AIR VENTS

Pamphlet M3600

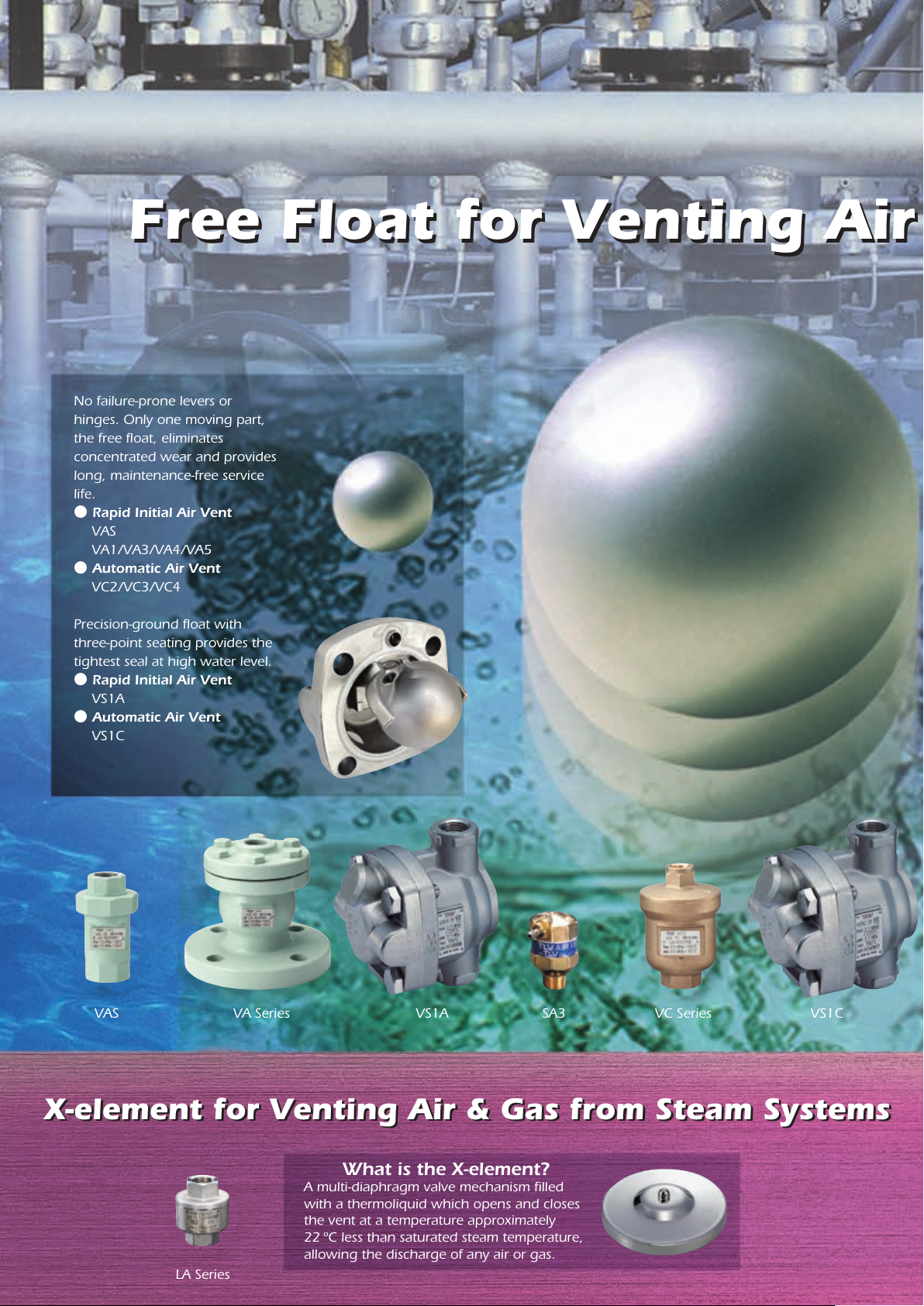

Free Float for Venting Air & Gas from Liquid Piping

Free Float for Venting Air & Gas from Liquid Piping

X-element for Venting Air & Gas from Steam Systems

X-element for Venting Air & Gas from Steam Systems

VAS VA Series VS1A

LA Series

SA3 VC Series VS1C

No failure-prone levers or

hinges. Only one moving part,

the free float, eliminates

concentrated wear and provides

long, maintenance-free service

life.

