Page 1

䠄 䠅

Page 2

[SPECIFICATION]

*Refer to the 2pages for other Cal. No. specifications.

φ23.70 mm

22.60 mm : between 12 o'clock and 6 o'clock sides

22.60 mm : between 3 o'clock and 9 o'clock sides

φ23.30 mm

22.10 mm : between 12 o'clock and 6 o'clock sides

21.40 mm : between 3 o'clock and 9 o'clock sides

3.45 mm

Cal. No.

Electronic circuit reset switch

Second setting device

Date setting

Day : Retrogade

SR920SW (Silver oxide battery)

Battery life is approximately 2 years

Use 10-second gate

* Set the winding stem with crown at the normal position

* All specifications are subject to change without notice.

Day -Calendar

Hand (10H)

-

○

SII Products

Driving System

Step motor

Additional mechanism

Antimagnetic

≧1600 A/m

Accuracy

Less than ±15seconds : Monthly rate at normal temperature range

Battery

Measuring gate

by quartz tester

Jewels

2 Jewels

1

Date -Calendar

Hand (12H)

--○

-

Date -Calendar

Hand (3H)

○--

○

VH88A

3Hands

(hour,minute,second)

○

○

○

○

Time

indication

24Hour hand (6H)

Date -Calendar

Hand (2H)

Day -Calendar

Hand (9H)

PARTS CATALOGUE / TECHNICAL GUIDE

VH8 Series

Version-01

Cal. No.

VH83A

Item

Movement

Movement

size

Outside diameter

Casing diameter

Total height

VH83A

Page 3

2

SII Products

MOVEMENT VARIATION

Version-01

VH8A

VH88

VH83

date

24hours

day

date

24hours

day

Page 4

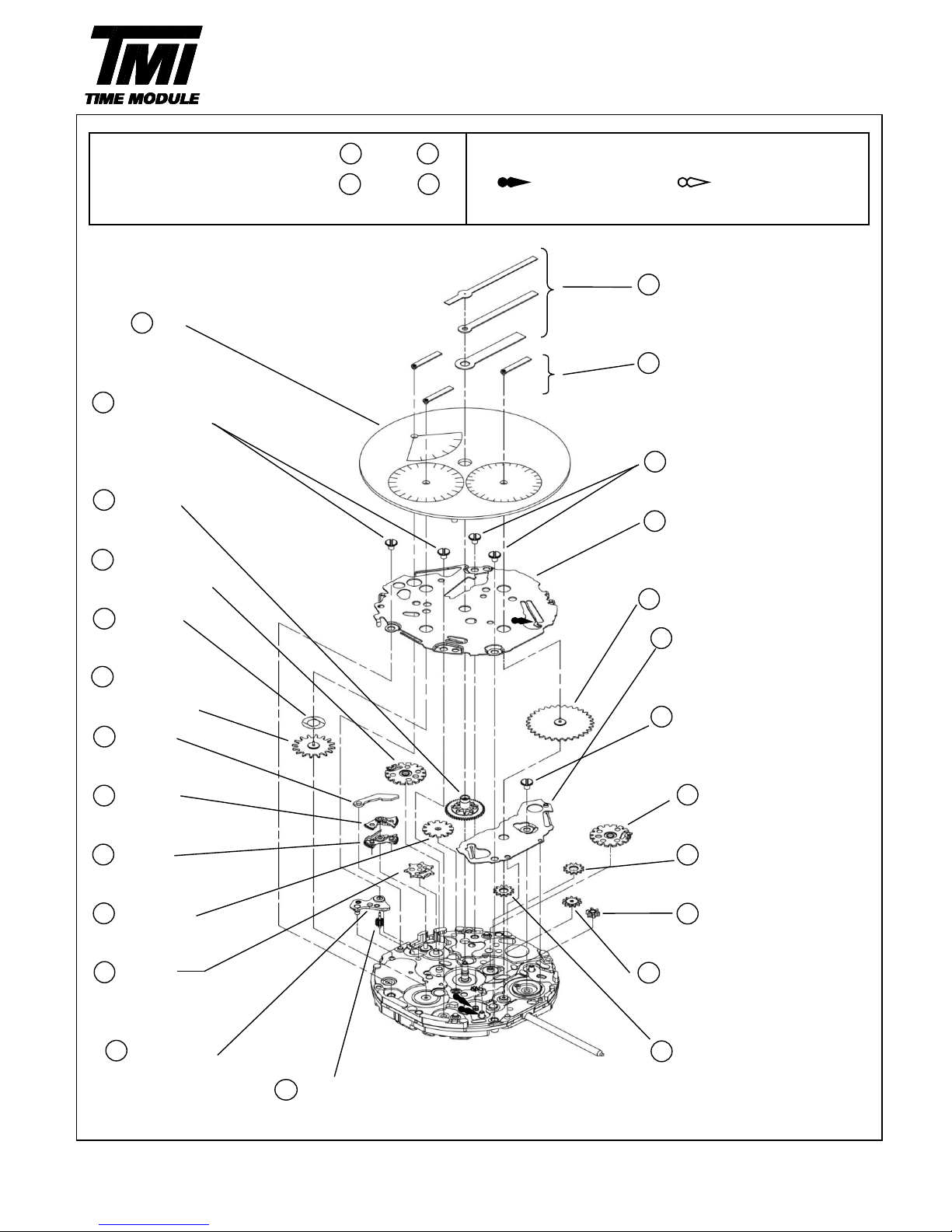

Disassembling procedures Figs. Lubricating : Types of oil Oil quantity

Reassembling procedures Figs.

