TLV SW1U-A, SW1U-B Instruction Manual

172-65288MA-02 (SW1U-A/SW1U-B) 6 February 2019

Process Lever Float Steam Trap

SW1U-A / SW1U-B

Copyright © 2019 by TLV CO., LTD.

All rights reserved

1

Contents

Introduction ....................................................................... 2

Safety Considerations ....................................................... 3

Checking the Piping .......................................................... 5

Operation .......................................................................... 5

Specifications .................................................................... 6

Configuration ..................................................................... 7

Installation ......................................................................... 8

Maintenance .................................................................... 10

Disassembly/Reassembly ............................................... 11

Troubleshooting .............................................................. 12

Product Warranty ............................................................ 13

172-65288MA-02 (SW1U-A/SW1U-B) 6 Feb 2019

2

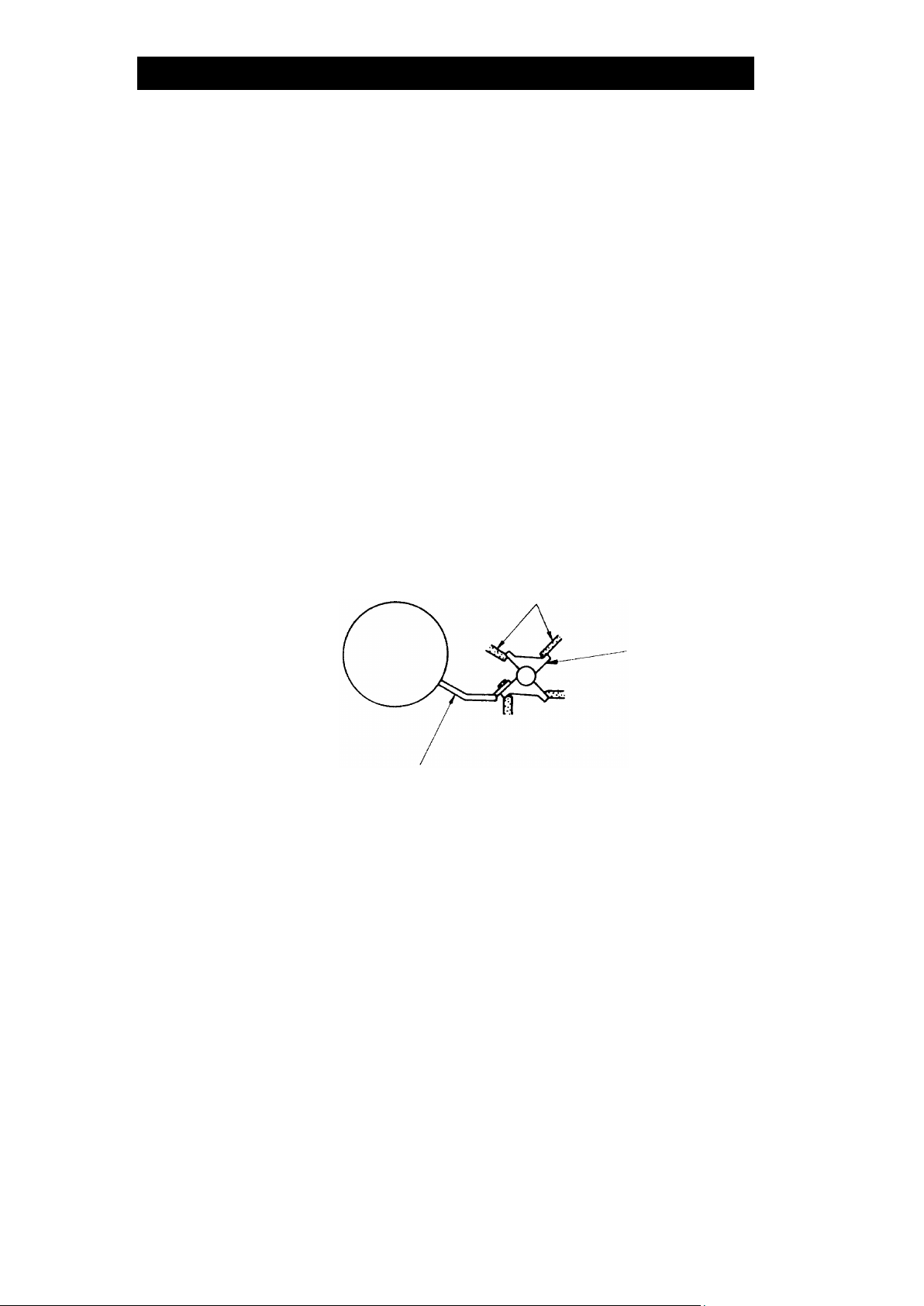

Valve Seat

Four-bladed

Lever Float

Introduction

Thank you for purchasing t he TLV process lever float steam trap.

