection

4.10.1. CobraNet connection outline ................................................................ 42

4.10.2. Redundant configuration of switching hubs ......................................... 44

Page 3

3

4.10.3. Non-redundant configuration of switching hubs ................................... 45

4.10.4. Largest-scale system connection example .......................................... 46

5. PC CONNECTIONS ......................................................................................... 47

6. RETURNING SETTINGS TO THEIR INITIAL FACTORY DEFAULT

(D-2008SP ONLY) ............................................................................................ 48

7. FIRMWARE UPDATE PROCEDURE (D-2012C ONLY) ....................... 49

8. OPERATIONS

8.1. D-2008SP Operation ........................................................................................ 51

8.1.1. Recalling preset memories .................................................................... 52

8.1.2. Selecting the input or output channel to be monitored ........................... 53

8.1.3. Selecting the D-2012C's monitor channels ............................................ 54

8.1.4. Selecting CobraNet's monitor channels ................................................. 55

8.1.5. Key lock function ON/OFF ..................................................................... 56

8.2. D-2012C Operation

8.2.1. Key-assignable functions ....................................................................... 57

8.2.2. Preset memory recall ............................................................................. 58

8.2.3. Storage in preset memory ...................................................................... 58

8.2.4. Switching Line Inputs

(valid only when the D-936R or D-937SP module is installed) .............. 59

8.2.5. D-2008SP level indicator control (LED control) ..................................... 59

8.2.6. Fader layer switching ............................................................................. 60

8.2.7. D-2008SP control output ON/OFF (console switch) .............................. 61

8.2.8. D-2008SP (ID 1) external control switch ................................................ 61

8.2.9. Key lock function ON/OFF ..................................................................... 62

8.2.10. Monitor channel clear ........................................................................... 63

8.2.11. Monitoring ............................................................................................ 63

8.3. D-911 Operation

8.3.1. Volume adjustment ................................................................................ 64

8.3.2. Contact control ....................................................................................... 64

9. BLOCK DIAGRAMS

9.1. D-2008SP ......................................................................................................... 65

9.2. D-2012C ........................................................................................................... 68

9.3. D-911 ............................................................................................................... 69

10. LEVEL DIAGRAMS

10.1. Analog Input/Output ....................................................................................... 70

10.2. Digital Input/Output ........................................................................................ 70

11. SPECIFICATIONS

11.1. D-2008SP Digital Mixing Processor Unit ....................................................... 71

11.2. D-2012C Remote Console Unit ..................................................................... 73

11.3. D-911 VCA Fader Unit ................................................................................... 74

11.4. D-921F Microphone/Line Input Module .......................................................... 74

11.5. D-921E Microphone/Line Input Module ......................................................... 75

11.6. D-922F Microphone/Line Input Module .......................................................... 75

11.7. D-922E Microphone/Line Input Module ......................................................... 76

11.8. D-2000AD1 Microphone/Line Input Module ................................................... 76

11.9. D-936R Stereo Input Module ......................................................................... 77

11.10. D-923AE Digital Input Module ........................................................................ 77

11.11. D-937SP Digital Input Module ........................................................................ 77

Page 4

4

11.12. D-971M Line Output Module .......................................................................... 78

11.13. D-971E Line Output Module .......................................................................... 78

11.14. D-971R Line Output Module .......................................................................... 78

11.15. D-2000DA1 Line Output Module .................................................................... 79

11.16. D-972AE Digital Output Module ..................................................................... 79

11.17. D-961SP Digital Output Module ..................................................................... 79

11.18. D-981 Remote Control Module ...................................................................... 80

11.19. D-983 Remote Control Module ...................................................................... 81

11.20. D-984VC VCA Control Module ...................................................................... 82

11.21. D-2000CB CobraNet Interface Module ......................................................... 83

11.22. D-2012AS Console Case ............................................................................... 83

Page 5

5

1. HANDLING PRECAUTIONS

• The power supply cords supplied with the D-2008SP and D-2012C are designed for exclusive use with each

equipment. Never use them with other equipment.

• Use the unit in locations where the temperature is between +5 to +40 °C (41 to 104 ºF) and the humidity is

less than 90 % (no condensation).

• The unit is a precision audio component. To prevent failure, do not give the unit strong shocks or vibrations.

• When mounting the D-2008SP in an equipment rack, be sure to mount a perforated panel larger than 1U

size*1above and below the unit.

• Do not position the heat-generating component such as a power amplifier immediately below the D-2008SP

in the rack even if the perforated panel is mounted between them. Also, keep such components away from

each other so that the ambient temperature around the D-2008SP should not exceed +40 ºC (104 ºF).

Failure to do so may shorten the product life.

• When mounting the D-2012C in an equipment rack, be sure to mount a perforated panel larger than 1U

size*1above the unit.

• Do not position the heat-generating component such as a power amplifier immediately below the D-2012C in

the rack. Also, keep such components away from each other so that the ambient temperature around the D2012C should not exceed +40 ºC (104 ºF). Failure to do so may shorten the product life.

• Do not place objects on the motorized faders of the D-2012C as these faders move up and down

automatically through operation such as preset memory recall.

• The largest-scale system can be configured with 4 D-2008SPs, 4 D-2012Cs, and 1 PC.

When using the multiple D-2008SP or D-2012C units, their firmware versions must be 3.0.0 or later, and the

D-2000 Setting software version must be 3.0.0 or later.

For details on how to check their versions, read the separate Setting Software Instructions, "Menu item

description."

Firmware of the D-2008SP and D-2012C can be updated using the Setting Software ver. 3.0.0 or later*2.

For details on how to update the firmware, read the separate Setting Software Instructions, "Method to

Enable Communications between the PC and the Unit."

The latest versions of the D-2000 Setting Software and Instruction Manual are made available on the TOA

product data download site (http://www.toa-products.com/international/).

• To clean, be sure to first switch off the unit's power, then wipe with a dry cloth. When the unit gets very dirty,

use a cloth damped in a neutral cleanser. Never use benzene, thinner, chemically-treated cleaning cloth, or

alcohol because such volatile liquids could deform or discolor the unit.

• About the wear-and-tear items

The D-2012C's following parts are wear-and-tear items. Replace them when they approach the end of their

useful lives, which vary depending on the environments or conditions of use. Note that the replacement of

such wear-and-tear parts is chargeable even when the unit is within the valid guarantee period.

· Motor fader: 30000 reciprocations (Approx. 6 years)

· Rotary encoder: 30000 rotations (Approx. 12 years)

*11U size = 44.5 mm or 1.75" (standard size)

*2To update the D-2012C firmware ver. 2.0.0, use the dedicated "D-2012C Firmware Updater Software

Program." (Refer to p. 49.)

Page 6

6

2. NOMENCLATURE AND FUNCTIONS

2.1. D-2008SP Digital Mixing Processor Unit

The D-2008SP Digital Mixing Processor Unit is designed to have up to 32 audio inputs and outputs in total.

A built-in multiple signal processing functions permit the unit to be used as both a mixer and a signal

processor.

Its audio input/output and control ports can accept plug-in modules, making the unit have a maximum of 32

inputs or 32 outputs and up to 2 control modules.

Using the following optional modules enables the unit to perform their functions: Two D-983s Remote Control

Module for providing a maximum of 48 contact inputs and 32 contact outputs, D-984VC VCA Control Module

for VCA control, and D-2000CB CobraNet Interface Module for audio data transfer between CobraNet

devices.

Each function can be set using the D-2000 Setting Software.

Operation can be performed through the front key operation and from a PC with the D-2000 Setting Software

installed.

The D-2012C Remote Console Unit, when connected, remotely controls the D-2008SP's basic operations

such as volume control.

It can be mounted in an EIA component rack (3U size*).

* 1U size = 44.5 mm or 1.75" (standard size)

Note

CobraNet is a trademark of Cirrus Logic, Inc.

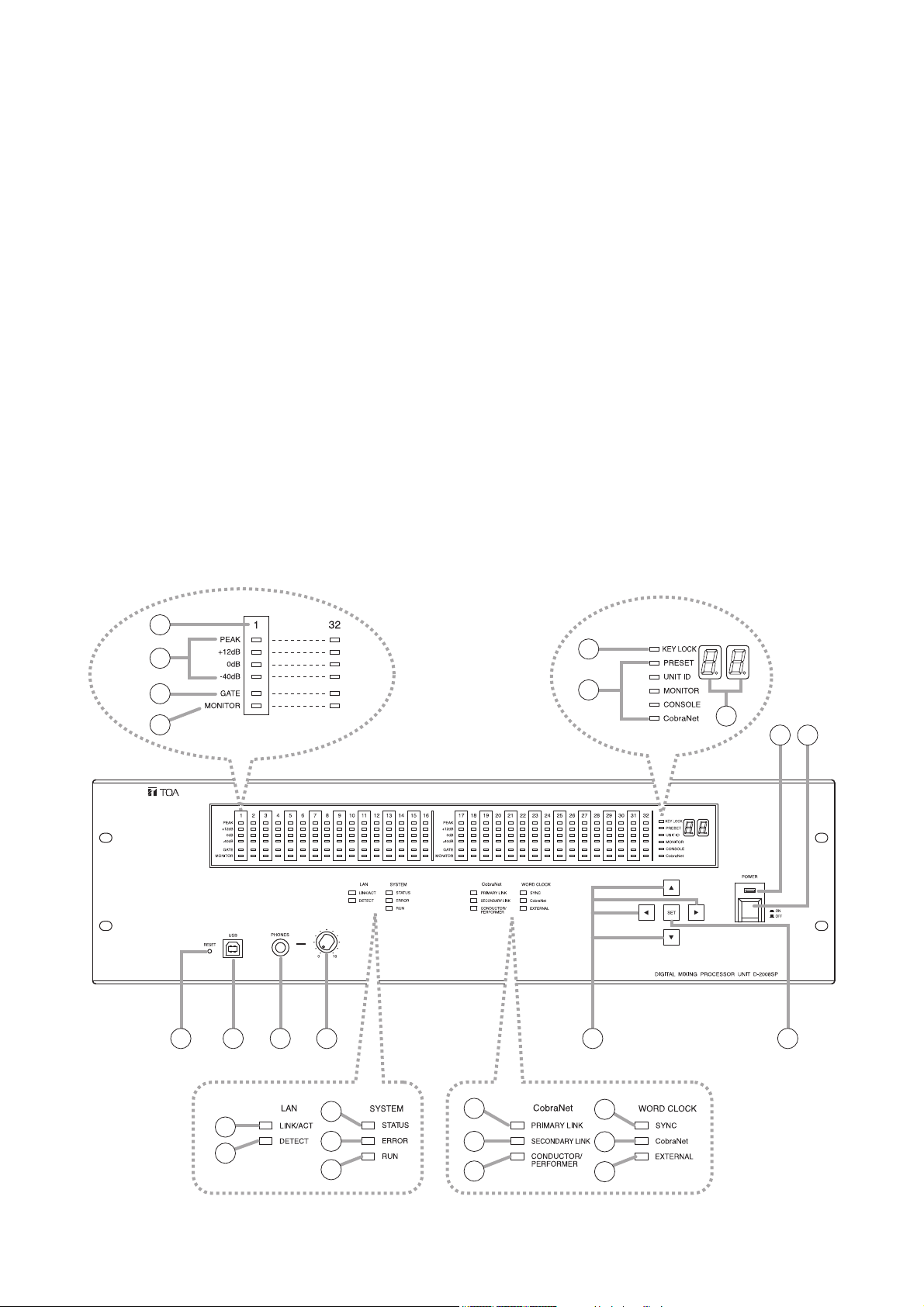

[Front]

3

4

5

6

7

8

9

2

1

10 11 12 13

18

16

17

19

20

21

22

23

14 15

24

25

26

Page 7

7

1. Power switch [POWER ON/OFF]

Power is switched on and off with each

depression of this switch.

2. Power lamp

Lights when the power switch is set to ON.

3. Monitor number

Number of channel to be monitored using

headphones.

4. Level indicators [PEAK, +12 dB, 0 dB, –40 dB]

Indicate the signal level of each individual

channel.

Indicate the PFL (pre-fader level) value for the

input channel, and the AFL (after-fader level)

value for the output channel.

When an output channel is muted, only the

PEAK indicator lights. When all output channels

are muted by the "All Mute" function, all the

PEAK indicators flash.

5. Gate indicator (Orange)

Lights when the gate* is activated.

* This function passes, attenuates, or cuts the

input signal depending on its signal level.

6. Monitor selection indicator (Orange)

Lights to indicate the corresponding channel is

selected for monitoring using headphones.

7. Key lock indicator (Red)

Lights when key lock function is enabled.

8. Item selection indicators [PRESET, UNIT ID,

MONITOR, CONSOLE, CobraNet] (Green)

The indicator of the item selected with the

Selection keys (14) lights.

9. Number display

Displays the number of the preset memory

recalled.

10. Reset switch

Restarts the D-2008SP when pressed.

Press the switch (recessed) with a pen tip.

Note

Reactivating the unit stops audio signals

currently being output.

11. USB terminal

Not used.

12. Headphone jack

Audio outputs for the channel of which Monitor

selection indicator (6) is lighting can be

monitored. Connect stereo headphones of 16 Ω

or more. Adjust the monitor volume with the

headphone volume control knob (13).

13. Headphone volume control knob

Adjusts the headphone volume.

14. Selection keys

Use the Up and Down keys to select the Item

selection indicator.

Use the Left and Right keys to select the preset

memory number when recalling the preset

memory or the desired monitor number when

MONITOR is selected.

15. Set key

Used for preset memory recall or key lock

setting.

16. LAN LINK/ACT indicator (Green)

Lights when the LAN connector on the rear panel

is connected, and flashes during LAN

communications.

17. LAN DETECT indicator (Orange)

Lights when this unit is selected on the D-2000

Setting Software.

18. SYSTEM STATUS indicator (Green)

Lights when the unit is in communication with a

PC.

19. SYSTEM ERROR indicator (Red)

Lights while the unit is being activated, and goes

out after the activation has been completed.

If this indicator remains lit even after activation

completion, this indicates an internal fan failure.

(For the relationship between the indicator and

D-2008SP status, refer to the table on p. 8.)

20. SYSTEM RUN indicator (Green)

Lights when the unit is in normal operation, and

goes out when a failure occurs.

(For the relationship between the indicator and

D-2008SP status, refer to the table on p. 8.)

21. CobraNet PRIMARY LINK indicator (Green)

Flashes during CobraNet communications via

the primary port.

22. CobraNet SECONDARY LINK indicator

(Green)

Flashes during CobraNet communications via

the secondary port.

23. CobraNet CONDUCTOR/PERFORMER

indicator (Green)

Flashes when the primary port is in operation as

the conductor, and lights when it is in operation

as the performer.

24. WORD CLOCK SYNC indicator (Green)

Lights when internal word clock synchronization

is stable. Goes out if the clock gets out of

synchronization, then the internal mute functions,

causing the audio outputs to be interrupted. Even

if once the clock had got out of synchronization,

when the internal clock has stabilized, such

operation state automatically returns to normal.

