Page 1

TMP High Performance Vector Control Inverter User Manual

.

.

.

.

.

.

The technical parameters are subject to change without notices.

All rights reserved.

Figures herein are for information only.

Page 2

TMP High Performance Vector Control Inverter User Manual

.

Instruction Manual

of

TMP Series

High Performance Vector Control Inverter

TM, control and protect your motors

TM Industry Co.Ltd.

Page 3

TMP High Performance Vector Control Inverter User Manual

Contents

Chapter 1 Introduction to TMP Series Inverter ................................................................................ 1

1.1 Product Model Description ............................................................................................................... 1

1.2 Product Nameplate Description ....................................................................................................... 1

1.3 Product Series ................................................................................................................................ 6

1.4 Product Specifications ..................................................................................................................... 8

1.5 Product Component Name ............................................................................................................. 11

1.6 Product Outline, Mounting Dimension, and Weight ................................ .......................................... 11

1.7 Operation Panel Outline and Mounting Dimension .......................................................................... 13

1.8 Pallet Outline and Mounting Dimension .......................................................................................... 14

1.9 Braking Resistor Lectotype ................................................................ ............................................ 15

Chapter 2 Inverter Installation ........................................................................................................ 16

2.1 Environment for Product Installation ............................................................................................... 16

2.2 Mounting Direction and Space ................................................................ ....................................... 16

2.3 Removal and Mounting of Operation Panel and Cover.................................................................... 17

Chapter 3 Wiring of Inverter ................................................................................................ ........... 21

3.1 Connection of the Product and Peripheral Devices ................................................................ ......... 21

3.2 Description of Peripheral Devices for Main Circuit .......................................................................... 22

3.3 Lectotype of mMain Circuit Peripheral Devices ................................ ............................................... 22

3.4 Product Terminal Configuration ...................................................................................................... 24

3.5 Functions of Main Circuit Terminal ................................................................................................. 25

3.6 Attention for Main Circuit Wiring ..................................................................................................... 25

3.7 Terminal Wiring ............................................................................................................................. 28

3.8 Functions of Control Circuit Terminals ............................................................................................ 29

3.9 Lectotype of Control Circuit Peripheral Devices ................................ .............................................. 30

3.10 Description of Jumper Function .................................................................................................... 30

.......................................................................................................................................................... 30

Chapter 4 Using Instructions of Operation Panel .......................................................................... 31

4.1 Introduction to Operation Panel ..................................................................................................... 31

4.2 Descriptions of Indicators .............................................................................................................. 31

4.3 Description of Keys on Operation Panel ......................................................................................... 32

4.4 Keypad Operating Status ............................................................................................................... 33

4.5 Panel Operation Method ................................................................................................................ 34

4.6 Parameter Display ......................................................................................................................... 35

4.7 Motor auto-tuning procedure .......................................................................................................... 36

4.8 Running for the First Time ............................................................................................................. 37

Page 4

TMP High Performance Vector Control Inverter User Manual

Chapter 5 List of Parameters ......................................................................................................... 38

5.1 Function Parameter Table .............................................................................................................. 38

Chapter6 Detail Function Introduction ............................................................................................. 56

P0 Basic function parameters .............................................................................................................. 56

P1 Auxiliary function parameters 1 ................................................................................................ ....... 61

P2 Auxiliary function parameters 2 ....................................................................................................... 65

P3 Motor parameters .......................................................................................................................... 70

P4 Dedicatd function for V/F control .................................................................................................. 71

P5 Vector control funtion ..................................................................................................................... 73

P6 I/O I/O output terminal .................................................................................................................... 77

P7 Analog input terminal function......................................................................................................... 90

P8 Analog output terminal ................................................................................................................... 92

P9 Program operating parameters ....................................................................................................... 94

PA PID parameter ................................................................ ............................................................... 97

Pb Traverse function ..........................................................................................................................100

PC Communication and Bus control function ......................................................................................102

Pd Faults and protection parameters ..................................................................................................103

PE Factory reserved ..........................................................................................................................106

PF Factory reserved ..........................................................................................................................106

PH Display function ............................................................................................................................106

Chapter 7 Fault diagnosis and troubleshooting ................................ ..............................................109

7.1 Fault query at fault .......................................................................................................................109

7.2 List of Fault and Alarm Information ................................................................................................109

7.3 Troubleshooting Procedures ......................................................................................................... 114

Chapter 8 Routine Repair and Maintenance .................................................................................... 115

8.1 Routine Maintenance ................................................................................................................... 115

8.2 Periodic Maintenance ................................................................................................ ................... 116

8.3 Component Replacement ............................................................................................................. 116

8.4 Insulation Test .............................................................................................................................. 117

Appendix A Communication Protocol ........................................................................................... 118

Appendix B Control Mode Setting Process ..................................................................................133

Page 5

TMP High Performance Vector Control Inverter User Manual

Chapter 1 Introduction to TMP−H Series Inverter

1

Chapter 1 Introduction to TMP Series Inverter

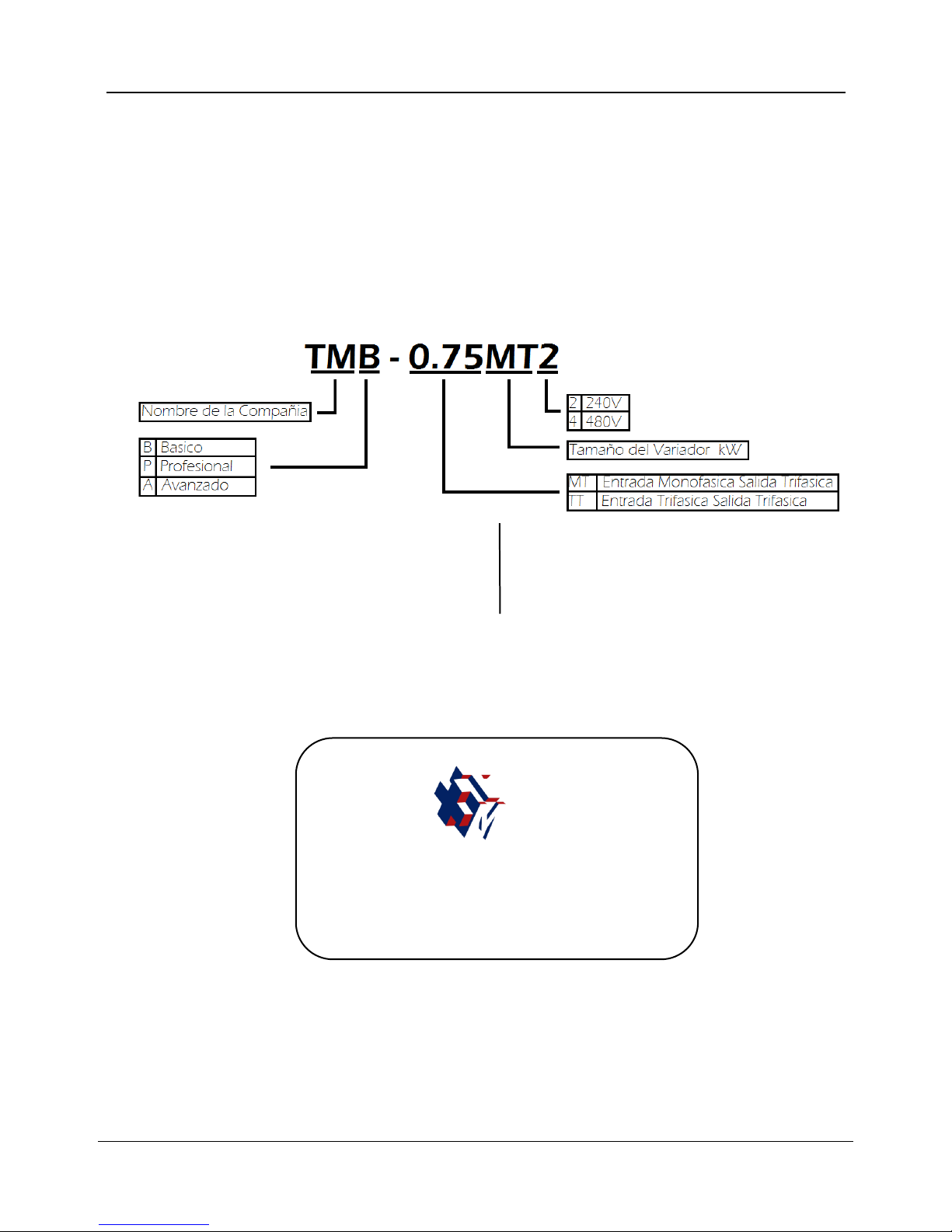

1.1 Product Model Description

The digits and letters in the inverter model field on the nameplate indicate such information as the

product series, power supply class, power class and software/hardware versions.

TM P – 7.5 □ -4

TM Input Voltage class

Inverter Series S2:1AC220V

2:3AC220V

4:3AC380V

Fig. 1-1 Inverter symbol description

1.2 Product Nameplate Description

Fig. 1-2 Inverter Nameplate

MODLE: TMP-7.5TT4

POWER:7.5KW

INPUT: 3PH AC480V 50Hz

Page 6

TMP High Performance Vector Control Inverter User Manual

2

Safety Precautions

Description of safety marks:

Danger: The misuse may cause fire, severe injury, even death.

Note: The misuse may cause medium or minor injury and equipment damage.

Use

DangerDanger

This series of inverter is used to control the variable speed operation of three-phase

motor and cannot be used for single-phase motor or other applications. Otherwise,

inverter failure or fire may be caused.

This series of inverter cannot be simply used in the applications directly related to the

human safety, such as the medical equipment.

This series of inverter is produced under strict quality management system. If the

inverter failure may cause severe accident or loss, safety measures, such as

redundancy or bypass, shall be taken.

Goods Arrival Inspection

NoteNote

If the inverter is found to be damaged or lack parts, the inverter cannot be installed.

Otherwise, accident may be caused.

Installation

NoteNote

When handling and installing the product, please hold the product bottom. Do not hold

the enclosure only. Otherwise, your feet may be injured and the inverter may be

damaged because of dropping.

The inverter shall be mounted on the fire retardant surface, such as metal, and kept far

away from the inflammables and heat source.

Keep the drilling scraps from falling into the inside of the inverter during the installation;

otherwise, inverter failure may be caused.

When the inverter is installed inside the cabinet, the electricity control cabinet shall be

equipped with fan and ventilation port. And ducts for radiation shall be constructed in

the cabinet.

Page 7

TMP High Performance Vector Control Inverter User Manual

3

Wiring

DangerDanger

The wiring must be conducted by qualified electricians. Otherwise, there exists the risk

of electric shock or inverter damage.

Before wiring, confirm that the power supply is disconnected. Otherwise, there exists the

risk of electric shock or fire.

The grounding terminal PE must be reliably grounded, otherwise, the inverter enclosure

may become live.

Please do not touch the main circuit terminal. The wires of the inverter main circuit

terminals must not contact the enclosure. Otherwise, there exists the risk of electric

shock.

The connecting terminals for the braking resistor are ⊕2/B1 and B2. Please do not

connect terminals other than these two. Otherwise, fire may be caused.

The leakage current of the inverter system is more than 3.5mA, and the specific value of

the leakage current is determined by the use conditions. To ensure the safety, the

inverter and the motor must be grounded.

NoteNote

The three-phase power supply cannot connect to output terminals U/T1, V/T2 and

W/T3, otherwise, the inverter will be damaged.

It is forbidden to connect the output terminal of the inverter to the capacitor or LC/RC

noise filter with phase lead, otherwise, the internal components of the inverter may be

damaged.

Please confirm that the power supply phases, rated voltage are consistent with that of

the nameplate, otherwise, the inverter may be damaged.

Do not perform dielectric strength test on the inverter, otherwise, the inverter may be

damaged.

The wires of the main circuit terminals and the wires of the control circuit terminals shall

be laid separately or in a square-crossing mode, otherwise, the control signal may be

interfered.

The wires of the main circuit terminals shall adopt lugs with insulating sleeves.

The inverter input and output cables with proper sectional area shall be selected

according to the inverter power.

When the length of the cables between the inverter and the motor is more than 100m, it

is suggested to use output reactor to avoid the inverter failure caused by the overcurrent

of the distribution capacitor.

The inverter which equipped with DC reactor must connect with DC reactor between the

terminal of ○,+1、○,+2, otherwise the inverter will not display after power on.

Page 8

TMP High Performance Vector Control Inverter User Manual

4

Operation

DangerDanger

Power supply can only be connected after the wiring is completed and the cover is

installed. It is forbidden to remove the cover in live condition; otherwise, there exists the

risk of electric shock.

When auto failure reset function or restart function is set, isolation measures shall be

taken for the mechanical equipment, otherwise, personal injury may be caused.

When the inverter is powered on, even when it is in the stop state, the terminals of the

inverter are still live. Do not touch the inverter terminals; otherwise electric shock may

be caused.

The failure and alarm signal can only be reset after the running command has been cut

off. Otherwise, personal injury may be caused.

NoteNote

Do not start or shut down the inverter by switching on or off the power supply, otherwise,

the inverter may be damaged.

Before operation, please confirm if the motor and equipment are in the allowable use

range, otherwise, the equipment may be damaged.

The heatsink and the braking resistor have high temperature. Please do not touch such

device; otherwise, you may be burnt.

When it is used on lifting equipment, mechanical contracting brake shall also be

equipped.

Please do not change the inverter parameter randomly. Most of the factory set

parameters of the inverter can meet the operating requirement, and the user only needs

to set some necessary parameters. Any random change of the parameter may cause

the damage of the mechanical equipment.

In the applications with industrial frequency and variable frequency switching, the two

contactors for controlling the industrial frequency and variable frequency switching shall

be interlocked.

Maintenance, Inspection

DangerDanger

In the power-on state, please do not touch the inverter terminals; otherwise, there exists

the risk of electric shock.

If cover is to be removed, the power supply must be disconnected first.

Wait for at least 10 minutes after power off or confirm that the CHARGE LED is off

before maintenance and inspection to prevent the harm caused by the residual voltage

of the main circuit electrolytic capacitor to persons.

The components shall be maintained, inspected or replaced by qualified electricians.

Page 9

TMP High Performance Vector Control Inverter User Manual

5

NoteNote

The circuit boards have large scale CMOS IC. Please do not touch the board to avoid

the circuit board damage caused by electro static.

Others

DangerDanger

It is forbidden to modify the inverter unauthorizedly; otherwise, personal injury may be

caused.

