Page 1

TM5

Guide Book

Hardware Version: 1.00

Software Version: 1.64

Page 2

ii

Release Date : 2017-10-01

Page 3

iii

The information contained herein is the property of Techman Robot Corporation (hereinafter referred to as the

Corporation). No part of this publication may be reproduced or copied in any way, shape or form without prior

authorization from the Corporation. No information contained herein shall be considered an offer or commitment.

It may be subject to change without notice. This Manual should be reviewed periodically. The Corporation will not

be liable for any error or omission.

and logos are the registered trademark of TECHMAN ROBOT INC. and the company reserves the

ownership of this manual and its copy and its copyrights.

Page 4

iv

I Hardware Installation Manual

1. Safety Information

1.1 Overview

1.2 Validation and Liability

1.3 Limitations on Liability

1.4 Warning and Caution Symbols

1.5 General Safety Warning

1.6 Scope of Use

1.7 Risk Assessment

1.8 Emergency Stop

1.9 Joint Rotation without Drive Power

2. Safety Functions and Interface

2.1 Overview

2.2 Safe Stop Time

2.3 Safety-related Limiting Mechanisms

2.4 Singularity/Singular Point

2.5 Safety Setting

2.5.1 Operating Position

2.6 Operating Mode

2.6.1 Auto Mode

2.6.2 Manual Mode

2.6.2.1 Manual Control Mode

2.6.2.2 Manual Trial Run Mode

2.6.3 Changing the Operating Mode

2.7 Hold to Run

2.8 Collaborative Mode and Safety Zone Setup

2.8.1 Collaborative Mode and Parameter Configuration

2.8.2 Collaborative Space Configuration for Safety

3. Transportation

4. System Hardware

4.1 Overview

4.2 System Overview

4.2.1 Robot Arm

4.2.1.1 Robot Range of Motion

4.2.1.2 Robot Arm Maximum Allowed Payload

4.2.1.3 Robot Arm Installation

4.2.2 Robot End Module

4.2.2.1 End Module Components

4.2.2.2 End Flange Surface

4.2.2.3 End Mounting Caution

4.2.2.4 End Indication Light Ring Table

4.2.3 Control Box

4.2.3.1 Robot Stick

2

2

2

3

4

5

5

6

6

8

9

10

10

14

16

16

16

16

16

16

17

17

18

18

20

26

27

27

27

28

28

32

33

34

34

36

37

37

39

39

Page 5

v

5. Electrical Interface

5.1 Overview

5.2 Electrical Warnings and Cautions

5.3 Control Box

5.3.1 Safety Connector

5.3.2 Power Connector

5.3.3 Digital In/Out

5.3.4 Analog In

5.3.5 Analog Out

5.3.6 EtherCAT: For EtherCAT Slave I/O Expansion

5.3.7 USB Port

5.4 Tool End I/O Interface

5.4.1 I/O Terminals

5.4.2 Connecting Tool End Digital Out

5.4.3 Connecting Tool End Digital In

5.4.4 Connecting Tool End Analog In

5.5 Control Box Interfaces

5.6 Control Box Power Interface and Robot Interface

5.6.1 Control Box Power Interface

5.6.2 Robot Interface

6. Maintenance and Repair

7. Warranty Statement

7.1 Product Warranty

7.2 Disclaimer

Appendix A. Stop Time and Distance

Appendix B. Technical Specifications

42

42

43

43

45

45

47

48

48

48

49

49

51

51

52

52

53

53

54

55

55

56

57

58

Page 6

1

Hardware Installation Manual

I

Hardware Version: 1.00

Software Version: 1.64

Page 7

I Hardware Installation Manual 1. Safety Information2

1. Safety Information

1.1 Overview

This chapter describes important safety information about the Techman Robot. The users and system

integrators of the Techman Robot should carefully read and understand this chapter before using this robot.

1.2 Validation and Liability

The information contained herein neither includes how to design, install, and operate a complete robotic arm

system, nor involves the peripherals which may affect the safety of the complete system. The design and

installation of the complete system must comply with the safety standards and regulations in the country of

use. The integrators of the robot should understand the safety laws and regulations in their countries and

prevent major hazards from occurring in the complete system.

This includes but is not limited to:

• Risk assessment of the whole system;

• Adding other machines and additional safety mechanisms based on the results of the risk assessment;

• Building appropriate safety mechanisms in the software;

• Ensuring the user will not modify any safety-related measures;

• Ensuring all systems are correctly designed and installed;

• Clearly labeling user instructions;

• Clearly marked symbols for installation of the robot arm and the integrator contact details; and

• Collecting all documents into the technology folder, including the risk assessment, and this Manual.

1.3 Limitations on Liability

No safety-related information shall be considered a guarantee by Techman Robot that TM5 will not cause

personnel injury or property damage.

Page 8

3I Hardware Installation Manual 1. Safety Information

Note

Danger

Warning

This symbol indicates that failure to observe these instructions will

lead to death or serious injuries.

This symbol indicates that failure to observe these instructions may

lead to injuries.

This symbol indicates that failure to observe these instructions may

lead to equipment damage.

Danger

Warning

Note

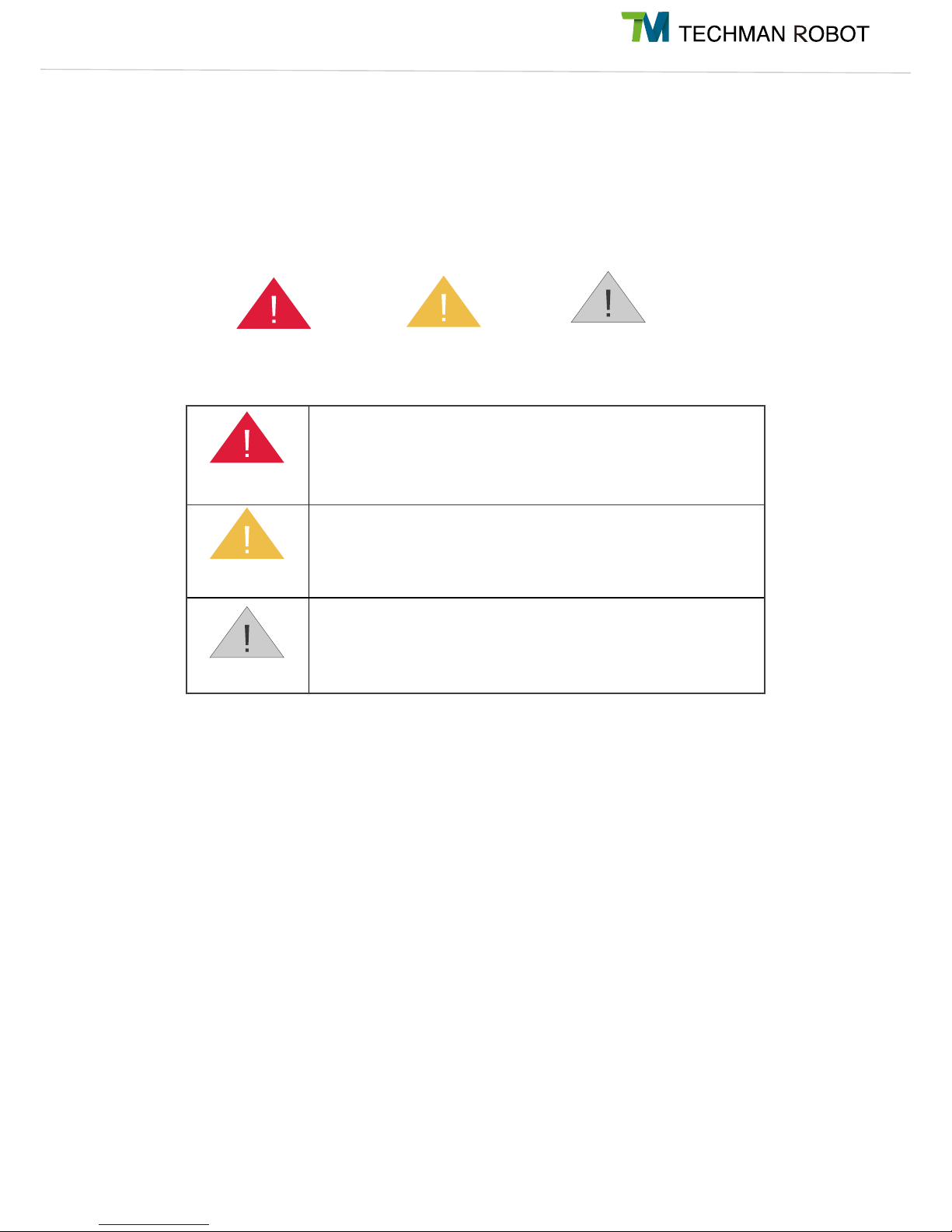

1.4 Warning and Caution Symbols

The Table below shows the definitions of the warning and caution levels described in each paragraph of this

Manual. Pay close attention to them when reading each paragraph, and observe them to avoid personal

injuries or equipment damage.

