CAST IRON

MODEL GP10L

CAST STEEL

STAINLESS STEEL

COMPACT MECHANICAL PUMP FOR CONDENSATE REMOVAL AND RECOVERY

Features

Pump for a wide range of applications. Ideal for low flow condensate

removal from vented receivers situated at low levels.

1. Handles high-temperature condensate without cavitation.

2. No electric power or additional level controls required, hence

INTRINSICALLY SAFE.

3. Pump will operate with a low filling head (min. 300 mm).

4. Easy, inline access to internal parts simplifies cleaning and reduces

maintenance costs.

5. High-quality stainless steel internals and hardened working surfaces ensure

reliability.

6. Compact design permits installation in a limited space.

7. Cycle Counter installable as option.

SDS U2404-02

Pressure Equipment Directive (PED)

Classification according to PED 2014/68/EU, fluid group 2

Size Category CE marking

DN 25, DN 40 I With CE marking and Declaration of Conformity

Specifications

Model GP10L

Connection

Size

Maximum Operating Pressure (barg) PMO 10.5

Maximum Operating Temperature (°C) TMO 185

Motive Medium Pressure Range (barg) 0.3 to 10.5

Maximum Allowable Back Pressure 0.5 bar less than motive medium pressure used

Volume of Each Discharge Cycle (litre) approximately 6

Motive Medium

Pumped Medium

Optional Specifications for Hazardous Locations ATEX:

*

For details of flange connection, see picture at bottom right ** Do not use with toxic, flammable or otherwise hazardous fluids. 1 bar = 0.1 MPa

***

Do not use for fluids with specific gravities under 0.85 or over 1, or for toxic, flammable or otherwise hazardous fluids.

PRESSURE SHELL DESIGN CONDITIONS (NOT OPERATING CONDITIONS):

Maximum Allowable Pressure (barg) PMA: 13 (Cast Iron), 21 (Cast Steel), 16 (Cast Stainless Steel)

Maximum Allowable Temperature (°C) TMA: 200 (Cast Iron), 220 (Cast Steel, Cast Stainless Steel)