Page 10

TMP High Performance Vector Control Inverter User Manual

6

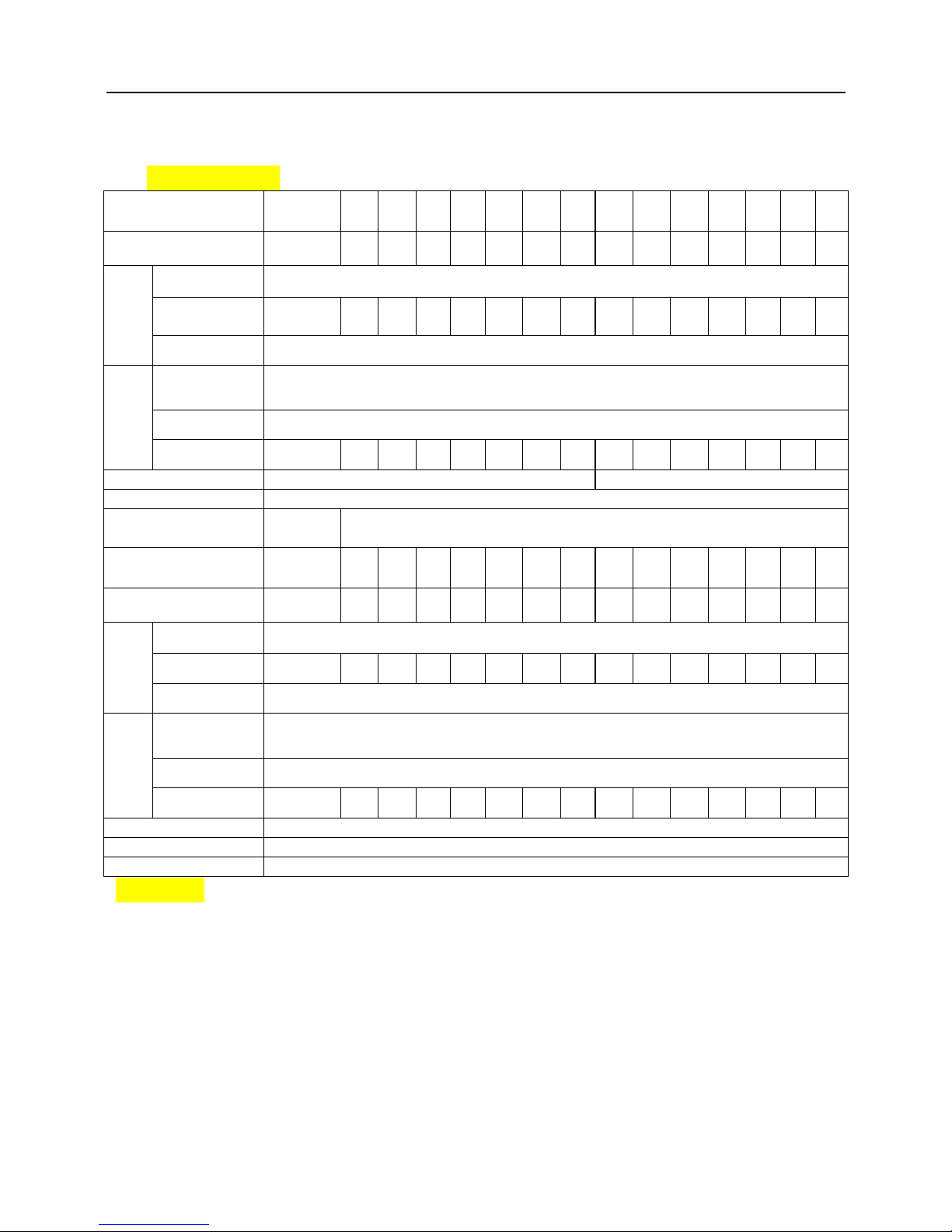

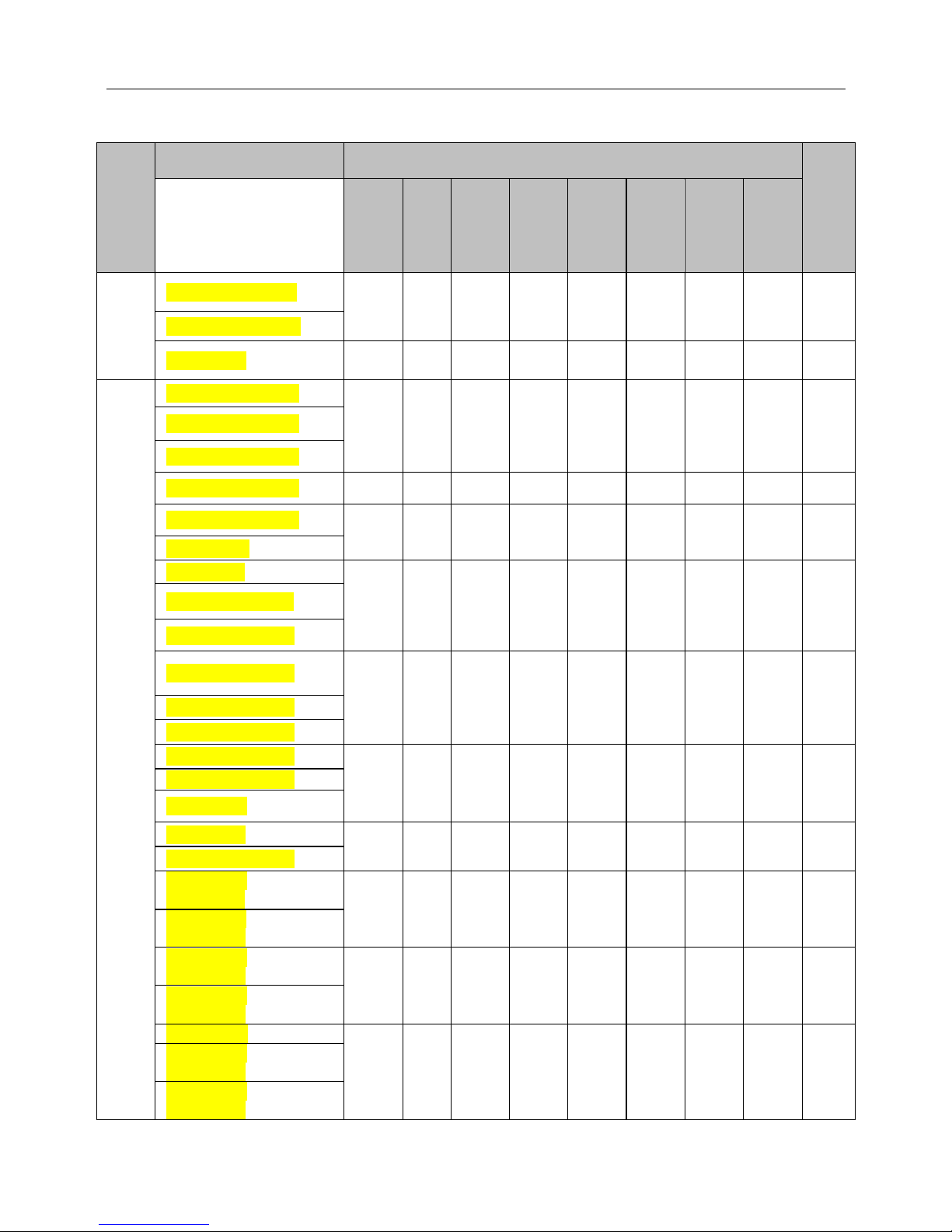

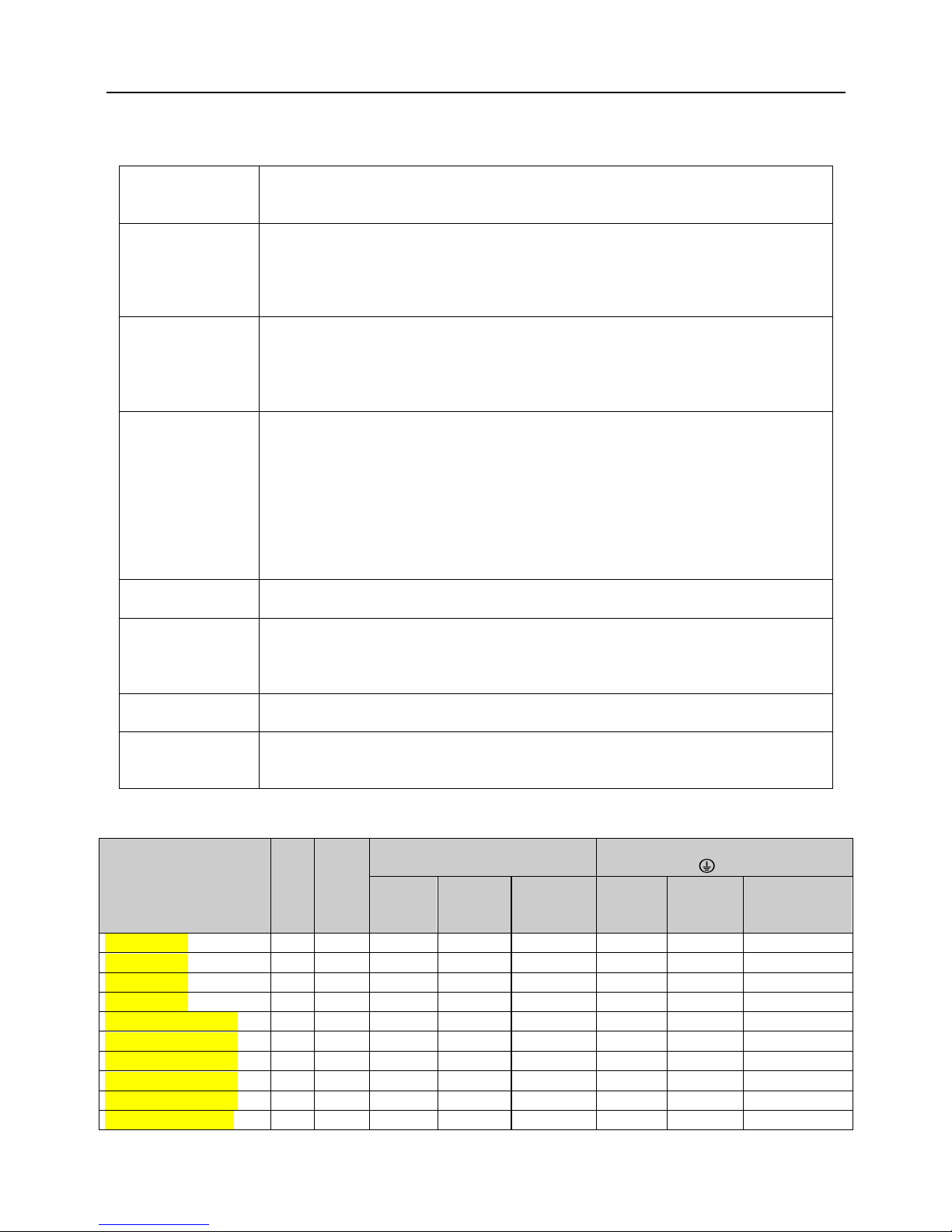

1.3 Product Series

TMP−□□□G-4 Three-phase 400V Constant torque/heavy-duty application

Power (kW)

0.75

1.5

2.2

4.0

5.5

7.5

11

15

18.5

22

30

37

45

55

75

Motor

power (kW)

0.75

1.5

2.2

4.0

5.5

7.5

11

15

18.5

22

30

37

45

55

75

Output

Voltage (V)

Three-phase 0 to rated input voltage

Rated current

(A)

2.5

3.8

5.5 9 13

17

24

30

39

45

60

75

91

112

15

0

Overload

capacity

feature)

Input

Rated

voltage/frequen

cy

Three-phase 380V/480V; 50Hz/60Hz

Allowable

voltage range

323V ~ 528V; Voltage unbalanceness ≤3%; allowable frequency fluctuation: ±5%

Rated current

(A)

3.5

6.2

9.2

14.9

21.5

27.9

39

50.3

60

69.3

86

104

124

150

20

1

Braking unit

Built-in as standard

Built-in as option

Protection class

IP20

Cooling mode

Self-coolin

g

Forced air convection cooling

Power (kW)

90

110

132

160

185

200

220

250

280

315

355

400

450

500

Motor

power (kW)

90

110

132

160

185

200

220

250

280

315

355

400

450

500

Output

Voltage (V)

Three-phase 0 to rated input voltage

Rated current

(A)

176

210

253

304

350

380

426

470

520

600

650

690

775

860

Overload

capacity

feature)

Input

Rated

voltage/frequen

cy

Three-phase 380V/480V; 50Hz/60Hz

Allowable

voltage range

323V ~ 528V; Voltage unbalancedness ≤3%; allowable frequency fluctuation: ±5%

Rated current

(A)

160*

196* 232* 282* 326* 352* 385* 437* 491* 580* 624* 670* 755* 840

*

Braking unit

External braking unit needed

Protection class

IP20

Cooling mode

Forced air convection cooling

*TMP −090G-4 and above products are equipped with external DC reactor as standard.

Page 11

TMP High Performance Vector Control Inverter User Manual

7

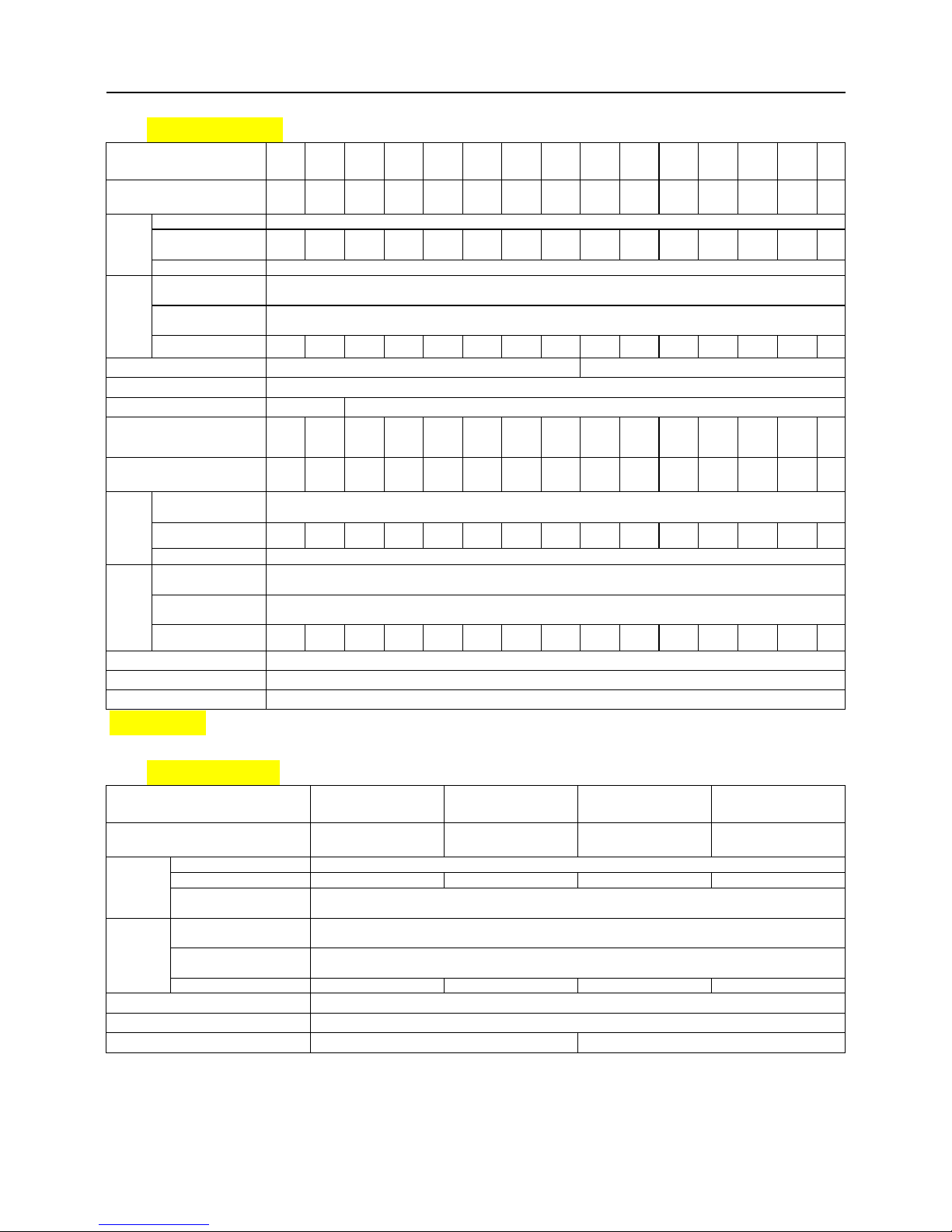

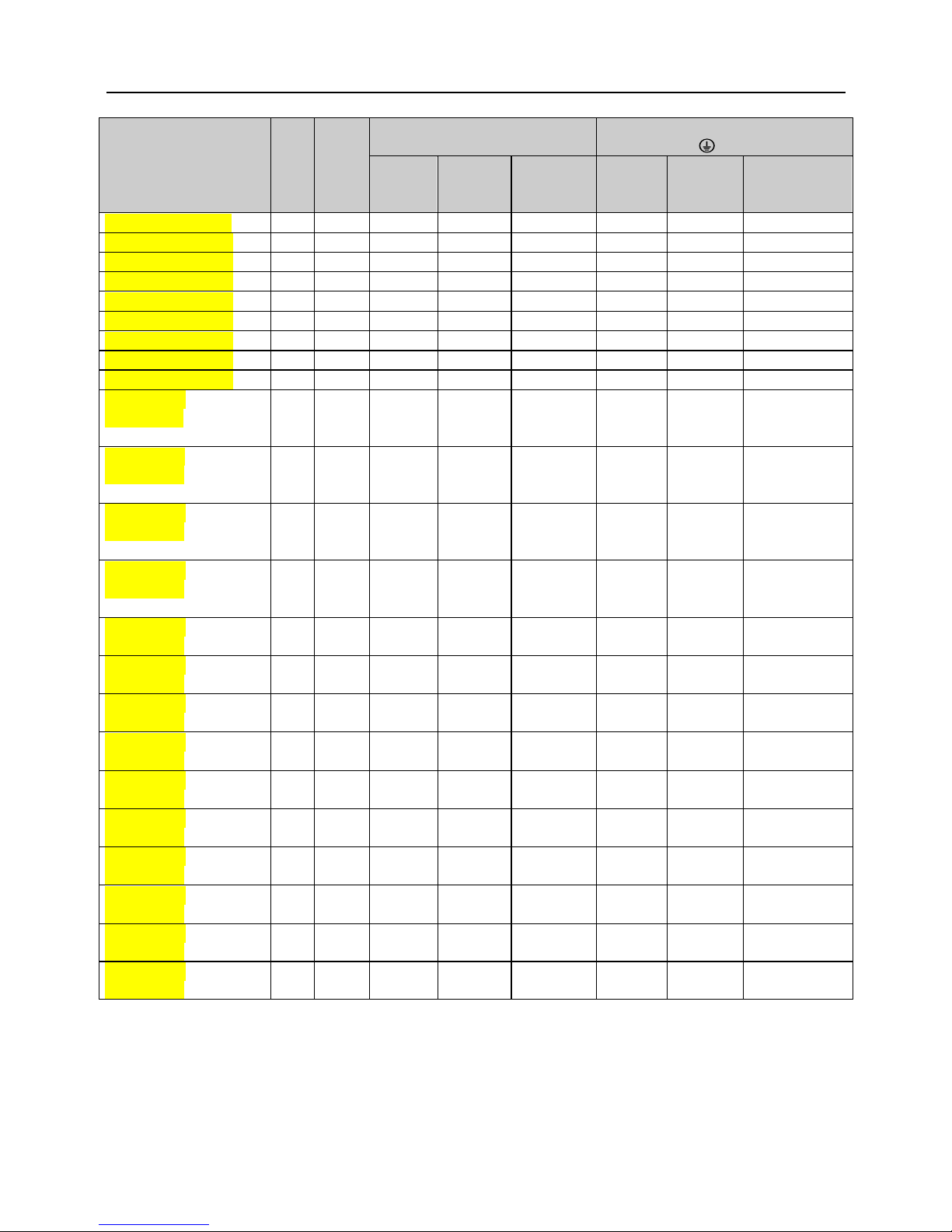

TMP−□□□P -4 Three-phase 400V Variable torque/light-duty application

Power (kW)

