172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 April 2021

Cycle Counter

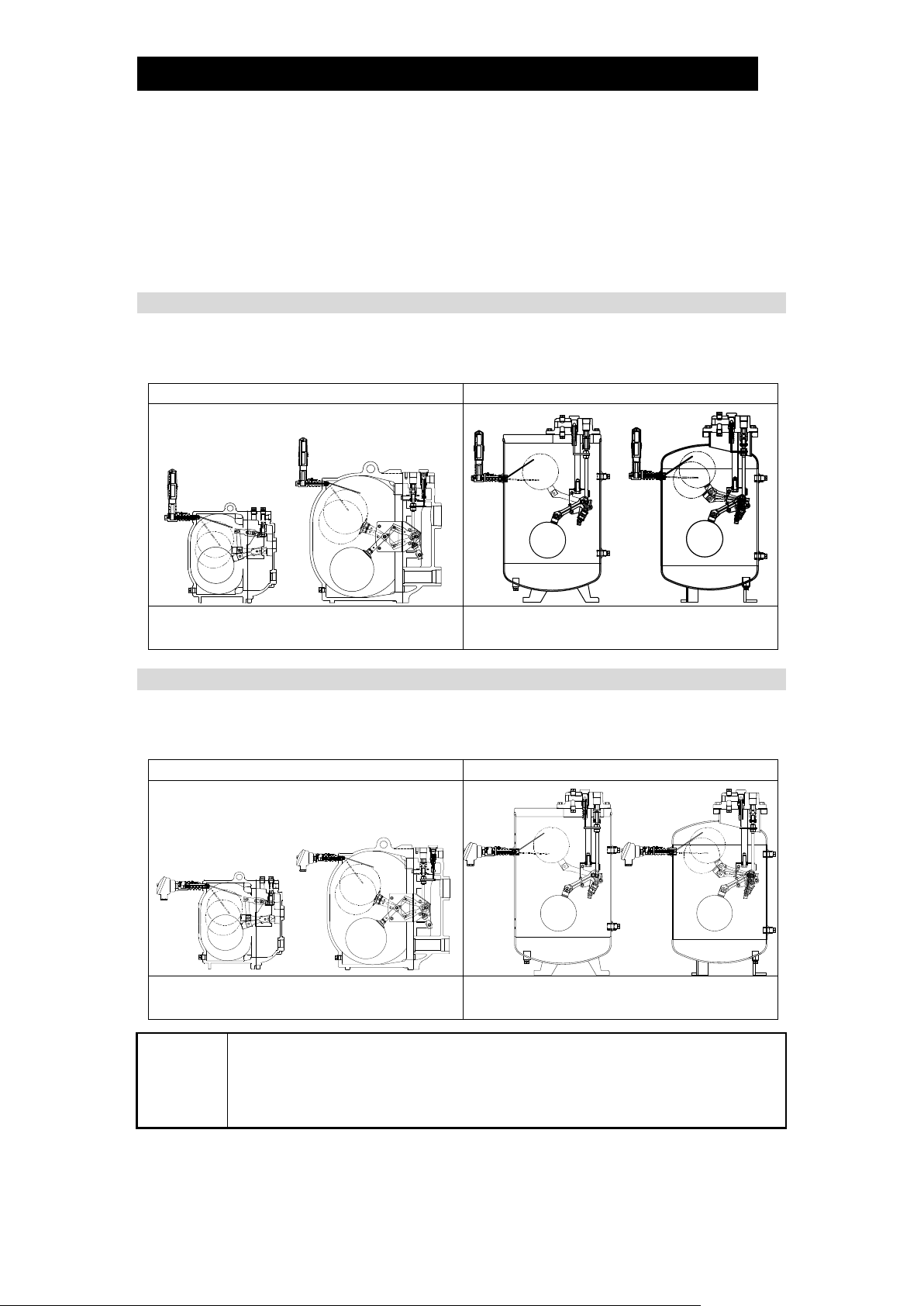

C1CM / C1CF

C1SM / C1SF

(Standard Model)

C1CM-EX / C1CF-EX

C1SM-EX / C1SF-EX

(ATEX & IECEx Intrinsically Safe Model)

NOTE: This instruction manual has been edited for use with both standard

and intrinsically safe models.

