Page 1

SII Products

TECHNICAL GUIDE

&

PARTS CATALOGUE

Cal. NH0*B

AUTOMATIC MECHANICAL

Revised on : 06. Feb. 2018

Page 2

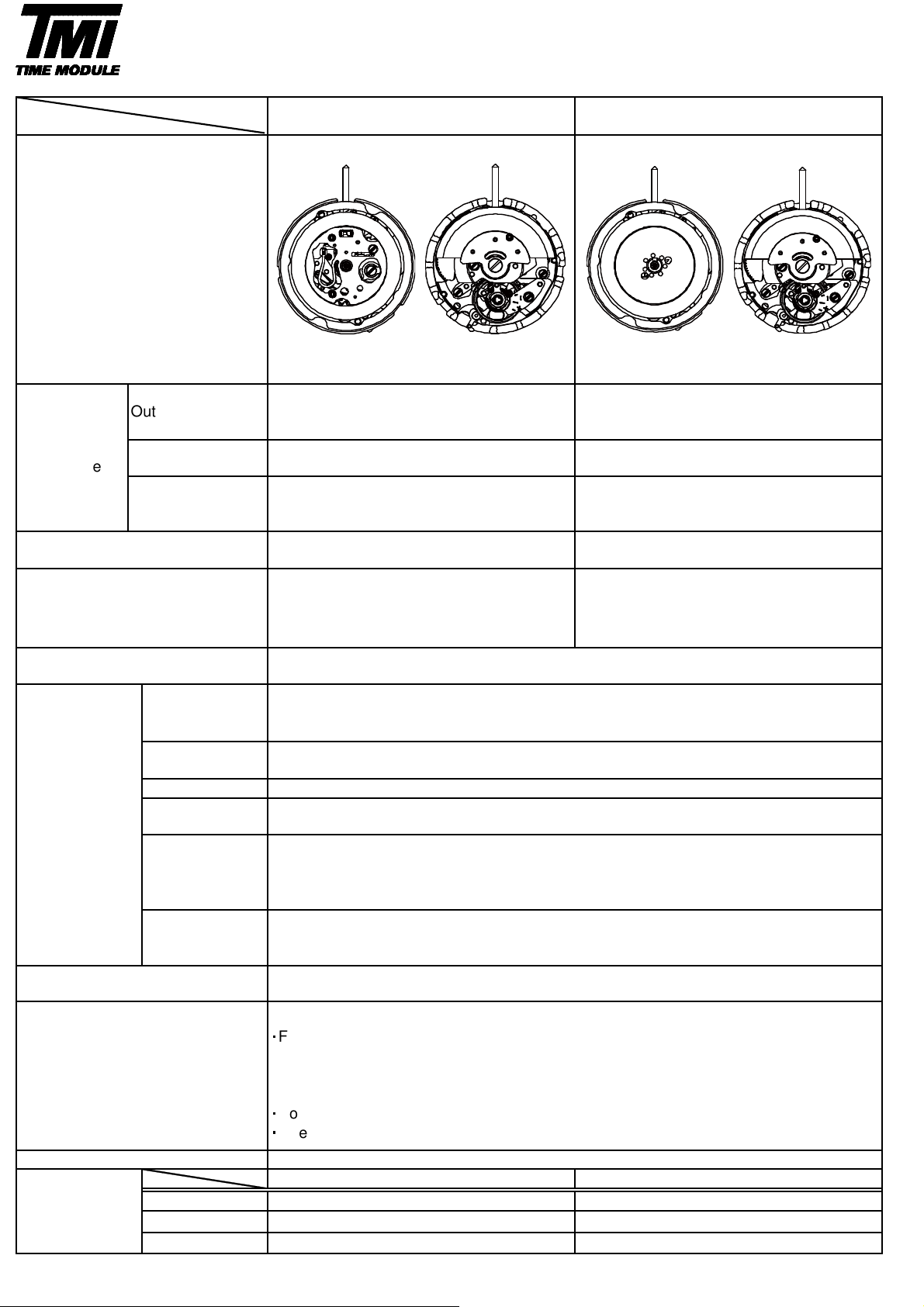

[SPECIFICATION]

SII Products

3 Hands ( Hour , Minute , Second )

3 Hands ( Hour , Minute , Second )

More than 40 hours … Mainspring after fully wound up.