1.5

2.2

4.0

5.5

7.5

11

15

18.5

22

30

37

45

55

75

90

Motor

power (kW)

1.5

2.2

4.0

5.5

7.5

11

15

18.5

22

30

37

45

55

75

90

Output

Voltage (V)

Three-phase 0 to rated input voltage

Rated current (A)

3.3

5.0

7.5

11

17

22

30

37

44

56

72

91

110

142

176

Overload capacity

120% 1 minute, 145% 2 second, interval: 10 minutes (inverse time lag feature)

Input

Rated

voltage/frequency

Three-phase 380V/480V; 50Hz/60Hz

Allowable voltage

fluctuation range

323V ~ 528V; Voltage unbalancedness: ≤3%; allowable frequency fluctuation: ±5%

Rated current (A)

5.6

8.1

13.5

19.5

26

39

50.3

60

69.3

86

104

124

150

190

235

Braking unit

Built-in as standard

Built-in as option

Protection class

IP20

Cooling mode

Self-cooling

Forced air convection cooling

Power (kW)

110

132

160

185

200

220

250

280

315

355

400

450

500

560

Motor

power (kW)

110

132

160

185

200

220

250

280

315

355

400

450

500

560

Output

Voltage (V)

Three-phase 0 to rated input voltage

Rated current (A)

210

253

304

350

380

426

470

520

600

650

690

775

860

950

Overload capacity

115% 1 minute, 160% 0.5 second, interval: 10 minutes (inverse time lag feature)

Input

Rated

voltage/frequency

Three-phase 380V/480V; 50Hz/60Hz

Allowable voltage

range

323V ~ 528V; Voltage unbalancedness ≤3%; allowable frequency fluctuation: ±5%

Rated current (A)

196*

232*

282*

326*

352*

385*

437*

491*

580*

624*

670*

755*

840*

920*

Braking unit

External braking unit needed

Protection class

IP20

Cooling mode

Forced air convection cooling

*TMP−110P-4 and above products are equipped with external DC reactor as standard.

TMP−□□□G-2 Three-phase 200V Constant torque/heavy-duty application

Power (kW)

0.4

0.75

1.5

2.2

Motor

power (kW)

0.4

0.75

1.5

2.2

Output

Voltage (V)

Three-phase 0 to rated input voltage

Rated current (A)

3 5 7.5

10

Overload capacity

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes

(inverse time lag feature)

Input

Rated

voltage/frequency

Three-phase or single-phase 200V~240V; 50Hz/60Hz

Allowable voltage

range

180V ~ 260V; Voltage unbalancedness ≤3%; allowable frequency fluctuation: ±5%

Rated current (A)

3.8

5.5

8.3

12

Braking unit

Built-in as standard

Protection class

IP20

Cooling mode

Self-cooling

Forced air convection cooling

Page 12

TMP High Performance Vector Control Inverter User Manual

8

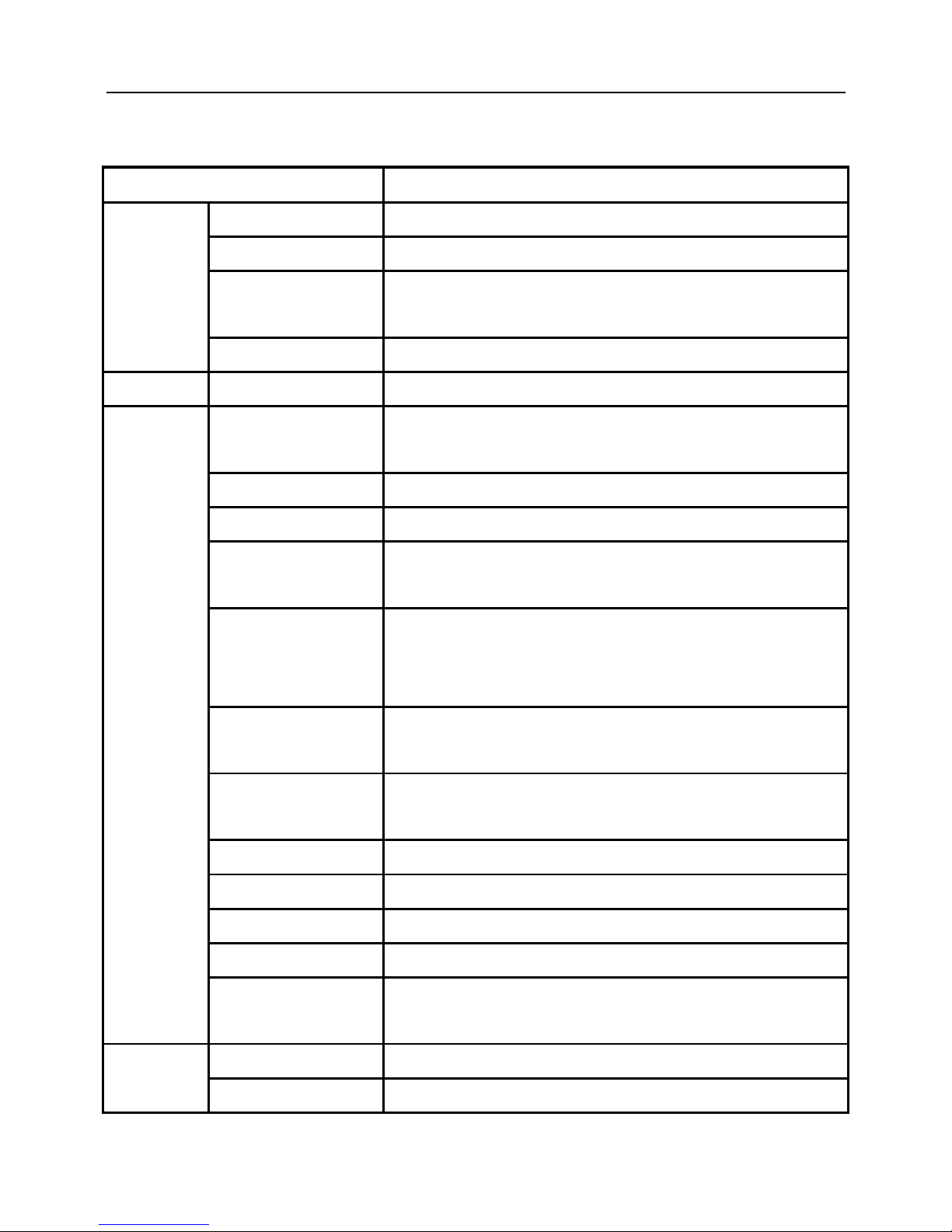

1.4 Product Specifications

Item

Specifications

OUTPUT

Rated Output Voltage

Three phase 380V (Max output voltage is equal to input voltage)

Max continuous current

100% rated output current

Overload ability

150% rated current for 1minutes,

180% rated current for 2 seconds.

Output frequency

0Hz~400Hz

Input

Rated input voltage

Three phase: 380V±20%, 50~60Hz±5%

Control

performance

AVR Function,

When AVR function is enable,output voltage is stable under input voltage

fluctuation

Modulation modes

Optimized space voltage vector PWM modulation

Control mode

Sensorless Vector control; V/F control.

Running command input

modes

Panel control, external terminal control, control by serial port of host computer

Speed setting mode

Ten kinds of main frequencysetting modes, seven kinds of Auxiliary

frequencysetting modes. Several combination kinds of main frequencysetting

modes and Auxiliary frequencysetting modes.

Speed setup resolution

Digital setting: 0.01Hz.

Analog setting: highest frequency×0.1%

Voltage/Frequency

characteristic

Rated voltage: 50-100%,adjustable, Base frequency 50Hz, adjustable, five type

V/F curves

Speed control accuracy

Sensorless vector control: ±0.05% rated speed(25℃±10℃)

Speed control range

vector control: 1:100

Starting torque

vector control: 150% rated torque at 0.5Hz.

Acc/dec characteristic

0.1seconde~3600 seconds

Braking torque

22 kW below: >20% rated torque,

30 kW above: >15% rated torque

Control I/O

Reference voltage output

1 channel, +10V, 50mA

Control voltage output

24V, 100mA

Page 13

TMP High Performance Vector Control Inverter User Manual

9

signal

Analog input

1 channel, 0~10V/0~20mA DC,10 bit;

1 channel, 0~10 V DC,10 bit

Analog output

1 channel, 0~10V, output programmable, various output selectable

1 channel, 0~10V/0-2 0mA, output programmable, various output selectable

Programmable terminal

input

7 programmable channels, 27 kinds of functions can be selected, such as Run

forward/reverse, Jog forward/reverse, multi-step speed selection, multi-step

Acc/Dec time, free run to stop, voltage/current switch, etc.

Open collector output

1 channel, 20 optional running states, the maximum output current is 50mA

Programmable relay output

1 channel, 20optional running states, contact capacity: 250V AC /3A or 30V DC

/1A

Serial port

RS-485 port

Standard function

urrent limit, torque boost, speed trace, DC braking, restart after power failure, slip

compensation, auto fault reset, high/low limit frequency, starting frequency, jump

frequency, frequency gain, Carrier frequency adjustment, Acc/Dec mode

selection, voltage meter output, current meter output, multi-frequency operation,

programming operation, traverse operation, PI close loop operation, proportional

control, remote control, FWD/REV dead time, etc.

Protection function

Over voltage, low voltage, over current, current limit, overload, over heat,

electronic thermal overload relay, over voltage stall, data protection, etc.

Display

4-digit display (LED)

15 kinds of parameters, such as frequency setting, output frequency, output

voltage, output current, motor speed, output torque, digital value terminals,

program menu parameters and 33kinds of Fault codes

Indicator (LED)

Parameter unit, RUN/STOP state, etc.

Operating

environment

Environment

Inside, low than 1000m, free from dust, corrosive gas and direct sunlight

Ambient temperature

-10℃~+40 ℃ (bare machine: -10℃~+50℃), 20%~90%RH, no condensing

Vibration

Lower than 0.5g

Storage temperature

-25℃~+65℃

Installation

Wall mounted or surface mounted inside a cabinet

Protection class

IP20

Page 14

TMP High Performance Vector Control Inverter User Manual

10

Cooling

0.75 kW and below: enclosed self-cooling,

Others: forced cooling.