Page 8

8

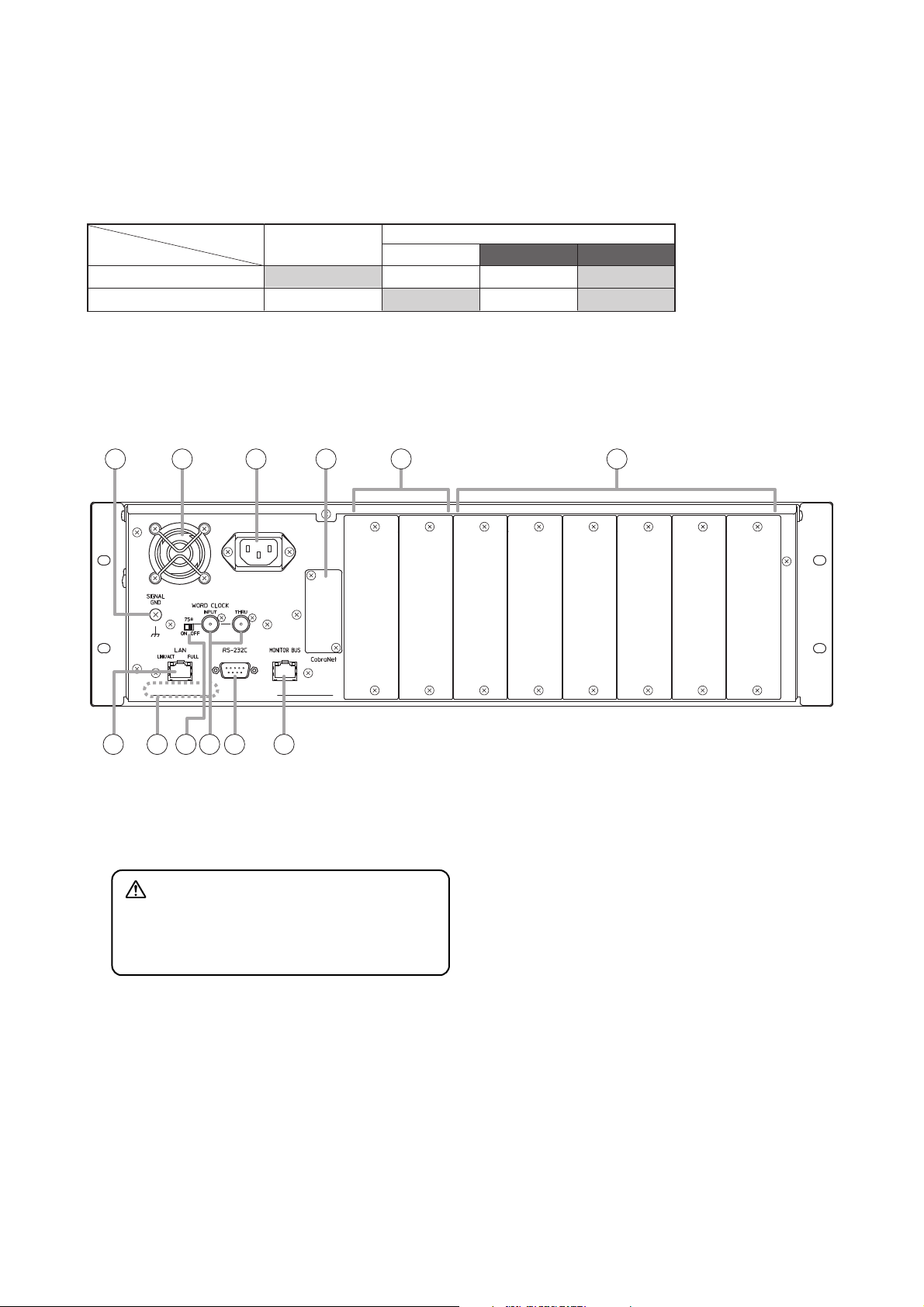

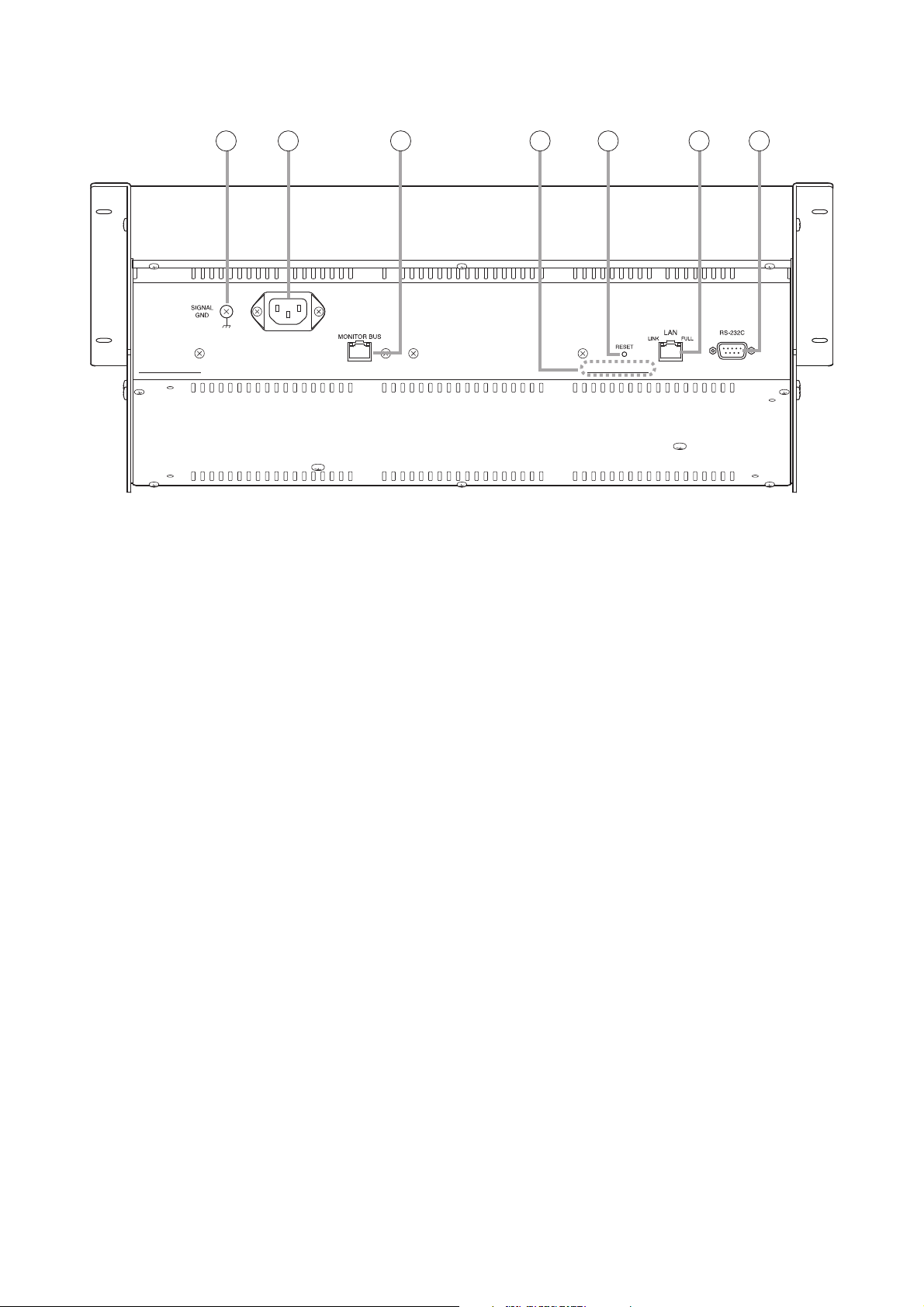

[Rear]

27. Functional earth terminal [SIGNAL GND]

Note: This terminal is not for protective earth.

28. Cooling fan

29. AC Inlet

Connect this inlet to the wall AC outlet using the

supplied power cord.

The socket-outlet shall be installed near the

equipment and the plug (disconnecting device)

shall be easily accessible.

30. CobraNet interface module slot

Accepts the D-2000CB CobraNet Interface

Module, allowing audio transmission with other

CobraNet equipment.

31. Input/output and remote control modules

slots (7 – 8)

Accept the input, output or remote control

modules.

Insert the input module to use as input, output

module to use as output, and remote control

module to use as control input.

32. Input/output module slots (1 – 6)

Accept the input or output modules.

Insert the input module to use as input, and

output module to use as output.

33. LAN connection terminal

Connect this terminal to a 10BASE-T- or

100BASE-TX-compatible network.

This terminal can also be connected to a PC and

D-2012C via a switching hub.

(For the IP address setting, refer to "Network

Settings" of the separate software setting

manual.)

CAUTION

Do not block the fan exhaust vent. Doing so

may cause heat to build up inside the unit and

result in fire.

25. WORD CLOCK CobraNet indicator (Green)

Lights when the master of the internal word clock

gets synchronization from CobraNet.

26. WORD CLOCK EXTERNAL indicator (Green)

Lights when the master of the internal word clock

gets synchronization from the external word

clock generator connected to the rear panel's

word clock input.

• SYSTEM ERROR and SYSTEM RUN indicators vs. D-2008SP status

D-2008SP status

Indicator

SYSTEM ERROR

SYSTEM RUN

Note

If both indicators light or remain unlit after the unit activation is complete, cycle the power. If the situation does not change

after the unit power-up, the unit may break down. Contact your TOA dealer.

During activation

Lit

Unlit Unlit

Normal state System error

Lit

After activation completion

Fan error

UnlitUnlit

Lit

Lit

27 28 29 30 31 32

33 34 35 36 37 38

Page 9

9

34. MAC address

This is the address* used by the unit. Since the

relationship of the unit's location to its MAC

address is established when setting the network

attributes, keep track of this relationship for later

use.

* The inherent address assigned to each network

component, expressed in 12-digit hexadecimal

notation.

35. Word clock termination switch

Terminates the word clock connection at 75 Ω.

To terminate the word clock connection at this

unit, shift the switch to the "ON" position. In other

cases, shift it to the "OFF" position. (Factory

preset: OFF)

36. Word clock terminals

Used to input and output the word clock which

synchronizes the audio signal processing with

that of external equipment. Connect a

commercially available word clock generator.*

Helps to stabilize the system that uses two or

more CobraNet devices.

As “Through output” (THRU) is not electrically

buffered, it can be used for input.

* Two or more CobraNet devices can be

connected in series using the Through output.

However, it is recommended to connect the

CobraNet device with the word clock generator

on a one-on-one basis.

37. RS-232C terminal

A communications connector for other control

equipment.

38. Monitor bus terminal

An audio transmission connector for the D2012C

Connects to the D-2012C's Monitor bus terminal.

Audio signals are output to the D-2012C's

headphone jack through the monitor bus or audio

signals from the D-2012C's Line input terminal

are input to the monitor bus.

Page 10

10

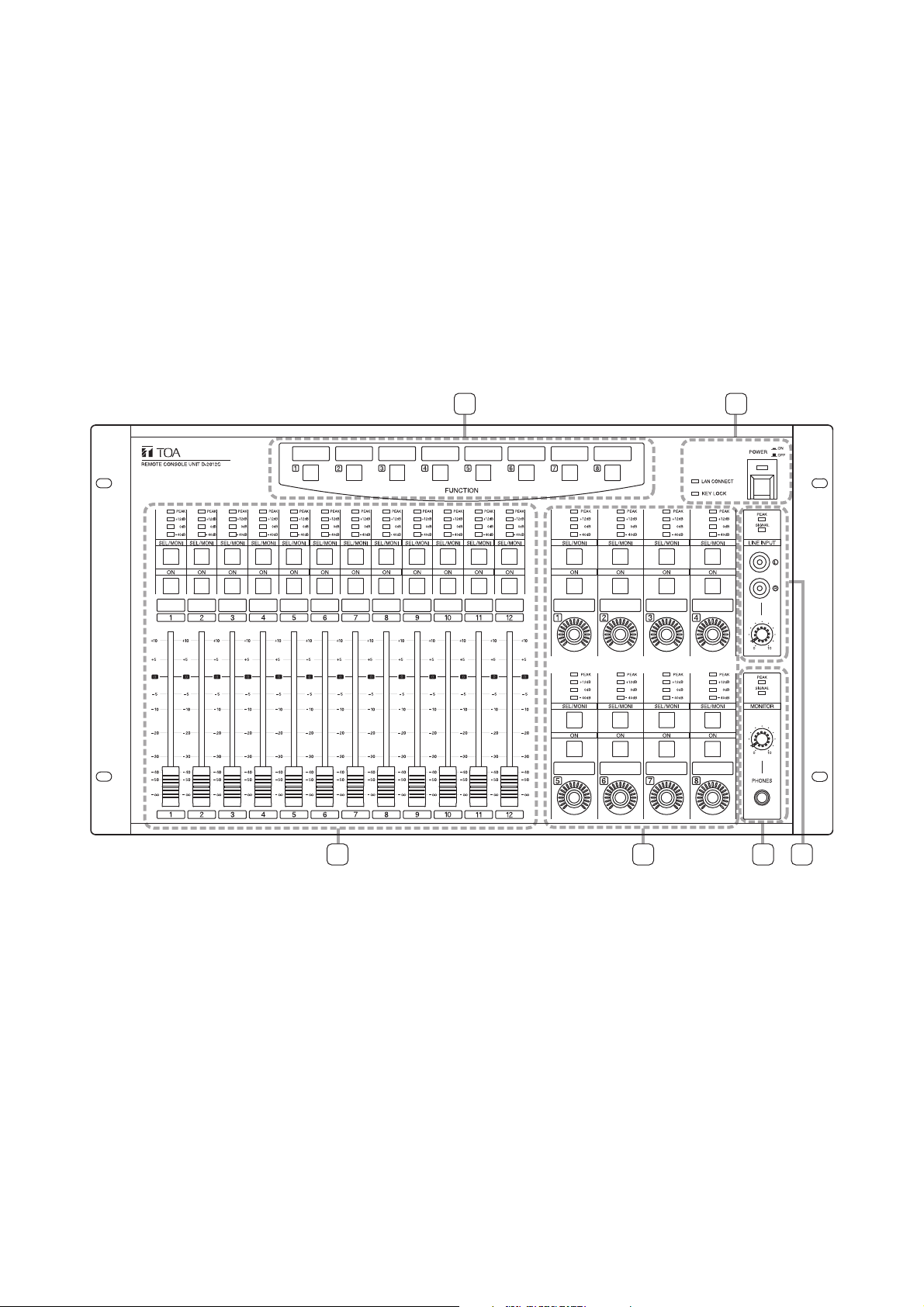

2.2. D-2012C Remote Console Unit

The D-2012C is designed to be used with the D-2008SP Digital Mixing Processor. The D-2012C can be LANconnected to the D-2008SP Processor to allow remote operation of input and output channel volume

adjustment, signal level monitoring, contact control and preset memory recall, etc. The D-2012C is equipped

with line inputs and audio monitor bus terminal. A PC can be connected to perform such settings as selection

of channels for operation and assigning functions to the function keys, using the D-2000 setting software

supplied with the D-2008SP Processor. Up to 4 different fader layers can be set when assigning channels to

each motorized fader and rotary encoder, allowing an individual D-2012C unit to operate up to 80 channels in

monaural. More channels can be operated by performing settings for stereo link and grouping (refer to p. 60

for details about the fader layer). It can be mounted in an EIA Standard component rack (6U* size). It can also

be used as a desktop unit in combination with the optional D-2012AS Console Case.

* 1U size = 44.5 mm or 1.75" (reference size)

[Operation panel]

AB

C D EF

Page 11

11

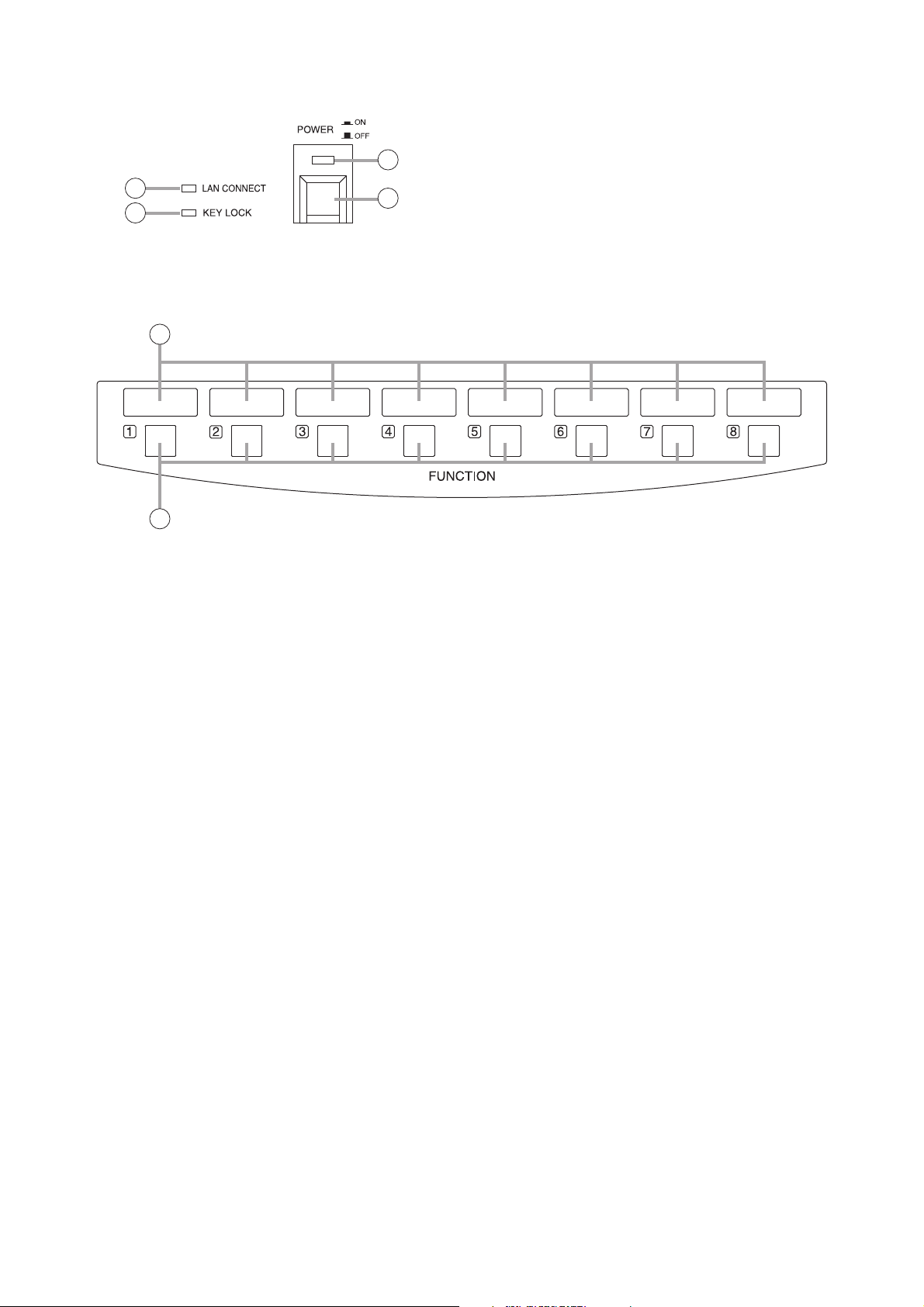

• A-Section

• B-Section

1. Power switch

Power is switched on and off with each

depression of this switch.

