172-65260m-05 (S-COS/S-COSR Pressure Reducing Valve) 27 October 2008

ISO 9001/ ISO 14001

Manufacturer

Kakogawa, Japan

is approved by LRQA LTD. to ISO 9001/14001

Pressure Reducing Valve for Steam

S-COS-16 / S-COSR-16

Copyright © 2008 by TLV CO., LTD.

All rights reserved

2

Introduction ........................................................................2

Safety Considerations........................................................3

Specifications.....................................................................5

Acceptable Operating Range.............................................5

Contents

Correct Usage of S-COS / S-COSR Pressure Reducing Valve

6

Configuration......................................................................8

Installation........................................................................10

Adjustment.......................................................................13

Maintenance.....................................................................14

Disassembly.....................................................................15

Reassembly .....................................................................20

Troubleshooting ...............................................................21

Product Warranty.............................................................24

Introduction

Thank you for purchasing the S-COS/S-COSR pressure reducing valve for

steam.

This product has been thoroughly inspected before being shipped from the factory.

When the product is delivered, before doing anything else, check the specifications

and external appearance to make sure nothing is out of the ordinary. Also be sure to

read this manual carefully before use and follow the instructions to be sure of using

the product properly.

Steam-using equipment can achieve its intended efficiency only if the steam being

used is very dry. Using steam in which matter such as condensate, scale, types of

grease or air is entrained can result not only in problems with the steam-using

equipment and in lowered productivity, but can also lead to shortened service life for

and malfunction of the pressure reducing valves.

The

problems and makes possible the supply of very dry steam at a constant pressure.

Both the

conventional pressure reducing valves. They are designed for long service life, with

all major componets made of stainless steel for superior durability.

If detailed instructions for special order specifications or options not contained in this

manual are required, please contact

S-COS, with a built-in separator and steam trap, eliminates these

S-COS and S-COSR provide a more stable secondary pressure than

for full details.

This instruction manual is intended for use with the model(s) listed on the front cover.

It is needed not only for installation, but also for subsequent maintenance,

disassembly/reassembly and troubleshooting. Please keep it in a safe place for

future reference.

172-65260m-05 (S-COS/S-COSR Pressure Reducing Valve) 27 Oct 2008

3

R

Safety Considerations

• Read this section carefully before use and be sure to follow the instructions.

• Installation, inspection, maintenance, repairs, disassembly, adjustment, and valve

opening/closing should be carried out only by trained maintenance personnel.

• The precautions listed in this manual are designed to ensure safety and prevent

equipment damage and personal injury. For situations that may occur as a result

of erroneous handling, three different types of cautionary items are used to

indicate the degree of urgency and the scale of potential damage and danger:

DANGER, WARNING and CAUTION.

• The three types of cautionary items above are very important for safety: be sure to

observe all of them as they relate to installation, use, maintenance, and repair.

Furthermore, TLV accepts no responsibility for any accidents or damage occurring

as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

WARNING

DANGE

WARNING

CAUTION

Indicates an urgent situation which poses a threat of death or

serious injury

Indicates that there is a potential threat of death or serious injury

Indicates that there is a possibility of injury or equipment / product

damage

NEVER apply direct heat to the float.

The float may explode due to increased internal pressure, causing

accidents leading to serious injury or damage to property and

equipment.

CAUTION

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the product

or malfunctions that may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

DO NOT use the product in excess of the maximum operating

pressure differential.

Such use could make discharge through the steam trap impossible

(blocked).

Take measures to prevent people from coming into direct

contact with product outlets.

Failure to do so may result in burns or other injury from the

discharge of fluids.

When disassembling or removing the product, wait until the

internal pressure equals atmospheric pressure and the surface

of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

injuries or damage.

172-65260m-05 (S-COS/S-COSR Pressure Reducing Valve) 27 Oct 2008

Safety considerations are continued on the next page.

4

CAUTION

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to modify the

product in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the discharge

of fluids.

Do not use excessive force when connecting threaded pipes to

the product.

Over-tightening may cause breakage leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge, which

may cause burns or other injury.

Use only under conditions in which no water hammer will

occur.

The impact of water hammer may damage the product, leading to

fluid discharge, which may cause burns or other injury.

172-65260m-05 (S-COS/S-COSR Pressure Reducing Valve) 27 Oct 2008

Specifications

CAUTION

CAUTION

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this pr oduct to below the conditions quoted.