Moebius A

Normal quantity

*Refer to the 6pages for the each parts code

Hour , Minute ,Second hands

Dial

Date-Day calendar,24Hour

hands

0012 354

4 0012 354

Support for dial side parts screw

0273 043

Hour wheel 5 0604 170 *

Support for dial side parts

0802 469

Day driving wheel

0970 004 Date Star

0491 014

Dial washer 0836 005 *

Intermediate wheel for date

0157 018 corrector holder

Small hour hand wheel

0012 354

0873 169 Intermediate wheel for date

Day jumper corrector holder screw

0585 169 0802 469

Hammer A Date driving wheel

0585 170 0962 033

Hammer B Intermediate wheel for

date corrector C

0817 049 0737 169

Intermediate hour wheel

Date corrector wheel

0505 169 0737 006

Day transmission wheel Intermediate wheel for

date corrector D

0125 324 0962 033

Day wheel bridge

Intermediate wheel for

1019 012 date corrector B

Day wheel

Version-01

VH8A

PARTS CATALOGUE

1⇒24

3

SII Products

24⇒1

1021241192023

22

Support for dial

side parts screw

14171819815161213

<<VH83A>>

124

3

6

7

Page 5

Disassembling procedures Figs. Lubricating : Types of oil Oil quantity

Reassembling procedures Figs.

Moebius A Normal quantity

*Refer to the 6pages for the each parts code

Hour , Minute ,Second hands

Dial

Date-Day calendar,24Hour

0012 354 hands

0012 354

Support for dial side parts screw

0273 043

Hour wheel 0604 160 *

Support for dial side parts

0802 469

Day driving wheel

0491 014

0970 004 Date Star

Dial washer

0836 006 *

0157 018 Intermediate wheel for date

Small hour hand corrector holder

wheel

0873 169 0012 354

Day jumper Intermediate wheel for date

corrector holder screw

0585 169

Hammer A 0802 469

Date driving wheel

0585 170 0804 170

Hammer B Intermediate wheel for

date corrector C

0125 324 0737 169

Day wheel bridge

Date corrector wheel

1019 012 0737 006

Day wheel

Intermediate wheel for

date corrector D

0962 033

0505 169 Intermediate wheel for

Day transmission wheel date corrector B

⇒

1

3

Version-01

VH8A

PARTS CATALOGUE

1⇒23

23

124520

4

SII Products

1314212312111516179221910

4

Support for dial

side parts screw

18

7

6

8

Page 6

Disassembling procedures Figs. Lubricating : Types of oil Oil quantity

Reassembling procedures Figs.

Moebius A

Normal quantity

Moebius F

Liberal quantity

*Refer to the 6pages for the each parts code

*Battery connection(+)

0351 177

27⇒1

PARTS CATALOGUE

Version-01

VH8A

1⇒2798111273

14

SII Products

1351517212061618

19

2 0012 168

Battery connection (+) screw

3 4268 076 *

Battery connection(+)

4 4216 103

Insulator

7 0144 004

Fourth wheel and pinion

8 0560 005

Friction spring for

fourth wheel and pinion

14 0281 015

Setting wheel

16 0261 052

Minute wheel

and pinion

25 0012 354

Center wheel

bridge screw

27 0221 089 *1

Center wheel

and pinion

23 4002 070

Coil block

5 4270 339

Battery

connection(-)

6 0125 321

Train wheel bridge

10 0701 017

Fifth wheel and pinion

15 0391 029

Train wheel

setting lever

17 0383 891

Setting lever

18 0384 452

Yoke

20 0282 452

Clutch wheel

21 0804 169

Intermediate wheel for

date corrector A

19 0351 177

Winding stem

13 4004 474

Circuit block

11 0706 008

Sixth wheel and pinion

9 0231 061

Third wheel and pinion

12 4146 104

Step rotor

26 0121 060

Center wheel bridge

24 4239 065

Stator

22 0012 354

Coil block screw

*1

Main plate

1 Battery

Page 7

Remarks:

Different parts for each CAL.

* All parts code are subject to change without notice.