● Rapid Initial Air Vent

VAS

VA1/VA3/VA4/VA5

● Automatic Air Vent

VC2/VC3/VC4

Precision-ground float with

three-point seating provides the

tightest seal at high water level.

● Rapid Initial Air Vent

VS1A

● Automatic Air Vent

VS1C

What is the X-element?

A multi-diaphragm valve mechanism filled

with a thermoliquid which opens and closes

the vent at a temperature approximately

22 ºC less than saturated steam temperature,

allowing the discharge of any air or gas.

*

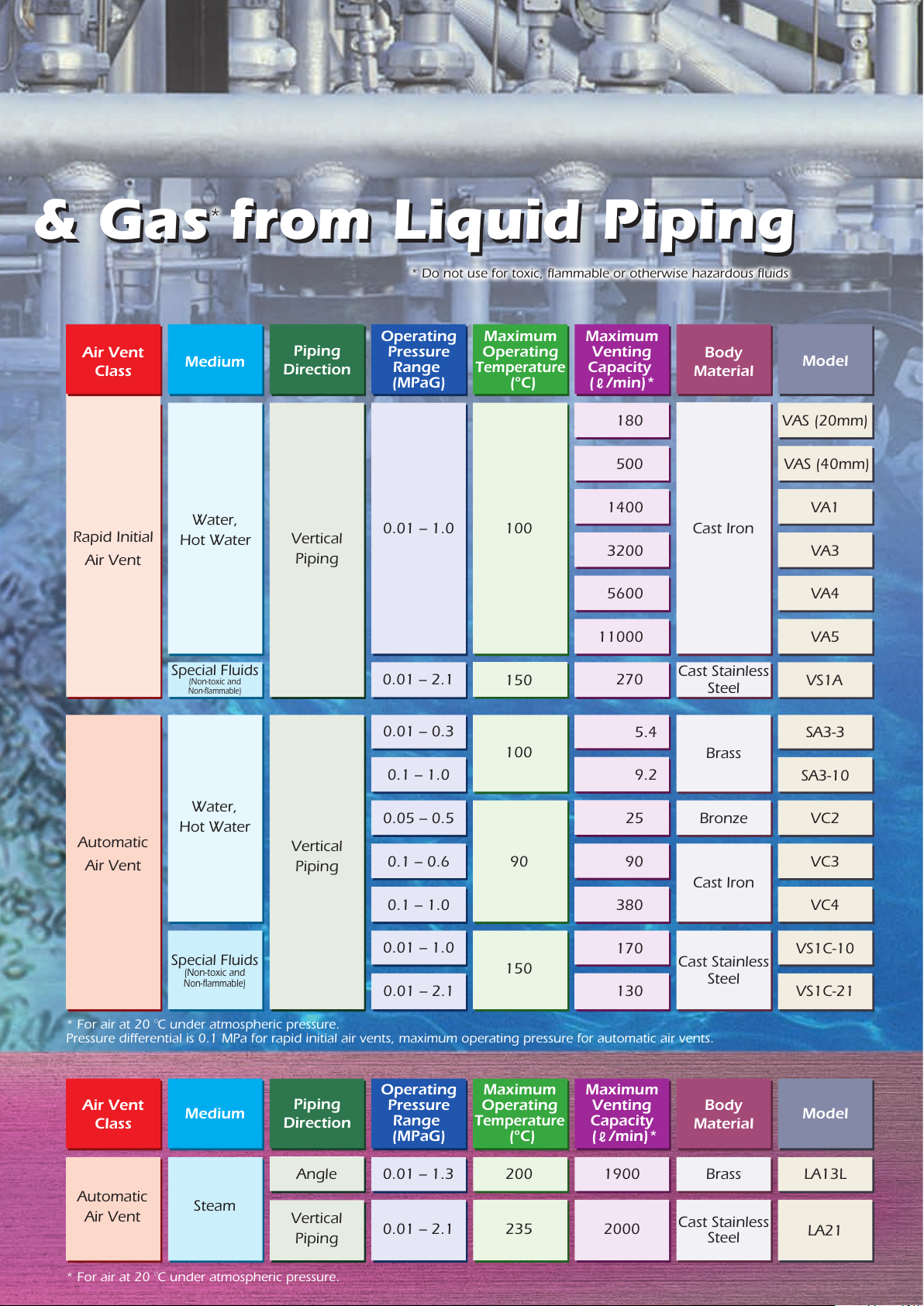

* Do not use for toxic, flammable or otherwise hazardous fluids

Air Vent

Class

Rapid Initial

Air Vent

Water,

Hot Water

Special Fluids

(Non-toxic and

Non-flammable)

Steam

Automatic

Air Vent

Automatic

Air Vent

* For air at 20 。C under atmospheric pressure.

Pressure differential is 0.1 MPa for rapid initial air vents, maximum operating pressure for automatic air vents.

* For air at 20 。C under atmospheric pressure.

Water,

Hot Water

Special Fluids

(Non-toxic and

Non-flammable)

Vertical

Piping

Vertical

Piping

0.01 – 2.1

0.01 – 0.3

0.1 – 1.0

VAS (20mm)

VAS (40mm)

180

500

1400

3200

5600

11000

270

5.4

9.2

25

90

380

170

130

VA1

VA3

VA4

VA5

VS1A

LA13L

SA3-3

SA3-10

VC2

VC3

VC4

VS1C-10

VS1C-21

0.05 – 0.5

0.1 – 0.6 90

0.1 – 1.0

0.01 – 1.0

0.01 – 2.1

Vertical