2. Power indicator

Lights when the power is switched on.

3. LAN connection indicator

Displays the connection status of the D-2008SP

to be controlled.

Lit: When all the D-2008SP units to be

controlled are in controllable state.

Flashing: When both controllable and

uncontrollable D-2000SP units exist in

a system where multiple D-2008SP

units to be controlled are used.

Unlit: When all the D-2008SP units to be

controlled are in uncontrollable state.

If there exists any uncontrollable D-2008SP,

check the D-2008SP's power supply and

connections.

4. Key lock indicator

Lights red when the operation keys or knobs are

locked.

5. Write-in space

Write the name of the function assigned to the

key, etc. in these spaces.

6. Function keys (1 – 8)

Execute contact control, preset memory recall or

other functions assigned to the keys.

Use the D-2000 Setting Software to set functions

and assign them to the keys.

2

3

1

4

5

6

Page 12

12

• C-Section

7. Level indicators [PEAK, +12 dB, 0 dB, –40 dB]

Indicate signal levels for each channel. Pre-fader

value is indicated for input channels and postfader value for output channels. Adjust the sound

volume so that the Peak indicator does not

continuously remain lit.

8. Monitor channel selector keys

Select the channel to be monitored. Pressing a

key causes it to light and allows its

corresponding channel to be monitored. Pressing

the key again causes the light to go out,

disabling monitoring.

It can be enabled to switch the D-2008SP's

selection channel on the D-2000 Setting

Software in synchronization with this key

operation. (For details, read the separate Setting

Software Instructions, "Console SEL/MONI key

interlock setting.")

9. Channel ON/OFF keys

Turn on or off the output for each channel.

Pressing a key causes it to light and the signal of

its corresponding channel to be output. When

pressed again, the light goes out and the

channel's signal output is stopped.

10. Write-in space

Write the name of the input or output channel,

etc. in these spaces.

11. Motorized faders (1 – 12)

Adjust the volume of each input or output

channel. With reference to fader position "0," the

position "–∞" provides the minimum volume, and

position "+10" the maximum volume.

Use the D-2000 Setting Software to perform

settings for the input or output channels for which

the volume is adjusted.

7

8

9

10

11

Page 13

13

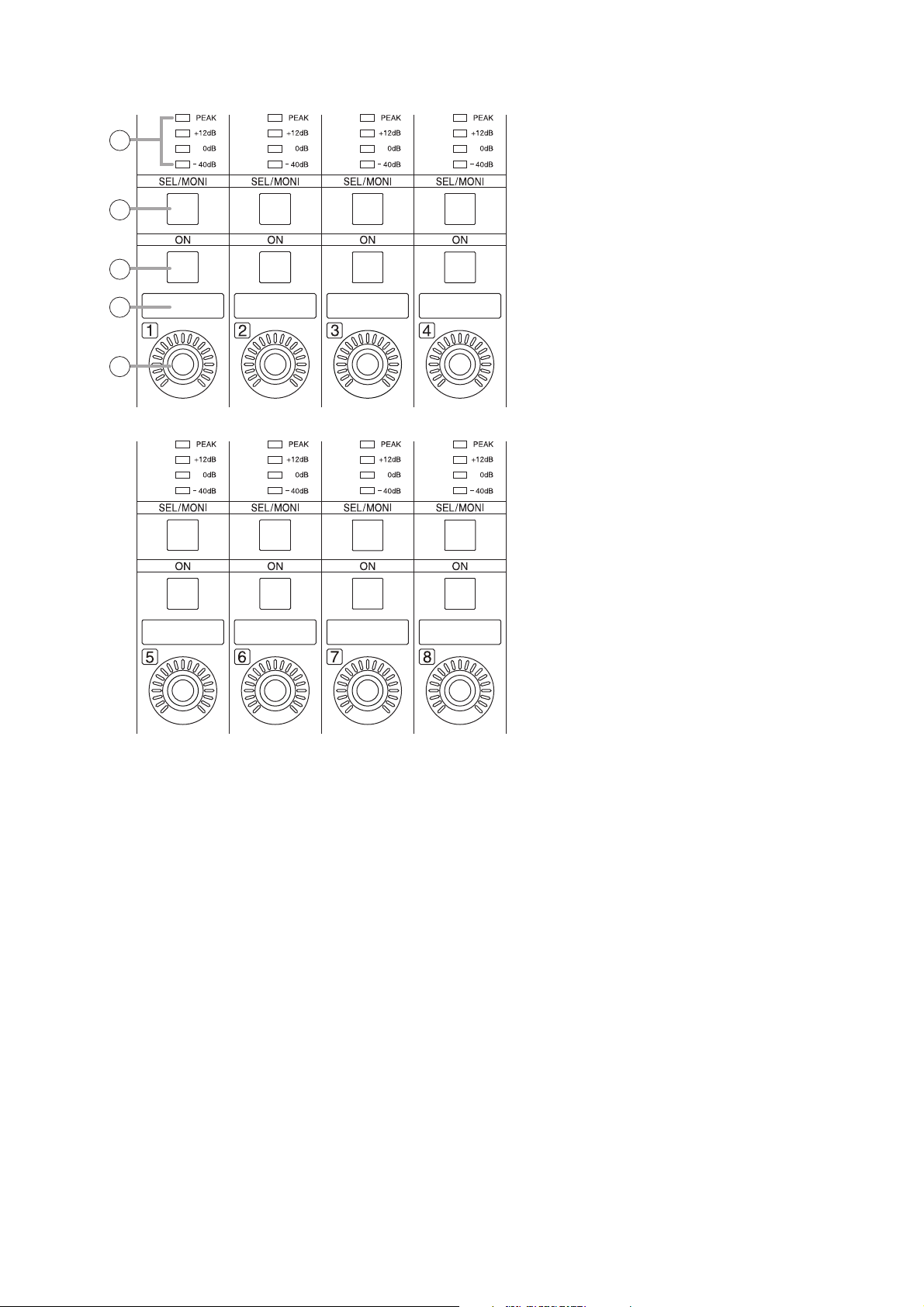

• D-Section

Note: Refer to p. 12 for names and functions of parts 7 – 10.

12. Rotary encoders (1 – 8)

Adjust the volume of each input or output

channel. The volume increases as the encoder is

rotated clockwise, and decreases as it is rotated

counterclockwise. (The knob rotates endlessly.)

The volume indicators around the knob light

depending on the rotation of the knob.

Use the D-2000 Setting Software to perform

settings for the input or output channels for which

the volume is adjusted.

7

8

9

10

12

Page 14

14

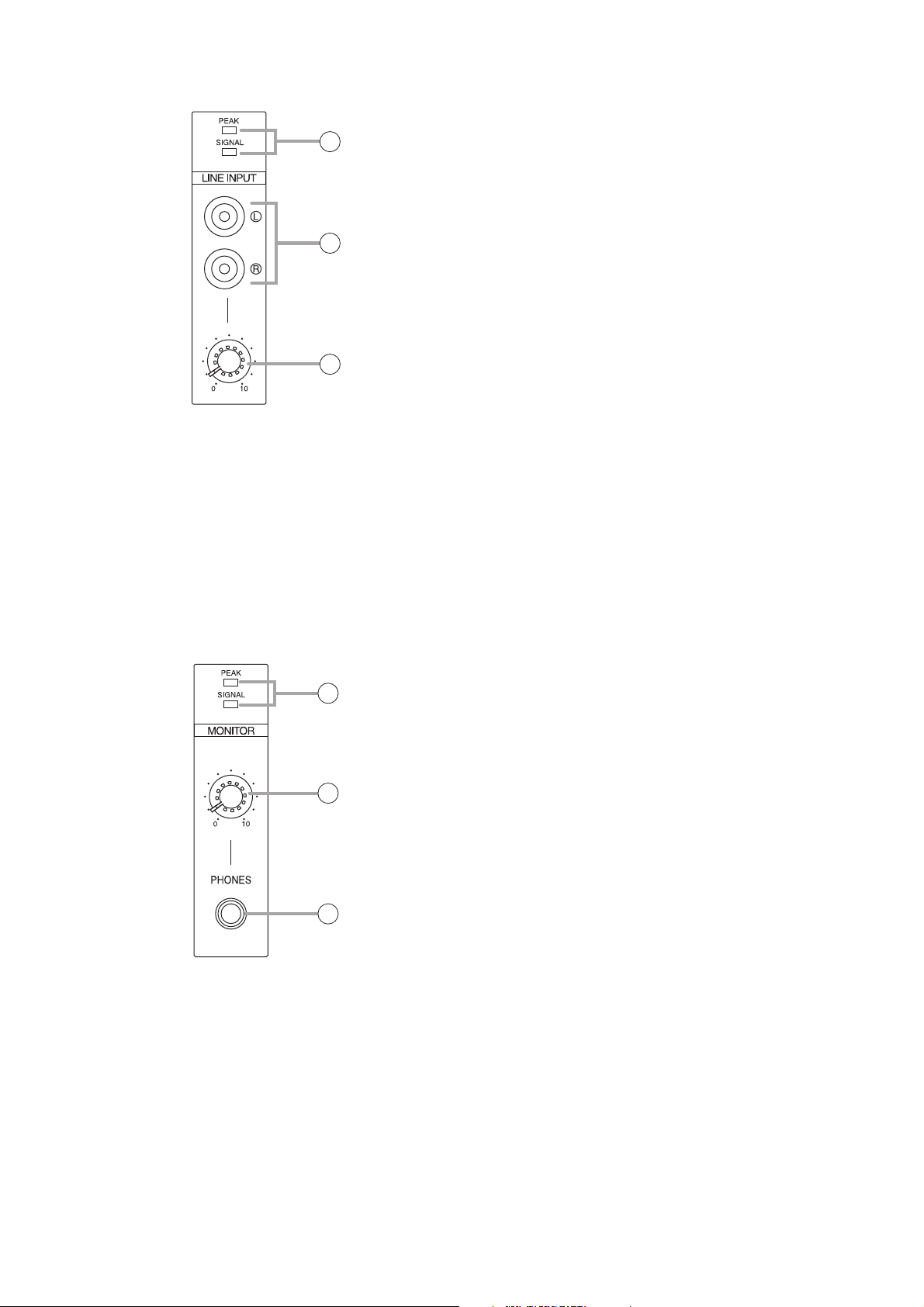

• E-Section

• F-Section

13. Line input signal level indicators

[SIGNAL, PEAK]

Display the signal level set with the Line input

volume control (15). The SIGNAL indicator lights

when a signal exceeding the reference level of

–20 dB is fed to the line input terminal. If a signal

at the line input terminals clips, the PEAK

indicator lights.

14. Line input terminals

Connect stereo equipment of stereo line level of

–10 dB* and 10 kΩ to these terminals. When

using these terminals, perform settings on the D2008SP side using the D-2000 Setting Software.

* 0 dB = 0.775 V

15. Line input volume control knob

Adjusts the signal input level from equipment

connected to the line input terminal. The volume

increases as the control knob is rotated

clockwise and decreases as it is rotated

counterclockwise. Adjust the level so that the

SIGNAL indicator lights without lighting the

PEAK indicator.

16. Monitor signal indicators [SIGNAL, PEAK]

Indicates the level of the signal being monitored.

The SIGNAL indicator lights when a signal being

monitored exceeding the reference level of –20

dB is fed to the line input terminal. If the signal

level approaches clipping volume, the PEAK

indicator lights. Select the channel to be

monitored using Monitor channel selector keys

(8).

17. Monitor volume control knob

Adjusts the volume of sound monitored by the

headphones connected to the Headphone jack.

The volume increases as the control knob is

rotated clockwise and decreases as it is rotated

counterclockwise.

18. Headphone jack

Applicable impedance is 16 Ω or greater. This

jack allows monitoring of the sound output from

the channel selected with the Monitor channel

selector keys (8). Plug in headphones of 16 Ω or

more to this jack. Adjust the monitor volume with

the Monitor volume control knob (17).

13

14

15

16

17

18

Page 15

15

[Connection panel]

19. Functional earth terminal

Note: This terminal is not for protective earth.

20. AC Inlet

Connect this inlet to the wall AC outlet using the

supplied power cord.

The socket-outlet shall be installed near the

equipment and the plug (disconnecting device)

shall be easily accessible.

21. Monitor bus terminal

An audio transmission connector for the D2008SP. Connects to the D-2008SP's Monitor

bus terminal. D-2008SP's audio signals are

output to the headphone jack through the

monitor bus or audio signals from the Line input

terminals (14) are input to the D-2008SP.

22. MAC address

This is the address* used by the unit. Since the

relationship of the unit's location to its MAC

address is established when setting the network

attributes, keep track of this relationship for later

use.

* The inherent address assigned to each network

component, expressed in 12-digit hexadecimal

notation.

23. Reset switch

Avoid touching this switch, as it is used only

during maintenance.

24. LAN connection terminal

Connect this terminal to a 10BASE-T- or

100BASE-TX-compatible network. This terminal

can also be connected to a PC and D-2008SP

via a switching hub.

(For the IP address setting, refer to "Network

Settings" of the separate software setting

manual.)

25. RS-232C terminal

This RS-232C connector is provided for

maintenance purposes.