CAUTION

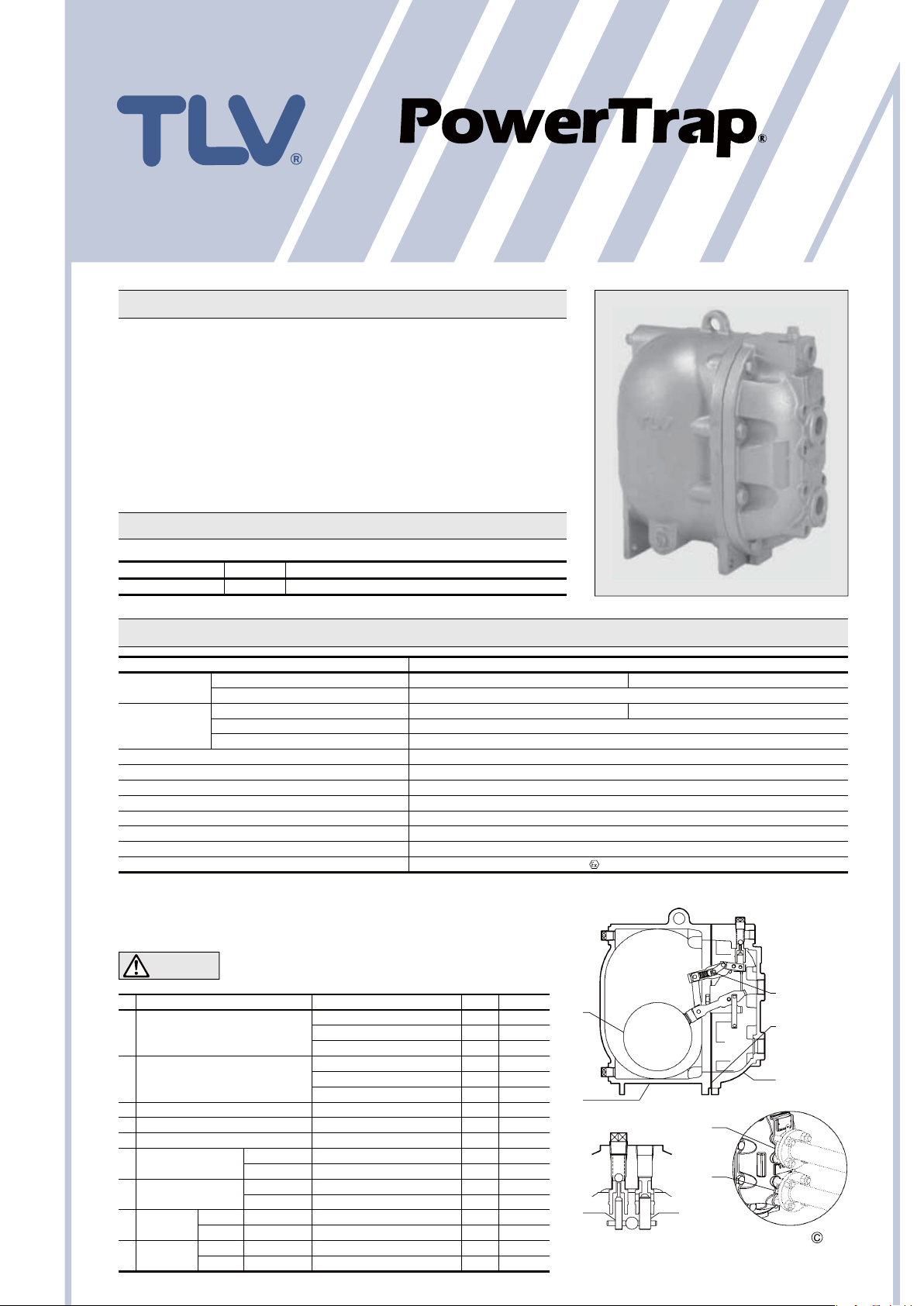

No. Description Material DIN*ASTM/AISI

Body

q

Cover

w

Cover Gasket Graphite Compound — —

e

Float Stainless Steel SUS316L 1.4404 AISI316L

r

Snap-action Unit Stainless Steel — —

t

Motive Medium

y

Intake Valve Unit

Exhaust Valve

u

Unit

Inlet

i

Check Valve

Outlet

o

Check Valve

*

Equivalent materials ** Not shown

Pumped Medium Inlet & Outlet Screwed and Flanged

Motive Medium & Pump Exhaust Screwed

Pumped Medium: Inlet × Outlet 1”/ DN 25 × 1”/ DN 25 1

Motive Medium Inlet

Pump Exhaust Outlet

**

***

To avoid abnormal operation, accidents or serious injury, DO NOT use

this product outside of the specification range. Local regulations may

restrict the use of this product to below the conditions quoted.

Cast Iron FC250 0.6025 A126 Cl.B

Cast Steel A216 Gr.WCB

Cast Stainless Steel A351 Gr.CF8 1.4312 —

Cast Iron FC250 0.6025 A126 Cl.B

Cast Steel A216 Gr.WCB

Cast Stainless Steel A351 Gr.CF8 1.4312 —

Intake Valve Stainless Steel SUS440C 1.4125 AISI440C

Valve Seat Stainless Steel SUS420F 1.4028 AISI420F

Exhaust Valve Stainless Steel SUS440C 1.4125 AISI440C

Valve Seat Stainless Steel SUS420F 1.4028 AISI420F

**

Screwed CK3MG

Flanged CKF5M Stainless Steel SUS304 1.4301 AISI304

Screwed CK3MG

Flanged CKF3M

Cast Stainless Steel A351 Gr.CF8

**

Cast Stainless Steel A351 Gr.CF8

Cast Stainless Steel A351 Gr.CF8

**

**

1.0619 —

1.0619 —

1.4312 —

1.4312 —

1.4312 —

Saturated Steam, Compressed Air, Nitrogen

*

1

⁄2”

1

⁄2”

Steam Condensate, Water

II2GExhIICT3Gb

*

r

q

i

o

yu

Screwed

1

⁄2” × 1”

t

w

e

Flange Connection (25 mm)