Piping

1900

LA21

Angle 0.01 – 1.3

0.01 – 2.1

200

235 2000

Medium

Piping

Direction

0.01 – 1.0 100

150

100

150

Operating

Pressure

Range

(MPaG)

Maximum

Operating

Temperature

(ºC)

Model

Medium

Piping

Direction

Operating

Pressure

Range

(MPaG)

Maximum

Operating

Temperature

(ºC)

Model

Brass

Cast Iron

Cast Stainless

Steel

Brass

Bronze

Cast Iron

Cast Stainless

Steel

Cast Stainless

Steel

Body

Material

Air Vent

Class

Body

Material

Maximum

Venting

Capacity

(

/min)*

Maximum

Venting

Capacity

( /min)*

TLV Air Vents

TLV Air Vents

For Liquid

For Liquid

Rapid Initial Air Vent

VAS / VA Series / VS1A

Used for venting large

amounts of initial air or gas at

system start-up. Once the

valve closes after discharging

initial air, it will not open

again, even if air accumulates

inside the product, until the

internal pressure drops to

near atmospheric pressure.

If air is expected to accumulate in the piping

during operation, use together with an

automatic air vent.

Automatic Air Vent

SA3 / VC Series / VS1C

Discharge air or gas

automatically as it enters the

vent at start-up and during

operation. Facilitates

drainage of the system by

introducing air at system

shutdown.

If a large volume of air needs to be discharged at

start-up, use together with a rapid initial air vent.

