Page 1

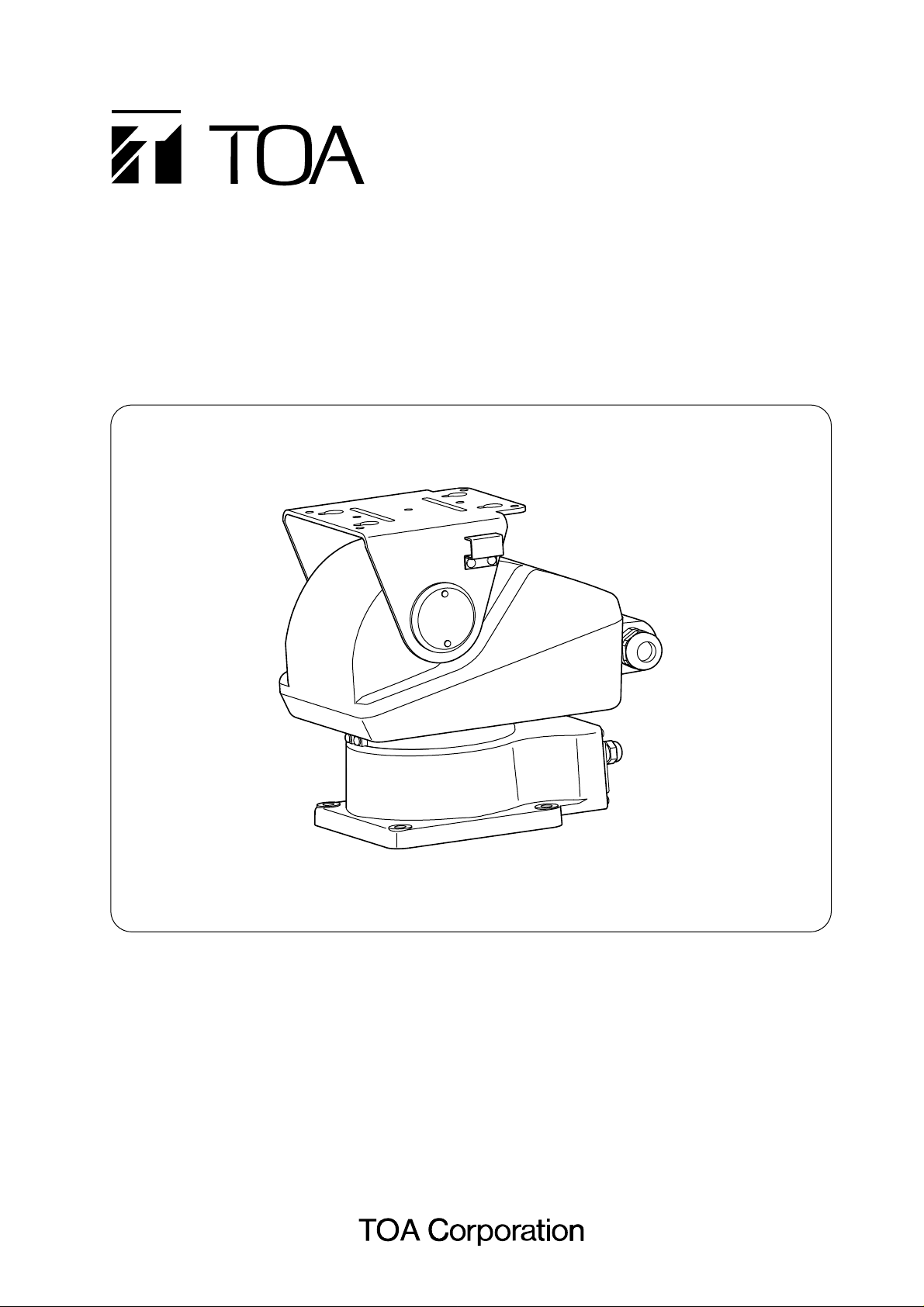

Thank you for purchasing TOA’s Outdoor Pan/Tilt Head. Please carefully follow the instructions in this

manual in order to ensure long, trouble-free use of your pan/tilt head.