19 20 21 22 23 24 25

Page 16

16

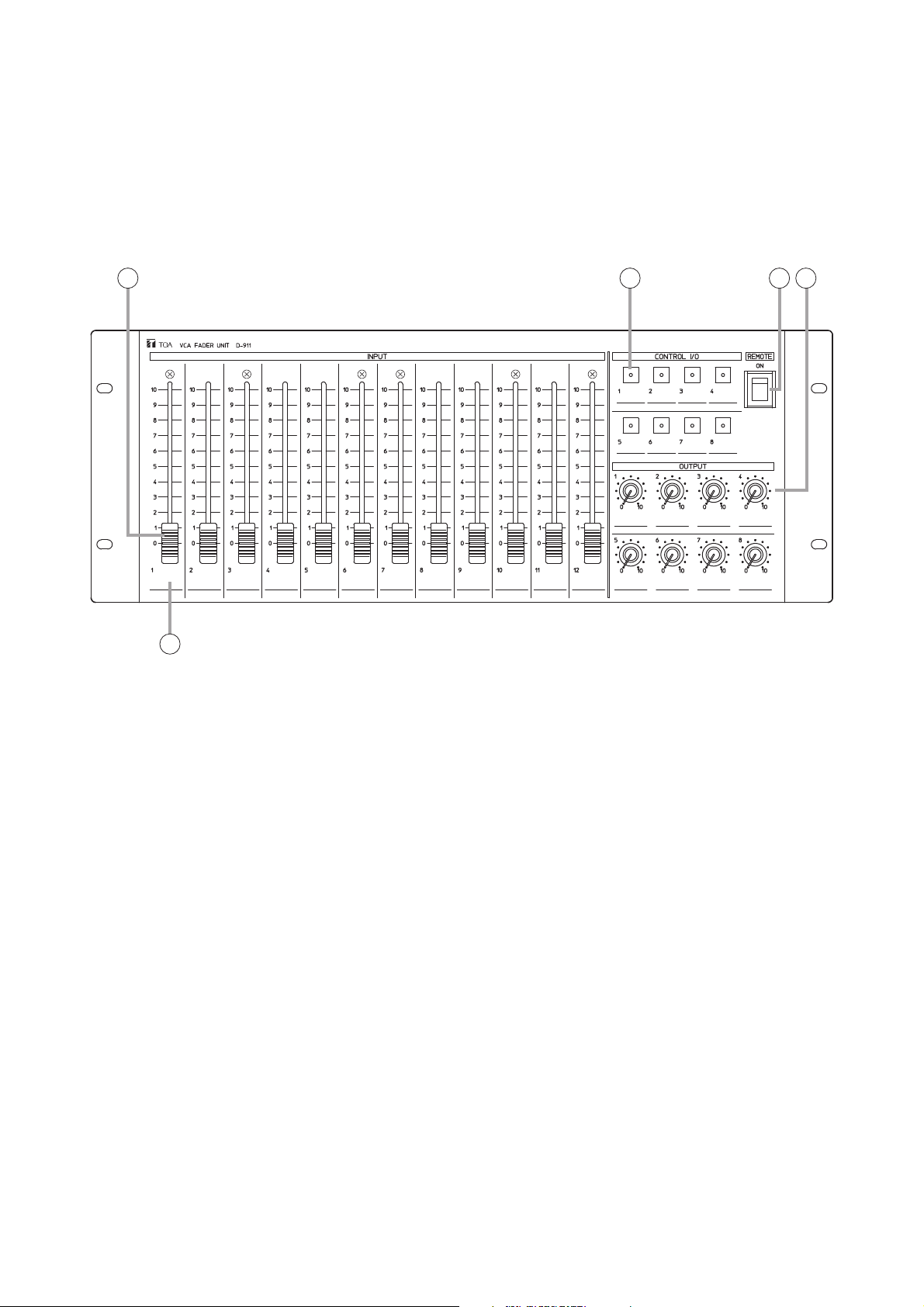

2.3. D-911 VCA Fader Unit

The D-911 VCA Fader Unit is designed for use with the D-2008SP.

Connecting to the D-984VC VCA Control Module installed in the D-2008SP permits volume adjustment of

input and output channels and contact controls of the D-2008SP. For details, refer to the instruction manual

enclosed with the D-911.

[Front]

1. Input fader

Adjusts the volume of each input equipment (i.e.

microphones and CD players). Fader position "0"

provides the minimum volume, and position "10"

the maximum volume.

Assign the channel to be operated using the D2000 Setting Software. It is also possible to

assign the channel as output fader.

2. Control key

Recalls preset memories or controls the contact.

Lights when the preset memory is recalled or the

contact is turned on.

Assign the contact functions using the D-2000

Setting Software.

3. Remote (Activation) switch

Setting this switch to the ON position closes the

remote (activation) output terminals (6) on the

rear panel, and setting this switch to the opposite

side opens the output terminals.

4. Output volume control knob

Adjusts the output volume. Position "0" provides

the minimum volume, and position "10" the

maximum volume.

Assign the channel to be operated using the D2000 Setting Software.

It is also possible to assign the knob as input

volume control knob.

5. Write-in space

Used to fill in input/output name, preset memory

contents, or other notes for convenience of

operation.

1

5

2 3 4

Page 17

17

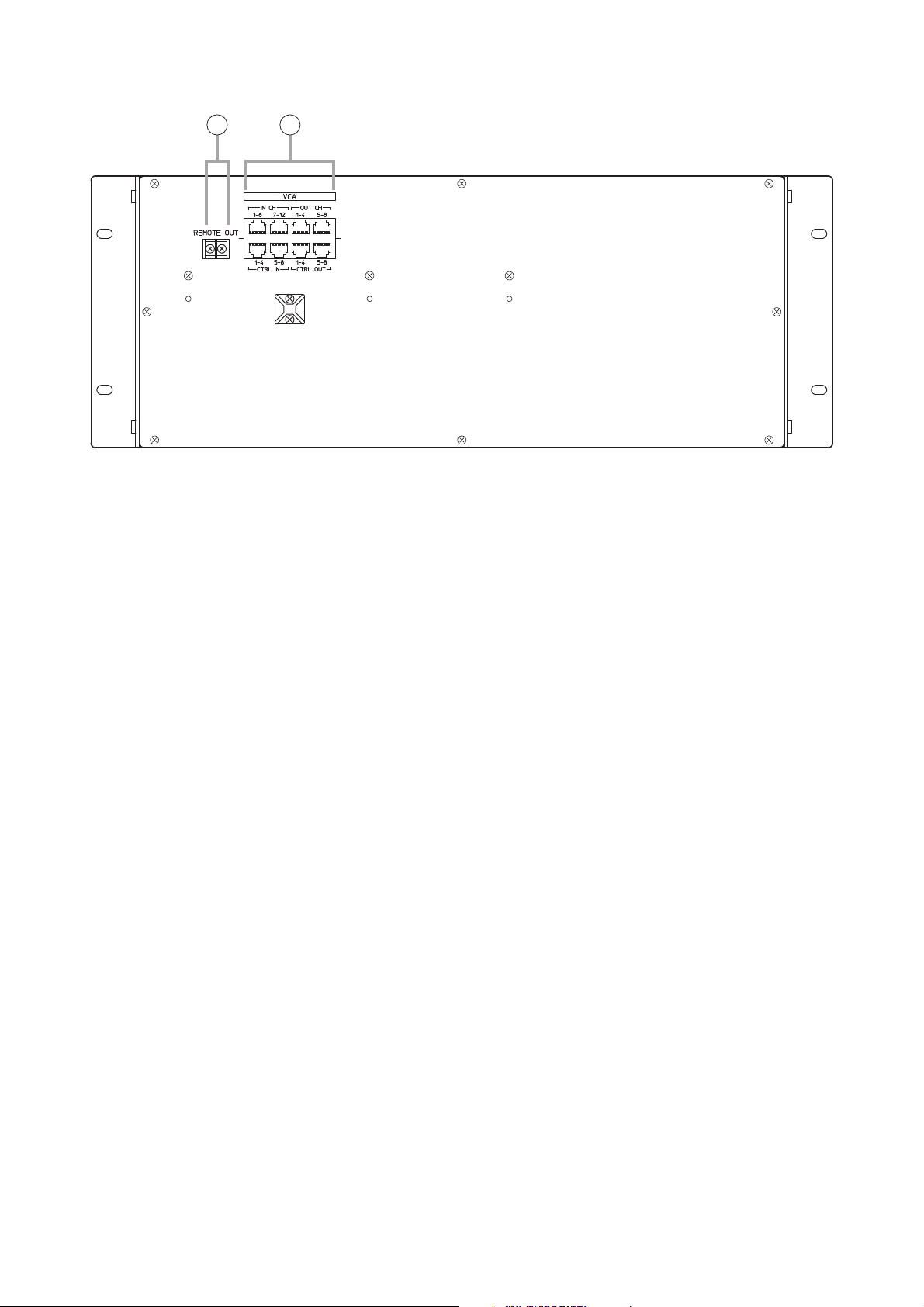

6. Remote (activation) output terminals

Setting the Remote (activation) switch (3) to the

ON position closes the output.

7. VCA control module connection terminals

These terminals are used exclusively for the D984VC VCA Control module. Use an RJ45

connector for connection.

Note

Avoid connecting any other than the D-984VC to

these terminals.

[Rear]

6 7

Page 18

18

2.4. Optional Modules

Notes

• Make sure that the power is switched OFF before attaching or detaching modules.

• To avoid failures due to static electricity, do not touch the parts or terminals on the circuit board of both the

unit and module.

• Ensure that the module is installed and secured with screws in the correct position.

• Cover idle slots with the blank panels attached to the unit as shipped by the factory.

• Two silver slotted screws at the upper and lower portion of the module face are handles used for module

detachment. Never rotate them because they do not function as screws.

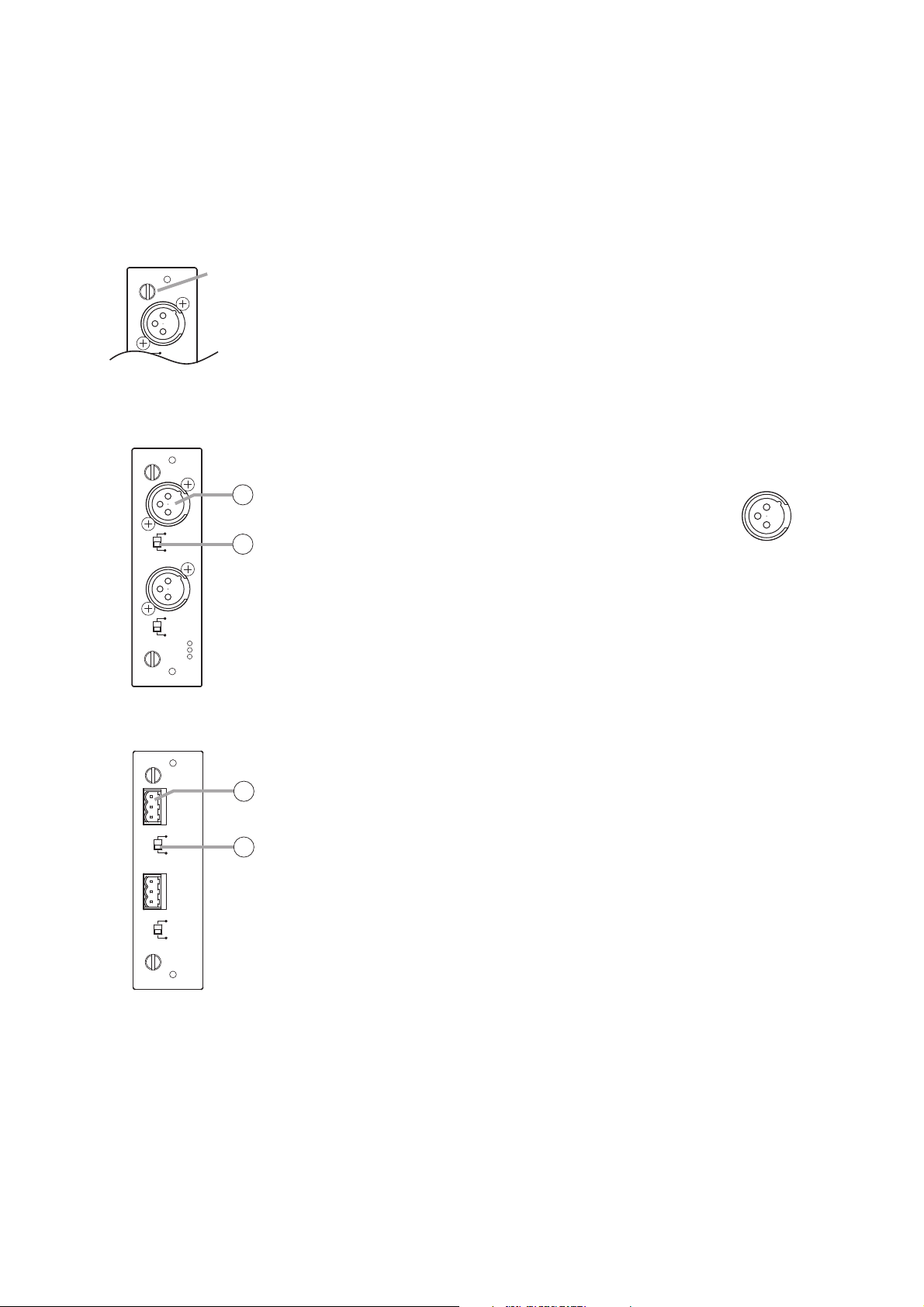

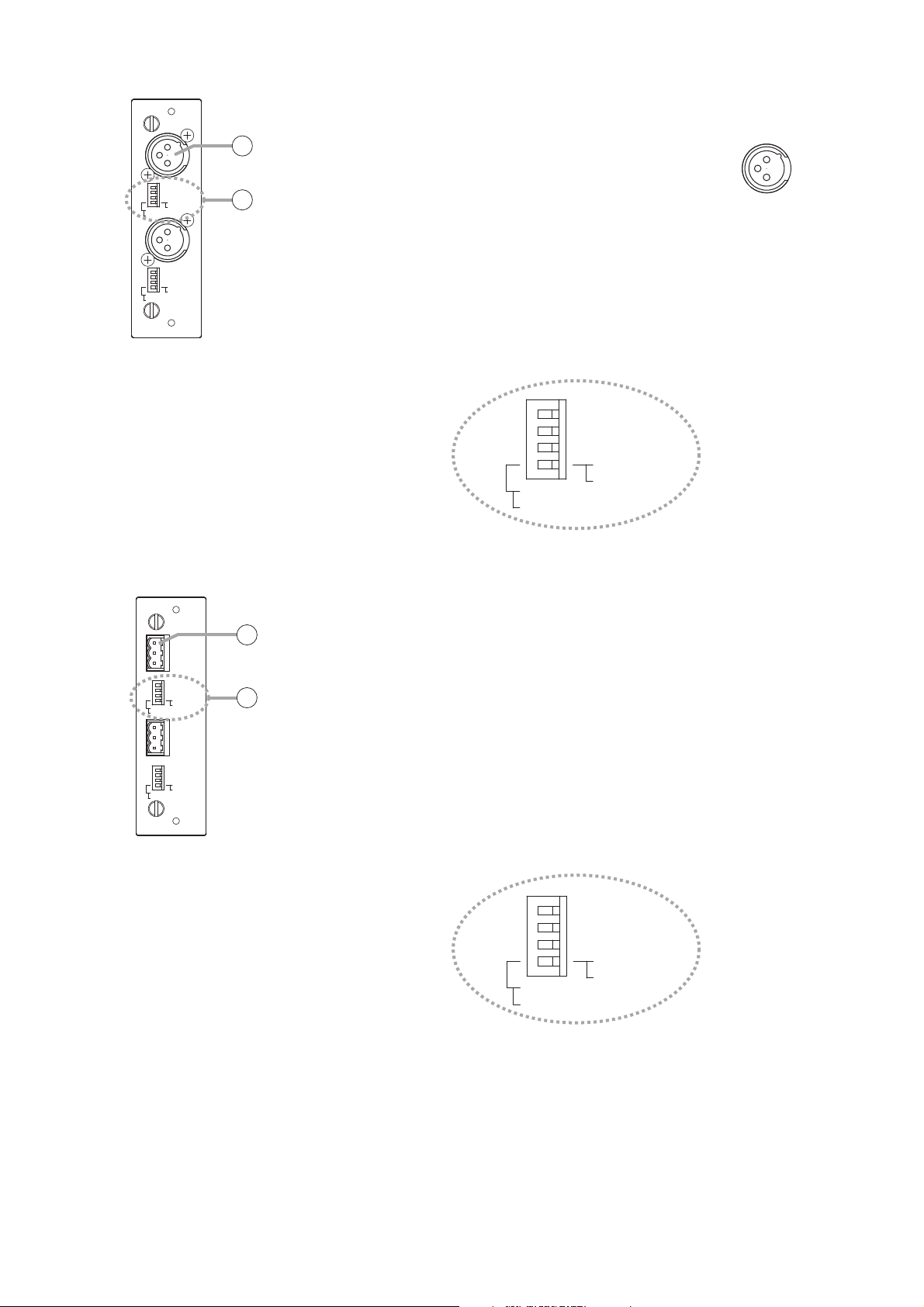

2.4.1. D-921F Microphone/Line Input Module

1. Monaural input terminal [1, 2] (XLR-3-31 equivalent)

Electronically-balanced input terminal.

(Pin 1: Ground, Pin 2: Hot, Pin 3: Cold)

Use XLR-3-12C or equivalent for connection.

Input sensitivity (–50/–36/–10/+4 dB) and

phantom power (+15 V) ON/OFF can be set by

a PC using the setting software supplied with

the D-2008SP.

2. Ground lift switch [GND LIFT/NORMAL]

Hum noise may be generated due to ground loops created when the unit

is connected to other equipment. Setting the switch to the GND LIFT

position cuts the ground loop.

2.4.2. D-921E Microphone/Line Input Module

3. Monaural input terminal [1, 2]

Electronically-balanced, removable terminal block.