Air Vent Class Selection

System for

Air Venting

Air Vent Class Required

Rapid Initial

Air Vent

Automatic

Air Vent

Rapid Initial Air Vent

Water ● Hot Water

VAS

a

c

a

c

t

p

t

p

m

m

o

o

C

C

Features

●

Small and compact with simple construction

●

Only one moving part, the free float, eliminates

concentrate wear and provides long service life

●

Precision-ground float and valve seat rubber

contact assures seal tightness when vent is closed

●

Also functions as a vacuum breaker

Application

●

Processes requiring the rapid supply of water

●Water supply pipe, water pump, water tank, etc.

Note: Once the valve closes it will not open again, even if air accumulates.

If air is expected to accumulate, use together with an automatic air vent.

Specifications

Model

Connection

Inlet

Size (mm)

Outlet

Body Material

Maximum Operating

Pressure (MPaG) PMO

Minimum Operating

Pressure (MPaG)

Maximum Operating

Temperature (ºC) TMO

Maximum Venting

Capacity ( /min)*

PRESSURE SHELL DESIGN CONDITIONS (NOT OPERATING CONDITIONS):

Maximum Allowable Pressure (MPaG) PMA: 1.6

Maximum Allowable Temperature (˚C) TMA: 100

20

15

180

VAS

Screwed (Rc(PT))

40

25

Cast Iron (FC250)

1.0

0.01

100

500

Water pumps

Air conditioners,

solar water heating systems

Supply water pipe,

storage tank

For Steam

LA Series

Remove air or gas from steam

systems and shorten start-up

time. Facilitates drainage of the

system by introducing air at

system shutdown.

Construction

9

2

●

10

●

8

●

1

●

6

●

No. No.Part Name Part Name

1

Body

○

2

Union

○

3

Cap Nut

○

4

Valve Seat

○

5

Valve Seat Holder

○

6

Float

○

To avoid abnormal operation, accidents or serious injury, DO NOT use this product outside of the specification range.

CAUTION

7

Float Guide

○

8

Snap Ring

○

9

Union Gasket

○

10

Valve Seat Gasket

○

11

Nameplate

○

●

3

●

5

●

4

●

11

●

7

●

Special Fluids (Non-toxic, Non-flammable)

VA Series VS1A

a

p

C

a

p

a

C

a

e

e

g

g

r

r

a

a

L

L

c

c

i

i

t

t

y

y

s

s

s

S

s

e

S

e

l

l

n

n

i

i

a

a

t

t

S

S

t

t

h

h

g

g

i

i

T

T

t

t

e

e

e

e

l

l

e

a

S

e

a

l

i

S

l

n

i

n

g

g

Features

●

Simple construction and trouble free operation

●

Only one moving part, the free float, eliminates

concentrate wear and provides long service life

●

Precision-ground float and valve seat rubber

contact assures seal tightness when vent is closed

●

Also functions as a vacuum breaker

Application

●

Processes requiring the rapid supply of water

●Water supply pipe, water pump, water tank, etc.

Note: Once the valve closes it will not open again, even if air accumulates.

If air is expected to accumulate, use together with an automatic air vent.

Specifications

Model

Inlet

Connection

Outlet

Inlet

Size (mm)

Outlet

Body Material

Maximum Operating

Pressure (MPaG) PMO

Minimum Operating

Pressure (MPaG)

Maximum Operating

Temperature (ºC) TMO

Maximum Venting

Capacity ( /min)*

PRESSURE SHELL DESIGN CONDITIONS (NOT OPERATING CONDITIONS):

Maximum Allowable Pressure (MPaG) PMA: 1.0

Maximum Allowable Temperature (˚C) TMA: 150

VA1

Screwed (Rc(PT))

50

20

1 400

VA3

Flanged (ASME 150RF)

80

32

Cast Iron (FC250)

3 200

VA4

Flanged (ASME 150RF)

100

65

1.0

0.01

100

5 600

VA5

150

100

11 000

Features

●

Achieves the tightest seal with three-point seating

●

Works in liquids with low specific gravity (ρ≥ 0.8)

●

High corrosion resistance due to stainless steel

body and fluorine rubber (FPM) valve seat

●

Useable with high pressures and temperatures

●

Also functions as a vacuum breaker

Application

●

Processes requiring rapid supply of special fluids

●Supply pipe, pump, liquid storage tank, etc.