Copyright

TLV

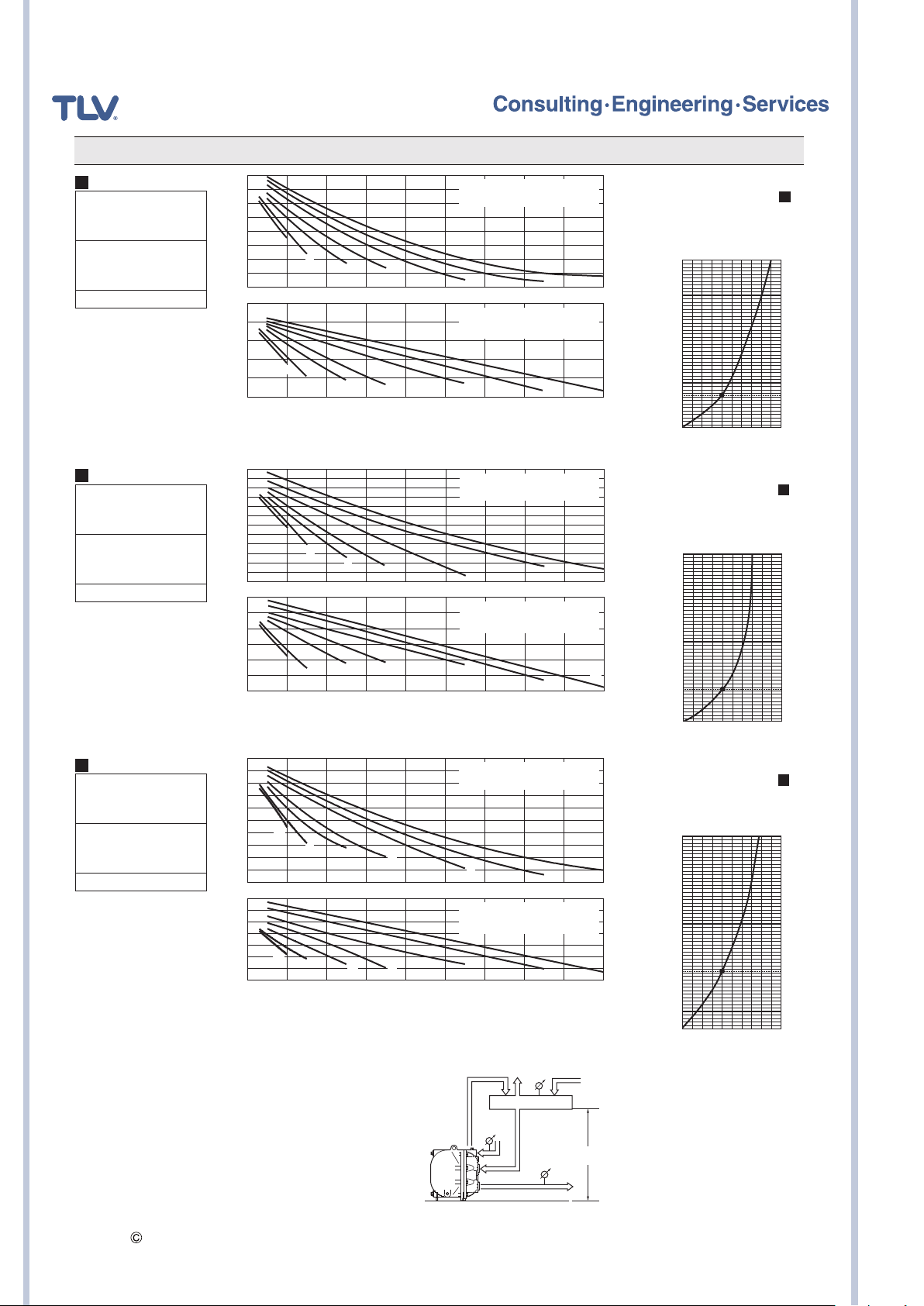

Discharge Capacity

A

Connection: Screwed

Inlet size: 1”

Outlet size: 1”

Check Valve: CK3MG

Inlet: 1”

Outlet: 1”

Filling Head: 630 mm

1200

1000

800

600

400

0123456789

1250

1200

115 0

Discharge Capacity (kg/h)Discharge Capacity (kg/h) Discharge Capacity (kg/h)