OUTDOOR PAN/TILT HEAD

C-PH200

INSTRUCTION MANUAL

Page 2

2

TABLE OF CONTENTS

1. SAFETY PRECAUTIONS ................................................................................ 3

2. GENERAL DESCRIPTION ............................................................................. 5

3. HANDLING PRECAUTIONS .......................................................................... 5

4. NOMENCLATURE AND FUNCTIONS ........................................................ 6

5. INSTALLATION

5.1. About the Center of Gravity of Mounted Components ...................................... 7

5.2. Housing Front End and Its Surrounding Impediments ...................................... 7

5.3. Rotation Angle Adjustment ............................................................................... 8

5.4. Control Input Cable and Coaxial Cable Connections......................................... 9

5.5. Coaxial Cable End Processing

5.5.1. 3C-2V Cable .......................................................................................... 10

5.5.2. 5C-2V Cable .......................................................................................... 10

5.6. Camera Housing Mounting (Upright Installation) ............................................. 11

5.7. Camera Housing Mounting (Suspended Installation) ...................................... 12

5.8. Housing Cable Specifications .......................................................................... 12

5.9. Notes on Operations by Auto-Pan Control

5.9.1. If using the CC-5011B Direct Control System Remote Control unit… ... 13

5.9.2. If using the CC-5120 Relay Box… ......................................................... 13

5.9.3. If using the C-RB100 Coaxial Multiplex Control Relay Box… ............... 13

6. DIMENSIONAL DIAGRAM ............................................................................ 14

7. SPECIFICATIONS ............................................................................................ 15

Page 3

1. SAFETY PRECAUTIONS

• Be sure to read the instructions in this manual section carefully before use.

• Make sure to observe the instructions in this section as the conventions of safety symbols and messages

regarded as very important are included.

• Please keep this instruction manual handy for future reference.

Safety Symbol and Message Conventions

Safety symbols and messages described below are used in this manual to prevent bodily injury and property

damage which could result from mishandling. Before operating your equipment, read this manual first so you

are thoroughly aware of the potential safety hazards as well as understand the safety symbols and messages.

3

Indicates a potentially hazardous situation which could result in death

or serious personal injury if ignored or mishandled.

WARNING

When Installing the Pan/Tilt Head

• Use the unit only with the voltage specified on the unit. Using a voltage higher than that which is specified

may result in fire or electric shock.

• To prevent lightning strikes, install the unit at least 5 meters away from a lightning conductor yet within the

protective range (angle of under 45 degrees) of the lightning conductor. Lightning may cause a fire, electric

shock or personal injury.

• Leave the installation of the unit to your TOA dealer because the installation requires expert knowledge. If an

inexperienced installer installs the unit, the unit may fall, possibly causing personal injury.

• Install the unit only in a location that can structurally support the weight of the unit and the mounting bracket.

Doing otherwise may result in the unit falling and causing personal injury.

• Avoid installing the unit in vibratory locations. Mounting screws and bolts loosen, which causes the unit to fall

off, possibly resulting in personal injury.

• When installing the unit in snowy areas, take appropriate measures to protect the unit against snow. The

accumulation of snow causes the unit to fall off, possibly resulting in personal injury.

• Be sure to install the unit with two or more persons. If it is handled by a single person, the unit may fall or

topple over, causing personal injury.

• Install the unit only with the specified method. Failure to follow this instruction may cause extreme force to

be applied to the unit and the unit to fall, resulting in personal injury.

Page 4

4

When Installing the Pan/Tilt Head

• Use nuts and bolts that are appropriate for the ceiling’s or wall’s structure and composition. Failure to do so

may cause the unit to fall, resulting in personal injury.

• Tighten each nut and bolt securely. Ensure that there are no loose joints after installation to prevent

accidents that could result in personal injury.

• Use the specified type of camera housing and wall mounting bracket. If the unit is installed in combination

with equipment not specified, the unit may fall, possibly resulting in personal injury.

• Avoid installing the unit in locations exposed to sea breeze or corrosive gas. The unit or its mount may be

subject to corrosion, which could cause the unit to fall, possibly resulting in personal injury.

• NEVER operate the Remote Controller while somebody is handling the pan/tilt head. Fingers can be caught

in the moving pan/tilt head mechanism, possibly resulting in personal injury.

When Using the Pan/Tile Head

• Should the following irregularities be found during use, immediately switch off the power, disconnect the

power supply plug from the AC outlet and contact your nearest TOA dealer. Do not attempt to further

operate the unit to avoid fire or electric shock.