Page 15

TMP High Performance Vector Control Inverter User Manual

11

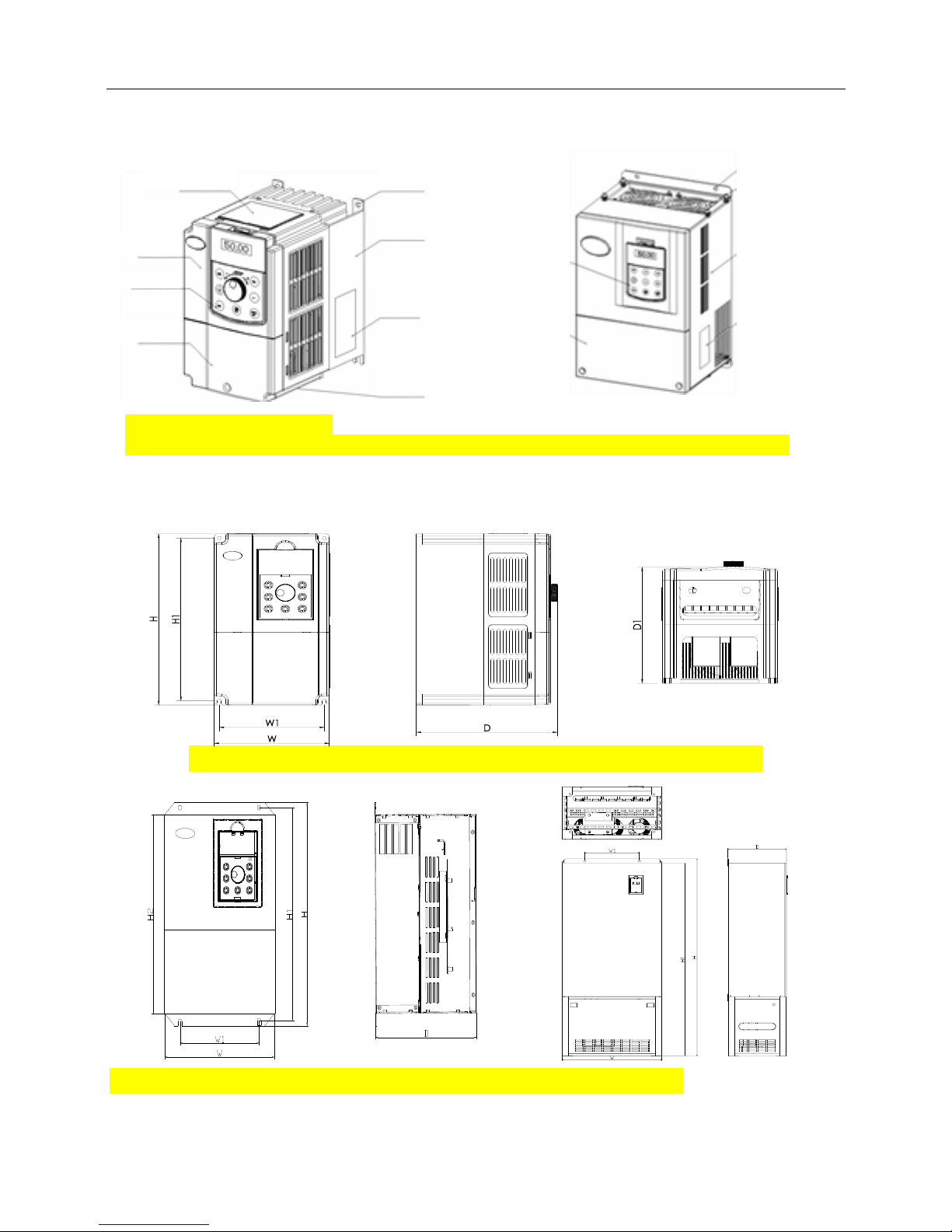

1.5 Product Component Name

TMP−0R4G-2~TMP−2R2G-2

TMP−7R5G-4 and below power class TMP-011G-4 and above power class

Fig.1−3 Product component name

1.6 Product Outline, Mounting Dimension, and Weight

TMP−0R4G-2~TMP−2R2G-2、TMP−0R7G-4~TMP-7R5G-4 and blow power class

TMP-011G-4~ TMP-220G-4 power class TMP-185G-4~TMP-400G-4

Fig.1−4 Product outline and mounting dimension

Nameplate

Dust guard

Upper cover

Operation panel

Lower cover

Heatsink

Mounting hole

Operation panel

Cover

Mounting hole

Cooling fan

Enclosure

Nameplate

Page 16

TMP High Performance Vector Control Inverter User Manual

12

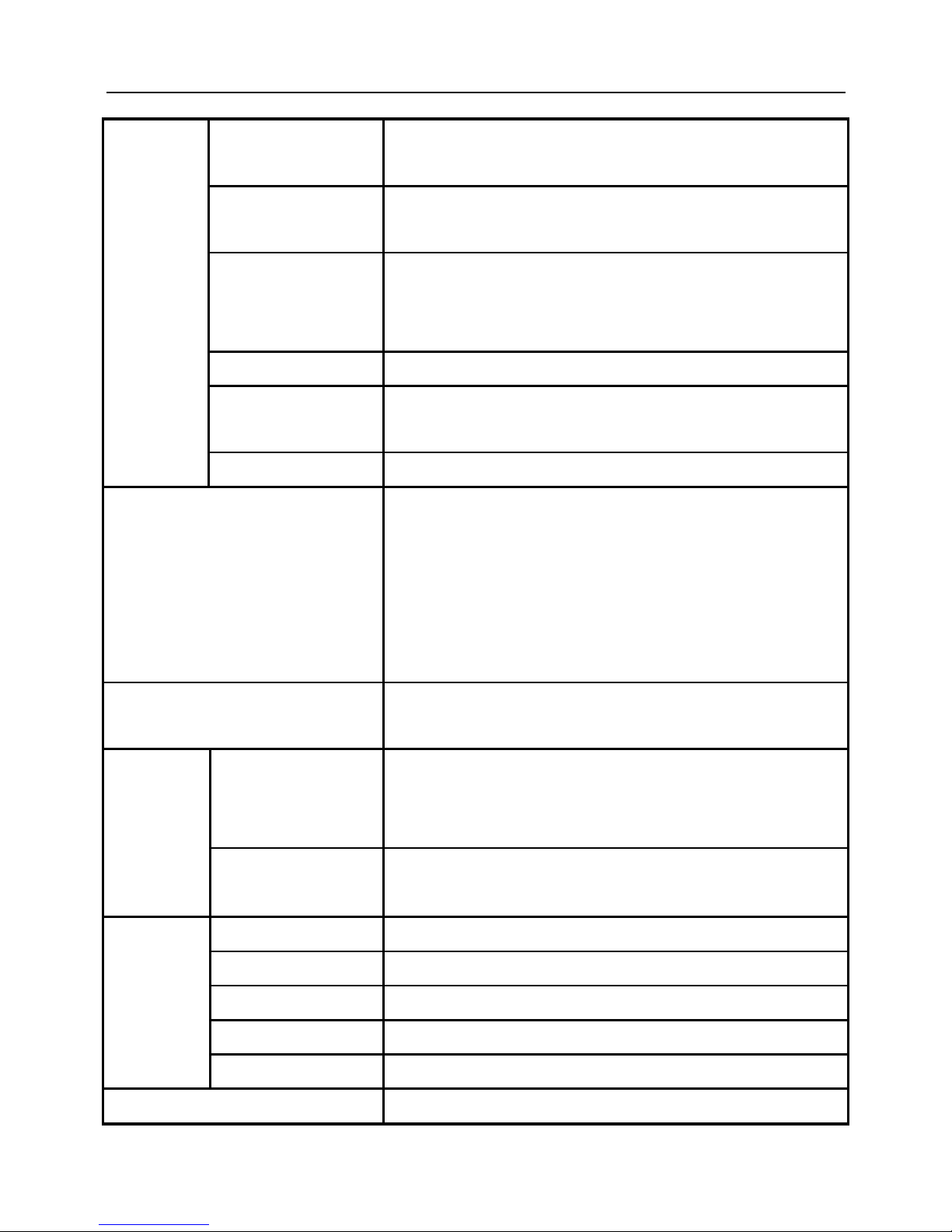

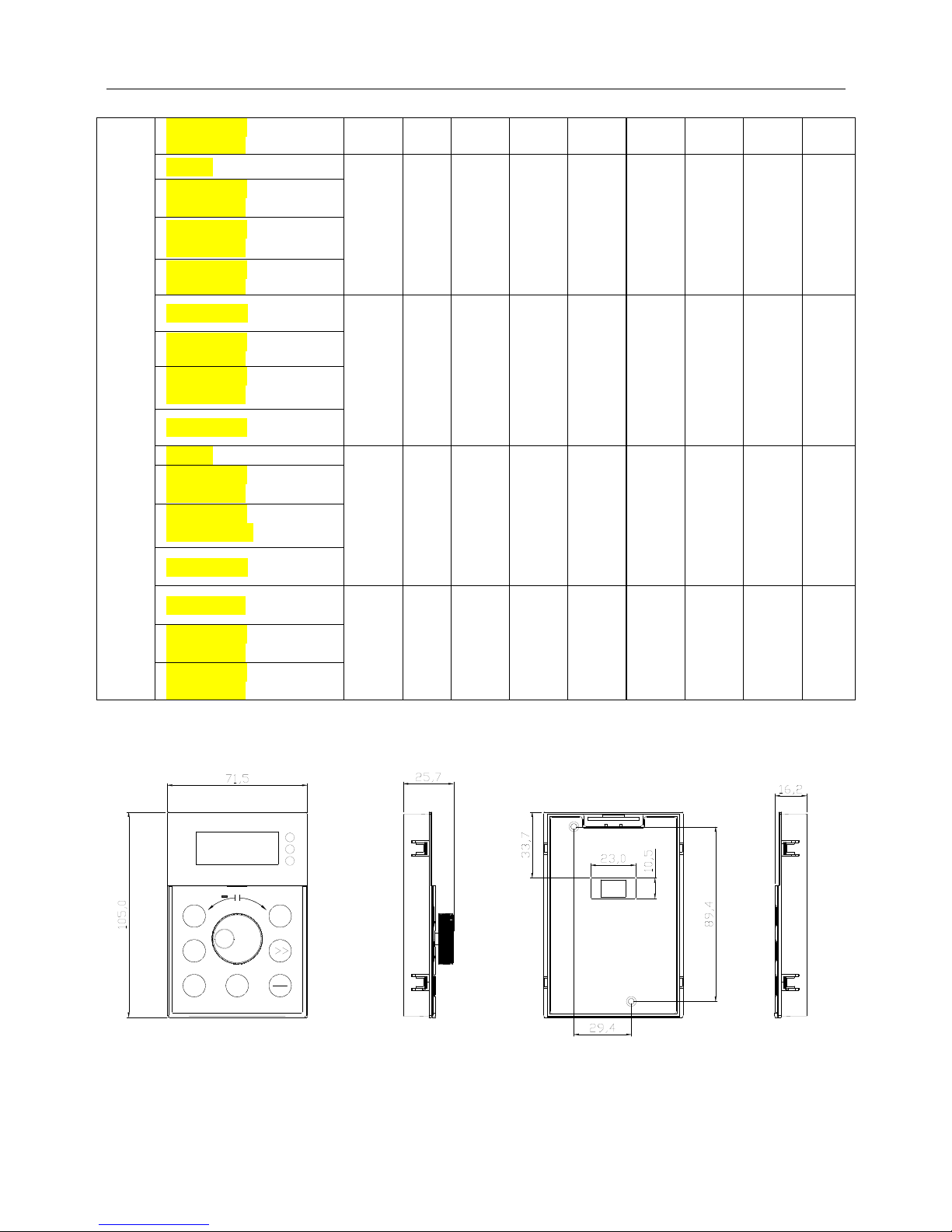

Product outline, mounting dimension, and weight

Volta

ge

class

Inverter model

Outline and mounting dimension (mm)

App

roxi

mat

e

weig

ht

(kg)

)

W H D

W1

H1

D1

H2

Moun

ting

hole

diam

eter

220V

TMP-0R4G-2/0R7G-2

118.5

185

159

106.5

174.5

150 5.5

2.0

TMP−1R5G-2/2R2G-2

TMP-3R7G-2

150

258

183.8

136.8

245

175.3 5.5

4.5

400V

TMP−0R7G-4/1R5P-4

118.5

185

159

106.5

174.5

150 5.5

2.0

TMP−1R5G-4/2R2P-4

TMP−2R2G-4/4R0P-4

TMP−4R0G-4/5R5P-4

118.5

195

169

106.5

184.5

160 5.5

3.0

TMP−5R5G-4/7 R5P-4

150

258

183.8

136.8

245

175.3 5.5

4.5

TMP−7R5G-4

TMP−011P-4

210

337

191

150

322.5

298 7 8.5

TMP−011G-4/015P-4

TMP−015G-4/018P-4

TMP−018G-4/022P-4

285

501

230.2

200

482 460 7 17

TMP−022G-4/030P-4

TMP−030G-4/037P-4

TMP−037G-4/045P-4

352

585

274.2

220

559 538

10

25

TMP−045G-4/055P-4

TMP−055G-4

TMP−075P-4

404

680

302.7

300

658 633

10

35

TMP−075G-4/093P-4

TMP−093G-4

TMP−110P-4

485

760

316

325

739 713

12

55

TMP−110G-4

TMP−132P-4

TMP−132G-4

TMP−160P-4

533

830

371.7

325

809 780

12

85

TMP−160G-4

TMP−185P-4

Wall Mounted

638

101

0

374

350

985 950

14

125

TMP−185G-4

TMP−200P-4

TMP−200G-4

TMP−220P-4

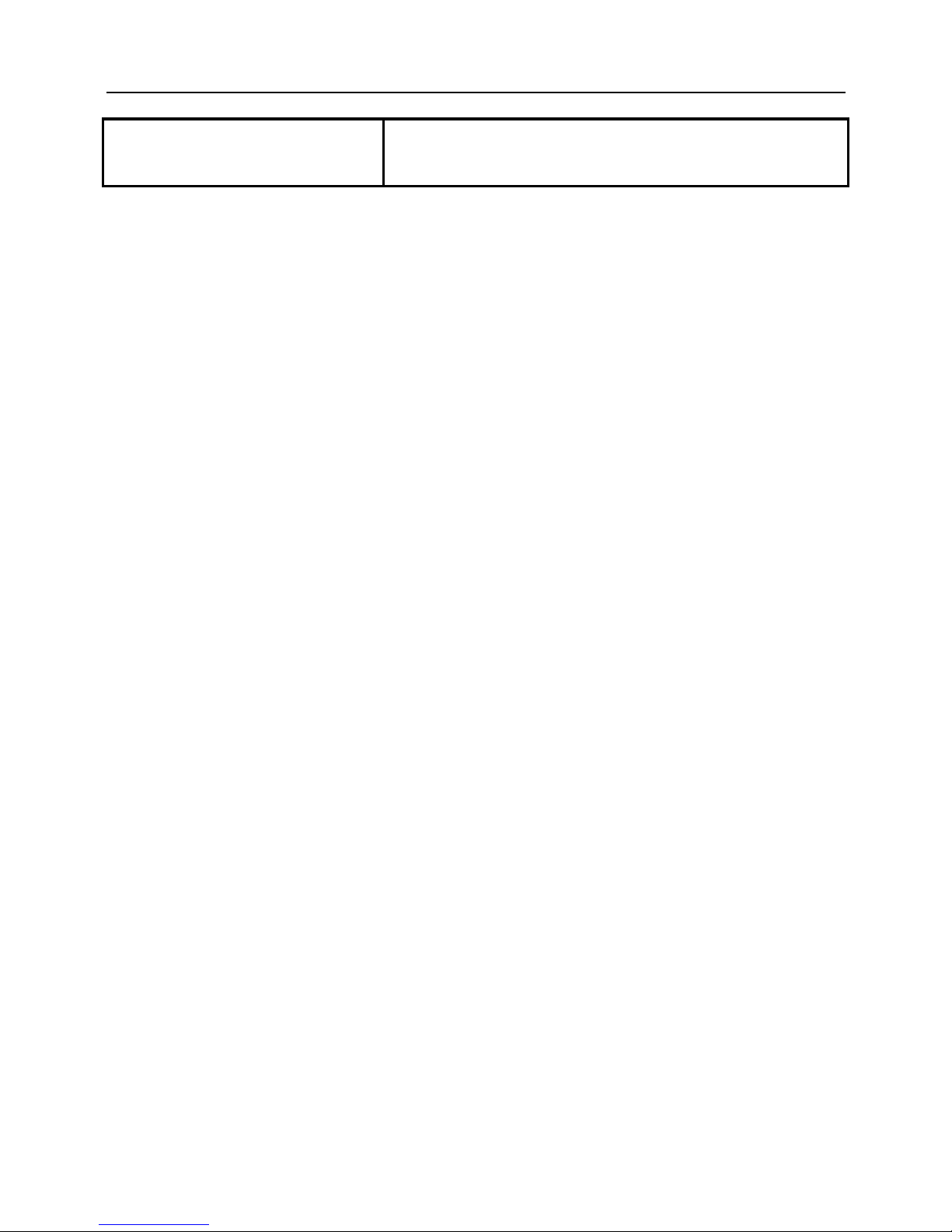

Page 17

TMP High Performance Vector Control Inverter User Manual

13

TMP−220G-4

TMP−250P-4

Cabinet

638

140

2

374

350

1372

14

140

TMP−185G-4

TMP−200P-4

TMP−200G-4

TMP−220P-4

TMP−220G-4

TMP−250P-4

Wall Mounted

700

124

0

460

520

1207.5

1168

14

150

TMP−250G-4

TMP−280P-4

TMP−280G-4

TMP−315P-4

TMP−315G-4

Cabinet

700

162

7

460

520

1592

14

180

TMP−250G-4

TMP−280P-4

TMP−280G-4

TMP−3150P-4

TMP−315G-4

TMP−355P-4

800

177

2

460

520

1737

14

215

TMP−355G-4

TMP−400P-4

TMP−400G-4

TMP−450P-4

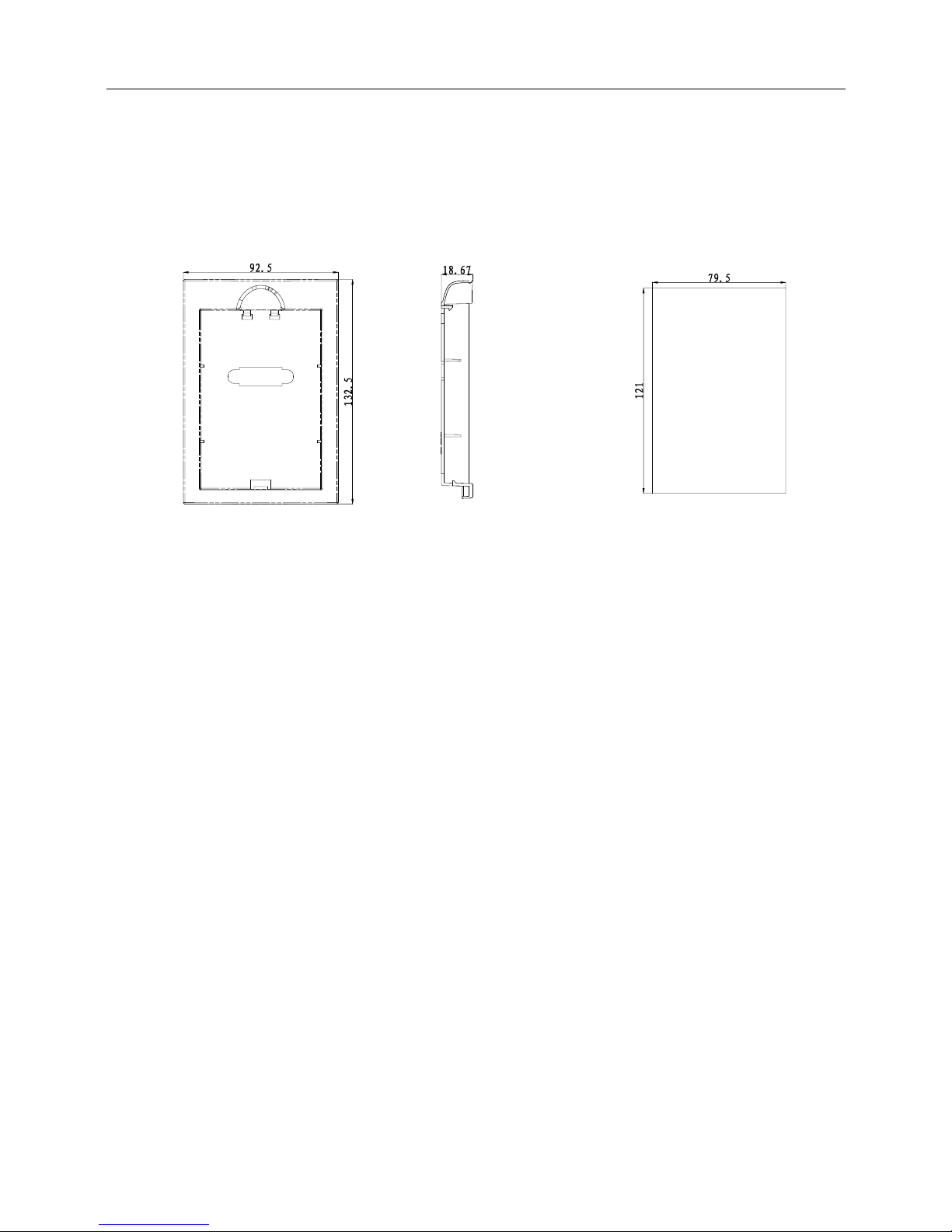

1.7 Operation Panel Outline and Mounting Dimension

Shuttle type operation panel (TMP-DP01) Rear view of operation panel

Fig.1−5 Operation panel outline and mounting dimension

SET

MF

JOG

RUN

STOP

+

RST

PRG

5 0.00

Page 18

TMP High Performance Vector Control Inverter User Manual

14

1.8 Pallet Outline and Mounting Dimension

TMP−DP03 is the mounting pallet when the operation panel is to install on the electric control cabinet.

