Page 1

The TMB

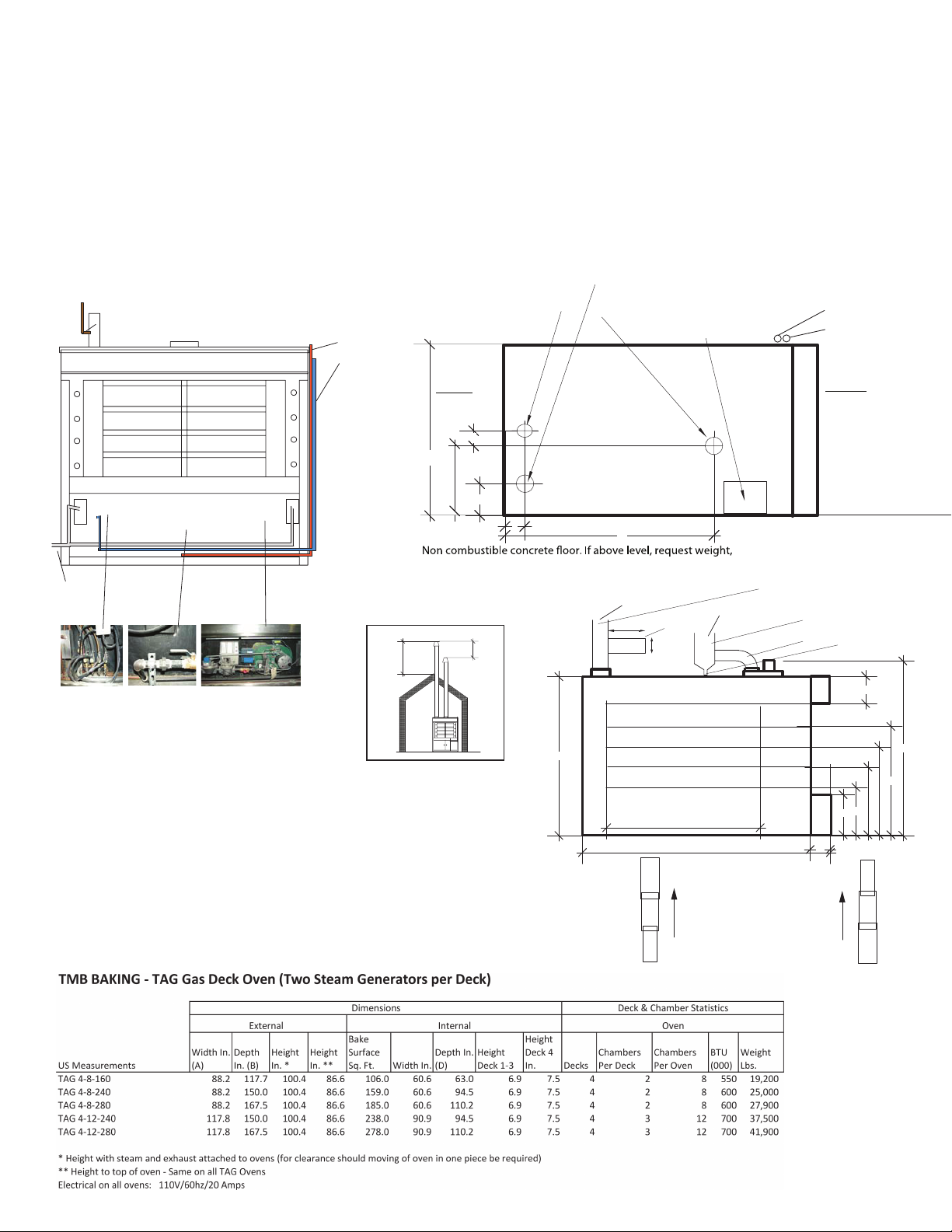

TAG Gas Deck Oven

The TMB TAG Gas Deck Oven is like none other because

of its thermal mass, oversized steam tubes and two steam

generators per deck, which provides fast recovery, even baking

and hard crusts, the hallmark of artisan baking. Designed by

world-renowned baker, Michel Suas, for the rigors of the North

American bakeries vs. their European counterparts, the TAG has

long-standing bakers’ loyalty spanning well over a decade in the

company’s quarter century of industry service.