Copyright © 2021 by TLV CO., LTD.

All rights reserved

1

Contents

Introduction ....................................................................... 1

Safety Considerations ....................................................... 2

Operation .......................................................................... 4

Specifications .................................................................... 5

Configuration ..................................................................... 7

Installation ......................................................................... 8

Troubleshooting .............................................................. 12

Product Warranty ............................................................ 14

Introduction

Thank you for purchasing the TLV cycle counter.

This product has been thoroughly inspected before being shipped from the

factory. When the product is delivered, before doing anything else, check the

specifications and external appearance to make sure nothing is out of the

ordinary. Also be sure to read this manual carefully before use and follow the

instructions to be sure of using the product properly.

For products with special order specifications or options, if detailed instructions

for the special order specifications or options are not contained in this manual,

please contact TLV for full details.

This instruction manual is intended for use with the model(s) listed on the front

cover. It is necessary not only for installation but for subsequent maintenance,

disassembly/reassembly and troubleshooting. Please keep it in a safe place

for future reference.

172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 Apr 2021

2

Indicates a DANGER, WARNING or CAUTION item.

DANGER

Indicates an urgent situation which poses a threat of death or

serious injury

WARNING

Indicates that there is a potential threat of death or serious injury

CAUTION

Indicates that there is a possibility of injury or equipment/product

damage

WARNING

C1CM, C1SM, C1CF, and C1SF are not explosion-proof.

Use only the intrinsically safe C1CM-EX, C1SM-EX, C1CF-EX, and

C1SF-EX in hazardous areas. Product markings are provided on

the nameplate attached on the product.

The C1CM-EX, C1SM-EX, C1CF-EX, and C1SF-EX are compliant

with:

ATEX:EN 60079-0:2012, EN 60079-11:2012

IECEx:IEC 60079-0:2011, IEC 60079-11:2011

The C1CM-EX, C1SM-EX, C1CF-EX, and C1SF-EX meet the

following standards for intrinsic safety:

C1CM-EX, C1CF-EX

ATEX:

nnnn II 2G Ex ib IIB T3/T2 Gb

CML 18ATEX2179X

IECEx: Ex ib IIB T3/T2 Gb

IECEx CML 18.0094X

C1SM-EX, C1SF-EX

ATEX:

nnnn II 2G Ex ib IIC T3/T2 Gb

DEKRA 13 ATEX 0039

IECEx: Ex ib IIC T3/T2 Gb

IECEx DEK 13.0004

For hazardous areas, the product should be selected and installed

by trained personnel with knowledge of the hazardous

locations/classifications.

When using the product in hazardous area, please connect it to the

earth in order to avoid the ignition from electrostatic charge.

Safety Considerations

Read this section carefully before use and be sure to follow the instructions.

Installation, inspection, maintenance, repairs, disassembly, adjustment

and valve opening/closing should be carried out only by trained

maintenance personnel.

The precautions listed in this manual are designed to ensure safety and

prevent equipment damage and personal injury. For situations that may

occur as a result of erroneous handling, three different types of cautionary

items are used to indicate the degree of urgency and the scale of potential

damage and danger: DANGER, WARNING and CAUTION.

The three types of cautionary items above are very important for safety: be

sure to observe all of them as they relate to installation, use, maintenance,

and repair. Furthermore, TLV accepts no responsibility for any accidents or

damage occurring as a result of failure to observe these precautions.

Symbols

Continued on the next page

172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 Apr 2021

3

CAUTION

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the product

or malfunctions that may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

Make sure that the sensor body is properly tightened.

Insufficient tightening may allow steam to blow out, resulting in burns.

When disassembling or removing the product, wait until the

internal pressure of the PowerTrap equals atmospheric

pressure and the surface of the PowerTrap has cooled to

room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

injuries or damage.