20 seconds

Difference is under 90 seconds within max value and min value.

Measurement

-35~+35 seconds per day.

Measurement

Cal. No.

Item

Movement

PARTS CATALOGUE / TECHNICAL GUIDE

Cal.NH0*B

Version-01

NH05B NH06B

Outside diameter

Movement

size

Time indication

Basic function

Frequency 21,600 vibrations per hour

Accuracy

Casing diameter

Total height

Date Calendar

Manual winding

Automatic winding with ball bearing

Quick date correction

-35~+55 seconds per day

Static accuracy

position

Lift angle 52 deg.

time

* Measurement should be done within 10~60 minutes after fully wound up.

* All measurements are made without the calendar in function.

Direction of 3 positions. (1) Dial up (2) 9 o'clock up (3) 6 o'clock up

* Equipment to be used : Witschi WATCH EXPERT

Ф19.8mm (with Dial support)

Ф17.5mm

5.92 mm

(with Dial support)

Ф17.5mm

Ф19.8mm (with Dial support)

Ф17.2mmФ17.2mm

5.92 mm

(with Dial support)

Day & Date Calendar

Manual winding

Automatic winding with ball bearing

Quick day-date correction

Posture

difference

Isochronisms

(24h-0h)

Duration time

Winding the mainspring

Jewels 21 jewels

Crown

position

Normal position Free Manual winding

First click

* Measurement should be done within 10~60 minutes after fully wound up.

* Direction of 4 positions.

(1) 12 o'clock up (2) 9 o'clock up (3) 6 o'clock up (4) 3 o'clock up

* Direction of position. : Dial up

* Difference of static accuracy of 24h and 0h

* Posture to confirmation : Dial up

<< Movements >>

・

Fully wound up by turning the crown minimum 55 times.

<< Complete Watch >>

A winding machine is needed to wind up the mainspring.