DO NOT use the trap in excess of the maximum operating pressure

differential; such use could make discharge imp o ssib le (block e d ).

5

CAUTION

Use only under conditions in which no freeze -up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

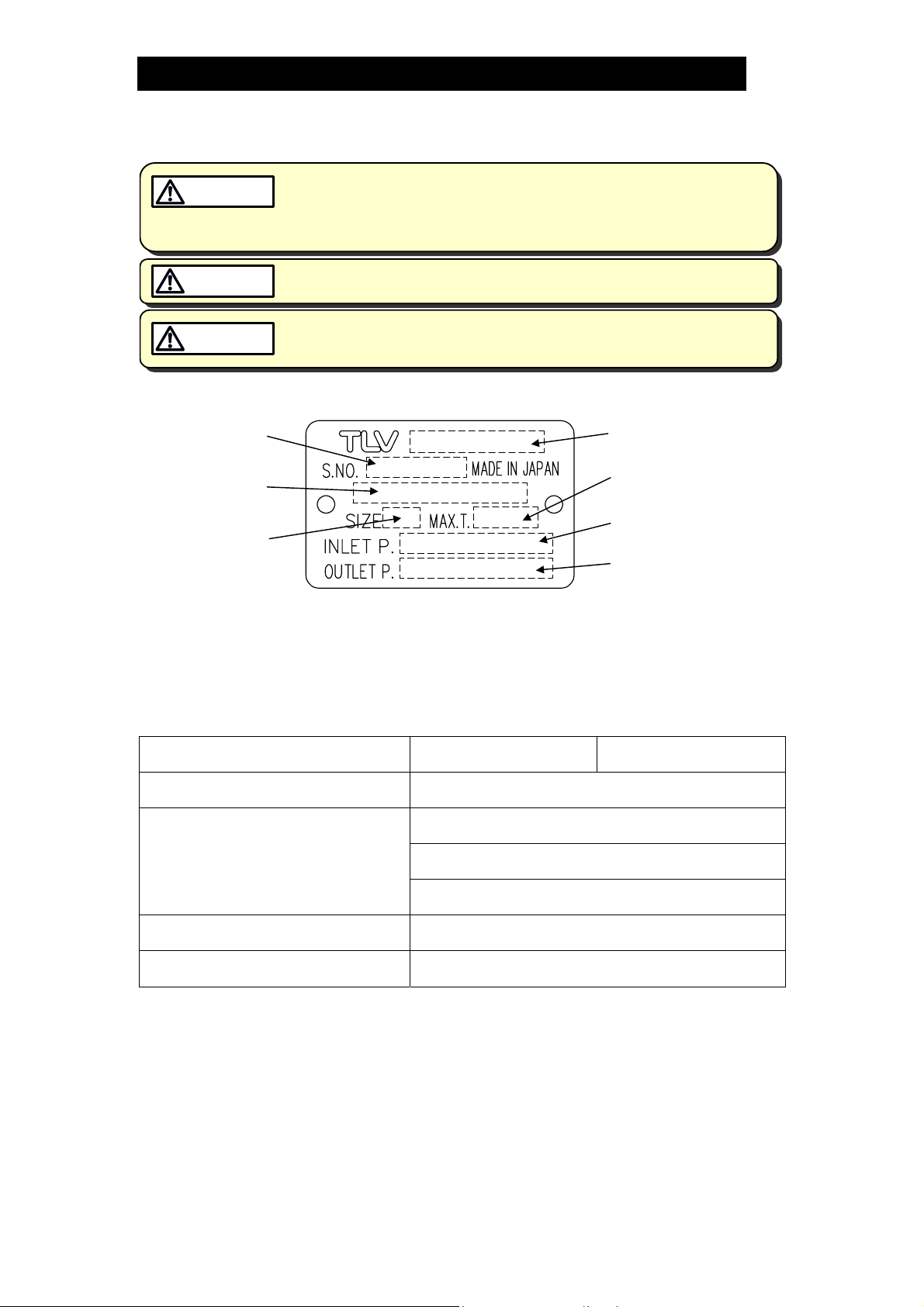

Refer to the product nameplate for detailed specifications.

Serial Number

Valve No.*

Nominal Diameter

* Valve No. is displayed for products with options. This item is omitted from the nameplate

when there are no options.