(H: Hot, C: Cold, E: Ground)

Input sensitivity (–50/–36/–10/+4 dB) and phantom power (+15 V)

ON/OFF can be set by a PC using the setting software supplied with the

D-2008SP.

Note

Be sure to use the supplied removable terminal plugs (3P) for

connection.

4. Ground lift switch [GND LIFT/NORMAL]

Hum noise may be generated due to ground loops created when the unit

is connected to other equipment. Setting the switch to the GND LIFT

position cuts the ground loop.

MIC/LINE INPUT MODULE

GND LIFT

Handle

1

MIC/LINE INPUT MODULE [–50 / –36 / –10 / +4 dB] model D-921F

GND LIFT

NORMAL

1

1

2

GND LIFT

NORMAL

2

1

: E

: H

2

: C

3

2: Hot

3: Cold

1: Ground

MIC/LINE INPUT MODULE [–50 / –36 / –10 / +4 dB] model D-921E

E

C

H

GND LIFT

NORMAL

E

C

H

GND LIFT

NORMAL

3

1

4

2

Page 19

19

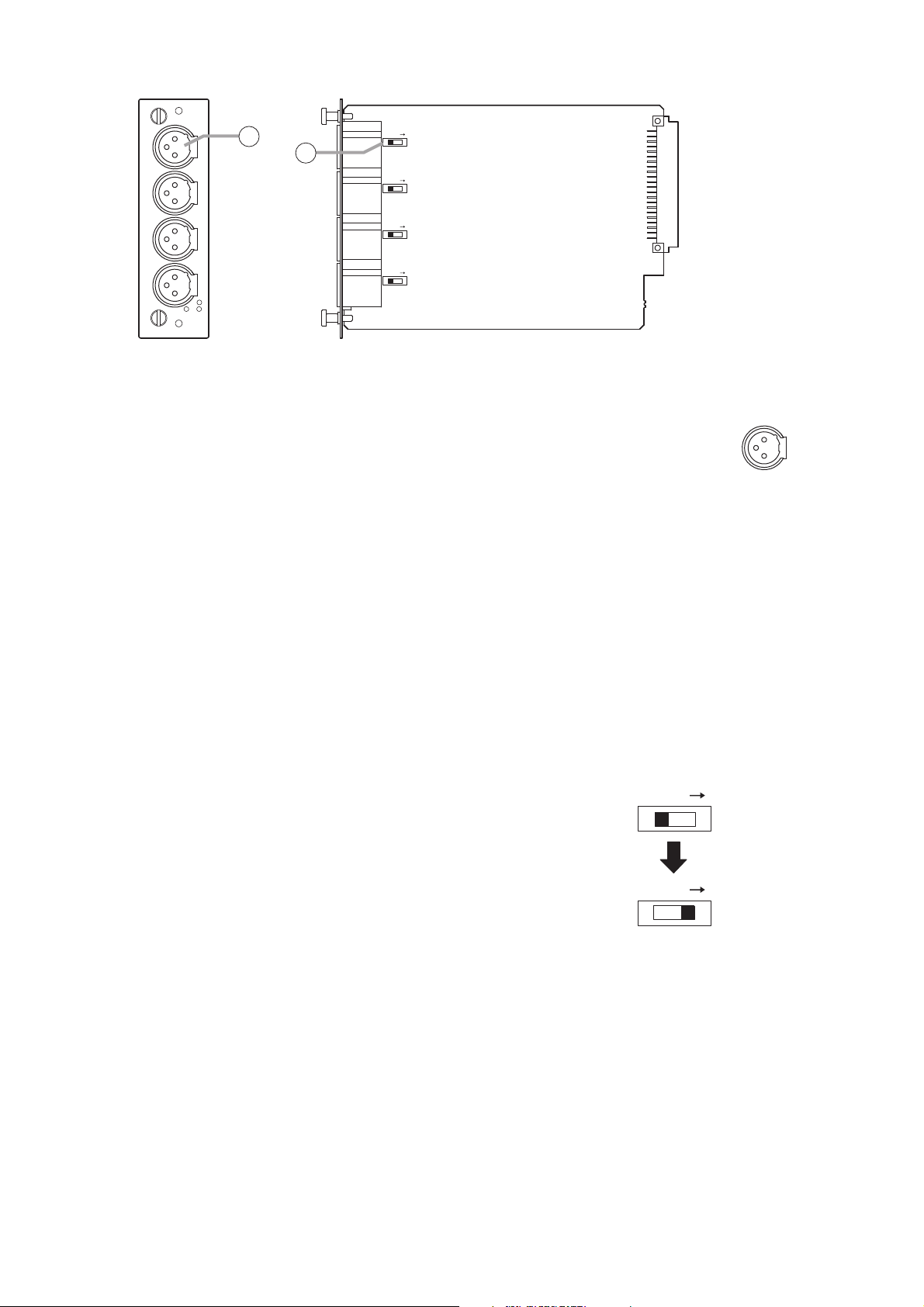

2.4.4. D-922E Microphone/Line Input Module

7. Monaural input terminal [1, 2]

Electronically-balanced, removable terminal block.

(H: Hot, C: Cold, E: Ground)

Note

Be sure to use the supplied removable terminal plugs (3P) for

connection.

8. Input sensitivity switch [PHANTOM, GND LIFT, MIC/LINE]

4-pole switch. Enables phantom power (+15V; ON/OFF, enabled only

when set to the MIC position), ground lift and input sensitivity.

Input sensitivity: –36 or –50 dB (MIC mode) / –10 or +4 dB (LINE mode)

Note

To use as monitor input, set the "PHANTOM" switch to OFF and "Input

sensitivity" switch to "+4 dB (LINE)."

2.4.3. D-922F Microphone/Line Input Module

5. Monaural input terminal [1, 2] (XLR-3-31 equivalent)

Electronically-balanced input terminal.

(Pin 1: Ground, Pin 2: Hot, Pin 3: Cold)

Use XLR-3-12C or equivalent for connection.

6. Input sensitivity switch [PHANTOM, GND LIFT, MIC/LINE]

4-pole switch. Enables phantom power (+15 V; ON/OFF, enabled only

when set to the MIC position), ground lift and input sensitivity.

Input sensitivity: –36 or –50 dB (MIC mode) / –10 or +4 dB (LINE mode)

Note

To use as monitor input, set the "PHANTOM" switch to OFF and "Input

sensitivity" switch to "+4 dB (LINE)."

MIC/LINE INPUT MODULE model D-922F

ON

NORMAL

MIC

-10dB(LINE)

-50dB(MIC)

ON

NORMAL

MIC

-10dB(LINE)

-50dB(MIC)

OFF : PHANTOM

LIFT : GND

LINE

+4dB(LINE)

-36dB(MIC)

OFF : PHANTOM

LIFT : GND

LINE

+4dB(LINE)

-36dB(MIC)

5

1

3: Cold

6

2

2: Hot

1: Ground

ON

NORMAL

MIC

OFF : PHANTOM

LIFT : GND

LINE

-10dB(LINE)

-50dB(MIC)

+4dB(LINE)

-36dB(MIC)

MIC/LINE INPUT MODULE model D-922E

7

8

2

NORMAL

NORMAL

ON

MIC

ON

MIC

-10dB(LINE)

-50dB(MIC)

-10dB(LINE)

-50dB(MIC)

E

CH1

OFF : PHANTOM

LIFT : GND

LINE

+4dB(LINE)

-36dB(MIC)

E

C

H

OFF : PHANTOM

LIFT : GND

LINE

+4dB(LINE)

-36dB(MIC)

ON

NORMAL

MIC

OFF : PHANTOM

LIFT : GND

LINE

-10dB(LINE)

-50dB(MIC)

+4dB(LINE)

-36dB(MIC)

Page 20

20

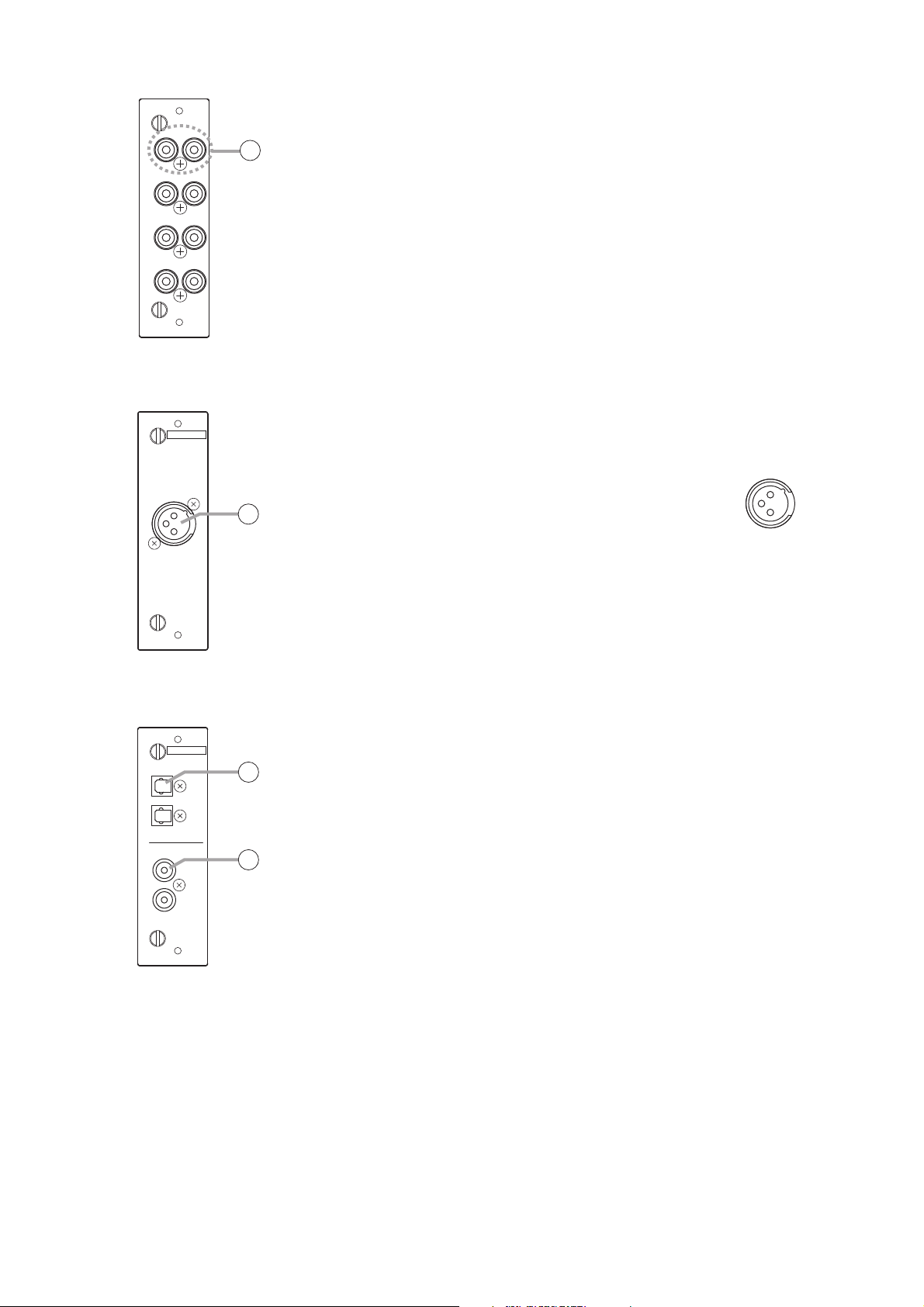

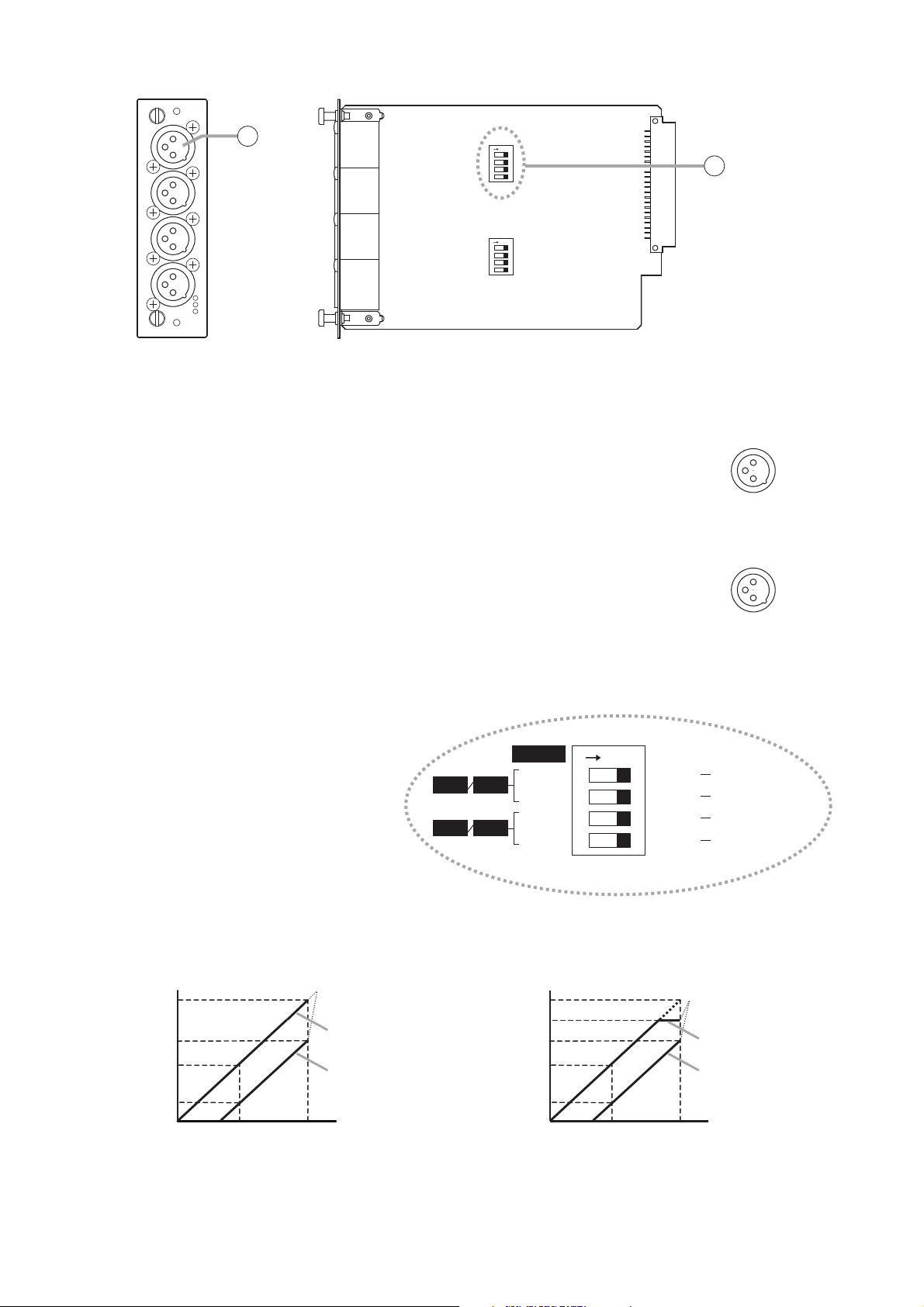

2.4.5. D-2000AD1 Microphone/Line Input Module

9. Monaural input terminal [1, 2, 3, 4] (XLR-3-31 or equivalent)

Electronically balanced input terminal.

(Pin 1: Ground, Pin 2: Hot, Pin 3: Cold)

Use XLR-3-12C or equivalent for connection.

Input sensitivity (–50/–36/–10/+4 dB) and phantom power (+48 V) ON/OFF

settings can be performed by a PC using the D-2000 Setting software

supplied with the D-2008SP.

Notes

• Be sure to turn off the phantom power (+48 V) when using an unbalanced microphone or equipment

such as a CD player or effecter other than a microphone. As doing otherwise may cause damage to the

unit.

• To insert or remove a condenser microphone that requires external power source, turn down the fader of

the corresponding channel, turn off its channel and the phantom power (+48 V), then wait at least 1

minute before inserting or removing. As doing otherwise may cause damage or failure to this module

and microphone.

• Noise may be produced when or after the phantom power (+48 V) is turned on or off. Be sure to turn on

or off the phantom power (+48 V) after turning down the fader of the corresponding channel and turning

off the channel.

Also, never operate the fader nor turn on and off the channel for 1 minute after turning on or off the

phantom power (+48 V).

• Current consumption of the phantom power supply must be 5 mA or less per channel.