The outline and dimension are as follows:

Pallet(TMP-DP03) Open pore dimension of pallet

Fig.1-6 Pallet outline and mounting dimension

Page 19

TMP High Performance Vector Control Inverter User Manual

15

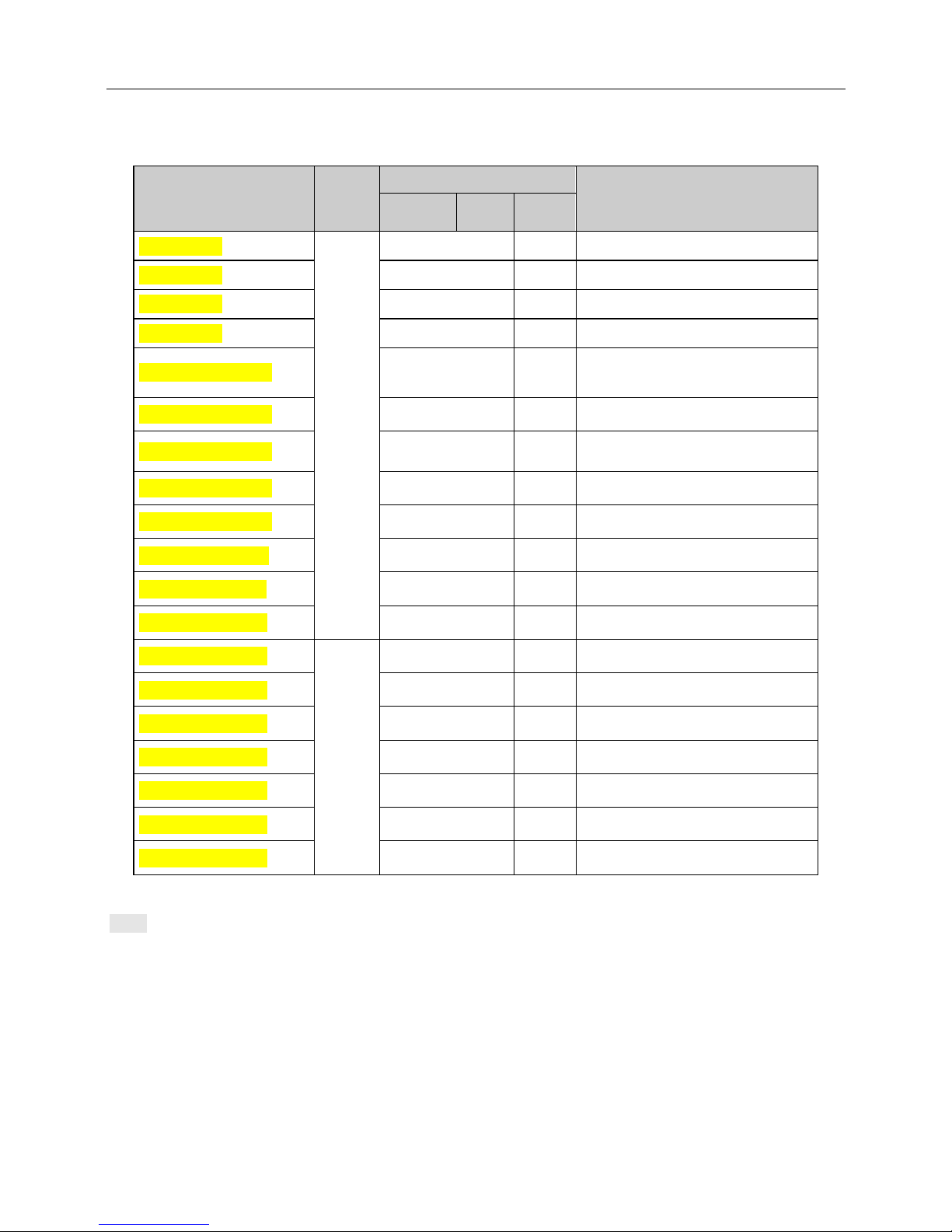

1.9 Braking Resistor Lectotype

Inverter model

Brakin

g unit

Braking resistor unit

Braking torque%

Power

Resis

tor

Qty.

TMP−0R4G-2

Built-

in as

stand

ard

70W

200Ω

1

220

TMP−0R7G-2

70W

200Ω

1

125

TMP−1R5G-2

260W

100Ω

1

125

TMP−2R2G-2

260W

70Ω

1

120

TMP−0R7G-4/1R5P-4

70W

750Ω

1

130

TMP−1R5G-4/2R2P-4

260W

400Ω

1

125

TMP−2R2G-4/4R0P-4

260W

250Ω

1

135

TMP−4R0G-4/5R5P-4

390W

150Ω

1

135

TMP−5R5G-4/7 R5P-4

520W

100Ω

1

135

TMP−7R5G-4/011P-4

780W

75Ω

1

130

TMP−011G-4/015P-4

1040W

50Ω

1

135

TMP−015G-4/018P-4

1560W

40Ω

1

125

TMP−018G-4/022P-4

Built-in as optio n

4800W

32Ω

1

125

TMP−022G-4/030P-4

4800W

27.2Ω

1

125

TMP−030G-4/037P-4

6000W

20Ω

1

125

TMP−037G-4/045P-4

9600W

16Ω

1

125

TMP−045G-4/055P-4

9600W

13.6Ω

1

125

TMP−055G-4/075P-4

6000W

20Ω

2

135

TMP−075G-4/090P-4

9600W

13.6Ω

2

145

Note: The connection mode for multiple braking resistors is parallel connection. For example, the inverter of

TMP-055G-4/075P-4, the braking resistor lectotype: it is suggest to select two 6000W, 20Ω braking resistor

parallel connection, amount to braking resistor is 12000W, 10Ω.

Page 20

TMP High Performance Vector Control Inverter User Manual

16

Chapter 2 Inverter Installation

2.1 Environment for Product Installation

Avoid installing the product in the sites with oil mist, metal powder and dust.

Avoid installing the product in the sites with hazardous gas and liquid, and corrosive, combustible

and explosive gas.

Avoid installing the products in salty sites.

Do not install the product in the sites with direct sunlight.

Do not mount the product on the combustible materials, such as wood.

Keep the drilling scraps from falling into the inside of inverter during the installation.

Mount the product vertically in the electric control cabinet, mount the cooling fan or air conditioner

to prevent the ambient temperature from rising to above 45 ºC.

For the sites with adverse environment, it is recommended to mount the inverter heatsink outside

the cabinet.

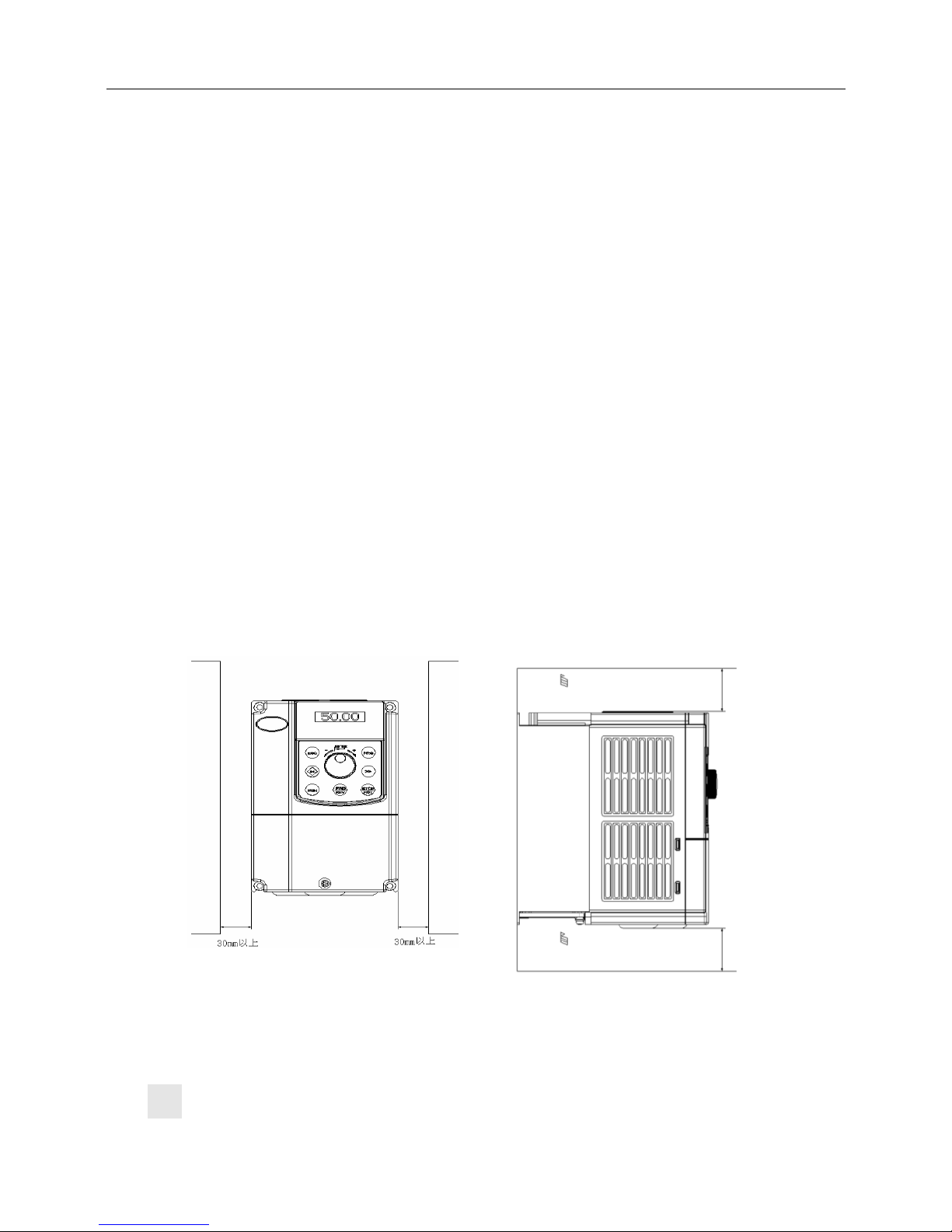

2.2 Mounting Direction and Space

In order not to reduce the inverter cooling effect, the inverter must be mounted vertically, and certain

space must be maintained, as shown in Fig. 2−1 and Fig.2−2.

Fig.2−1 Fig.2−1 Mounting direction and space forTMP-0R4G-2~TMP-2R2G-2 and TMP-0R7G-4/1R5P-4

and below power class

Note:

Air circulation position

Air circulation position

Above 120mm

Above 120mm

Air circulation position

Air circulation position

Above 120mm

Above 120mm

Above 30mm

Above 30mm

Page 21

TMP High Performance Vector Control Inverter User Manual

17

When the TMP inverters are mounted side by side in the cabinet, please remove the upper dust

guard and the lower leading board.

2.3 Removal and Mounting of Operation Panel and Cover

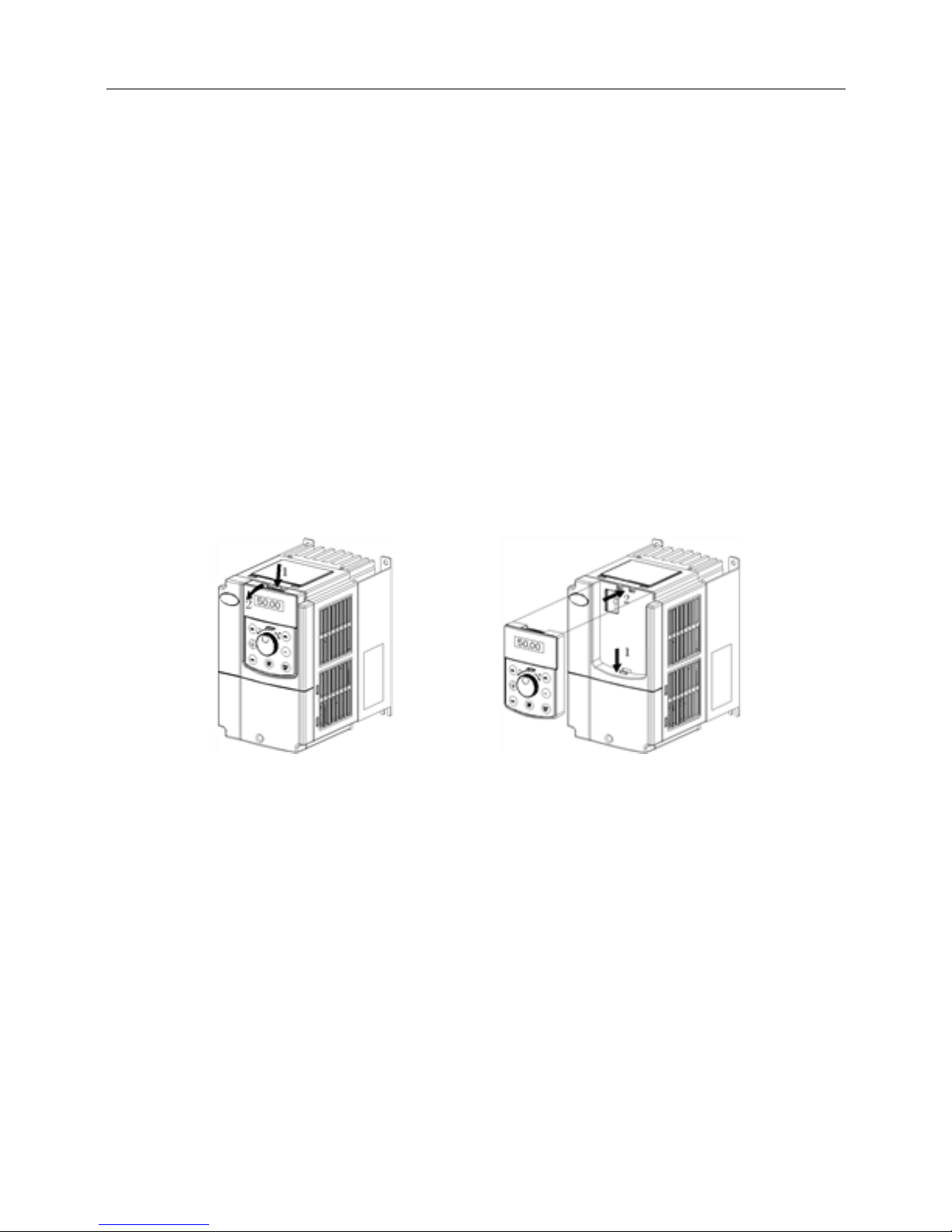

2.3.1 Removal and Mounting of Operation Panel

Removal of operation panel

As shown in Fig. 2−3, the grab on the operation panel forcefully in direction 1, and then lift the panel

body in direction 2.

Mounting of operation panel

As shown in Fig.2−4, align with the lower clamping position of the operation panel in direction 1,

and then press down the operation panel in direction 2, until the “crack” sound is heard.

Do not mount the operation panel in any other direction; otherwise, the operation panel will have

poor contact.

