TLV P46S, P21S Instruction Manual

INSTRUCTION MANUAL

Keep this manual in a safe place for future reference

THERMODYNAMIC STEAM TRAP

MODEL P46S/P21S ver.C

P46S/P21S ver.C

Option

( )

BD1

Manufacturer

881 Nagasuna, Noguchi, Kakogawa, Hyogo 675-8511, Japan

Tel: [81]-(0)79-422-1122 Fax: [81]-(0)79-422-0112

Copyright (C) 2021 by TLV CO., LTD. All rights reserved.

Introduction

Before beginning installation or maintenance, please read this manual to ensure correct use of

the product. Keep the manual in a safe place for future reference.

The P46S steam trap can be used without adjustment for small capacity applications between

0.03 and 4.6 MPaG (5 and 650 psig). For best performance over extended periods, it is

recommended that the trap be operated at or below 2.1 MPaG (300 psig).

The P21S ver.C steam trap can be used without adjustment for small capacity applications

between 0.025* and 2.1 MPaG (3.5* and 300 psig).

These models are suitable for steam mains, branch pipes, tracer lines, etc. In particular, the P21S

ver.C is purpose-built for troublesome Copper Tracing applications, whereas the P46S is

designed for multi-purpose applications.

* Vertical installation: 0.04 MPaG (6 psig)

1 MPa = 10.197 kg/cm

For products with special specifications or with options not included in this manual, contact TLV

for instructions.

The contents of this manual are subject to change without notice.

2

, 1 bar = 0.1 MPa

1. Safety Considerations

• Read this section carefully before use and be sure to follow the instructions.

• Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

• The precautions listed in this manual are designed to ensure safety and prevent equipment

damage and personal injury. For situations that may occur as a result of erroneous handling,

three different types of cautionary items are used to indicate the degree of urgency and the

scale of potential damage and danger: DANGER, WARNING and CAUTION.

• The three types of cautionary items above are very important for safety; be sure to observe

all of them, as they relate to installation, use, maintenance, and repair. Furthermore, TLV

accepts no responsibility for any accidents or damage occurring as a result of failure to

observe these precautions.

Indicates a DANGER, WARNING or CAUTION item.

DANGER

WARNING

CAUTION

CAUTION

Indicates an urgent situation that poses a threat of death or serious injury.

Indicates that there is a potential threat of death or serious injury.

Indicates that there is a possibility of injury, or equipment/product

damage.

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions, which may lead to serious accidents. Local regulations may

restrict the use of this product to below the conditions quoted.

DO NOT subject this product to condensate loads that exceed its

discharge capacity. Failure to observe this precaution may lead to

condensate accumulation upstream of the trap, resulting in reduced

equipment performance or damage to the equipment.

Take measures to prevent people from coming into direct contact

with product outlets. Failure to do so may result in burns or other injury

from the discharge of fluids.

Continued on the next page

1

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the

product has cooled to room temperature. Disassembling or removing

the product when it is hot or under pressure may lead to discharge of

fluids, causing burns, other injuries or damage.

Be sure to use only the recommended components when repairing

the product, and NEVER attempt to modify the product in any way.

CAUTION

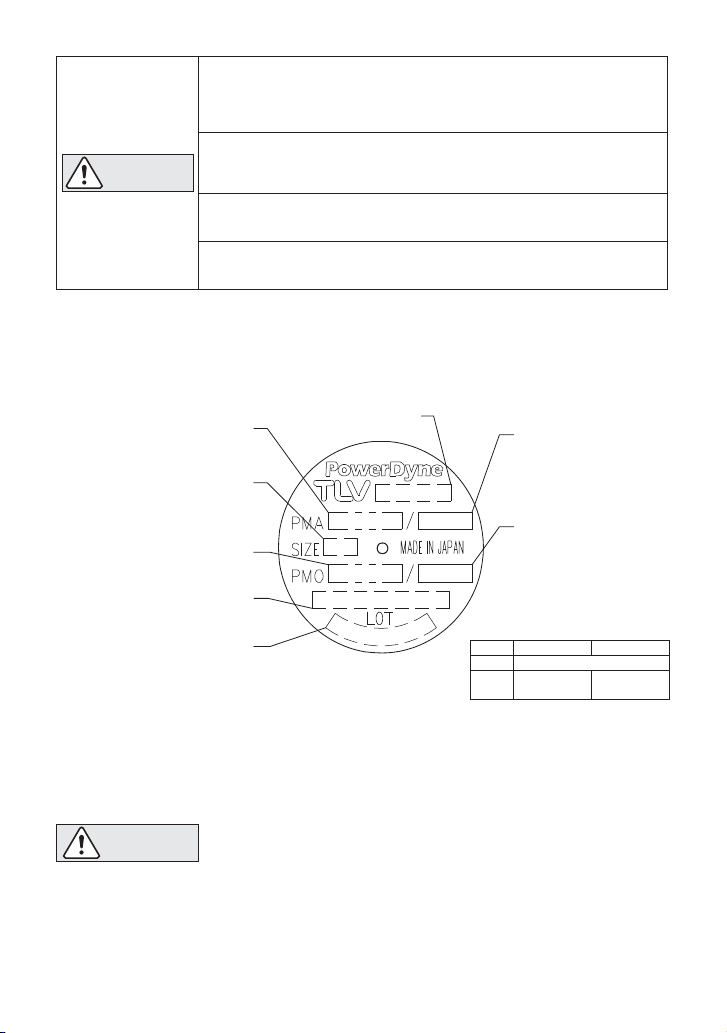

2.