NEVER attempt to modify the product in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the

discharge or fluids.

Use only under conditions in which no water hammer will occur.

The impact of water hammer may damage the product, leading to

fluid discharge, which may cause burns or other injury.

When installing the product, use the appropriate tool such as

an adjustable wrench.

Using the improper tool may lead to injury or damage to the product.

DO NOT disassemble/modify the product.

This could damage the product and/or the built-in battery, or

cause leakage of battery fluid, leading to burns or other injury.

Battery cells are not user replaceable.

172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 Apr 2021

4

Installation location

C1CM/C1CM-EX

C1CF/C1CF-EX

GP10, GP10L, GP10M

GP14, GP14L, GP14M

GP10F*

GP21F*

Installation location

C1SM/C1SM-EX

C1SF/C1SF-EX

GP10, GP10L, GP10M

GP14, GP14L, GP14M

GP10F*

GP21F*

NOTE

Cycle counter protrudes from the PowerTrap body when installed on the

PowerTrap. Make sure to maintain sufficient installation space as described in

the instruction manual for the PowerTrap.

Do not put extra force onto the cycle counter when lifting the PowerTrap up (for

disassembly or maintenance, etc.).

Operation

Cycle counter is a counter designed for use with GP series TLV PowerTraps. Cycle

counter registers each cycling of the PowerTrap by using its sensor arm to detect the

vertical movement of the PowerTrap's internal float. When the contact points of the

reed switch inside the counter body (or the switch unit) connect, each cycling of the

PowerTrap is counted.

There are two different types of cycle counter available.

Counter Unit Type (with a built-in LCD display) (C1CM/C1CM-EX, C1CF/C1CF-EX)

This type includes a built-in LCD display to display the number of pump cycles of the

PowerTrap. Install the cycle counter using the installation hole on the PowerTrap.

Terminal Box Type (no display) (C1SM/C1SM-EX, C1SF/C1SF-EX)

There is no display on this type. Use the product with a separately prepared selfpowered counter, etc.

*Only available in some countries.

172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 Apr 2021

5

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Model

Counter Unit Type*4

Standard Model

Intrinsically Safe Model

C1CM

C1CF

C1CM-EX

C1CF-EX

Installable PowerTrap

Models

GP10, GP14,

GP10L, GP14L,

GP10M, GP14M,

GP10F

GP21F

GP10, GP14,

GP10L, GP14L,

GP10M, GP14M

GP10F

GP21F

Connection

Screwed R(PT) or NPT

Size

15 mm

Maximum Operating

Pressure (PMO)*1/

Maximum Operating

Temperature (TMO)*1

2.1 MPaG / 220 C

Maximum Allowable

Pressure (PMA)*2/

Maximum Allowable

Temperature (TMA)*2

2.1 MPaG/ 260 C

Applicable Fluids*3

Steam Condensate, Water, Steam, Air, Nitrogen

Protection Class

IP 65

Ambient Pressure /

Temperature

Atmospheric / -10 to 55 C

Process Temperature

―

T3:185 C

T2:220 C

Intrinsically Safe:

Certified to meet all of

these standards

―

ATEX:

nnnn II 2G Ex ib IIB T3/T2 Gb

CML 18ATEX2179X

IECEx:

Ex ib IIB T3/T2 Gb

CML 18.0094X

Display

8-digit display LCD

(can be reset*5)

Power Supply

Special built-in lithium battery (3.6 V)

Battery life: Approx. 10 years

(Battery not replaceable*4)

Weight

Approx. 660 g

Accessories

Counter Resetter

*1

Maximum Operating Pressure (PMO) and Maximum Operating Temperature (TMO) are

operating conditions for the inserted portion only.

*2

Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are

DESIGN CONDITIONS FOR THE INSERTED PORTION, NOT OPERATING

CONDITIONS.

*3

Do not use with toxic, flammable or otherwise hazardous fluids.