This product has been thoroughly inspected bef or e being shipped from the fact or y.

When the produc t is delivered, before doing anything else, check the spec ifications

and external appearance to make sure nothing is out of the ordinary. Also be sure to

read this manual carefully before use and follow the instructions to be sure of using

the product properly.

This steam trap employs TLY

stable operation and long service life. TLY construction was developed for process

lever float steam traps, and compr ises a four-bladed valve connected directly to a

lever float.

As the valve opening and closing forces created by the pressure differential

between inlet and outlet pressures are balanced, a four -bladed valve ensures stable

trap operation at all times.

(Tetra-Leaf & Yok e) construction, which affords it

®

Valve

This trap is ideal for applications requir ing the removal of condensate from

equipment using large quant it ies of steam and from proces s m ac hinery.

Additionally, it quickly and automatically discharges large quant it ies of condensate

at a temperature slightly lower than saturation t em per ature.

For products with special order specifications or options, if detailed instructions for

the special order specifications or options are not c ont ained in this m anual, please

contact TLV for full details.

This instruction manual is intended for use with the m odel( s) list ed on t he front

cover. It is necessary not only for installation but for subsequent maintenance,

disassembly/reassembly and troubleshooting. Please keep it in a safe place for

future referenc e.

TLY is a registered trademark of TLV CO., LTD.

172-65288MA-02 (SW1U-A/SW1U-B) 6 Feb 2019

3

DANGER

Indicates an urgent situation which poses a threat of death or

serious injury

WARNING

CAUTION

Indicates that there is a possibility of injury or equipment / product

damage

WARNING

NEVER apply direct heat to the float.

equipment.

CAUTION

Install properly and DO NOT use this product outside the

conditions quoted.

Such use could make discharge impossible (blocked) .

Use hoisting equipment for heavy objects (weighi ng

object should fall.

Safety Considerations

• Read this section carefully before us e and be sur e to foll ow the instructions.

• Installation, inspection, maintenance, repairs, disassembly, adjustment,

and valve opening/closing should be carried out only by trained

maintenance personnel.

• The precautions listed in this manual are designed to ensure safety and

prevent equipment damage and personal injury. For situations that may

occur as a result of erroneous handling, three different types of cautionary

items are used to indicate the degree of urgency and the scale of potential

damage and danger: DANGER, WARNING and CAUTION.

• The three types of cautionary items above are very important for safety:

be sure to observe all of them as they relate to installation, use,

maintenance, and repair. Furthermore, TLV accepts no responsibility for

any accidents or damage occurring as a result of failure to observe these

precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

Indicates that there is a potential thr eat of death or serious injury

The float may explode due to increased internal pressure, causing

accidents leading to serious injury or damage t o pr oper t y and

recommended operating pressure, temperat ur e and ot her

specification ranges.

Improper use may result in such hazards as damage t o t he

product or malfunctions that m ay lead to ser ious acc ident s. Local

regulations may restrict the use of this product to below the

DO NOT use this product in excess of the maximum

operating pressure differenti al .

approximately 20 kg (44 lb) or more).

Failure to do so may result in back strain or other inj ur y if t he

Continued on the next page

172-65288MA-02 (SW1U-A/SW1U-B) 6 Feb 2019

4

CAUTION

Take measures to prevent people from coming into direct

discharge of fluids.

When disassembling or removing the product, wait until t he

injuries or damage.

discharge of fluids.

Use only under conditions in which no freez e-up will occur.

which may cause burns or other injury.

fluid discharge, which may cause burns or other injury.

contact with product out lets.

Failure to do so may result in burns or other injury from the

internal pressure equals atmospheric pr essur e and t he

surface of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to m odify the

product in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the

Freezing may damage the product, leading to fluid discharge,

Use only under conditions in which no water hammer w i l l

occur.

The impact of water hammer may damage t he product, leading to

172-65288MA-02 (SW1U-A/SW1U-B) 6 Feb 2019

Loading...

Loading...