• If you detect smoke or a strange smell coming from the unit.

• If water or other foreign objects get into the unit.

• If the unit falls, or the unit case breaks.

• If the power supply cord is damaged (exposure of the core, disconnection, etc.)[Remove a power

supply cord.]

• Do not open the unit’s case for modification. Since there are high voltage components inside the unit,

opening or modifying the case may result in fire or electric shock. Refer all servicing to your TOA dealer.

Indicates a potentially hazardous situation which could result in death

or serious personal injury if ignored or mishandled.

WARNING

Indicates a potentially hazardous situation which could result in

moderate or minor personal injury, and/or property damage if ignored

or mishandled.

CAUTION

When Installing the Pan/Tilt Head

• Notes on Housing Cable Connections

Be sure to observe the following precautions. Failure to do so could cause damage to the cable when the

pan/tilt head rotates, possibly causing a fire.

• Fix the housing cable securely with a cable clamp to prevent its contact with other parts and

components.

• Fix the housing cable so that extreme force is not applied to the cable when the pan/tilt head rotates in

the vertical direction.

Page 5

5

Indicates a potentially hazardous situation which could result in

moderate or minor personal injury, and/or property damage if ignored

or mishandled.

CAUTION

When Installing the Pan/Tilt Head

• Take care so that the housing’s front end does not contact a control input cable.The cable may be damaged

by the rotation of the pan/tilt head, possibly causing a fire.

When Using the Pan/Tile Head

• Do not place heavy objects on the unit as this may cause the unit to topple over or fall down and personal

injury could result.

• Use a dedicated power supply unit. The use of other power supply unit could cause a fire.

• Do not stand or sit on, nor hang down from the unit as this may cause the unit to topple over or fall down,

possibly resulting in personal injury.

• Have the unit periodically checked by the dealer from where it was purchased. Should the unit or its mount

corrode or structurally deteriorate, the unit could fall down, possibly resulting in personal injury.

2. GENERAL DESCRIPTION

The TOA C-PH200 is a rainproof and dustproof motorized pan/tilt head designed for both indoor and outdoor

applications. Mounted with a camera housing (TOA’s C-CH100, C-CH100FH and C-CH200 Series) containing

television camera and zoom lens, etc., the C-PH200 pan/tilt head can be rotated vertically and horizontally by

remote control, thus greatly extending the camera’s range of surveillance capability.

The C-PH200 also features an Auto-Pan function (continuous horizontal rotation with automatic reverse).

3. HANDLING PRECAUTIONS

• Be sure to switch off the power before cleaning. To clean, wipe with a dry cloth. When the unit is extremely

dirty, use a cloth dampened in a neutral detergent. Never use benzene, thinner and chemically treated towel

as the use of such volatiles could damage the unit’s finish.

• Avoid leaving the Auto-Pan function enabled for extended periods of time, as the unit’s operating life may be

diminished due to lubricant loss and resulting gear wear. The unit’s estimated life span is approximately

5,000 hours or 200,000 Auto-Pan reverse operations.

• Avoid exposing the moving assembly to strong shocks, as operating parts could be damaged or the unit’s

life span shortened.

• Adjust the center of gravity of mounted components to within the permissible range of tolerance. If the center

of gravity is set outside the tolerance range, the unit may not be able to move on its own, even if the

mounted component is within the permissible weight limit. The movement’s gears may also become

damaged and their life span shortened.

• Unit operation may be impaired due to freezing winter temperatures. Take appropriate anti-freezing

measures when operating in such cold conditions.

Page 6

6

4. NOMENCLATURE AND FUNCTIONS

Cable clamp

Fixes housing cables. Refer to p. 11.

Camera mounting plate

Attach a camera housing (C-CH200 Series,

C-CH100 and C-CH100FH) to this plate.

Refer to p. 11.

Housing mounting slot

Used to mount a camera housing. Refer to p. 11.

Pan/tilt head

mounting hole

(for horizontal rotation angle adjustment)

Horizontal rotation angle is adjustable in the

range of 175°(left) to 175°(right). Both left and

right angles are factory-preset to 175°.

Refer to p. 8.