PARTS CATALOGUE

Version-01

VH8A

Parts name

Parts code

VH83A

VH88A

Battery connection(+)

4268 076

O

―

4268 078―O

Intermediate wheel for

date corrector C

0962 033

O

―

0804 170―O

Intermediate wheel for

date corrector holder

0836 005

O

―

0836 006―O

SII Products

6

Support for dial side parts

0604 017

O

―

0604 016―O

Page 8

・The explanation here is only for the particular point of Cal.VH8A

1.REMARKS ON DISASSEMBLING AND REASSEMBLING

(1) Day wheel

・How to install:

①Set Lever of Hammer A along the pin of the main plate.

②After confirm that gears of Hammer A and B are engaged each other, set Day wheel vertically.

【VH83】

【Hammer A 】

(2)HAND

・How to install hands:

Place the movement directly on a flat metal plate

or such a hard plate when you install the hands.

Necessary procedure to setting hands:

①The state of movement is confirmed by the position of

a right picture.

Day transmission wheel

Pull out the crown to the second click position and

rotate to set the position of Day transmission wheel

and Support for dial side parts.

②Set the dial.

③Install the date calendar hand at the 12 o'clock position.

④Install the Day calendar hand at the first position.

⑤Pull out the crown to the second click position,

and change the date by rotating the crown clockwise.

⑥Install the 24hour, hour, minute and second hands

at the 12 o'clock position.

Necessary procedure to setting hands:

(3)Day calendar (Retrograde) hand

first position

・Quick moving of Day calendar hand

The hand instantaneously returns from B position

to A position when one week passes.

TECHNICAL GUIDE

Version-01

VH8A

SII Products

7

Support for dial side parts

Direction of rotation

Metal plate

B position

A position

Lever

Pin of the

Main plate

Day

Page 9

(4)Winding stem

・How to remove:

Pull out the winding stem while pushing

the indented portion of the arrow.

(5)Battery

・How to install:

Insert the battery in the aslant direction as shown by the arrow.

Check that the battery connection (+) touches securely

the side face of the battery.

・How to remove:

Firstly slide the battery in the direction of the arrow with

tweezers,and then lift the battery.

(6)Insulator

・How to set:

To insulate between the battery connection (+)

and the battery connection (-), the insulator

should be put at the two pins securely as bellow.

(7)Day jumper and Support for dial side parts

・Reassembling procedures

The support for dial side parts spring sets to the

day jumper. (A position)

Day jumper

Support for dial side parts spring

A position

TECHNICAL GUIDE

Version-01

VH8A

SII Products

8

Insulator

Pin

Push

Page 10

(8)Setting position (at the time of disassembling and reassembling)

・How to set the Date & Day driving wheels in the correct position:

Note:

Set the indicator finger of a Date & Day driving wheels to the setting position mark on the Main plate.

≪Cal.VH83A setting position≫ ≪Cal.VH88A setting position≫

Indicator finger

Setting position

SII Products

9

TECHNICAL GUIDE

Version-01

VH8A

Setting position

Setting position

Indicator finger

Date driving wheel

Indicator finger

Day driving

wheel

Enlargement

Enlargement

Page 11

・How to assemble and set the Date & Day jumpers of the support of dial side parts:

There are two hooks on the support for dial side parts. (Fig.1)

First, assemble the two hooks on the support for dial side parts

to the position of the built-in height A of the base plate. (Fig.2)

Set the Date & Day jumper to the teeth of the Date star & Day wheel.

Second,assemble the two hooks on the position of the built-in height B of the base plate. (Fig.3)

example VH83A

Fig.1 (example VH83A)

Fig.2 (built-in height A) Fig.3 (built-in height B)

TECHNICAL GUIDE

Version-01

VH8A

SII Products

10

height A position

height B position

Page 12

*1: Hour hand

*4:

Date calendar hand

*7:

Crown at normal position *9: Second click

*2:

Minute hand

*5:

Day calendar hand

*8:

First click

・Time setting

*3:

Second hand

*6:

24Hour hand

・Date setting (Quick change function)

1.Pull out the crown to the 2.Push the crown back 3.Pull out the crown to 4.Push the crown back

second click when the into the normal position the first clik. into the normal position.

second hand is at the

in signal. Turn the crown counter-

12 O'clock position.

clockwise to set the date.

Turn the crown rotation to

set the day of the week.

Turn the crown to set the

hour and minute hands

to the time.

(Check that AM / PM is

set correctly)

*Do not set the date between 10:00 PM and 2:00 AM

Otherwise the day could not change properly. If it is necessary to set the date during that time period,

once change the time to any time except the period, and then set the date.

After that set the time correctly.

Notes in time setting of Cal.VH8 series

When time setting is done with counterclokwise, date hand might reverse but there is no problem

for the function.

Please set the date by using quick change function when date showing is incorrect.

OPERATION

Version-01

VH8A

DISPLAY AND CROWN OPERATION

≪VH83A≫

≪VH88A≫

SII Products

11

TIME SETTING

Note:

*4

*7

*8

*9

*5

*1

*3

*6

*2

*1

*5

*3

*6

*2

*7

*8

*9

*4

Loading...

Loading...