172-65441A-04 (JL14-X/JLH14-X/JLH14-B) 20 January 2021

Process Float Steam Trap

JL14-X / JLH14-X

(Optional Model)

JLH14-B

Manufacturer

881 Nagasuna, Noguchi, Kakogawa, Hyogo, 675-8511, Japan

Tel: [81]-(0)79-422-1122 Fax: [81]-(0)79-422-0112

Copyright © 2021 by TLV Co., Ltd. All rights reserved

1

Contents

Introduction ....................................................................... 1

Safety Considerations ....................................................... 2

Checking the Piping .......................................................... 4

Specifications .................................................................... 5

Installation ......................................................................... 7

Maintenance ...................................................................... 9

Disassembly/Reassembly ............................................... 10

Troubleshooting .............................................................. 15

TLV EXPRESS LIMITED WARRANTY ............................. 17

Introduction

Thank you for purchasing the TLV process float steam trap.

This product has been thoroughly inspected before being shipped from the

factory. When the product is delivered, before doing anything else, check the

specifications and external appearance to make sure nothing is out of the

ordinary. Also be sure to read this manual carefully before use and follow the

instructions to be sure of using the product properly.

The process float steam trap is a large-capacity lever float type mechanical

steam trap that uses a high-performance X-element or high-temperature

bimetal for the air vent. With the unique sensitivity of mechanical steam traps

for condensate discharge, the trap reduces the time required to start up

process equipment and improves heating efficiency.

For products with special order specifications or options, if detailed

instructions for the special order specifications or options are not contained in

this manual, please contact TLV for full details.

This instruction manual is intended for use with the model(s) listed on the

front cover. It is necessary not only for installation but for subsequent

maintenance, disassembly/reassembly and troubleshooting. Please keep it in

a safe place for future reference.

172-65441A-04 (JL14-X/JLH14-X/JLH14-B) 20 Jan 2021

2

Indicates a DANGER, WARNING or CAUTION item.

DANGER

Indicates an urgent situation which poses a threat of death or

serious injury

WARNING

Indicates that there is a potential threat of death or serious injury

CAUTION

Indicates that there is a possibility of injury or equipment / product

damage

WARNING

NEVER apply direct heat to the float.

The float may explode due to increased internal pressure, causing

accidents leading to serious injury or damage to property and

equipment.

CAUTION

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the product

or malfunctions that may lead to serious accidents. Local

regulations may restrict the use of this product to below the

conditions quoted.

DO NOT use this product in excess of the maximum operating

pressure differential.

Such use could make discharge impossible (blocked).

Use hoisting equipment for heavy objects (weighing

approximately 20 kg (44 lb) or more).

Failure to do so may result in back strain or other injury if the object

should fall.

Take measures to prevent people from coming into direct

contact with product outlets.

Failure to do so may result in burns or other injury from the

discharge of fluids.

Safety Considerations

Read this section carefully before use and be sure to follow the instructions.

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

The precautions listed in this manual are designed to ensure safety and prevent

equipment damage and personal injury. For situations that may occur as a result

of erroneous handling, three different types of cautionary items are used to

indicate the degree of urgency and the scale of potential damage and danger:

DANGER, WARNING and CAUTION.

The three types of cautionary items above are very important for safety: be sure to

observe all of them as they relate to installation, use, maintenance, and repair.

Furthermore, TLV accepts no responsibility for any accidents or damage occurring

as a result of failure to observe these precautions.

Symbols

172-65441A-04 (JL14-X/JLH14-X/JLH14-B) 20 Jan 2021

Continued on the next page

3

CAUTION

When disassembling or removing the product, wait until the

internal pressure equals atmospheric pressure and the surface

of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

injuries or damage.

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to modify the

product in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the

discharge of fluids.

Do not use excessive force when connecting threaded pipes to

the product.

Over-tightening may cause breakage leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge, which

may cause burns or other injury.

Use only under conditions in which no water hammer will

occur.

The impact of water hammer may damage the product, leading to

fluid discharge, which may cause burns or other injury.