10. Ground lift switch

When the D-2008SP is connected to other equipment, a ground may

create a loop, potentially generating hum noise. In such cases, the ground

loop can be cut off by setting the DIP switch on the circuit board to the

LIFT position.

Note

When shifting the DIP switch, never touch other parts on the circuit board.

MIC/LINE INPUT MODULE [–50

LIFT

LIFT

LIFT

LIFT

/

–36

/

–10

/

+4 dB]

model D-2000AD1

9

1

2

3

4

2

: H

1

3

: E

: C

10

3: Cold

2: Hot

1: Ground

LIFT

(Factory preset)

LIFT

(To the LIFT side)

Page 21

21

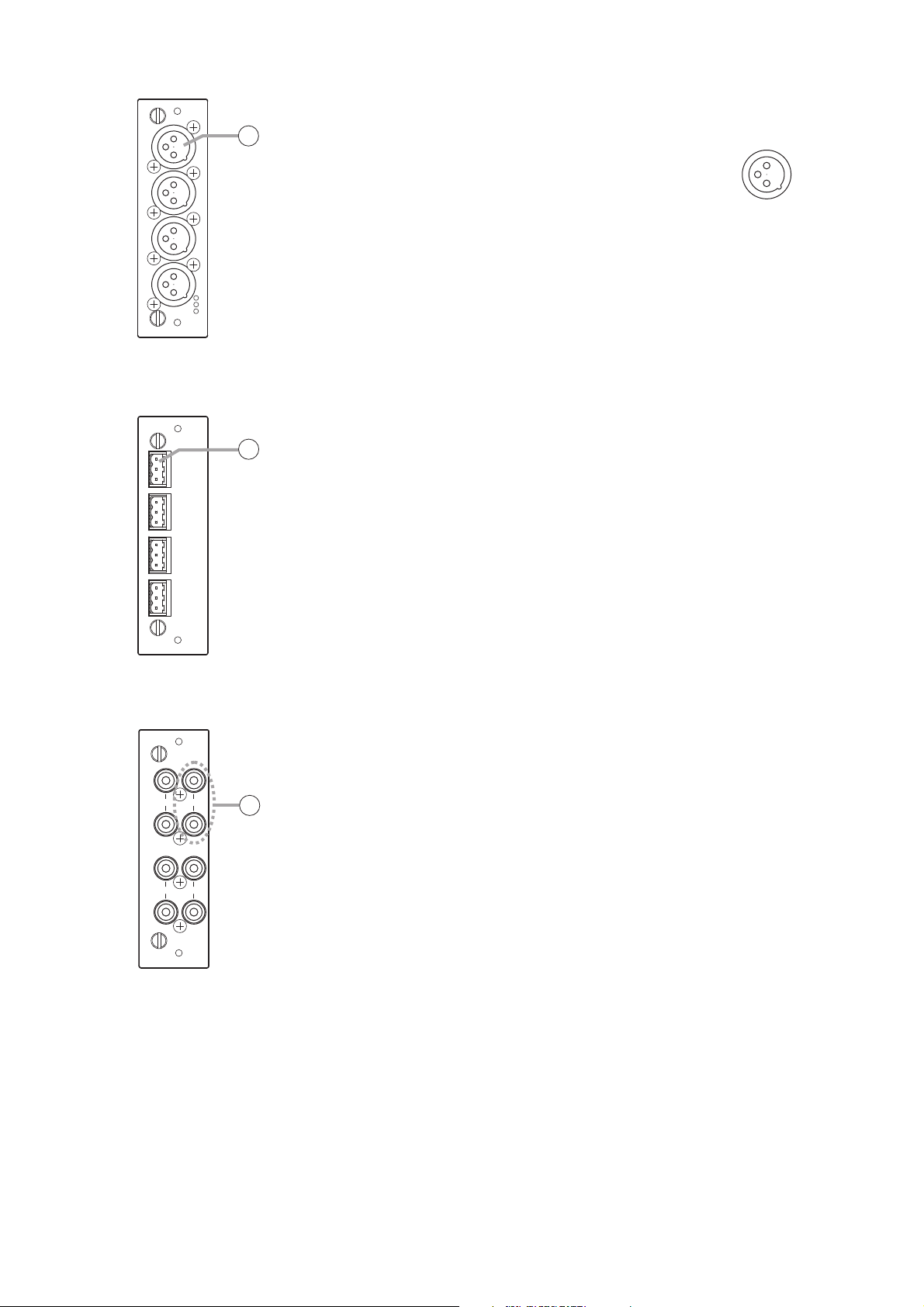

2.4.8. D-937SP Digital Input Module

Note

This module cannot be used as a monitor input.

13. Optical input terminal [OPTICAL, 1, 2]

Optical input terminal of S/PDIF format.

14. Coaxial input terminal [COAXIAL 3, 4]

Coaxial input terminal of S/PDIF format.

Notes

• Use a coaxial cable with characteristic impedance of 75 Ω for

connection.

• One of four line inputs (stereo) is selected. Input selection is performed

by a PC using the setting software supplied with the D-2008SP.

2.4.7. D-923AE Digital Input Module

12. AES/EBU digital input terminal [AES/EBU, 1/2]

(XLR-3-31 equivalent)

Digital input terminal of AES/EBU format.

(Pin 1: Ground, Pin 2: Signal, Pin 3: Signal)

Use the XLR-3-12C or equivalent for

connection.

Note

Use a digital audio cable with characteristic

impedance of 110 Ω for connection.

2.4.6. D-936R Stereo Input Module

Note

This module cannot be used as a monitor input.

11. Stereo input terminal [1L/1R, 2L/2R, 3L/3R, 4L/4R]

Unbalanced, RCA jack stereo input terminals. Either a single stereo input

can be selected from the 4 available stereo inputs or all 4 stereo

channels can be mixed.

Mode setting and stereo selection are performed by a PC using the

setting software supplied with the D-2008SP. They can also be remotely

selected by way of connected external equipment through the use of the

control module.

Input signal level: –10 dB

1R2R1L

11

2L

3L3R

4L4R

model D-936RSTEREO SELECT INPUT MODULE [ –10 dB]

DIGITAL IN

12

1/2

AES/EBU

model D-923AEDIGITAL INPUT MODULE

OPTICAL

DIGITAL IN

13

1

2

14

3

model D-937SPDIGITAL INPUT MODULE

COAXIAL

4

3: Signal

2: Signal

1: Ground

Page 22

22

2.4.9. D-971M Line Output Module

15. Monaural output terminal [1, 2, 3, 4] (XLR-3-32 equivalent)

Electronically-balanced output terminal.

(Pin 1: Ground, Pin 2: Hot, Pin 3: Cold)

Output signal level: +4 dB

Use XLR-3-11C or equivalent for connection.

2.4.10. D-971E Line Output Module

16. Monaural output terminal [1, 2, 3, 4]

Electronically-balanced, removable terminal block.

(H: Hot, C: Cold, E: Ground.)

Output signal level: +4 dB

Note

Be sure to use the supplied removable terminal plugs (3P) for

connection.

2.4.11. D-971R Line Output Module

17. Monaural output terminal [1(L), 2(R), 3(L), 4(R)]

Unbalanced, RCA jack output terminals. Each output is equipped with a

2-channel splitter.

Output signal level: –10 dB

LINE OUTPUT MODULE

[+4 dB]

model D-971M

15

1

2

3

4

1

: E

: H

2

: C

3

LINE OUTPUT MODULE [+4 dB]

E

C

1

H

E

C

2

H

E

C

3

H

E

4

C

model D-971E

H

16

3: Cold

1: Ground

2: Hot

2(R) 1(L)

4(R) 3(L)

model D-971RLINE OUTPUT MODULE [–10 dB]

17

Page 23

23

Notes

• Do not touch any other parts on the pc board when operating the switch.

• The maximum output level is +18 when set to +4 dB/unbalanced output.

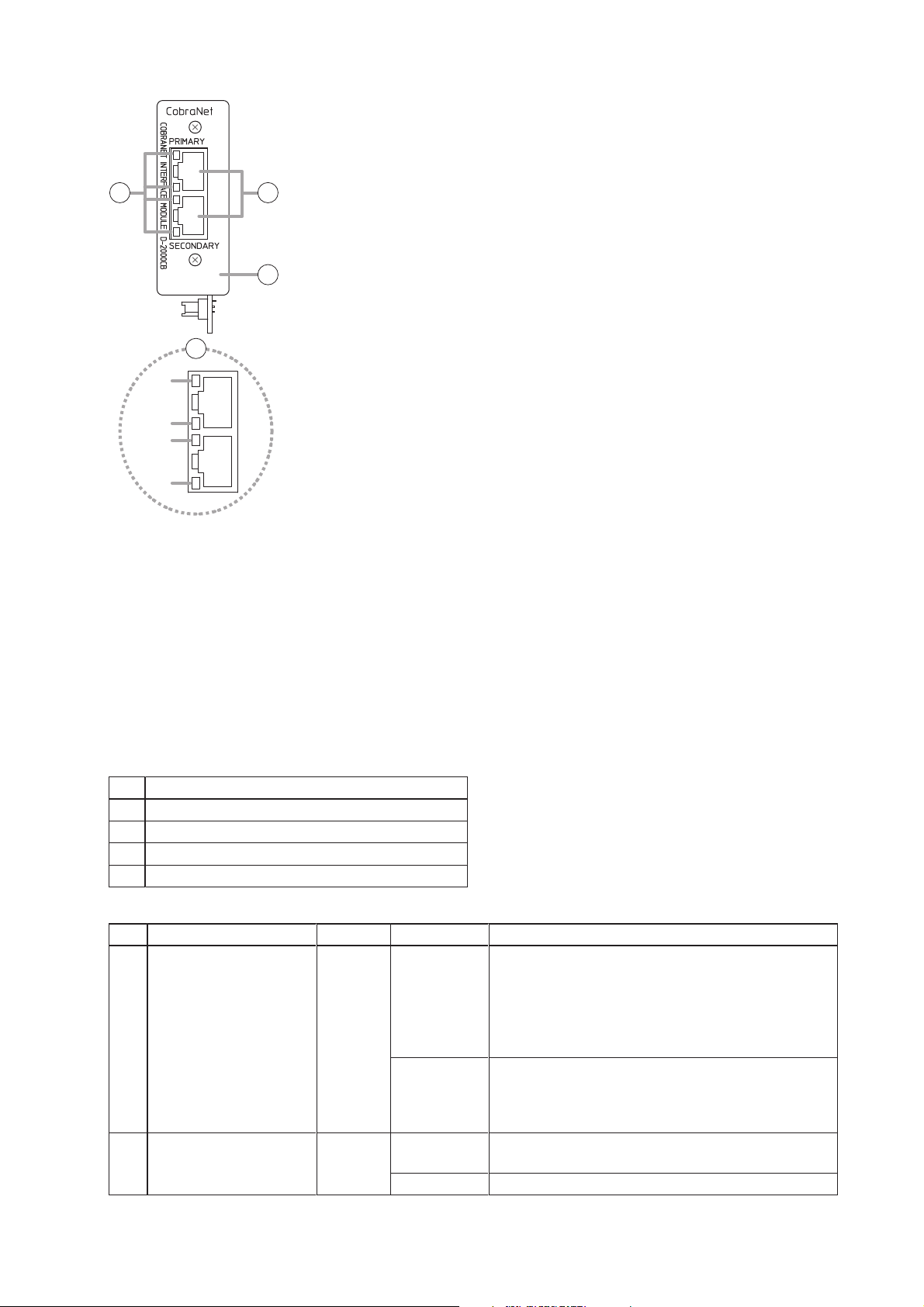

2.4.12. D-2000DA1 Line Output Module

18. Monaural output terminal [1, 2, 3, 4] (XLR-3-32 equivalent)

Balanced (electronically-balanced) or unbalanced output, switchable.

• Balanced output mode (factory preset)

(Pin 1: Ground, Pin 2: Hot, Pin 3: Cold)

• Unbalanced output mode

(Pin 1: Ground, Pin 2: Hot, Pin 3: No connection but may be

connected to Pin 1 Ground)

The output level can be set to either +4 dB or –10 dB.

Use XLR-3-11C or equivalent for connection.

Notes

• Be sure to place this terminal in Unbalanced output mode for

accepting an Unbalanced input device. Balanced output mode can

also be used in this case, but the output level decreases by 6 dB.

• Be sure to place this terminal in Balanced output mode for accepting

a Balanced input device. Unbalanced output mode can also be used

in this case, but the maximum output level decreases by 6 dB.

19. Output level/output mode setting switch

4-position DIP switch for setting the

output level and output mode.

The output level can be set to either

+4 dB or –10 dB.

The output mode can be set to either

balanced output (electronicallybalanced, BAL) or unbalanced output

(UNBAL).

The output is factory-preset to

+4 dB/balanced output (BAL). (All

switches are set to ON.)

The output level in each output mode is shown below.

LINE OUTPUT MODULE

18

1

[–10/+4 dB]

2

ON

19

model D-2000DA1

3

4

1

: E

: H

2

: C

3

ON

[Balanced output mode]

3. Cold

[Unbalanced output mode]

3. No connection

(may be connected

to Pin 1 Ground)

1. Ground

2. Hot

1. Ground

2. Hot

[Balanced output mode] [Unbalanced output mode]

+24 dB

+10 dB

+4 dB

Output level

–10 dB

Input level

Max. output level

Output level: +4 dB

Output level: –10 dB

0 dBFS–20 dBFS

DIP SW

–10 dBu

CH 3CH 1

UNBAL

–10 dBu

CH 4CH 2

UNBAL MODE

+24 dB

+18 dB

+10 dB

+4 dB

Output level

–10 dB

ON

Input level

(DEFAULT)

+4 dBu SIGNAL LEVEL

BAL MODE

+4 dBu SIGNAL LEVEL

BAL

Max. output level

Output level: +4 dB

Output level: –10 dB

0 dBFS–20 dBFS

Page 24

24

2.4.13. D-972AE Digital Output Module

18. AES/EBU digital output terminal [AES/EBU, 1/2, 3/4]

(XLR-3-32 or its equivalent)

Digital output terminal of AES/EBU format.

(Pin 1: Ground, Pin 2: Signal, Pin 3: Signal)

Use the XLR-3-11C or equivalent for

connection.

Note

Use the digital audio cable with characteristic

impedance of 110 Ω for connection.

2.4.14. D-961SP Digital Output Module

19. Optical output terminal [OPTICAL 1, 2]

Optical output terminal of S/PDIF format.

20. Coaxial output terminal [COAXIAL 1, 2]

Coaxial output terminal of S/PDIF format.

Note

Use a coaxial cable with characteristic impedance of 75 Ω for

connection.

Each pair of the S/PDIF optical output and the coaxial RCA jack output

delivers output in parallel.

2.4.15. D-981 Remote Control Module

21. Contact input terminal [INPUT, C, 1, 2, 3, 4, 5, 6, 7, 8, C]

Removable terminal block, 8-circuit contact input terminal.

Individual contact functions are assigned by a PC using the D-2000

Setting Software supplied with the D-2008SP.

Note

Be sure to use the supplied removable terminal plugs (10P) for

connection.

22. Contact output terminal [OUTPUT, C, 1, 2, 3, 4, 5, 6, 7, 8, C]

Removable terminal block, 8-circuit contact output terminal.

Individual contact functions are assigned by a PC using the D-2000

Setting Software supplied with the D-2008SP.