Page 9

I Hardware Installation Manual 1. Safety Information4

1.5 General Safety Warning

The following shows the general warnings and cautions. Note that there may be related warnings and

cautions listed in the remaining sections, in addition to the ones described in this section. Read them

carefully as well.

Danger:

1. Before handling, installation, operating, maintaining and servicing this product, carefully read the

product's specifications and operating manual. Make sure that all conditions meet the requirements of the

specifications and manual to avoid unexpected accidents during use (e.g. improper operation or operating

conditions that exceed the product specifications) that may cause personnel injury or damage to this

product.

2. Before using and installing this product, the installer must perform the necessary risk assessments

based on the conditions of use to avoid serious personal injuries during operation (e.g. Collision between

equipment and personnel) due to improper parameter settings.

Warning:

1. Before using this product, make sure that there is at least 1 or more emergency stop device on the

machine to stop the movement of the robot in case of accidents. Always make sure that the devices are

functioning properly.

2. Prior to assembly and disassembly, or servicing and maintenance of this product, make sure that the

power is disconnected and the rear area is clear before proceeding. Doing so will help prevent injury to

personnel or damage to equipment due to accidental short-circuits or electrocution during use.

3. When operating this product, the operator should not wear loose clothing or other accessories (e.g.

necklaces, ties,and bracelets) to avoid injuries which may happen when said clothes or accessories are

drawn into the machine during operation.

4. In the event of product malfunction, follow the proper procedures and channels to contact qualified

personnel for troubleshooting and repair. To prevent damage to the equipment due to improper disassembly,

the operator is strictly prohibited against attempting to make direct repairs.

5. Before the robot begins operations, make sure that each part is secured in place to prevent any accidents

due to the robot being improperly secured during operation.

6. Before the robot begins operations, always make sure that no personnel or obstacles are within its range

of motion. If the operating environment involves human-machine collaborative work, always perform the

necessary risk assessments before the start of operations.

7. Unauthorized personnel are not allowed to operate this product in order to prevent any possibility of

personal injury or damage to the machine caused by improper operation.

8. Do not install or operate this product in dangerous environments (e.g. in the presence of a strong

magnetic field; dangerous gases; fire, or flammables) to avoid dangers which may occur due to external

conditions during operation.

Page 10

5I Hardware Installation Manual 1. Safety Information

Note:

1. Personnel approaching or operating the robot should check the machine warning lights before proceeding.

2. After editing the task flow, always start operations in Manual Mode to check that all actions can be

performed correctly during operation before switching the operating mode to Auto.

3. Do not turn off power to the machine while it is in motion unless absolutely necessary.

1.6 Scope of Use

The TM Robot is a collaborative robot with a built-in vision system. The dedicated HMI simplifies robot

deployment and increases its operational flexibility, making it suitable able for the production and

manufacturing industries.

The design of the TM Robot focuses on the safety of the human-machine collaboration. However, the

collaborative robot is intended only for the applications for which risk assessment has been conducted

without any hazards identified. The risk assessment involves the robot and the related peripherals as well

as environment.

The risk assessment has been performed for any use or application and no hazard is found. The use of the

robot for any purpose other than the intended is prohibited. The Corporation shall not in any event be liable

for any conditions including, but not limited to, the following:

- Use in a potentially hazardous environment

- Use in any applications that may threaten human lives

- Use in any application that may cause personal injuries

- Use before completion of the risk assessment

- Use for auxiliary support

- Use when the rated performance cannot be reached

- Use when the reaction time of safety functions is insufficient.

- Use with inappropriate parameters for operations

- Applications which may cause damage to the robot itself

1.7 Risk Assessment

Before using and installing this product, the user must perform the necessary risk assessments based on

the conditions of use. Refer to the regulations specified in the documentation, such as ISO-10218-2, ISO-

12100, and ISO-15066 for details. The purpose of the risk assessment is to predict possible accidents

during the operation, and prevent the occurrence of accidents or reduce the severity of injuries effectively

with appropriate protective measures. Therefore, the scope of the risk assessment must include any oper-

ation of the machine. Once a risk assessment has been conducted, the user may use the relevant external

components (e.g. sensors, emergency stop devices, fencing or other barrier devices) and configuration of

safety-related parameters in the operating system to prevent potential accidents during operations. External

safety-related components should be installed as directed. Refer to Chapter 2 for the safety settings of the

operating system and how other safety components should be used.

Page 11

I Hardware Installation Manual 1. Safety Information6

TM Robot expressly indicates that the major significant residual risk below may exist:

1. Excessive rotation of the 6th joint may result in the fingers being caught between the rear-end of the

camera module and the 5th joint module.

2. The palm or fingers may get caught between the end module and the body of the robot during robot

motion or Hand Guide Instruction.

3. Injuries due to collision with the robot.

4. Injuries due to being hit, crushed, or pinched between the robot and a hard surface.

5. Injuries caused by loose screws which are used to fix the robot to the base.

6. TM Robot explicitly states that serious residual risk may exist in the following scenarios: There is a risk

that improper configuration of the collaborative zone or safety space, as well as the running of incorrect

projects, may lead to the robot colliding at full speed with the human body within the collaborative space.

1.8 Emergency Stop

If any accidents occur during the operation of the robot, the user can stop all movement by pressing the

Emergency Stop button. When the robot stops, the user must ensure that all fault conditions are eliminated

before manually turning off the limit switch for the Emergency Stop button and restarting the robot.The

Emergency Stop button is only used in critical conditions, to stop the robot during normal operations please

use the Stop button on the system controller.

Once the risk assessment has been conducted, if an Emergency Stop button needs to be installed then the

selected device must comply with the requirements of ISO-60204-1.

1.9 Joint Rotation without Drive Power

1. When the Emergency Stop Button is triggered during the operation of the robot, the control system will

stop its movement and cease supplying sufficient power to its joint actuators to achieve an effect equivalent

to disconnecting the power for actuation to the robot. In this case, the brake at each joint automatically locks

the joint to prevent each joint of the robot from drooping continuously under gravity. If the robot needs to

be moved to clear the fault condition, press and hold the FREE button on the end module of the robot. Two

seconds later, the braking device at the joint will disengage the brakes. Before releasing the FREE button,

the user can move the machine by pushing the joint to clear the fault condition.

When an emergency button is pressed, the robot system issues a command to stop the robot,

and stops supplying sufficient power to its joint actuators for an effect equivalent to disconnecting

the power for the actuation of the robot. In this case, the braking device at each joint automatically

locks the joint. However, before the brake completely stops the robot, the robotic link will, under

the force of gravity, make the unpowered joint slightly droop in the direction of gravity. In this

case, be aware of the possibility that the robot end module may pinch the body or collide with the

surroundings.

Warning

Page 12

7I Hardware Installation Manual 1. Safety Information

2. If the robot needs to be moved when the power is disconnected (e.g. disengaging packaging posture),

the user can first press the Emergency Stop button while there is no power, then press the Power Button on

the controller to supply power to the system. When the control system is turned on, the light blue indicator

light on the end module will blink. At this time, press the FREE button on the end module to release the

braking device at the joint. The user can move the joint by pushing it.

When overriding the brake during the movement without drive power, note that the robot limb will

droop back down due to the gravity when the FREE button is pressed for 2 seconds. Be sure

to grab the end module securely and prepare for the added weight when you press the FREE

button to unlock the brake. Lift the end module upwards to avoid increasing the severity of injury

if someone is caught under the machine. If the end module can't be held securely or you lack

sufficient strength to prevent the robot arm from lowering, release the FREE button immediately.

Each joint of the robot will be locked again to avoid personal injury or machine damage.

Danger

Page 13

I Hardware Installation Manual 2. Safety Functions and Interface8

2. Safety Functions and Interface

2.1 Overview

The control system of the Techman Robot features a series of built-in safety-related functions, and provides

an interface for connecting with external safety devices.