Fig. 2−3 Removal of operation panel Fig.2−4 Mounting of operation panel

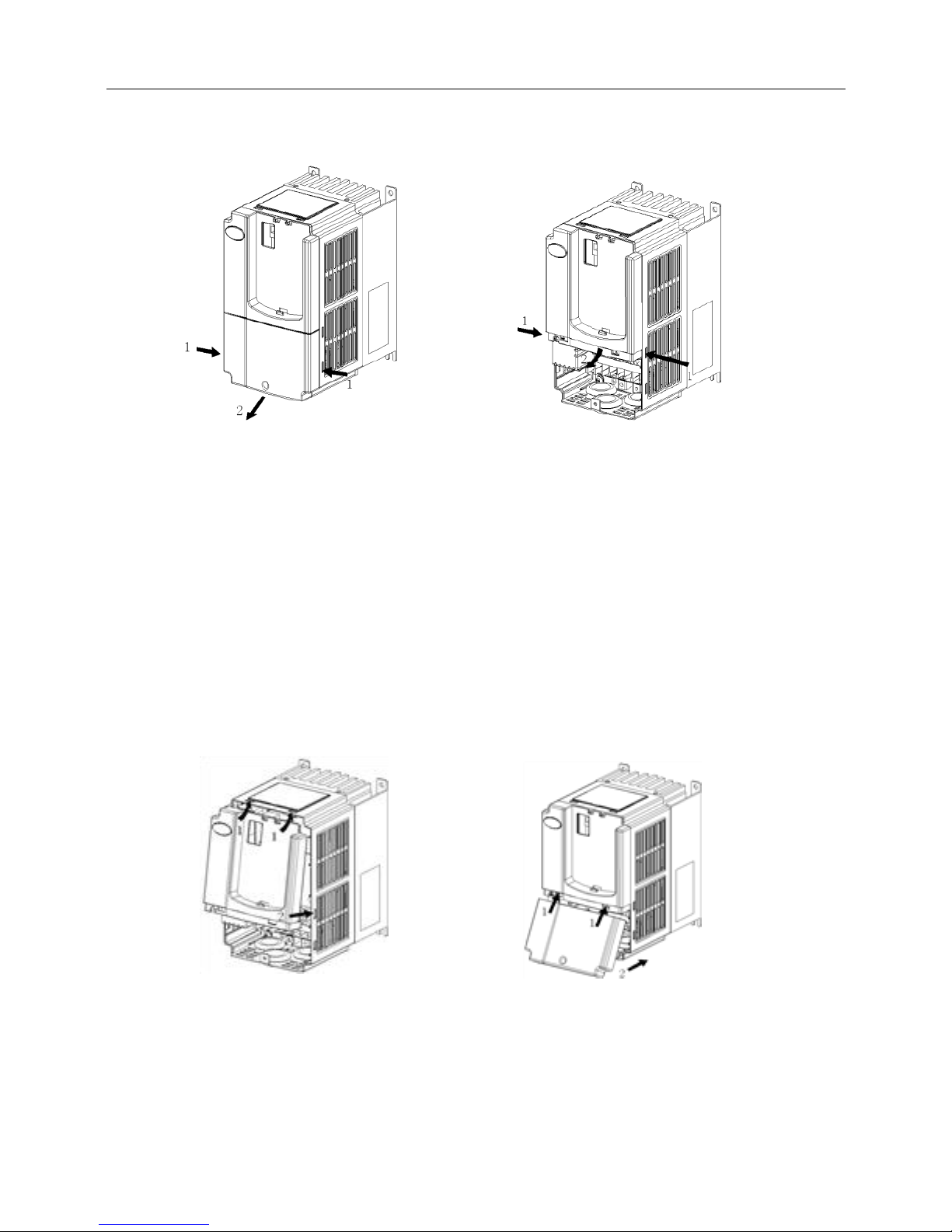

2.3.2 Removal and Mounting of Covers of Inverter with Plastic Enclosure

Removal of operation panel

Please refer to 2.3.1 removal and mounting of operation panel.

Removal of lower cover

After removing the mounting screws of the cover, press the left and right sides of the cover

forcefully in direction 1 and at the same time lift the cover in direction 2, as shown in Fig. 2−5.

Removal of upper cover

As shown in Fig.2−6, press the left and right sides of the cover forcefully in direction 1, and at the

same time lift the cover in direction 2.

Page 22

TMP High Performance Vector Control Inverter User Manual

18

Fig.2−5 Removal of lower cover Fig.2−6 Removal of upper cover

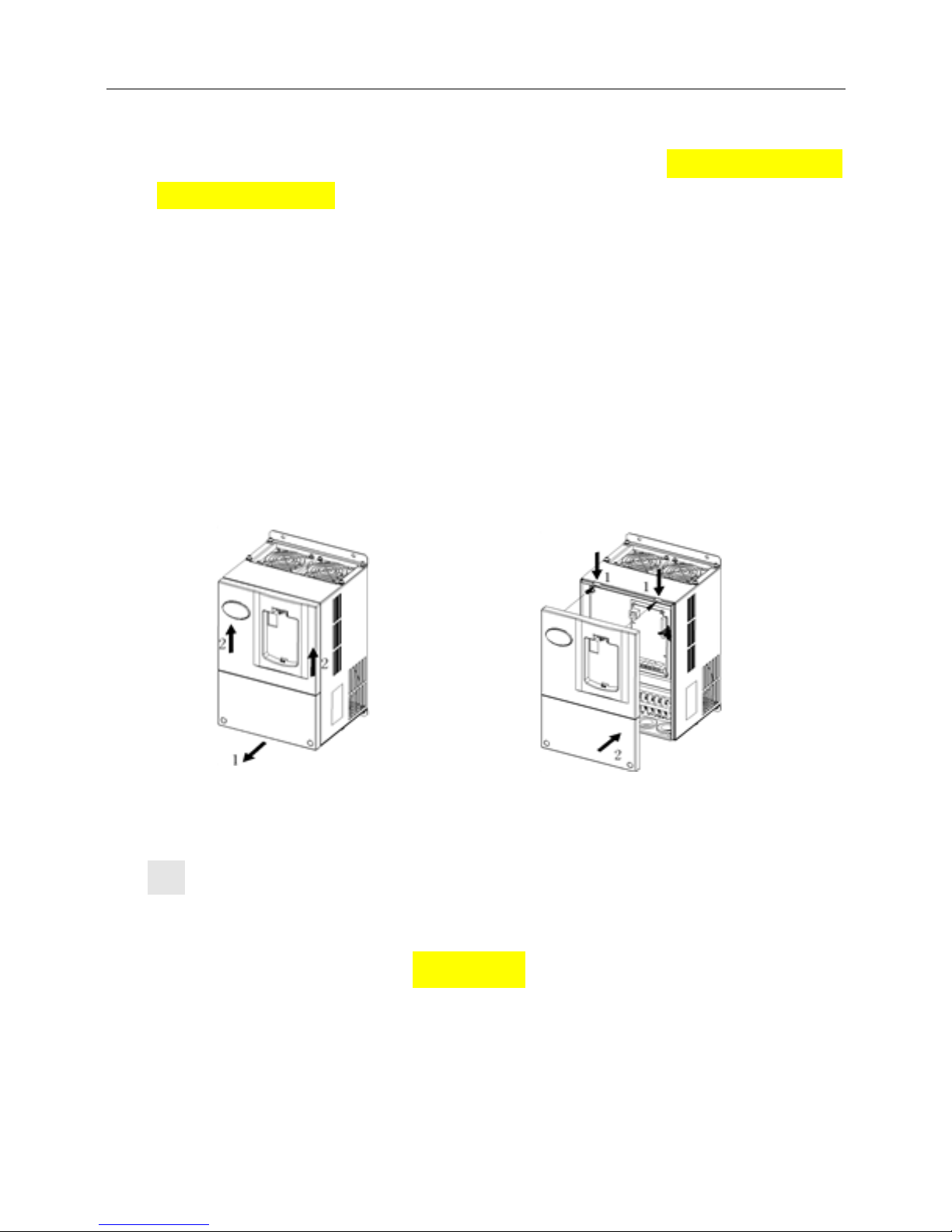

Mounting of upper cover

After the wiring of main circuit terminals and control circuit terminals, insert the upper claw grab of

the upper cover into the groove of the inverter body, as shown in position 1 in Fig.2−7, and then

press the lower part of the upper cover in direction 2 as shown in Fig.2−7, until the “crack” sound is

heard.

Mounting of lower cover

Insert the upper claw grab on the lower cover into the groove of the upper cover, as shown in

position 1 of Fig.2−8, and then press the lower part of the lower cover in direction 2 of Fig.2−8, until

the “crack” sound is heard. Now, tighten the cover screws.

Fig.2−7 Mounting of upper cover Fig.2−8 Mounting of lower cover’

Mounting of operation panel

Please refer to 2.3.1 Removal and mounting of operation panel.

Page 23

TMP High Performance Vector Control Inverter User Manual

19

2.3.3 Removal and Mounting of Covers of TMP−011G-4/015P-4 ~

TMP−075G-4/090P-4and Above Power Class Inverter with Sheet-metal Enclosure

Removal of operation panel

Please refer to 2.3.1 Removal and mounting of operation panel.

Removal of cover

Remove the mounting screws on the lower part of the cover, lift the cover in direction 1 as shown in

Fig.2−9, and then take out the cover in direction 2.

Mounting of cover

After the wiring of the main circuit terminals and control circuit terminals, cramp the cover in

direction 1 as shown in Fig.2−10, press down the cover in direction 2 and then tighten the cover

screws.

Fig.2−9 Removal of cover Fig.2−10 Mounting of cover

Mounting of operation panel

Please refer to 2.3.1 Removal and mounting of operation panel.

Note:

Do not directly mount the cover with operation panel on the inverter, otherwise, the operation panel will

have poor contact.

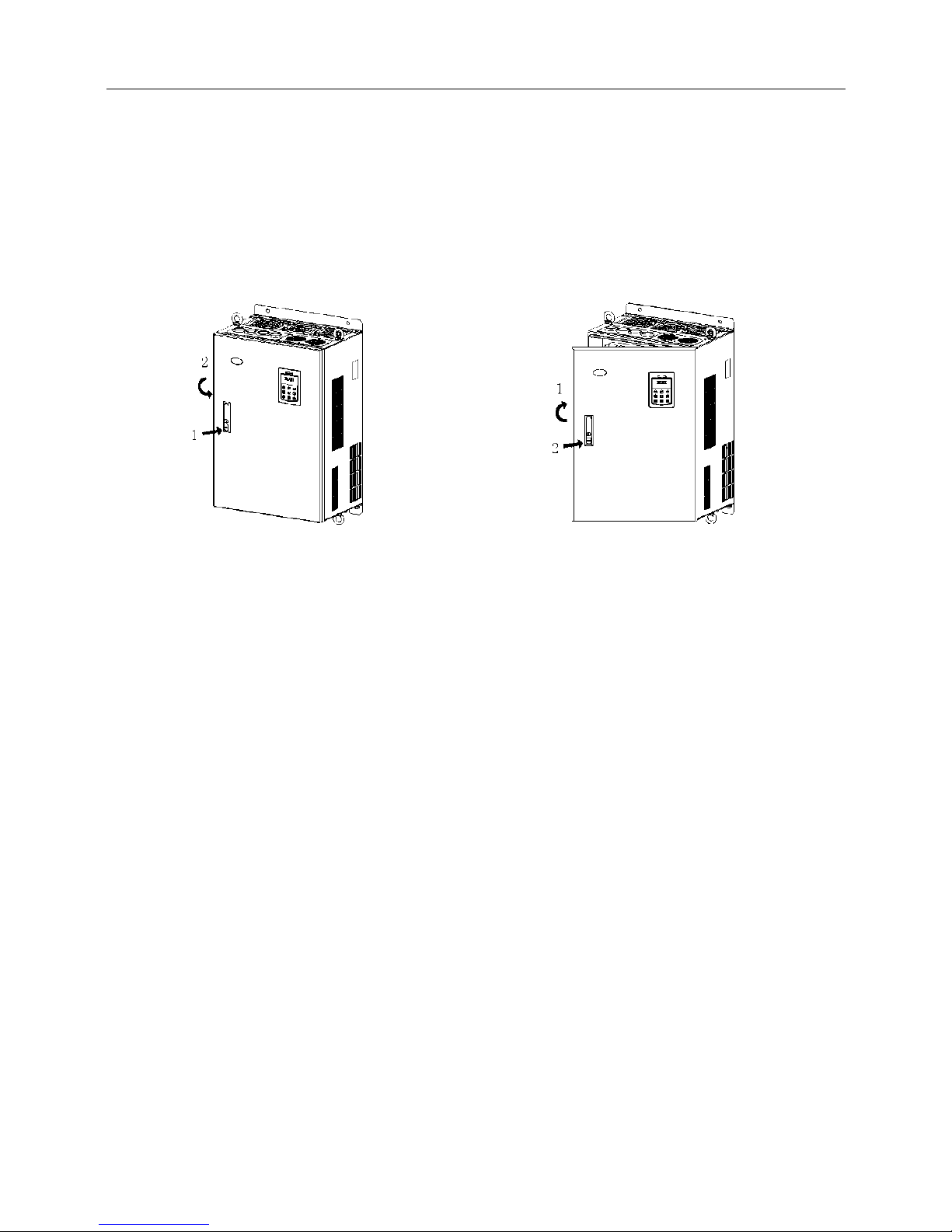

2.3.4 Open and Close of Doors of TMP−090G-4 and Above Power Class Inverter with

Sheet-metal Enclosure

Opening of the door

Press the latch following direction 1 in Fig.2−11 and open the door following direction 2.

Removal of operation panel

Page 24

TMP High Performance Vector Control Inverter User Manual

20

The operation panel is connected to the control board through the standard network cable and will not

interfere with the open/close of the door. To remove the operation panel, refer to section 2.3.1 Removal

and Mounting of Operation Panel

Mounting of cover

After the wiring operation of main circuit terminals and control circuit terminals is completed, close the

door following direction 1 in Fig.2−12, and then press down the latch following direction 2 to lock the

door.

Fig. 2−11 opening the door Fig. 2−12 closing the door

Page 25

TMP High Performance Vector Control Inverter User Manual

21

Chapter 3 Wiring of Inverter

3.1 Connection of the Product and Peripheral Devices

Fig.3−1 Connection diagram of the product and peripheral devices

Power supply

Contactor

Input AC reactor

DC reactor

Inverter

Grounding

Motor

Grounding

Circuit breaker or

leakage circuit breaker

Input noise filter

Output noise filter

Braking resistor

Output AC reactor

Page 26

TMP High Performance Vector Control Inverter User Manual

22

3.2 Description of Peripheral Devices for Main Circuit

Circuit breaker

The capacity of the circuit breaker shall be 1.5 ~ 2 time of the rated current of the inverter.

The time features of the circuit breaker shall fully consider the time features of the inverter

overload protection.

Leakage circuit

breaker

Because the inverter output is the high-frequency pulse, there will be high-frequency leakage

current. Special leakage circuit breaker shall be used when installing leakage circuit breaker

at the input end of the inverter.

It is suggested that B type leakage circuit breaker be used, and the leakage current value

shall be set as 300mA.

Contactor

Frequent open and close of contactor will cause inverter failure, so the highest frequency for

the open and close of contactor shall not exceed 10 times/min.

When braking resistor is used, to void the overtemperature damage of the braking resistor,

thermal protection relay with braking resistor overtemperature detection shall be installed to

disconnect the contactor at the contact control power side of the thermal protection relay.

Input AC reactor

or DC reactor

1. The inverter power supply capacity is more than 600kVA or 10 times of the inverter capacity.

2. If there is switch type reactive-load compensation capacitor or load with silicon control at

the same power node, there will be high peak current flowing into input power circuit,

causing the damage of the rectifier components.

3. When the voltage unbalancedness of the three-phase power supply of the inverter

exceeds 3%, the rectifier component will be damaged.

4. It is required that the input power factor of the inverter shall be higher than 90%.

When the above situations occur, install the AC reactor at the input end of the inverter or DC

reactor to the DC reactor terminal.

Input noise filter

The noise input from the power end to the inverter and output from the inverter to the power

end can be reduced.

Thermal protection

relay

Although the inverter has motor overload protection function, when one inverter drives two or

more motors or multi-pole motors, to prevent the motor overtemperature failure, thermal

protection relay shall be installed between the inverter and each motor, and the motor

overload protection parameter P9.16 shall be set as “2” (motor protection disabled).

Output noise filter

When the output end of the inverter is connected with noise filter, the conduction and

radiation interference can be reduced.

Output AC reactor

When the cable connecting the inverter and the motor is longer than 100m, it is suggested to

install AC output reactor to suppress the high-frequency oscillation to avoid the damage to

motor insulation, large leakage current and frequent inverter protective action.