110 0

1050

1000

0123456789

Motive Medium: Saturated Steam

Motive Steam Pressure: barg

Condensate Temperature: 90 °C

¡CORRECTION FACTOR

For discharge capacity graph

installed with filling head

A

other than 630 mm

1.5

2

3

4

1.5

2

3

4

6

Motive Medium: Compressed Air

Motive Air Pressure: barg

Condensate Temperature: 20 °C

6

8

8

System Back Pressure (barg) 1 bar = 0.1 MPa

(minimum filling head: 450 mm)

1400

10

10

1300

1200

110 0

(mm)

1000

900

800

700

Filling Head

630

500

450

0.6

1. 0

1. 5

B

Connection: Screwed

Inlet size: 11⁄2”

Outlet size: 1”

Check Valve: CK3MG

Inlet: 1

Outlet: 1”

Filling Head: 630 mm

1

⁄2”

1600

1400

1200

1000

1700

1600

1500

1400

1300

1200

110 0

1.5

800

600

400

0123456789

0123456789

2

3

1.5

3

2

System Back Pressure (barg) 1 bar = 0.1 MPa

C

Connection: Flanged

Inlet size: DN 25

Outlet size: DN 25

Check Valve:

Inlet

(CKF5M)

: DN 25

Outlet

(CKF3M)

: DN 25

Filling Head: 630 mm

1200

110 0

1000

900

800

700

1.5

600

500

400

300

200

0123456789

1250

1200

115 0

110 0

1050

1000

950

900

0123456789

2

3

1.5

2

3

System Back Pressure (barg) 1 bar = 0.1 MPa

NOTE:

¡

A check valve must be installed at both the pumped medium inlet and

outlet. To achieve the above capacities with the standard GP10L

configuration, either TLV check valves CK3MG (inlet & outlet), or

CKF5M (inlet) and CKF3M (outlet) must be used. depending on

connection type.

¡

Motive medium pressure minus back pressure must be greater than

0.5 bar.

¡

In closed system applications, the motive medium must be compatible

with the liquid being pumped. If a non-condensable gas such as air or

nitrogen is used as the motive medium, consult TLV for assistance.

¡

A strainer must be installed at the motive medium and pumped

medium inlets.

Copyright

TLV

Motive Medium: Saturated Steam

Motive Steam Pressure: barg

Condensate Temperature: 90 °C

4

4

4

4

6

Motive Medium: Compressed Air

Motive Air Pressure: barg

Condensate Temperature: 20 °C

6

Motive Medium: Saturated Steam

Motive Steam Pressure: barg

Condensate Temperature: 90 °C

6

Motive Medium: Compressed Air

Motive Air Pressure: barg

Condensate Temperature: 20 °C

6

¡FILLING HEAD AND PRESSURES

Condensate Receiv

Pm

GP10L

¡CORRECTION FACTOR

For discharge capacity graph

with filling head other than 630 mm

(minimum filling head: 450 mm)

8

10

10

8

1400

1300

1200

110 0

(mm)

1000

900

800

700

Filling Head

630

500

450

0.6

1. 0

B

1. 5

¡CORRECTION FACTOR

For discharge capacity graph

with filling head other than 630 mm

(minimum filling head: 300 mm)

1400

1300

10

8

8

10

P

1

er

The discharge capacity is determined by

the motive

pressure (Pm) and back pressure (P

1200

110 0

(mm)

1000

900

800

700

630

Filling Head

500

400

300

0.6

1. 0

medium, motive medium

Make sure that:

Discharge Capacity

Filling

Head

P

2

Correction Factor

×

>

Required Flow Rate

C

1. 5

2).

SDS U2404-02

Dimensions

Units: mm

Weight (kg)

Pump Exhaust Outlet

BSP ½

Note: All Plug Holes BSP ½

360 250

16

300

410

375

237

107

16

Motive Medium Inlet

BSP ½

Pumped Medium Inlet

BSP 1/DN 25

PN 10, 16, 25

Pumped Medium Outlet

352

BSP 1/DN 25

PN 10, 16, 25

Cast steel/

*

cast stainless steel only

*

, 40* or BSP 1½

*

, 40

*

Cast Iron

Cast Steel

Cast Stainless Steel

* Approx.