172-65441A-04 (JL14-X/JLH14-X/JLH14-B) 20 Jan 2021

4

Use only under conditions in which no water hammer will occur. The

impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

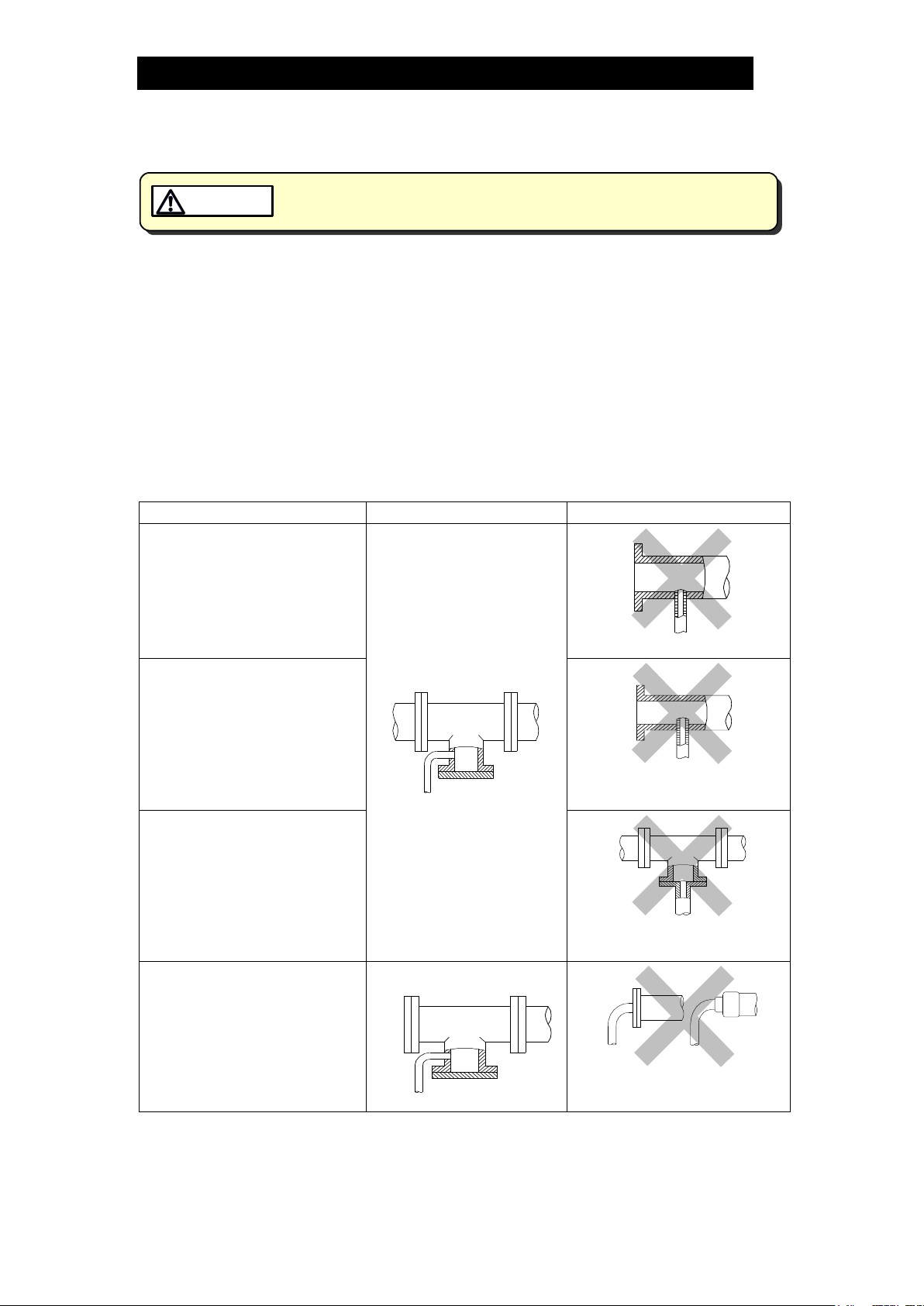

CAUTION

Requirement

Correct

Incorrect

Install catchpot with the proper

diameter.

Diameter is too small.

Make sure the flow of

condensate is not obstructed.

Diameter is too small and inlet

protrudes into pipe interior.

To prevent rust and scale from

flowing into the trap, the inlet

pipe should be connected 25 –

50 mm

(1 – 2 in) above the base of the

T-pipe.

Rust and scale flow into the

trap with the condensate.

When installing on the blind

end, make sure the flow of

condensate is not obstructed.

Condensate collects in the

pipe.

Checking the Piping

Check to make sure that the pipes to be connected to the trap have been installed

properly.

1. Is the pipe diameter suitable?

2. Is the piping where the trap is to be installed horizontal?

3. Has sufficient space been secured for maintenance (refer to the “Installation”

section)?

4. Have isolation valves been installed at the inlet and outlet? If the outlet is subject

to back pressure, has a check valve (TLV-CK) been installed?

5. Is the inlet pipe as short as possible, with as few bends as possible, and installed

so the liquid will flow naturally down into the trap?

6. Has the piping work been done correctly, as shown in the figures below?

172-65441A-04 (JL14-X/JLH14-X/JLH14-B) 20 Jan 2021

5

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

DO NOT use this product in excess of the maximum operating pressure

differential; such use could make discharge impossible (blocked).