*4

Repair parts are not supplied. Once the battery is depleted the entire unit must be

replaced as the battery for the counter unit cannot be taken out or replaced. In addition,

as a used counter unit still contains its built-in battery, please return the unit to TLV or

follow local regulations for disposal.

*5

Once the counter is reset, the previous value is lost and cannot be recovered.

GP10, GP10L, GP10M, GP14, GP14L and GP14M cannot be equipped with a cycle counter

and a liquid level gauge simultaneously but GP10F and GP21F can. GP10F and GP21F are

only available in some countries.

Specifications

C1C Series

172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 Apr 2021

6

C1S Series

Model

Terminal Box Type*4

Standard Model

Intrinsically Safe Model

C1SM

C1SF

C1SM-EX

C1SF-EX

Installable PowerTrap

Models

GP10, GP14,

GP10L, GP14L,

GP10M, GP14M

GP10F

GP21F

GP10, GP14,

GP10L, GP14L,

GP10M, GP14M

GP10F

GP21F

Connection

Screwed R(PT) or NPT

Size

15 mm

Maximum Operating

Pressure (PMO)*1/

Maximum Operating

Temperature (TMO)*1

2.1 MPaG / 220 C

Maximum Allowable

Pressure (PMA)*2/

Maximum Allowable

Temperature (TMA)*2

2.1 MPaG/ 260 C

Applicable Fluids*3

Steam Condensate, Water, Steam, Air, Nitrogen

Protection Class

IP 65*5

Ambient Pressure /

Temperature

Atmospheric /

-45 to 90 C

Atmospheric /

-20 to 80 C

Process Temperature

―

T3:185 C

T2:220 C

Intrinsically Safe:

Certified to meet all of

these standards

―

ATEX:

nnnn II 2G Ex ib IIC T3/T2 Gb

DEKRA 13 ATEX 0039

IECEx:

Ex ib IIC T3/T2 Gb

IECEx DEK 13.0004

Display

―

Power Supply

Max. input power (Pi): 1 W

Max. incoming voltage (Ui): 28 V

Max. incoming current (Ii): 120 mA

Max. internal capacitance (Ci): 3 nF

Max. internal inductance (Li): 0

Note: (Ui)V x (Ii)A ≤ 1 W (Pi)

Weight

Approx. 700 g

Accessories

―

*1

Maximum Operating Pressure (PMO) and Maximum Operating Temperature (TMO) are

operating conditions for the inserted portion only.

*2

Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are

DESIGN CONDITIONS FOR THE INSERTED PORTION, NOT OPERATING

CONDITIONS.

*3

Do not use with toxic, flammable or otherwise hazardous fluids.

*4

Repair parts are not supplied.

*5

Waterproofing of the wiring inlet should be carried out by the user using a waterproof

cable gland, etc.

GP10, GP10L, GP10M, GP14, GP14L and GP14M cannot be equipped with a cycle counter

and a liquid level gauge simultaneously but GP10F and GP21F can. GP10F and GP21F are

only available in some countries.

172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 Apr 2021

7

R(PT)* or

NPT1/

2

Inserted portion

C1CF

C1CF-EX

C1CM

C1CM-EX

No.

Name

1

Sensor Body

2

Sensor Arm

3

Counter Body

4

Cap

5

Display (LCD)

6

Hex Socket Head Bolt

7

Nameplate

8

LED

9

Magnet Booster Kit

Cycle Counter cannot be

installed on GP series

PowerTraps insulated with

an insulation thickness

exceeding 40 mm.

R(PT)* or

NPT1/

2

Inserted portion

Electrical conduit connection G1/

2

C1SF

C1SF-EX

C1SM

C1SM-EX

No.

Name

1

Sensor Body

2

Sensor Arm

3

Switch Unit

4

Hex Socket Head Bolt

5

Washer

6

Nameplate

7

Terminal Box

8

Magnet Booster Kit

Cycle Counter cannot be

installed on GP series

PowerTraps insulated with an

insulation thickness exceeding

40 mm.

The year of manufacture is included in S. NO. (Serial

Number) on the nameplate.

Please contact TLV for details.