Cam fixing screw

Cam fixing screw

(for vertical rotation angle adjustment)

Vertical rotation angle is adjustable in the

range of 20°(upward) and 70°(downward).

Upward angle is factory-preset to 20°and

downward angle to 70°. Refer to p. 8.

Control input cable bushing

Run the pan/tilt head control cable through this bushing. Refer to p. 9.

Coaxial cable bushing

Run the video signal cable through this bushing. Refer to p. 9.

Housing cable

Used for connections to a camera housing.

Page 7

7

y

g

5. INSTALLATION

5.1. About the Center of Gravity of Mounted Components

When mounting components, adjust their center of gravity (G) to within the permissible range of tolerance

shown below.

Note

If the center of gravity is set outside the tolerance range, the pan/tilt head may not be able to move on its own,

even if the mounted component is within the permissible weight limit. The movement’s gears may also

become damaged and their life span shortened.

5.2. Housing Front End and Its Surrounding Impediments

Mounted component

(such as a camera, lens, housing and lighting fixture)

30 mm 30 mm

Center of gravity permissible

tolerance range

90 mm

GG

Camera mounting plate

Camera mounting plate

When mounting a camera housing, take care so that its front end

does not contact the surrounding walls or poles while the pan/tilt

head is moving.

Horizontal rotation

Mounted component’s center of gravit

Vertical rotation

CAUTION

When installing the housing face-down,

adjust its position and mounting angle

to prevent its front end from contacting

a control input cable.

The control cable may be damaged,

and this could cause a fire.

Horizontal rotation

Wall mountin

Wall

Control input cable

bracket

Page 8

8

Do not operate the Remote Controller while somebody

is handling the pan/tilt head, as fingers may become

caught in the pan/tilt head, resulting in personal injury!

WARNING

5.3. Rotation Angle Adjustment

• The C-PH200 is shipped preset to the maximum horizontal and vertical rotation angles including 20° upward,

70° downward, and 175° left and right. These rotation angles can be adjusted as shown below to

accommodate particular requirements of installation location and/or purpose of use.

• Use a Phillips screwdriver to adjust rotation angles.

Note

• The C-PH200 does not come with a graduated angle plate for setting rotation angles. Therefore, be sure to

check the unit’s full rotation angle with an operation test.

• If the C-PH200 is suspended (i.e. is mounted “upside-down”), then throughout this manual the word “left”

should be read as “right”, and the word “right” should be read as “left”. (For example, read “leftward” rotation

cam as “rightward” rotation cam.) Similarly, read “upward” as downward” and vice versa.

Camera mounting plate

Adjusting the horizontal rotation angle

Loosen the cam fixing screw to allow the cam to

move in the direction indicated by the arrow,

and tighten while set in the desired position.

Cam fixing screw

Leftward rotation cam

Rotation angle

narrows

Adjusting the Vertical Rotation Angle

Loosen the cam fixing screw to allow the cam to move in the direction indicated by the arrow,

and tighten while set in the desired position. If the cam movement distance is insufficient,

install the cam fixing screw in the adjacent auxiliary hole.

Rightward rotation cam

Rotation angle

narrows

Upward rotation cam

Rotation angle narrows

Cam fixing screw auxiliary hole (4 places)

Downward rotation cam

Rotation angle narrows

Cam fixing screw

Page 9

9

5.4. Control Input Cable and Coaxial Cable Connections

Note

• Be sure to mount a rubber packing ring when routing the control input and coaxial cables through the

bushing.

• If a gap is created between cable and bushing, wrap the self-adhesive butyl rubber tape around the cable to

prevent the entry of rainwater.

• Ensure the routed cable is correctly fixed by lightly pulling it.

1. Remove bushing plate fixing screws (4 pieces) to pull out

the terminal chassis that is integral with the bushing plate.

Bushing plate fixing screw (4 pieces)

Control input cable

Bushing

2. Install the control input and coaxial cables by routing both

cables through the bushing.

Bushing

Control input cable

Coaxial cable

Rubber packing ring

(Mount securely)

Bushing plate

Page 10

10

20

155

10 20

155

3. Connect lead wires to the terminal.

Note

Take care not to confuse the upper terminal with the lower terminal when making terminal connections.

5.5. Coaxial Cable End Processing

Process the coaxial cable end as follows:

5.5.1. 3C-2V Cable

1. Strip the cable sheath 20 mm from the cable end.

2. Bend back braided copper shields over the cable sheath, then remove

the insulating material 15 mm from the cable end.