Specifications Technische Daten Données techniques

Refer to the product nameplate for detailed specifications.

Maximum Allowable Pressure*

Nominal Diameter

Maximum Operating Pressure

Production Lot No.

Maximum Allowable Back Pressure: 80% of inlet pressure

* Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are

PRESSURE SHELL DESIGN CONDITIONS, NOT OPERATING CONDITIONS.

** P46S : For best performance over extended periods, it is recommended that the trap be

operated at or below 2.1 MPaG (300 psig).

*** Valve No. is displayed for products with options. This item is omitted from the nameplate when

there are no options.

CAUTION

Failure to observe these precautions may result in damage to the product

or burns or other injury due to malfunction or the discharge of fluids.

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

Use under conditions in which no water hammer will occur. The

impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

Model

**

Valve No.***

To avoid malfunctions, product damage, accidents or serious injury,

install properly and DO NOT use this product outside the specification

range. Local regulations may restrict the use of this product to below the

conditions quoted.

Max. Allowable

Temperature* TMA

Max. Operating

Temperature TMO

Minimum Operating Pressure

Horizontal Vertical

P46S

P21S

ver.C

0.03 MPaG (5 psig)

0.025 MPaG

(

3.5 psig

)

0.04 MPaG

(

6 psig

)

2

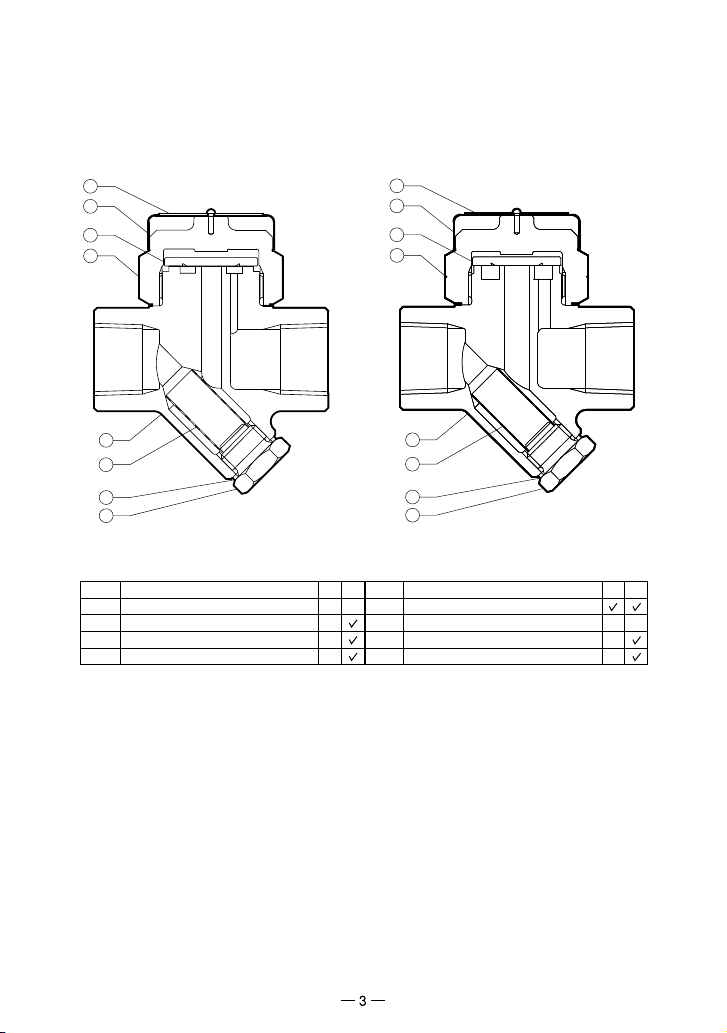

3. Configuration

P46S P21S ver.C

8

7

3

2

8

7

3

2

1

4

5

6

Body

Cover

Disc

Screen

Description

M*

R*

-

-

-

-

No.

1

2

3

4

* M = Maintenance Kit; R = Repair Kit; replacement parts are available only in their respective kits.

1

4

5

6

No.

Screen Holder Gasket

5

Screen Holder

6

Cap

7

Nameplate

8

Description

M*

R*

-

-

-

-

Loading...

Loading...