Configuration

Counter Unit Type: C1CM/ C1CM-EX, C1CF/C1CF-EX)

Terminal Box Type: C1SM/C1SM-EX, C1SF/C1SF-EX)

*R(PT) is equivalent to BSPT

172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 Apr 2021

8

C1CM, C1SM, C1CF, and C1SF are not explosion-proof. Use only the

intrinsically safe C1CM-EX, C1SM-EX, C1CF-EX and C1SF-EX in hazardous

areas. For hazardous areas, the product should be selected and installed by

trained personnel with knowledge of the hazardous locations/classifications.

WARNING

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use only under conditions in which no water hammer will occur. The

impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

CAUTION

NEVER attempt to modify the product in any way.

Failure to observe these precautions may result in damage to the product

and burns or other injury due to malfunction or the discharge or fluids.

CAUTION

Make sure that the sensor body is properly tightened.

Insufficient tightening may allow steam to blow out, resulting in burns.

CAUTION

When disassembling or removing the product, wait until the internal

pressure of the PowerTrap equals atmospheric pressure and the surface

of the PowerTrap has cooled to room temperature. Disassembling or

removing the product when it is hot or under pressure may lead to

discharge of fluids, causing burns, other injuries or damage.

CAUTION

Make sure to install the sensor arm without bending.

Make sure to remove any sealing tape or

debris when removing the plug.

NOTE

- Wrap the threaded portion of the sensor body with sealing tape for screwing

into the PowerTrap.

Ensure not to wrap the tape around any part of the sensor body other than

the threaded portion. The cycle counter may not operate properly if tape is

wrapped around a moving part such as the sensor arm.

- Do not use sealant. If sealant adheres to the moving part of the sensor arm it

may interfere with the arm’s movement.

NOTE

Sometimes the display on the counter unit type does not show “0” when

delivered. The number can be reset after installation. Reset as needed. (Refer

to the “Resetting the counter on the LCD display of the counter unit type”

section described later in this manual.)

Installation

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

An explanation for installing cycle counter onto the GP14M PowerTrap is given as

an example. The same procedure should be followed for other models.

1. Remove the plug from the PowerTrap in reference with the installation position in

the “Operation” section. Screw the cycle counter into the place where the plug has

been removed on the PowerTrap by turning it clockwise 4 to 5 times.

172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 Apr 2021

9

For both the counter unit and terminal box types,

use a tool such as an adjustable wrench to grip the

square portion of the sensor body (distance across flats:

30 mm and screw the product in.

Applying a force to any part of the product other than the

square portion may deform or damage the product.

Make sure that the LED on

the tip is facing upwards.

Make sure that the switch

unit is facing upwards.

5

5

°

°

5

5

°

°

Inclination should be within 5.

Connect the wires by

loosening these screws

(size: M4).

(Polarity: left –, right: +)

Do not loosen

these screws.

For the terminal box type, wiring is

necessary to the terminal box.

Before wiring, refer to the

“Specifications” section to make

sure that the supply power voltage

meets these specifications. Make

sure that the wires are securely

connected to the terminal box using

the ring or the spade terminals.

Waterproofing of the wiring inlet

should be carried out using a

waterproof cable gland, etc.

2. The following figure shows the product once installation is complete. Make sure to

screw in the product with the body centered and facing upwards.

3. Before use, the wiring needs to be carried out for the terminal box type. Follow

the figure shown below for the location of the wiring connections.

4. Make sure that the product is properly tightened before proceeding with the test

operation.

For performing a test operation after the product has been installed, follow the

procedure in the PowerTrap instruction manual.

Check motive medium supply piping and other piping connections before

operation. Operation should be carried out by trained personnel.

If the display needs to be reset on the counter unit after the test operation, refer

to the “Resetting the counter on the LCD display of the counter unit” section

described later in this manual.

172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 Apr 2021

10

Cap

Hex Key (2 mm)

Allen Head Bolt

Counter Body

Hex Socket Head Bolt

Lift this part slightly and turn.