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

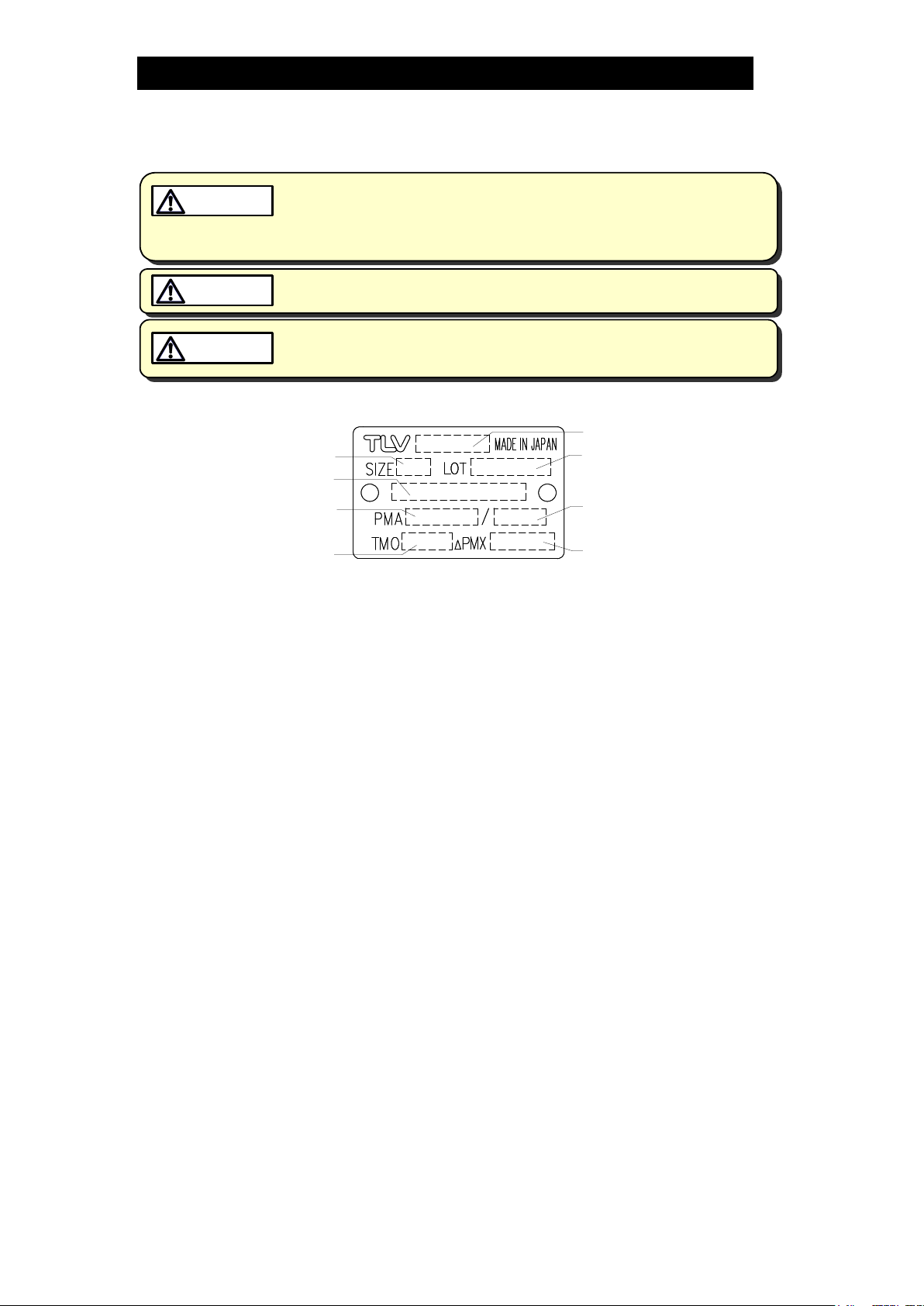

Model

Maximum Allowable

Temperature (TMA)*

Maximum Allowable

Pressure*

Nominal Diameter

Maximum Differential

Pressure

Production Lot No.

Valve No.**

Maximum Operating

Temperature

Specifications

Refer to the product nameplate for detailed specifications.

* Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are

PRESSURE SHELL DESIGN CONDITIONS, NOT OPERATING CONDITIONS.

** Valve No. is displayed for products with options. This item is omitted from the nameplate

when there are no options.

172-65441A-04 (JL14-X/JLH14-X/JLH14-B) 20 Jan 2021

Loading...

Loading...