For human-machine collaborative tasks, the user or system integrator must configure the safety-

related parameters based on the results of the risk assessment. For tasks during which human

and machine are separated, evaluate the selection and configuration of external protection

equipment. Failure to do so may result in personal injuries or death.

For instructions on how to configure the safety-related parameters in the UI, refer to Section 2.5.

For instructions on how to connect external safety devices to the system, refer to Chapter 5.

Note:

1. The user or system integrator should configure the safety-related parameters based on the

results of the risk assessment.

2. If any of the safety-related functions is triggered, protection stop is activated. Stop time is

provided in Appendix A and this time should be considered as part of the task risk assessment.

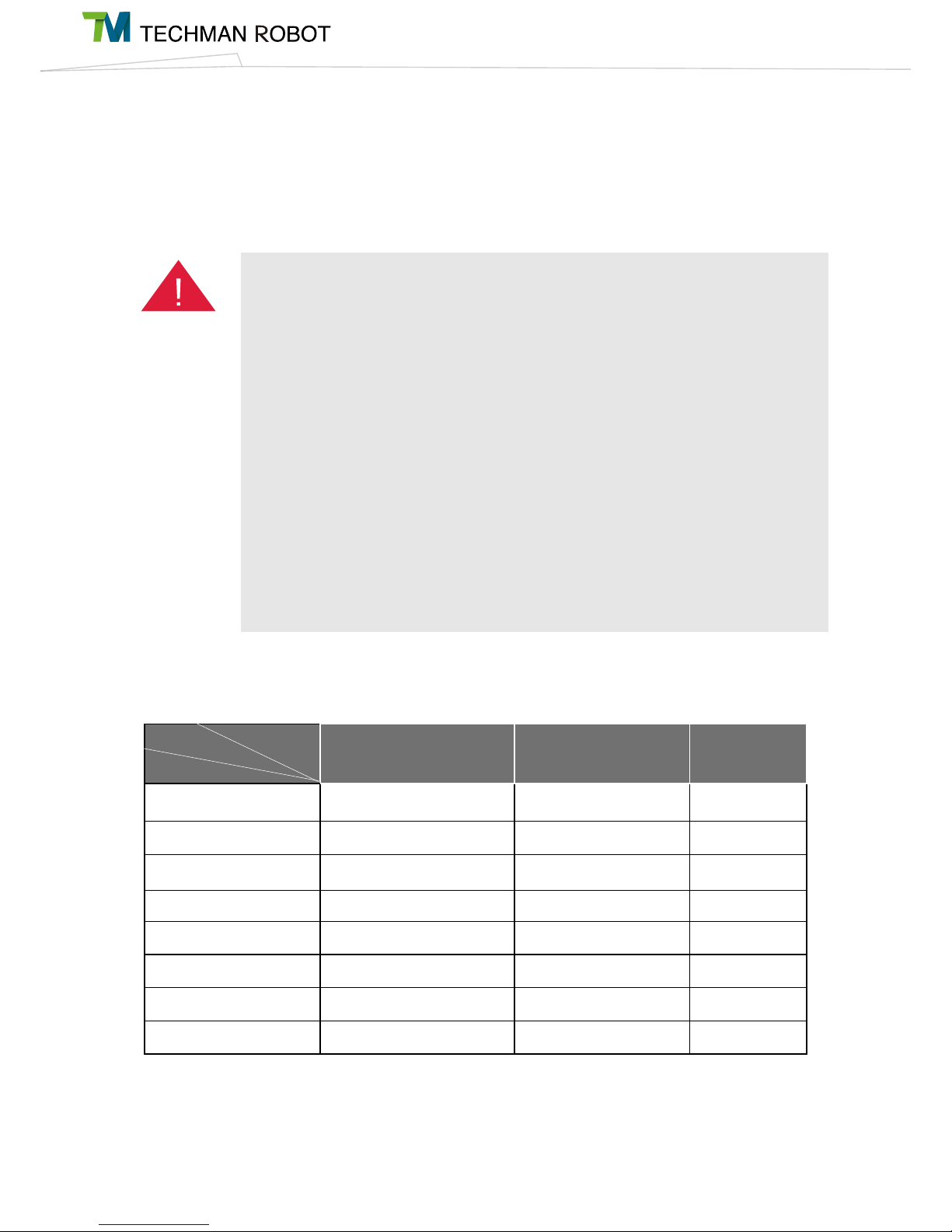

The Techman Robot System limits physical values such as offset, speed, force, or even

momentum and power, for the robot arm, tool end, and each movable axis. These are monitored

and protected by dozens of safety-related protection functions through the real-time system. The

figure below lists each protective function.

Location Speed/Momentum Force/Power

Robot

N.A Maximum robot momentum

Maximum robot power

Tool end

N.A Maximum speed of tool end

Force Applied to Tool

Endpoint

Axis 1

Minimum/Maximum axis position Maximum axis speed

Maximum axis torque

Axis 2

Minimum/Maximum axis position Maximum axis speed

Maximum axis torque

Axis 3

Minimum/Maximum axis position Maximum axis speed

Maximum axis torque

Axis 4

Minimum/Maximum axis position Maximum axis speed

Maximum axis torque

Axis 5

Minimum/Maximum axis position Maximum axis speed

Maximum axis torque

Axis 6

Minimum/Maximum axis position Maximum axis speed

Maximum axis torque

Limit type

Limit condition

Personnel limit

Danger

Page 14

9I Hardware Installation Manual 2. Safety Functions and Interface

2.2 Safe Stop Time

The safe stop time is defined as the period from the moment when the Emergency Stop button is pressed

or any safety-related function is triggered to the moment when the robot comes to a complete stop. In this

system, pressing the Emergency Stop Button is a Category 1 Stop, while triggering built-in safety-related

functions or externally connected safety-related equipment is a Category 2 Stop. In certain cases, the user

or system integrator must include this time in the risk assessment, because the robot may operate at a

certain speed during this period, allowing transfer of energy, which may cause personal injury or equipment

damage, please refer to Appendix A for the actual stopping distance.

Both (A) and (B) are actuated during a Cat. 1 stop by the system; only (A)

actuates during a Cat. 2 stop.

The "Force Applied to Tool Endpoint" is the external force which is applied at the center point of

the tool, and estimated by models. It is not the protection value for the force externally applied

by the robot system to the center point of the tool. When the external force applied to the center

point of the tool estimated by the robot system exceeds this setting value, the event "Exceed

Limit of Force Applied to Tool Endpoint" is triggered. At this time, the robot performs Category

2 Stop and starts deceleration. The robot may still apply force externally until it comes to a

complete stop. Thus, it should be understood that the force externally applied by the robot

during the period from this time to a complete stop will exceed this setting value. This setting

must not be mistakenly used as a basis to assess the force of collision between human and

machine.

Warning

500ms

20A

3A

800ms

Joint speed

Motor driving

current

(A)

(B)

Trigger of safety alarm event

Page 15

I Hardware Installation Manual 2. Safety Functions and Interface10

2.3 Safety-related Limiting Mechanisms

All safety-related functions described in Section 2.1 are monitored and controlled by a dedicated safety

thread (with a cycle of 10ms) at system level, which provides a trigger signal to another dedicated motion

thread (with a cycle of 1ms) to make related responses. In this dedicated safety thread, all physical

quantities used for calculation of the required information about each robot axis (angle, angular velocity,

torque, etc.) are also updated every 1ms. When any safety related function is triggered, every axis of the

robot will stop within 800ms under a Category 2 Stop. When the Emergency Stop button is pressed, the

robot will stop movement within 610ms and the system will lower the upper limit of the total drive current

from 20 A to 3 A to activate a Category 1 Stop. In addition, when system hardware is operating beyond

limits (such as too high joint drive current, overheating motor, unstable power supply, or disconnection of

the system communications), a Category 2 Stop is triggered. When a Category 1 Stop or Category 2 Stop is

triggered, the Indication Light Ring on the end of the robot will change to a solid red light and the system will

beep continuously. When this happens, restart the system according to standard procedure, or contact the

distributor for servicing.

2.4 Singularity/Singular Point

Robot arm do not move through whole space always, it has a number of safety-related issues. Kinematic

singularities play a significant role in the motion control of robot arm. Singularity can be defined as a posi-

tion in the robot workspace where two or more joints no longer independently control the position and orien-

tation of the tool. Namely, for a general 6-axis manipulator, this means that singularity is a point where the

robot loses its ability to move the tool center point in some orientations. The error code are 0x09、0X14.