Baking System—At the heart of the TAG oven are a series of

closed circuit steam tubes, spaced at varying intervals designed

to provide even baking temperature from front to back. These

tubes are manufactured under high-pressure using the Mannesmann process UNI 663/68 standard, with steel Fe 45,2 measuring

0.35 x 5.5mm and guaranteed by certificate, tested one-by-one at

the end of the production cycle. No other manufacturer has this

design and standards resulting in perfect heat distribution.

Double Steam Generators—While most other deck ovens

only steam from the back of the oven with the steam generator located in the base of the oven, the TMB TAG oven has two

steam generators on each deck. This allows the steam to be

injected the full length of each baking chamber for even distribution of steam and maximum, instantaneous and consistent steam

delivery, which is particularly beneficial for special types of bread.

Foundation, Flues and Burner—The foundation of the oven

is made of steel, followed by thermal insulation, steel panels

and finally high-temperature, refractory brick and concrete (flue)

for the heat generated by the burner. The TMB TAG uses more

of these materials than most, if not all other ovens, ensuring the

maximum thermal mass for heat retention and more consistent

heat distribution for the perfect backing system of any style of

bread. TMB employs a US manufactured, UL and AGA listed gas

burner, generating up to 600,000 BTU’s.

Façade and Baking Chambers—The façade and main

panels of the TAG oven are made with ANSI 304 Stainless Steel

to ensure durability in high-temperature, high-humidity environment. The baking chamber windows are made of tempered

glass (when window panels or full glass windows are ordered)

or all stainless steel, and are self-balance and easy to remove for

cleaning. Ovens may be ordered with widows opening downward, or upward, based on the baker’s preference. Baking stone

decks with inner reinforcement deliver longer-lasting heat, evenly

distributed for perfect baking. Finally, the bed plate is provided

with removable doors to ensure easy access to the burner, the

fire box and the flues for easier cleaning.

The Control Panel—TMB Baking designed a custom, ETL-

approved control panel with touch screen and PLC brain to help

deliver consistent baking results for every style of bread. Steam

482 Grandview Drive, South San Francisco, CA 94080 | (650) 589-5724 tel | (650) 589-5729 fax | info@tmbbaking.com email

www.tmbbaking.com

Page 2

The TMB TAG Gas Deck Oven

36

can be delivered in left or right baking chamber when and how

much needed, with timers and warnings keeping the baker informed of my issues of which they should be aware. The control

also interlocks with make-up air and exhaust fans to shut down

ing. The TMB Baking TAG control also comes with a standard,

manual override should the baker wish to use it, or should the

computer be down for any reason. This assures that the baker

will not lose valuable bakery operation.

the oven, or not allow it to start, should the fans not be operat-

For good reason, the TMB Baking TAG Gas Deck Oven is the choice of bakers throughout North America and

around the globe. A summary of technical specs follows:

2

6

110v Power

1

TMB baking

Gas Exhaust: 8”Double Wall

Gas Line

Water Line

Damper Steam Water Supply

BACK

7

Steam: 8” Single Wall/SS Vent

Electrical Supply (On Top)

A

G

14

9

3

E

Gas Supply

FRONT

Water Condensate

18

TMB baking

Specs common to all models:

1. Water supply: 1/2” cold water (65 to 100 psi)

Valve and union connection to manifold

2. Electrical: 110v/60hz/G+N 20 amps

3. Gas: 4” to 7” W.C., 1” Union connection to burner

4. Gas Exhaust: 8” Ø Double Wall

Pressure inside heat exchanger: —.10” WC with burner off “T” Connector

and Humidity trap provided by customer

5. Steam Exhaust: 8” Ø S/S Single Wall. Optional steam exhaust fan (800 cfm)

6. Water Discharge: 3/4” connection from right and left drain manifold to

closest floor sink.

Floor sink required.

86 1/2

4

24"

Gas Exhaust: (Double Wall 8”)

83 1/2

5

135

B

"T" Connector

8" Ø

D

Smoke Exhaust Steam Exhaust

Steam Exhaust:

(8” Single Wall)

º

90

Humidity Trap

15

48

37

26

22

11

95

59

Loading...

Loading...