NOTE

In order to prevent burns, make sure the product is removed from the

PowerTrap before starting to work.

NOTE

Do not turn the LCD display part more than 360 to the left or right. Turning the

display more than one rotation in either direction could cause disconnection of

internal wiring or other malfunctions.

Adjusting the angle of the LCD display on the counter unit

The angle of the LCD display on the counter unit can be changed.

1. Remove the hex socket head bolt on the counter body.

Turn the cap counterclockwise, then pull up to remove it from the counter body.

2. Once the cap is removed, turn the silicon-molded LCD display so that the LCD

display is readable. After the adjustment is made, put the transparent cap back

on and retighten the hex socket head bolt (tightening torque: 0.5 Nm).

172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 Apr 2021

11

LCD Display

(Counter cannot be reset, by putting

resetter close to the display side.)

Resetter

C1CM/C1CM-EX

C1CF/C1CF-EX

C1SM/C1SM-EX

C1SF/C1SF-EX

Sensor Body

Magnet Booster Kit

Fixed in place

by the counter body

NOTE

Once the counter is reset, the previous value is lost and cannot be recovered.

In addition, failures of the PowerTrap caused by resetting the counter will not

be covered under warranty.

Resetting the counter on the LCD display of the counter unit

The numeric value displayed on the LCD of the counter unit can be reset.

Put the counter resetter close to the back of the LCD display as shown below. (The

cap is removed in the figure below. The counter can be reset without removing the

cap.) After the display clears momentarily, “0” will be displayed. Do not put the

counter resetter close to the cycle counter other than for the purpose of resetting the

counter display. Once the counter is reset to zero, it can not be returned to displaying

the previous numeric value.

Magnet booster kit

If the cycle counter has been used in a high-temperature environment for a long

period of time, the magnetic force of the reed switch becomes weaker, resulting in

operational failure (the counter does not count).

For this reason, the magnet booster kit is installed on the upper part of the sensor

body to prevent operational failure.

This booster kit has a built-in magnet to restore the magnetic force of the reed switch,

preventing operational failure.

Contact TLV in the event if the magnet booster kit falls from the cycle counter.

172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 Apr 2021

12

When disassembling or removing the product, wait until the internal

pressure of the PowerTrap equals atmospheric pressure and the surface

of the PowerTrap has cooled to room temperature. Disassembling or

removing the product when it is hot or under pressure may lead to

discharge of fluids, causing burns, other injuries or damage.

CAUTION

Problem

Cause

Remedy

Counter Unit Typ

e

Nothing is displayed

on the LCD display

Battery has been completely

discharged

Replace with a new counter unit

(The battery itself cannot be

replaced)

Cycle counter is not

operating even though

the PowerTrap is in

operation

(you can hear the

snap action unit

operating sound)

Sensitivity of the sensor is

reduced

Adjust the sensitivity

(See the “Adjusting the sensitivity

for the counter unit type” section)

Dirt or foreign matter has

clogged the hinge part of the

sensor arm, hindering its

movement

Clean the moving area

Terminal Box Type

Cycle counter is not

operating even

though the PowerTrap

is in operation

(you can hear the

snap action unit

operating sound)

Sensitivity of the sensor is

reduced

Adjust the sensitivity

(See the “Adjusting the sensitivity

for the terminal box type” section)

Dirt or foreign matter has

clogged the hinge part of the

sensor arm, hindering its

movement

Clean the moving area

Improper wiring

Readjust the wiring

Troubleshooting

When the product fails to operate properly, use the following table to locate the cause

and remedy.

If problems do not improve even after applying the remedies listed in “Troubleshooting”,

contact TLV.

Sensitivity adjustment for the counter unit type

When operating sounds can be heard from the PowerTrap however the cycle counter

does not count or other symptoms appear, it is possible that the sensitivity of the

sensor (the sensing accuracy of the reed switch) may have lowered due to aging of

the product.

In such cases, the sensitivity of the sensor can be restored by readjusting the

distance between the magnet built in to the sensor body and the built-in reed switch

in the counter body (or the switch unit for the terminal box type)

In this section, this operation is called sensitivity adjustment.