TM robots with 6 degrees of freedom have three clarifications in singularity:

● Inner singularity

● Extended singularity

● Wrist axis singularity

Operating on the periphery of the non-working area of the Techman robot or if the range of motion

passes through the non-working area (Jacobian matrix is unstable near singularities) may also

cause the end tool output force to incorrectly trigger safety conditions even at low speeds. Please

set the task requirements of the robot inside its working space to ensure the correct operation of

the safety protection.

Warning

Page 16

11I Hardware Installation Manual 2. Safety Functions and Interface

Inner singularity

In the inner singularity, the wrist root point is close to cylindrical as shown in below. The definition of cylin-

drical radius , is distance between center of J1 and J6. Once robot arm close the inner singularity, robot arm

will stop and sent out a warning.

The d

offset

is 122.2 mm.

Extended singularity

In the outer singularity, the wrist root point is located at the limit of its work envelope. Namely, J3 is almost in

zero degree. Robot arm stop and send out a warning when end-effector beyond working space.

Joint coordinate system and d

offset

definition.

Page 17

I Hardware Installation Manual 2. Safety Functions and Interface12

Wrist axis singularity

In the wrist singularity position, the J4 and J6 line up each other. In this case, these joints will try and spin

180 degrees instantaneously. There is an infinite number of possible for J4 and J6 with identical axis angle.

Once situation mentioned occur, robot arm will stop and send out a warning.

The workspace explanation when J3 is almost in zero degree.

There is an infinite number of solution space when axes J4 and J6 with

identical axis angle.

Page 18

13I Hardware Installation Manual 2. Safety Functions and Interface

When encountered singularity

When the robot reports the error code 0x09 or 0x14, it may be caused by singularity, please confirm robot

pose. If robot trajectory passes through inner Cylinders like picture as below, please refer to the first point

as below. If J4 and J6 with identical axis angle, please refer to the second point as below.

1.While robot arm send out a warning because of inner singularity, user can press the FREE bottom to

get rid of warning. Please reconsider the position of the points or change the trajectory between the points.

Please avoid the robot trajectory between the points cross the inner singularity.

2 .While robot arm send out a warning because of wrist axis singularity, user can press the FREE button to

get rid of warning. Try to move the robot along z-axis in tool base when J4 and J6 with identical axis angle

will cause wrist axis singularity. The picture below shows an example to prevent wrist axis singularity.

When robot trajectory passes through inner singularity, it will send out a

warning.

An example to prevent wrist axis singularity

Page 19

I Hardware Installation Manual 2. Safety Functions and Interface14

2.5 Safety setting

Safety setting of TM Robot is divided to Safety Stop Criteria, Safety IO Setting and Collaboration mode.

Safety Stop Criteria :

User can modify the maximum allowable values of robot momentum, power con-

sumption, TCP speed, TCP force, joint position, joint speed and joint torque in Safety Stop page.

Min/Max Joint Position Setting :

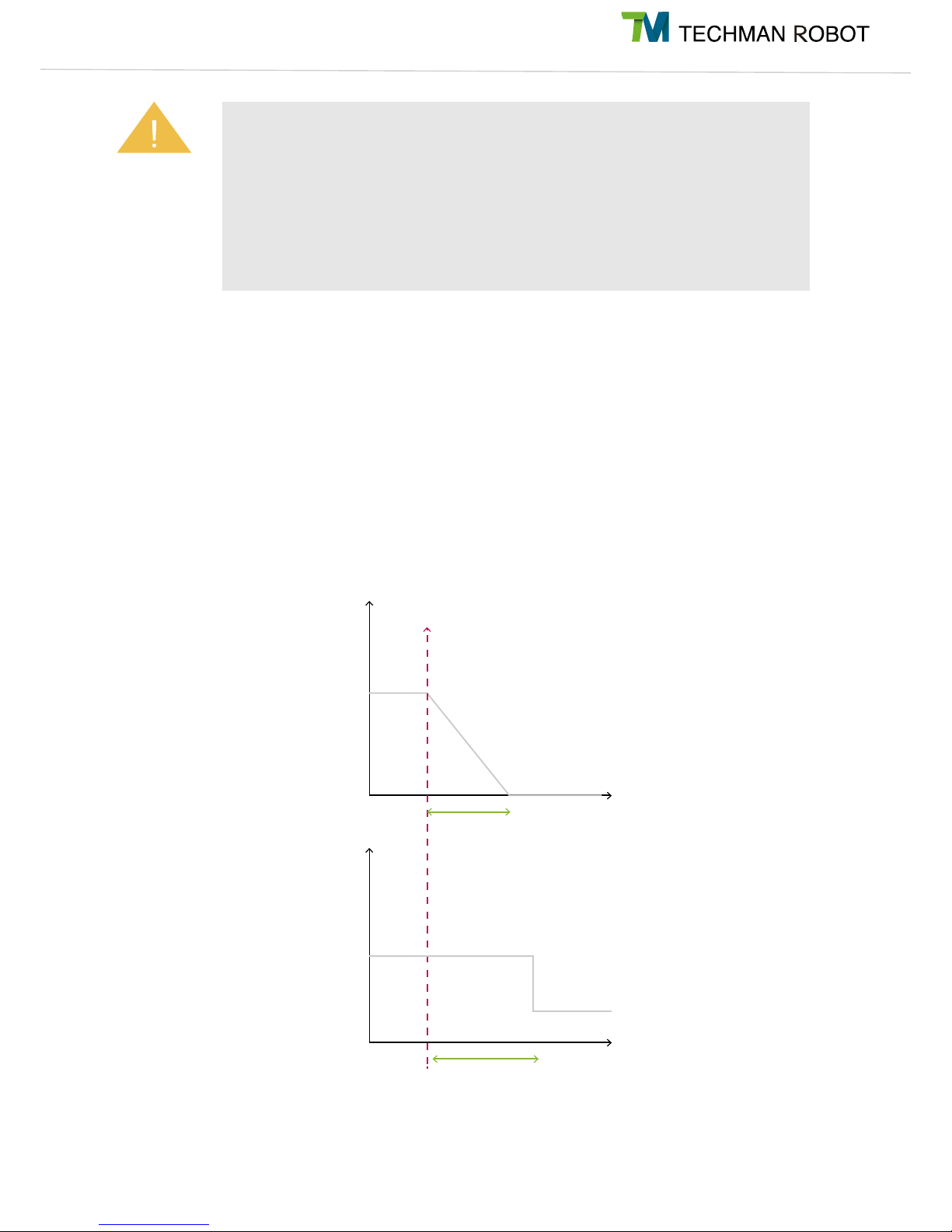

If you set the Min/Max position of first joint with 270˚ and -270˚, then the angle range in 270˚~ 271˚and

-270˚~ -271˚ will become reducing range as the blue area showed in the picture. When the first joint

move into this range the basic moving speed of the robot will be switched to 250mm/sec for path motion

and 5% for PTP motion, to forming an angle buffer region to prevent possible overshoot to the joint limit.

At the same time, the angle range in 271˚~ 274˚and -271˚~ -274˚ is the 2nd buffer range for joint limit as

the red area in the picture. When the joint angle arrives this area robot will stop moving. User can only

operate the robot by press free robot button until robot leaves this area.

Page 20

15I Hardware Installation Manual 2. Safety Functions and Interface

Safety IO Setting :

Safety IO Setting (Please refer to description in 5.3.1) compose two modes: Pause and

collaboration mode. User can choose either pause or collaboration mode in safety IO setting.

ause: Setting the configuration of the safety IO of TM Robot with risk evaluation, user can choose either

“

manual reset” or “automatic reset” to manually restart or automatically restart the project when the project

is previously paused by safety IO triggered.

Collaboration mode:

Setting the configuration of the safety IO of TM Robot with risk evaluation, user can

utilize the collaboration mode to switch the project from full speed mode to collaboration mode, when safety

IO triggered.

Collaboration Mode setting: Parameter configuration for TM Robot’s collaborative mode can be divided into

two parts. One is hazard configuration and the other is limit configuration. (Please refer to description in 2.8.1).

Page 21

I Hardware Installation Manual 2. Safety Functions and Interface16

2.5.1 Operating Position

Except for Hand Guide Mode, for correct operating positions, the user should stay outside of the mo-

tion range of the robot to perform operations. At least one emergency switch is installed outside of

the motion range of the robot. When no motion limit is set for the robot, the motion range of the robot

is equal to the maximum motion range of the robot arm (refer to Section 4.2.1). When the user sets

a limit for the TM Robot, he/she can avoid the situation whereby all operations have to be out of the

maximum motion range of the robot arm.