3.3 Lectotype of mMain Circuit Peripheral Devices

Inverter model

Circuit

(A)

(A)

R/L1, S/L2, T/L3, ⊕1, ⊕2/B1, B2,

Ө

, U/T1, V/T2, W/T3

Grounding terminal PE

Terminal

screw

Tightenin

g torque

(N·m)

Wire

specificatio

n (mm2)

Terminal

screw

Tightening

torque

(N·m)

Wire

specification

(mm2)

TMP−0R4G-2

16

10

M4

1.2~1.5

2.5

M4

1.2~1.5

2.5

TMP−0R7G-2

25

16

M4

1.2~1.5

2.5

M4

1.2~1.5

2.5

TMP−1R5G-2

32

25

M4

1.2~1.5

4

M4

1.2~1.5

2.5

TMP−2R2G-2

40

32

M4

1.2~1.5

6

M4

1.2~1.5

4

TMP−0R7G-4/1R5P-4

10

10

M4

1.2~1.5

2.5

M4

1.2~1.5

2.5

TMP−1R5G-4/2R2P-4

16

10

M4

1.2~1.5

2.5

M4

1.2~1.5

2.5

TMP−2R2G-4/4R0P-4

16

10

M4

1.2~1.5

2.5

M4

1.2~1.5

2.5

TMP−4R0G-4/5R5P-4

25

16

M4

1.2~1.5

4

M4

1.2~1.5

4

TMP−5R5G-4/7 R5P-4

32

25

M4

1.2~1.5

6

M4

1.2~1.5

6

TMP−7R5G-4/011P-4

40

32

M4

1.2~1.5

6

M4

1.2~1.5

6

Page 27

TMP High Performance Vector Control Inverter User Manual

23

Inverter model

Circuit

(A)

(A)

R/L1, S/L2, T/L3, ⊕1, ⊕2/B1, B2,

Ө

, U/T1, V/T2, W/T3

Grounding terminal PE

Terminal

screw

Tightenin

g torque

(N·m)

Wire

specificatio

n (mm2)

Terminal

screw

Tightening

torque

(N·m)

Wire

specification

(mm2)

TMP−011G-4/015P-4

63

40

M5

2.5~3.0

6

M5

2.5~3.0

6

TMP−015G-4/018P-4

63

63

M5

2.5~3.0

6

M5

2.5~3.0

6

TMP−018G-4/022P-4

100

63

M6

4.0~5.0

10

M6

4.0~5.0

10

TMP−022G-4/030P-4

100

100

M6

4.0~5.0

16

M6

4.0~5.0

16

TMP−030G-4/037P-4

125

100

M6

4.0~5.0

25

M6

4.0~5.0

16

TMP−037G-4/045P-4

160

100

M8

9.0~10.0

25

M8

9.0~10.0

16

TMP−045G-4/055P-4

200

125

M8

9.0~10.0

35

M8

9.0~10.0

16

TMP−055G-4/075P-4

315

250

M10

17.6~22.5

50

M10

14.0~15.0

25

TMP−075G-4/090P-4

350

330

M10

17.6~22.5

60

M10

14.0~15.0

35

TMP−093G-4

TMP−110P-4

315

250

M10

17.6~22.5

70

M10

14.0~15.0

35

TMP−110G-4

TMP−132P-4

350

330

M10

17.6~22.5

100

M10

14.0~15.0

50

TMP−132G-4

TMP−160P-4

400

330

M12

31.4~39.2

150

M12

17.6~22.5

75

TMP−160G-4

TMP−185P-4

500

400

M12

31.4~39.2

185

M12

17.6~22.5

50×2

TMP−185G-4

TMP−200P-4

630

500

M12

48.6~59.4

240

M12

31.4~39.2

60×2

TMP−200G-4

TMP−220P-4

630

500

M12

48.6~59.4

240

M12

31.4~39.2

60×2

TMP−220G-4

TMP−250P-4

800

630

M12

48.6~59.4

150×2

M12

31.4~39.2

75×2

TMP−250G-4

TMP−280P-4

1000

630

M12

48.6~59.4

185×2

M12

31.4~39.2

100×2

TMP−280G-4

TMP−315P-4

1000

630

M12

48.6~59.4

185×2

M12

31.4~39.2

100×2

TMP−315G-4

TMP−355P-4

1000

800

M14

48.6~59.4

250×2

M14

31.4~39.2

125×2

TMP−355G-4

TMP−400P-4

1200

800

M14

48.6~59.4

325×2

M14

31.4~39.2

150×2

TMP−400G-4

TMP−450P-4

1500

1000

M14

48.6~59.4

325×2

M14

31.4~39.2

150×2

TMP−450G-4

TMP−500P-4

2000

1500

M14

48.6~59.4

350×2

M14

31.4~39.2

175×2

TMP−500G-4

TMP−560P-4

2000

1500

M14

48.6~59.4

350×2

M14

31.4~39.2

175×2

Page 28

TMP High Performance Vector Control Inverter User Manual

24

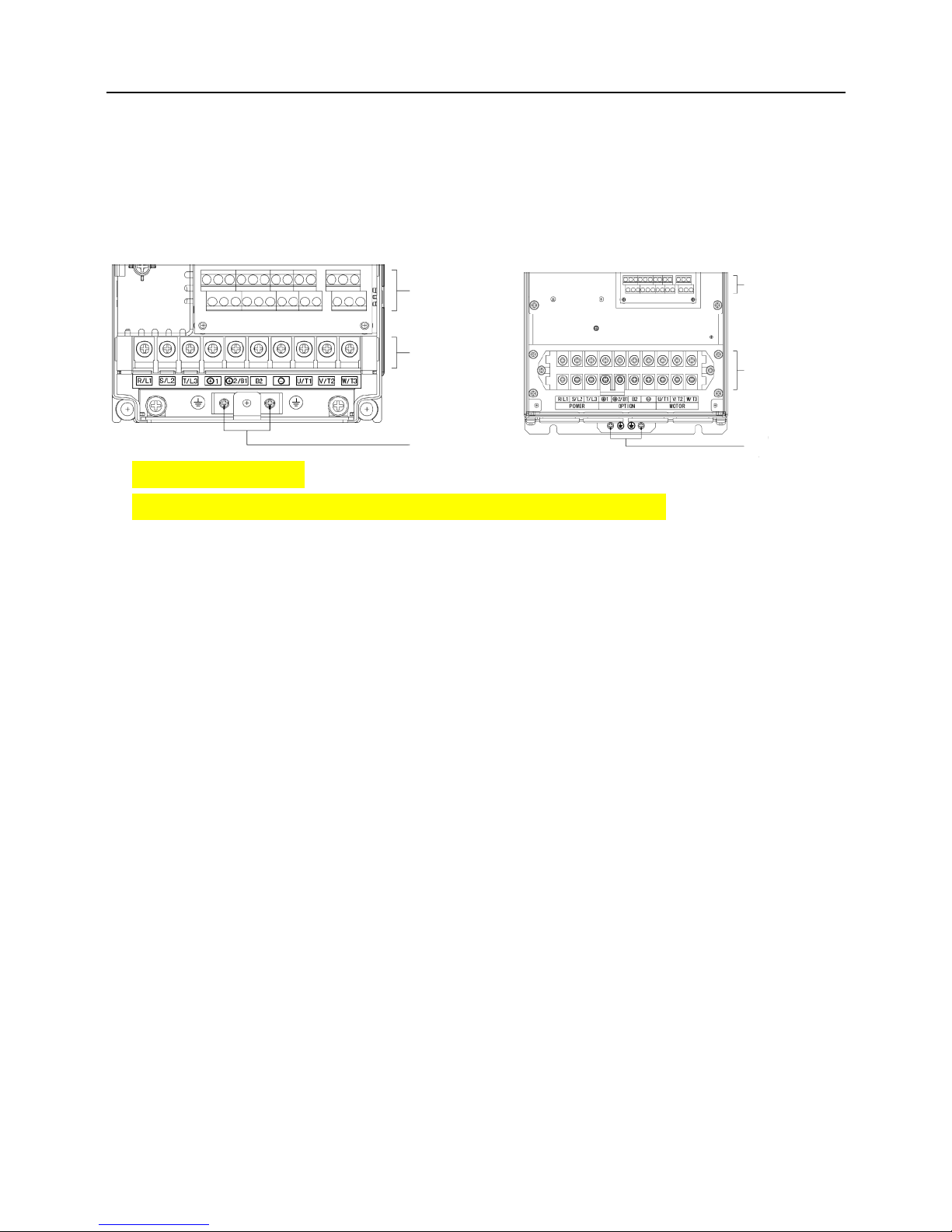

3.4 Product Terminal Configuration

TMP−0R4-2G~TMP−2R2G-2

TMP−7R5G-4/011P-4 and below power class TMP−7R5G-4/011P-4 and above power class

Fig.3−2 Product terminal configuration

Control circuit

terminal

Main circuit

terminal

Grounding

terminal

Control circuit

terminal

Main circuit

terminal

Grounding

terminal

Page 29

TMP High Performance Vector Control Inverter User Manual

25

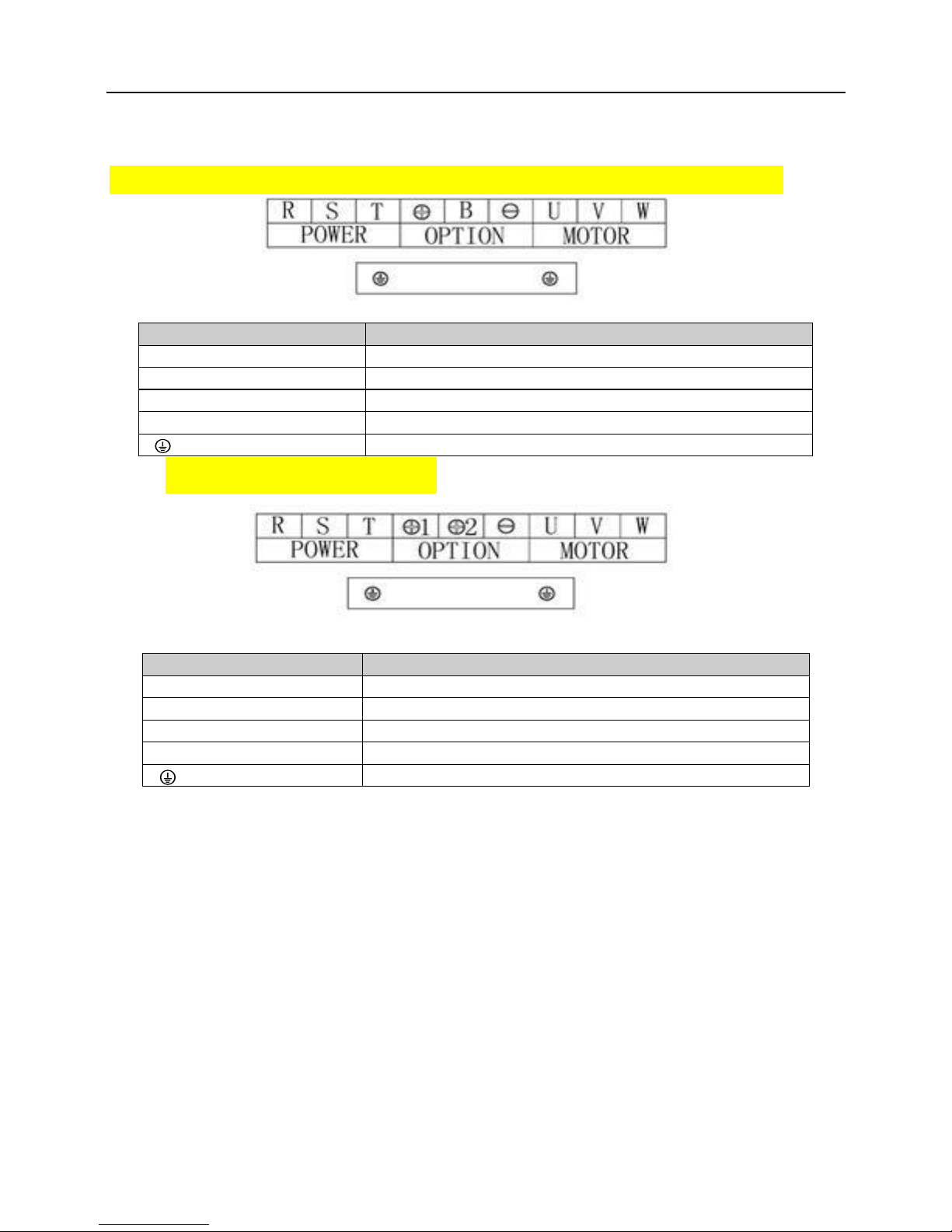

3.5 Functions of Main Circuit Terminal

3.5.1 TMP−0R4G-2~TMP−2R2G-2 和 TMP−0R7G-4/1R5P-4~TMP−015G-4/018P-4

3.5.2 TMP−018G-4/022P-4~TMP-630G-4

Terminal symbol

Terminal name and function description

R、S、T

Three-phase AC input terminal

⊕1、⊕

2

DC reactor connecting terminal, short circuited with copper bus upon

⊕

2、 Ө

DC power input terminal; DC input terminal of external braking unit

U、V、W

Three-phase AC output terminal

Grounding terminal PE

3.6 Attention for Main Circuit Wiring

3.6.1 Power Supply Wiring

It is forbidden to connect the power cable to the inverter output terminal, otherwise, the internal

components of the inverter will be damaged.

To facilitate the input side overcurrent protection and power failure maintenance, the inverter shall

connect to the power supply through the circuit breaker or leakage circuit breaker and contactor.

Please confirm that the power supply phases, rated voltage are consistent with that of the nameplate,

otherwise, the inverter may be damaged.

3.6.2 Motor Wiring

It is forbidden to short circuit or ground the inverter output terminal, otherwise the internal

components of the inverter will be damaged.

Terminal symbol

Terminal name and function description

R、S、T

Three-phase AC input terminal

⊕

、B

Connecting terminal of braking resistor

⊕

、

Ө

DC power input terminal; DC input terminal of external braking unit

U、V、W

Three-phase AC output terminal

Grounding terminal PE

Page 30

TMP High Performance Vector Control Inverter User Manual

26

Avoid short circuit the output cable and the inverter enclosure, otherwise there exists the danger of

electric shock.

It is forbidden to connect the output terminal of the inverter to the capacitor or LC/RC noise filter with

phase lead, otherwise, the internal components of the inverter may be damaged.

When contactor is installed between the inverter and the motor, it is forbidden to switch on/off the

contactor during the running of the inverter, otherwise, there will be large current flowing into the inverter,

triggering the inverter protection action.

Length of cable between the inverter and motor

If the cable between the inverter and the motor is too long, the higher harmonic leakage current of the

output end will cause adverse impact on the inverter and the peripheral devices. It is suggested that

when the motor cable is longer than 100m, output AC reactor be installed. Refer to the following table for

the carrier frequency setting.

Length of cable between the

inverter and motor

Less than 50m

Less than 100 m

More than 100m

Carrier frequency (PA.00)

Less than 15kHz

Less than 10kHz

Less than 5kHz

3.6.3 Grounding Wiring

The inverter will produce leakage current. The higher the carrier frequency is, the larger the leakage

current will be. The leakage current of the inverter system is more than 3.5mA, and the specific value of

the leakage current is determined by the use conditions. To ensure the safety, the inverter and the motor

must be grounded.

The grounding resistance shall be less than 10ohm. For the grounding wire diameter requirement,

refer to 3.3 lectotype of main circuit peripheral devices.

Do not share grounding wire with the welding machine and other power equipment.

In the applications with more than 2 inverters, keep the grounding wire from forming a loop.

Correct Wrong

Fig. 3−3 Grounding wiring

Page 31

TMP High Performance Vector Control Inverter User Manual

27

3.6.4 Countermeasures for Conduction and Radiation Interference

Fig.3−4 Noise current illustration

When the input noise filter is installed, the wire connecting the filter to the inverter input power end

shall be as short as possible.

The filter enclosure and mounting cabinet shall be reliably connected in large area to reduce the back

flow impedance of the noise current Ig.

The wire connecting the inverter and the motor shall be as short as possible. The motor cable adopts

4-core cable, with the grounding end grounded at the inverter side, the other end connected to the motor

enclosure. The motor cable shall be sleeved into the metal tube.

The input power wire and output motor wire shall be kept away from each other as long as possible.

The equipment and signal cables vulnerable to influence shall be kept far away from the inverter.

Key signal cables shall adopt shielding cable. It is suggested that the shielding layer shall be

grounded with 360-degree grounding method and sleeved into the metal tube. The signal cable shall be

kept far away from the inverter input wire and output motor wire. If the signal cable must cross the input

wire and output motor wire, they shall be kept orthogonal.

When analog voltage and current signals are adopted for remote frequency setting, twinning

shielding cable shall be used. The shielding layer shall be connected to the grounding terminal PE of the

inverter, and the signal cable shall be no longer than 50m.

The wires of the control circuit terminals RA/RB/RC and other control circuit terminals shall be

separately routed.

It is forbidden to short circuit the shielding layer and other signal cables or equipment.

When the inverter is connected to the inductive load equipment (e.g. electromagnetic contactor, relay

and solenoid valve), surge suppressor must be installed on the load equipment coil, as shown in Fig.3-5.

Fig.3−5 Application of inductive load surge suppressor

Input filter

Inverter

Filtering cable

Input filter

Inverter

Filtering cable

DC 24V AC 220V

AC 220V

感性

负载

感性

负载

感性

负载

压敏

电阻

Inductive

load

Inductive

load

Inductive

load

Piezoresistor

DC 24V AC 220V

AC 220V

感性

负载

感性

负载

感性

负载

压敏

电阻

Inductive

load

Inductive

load

Inductive

load

Piezoresistor

Page 32

TMP High Performance Vector Control Inverter User Manual

28

3.7 Terminal Wiring

Braking resistor

B

R

S

T

U

V

W

M

Morotr

Three phase AC

power supply

Circult braker

Power grounding

Mortor grounding

Main circult

X1

X2

X3

X4

X5

X6

X7/DI

CM

+10V

AI1

GND

AI2

485+

485-

GND

(Compatible with pulse input)

Multi function input 1

Analog input reference voltage

(DC 0~10V)

10kΩ

P

P

Analog input

DC 0~10V

DC 0~20mA

Switchable)

(

P

Modbus

communication

RS485

AO1

AO2

GND

A1

+24V

Y1

P

+

-

P

+

-

(DC 0~10V)

DC 0~10V

DC 0~20mA

Switchable)

(

C1

B1

Relay output

250V AC/1A

30V DC/1A

Relay

CM

Analog input/analog output

AI2

V

I

AO2

V

I

485

ON

OFF

P

Shielding

cable

Twisted shielding

cable

Operation panel

interface

CN2

Control circult

Multi function input 2

Multi function input 3

Multi function input 4

Multi function input 5

Multi function input 6

Multi function input 7

485 terminal resistor selecting switch

Analog output 1

Analog output 2

Fig.3−6 Terminal wiring diagram (take TMP−015G-4/018P-4 as an example)

Page 33

TMP High Performance Vector Control Inverter User Manual

29

3.8 Functions of Control Circuit Terminals

Type

Terminal

symbol

Terminal function

description

Technical specification

Terminal

485

485+

Positive end of 485

differential signal

Rate: 4800/9600/19200/38400/57600bps

Up to 32 sets of equipment can be paralleled. Relay

shall be used if the number exceeds 32.