Model

Maximum Operating

Temperature

Primary Pressure Range

Secondary Pressure

Adjustable Range

Acceptable Operating Range

Model

S-COS-16 S-COSR-16

Primary Pressure Range 0.2 – 1.6 MPaG

Adjustable Secondary Pressure

Range

(all conditions must be met)

Within 10 – 84% of the primary pressure

Minimum adjustable pressure of 0.03 MPaG

Pressure differential between 0.07 – 0.80 MPa

Maximum Operating Temperature 220 °C

Minimum Adjustable Flow Rate 10% of rated flow rate

172-65260m-05 (S-COS/S-COSR Pressure Reducing Valve) 27 Oct 2008

6

Correct Usage of S-COS / S-COSR Pressure Reducing Valve

CAUTION

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

1. The pressure reducing valve should be operated only within its specifications.

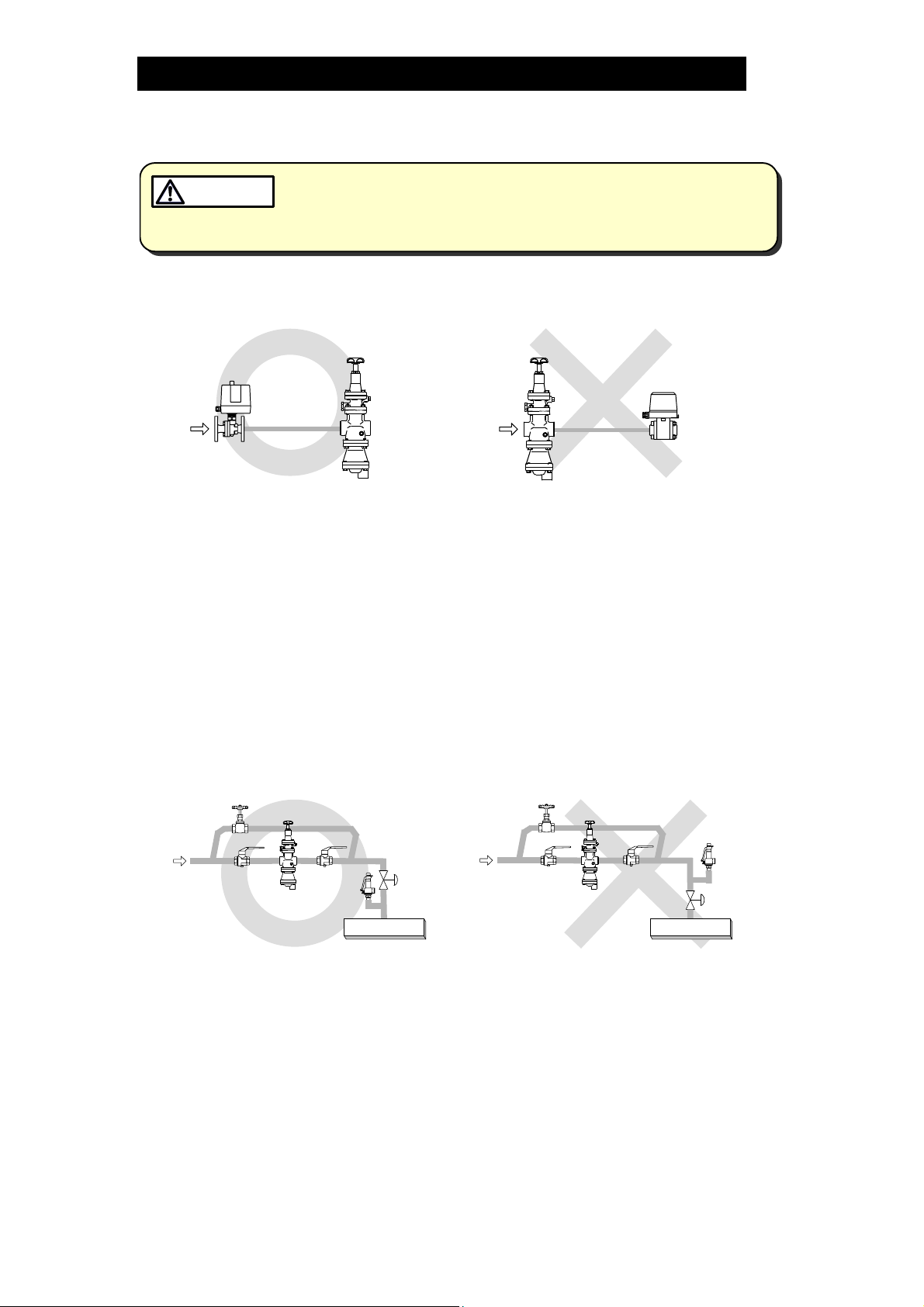

2. Installing an ON / OFF Valve (Solenoid Valve or Motorized Valve)

Motorized

Valve

Inlet Side Outlet Side

PRV

PRV

Solenoid

Valve

If an on-off valve, such as a motorized valve, is required to stop supply of steam