Full wind up conditions

・

Rotary speed : 30 rpm

・

Operating time: 60 minutes

Counterclockwise Clockwise

Date setting NH05B:Free NH06B:Day setting

Time settingSecond click Time setting

1

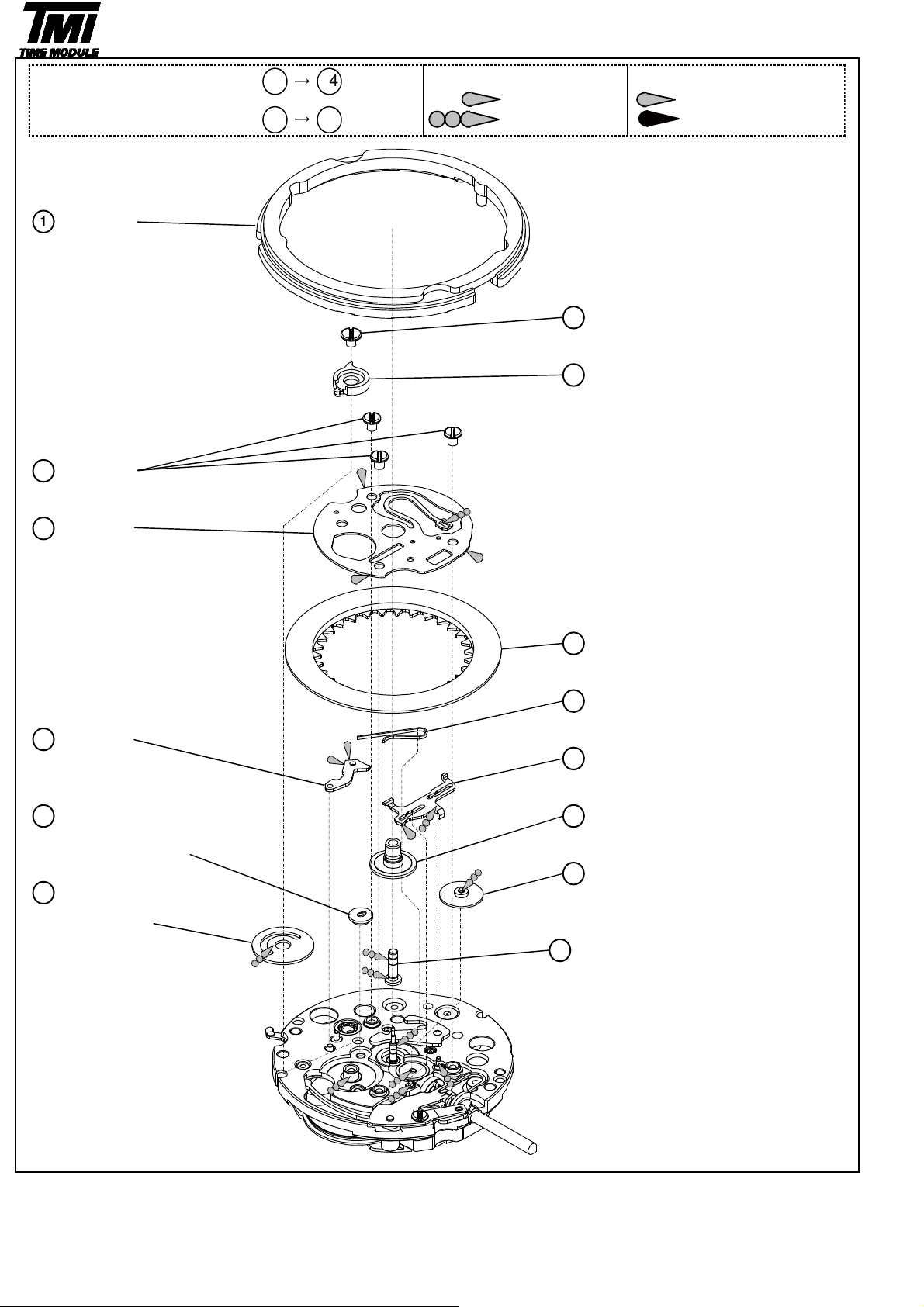

Page 3

*Hour Wheel

*Cannon pinion

*Refer to the page 8 for the each

parts code

SII Products

10

14

Version-01

Cal.NH0*B

PARTS CATALOGUE

1→14

1

14

Disassembling procedures Figs.

Reassembling procedures Figs.