DIGITAL OUT

AES/EBU

20

1/2

model D-972AEDIGITAL OUTPUT MODULE

3/4

AES/EBU

OPTICAL

1

COAXIAL

OPTICAL

2

DIGITAL OUT

21

22

COAXIAL

model D-961SPDIGITAL OUTPUT MODULE

1: Ground

3: Signal

2: Signal

REMOTE CONTROL MODULE model D-981

C

1

2

3

4

INPUT

5

6

7

8

C

C

1

2

3

4

OUTPUT

5

6

7

8

C

23

24

Page 25

25

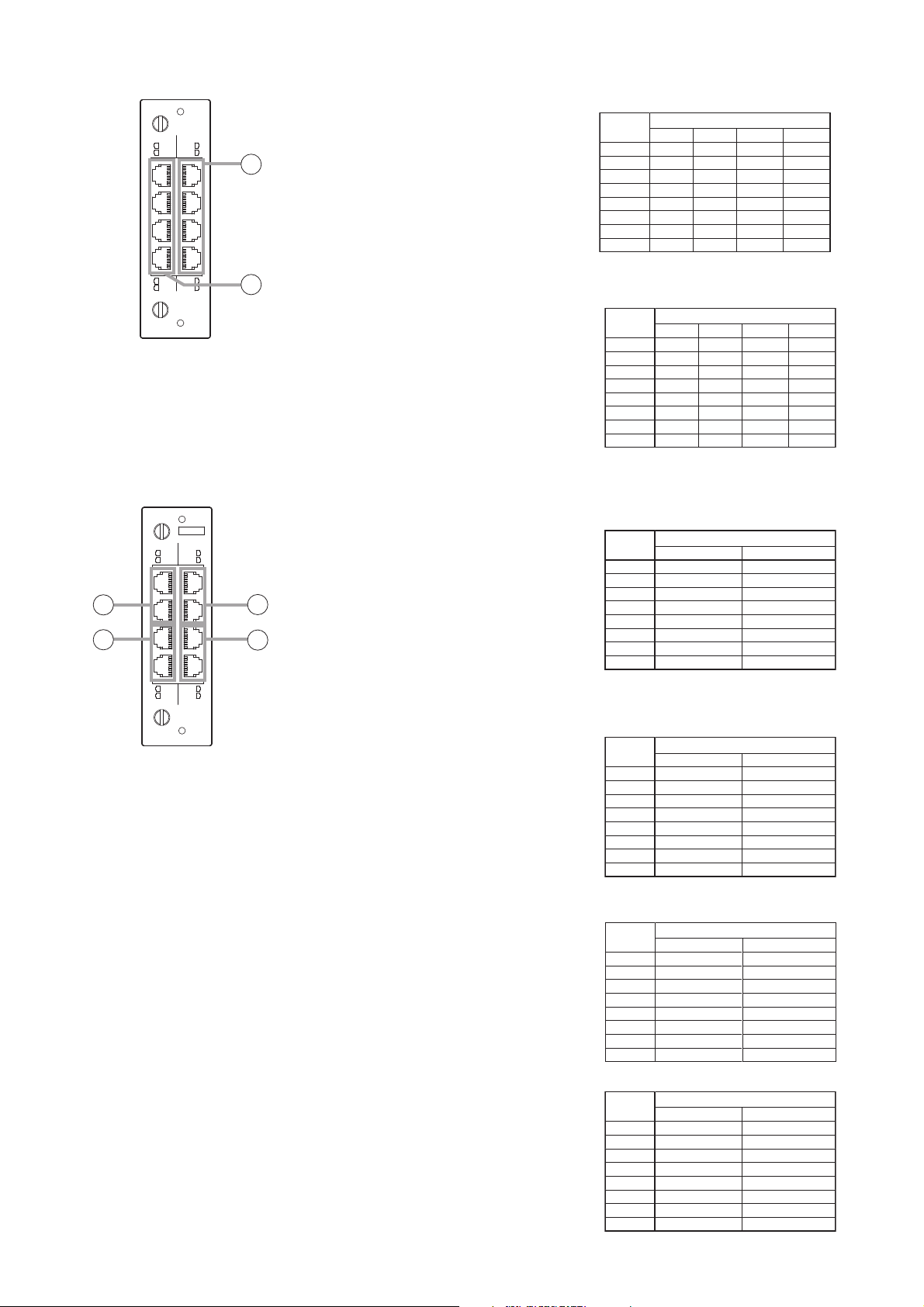

2.4.16. D-983 Remote Control Module

23. Contact input terminal [CTRL IN, 1-6, 7-12, 13-18, 19-24]

Six-circuit RJ45 contact input terminals.

Individual contact functions are assigned

by a PC using the D-2000 Setting

Software supplied with the D-2008SP.

24. Contact output terminal [CTRL OUT,1-4, 5-8, 9-12, 13-16]

Four-circuit RJ45 contact output

terminals.

Individual contact functions are assigned

by a PC using the D-2000 Setting

Software supplied with the D-2008SP.

2.4.17. D-984VC VCA Control Module

25. Input channel VCA terminal [IN CH, 1 – 6, 7 – 12]

RJ45 VCA terminals.

Assign the VCA channels to this terminal.

Up to 12 channels can be controlled.

The channel assignment can be

performed by a PC using the D-2000

Setting Software supplied with the D2008SP.

26. Output channel VCA terminal [OUT CH, 1 – 4, 5 – 8]

RJ45 VCA terminals.

Assign the VCA channels to this terminal.

Up to 8 channels can be controlled.

The channel assignment can be

performed by a PC using the D-2000

Setting Software supplied with the D2008SP.

27. Control input terminal [CTRL IN, 1 – 4, 5 – 8]

RJ45 Control Input terminals.

These RJ45 Control Input terminals

correspond to 8 control inputs.

Individual contact functions are assigned

by a PC using the D-2000 Setting

Software supplied with the D-2008SP.

28. Control output terminal [CTRL OUT, 1 – 4, 5 – 8]

RJ45 Control output terminals.

These RJ45 Control output terminals

correspond to 8 control outputs.

Individual contact functions are assigned

by a PC using the D-2000 Setting

Software supplied with the D-2008SP.

CTRL OUT CTRL IN

1-4

1-6

5-8

7-12

CONTROL UNITS FOR D-901 ONLY

25

9-12

13-18

13-16

19-24

model D-983REMOTE CONTROL MODULE

26

VCA

CTRL IN IN CH

1-4

1-6

5-8

7-12

CONTROL UNITS FOR D-901 ONLY

29

27

30

1-4

model D-984VCVCA CONTROL MODULE

5-8

CTRL OUT OUT CH

1-4

5-8

28

Pin No.

1

2

3

4

5

6

7

8

Pin No.

1

2

3

4

5

6

7

8

Pin No.

1

2

3

4

5

6

7

8

Pin No.

1

2

3

4

5

6

7

8

1 – 6

IN 1

IN 2

IN 3

IN 6

IN 5

IN 4

C

C

1 – 4

OUT 1

C 1

OUT 2

C 3

OUT 3

C 2

OUT 4

C 4

IN CH 1

IN CH 2

IN CH 3

IN CH 6

IN CH 5

IN CH 4

OUT CH 1

OUT CH 2

OUT CH 3

OUT CH 4

1 – 6

V

C

1 – 4

C

V

V

C

CTRL IN

7 – 12

IN 7

IN 8

IN 9

IN 12

IN 11

IN 10

C

C

CTRL OUT

5 – 8

OUT 5

C 5

OUT 6

C 7

OUT 7

C 6

OUT 8

C 8

IN CH

OUT CH

13 – 18

IN 13

IN 14

IN 15

IN 18

IN 17

IN 16

C

C

9 – 12

OUT 9

C 9

OUT 10

C 11

OUT 11

C 10

OUT 12

C 12

OUT CH 5

OUT CH 6

OUT CH 7

OUT CH 8

19 – 24

IN 19

IN 20

IN 21

IN 24

IN 23

IN 22

C

C

13 – 16

OUT 13

C 13

OUT 14

C 15

OUT 15

C 14

OUT 16

C 16

7 – 12

IN CH 7

IN CH 8

IN CH 9

IN CH 12

IN CH 11

IN CH 10

V

C

5 – 8

C

V

V

C

Pin No.

1

2

3

4

5

6

7

8

Pin No.

1

2

3

4

5

6

7

8

1 – 4

CTRL IN 1

C

CTRL IN 2

C

CTRL IN 3

C

CTRL IN 4

V

CTRL OUT

1 – 4

CTRL OUT 1

C 1

CTRL OUT 2

C 3

CTRL OUT 3

C 2

CTRL OUT 4

C 4

CTRL IN

5 – 8

CTRL IN 5

C

CTRL IN 6

C

CTRL IN 7

C

CTRL IN 8

V

5 – 8

CTRL OUT 5

C 5

CTRL OUT 6

C 7

CTRL OUT 7

C 6

CTRL OUT 8

C 8

Page 26

26

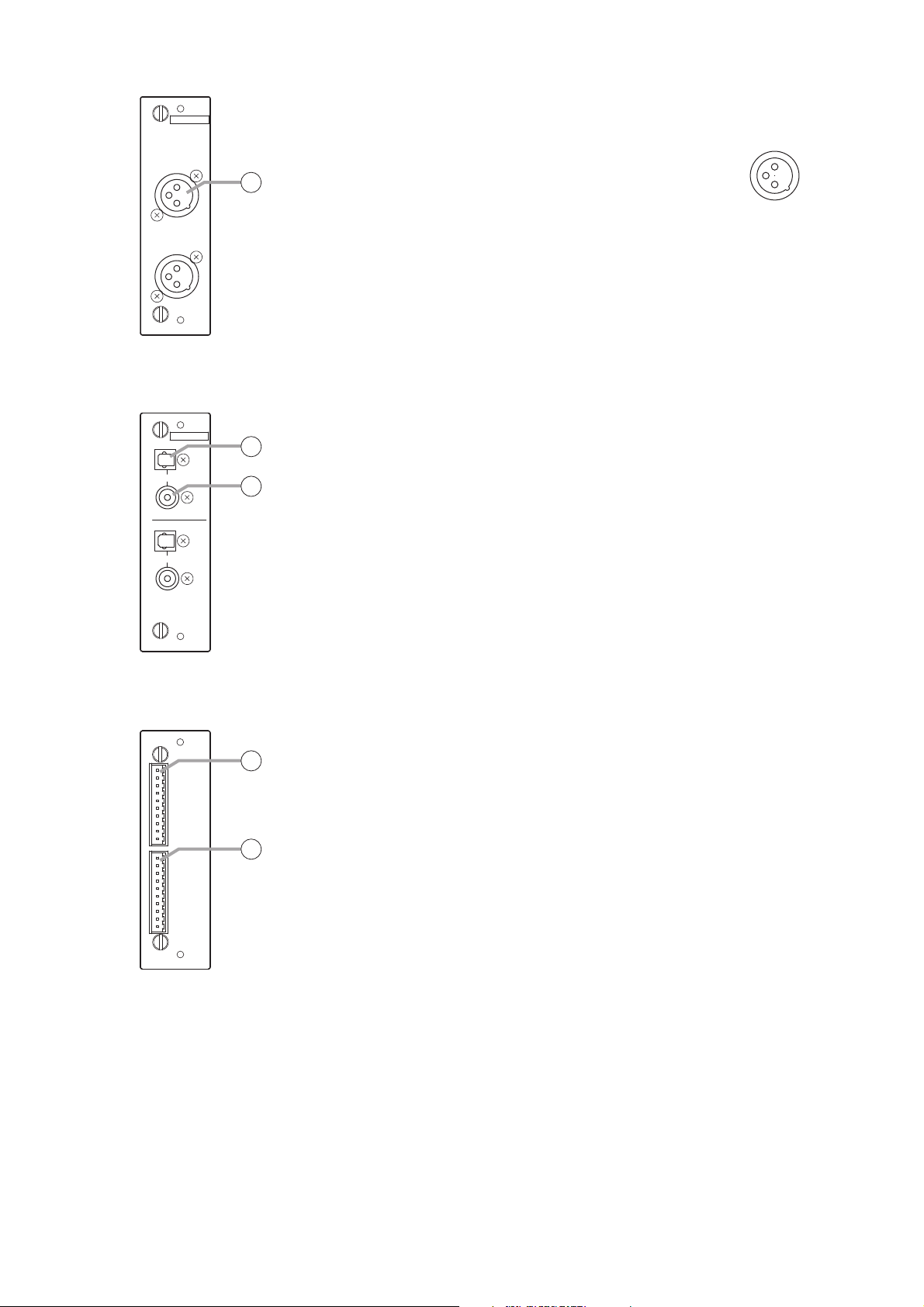

2.4.18. D-2000CB CobraNet Interface Module

29. CobraNet terminals [PRIMARY/SECONDARY]

Terminals used for CobraNet connection. Connect with the commercially available CobraNet device via a

switching hub.

Connect the Primary and Secondary terminals to each single switching hub or two cascade-connected

switching hubs.

Notes

• Be sure to connect both the Primary and Secondary terminals to a switching hub.

• After connection completion, press the D-2008SP's front-mounted Reset switch to restart the D-2008SP.

• Concerning a switching hub, contact TOA dealer.

30. Indicators

31. Panel

30

29

31

30

(a)

(b)

(c)

(d)

LED name

LED Name

PRIMARY operation/CONDUCTOR indicator

(a)

(b)

PRIMARY LINK/ACT indicator

(c)

SECONDARY operation/ CONDUCTOR indicator

(d)

SECONDARY LINK/ACT indicator

Detailed function

LED Function LED color LED status System status

Operation/CONDUCTOR

indicator

(a)

(c)

LINK/ACT indicator Green Flashing or lit

(b)

(d)

Orange Flashing or lit

Unlit

Unlit

CobraNet operation

Flashing: Conductor

Lit: Performer

Note

One of the PRIMARY and SECONDARY indicators

flashes or lights.

Not operating

Note

Both of the PRIMARY and SECONDARY indications

could not go out at a time.

Link to the switching hub, or data transmission and

reception

Unconnected

Page 27

27

Note

Never touch the parts on the

circuit board.

3. INSTALLATION

3.1. Inserting the D-2000CB

To prevent a fire or electric shock, never open nor remove the unit

case, as there are high voltage components inside the unit. Refer all

servicing to qualified service personnel.

WARNING

Step 1. Remove the D-2008SP's power plug from an AC wall outlet.

Never do this work with the power cord connected to the AC

outlet, as doing so may cause electric shock.

WARNING

Step 2. Remove 8 blank panels by unscrewing

16 screws on the D-2008SP's rear panel.

Step 3. Remove the blank panel covering the

CobraNet interface module slot by

unscrewing 2 screws on the D-2008SP's

rear panel.

The removed screws are not used.

Be sure to install the D-2000CB first before inserting other modules into the slots.

D-2008SP

Connector

Blank panel

Blank panels

D-2008SP

Screw post (female)

2

23

3

4

Machine screw M3 x 8

D-2000CB

5

6

Machine screw M3 x 8

(supplied with the D-2000CB)

Connector

Page 28

28

Step 7. Secure the panel to the CobraNet interface

module slot section with 2 screws.

Ensure that 2 connectors of the D-2000CB

project from the rectangle hole in the panel

before tightening screws.

[Installing the input, output, and control modules]

After mounting completion of the D-2000CB, install

other modules with the removed screws that held the

blank panels.

Further, replace the removed blank panels to the idle

slots.

Terminal pins of the connector are exposed on the solder side of

the D-2000CB board. Never touch these terminal pins when

inserting the connector to prevent finger injury.

CAUTION

Step 6. Secure the D-2000CB to the inside of the D-2008SP with 1 screw.

Note

Be sure to secure the D-2000CB with the screw.

Doing otherwise may cause its connector to be disconnected, resulting in malfunction.

Step 4. Remove the D-2000CB's panel.

Note: The removed 2 screws are used in step 7.

Step 5. Insert the D-2000CB's connector into the D-2008SP's internal connector.

D-2008SP

D-2000CB's connector

D-2000CB

7

Panel

(removed in step 4)

Machine screw M3 x 8

(removed in step 4)

Page 29

29

3.2. Rack Mounting

Notes

• To achieve sufficient ventilation, be sure to mount a perforated panel larger than 1U size* above and below

the unit.

• Do not position the heat-generating component such as a power amplifier immediately below the D-2008SP

in the rack even if the perforated panel is mounted between them. Also, keep such components away from

each other so that the ambient temperature around the D-2008SP should not exceed +40 ºC (104 ºF).

Failure to do so may shorten the product life.

* 1U size = 44.5 mm or 1.75" (standard size)

3.2.1. D-2008SP

(When rack mounting screws are supplied)

The supplied rack-mounting screws can be used for the TOA equipment

rack only. Do not use them for other racks.

When installing the unit in a rack other than that of TOA, be sure to use

the screws with a diameter of over 5 mm

(0.2")

and length of over 12 mm

(0.47")

to mount the unit.

Failure to do so may cause personal injury.

(When rack mounting screws are not supplied)

Rack mounting screws are not supplied with the unit.

Be sure to use the screws with a diameter of over 5 mm (0.2") and length

of over 12 mm (0.47") to mount the unit.

Failure to do so may cause personal injury.

CAUTION

D-2008SP

D-2008SP

Perforated panel

(with ventilation slots)

Page 30

30

Notes

• To achieve sufficient ventilation, be sure to mount a perforated panel larger than 1U size* above the unit.