Size of Receiver/Reservoir

The receiver/reservoir must have a capacity sufficient to store the condensate produced during the PowerTrap operation and

discharge. A receiver will generally be larger than a reservoir because it must handle the condensate both as a liquid and as

flash steam, and separate one from the other so that only condensate is sent to the PowerTrap.

45

49

42*

1.Size of Receiver (flash steam is involved)

(Length: 1 m)

Flash steam up to

(

kg/h

)

25 80 25

50 100 50

75 125 50

100 150 80

150 200 80

200 200 100

300 250 125

400 300 125

500 350 150

700 400 200

800 450 200

1000 500 200

1100 500 250

1400 550 250

1500 600 250

Receiver diameter

(mm)

Vent pipe diameter

(mm)

3.If flash steam is condensed before it enters

the receiver/reservoir, compare tables 1and 2

2.Size of Reservoir (flash steam is not involved)

Amount of

condensate

(kg/h)

300 or less 1.2

400 1.5 1.0

500 2.0 1.2 0.5

600 1.5 0.6

800 2.0 0.8 0.5

1000 1.0 0.7

1500 1.5 1.0

2000 2.0 1.3 0.6

3000 2.0 0.9 0.5

4000 1.2 0.7

5000 1.4 0.8 0.5

6000 1.7 1.0 0.6

7000 2.0 1.2 0.7

8000 1.3 0.8

9000 1.5 0.9

10000 1.7 1.0

Reservoir length can be reduced by 50% when the motive medium pressure

(Pm) divided by back pressure (P

and choose the larger of the two sizes.

Steam or Air Consumption (Motive Medium)

10

9

8

6

(kg)

5

4

Steam Consumption

3

2

(per 1 tonne condensate)

1. 7

Steam Consumption

1

12345678910

Air Consumption

Back Pressure (barg) 1 bar = 0.1 MPa

*

Equivalent consumption of air at 20 °C

under atmospheric pressure

7

*

6

)

3

5

(m

Air Consumption

Cycle Counter (option)

Two types of counter can be installed on

the GP10L to monitor the number of

pumping cycles and help to determine the

timing of maintenance, or estimate the

volume of pumped condensate.

C1CM – (Counter Unit

・

Type): Self-contained

standalone unit.Includes an

LCD counter display and an

operation indicator LED

(per 1 tonne condensate)

C1SM – (Terminal Box

・

Type): Designed for use with

remote monitoring equipment

and systems.

See the Cycle Counter SDS for further details.

Reservoir diameter (mm) and length (m)

40 50 80 100 150 200 250

m 0.7

2

) equals 2 or greater (when Pm ÷ P2 ≧ 2).

LED

LCD

C1CM

C1SM

Copyright

TLV

SDS U2404-02

System Package (Open Systems)

Single System Package Type S1L

Discharge Capacity: see discharge capacity graph (no correction factor required, max. capacity 1 t/h)

Maximum Allowable Flash Steam: 100 kg/h Tank Size: 12ℓ Weight: 120 kg

445

Exhaust Outlet DN 50 PN 16

A

φ

165

460

For Level Gauge

300

106

Pumped Medium

Inlet DN 50 PN 16

Motive Medium

Inlet BSP ½

Pumped Medium

Outlet BSP 1

100

660 135 290

approx. 745

approx.

85

930

705

408

163

151

95

520

Single System Package Type S1M

Discharge Capacity: see discharge capacity graph (no correction factor required, max. capacity 1.5 t/h)

Maximum Allowable Flash Steam: 200 kg/h Tank Size: 22ℓWeight: 130 kg

165

Exhaust Outlet DN 80 PN 16

B

151

Pumped Medium

Inlet DN 50

PN 16

460

For Level Gauge

300106

660

approx. 745

Standards:

Flanged connections: DIN 2501

Screwed connections: DIN 2999

Other standards available

Actual specifications may differ from the ones shown. Please consult TLV for details.

Copyright

TLV

Motive Medium

Inlet BSP ½

Pumped Medium

Outlet BSP 1

91

approx.

85

https://www.tlv.com

930

408

163

(O)

705

135 275

520

110

Units: mm

SDS U2404-02 Rev. 2/2021

Products for intended use only.

Specifications subject to change without notice.

Loading...

Loading...