<<NH05B>>

1

0884 172

Dial support

4

0012 485

Date indicator maintaining plate screw

5

0808 424

Date indicator maintaining plate

→

Type of oil Oil quantity mark

Moebius 9010

S-6

2

0016 139

Date indicator driving wheel screw

3

0556 423

Date indicator finger

NORMAL QUANTITY

SUFFICIENT QUANTITY

6

*Date indicator

7

0811 420

Date jumper spring

8

0810 420

Date jumper 0972 423

12

0817 421

Intermediate date driving

wheel and pinion

13

0802 423 Minute wheel and pinion

Date indicator driving wheel

9

Day-Date corrector finger

11

0261 422

2

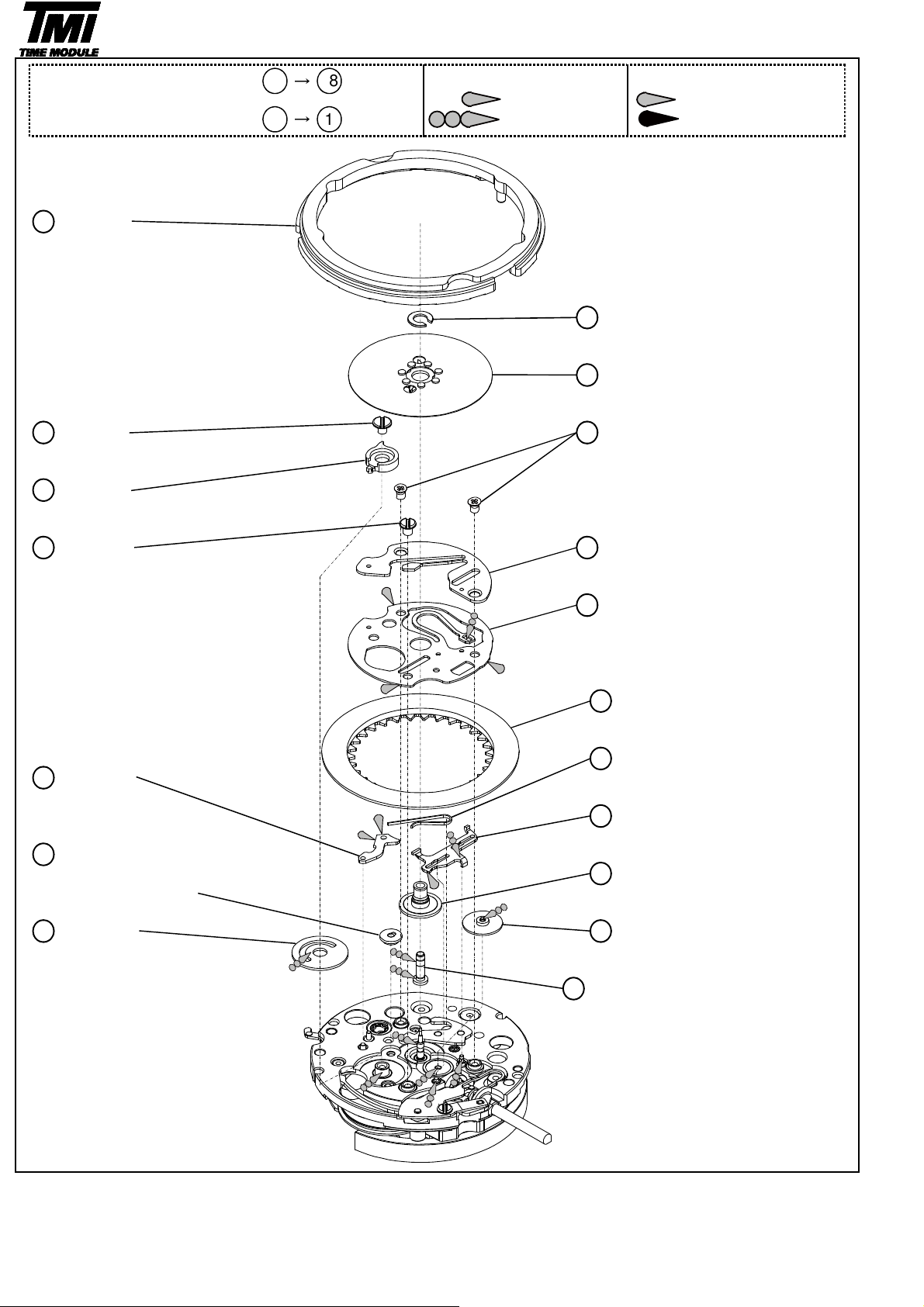

Page 4

*Day star with dial disk

*Hour Wheel

*Cannon pinion

18

10

*Refer to the page 8 for the each

parts code

14

SII Products

3

18→1

Version-01

PARTS CATALOGUE

Cal.NH0*B

1→18

Disassembling procedures Figs.

Reassembling procedures Figs.

Type of oil Oil quantity mark

Moebius 9010

S-6

<<NH06B>>

1

0884 172

Dial support

2

0963 420

Snap for day star with dial disk

4

0016 139 0016 705

Date indicator driving wheel screw Day jumper screw

5

0556 423

Date indicator finger

6

NORMAL QUANTITY

SUFFICIENT QUANTITY

7

0012 485 0873 422

Date indicator maintaining plate screw Day jumper

12

0810 420 Date jumper spring

Date jumper

16

0817 421

Intermediate date driving

wheel and pinion

0802 423 0261 422

Date indicator driving wheel Minute wheel and pinion

8

9

0808 424

Date indicator maintaining plate

*Date indicator

11

0811 420

13

0972 423

Day-Date corrector finger

1517

3

Page 5

*Oscillating weight

*Refer to the page 8 for the each

parts code

9

10

11

12

8

1

3

2

4

7

5

6

1

Version-01

SII Products

PARTS CATALOGUE

Cal.NH0*B

1

40

40

Disassembling procedures Figs.

Reassembling procedures Figs.