to the steam-using equipment, install it at the inlet side of the pressure reducing

valve. If a solenoid valve is installed at the outlet of the reducing valve, its

opening and closing will cause heavy chattering and may lead to damage of the

piston and main valve. (When the on-off valve opens, the secondary pressure of

the reducing valve changes from zero to the set pressure. Passing through an

area of the reducing ratio of less than 10:1, where adjustment is impossible,

chattering occurs momentarily. To save energy, install the on-off valve as near to

the boiler as possible.

NOTE: To prevent water hammer, it is recommended that a slow-acting

motorized on-off valve be used. In particular, if a fast-acting on-off solenoid valve

is used for frequent temperature control, the potential water hammer effect can

damage the steam equipment and the pressure reducing valve.

3. Installing a Control Valve

Safety

Valve

Control

PRV

Safety

Valve

Equipment

Valve

PRV

Control

Valve

Equipment

A control valve installed between the pressure reducing valve and the steam

equipment (downstream of the reducing valve) for controling equipment

temperature may raise the pressure between the pressure reducing valve and

the control valve when the control valve is closed, depending on the spatial

relationship. A safety valve should be installed downstream of the control valve.

Note: When installing a safety valve to protect the steam equipment, be sure to

install it on the steam equipment or directly before the inlet of the steam

equipment. If the safety valve is installed on the outlet side of the pressure

reducing valve between the pressure reducing valve and a control valve, an

eventual pressure rise could activate the safety valve.

172-65260m-05 (S-COS/S-COSR Pressure Reducing Valve) 27 Oct 2008

7

4. Precautions for the Installation of Additional Fittings Before or After the Reducing

Valve

In order to ensure stable steam flow, the piping upstream and downstream of the

reducing valve must be straight runs. If a pressure reducing valve is installed

either directly before or after an elbow or control valve, unevenness in steam

flow may result in chattering and unstable pressure.

To ensure stable steam flow, it is recommended that the pressure reducing valve

be installed on straight runs of piping, as illustrated below.

① Inlet (primary side) of the pressure reducing valve NOTE: d = pipe diameter

Maintain a straight piping

run of 10 d or more

when a

manual valve, a strainer or

an elbow, etc. is installed.

(Example: if nominal size is 25

mm, have 250 mm or more)

Maintain a straight piping

run of 30 d or more

when

an automated valve (on-off

valve) is installed.

(Example: if nominal size is 25

mm, have 750 mm or more)

② Outlet (secondary side) of the pressure reducing valve

Maintain a straight piping

run of 15 d or more

when

a manual valve, a strainer

or an elbow, etc. is

installed.

(Example: if nominal size is 25

mm, have 375 mm or more)

Maintain a straight piping

run of 30 d or more

when a

safety valve is installed.

(Example: if nominal size is 25

mm, have 750 mm or more)

Maintain a straight piping

run of 30 d or more

another pressure reducing

valve is installed.

pressure reduction)

(Example: if nominal size is 25

mm, have 750 mm or more)

Maintain a straight piping

run of 30 d or more

control valve or an

automated valve (on-off

valve) is installed.

(Example: if nominal size is 25

mm, have 750 mm or more)

when

(Two-stage

when a

Valve, strainer,

elbow, etc.

PRV

Valve, strainer,

elbow, etc.