The robot stick should be placed in an area that the robot cannot reach. The user should also make

sure that the movement of the robot will not be within any area where personnel will enter to press

any buttons on the robot stick.

2.6 Operating Mode

TM Robot comes with two operating modes: Manual Mode and Auto Mode. Current mode can be deter-

mined visually via the mode indicator (see Section 4.2.3.1) on the Robot Stick, and the color of the Indica-

tion Light Ring on the robot's end module (see Section 4.2.2.4). The robot starts in Auto Mode.

2.6.1 Auto Mode

When the robot is in Auto Mode the Indication Light Ring on the end module is blue and the mode in-

dicator on the Robot Stick is in the Auto position. Under auto mode, pressing the Play/Pause buttons

on the Robot Stick runs or pauses the project. Robot speed is determined by the project speed. The

FREE button of the end module does not work under Auto Mode so there is no guiding by hand.

2.6.2 Manual Mode

When the robot is in Manual Mode the Indication Light Ring on the end module is green and the

mode indicator on the Robot Stick is in the Manual position. Manual Mode can be further broken

down into Manual Control mode and Manual Trial Run Mode. The user can tell the difference using

the status of the green Indication Light Ring on the end module as well. Constant green light indi-

cates Manual Control mode while flashing green light indicates Manual Trial Run Mode.

2.6.2.1 Manual Control Mode

In Manual Mode, if the robot is not moving then it is in Manual Control mode. Press the FREE

button on the end module to guide the robot by hand or use the controller page to jog the

robot. When the robot is in Manual Control Mode, all robot motion will be limited to less than

250mm/sec. If the robot speed exceeds 250mm/sec then it will stop on an error.

2.6.2.2 Manual Trial Run Mode

When the user is in the HMI's project editing page, pressing the Play/Pause button on the

Robot Stick enters Manual Trial Run Mode. The 250mm/sec speed limit does not apply while

editing projects in Manual Trial Run Mode but the project run speed will be reduced to 10%

during each trial run. The add/subtract buttons on the Robot Stick can be used to adjust the

project run speed in Manual Trial Run Mode. Each button press increases or decreases proj-

ect run speed by 5%. This is used to adjust the project run speed.

Page 22

17I Hardware Installation Manual 2. Safety Functions and Interface

2.6.3 Changing the Operating Mode

To change the operating mode of the robot, please use the Mode Switch Button on the robot control

to cycle between Auto/Manual mode. The system cannot be changed from Auto to Manual mode

while the robot is running a project in Auto mode. The robot must be stopped by pressing the Stop

Button on the Robot Stick before it can be switched to Manual mode. When the robot is switched

from Manual Trial Run Mode to Auto mode by pressing the Mode Switch Button, the project run

speed will be set to the default project running speed. In other words, the run speed in Auto mode for

this project will now be fixed unless it is changed by another trial run.

2.7 Hold to Run

TM Robot can not only record points through hand guide instruction but also use TM Flow to move the coor-

dinates of each coordinate system. These include: moving the joint angle, moving the end module through

the robot coordinate system, moving the end module through the tool coordinate system, moving the end

module through a custom coordinate system, moving to the vision initialization position, visual servo oper-

ations, execute step run function, and move to point. In all of the above functions, a hold to run design was

adopted by TM Robot for enhanced safety. There are two types of hold to run in the TM Robot system. For

operations with a higher level risk, the Robot Stick should be used to carry out different types of hold to

run functions. Type 1 is holding down the add/subtract buttons on the Robot Stick to keep the robot mov-

ing. Type 2 is holding down the software buttons on the HMI to keep the robot moving. Both move the robot

while

the button is held down and stops immediately when the physical or virtual button is released. The robot will

resume running if the button is held down again. Some of the functions can be used by both types of hold

to run functions so the user can choose one of the Types to operate. However, if you are using the software

hold to run button from a HMI connected to the robot via TCP/IP or Wi-Fi, if the network is disconnected

then the TM Robot system will automatically disengage the robot and make it stop. In this situation however,

it may take up to 0.7 second for a disconnection to be detected under different network environments. This

means that even if you release the software button the robot may continue to execute the original command.

If the physical button on the Robot Stick is used for hold to run, the system's detection time for button re-

lease is 30 ms. For operations with a higher level risk, the Robot Stick should therefore be used with all hold

to run operations.

Page 23

I Hardware Installation Manual 2. Safety Functions and Interface18

Danger

Danger

Please note that the functions described in this chapter are only intended to speed up the con-

figuration of collaborative safety parameters and settings by the user. It is still up to the user to

conduct a full risk assessment based on the robot's operating environment and conditions be-

fore use. TM Robot explicitly states that serious residual risk may exist in the following scenari-

os: Improper configuration of safety space or running incorrect project may lead to the risk of the

robot colliding with the human body at full speed.

When the TM Flow Compliance function is used within the safety zone, the robot will run the

Compliance function at the set force since it is not controlled by collaborative mode. Please

complete a thorough risk assessment and set an appropriate level of force before using the

Compliance function in collaborative mode.

2.8 Collaborative Mode and Safety Zone Setup

TM Robot can run in standard mode or collaborative mode. In collaborative mode, the robot will run at a

slower speed and use a lower torque based on the user settings. The robot status light will add purple light

display to let the user know whether the robot is in collaborative mode. Please refer to the table in Section

4.2.2.4 for complete light information.

2.8.1 Collaborative Mode and Parameter Configuration

Parameter configuration for TM Robot’s collaborative mode can be divided into two parts. One is

hazard configuration and the other is limit configuration. The hazard configuration page is as shown

below.

Page 24

19I Hardware Installation Manual 2. Safety Functions and Interface

Danger

In this function, the robot speed is calculated according to the durable force and pressure on

medical reports which conform to ISO/TS15066. In addition to the body parts showed in the fig-

ure, other vulnerable body parts such as spine, hindbrain and etc., should be taking into consid-

eration for risk assessment to avoid any possible of collision with TM robot.

For hazard configuration, user can define the locations with risk of robot contact with the human body

within the collaborative space. The robot’s operating speed in collaborative mode and other data

will be shown on the right side of the interface. The settings can be saved once they are confirmed

by the user. The data include the automatic pathing speed and automatic point-to-point movement

speed, when entering the collaborative zone and the surface area of tools that may come into con-

tact with the human body. User should tick the confirmation box in the lower right corner before sav-

ing the settings to confirm the surface area of any potential contact between tools mounted on the

robot and the human body will be larger than or equal to the surface area being confirmed.

Please note that while the values for some calculated data can be modified by the user, only smaller

values can be used. If more detailed parameters must be configured by the user, they can be modi-

fied from the “Additional Limit Configuration Page” as shown below.

In this configuration page for collaborative mode, the user can set servo speed, and servo torque.

Please note that these settings must be smaller than the settings of standard mode. Settings can be

saved once they have been confirmed by the user.

Page 25

I Hardware Installation Manual 2. Safety Functions and Interface20

Danger

Except for defining the safety space setting as all safety space setting as all safety space, the

TM Robot safety space cannot be utilized as a safety device solely. User must conduct a full risk

assessment based on the robot’s operating environment and conditions before use. User can

utilize the qualified safety light curtain, safety laser scanner or other safety devices accompanied

with the instructions in section 2.5 & 5.3.1 about the pause or collaboration actions triggered by

external device via safety IO for correct setup. Other proper design or setup of safety working

environment can also be conducted to prevent people from entering the full speed area. Please

note that the functions described in this chapter are only intended to provide user a clear view of

the safety space setting in 3D space during teaching mode and programming. Also, the safety

planes and spaces setup for collaboration are only intended to assist user recognizing the set-

up of collaboration area and full speed area. The safety planes and spaces cannot be utilized

as a safety function to switch between collaboration mode and full speed mode solely. When

applying the stop planes and spaces in teaching mode, points and motion in forbidden area are

not allowed. The stop planes and spaces cannot be utilized as a safety function to constrain the

robots work space solely. TM Robot explicitly states that serious residual risk may exist in the

following scenarios: Improper configuration of safety space or running incorrect project may lead

to the risk of the robot colliding with the human body at full speed.

2.8.2 Collaborative Space Configuration for Safety

TM Robot offers two ways of configuring the safety space attributes: Planar and Cubic. If the robot

enters the safety space during operation, it will switch to collaborative mode. Planar attributes allow

the user to set either safety plane or stop plane. Cubic can only be used to define safety spaces.

The left side of this page is used for collaborative space configuration. The 3D simulator is in the mid-

dle and the controller interface is on the right side.