Make sure that the product is removed from the PowerTrap before you make

adjustments. Take precautions against burns, etc. when removing the unit.

1. Loosen the hex socket head bolt holding the counter body in place.

2. Then rotate the counter body as shown in the figure on the next page while

moving the sensor arm up and down. The counter body may be turned in either

direction. Check the sensitivity by turning both ways (to the left and right).

However do not turn more than 15 to the left or right.

3. Once the LED lights up in time with the movement of the sensor arm and has

begun to count properly, the counter is considered to be operating normally.

4. Secure the counter by re-tightening the hex socket head bolt (tightening torque:

1.5 Nm).

172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 Apr 2021

13

Loosen the hex socket head bolt and turn the

counter body slightly to make sure that the

counter is functioning properly.

Adjust the counter body by twisting within 15 to

the left or right. The angle should be adjusted

based on the matching mark on the body.

Loosen the

hex socket head bolt

(Hex key: 3 mm)

Matching Mark

Screw Hole

15

Loosen the hex socket head bolt

(Hex key: 3 mm)

15

Loosen the hex socket head

bolt and turn the switch unit

slightly with a coin, etc. to

make sure that the counter

is functioning properly.

Do not turn the switch unit more than

15 to the left or right. The position of

the hex socket head bolt should be

used to determine the angle.

NOTE

DO NOT turn the body more than 15 to the left or right when adjusting the

sensitivity.

NOTE

When removing/installing the hex socket head bolt, coat threaded portion with

sealing agent to maintain waterproofing.

NOTE

DO NOT turn the body more than 15 to the left or right when adjusting the

sensitivity.

Sensitivity adjustment for the terminal box type

Make sure that the product is removed from the PowerTrap before you make

sensitivity adjustments. Take precautions against burns, etc. when removing the unit.

To adjust the sensitivity, you can use a circuit tester, or else rewiring will be

necessary after removing the unit from the PowerTrap. In this section, we will

describe the adjustment method using a circuit tester.

First, set the range of the circuit tester so that the resistance measurement can be

carried out, then connect the leads to the plus and minus terminals on the terminal

box (refer to the “Installation” section).

Then move the sensor arm up and down and turn the switch unit little by little. The

switch unit may be turned in either direction, however do not turn more than 15 to

the left or right. When the resistance value of the circuit tester changes in time with

the movement of the sensor arm, the unit is considered to be operating normally

After the adjustment is made, retighten the hex socket head bolt (tightening torque:

1.5 Nm).

172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 Apr 2021

14

Product Warranty

1. Warranty Period

One year following product delivery.

2. Warranty Coverage

TLV CO., LTD. warrants this product to the original purchaser to be free from

defective materials and workmanship. Under this warranty, the product will be

repaired or replaced at our option, without charge for parts or labor.

3. This product warranty will not apply to cosmetic defects, nor to any product

whose exterior has been damaged or defaced; nor does it apply in the

following cases:

1) Malfunctions due to improper installation, use, handling, etc., by other

than TLV CO., LTD. authorized service representatives.

2) Malfunctions due to dirt, scale, rust, etc.

3) Malfunctions due to improper disassembly and reassembly, or

inadequate inspection and maintenance by other than TLV CO., LTD.

authorized service representatives.

4) Malfunctions due to disasters or forces of nature.

5) Accidents or malfunctions due to any other cause beyond the control

of TLV CO., LTD.

4. Under no circumstances will TLV CO., LTD. be liable for consequential

economic loss damage or consequential damage to property.

* * * * * * *

For Service or Technical Assistance:

Contact your TLV representative or your regional TLV office.

Manufacturer

881 Nagasuna, Noguchi

Kakogawa, Hyogo 675-8511, JAPAN

Tel: 81-(0)79-427-1800

172-65599M-04 (C1CM(-EX)/C1CF(-EX), C1SM(-EX)/C1SF(-EX)) 7 Apr 2021

Loading...

Loading...