0012 485 *1 Oiling position

Framework for automatic device screw

0193 421

Framework for automatic device with ball bearing

0012 484

Balance bridge screw

8-1

Upper shock

absorbing spring

→

→

Type of oil Oil quantity mark

Moebius 9010

S-6

0012 488

Oscillating weight (without pinion) screw

*1

0831 421

Pawl lever

NORMAL QUANTITY

SUFFICIENT QUANTITY

8-2

Upper shock absorbing

cap jewel

8-3

Upper hole jewel frame

for shock-absorber

0173 426

Balance bridge 0012 485

0310 421

Balance complete

with stud 0161 420

*3

*3 Oiling position

*2

0505 421

Reduction wheel and pinion

*2 Oiling position

whole tooth

Pallet bridge screw

Pallet bridge

0301 420

Pallet fork

4

Page 6

Type of oil

Oil quantity mark

SUFFICIENT QUANTITY

*Center seconds pinion

*Center wheel and pinion

*Refer to the page 8 for the each parts code

SII Products

20

31

Version-01

Cal.NH0*B

PARTS CATALOGUE

Moebius 9010 S-6 NORMAL QUANTITY

13

0012 485

Barrel and train wheel bridge screw (B)

14

0396 421

Friction spring for center seconds pinion

15

0012 484

Barrel and train wheel bridge screw (A)

16

0112 427

Barrel and train wheel bridge

17

0381 420

Click

18

0285 420

Ratchet wheel

19

0201 420

Complete barrel with mainspring

*1

21

0231 421

Third wheel and pinion

22

0241 421

Fourth wheel and pinion

23

0012 484

Screw for rocking sheet for sliding crown wheel

24

0363 420

Sliding crown wheel spring

25

0237 421

Intermediate ratchet wheel

26

0542 421

Rocking sheet for sliding

27

0105 421

28

0012 485

29

0121 422

Center wheel bridge

*1 Oiling position (side view)

30

0251 420

Escape wheel and pinion

5

Page 7

Type of oil

Oil quantity mark

Moebius 9010

S-6

NORMAL QUANTITY

*Refer to the page 8 for the each parts code

37

38

39

40

SII Products

35

36

Version-01

Cal.NH0*B

32

33

34

PARTS CATALOGUE

SUFFICIENT QUANTITY

0012 484

Setting lever spring screw

0388 420

Setting lever spring

0384 420

Yoke

0383 420

Setting lever

0390 421

Setting lever axle

40-1

Lower shock absorbing spring

40-2

Lower shock absorbing cap jewel

40-3

Lower hole jewel frame for

shock-absorber

0282 422

Clutch wheel

0283 421

Winding pinion

0351 420

Winding stem

Main plate

6

Page 8

Remarks

List of screws

SII Products

Version-01

Cal.NH0*B

●●●●

PARTS CATALOGUE

Parts No.

0012 485

0012 484

Appearance

4

P-2

Date indicator maintaining plate screw

7

P-3

Framework for automatic device screw

3

P-4

10 Pallet bridge screw

P-4

13

P-5

P-5

P-4

P-5

P-5

P-6

Barrel and train wheel bridge screw (B)

Center wheel bridge screw

28

7

Barrel and train wheel bridge screw (A)

15

23

Screw for rocking sheet for sliding crown wheel

32 Setting lever spring screw

Parts Name

Q'ty

3

1

2

2

1

1

1Balance bridge screw

2

2

1

P-2

2

0016 139

0012 488

0016 705

P-3

P-4

P-3

Date indicator driving wheel screw

4

Oscillating weight (without pinion) screw

1

Day jumper screw

6 2

*All parts code are subject to change without notice.

1

1

7

Page 9

Remarks

Cannon pinion (P-2)

Cannon pinion (P-3)

SII Products

Version-01

Cal.NH0*B

3

Day star with dial disk (P-3)

Cal. code

NH06B

6

Date indicator (P-2)

Cal. code

Parts code

0160 355 3H

Parts code

Position of

crown

Position of

crown

PARTS CATALOGUE

Position of

day frame

3H

Position of

date frame

Color of letters

MON~FRI :Black

SAT

Color of numbers

:Blue

:RedSUN

Color of

background

White

Color of

background

Language

English & Chinese

NH05B

10

Date indicator (P-3)

Cal. code

NH06B

10

Hour Wheel (P-2) Hour Wheel (P-3)

Cal. code

NH05B

14

Cal. code

2

Oscillating weight (P-4)

Cal. code

NH05B

0878 425 3H

Parts code

0148 085

Parts code

0271 425

Parts code

0225 422NH05B

Parts code

1500 436

1500 446

Position of

crown

3H

Marking

Japan mark

Malaysia mark

3H

Position of

date frame

3H Black

14

Cal. code

NH06B

18

Cal. code

NH06B

Color of numbers

Parts code

0271 425

Parts code

0225 422

Black

White

Color of

background

White

1500 438

NH06B

1500 448

20

Center second pinion (P-5) Center wheel and pinion (P-5)

Cal. code

NH05B

NH06B

Parts code

0245 425

*All parts code are subject to change without notice.