Safety Space Configuration Tab:

Click on the safety space to enter this safety space setting page in robot setting page.

Page 26

21I Hardware Installation Manual 2. Safety Functions and Interface

Previously defined attributes will be shown in the list. When the user selects a listed attribute, the 3D

simulator in the middle will display the selected attribute in a transparent blue color. The user can

then delete or reset the selected attribute. The window for setting start reduce distance will appear

after the Start Reduce Distance setting button pressed, and the user can set the distance for the

collaboration area and stop space separately. The robot will start to reduce the motion speed when

moving in the start reduce zone, but the status of the indication light ring would not be change.

Add/Edit Plane Tab:

The collaborative space configuration functions are as shown below.

Add Plane

Add Cube

Delete Selected Attribute

Reset Attributes

Set Start Reduce Distance

Switch to Safety Plane

Switch to Stop Plane

Reverse Stop Space

Safety Plane

Stop Plane

Delete

Set Point

Plane chareacters

Page 27

I Hardware Installation Manual 2. Safety Functions and Interface22

Press the Add Plane button or select a planar attribute then click on the Reset Attribute button to en-

ter the Add/Edit Plane page. In this page, the user can use TCP to define 3 points and create a plane.

The 3 points can be defined in any order and corresponding colored spheres will appear in the 3D

simulator. Once all 3 points have been set, then a transparent blue virtual plane will appear. Now,

click on the Confirm button to create the plane. Please note that the virtual plane will not appear if

there are common points or the points are collinear. In this case clicking on Confirm will not create a

plane.

The button functions are as shown below.

Add/Edit Cube Tab

Set the first point

Set the second point

Confirm plane creation

Cancel plane creation

OK Cancel

Set the third point

Page 28

23I Hardware Installation Manual 2. Safety Functions and Interface

Danger

The safety space setting is achieved by complex algorithms. Under specific settings, the setting

result may not be as expected. User is responsible for assuring the result shown in 3D figure is

correct. Improper configuration of safety space or running incorrect project may lead to the risk

of the robot colliding with the human body at full speed.

Set the first point Set the second point

Confirm cube creation

Cancel cube creation

OK Cancel

Set the third point Set the fourth point

When finishing the safety space setting, user can access the safety space setting through the col-

lapsible on the right side of the project page.

Press the Add Cube button or select a cubic attribute then click on the Reset Attribute button to enter

the Add/Edit Cube page. In this page, the user can use TCP to define 4 points and create a cube.

The 4 points can be defined in any order and corresponding colored spheres will appear in the 3D

simulator, but it should follow the indicated rules. Once all 4 points have been set then a transparent

blue virtual cube will appear. Now click on the Confirm button to create the cube. Please note that

the virtual cube will not appear if there are common points or the points are collinear. In this case

clicking on Confirm will not create a cube.

The button functions are as shown below.

Page 29

I Hardware Installation Manual 2. Safety Functions and Interface24

Danger

The Intelligent Slowdown function will be activated if the position of the TCP start point is in the

full speed area and the TCP end point is in the collaboration area. As a result, the Intelligent

Slowdown function will not be activated if the start point and the end point are both located in

the full speed area, even though the motion path passes through the collaboration area.

Intelligent Slowdown function can force the robot to slow down before exiting the full speed area to

collaboration area. The motion of TM ROBOT when applying Intelligent Slowdown is in accordance

with the position of the start point and the end point and the type of motion setting.

Please access the safety setting via the collapsible on the right side of the project page. When pre-

view button is pressed, the 3D simulator will show the bound safety space with the chosen safety

setting and binding base. Edit function allows the user to modify the safety space shown in 3D sim-

ulator. User should be responsible for his own safety and assure the result shown in 3D figure is

correct. For safety space not shown as expected, please delete the latest safety plane and reset the

safety space via edit function.

The generated safety space is displayed on the 3D simulator.

Remove/add/edit planes to modify the safety space shown in

3D simulator.simulator.

Save the safety space shown in 3D simulator.

Preview

Edit

Save

Page 30

25I Hardware Installation Manual 2. Safety Functions and Interface

Click on the preview button. If the safety space needs to be modified, then click on the Edit button

below Step 2 and modify it in the setting page.

If the modification is complete, click on the Save button at the top to save and leave this page.

If you do not need to modify, you can click on the X button at the top right corner and return to the

settings page without save.

Page 31

I Hardware Installation Manual 3. Transportation 26

3. Transportation

Transport the Techman Robot using its original packing materials. If you will need to transport the Techman

Robot after unpacking, store the packing materials in a dry place. Hold both arms of the Techman Robot

during transportation. Support the arms before tightening the base screws.

Transport the control box by its handles. Store the cables before transportation.

Pay attention to your posture when moving the arm and control box cartons to avoid back injury. Tech-

man Robot will not be liable for any injuries cased during transportation.

Warning

Page 32

27I Hardware Installation Manual 4. System Hardware

Robot arm

Control Box

Robot Stick

4. System Hardware

4.1 Overview

This chapter introduces the mechanical interface of the Techman Robot System.

4.2 System Overview

Techman Robot is made up of the robot arm and control box (including a robot stick).

Page 33

I Hardware Installation Manual 4. System Hardware28

4.2.1 Robot Arm

4.2.1.1 Robot Range of Motion

Techman Robot's working range is a spherical space with a 700mm radius at the base (for

TM5-900, it is a 900mm radius). Due to the limitations of configuration, try to avoid moving the

center of the tool to the cylindrical space below and above the base.

TM5-700 Movement Range Diagram

Page 34

29I Hardware Installation Manual 4. System Hardware

Operator Position

Warning: Risk of crushing

within the operating area of

the arm.

Warning: Risk of collision within

the operating area of the arm.

Page 35

I Hardware Installation Manual 4. System Hardware30

TM5-900 Movement Range Diagram

Operator Position

Warning: Risk of crushing

within the operating area of the

arm.

Warning: Risk of collision within

the operating area of the arm.

Page 36

31I Hardware Installation Manual 4. System Hardware

Page 37

I Hardware Installation Manual 4. System Hardware32

TM5-900/TM5X-900

4.2.1.2 Robot Arm Maximum Allowed Payload

The maximum allowed payload of the robot arm is related to its center of gravity offset, which

is defined as the distance from the center point of tool flange to the payload’s center of gravity.

The following figure shows the relationship between payload and the center of gravity offset:

TM5-700/TM5X-700

Page 38

33I Hardware Installation Manual 4. System Hardware

4.2.1.3 Robot Arm Installation

The TM5 is secured by four holes with a diameter of 11mm on the base and four M10 screws.

A tightening torque of 35Nm (can be adjusted based on the strength of the bolts used) is

recommended. If your application requires more precision, you can use two positioning pins

with a diameter of 6mm for a more secure mounting.

1. The Techman Robot must be securely and tightly screwed down before use. The mounting

surface should have sufficient strength.

2. Do not immerse the Techman Robot in water. Installation in the water or a humid environment

may lead to damage.

Danger

Page 39

I Hardware Installation Manual 4. System Hardware34

Analog I/O

VISION button

POINT button

FREE button

Digital I/O

Indication Light Ring

4.2.2 Robot End Module

4.2.2.1 End Module Components

GRIPPER button

Camera module

Flange (ISO 9409-1-50-4-M6)

Page 40

35I Hardware Installation Manual 4. System Hardware

GRIPPER button

POINT button

Digital I/OAnalog I/O

FREE button

TM5X End Module Components

Flange (ISO 9409-1-50-4-M6)

Indication Light Ring

Page 41

I Hardware Installation Manual 4. System Hardware36

4.2.2.2 End Flange Surface

Page 42

37I Hardware Installation Manual 4. System Hardware

4.2.2.3 End Mounting Caution

The TM5 uses four M6 threaded holes on the end flange and four M6 screws for mounting

tools. A tightening torque of 9Nm is recommended. If your application requires higher precision,

you can use two positioning pins with a diameter of 6mm for a more secure mounting.

4.2.2.4 End Indication Light Ring Table

The Indication Light Ring of the TM Robot has several colors which represent different modes

and error statuses. Look up the following table which contains troubleshooting methods:

Tools must be appropriately and securely tightened when using this product. Improper tightening

may cause the tool or part to fall out, or even cause personal injury and death.