PRV

Less

Valve

than

10 d

Less than

30 d

PRV

Automatic

Valve

10 d or

more

Automatic

PRV

30 d or more

PRV PRV

15 d or more

Safety

Valve

PRV PRV

30 d or more

PRV

30 d or more

PRV PRV

172-65260m-05 (S-COS/S-COSR Pressure Reducing Valve) 27 Oct 2008

30 d or more

Second

PRV

Control or

Automated Valve

Less than

15 d

Safety

Valve

Less than

30 d

Second

PRV

PRV

Less than

30 d

Control or

Automated Valve

Less than

30 d

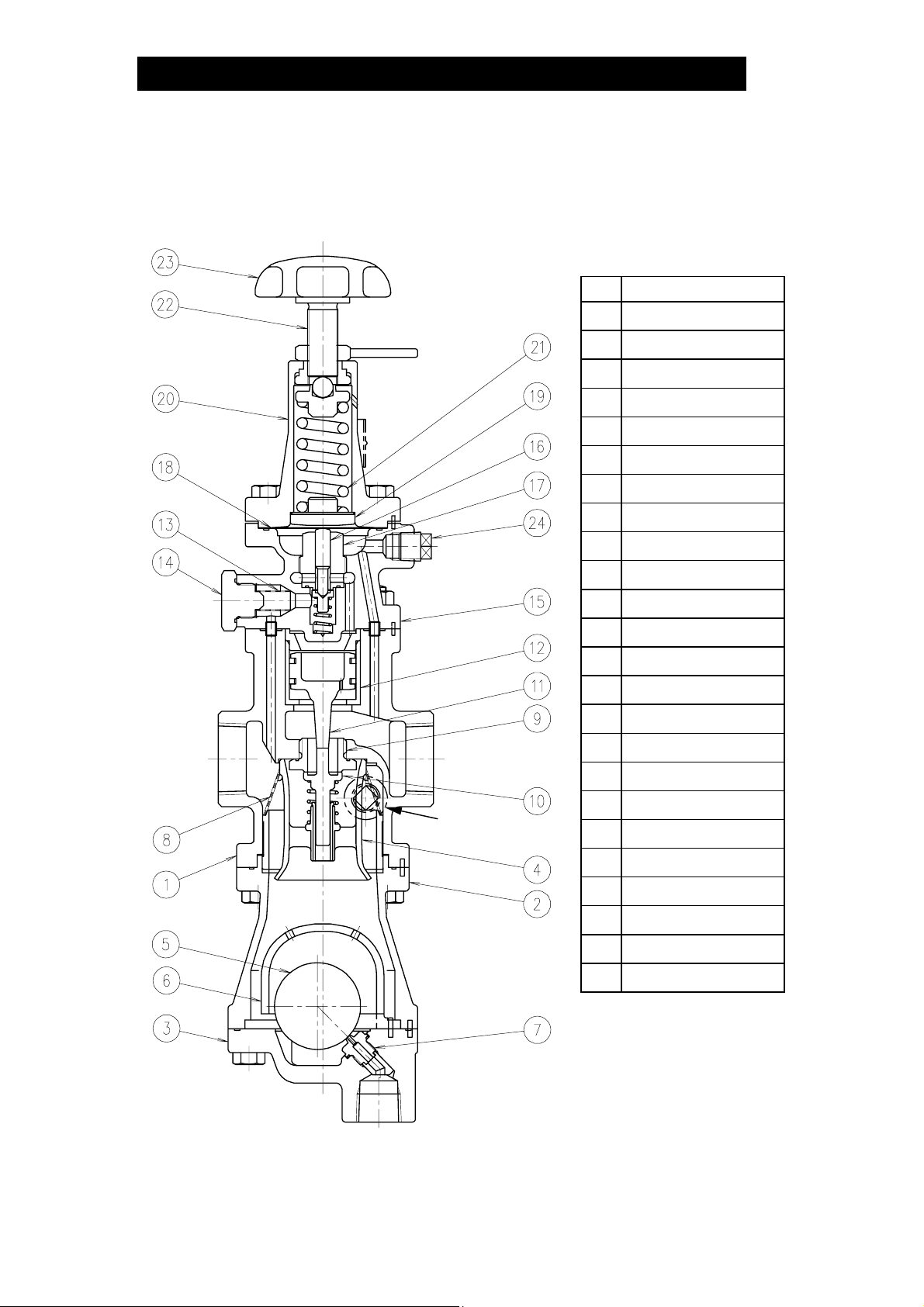

Configuration

S-COS-16

No. Name

1 Main Body

2 Trap Body

3 Trap Cover

4 Separator

5 Float

6 Float Cover

7 Trap Valve Seat

8 Separator Screen

8

Plug

(option)

9 Main Valve Seat

10 Main Valve

11 Piston

12 Cylinder

13 Pilot Screen

14 Pilot Screen Holder

15 Pilot Valve Body

16 Pilot Valve Stem

17 Pilot Valve Seat

18 Diaphragm

19 Diaphragm Support

20 Spring Housing

21 Coil Spring

22 Adjustment Screw

23 Adjustment Handle

24 Plug

172-65260m-05 (S-COS/S-COSR Pressure Reducing Valve) 27 Oct 2008

Loading...

Loading...