5.5.2. 5C-2V Cable

1. Strip the cable sheath 30 mm from the cable end, and braided copper

shields 20 mm.

2. Remove the insulating material 15 mm from the cable end.

Video connection terminal

Bushing plate

Bushing for coaxial cable

Applicable cable diameter: 4 – 8 mm

DOWN

RIGHT

LEFT

COMMON

AUTOPAN

LAMP1

LAMP2

BODY

Coaxial cable

(下)(上)

LOW

UP

UP ACPOWER(COMMON)

1

2

3

4

5

6

7

8

9

10

11

12

Terminal

ACPOWER

CAMPOWER

DEFROST

WIPER

UTT

LENSCOMMON

IRIS

FOCUS

ZOOM

UTT

Control input cable

Bushing for control input cable

Applicable cable diameter: 13 – 18 mm

Page 11

11

p

g

1. Install M6 hexagonal head bolts on the camera

housing.

Provide a space of approximately 5 mm between

the housing’s mounting base and plain washer.

Note

Hexagonal head bolts are preinstalled in some

camera housings. In such cases, loosen the bolts

and create an approximately 5 mm gap between the

two.

2. Insert the hexagonal head bolt head/spring

washer/plain washer assembly into the housing

mounting hole, then pull the camera housing

forward to fit it to the camera mounting plate.

3. Retighten the hexagonal head bolts to fix the

camera housing to the camera mounting plate.

Note

Check to ensure that each bolt is securely

tightened.

Run a housing cable through a cable clamp next.

4. Loosen 2 cable clamp mounting screws.

Loosen to allow the housing cable to be routed

through the clamp.

5. Route the housing cable through the cable clamp.

6. Retighten the two cable clamp screws loosened in

Step 4.

5.6. Camera Housing Mounting (Upright Installation)

TOA’s C-CH200 Series, C-CH100 and C-CH100FH Outdoor Camera Housings can be used for the C-PH200

Pan/Tilt Head.

Mount the camera housing on the C-PH200 first.

Fix the housing cable in the position that does not allow extreme force

to be applied to the cable when the pan/tilt head moves vertically.

Selection of the incorrect position could cause damage to the cable,

possibly resulting in fire.

CAUTION

Camera housing

Mounting base

2,3

Camera

mounting plate

Cable clamp

1

Gap of approximately 5 mm

M6 plain washer

M6 spring washer

M6 hexagonal head bolt

Pan/tilt head

Wrong cable routing example 1

Wrong cable routing example 2

4,6

Cable clamp

mounting screw

5

Housing cable

If a cable slack is too ample,

it contacts the pan/tilt head’s

rear and extreme force could be

applied to the cable while the

unit is rotating vertically.

Since the cable is not routed through

a cable clamp, the cable is damaged

when the

an/tilt head rotates horizontally.

Because no appropriate slack is provided in the cable,

extreme force is applied to the cable while the pan/tilt head

is rotatin

vertically.

Page 12

Application

24 VAC (Common)

24 VAC

Camera power supply

Defroster

Wiper

Unused

Lens (Common)

Iris

Focus

Zoom

Unused

Video (coaxial cable shields)

Video (coaxial cable core)

12

5.7. Camera Housing Mounting (Suspended Installation)

TOA’s C-CH Series Camera Housings can be installed in a suspended position.

Note: Since a waterproof function is disabled, avoid suspending such housings outdoors.

1. Using the housing suspension slots, attach the camera housing to the C-PH200 Pan/Tilt Head.

Note: Housings do not come with their mounting bolts. Prepare the following nuts and bolts:

• M6x12 hexagonal head bolt with washer : 2 pieces

2. Route the housing cable.

5.8. Housing Cable Specifications

Lead No.

1

2

3

4

5

6

7

8

9

10

11

12

13

Color

Green

Yellow

Blue

Gray

Red

Black

Purple

Orange

White

Peach

Brown

Coaxial cable shields

Coaxial cable core

Ceiling

Pan/tilt head

2

Housing cable

Note

Do not use the bolts attached to the camera housing when suspending.

Removing the bolts allows dust to enter, causing equipment failures.