Danger

Color/blinking Description Troubleshooting

Solid green light

Standby status in Manual Mode

(Manual Control mode)

N/A

Flashing green light

Project running in Manual Mode

(Trial Run mode)

N/A

Short Flashing Green light Project paused in Manual Mode. N/A

Alternating between Green/Red light

(with buzzer 2 beeping)

Manual Mode Error

Press the FREE button to troubleshoot

the error.

Solid blue light Standby status in Auto Mode N/A

Flashing blue light Project running in Auto Mode N/A

Short Flashing Blue light Project paused in Auto Mode N/A

Alternating between Blue/Red light

(with buzzer 2 beeping)

Auto Mode Error

After switching to Manual Mode, press

the FREE button to troubleshoot.

Light blue light Safe Startup Mode

Release the Emergency button to return

to the original mode.

Flashing red light Robot is initializing. N/A

Flashing red light (with buzzer 1

beeping)

Emergency stop pressed

Release the Emergency button to return

to the original mode.

Solid red light Buzzer emits a long

beep

Fatal error Shutdown and Restart required

Page 43

I Hardware Installation Manual 4. System Hardware38

When the user sets the safety space and the robot moves into the safety space, the robot will

enter the collaborative mode. At this time, the purple light will be added. Please refer to the fol-

lowing table for the definition of each status:

Mode Standby/running Space Color/blinking

Manual Mode

Standby status

Full speed Space Solid green light

Collaboration Space Alternating between Green(9)/Purple(1)

Stop Space Alternating between Green/Red

Project running

Full speed Space Flash green light

Collaboration Space Alternating between Purple/Red

Stop Space Alternating between Green/Red

Auto Mode

Standby status

Full speed Space Solid blue light

Collaboration Space Alternating between Blue(9)/Purple(1)

Stop Space Alternating between Blue/Red

Project running

Full speed Space Flash blue light

Collaboration Space Alternating between Purple/Red

Stop Space Alternating between Blue/Red

Page 44

39I Hardware Installation Manual 4. System Hardware

4.2.3 Control Box

The control box can be placed on the floor or on a rack. Note that 5cm clearance should be left at

both sides for air flow.

Note

4.2.3.1 Robot Stick

The Robot Sticks has 6 function buttons, 3 indicator lights, 1 emergency button, and 1 QR-

code. There functions are as follow:

Page 45

I Hardware Installation Manual 4. System Hardware40

Item Basic Function

Emergency Button Default emergency button for the robot

Power Button Bootup (single press)/ Shutdown (long press)

Mode Switch Button Cycle Manual/Auto Mode (single press). See Section 2.6 for details.

Play/Pause button Play/Pause Project (press once)

Stop button Stop Project (press once)

Add/Subtract button Adjust project speed (press once) under Manual Trial Run Mode. See Section 2.6

for details.

Power Indicator

Shows the robot's power status.

Not on: Switched off

Flashing: Booting

Constant:Startup completed

Mode Indicator Lights The two lights are Manual and Auto. They show the robot's current operating mode.

Once bootup is complete only one will always be on.

QR Code Label Shows the SSID of the robot's own software AP. The content of the SSID is also the

robot's name in TCP/IP network.

Item Advanced Function

Emergency Button Hold down before bootup to enter Safe Startup Mode.

Play/Pause button Play/pause visual calibration operation (press once)

Stop button Stop visual calibration operation (press once)

Add/Subtract button

- Hold to jog the robot at the HMI robot controller page (Hold to Run).See Section 2.7

details.

- Lock/ Unlock: hold down both add and subtract until the mode indicator flashes,

then follow the sequence "Subtract Add Subtract Subtract Add" when pressing the

add/subtract buttons to lock/unlock the Robot Stick (except the Power button)

Some of the function buttons offer the following advanced functions:

Page 46

41I Hardware Installation Manual 4. System Hardware

The robot stick is magnetic so that it can be attached to magnetic surfaces. However, the risk of

falling or rotating caused by poor attachment should be taken into account. It is recommended us-

ing the official Robot Stick Stand (official accessasory) to secure the robot stick. In that case, the

Robot Stick Stand should be fixed with screws. Do not freely place the robot stick when it is not

fixed. The robot stick should be placed in a way that the signal cables are routed properly to avoid

damage caused by pulling.

1. The control box, cables, power signal cables, and robot stick cannot be used when any of them

is in contact with liquids. This may result in personal injury or death.

2. The control box has an IP20 rating so that it cannot be used in environments with powder and

moisture. Particular attention should be paid to environments with conductive dust (such as metal

swarf).

Note

Danger

Page 47

I Hardware Installation Manual 5. Electrical Interface42

5. Electrical Interface

5.1 Overview

This chapter introduces all electrical interfaces of the robot arm and control box.

5.2 Electrical Warnings and Cautions

The application design and installation of the robot should comply with the warnings and cautions below.

1. Ensure all pieces of the equipment are kept dry. If water enters the equipment, disconnect the

power and contact your supplier.

2. Only use the original cables included with the robot. If you need longer cables, contact your

supplier.

3. Ensure the robot is properly grounded. If the grounding is not correct, it may cause a fire or

electric shock.

Danger

The I/O cables used for the link between the control box and other equipment should not be lon-

ger than 30 meters, unless testing shows that longer cables are feasible.

Warning

Page 48

43I Hardware Installation Manual 5. Electrical Interface

5.3 Control Box

5.3.1 Safety Connector

Provides expansion ports for Emergency Stop(ESTOP) & Safety Stop.

A) ESTOP is a N.C. contact (Normally closed). When ESTOP SW is OPEN,the robot arm enters the

Emergency STOP state.

B) Safety A&B is a N.C. contact (Normally closed). When Safety SW is OPEN,the robot arm enters

the Pause state.

Front control box configuration

Except for USB ports, other interfaces have to be installed while arm is shutdown. Do not install

while arm is on to avoid abnormal shutdown.

Warning

Page 49

I Hardware Installation Manual 5. Electrical Interface44

The factory safety settings are shown below. Operations can be performed without addition of safety

devices, as shown below.

Application settings of the arm safety device

Page 50

45I Hardware Installation Manual 5. Electrical Interface

5.3.2 Power Connector

A) During boot, the control box will check for an external 24V input. If none is available then it will

switch to the internal 24V supply.

B) The control box itself offers a 24V1.5A output (24_EX). If the 24V load exceeds 1.5A, it enters

Safe Mode and disables the 24V output.

C) EX24V provides an external 24V input port. If the load exceeds 1.5A an external power supply

can be used instead. The load on EX24V must not exceed 3.5A.

5.3.3 Digital In/Out

Digital In/Out have 16 Channel each, it should be connected as follows,

A) Digital Input: If sensors are connected directly then they should be of the NPN type.

Page 51

I Hardware Installation Manual 5. Electrical Interface46

B) Digital Output: The maximum drive current is 100mA per channel. If the load exceeds 100mA, a

relay should be used to drive it.

Page 52

47I Hardware Installation Manual 5. Electrical Interface

5.3.4 Analog In

Analog In only supports voltage mode and detection range of -10.00 V ~ +10.00 V.

Page 53

I Hardware Installation Manual 5. Electrical Interface48

5.3.5 Analog Out

Analog Out only supports voltage mode and detection range of -10.00 V ~ +10.00 V.

5.3.6 EtherCAT: For EtherCAT Slave I/O Expansion

5.3.7 USB Port

The USB port of the control box is used for connecting the keyboard, mouse and external storage

devices. External storage devices should only be used for the import/export functions of TM Flow. No

USB devices other than those listed above should be connected.

Robot must be powered off when installing the EtherCAT Slave. Do not plug or unplug the con-

nector while robot is on.

Warning

The large differences in the specifications of external storage devices on the market may inter-

fere with high-speed vision transmission while the robot is in operation so do not use your own

external storage devices while the robot is running. TM Robot's vision image storage function is a

value-added function that can only be used with the dedicated SSD kit sold through the TM Robot

website. Interested buyers should contact the TM Robot website.

Note

Page 54

49I Hardware Installation Manual 5. Electrical Interface

Pin Wire color Pin define

ᅠ

1 Brown +24V 24V output

2 Red DI_0 Digital intput0

3 Orange DI_1 Digital intput1

4 Yellow DI_2 Digital intput2

5 Green DO_0 Digital outtput0

6 Blue DO_1 Digital outtput1

7 Purple DO_2 Digital outtput2

8 Black +0V +0V

Pin Wire color Pin define

ᅠ

1 Brown +24V 24V output

2 Red DI_0 Digital intput0

3 Orange DI_1 Digital intput1

4 Yellow DI_2 Digital intput2

5 Green DO_0 Digital outtput0

6 Blue DO_1 Digital outtput1

7 Purple DO_2 Digital outtput2

8 Black +0V +0V

8-pin digital I/O connector of Robot

8-pin digital I/O connector of Cable

5.4 Tool End I/O Interface

There are two small connectors on the tool end of the robot: a 8-pin connector and a 5-pin connector.