Note: Once the valve closes it will not open again, even if air accumulates.

If air is expected to accumulate, use together with an automatic air vent.

Specifications

Model

Connection

Size (mm)

Body Material

Maximum Operating

Pressure (MPaG) PMO

Minimum Operating

Pressure (MPaG)

Maximum Operating

Temperature (ºC) TMO

Maximum Venting

Capacity ( /min)*

PRESSURE SHELL DESIGN CONDITIONS (NOT OPERATING CONDITIONS):

Maximum Allowable Pressure (MPaG) PMA: 2.1

Maximum Allowable Temperature (˚C) TMA: 220

Cast Stainless Steel (CF8)

VS1A

Screwed (Rc(PT))

15, 20, 25

2.1

0.01

150

270

Construction

5

●

2

●

4

●

8

●

●

1

●

No. No.Part Name Part Name

1

Body

○

2

Cover

○

3

Float

○

4

Cover Gasket

○

5

Cover Bolt

○

6

Valve Seat

○

* For air at 20 ºC under atmospheric pressure. Discharge capacities are for a Δp of 0.1 MPa. Larger pressure differentials have greater discharge capacities. 1 MPa = 10.197 kg/cm

7

Valve Seat Holder

○

8

Set Screw

○

9

Float Guide

○

10

Snap Ring

○

11

Nameplate

○

6

●

7

●

3

●

●

9

●

Construction

1

●

12

●

11

●

10

●

8

●

3

●

No. No.Part Name Part Name

1

Body

○

2

Cover

○

3

Float

○

4

Valve Seat

○

5

Valve Seat Gasket

○

6

Cover Gasket

○

7

Cover Bolt

○

8

Nameplate

○

9

Connector

○

10

Screw

○

11

Spring Washer

○

12

Plate

○

6

●

9

●

4

●

5

●

2

●

7

●

2

For Liquid

Automatic Air Vent

Water ● Hot Water

SA3 VC Series

l

l

l

l

a

a

m

m

S

S

e

W

i

e

W

g

i

g

t

t

h

h

g

g

i

i

L

L

h

h

t

t

Features

●

Extremely compact size

●

Auxiliary valve seat enables maintenance during

operation

●

Provides a tight seal, even at extremely low

pressure (0.01 MPa for SA3 with no.3 orifice)

Application

●

Suitable for small and narrow installation spaces

●

Suitable for small air conditioning equipment

●Fan coil, radiator, etc.

Specifications

Model

Connection

Size (mm)

Body Material

Orifice Number

Maximum Operating

Pressure (MPaG) PMO

Minimum Operating

Pressure (MPaG)

Maximum Operating

Temperature (ºC) TMO

Maximum Venting

Capacity ( /min)*

PRESSURE SHELL DESIGN CONDITIONS (NOT OPERATING CONDITIONS):

Maximum Allowable Pressure (MPaG) PMA: 1.0

Maximum Allowable Temperature (˚C) TMA: 100

3

0.3

0.01

5.4

SA3

Screwed (Rc(PT))

10, 15, 20

Brass (C3771)

10

1.0

0.1

100

9.2

Features

●

Simple construction and trouble free operation

●

Only one moving part, the free float, eliminates

concentrate wear and provides long service life

●

Free float and valve seat with rubber contact

assures seal tightness when vent is closed

●

Also functions as a vacuum breaker

Application

●

General use air vent

●Water supply pipe, cooling/heating equipment,

etc.