• Do not position the heat-generating component such as a power amplifier immediately below the D-2012C in

the rack. Also, keep such components away from each other so that the ambient temperature around the D2012C should not exceed +40 ºC. Failure to do so may shorten the product life.

* 1U size = 44.5 mm or 1.75" (standard size)

3.2.3. D-911

3.2.2. D-2012C

D-2012C

Perforated pane

(with ventilation slots)

D-2012C

D-911

Page 31

31

3.3. When Installing the D-2012C on a Desk

Attaching the D-2012AS Console Case to the D-2012C allows the D-2012C to be used on a desk.

3.3.1. Components of the D-2012AS Console Case

3.3.2. Attaching the D-2012AS Console Case

Step 1. Remove 3 screws on each side of the D-2012C to detach the rack mounting brackets.

The removed screws are not used.

Step 2. Attach the 4 rubber feet to the bottom surface of the

D-2012C using the 4 supplied screws.

Be sure to attach the rubber feet, as the air vents

are provided at the bottom surface.

* Component parts of the D-2012AS.

Machine screw M4 x 10:

4 pieces

Side panel L

Side panel R

Decorative panels

Armrest

Machine screw

M4 x 25 (with washer):

11 pieces

Rubber foot: 4 pieces

Rack mounting bracket

D-2012C

Machine screw

M4 x 10*

Rubber foot*

Page 32

32

Step 3. Attach the side panel L to the left side of the D-2012C and side panel R to its right side with 2 each

screws.

Step 4. Fit each decorative panel into the holes on the side panels L and R, then secure them with 2 each

screws from the side panels inside.

Step 5. Attach the armrest to the D-2012C's front panel with 3 screws.

* Component parts of the D-2012AS.

Decorative panel*

3

Machine screw M4 x 25

(with washer)*

Side panel L*

Machine screw M4 x 25

(with washer)*

Machine screw

M4 x 25

(with washer)*

4

Armrest*

Side panel R*

[Finished assembly]

Page 33

33

4. CONNECTION

4.1. Connection Example 1

AMX, Crestron, or other

control equipment

BGM player (Cassette deck, CD

player, MD player, etc.)

D-971M D-2000DA1

REMOTE CONTROL MODULE model D-981

C

1

2

3

4

INPUT

5

6

7

8

C

C

1

2

3

4

OUTPUT

5

6

7

8

C

LINE OUTPUT MODULE

[+4 dB]

model D-971M

D-981

1

2

3

4

1

: E

: H

2

: C

3

LINE OUTPUT MODULE [–10/+4 dB] model D-2000DA1

Microphone

MIC/LINE INPUT MODULE [–50

1

2

3

4

1

: E

: H

2

: C

3

1R2R1L

2L

/

–36

/

–10

/

3L3R

+4 dB]

4L4R

model D-936RSTEREO SELECT INPUT MODULE [ –10 dB]

model D-2000AD1

MIC/LINE INPUT MODULE [–50

1

2

/

–36

/

–10

/

+4 dB]

3

model D-2000AD1

4

2

: H

1

3

: E

: C

1

2

3

4

2

: H

1

3

: E

: C

D-2000AD1D-936R

PC

Switching hub

D-2012C

Remote controller

Speaker

Power amplifier

Speaker

Page 34

34

4.2. Connection Example 2

BGM player (Cassette deck, CD player, MD player, etc.)

D-2008SP

PC

Switching hub

REMOTE CONTROL MODULE model D-981

REMOTE CONTROL MODULE model D-981

C

1

2

3

4

INPUT

5

6

7

8

C

C

1

2

3

4

OUTPUT

5

6

7

8

C

Power amplifier

C

1

2

3

4

5

6

7

8

C

C

1

2

3

4

5

6

7

8

C

INPUT

OUTPUT

LINE OUTPUT MODULE

[+4 dB]

model D-971M

D-2000DA1

LINE OUTPUT MODULE [–10/+4 dB] model D-2000DA1

1

2

3

4

1

: E

: H

2

: C

3

D-2000AD1D-936RD-971MD-981

MIC/LINE INPUT MODULE [–50

1

2

3

4

1

: E

: H

2

: C

3

1R2R1L

2L

/

–36

/

–10

/

3L3R

+4 dB]

4L4R

model D-936RSTEREO SELECT INPUT MODULE [ –10 dB]

model D-2000AD1

MIC/LINE INPUT MODULE [–50

1

2

/

–36

/

–10

/

+4 dB]

3

model D-2000AD1

4

:E

:H

:C

1

2

3

4

:E

:H

:C

Remote controller

Main speaker (R)

Main speaker (L)

Microphone

Remote controller

Speaker Speaker

D-2012C D-2012C

Microphone

Zone A Zone B

Page 35

35

4.3. Removable Terminal Plug Connection

Notes

• Avoid soldering stranded or shielded cable, as contact resistance may increase when the cable is tightened

and the solder is crushed, possibly resulting in an excessive rise in joint temperatures.

• When connecting 2 cables or a shielded cable to a single terminal,

use a ferrule terminal with an insulation sleeve to crimp the cables

because such cable conductors could become loose.

Recommended ferrule terminals for signal cables

(made by Phoenix Contact)

Recommended ferrule terminals for power supply cables

(made by Phoenix Contact)

Crimping tool: CRIMPFOX UD6-4 (made by Phoenix Contact)

Wiring procedures

Step 1. Wiring the supplied removable terminal plug.

1-1. Loosen the terminal screws to insert the wire.

1-2. Tighten the terminal screws.

Ensure that the wire does not break free when

pulled. If the wire does pull free, repeat the

connection procedure from the start.

Step 2. Insert the wired terminal plug into the

corresponding terminal block in the unit's rear

panel.

Note

Do not reverse Steps 1 and 2 above. Force is applied

to the connected receptacle pins while tightening the

terminal screw and they may be damaged, resulting in

bad connector contact.

Cable sheath to trim

* Expose 8 mm (0.31'') or more when using

the above ferrule terminal, and cut off an

extra conductor protruding from the sleeve.

Model Number a l

AI 0,34-8 TQ

AI 0,5-8 WH

2 (0.08)

2.5 (0.1)

0.8 (0.03)

1.1 (0.04)

b

12.5 (0.49)

14 (0.55)

Unit: mm (in)

1

2

l

8 (0.31)

8 (0.31)

Insulation sleeve

a

Contact section

2

l

1

l

bb

Model Number a

AI 1,5-8 BK

AI-TWIN 2 x 1,5-8 BK

a

3.4 (0.31)

1

6.6 (0.26)

2

a

3.6 (0.14)

b

1.8 (0.07)

Solid cable and stranded cable

7 mm*

(0.28'') (0.28'')

Shielded cable

7 mm*

15 mm

(0.59'')

Unit: mm (in)

1

l

14 (0.55)

16 (0.63)2.3 (0.09)

Terminal screw

8 (0.31)

8 (0.31)

Tightens

Insulation sleeve

1

a

2

l

2

a

Slotted screwdriver

Loosens

Removable terminal plug

Contact section

2

l

1

l

Tip

Recommended slotted screwdriver type:

Screwdriver with blade that is 3 mm (0.12'') in width

Bit shape 3 mm

(0.12'')

Page 36

36

4.4. Connecting the Monitor Bus Terminal of the D-2008SP and D-2012C

When using the D-2012C's Line input terminal or headphone jack, connect the D-2012C's Monitor bus

terminal to the Monitor bus terminal on the D-2008SP.

Notes

• Set the identical ID number for the D-2008SP and D-2012C to be connected through monitor bus terminals.

Use the D-2000 Setting Software to set the ID number.

• If D-2008SP Console Setting is performed using the D-2000 Setting Software, the D-2008SP can be set to

receive audio signal from the D-2012C's line input terminal. If D-2012C Function Setting is set, the D2012C's monitor channel output can also be monitored with headphones.

Additionally, if the D-2008SP's output channel is set to "Monitor," output from the monitor channel selected

at the D-2012C can also be output to the D-2008SP's output channel.

D-2008SP

Category 5 or higher shielded

twisted pair cable for LAN

(with RJ45 connectors)

D-2012C

Monitor bus terminals

Page 37

37

4.5. Audio Monitor Line Connection When Multiple Units Are Connected

Connecting multiple D-2008SP units through monitor input and output terminals allows audio signals other

than that of the main unit to be monitored.

[Connection Example]

Notes

• Set the identical ID number for the D-2008SP and D-2012C to be connected through monitor bus terminals.

Use the D-2000 Setting Software to set the ID number.

• Insert the audio module used for monitor input into one of Slots 5 – 8.

• Neither the D-936R Stereo input module nor D-937SP Digital input module can be used as a monitor input.

• When using the D-922F and D-922E Microphone/Line input module as monitor inputs, set the "PHANTOM"

switch to "OFF" and "Input sensitivity" to "+4 dB (LINE)."

• The headphones connected to the D-2008SP can only monitor audio signals from the channels of this D-

2008SP.

Speaker

Power amplifier

Note:

Audio signals of the

D-2008SP units with

ID1 and ID2 only can

be monitored

D-2008SP

(ID1)

Slot 3: D-2000DA1

Slot 4: D-2000DA1

Slot 5: D-2000AD1

Slot 8 Slot 1345

Monitor input

D-2012C (ID 1)

Monitor output 1

Monitor output 2

D-2008SP

(ID 2)

Monitor input

D-2008SP

(ID 3)

Monitor output 2

Monitor output 1

Switching hub

Slot 8 Slot 15

Slot 5: D-2000AD1

Slot 8: D-2000DA1

Slot 7: D-2000AD1

Slot 8 Slot 17

Monitor input

Monitor input

Monitor bus

Monitor bus

Monitor bus

D-2012C (ID 2)

D-2012C (ID 3)

Note:

Audio signals of the

D-2008SP units with

ID1 through ID3 can

be monitored.

Note:

Audio signals of the

D-2008SP units with

ID1 and ID3 only can

be monitored.

Page 38

38

4.7. D-911 Connection

Connect the D-911 to the D-984VC VCA Control Module installed in the D2008SP.

Connect each of eight terminals to the D-984VC's terminal of the same

name by way of the fully-connected straight cable as shown on the right.

4.6. D-2012C's AC Power Cord Connection

To prevent the AC power cord from accidentally coming off, secure it with the supplied cable clamp as shown

below.

D-2012C

Connection panel

Machine screw

M3×6 (accessory)

Cable clamp

(accessory)

Screw hole

D-984VC

Power cord

(accessory)

[Connection]

1

2

3

4

5

6

7

8

1

2

3

4

5

6

1 – 81 – 8

7

8

Control Input terminal 1 – 4

Control Input terminal 5 – 8

Control Output terminal 1 – 4

Control Output terminal 5 – 8

E

F

G

H

CTRL IN IN CH

1-4

5-8

1-4

model D-984VCVCA CONTROL MODULE

5-8

CTRL OUT OUT CH

VCA

1-6

7-12

CONTROL UNITS FOR D-901 ONLY

Input channel VCA terminal 1 – 6

A

Input channel VCA terminal 7 – 12

B

Outnput channel VCA terminal 1 – 4

C

Outnput channel VCA terminal 5 – 8

D

1-4

5-8

D-911

A B C D

E F G H

Page 39

39

4.8. D-984VC Specifications

The optional VCA Fader Unit D-911 can remotely control the VCA Control Module D-984VC.

However, You can make a special unit having the same functions as the D-911 referring to the technical

information described here.

4.8.1. Connection cable and pin arrangements of each terminal

• For connecting to each terminal, use a CAT5 (Category 5) UTP cable fitted with RJ45 connectors at both

ends.

Note

Use a STP cable in an environment where the cable is susceptible to noises.

• Maximum cable length is 100 m.

• Pin arrangement of the D-984VC's terminals

4.8.2. Input and output channel VCA controls (1) – (4)

• With 5 V at an input channel VCA pin (IN CH 1 – 12) or at an output channel VCA pin (OUT CH1 – 8), the

corresponding channel's sound volume is minimum. With 0 V, the sound volume is at the level set by the D2008SP.

• Use 10 kΩ potentiometers of taper B.

• Up to 6 volume controls can be connected to each V pin.

[Connections to the input channel VCA terminal]

D-984VC

VCA

CTRL IN IN CH

1-4

1-6

5-8

7-12

1-4

1-4

model D-984VCVCA CONTROL MODULE

5-8

5-8

CTRL OUT OUT CH

Control input

terminals

CONTROL UNITS FOR D-901 ONLY

Input channel

VCA terminals

Output channel

VCA terminals

Control output

terminals

[Input channel VCA terminals] [Output channel VCA terminals]

Pin No.

1

2

3

4

5

6

7

8

1 – 6

IN CH 1

IN CH 2

IN CH 3

IN CH 6

IN CH 5

IN CH 4

V

C

IN CH

7 – 12

IN CH 7

IN CH 8

IN CH 9

IN CH 12

IN CH 11

IN CH 10

V

C

Pin No.

1

2

3

4

5

6

7

8

OUT CH 1

OUT CH 2

OUT CH 3

OUT CH 4

1 – 4

C

V

V

C

OUT CH

5 – 8

OUT CH 5

OUT CH 6

OUT CH 7

C

V

OUT CH 8

V

C

1 2 3 4

[Control input terminals] [Control output terminals]

Pin No.

1

2

3

4

5

6

7

8

1 – 4

CTRL IN 1

C

CTRL IN 2

C

CTRL IN 3

C

CTRL IN 4

V

CTRL IN

5 – 8

CTRL IN 5

C

CTRL IN 6

C

CTRL IN 7

C

CTRL IN 8

V

Pin No.

1

2

3

4

5

6

7

8

CTRL OUT 1

CTRL OUT 2

CTRL OUT 3

CTRL OUT 4

1 – 4

C 1

C 3

C 2

C 4

CTRL OUT

5 – 8

CTRL OUT 5

C 5

CTRL OUT 6

C 7

CTRL OUT 7

C 6

CTRL OUT 8

C 8

5 6 7 8

1 IN CH 1

2 IN CH 2

3 IN CH 3

D-2008SP's volume

Minimum level

0 V

+5 V

RJ45

4 IN CH 6

5 IN CH 5

6 IN CH 4

7 V (+5 V)

8 C (GND)

D-984VC

[IN CH 1 – 6]

Page 40

40

[Connections to the output channel VCA terminal]

4.8.3. Contact controls (5) – (8)

• Preset memory recall function is assigned to the contact input and output pins at the factory. To change this

function assignment to give channel ON/OFF or stereo input selection, refer to the separate Setting

Software Instructions .

• The V pins of the control input terminals (5) and (6) can be used for LED connections. To do this, connect

the contact COM pins to use out of the C1 – 4 pins of the control output (7) or the C5 – 8 pins of the control

output (8) to the C pins of the control input (5) or (6). (The diagram below is an example where the control

output's C1 – 4 pins are connected to the control input's C pins.)

• The current capacity is 40 mA per V pin. When more current is needed, connect a power supply separately

as shown below.

• Never connect the V pins of control inputs (5) and (6) to the V pins of VCA pins (1) – (4) as the sound

volume may be affected due to voltage drop caused by these connections.

D-2008SP's volume

0 V

RJ45

1 OUT CH 1

2 OUT CH 2

3 OUT CH 3

4 C (GND)

5 V (+5 V)

6 OUT CH 4

7 V (+5 V)

8 C (GND)

D-984VC

[OUT CH 1 – 4]

Minimum level

+5 V

1 CTRL IN 1

2 C (GND)

3 CTRL IN 2

RJ45

RJ45

4 C (GND)

5 CTRL IN 3

6 C (GND)

7 CTRL IN 4

8 V (+5 V)

1 CTRL OUT 1

2 C1

3 CTRL OUT 2

4 C2

5 CTRL OUT 3

6 C3

7 CTRL OUT 4

8 C4

D-984VC's control

input terminal (5)

[CTRL IN 1 – 4]

D-984VC's control

output terminal (7)

[CTRL OUT 1 – 4]

1 CTRL IN 1

2 C (GND)

3 CTRL IN 2

4 C (GND)

5 CTRL IN 3

6 C (GND)

7 CTRL IN 4

8 V (+5 V)

D-984VC's control

input terminal (5)

[CTRL IN 1 – 4]

RJ45

1 CTRL OUT 1

2 C1

3 CTRL OUT 2

DC

4 C2

5 CTRL OUT 3

6 C3

7 CTRL OUT 4

8 C4

D-984VC's control

output terminal (7)

[CTRL OUT 1 – 4]

RJ45

Page 41

41

4.9. Ferrite Cable Clamp Attachment (For D-972AE only)