5.4.1 I/O Terminals

The tool end 24V has a maximum output current 1.5A. If overloading, overload protection is activated

and the robot will turn off the 24V output power.

Page 55

I Hardware Installation Manual 5. Electrical Interface50

Pin Wire color Pin define

ᅠ

1 Black AI Analog Input

2 Brown RSV Reserve

3 Red RSV Reserve

4 Orange GND GND

5 Yellow GND GND

Pin Wire color Pin define

ᅠ

1 Black AI Analog Input

2 Brown RSV Reserve

3 Red RSV Reserve

4 Orange GND GND

5 Yellow GND GND

5-pin analog I/O connector of Cable

5-pin analog I/O connector of Robot

Page 56

51I Hardware Installation Manual 5. Electrical Interface

5.4.2 Connecting Tool End Digital Out

The following figure shows how to connect the tool end digital output:

5.4.3 Connecting Tool End Digital In

The following figure shows how to connect the tool end digital input:

A) If sensors are connected directly then they should be of the NPN

type.

Page 57

I Hardware Installation Manual 5. Electrical Interface52

5.4.4 Connecting Tool End Analog In

The following figure shows how to connect the tool end Analog input:

5.5 Control Box Interfaces

USB2.0

USB2.0

USB2.0

USB2.0

ETHERCAT

Robot Status Display

Robot Controller Stick Cable

Adjustable Wi-Fi Antenna

Page 58

53I Hardware Installation Manual 5. Electrical Interface

5.6 Control Box Power Interface and Robot Interface

5.6.1 Control Box Power Interface

The power cable of the control box has an IEC plug. The local power plug is connected to the IEC

plug.

The ETHERCAT interface can only be used to connect ETHERCAT devices. Improper connection may

cause stopping of the robot.

Note

The power supply should be equipped with the following

devices:

• Grounding

• Main fuse

• Residual current device (RCD)

It is recommended to install a main switch on the equipment

power supply for robot applications for servicing and

inspection purpose.

Page 59

I Hardware Installation Manual 5. Electrical Interface54

Parameters Minimum value Typical valueᅠMaximum value Unit

Input voltage 100 - 240 VAC

External mains fuse

(100V~120V)

- - 15 A

External mains fuse

(200V~240V) - - 8 A

Input frequency 43 - 63 Hz

The table below shows the electrical specifications:

1. Ensure that the robot is correctly grounded (electrical grounding).

2. Ensure that the input current of the control box is protected by the Residual Current Device

(RCD) and appropriate fuses.

3. Ensure that all cables are correctly connected before the control box is energized. Always use

genuine power cables correctly.

Danger

5.6.2 Robot Interface

The following figure shows the connection interface of the robot. The cables of the robot are

connected to the control box through the interface.

1. When the robot is turned on, do not disconnect cables of the robot. When cables of the robot

are not connected to the connection interface, do not turn on the robot.

2. Do not extend or modify the original cables of the robot.

Warning

Page 60

55I Hardware Installation Manual 6 ~ 7

6. Maintenance and Repair

Maintenance of Techman Robot: Clean the exterior of the Techman Robot periodically, and keep the moving

joints clean. The filter of the control box must be cleaned or replaced periodically (determine how often the

filter is cleaned or replaced depending on the cleanliness of surroundings).

Only the legal distributor or authorized service center should repair the Techman Robot. The user should

not repair it himself or herself.

7. Warranty Statement

7.1 Product Warranty

The user (customer) may make a request to his/her dealer and retailer within any reasonable situation. The

manufacturer will provide warranty under the following conditions:

During the first twelve months of the warranty period (no more than 15 months from the date of shipment),

Techman Robot will provide necessary spares for malfunctioned parts of new equipment due to production

and manufacture error or damage. If the user (customer) has to bear labor costs, a new or refurbished part

can be used for servicing. If equipment defects are caused by improper handling or failure to comply with

manual requirements, this guarantee is invalid. Warranty services do not cover operations conducted by

the dealer or user, such as arm installation, software download. Your warranty request must be made two

months before the warranty is expired. All replaced or returned items are the property of Techman Robot.

This warranty does not cover other requests directly or indirectly related to equipment. No conditions of this

warranty shall attempt to limit or exclude customer's statutory rights or manufacturer's responsibility for

personal injury or death due to negligence. The warranty cannot be extended, even if it is the initial warranty.

Techman Robot reserves the right to charge customers for replacement or service costs, as long as no

warranty terms are violated.

The above-mentioned rules shall not imply a change in the burden of proof to the detriment of the interests

of customers. When equipment becomes defective, we are not liable for compensation for any indirect,

incidental, special, or corresponding damage, including but not limited to profit loss, loss of use, production

loss or other production equipment damage.

When the robot finishes a job and enters maintenance or servicing status, the user should record the

details of each setting for the job; after repairing and installing it to the work position, the user must

make sure that each setting satisfies the original conditions before resuming working status, including

but not limited to:

- Safety Software Settings

- Safety I/O

- Preset operation project

- TCP Settings

- I/O Settings

- I/O Wiring

Danger

Page 61

I Hardware Installation Manual 6 ~ 756

7.2 Disclaimer

Techman Robot will continuously improve the reliability and performance of the product. Therefore, we

reserve the right to upgrade the product without prior notice. Techman Robot has verified the accuracy and

correctness of this Manual, but will not liable for any erroneous or omitted information.

Page 62

57Appendix

Stop Time and Distance Table

Axis 1 Axis 2 Axis 3

Load (kg) Axis speed

(˚/sec)

Stop time

(ms)

Stop distance

(˚)

Stop time

(ms)

Stop distance

(˚)

Stop time

(ms)

Stop distance

(˚)

2

36 600.44

6.912 600 7.25 598.78 7.238

72 601.3 13.764 600.52 14.042 601.08 14.22

108 598.794 20.61 600.2 21.034 599.98 21.244

144

593.07 27.438 597.56 27.876 600.68 27.95

180 594.94 33.28 600.84 34.006 598.36 34.95

4

36

602.25

6.86 598.82 7.148 600.16 7.114

72 600.31 13.71 600.04 14.222 600.5 14.27

108

600.55 20.51 600.02 21.012 600.74 21.076

144 601.08

27.346

601.3 27.862 598.96 28.082

180 594.44 33.834 598.82 34.972 601.72 34.976

6

36 600.14 6.83 598.976 7.194 599.56 7.162

72 599.64 13.616 598.3 14.19 601.68 14.186

108 599.98 20.526 598.7 21.034 599.24 20.962

144 600.48 26.766 600.04 27.76 599.68 27.98

180 598.09 33.986 600.68 34.892 600.76 35.044

Appendix A. Stop Time and Distance

Page 63

Appendix58

Model TM5-700 TM5-900 TM5X-700 TM5X-900

Weight

22kg 22.2kg 21.7kg 21.9kg

Payload

6kg 4kg 6kg 4kg

Reach

700mm 900mm 700mm 900mm

Joint ranges:

J

1

:

+/- 270˚

J

2,J4,J5

:

+/- 180˚

J

3

:

+/- 155˚

J

6

:

+/- 270˚

Speed:

J

1~J3

:

180˚/s.

J

4~J6

:

225˚/s.

Repeatability

+/- 0.05 mm

Degrees of freedom

6 rotating joints

I

/

O ports:

Digital in

Digital out

Analog in

Analog out

Control box

16

16

2

1

Tool conn.

3

3

1

0

I

/

O power supply

24V 1.5A for control box and 24V 1.5A for tool

IP classification

IP54(Arm)

Power consumption

Max. 1300 watts

Temperature

The robot can work in a temperature range of 0-50˚c

Power supply

100-240 VAC, 50-60 Hz

I

/

O Interface of Control Box

3×COM, 1×HDMI, 1×EtherCAT, 2×GigE, 1×LAN,

4×USB2.0, 2×USB3.0, 1×VGA

Robot Vision

Eye in Hand

(

Built in

)

1.2M/5M pixels, color camera N/A

Eye to Hand

(

Optional

)

Support Maximum 2 GigE cameras

Technical Specifications

Appendix B. Technical Specifications

Page 64

59Appendix

Loading...

Loading...