Specifications

Model

Connection

Inlet

Size (mm)

Outlet

Body Material

Maximum Operating

Pressure (MPaG) PMO

Minimum Operating

Pressure (MPaG)

Maximum Operating

Temperature (ºC) TMO

Maximum Venting

Capacity ( /min)*

PRESSURE SHELL DESIGN CONDITIONS (NOT OPERATING CONDITIONS):

Maximum Allowable Pressure (MPaG) PMA: 0.5 (VC2), 0.6 (VC3), 1.0 (VC4)

Maximum Allowable Temperature (˚C) TMA: 185 (VC2), 220 (VC3), 150 (VC4)

VC2

15

Bronze (CAC406)

0.5

0.05

25

VC3

Screwed (Rc(PT))

10

Cast Iron (FC250)

0.6

0.1

90

90

VC4

25

1.0

0.1

380

Construction

No. Part Name

Body

1

○

Valve Seat

2

○

Base

3

○

Float

4

○

Valve Holder

5

○

Coil Spring

6

○

Siphon Rod

7

○

Body Gasket

8

○

Valve

9

○

Valve Seat Holder

10

○

O-ring

11

○

Snap Ring

12

○

Valve Seat

13

○

To avoid abnormal operation, accidents or serious injury,DO NOT use this product outside of the specification range

CAUTION

No. Part Name

Nameplate

14

○

Worm-drive Clamp

15

○

Clamp Screw

16

○

Construction

No. Part Name

1

Body

○

2

Cover

○

3

Float

○

4

Valve Seat

○

5

Cover Gasket

○

6

Nameplate

○

2

●

1

●

3

●

4

●

5

●

6

●

Special Fluids (Non-toxic, Non-flammable)

For Steam

VS1C

s

s

S

s

s

S

e

t

e

l

l

n

n

i

i

a

a

t

t

S

S

t

t

h

h

g

g

i

i

T

T

Features

●

Achieves the tightest seal with three-point seating

●

Works in liquids with low specific gravity (ρ≥0.8)

●

High corrosion resistance due to stainless steel

body and fluorine rubber (FPM) valve seat

●

Useable with high pressures and temperatures

●

Also functions as a vacuum breaker

Application

●

Suitable for facilities and piping using special fluids

●Supply pipe, pump, liquid storage tank, etc.

Specifications

Model

Connection

Size (mm)

Body Material

Orifice Number

Maximum Operating

Pressure (MPaG) PMO

Minimum Operating

Pressure (MPaG)

Maximum Operating

Temperature (ºC) TMO

Maximum Venting

Capacity ( /min)*

PRESSURE SHELL DESIGN CONDITIONS (NOT OPERATING CONDITIONS):

Maximum Allowable Pressure (MPaG) PMA: 2.1

Maximum Allowable Temperature (˚C) TMA: 220

Cast Stainless Steel (CF8)

10

1.0

170

VS1C

Screwed (Rc(PT))

15, 20, 25

0.01

150

t

e

e

e

e

l

l

a

e

l

a

i

e

S

l

n

i

S

21

2.1

130

n

g

g

LA Series

e

n

e

n

m

t

m

t

a

a

c

t

c

t

LA21

15

(CF8)

2.1

0.01

235

2 000

e

e

l

X

C

X

C

l

e

e

-

-

p

p

m

m

o

o

Features

●

Vents hot air up to just 22 ºC below saturated

steam temperature

●

Fail-open mechanism

●

High heat resistance

●

Compact with large venting capacity

Application

●

Batch processes requiring large volume air venting

●

Where hot-air locking occurs during operation

●Double-jacketed kettle, pressing machine, etc.