Maximum distance: 500m (adopt standard twisted

shielding cable)

485−

Negative end of 485

differential signal

GND

Shielding grounding of 485

communication

Internal isolated with COM

Operation

panel 485

CN2

485 port of operation panel

When used for communication connection with host

The maximum distance is 15m for the communication

connection of operation panel

Digital input

+24V

+24V

24V±10%, internal isolated with GND,

Maximum load: 200mA, with overload and short

circuit protection

X1~X6

Multi-functional input

terminals 1 ~ 6

Input specification: 24VDC,5mA

Frequency range: 0~200Hz

Voltage range: 24V±20%

X7/DI

Multi-functional input or

pulse input

Multi-functional input: same as X1~X6

Pulse input: 0.1Hz~10kHz; voltage range: 24V±20%

CM

+24V grounding

Internal isolated with GND

Digital

outpu

Y1

Open collector output

Voltage range: 24V±20%, maximum input current:

50mA

CM

Open collector output

common end

Internal isolated with GND

Analog

input

+10V

Analog input reference

voltage

10V ±3%, internal isolated with COM,

Maximum output current: 10mA, with short circuit

and overload protection

AI1

Analog input channel 1

0~10V: Input impedance 20kΩ, maximum input

voltage : 15V

Resolution: 10 bits (0.025%)

AI2

Analog input channel 2

0~20mA: Input impedance 500Ω, maximum input

current: 30mA

0~10V: Input impedance 20kΩ, maximum input

voltage : 15V

Resolution: 10 bits (0.025%)

0~20mA or 0~10V analog input can be selected

through jumper.

GND

Analog grounding

Internal isolated with COM

Analog

output

AO1

Analog output 1

0~20mA: allowable output impedance 200~500Ω

0~10V: allowable output impedance ≥10kΩ

Output precision: 2%, resolution: 10 bits (0.1%)

with short circuit protection function,

0~20mA or 0~10V analog output can be selected

through jumper.

AO2

Analog output 2

0~20mA: allowable output impedance 200~500Ω

0~10V: allowable output impedance ≥10kΩ

Output precision: 2%, resolution: 10 bits (0.1%)

with short circuit protection function,

0~20mA or 0~10V analog output can be selected

through jumper.

Page 34

TMP High Performance Vector Control Inverter User Manual

30

GND

Analog grounding

Internal isolated with COM

Relay

output

A1/B1/C1

Relay output

A1-B1:Normally open

C1-B1: Normally closed

Contact capacity: 250VAC/1A, 30VDC/1A

Note: ﹡ If the user connects adjustable potentiometer between +10V and GND, the resistance of the

potentiometer shall be no less than 5kΩ,

Note:

1. The arrangement sequence of the control circuit terminals is as follows:

3.9 Lectotype of Control Circuit Peripheral Devices

Terminal number

Terminal

screw

Tightening

torque

(N·m)

Wire

specification

mm2

Wire type

+10V、AI1、AI2、485+、485−、AO1、

AO2、GND

M3

0.5~0.6

0.75

Twinning shielding

cable

+24V、X1、X2、X3、X4、X5、X6、X7/DI、

CM、Y1、CM、A1、B1、C1

M3

0.5~0.6

0.75

Shielding cable

3.10 Description of Jumper Function

Jumper selecting switch in Fig.3-7:

AI2

V

I

AO2

V

I

485

ON

OFF

Name

Function

Leave-factory

AI2

I is the current input (0~20mA), V is the voltage input (0~10V)

0~20mA

AO2

I is the current input (0~20mA), V is the voltage input (0~10V)

0~20mA

485

485 terminal resistor selection: ON: there is 100Ω terminal resistor, OFF: there

is no terminal resistor

There is no terminal

resistor

Page 35

TMP High Performance Vector Control Inverter User Manual

31

Chapter 4 Using Instructions of Operation Panel

4.1 Introduction to Operation Panel

Shuttle type operation pane(TMP−DP01) Analog type operation pane(TMP−DP02)

Fig. 4−1 Display unit of operation panel

4.2 Descriptions of Indicators

Symbol of

Name

Meanings

Color

Hz

Frequency indicator

On: Current display parameter is running

frequency

red

A

Current indicator

On: Current display parameter is current

red V Voltage indicator

On: Current display parameter is voltage

red

Hz+A

Rotating speed indicator

On: Current display parameter is rotating

speed

red

A+V

Time indicator

On: Current display parameter is time

red

Hz+A+V

% indicator

On: Current display parameter is rotating

red

No unit indicator

Off: Current display parameter is no unit

−

L/R

Running command

reference mode indicator

On: Running command is given via operation

panel

Off: Running command is given via terminals

Flash: Running command is given via host

computer

red

RUN

Running status indicator

On: Inverter is running

Off: Inverter has stopped

Flash: Inverter is stopping

green

F/R

Run forward indicator

On: In stop status, inverter has run forward

command;

In running status, inverter is running

forward

Flash: Changing from running forward to

running reverse

red

TRIP

Faule/Alarm indicator

ON:Normal condition

Off:Fault condition

Flash:Alarm

red

Page 36

TMP High Performance Vector Control Inverter User Manual

32

4.3 Description of Keys on Operation Panel

Symbol

Name

Function

Analog type

Shuttle-type

Programming

key PRG

1、 Switch between program and other states, which includes

parameters display and programming; In menu status, press

this key to return previous menu.

Function

Selection/Save

SET

1、 In program status, press this key to enter next menu.

2、 In menu level 3, press this key to save parameters value.

Increase +

Decrease −

Increase Key

∧

1、 In first level menu, increase function code PX according to edit bit

2、 In second level menu, increase the function code PX YZ data.

3、 In third level menu ,Increase the function code data

Decrease ∨

1、 In first level menu, decrease function code PX according to edit bit

2、 In second level menu, decrease the function PX YZ code data

3、 In third level menu ,decrease the function code data

Shift

>>

1、 In third level menu ,use key >> to shift edit bit of the data

2、 In stop/run status, switch the panel display parameters such

as frequency, current and voltage.

Run Key

RUN

1、 When running command is given via operation panel, the key is

used to control the start of inverter.

2、 After setting the parameter auto tuning,start parameter auto tuning

for inverter startup

Stop/Reset

Key

STOP/RST

1、 When running command is given via operation panel, the key is

used to control the stop of inverter.

2、 When the inverter has fault and has stopped, this key is used as

RESET key to clear the fault alarm.

Multi-function

Key MF

0:Nonfunction;1:Reversal

JOG KEY

JOG

Press this key to start jog operation, release this key to stop the drive.

Page 37

TMP High Performance Vector Control Inverter User Manual

33

4.4 Keypad Operating Status

4.4.1 Initialization after power on

When the power is switched on, panel will start 5 seconds’ initiation process. During this

process, LED displays "8.8.8.8.” , and all LED indicators on the panel are in ON state

4.4.2 Stopping State

In stopping state, LED displays default parameters in flashing mode, and the unit

indicator in right side displays the unit of this parameters. In this state, all status

indicators are OFF, press ►► key ,LED displays fault code“n-xx”(xx=00-08),press

SET key to enter and view the parameter; press PRG key to exit; and press ►► key to

scroll through parameters in stopping state.

4.4.3 Running state

In stopping state, after receiving running command, the drive enters running

state. The LED and unit indicator display parameter and its unit respectively.

At this time, running status indicator is ON all the time. Press PRG key to

enter programming menu and view parameter value.

Press ►► key, LED displays running parameter “r-xx” (xx=00~14). Press

SET key to enter and view parameter value; press PRG key to exit this parameter

menu; press ►► key to scroll through monitoring parameters.

4.4.4 Fault alarm state

In stopping, running or programming state, correspondent fault information

will be reported if fault is detected. At this time, LED displays the fault code in

flashing mode. When fault alarm occurs, press PRG key to enter programming

menu and look up the fault log.

When fault alarm occurs, the alarm picture is displayed, and the fault can be

reset by press STOP/RESET key. The drive restores to normal operation upon

clearing the fault, and the fault code is displayed again if the fault has not been

cleared.

Page 38

TMP High Performance Vector Control Inverter User Manual

34

4.5 Panel Operation Method

4.5.1 Panel Operation Procedure

Parameter setting method via panel: through three-level menu, users can look

up and modify the function codes very easily.

Three level menu structure: function parameters (first level)→ function

codes(second level)→value of function code(third level). Operation process is

shown in Fig.4-1.

Stop/run

first level

second level

third level

PRG

PRG

SET

PRG

PRG

SET

function codes set

Fig.4-1 Menu Operation Procedure

In the third level menu, user can return second level menu by pressing PRG key or

SET key. The difference is: Parameter settings can be saved in control board if SETkey

is pressed, then LED returns to second level menu and shifts to next function code

automatically; If user presses PRG key, LED returns to second level menu directly, but

the parameters can not be saved and stop at current function code.

4.5.2 Parameter setup

Setting parameters correctly is a premise for actualizingTMP’s performances.

Parameter setting method via panel will be introduced in the following part with rated

power as an example (Change 18.5kW into 7.5kW).

Operation process is shown in Fig.5-2. Press the SHIFT key with single direction

shifting function to shift the flashing bit of parameters (that is modification bit). After

finishing the parameters setup, press the MENU key twice to exit programing state.

Page 39

TMP High Performance Vector Control Inverter User Manual

35

50.00

P0

-P0-

P3

-P3-

P3.00

0.4~999.9KW

018.5

018.5

008.5

008.5

007.5

P3.01

50.00

0.4~999.9KW

0.4~999.9KW

0.4~999.9 KW

0.4~999.9 KW

PRG

SET

SET

PRG

SET

stopping state

/ running state

Basic

parameters

Stop monitoring

parameters

motor

parameters

Motor rated power

By three

times

By two

times

Motor rated

voltage

At a time

Stop monitoring

parameters

stopping state

/ running state

Fig 4-2 Procedure of parameter setup

4.6 Parameter Display

In stopping state or running state, various state parameters can be displayed by

LED. The displayed parameters can be decided by PH.00 ~ PH.01 and can be scrolled

through by pressing the SHIFT key. The following is an explanation for the parameters

operation method in stopping and running state.

4.6.1 Switch of Parameter Display in Stopping State

In stopping state, the drive has 9 state parameters which can be scrolled by SHIFT

key, they are: frequency setting, external counting value, digital value input terminal

state, digital value output terminal state, panel potentiometer, analog input AI1, analog

input AI2 and DC bus voltage. Please refer to the explanation of PH.01.

The default value of PH.01 is "preset frequency". If PH.01 value is set to 2, default

display parameter in stopping state will be changed into "DC bus voltage".

User can look up other parameters during stopping state by pressing SHIFT key:

Everytime you press SHIFT key, the next parameter in stopping state will be displayed.

Page 40

TMP High Performance Vector Control Inverter User Manual

36

4.6.2 Switch of the running parameters

In running state, maximum 15 running state parameters can be displayed by TMP drive

via SHIFT key.

4.7 Motor auto-tuning procedure

Before selecting vector control mode, user should input motor parameters correctly.

TMP drive can get motor’s standard parameters according to the parameters on

nameplate; In order to get better control performance, you can control the drive to

perform auto-tuning on the motor, so as to get accurate motor parameters.

Parameter tuning can be done through P3.05.

1. Set F0.01 parameter to 0 to select panel running command control mode;

2. According the motor’s name-plat,Set P3.00、P3.01、P3.02、P3.03、P3.04 parameter in proper order。

3. Set P3.05 to1,Slect static auto- tuning,Or set P3.05 to 2,Slect overall auto- tuning ,Press“SET”

key。

4. Press RUN key to start motor auto-tuning, After tuning, the motor stops.

Page 41

TMP High Performance Vector Control Inverter User Manual

37

4.8 Running for the First Time

Please follow the procedures to run the inverter for the first time:

P7.10

P7.10

50Hz

FWD

50Hz

REV

5V

10V

AI1

AI2

P7.01=50%

P7.02=0Hz

P7.06=50%

P7.07=0Hz

OR

Note:

◆If fault happens, please judge the fault

causes and clear the fault according to

7.1 Fault and alarm information list.

◆If motor can without connecting the load

rotating auto tuning can be selected

(P3.05=2),otherwise only static auto

tuning can be selected .When enabling

the auto tuning please ensure the motor is

in standstill status .If over voltage or over

current happens in auto tuning process,

you can prolong the acceleration and

deceleration times of P0.16 and P0.17.

Page 42

TMP High Performance Vector Control Inverter User Manual

38

Chapter 5 List of Parameters

Meanings of Each Item in Function Code Parameter Table

Item

Mean in gs

Function code

number

The number of function code, such as P0.00

Function code

name

The name of function code, which explains the function code’s meanings.

Function code

selection

Function code parameter setting list

Factory setting

Restore the settings of the function code after the product is delivered (see P0.19).

Order number

The order number of function code

Property

#: This function code can be changed during operation; +: This function code can only be changed

during stopping status; *: The setting of this function code is read-only and cannot be changed.

5.1 Function Parameter Table

Function

code

Name

Description

Factory

setting

Order

number

Property

P0 Group Basic parameter

P0.00

reserved

0

*

P0.01

Running command

selection

0: Keypad control

1: External terminal

2: Commuincation

0

1

+

P0.02

Control mode

0: open loop vector control

1: V/F control

1

2

+

P0.03

Main Frequency

Source

0:Panel setting

1:External analog signal AI1(0~10V)

2 : External analog signal AI2(0~10V) or

0~20mA

3: up/down 1 setting

4: up/down 1 setting

5:Pulse frequency setting

6:Multi Frequency

7:PID

8:Communication setting mode

9:Program run

0

3

+

Page 43

TMP High Performance Vector Control Inverter User Manual

39

10:Panel potentiometer setting (0~5V)

P0.04

Main Frequency gain

0.000-9.999

1.000 4 +

P0.05

Zero frequency

source of

multi-speed mode

0:Digital frequency of P0.11

1:External analog signal: AI1

2:External analog signal: AI2

3: Panel potentiometer setting (0~5V)

0

5

+

P0.06

Auxiliary frequency

source

0:External analog signal: AI1(0~10V)

1:External analog signal: AI2(0~10V) or

0~20mA

2: External analog signal:AI1(0~10V)( +/polarity)

3:External analog signal: AI2

AI2(0~10V) or 0~20mA(+/- polarity)

4:pid

0

6

+

P0.07

Auxiliary frequency

range selection

0:Maximum output frequency

1:Main frequency

0

7

+

P0.08

Auxiliary frequency

range

0-100%

100

8

+

P0.09

Setting Frequency

selection

0:Main frequency

1:Auxiliary frequency

2:Main frequency + Auxiliary frequency

3:Main frequency - Auxiliary frequency

4 : switch between Main frequency and

Auxiliary frequency

5:switch between Main frequency and (Main

frequency + Auxiliary frequency)

6:switch between Main frequency and (Main

frequency - Auxiliary frequency)

7 : MAX ( Main frequency , Auxiliary

frequency)

8 : MIN ( Main frequency , Auxiliary

frequency)

9:Traverse operation

0

9

+

P0.10

up/down setting store

selection

0:Store

1:Not Store

0

10

#

Page 44

TMP High Performance Vector Control Inverter User Manual

40

P0.11

Digital frequency

setting

0~400.0Hz

50.00

11

#

P0.12

Rotating direction

(Keypad operation)

0: FWD

1: REV

0

12

+

P0.13

Maximum output

frequency

50.00~400.0 Hz

50.00

13

+

P0.14

High frequency limit

0.00~ Maximum output frequency

50.00

14 + P0.15

Low frequency limit

0.00Hz~ High frequency limit

0

15

+

P0.16

Acc time 1

0.1~3600.0s

20.0

16

#

P0.17

Dec time 1

0.1~3600.0s

20.0

17

#

P0.18

Inverter type

select

0:General load mode

1:light load mode (for fan,punp)

0

18

+

P0.19

Parameter

initialization

0: No operation

1: Clear fault information

2: Recover factory setting