1

Camera housing

When suspending the housing, reverse

the housing mounting directions referred

to in the instructions for upright mounting.

Page 13

13

5.9. Notes on Operations by Auto-Pan Control

When using an auto-pan function to operate the C-PH200 Pan/Tilt Head, be sure to make the following

changes to best meet particular requirements of connected control equipment. Failure to do so could cause

the pan/tilt head’s malfunctions.

5.9.1. If using the CC-5011B Direct Control System Remote Control unit…

Open the CC-5011B’s case and cut JP1 on the RC-1A circuit board with nippers. For details, please read the

section “Connections” of the instruction manual for the CC-5011B.

5.9.2. If using the CC-5120 Relay Box…

Open the CC-5120’s case and cut JP1 on the RB-1A circuit board with nippers.

5.9.3. If using the C-RB100 Coaxial Multiplex Control Relay Box…

Open the C-RB100’s case and perform settings for the SW3 Pan/Tilt Head Installation Setting switch. Set the

switch to “0,” “7,” “8,” or “9” when installing the C-PH200 unit upright, and to “1” when installing it in a

suspended (upside-down) position. (Factory-preset to “0.”)

For more information about this, refer to the section “Settings” of the instruction manual for the C-RB100.

RC-1A

JP1

Terminal block

CC-5941BCC-5011B

C-PH200

RB-1A

CC-5120 CC-5111B

C-PH200

JP1

C-PH200

C-RB100

Coaxial Multiplex

Controler

C-RB100

SW3

3

2

4

1

5

0

6

9

7

8

Page 14

14

6. DIMENSIONAL DIAGRAM

15

Rightward

rotation 175°

Front

Leftward

rotation 175°

Downward rotation 70°

70

93

259

120

70

46

168

Upward rotation 20

2568

Unit: mm

7 x 80 housing suspension slot

(for suspension)

11.5

Ø16

7

Housing mounting hole

Housing mounting hole

Note: Use the housing suspension slots when suspending.

°

18010

282

168

199.4

142

108

84

142

168

131.6

313

Ø10 pan/tilt head mounting hole (4 pieces for M8 bolt)

Page 15

15

24 VAC, 50/60 Hz

46 VA

Video signal : Applicable diameter : ø4 – ø8 mm

Screw terminal for 3C-2V or 5C-2V

Powercontrol: Applicable diameter : ø13 – ø18 mm

M3 screw terminal (12 P) with free terminal screw x 2

Output line : Connected to the housing using dedicated cable

Tilt : –70 to +20°±5°

Pan : Over 340°(automatic reverse), 350°±5°(manual operation)

Tilt : 3°±0.5°/sec (50 Hz), 3.6°±0.6°/sec (60 Hz)

Pan : 6°±0.5°/sec (50 Hz), 7.2°±0.6°/sec (60 Hz)

Vertical : 15 minutes

Horizontal : Continuous

5,000 hours or 200,000 reverse operations

11 kg (upright installation)

10 kg (indoor suspension)

IP-54

(Waterproof capability only applies to upright installation.)

Operable at average wind velocity of 40 m/s or less.

Not destructed at maximum wind velocity of 60 m/s (provided the unit is installed

at a height of 15 m above the ground and C-CH200 Series camera housings are

mounted)

Indoors and outdoors (except seaside and industrial districts where the unit is

subject to corrosion, and heights that expose the unit to strong wind pressure)

Because a waterproof function is disabled, unit cannot be installed in a

suspended position outdoors.

–10° to +50° (standard specifications and not frozen)

30 to 90% RH (relative humidity)

Die-cast aluminum and anti-corrosion aluminum plate, off white, powder coating

190 (W) x 282 (H) x 313 (D) mm

10.2 kg

Camera housing : C-CH200 series, C-CH100 series

Wall mounting bracket : C-BC200K

Power Source

Power Consumption

Input/Output Lines

Rotation Angle

Operation Speed

(No load)

Rated Time

Auto-Pan Life

Load Rating

Waterproof / Dustproof

Capability

Wind Pressure

Applications

Operating Temperature

Operating Humidity

Finish

Dimensions

Weight

Applicable Model

Option

Note: Specifications and external view of the C-PH200 Pan/Tilt Head are subject to change without notice.

7. SPECIFICATIONS

Page 16

Loading...

Loading...