Specifications

Model

Connection

Size (mm)

Body Material

Maximum Operating

Pressure (MPaG) PMO

Minimum Operating

Pressure (MPaG)

Maximum Operating

Temperature (ºC) TMO

Maximum Venting

Capacity ( /min)*

PRESSURE SHELL DESIGN CONDITIONS (NOT OPERATING CONDITIONS):

Maximum Allowable Pressure (MPaG) PMA: 1.6 (LA13L), 6.3 (LA21)

Maximum Allowable Temperature (˚C) TMA: 220 (LA13L), 425 (LA21)

LA13L

Screwed (Rc(PT))

15, 20

Brass (C3771)

1.3

0.01

200

1 900

Cast Stainless Steel

Construction

1

●

12

●

11

●

10

●

8

●

3

●

No. Part Name No. Part Name

1

Body

○

2

Cover

○

3

Float

○

4

Valve Seat

○

5

Valve Seat Gasket

○

6

Cover Gasket

○

7

Cover Bolt

○

8

Nameplate

○

9

Connector

○

10

Screw

○

11

Spring Washer

○

12

Plate

○

Construction

6

●

9

●

4

●

5

●

2

●

7

●

* For air at 20 ºC under atmospheric pressure and maximum operating pressure. 1 MPa = 10.197 kg/cm

4

●

6

●

7

●

5

●

LA21 LA13L

No. Part Name No. Part Name

Body

1

○

Cover

2

○

X-element

3

○

Valve Seat

4

○

●

●

●

●

2

8

3

1

5

○

6

○

7

○

8

○

Screen

Nameplate

Snap Ring

Cover Gasket

2

Application Examples

For Liquid

For Steam

Rapid Initial Air Vent

Automatic Air Vent

VC2

SA3

LA21

VA1

Note:・Inlet piping with no horizontal portion is recommended for water/air displacement. If there is a horizontal portion, make the pipe diameter of the

horizontal portion larger than the vertical portion or make the horizontal portion as short as possible.

・Make sure the inlet piping diameter is at least as large as the product’s inlet diameter. For the inlet connection especially for products* with a nominal

diameter of 15 mm, use a pipe/fitting, etc. with an inner diameter of at least 16 mm, such as a schedule 40 pipe nipple with a nominal diameter of

15 mm. A smaller pipe may prevent water/air displacement. (*Except SA3)

Operation

For Liquid

Rapid Initial Air Vent

VA Series

Gas from inside the

piping is very

quickly pushed out

around the float

guide by liquid

pressure.

After venting, the

float rises with the

rising liquid level,

closing the valve.

Once closed, the

valve will not reopen,

even if gas enters the

vent and the water

level drops.

When the pressure

inside the piping

drops to equal to or

less than atmospheric

pressure, the float

drops, opening the

vent. Air is allowed to

enter to facilitate the

drainage of liquid

from the piping.

Automatic Air Vent

VS1C

Gas from inside

the piping is

quickly pushed

out around the

float by liquid

pressure.

For Steam

Automatic Air Vent

LA Series

Initially, the X-element

is open and gas from

inside the piping is

quickly vented,

significantly shortening

equipment start-up

time.

After venting,

the float rises

with the rising

liquid level,

closing the

valve.

When steam flows in,

the increased

temperature causes the

X-element to close

immediately. If ambient

temperature is near

steam saturation

temperature, the vent

will remain closed.

When gas flows

into the vent

body, the liquid

level decreases.

The float drops,

opening the vent

and allowing gas

discharge. When

the liquid level

rises after venting,

the float again

closes the vent.

At system

shutdown, when

the pressure

inside the piping

drops to equal to

or less than

atmospheric

pressure, air is

allowed to enter

to facilitate the

drainage of liquid

from the piping.

When the temperature

of the X-element

decreases due to

inflowing gas, the

X-element contracts

opening the vent and

allowing further gas

discharge.

881 Nagasuna, Noguchi, Kakogawa, Hyogo 675-8511, JAPAN

Tel: [81]-(0)79-427-1818 Fax: [81]-(0)79-425-1167

E-mail: tlv-japan@tlv.co.jp https://www.tlv.com

Copyright

(M)

C

TLV

Specifications subject to change without notice.

Pamphlet M3600 Rev. 10/2020

Loading...

Loading...