Japan mark

Malaysia mark

31

Cal. code

NH05B

NH06B

Parts code

0224 425

8

Page 10

The following explanation is only for Cal.NH05/06B.

Pawl lever (P-4)

Sliding crown wheel spring (P-5)

SII Products

5

5

24

9

NH05B

NH06B

Version-01

Cal.NH0*B

TECHNICAL GUIDE

・

(P-2)

Date indicator maintaining plate

(P-3)

Day-Date corrector finger is set to the hole of Date indicator maintaining plate.

Enlarged

view

Date indicator maintaining plate

Pawl lever has to be set to engage with the teeth of Reduction wheel and pinion.

Reduction wheel and pinion

Enlarged

view

Pawl lever

Please set Sliding crown wheel spring to the side of Sliding crown wheel.

Sliding crown wheel spring

Enlarged

view

Day-Date corrector finger

Intermediate ratchet wheel

Rocking sheet for sliding crown wheel (Attach the Rocking sheet for

Sliding crown wheel

sliding crown wheel)

9

Page 11

1.Setting position

SII Products

Version-01

Cal.NH0*B

Date jumper spring *1 Day-Date corrector finger *3

Date jumper *2

Parts code Cal.

*1 0811 420

*2 0810 420

*3

0972 423

NH05B

NH06B

NH05B

NH06B

NH05B

NH06B

7

11

8

12

9

13

(P-2)

(P-3)

(P-2)

(P-3)

(P-2)

(P-3)

TECHNICAL GUIDE

34

0384 420 (P-6)

Yoke

35

0383 420 (P-6)

Setting lever

2.Setting position of oscillating weight

・

Before assembling oscillating weight.

Please set Oscillating weight according to the straight part of Framework for automatic device.

Framework for automatic device with ball bearing

Enlarged

view

Oscillating weight

10

Page 12

SII Products

Version-01

Cal.NH0*B

TECHNICAL GUIDE

3.How to attach hands

Place the movement directly on a flat metal plate or something

similar to attach the hands.

We recommend the use of movement holder to attach hands.

For hands attachment, please use a special equipment.

When the movement receives a strong shock, it may be damaged.

4.Accuracy measurement condition

Static Accuracy : -35~+55 seconds per day

Measurement Conditions

1) Measurement should be done within 10~60 minutes after fully wound up.

2) Lift angle : 52 deg.

3) Measurement position : (1) Dial up (2) 9 o'clock up (3) 6 o'clock up

4) Minimum measurement Time : 20 seconds

5) Stabilizing Time :

Leave the watch for at least 20 seconds to stabilize after you change its measurement position.

Static weighting

Metal plate

11

Page 13

SII Products

Version-01

Cal.NH0*B

OPERATION

[ NH05B ] [ NH06B ]

Hour hand Minute hand Hour hand Minute hand

Second click Second click

First click First click

Crown at normal position

Crown at normal position

Second hand Second hand

1.Time setting

1) Pull out the crown to the second click position.

2) Turn the crown to set hour and minute hands.

(Check that AM/PM is set correctly.)

3) Push the crown back into the normal position.

2.Date setting

1) Pull out the crown to the first click position.

2) Turn the crown to left for date setting.

* Do not set the calendar between 10:00 P.M. and 1:00 A.M. If the setting of the calendar is made during this period,

the date will not change to the next date. Please set the calendar after changing the time other than

the above period.

3) Turn the crown to right for day setting. … Cal.NH06B only

4) Push the crown back into the normal position.

3.To wind up the mainspring

1) Manual winding

Rotate crown clockwise at normal position by minimum 55 times.

2) To wind up with winding machine.

Full wind up conditions

・

Rotary speed : 30 rpm

・

Operating time : 60 minutes

12

Loading...

Loading...