172-65694MA-01 (BD800) 25 July 2018

Bypass Blow Valve

BD800

Copyright © 2018 by TLV CO., LTD.

All rights reserved

1

Contents

Introduction ........................................................................ 1

Safety Considerations ........................................................ 2

Specifications ..................................................................... 4

Configuration ...................................................................... 4

Installation .......................................................................... 5

Operation ........................................................................... 6

Maintenance ....................................................................... 8

Disassembly/Reassembly ................................................ 10

Cleaning the Valve Seat Section ...................................... 13

Troubleshooting ............................................................... 14

Product Warranty ............................................................. 15

Introduction

Thank you for purchasing t he bypass blow valve.

This product has been thoroughly inspected bef or e being shipped from the fac t or y.

When the produc t is delivered, before doing anything else, check t he spec ifications

and external appearance to make sure nothing is out of the ordinary. Also be sure to

read this manual carefully before use and follow the instructions to be sure of using

the product properly.

The

performance in addition to a structure which can clean its seating surfaces in a

simple operation. In support of t his long-life product, the m ain components of the

valve are replaceable.

In conventional valves, when dust or scale adheres to the seating surf ace of the

valve seat section, leakage occurs eventually leading to erosion, and ultimately the

valve will no longer function properly.

This bypass blow valve utilizes a special material for the valve stem and valve seat

sections and together with its unique f or m , rotational contact between the seating

surfaces scrapes off scale and restores the sealing performance of the valve.

The proven special material, combined with the unique cleaning mechanism reduces

the burden of valve maintenance and operation.

If detailed instructions f or spec ial order spec ifications or options not contained in this

manual are required, please contact

bypass blow valve has excellent durability and reliable sealing

for full details.

This instruction manual is intended for use with the m odel(s ) l ist ed on t he front cover.

It is necessary not only for installation but f or subs equent maintenance,

disassembly/reassembly and troubleshooting. Please keep it in a safe place for

future referenc e.

172-65694MA-01 (BD800) 25 Jul 2018

2

DANGER

Indicates an urgent situation which poses a threat of death or

serious injury

WARNING

CAUTION

Indicates that there is a possibility of injury or equipment/product

damage

WARNING

DO NOT use for any other fluids than applicable flui ds. DO

or malfunctions that may lead to serious accident s .

CAUTION

Install properly and DO NOT use this product outside the

conditions quoted.

Take measures to prevent people from coming into direct

discharge of fluids.

Safety Considerations

• Read this section carefully before use and be sure to follow the instructions.

• Installation, inspection, maintenance, repairs, disassembly, adjust m ent and valve

opening/closing should be carried out only by trained maintenance personnel.

• The precautions listed in this manual are designed to ensure saf et y and prevent

equipment damage and personal injury. For sit uations that may occur as a result

of erroneous handling, three different types of caut ionar y items are used to

indicate the degree of urg ency and the scale of potential damage and danger:

DANGER, WARNING and CAUTI ON.

• The three types of cautionary items above are very important for safety: be sure to

observe all of them as they relate to installation, use, maintenance, and repair.

Furthermore, TLV accepts no r es ponsibility f or any accident s or damage occurring

as a result of failure to obser ve these pr ec aut ions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

Indicates that there is a potential thr eat of death or serious injury

NOT use for toxic, flammable or other wise hazardous fluids.

This product is for intended use only.

Improper use may result in such hazards as damage t o t he pr oduc t

recommended operating pressure, temperat ur e and ot her

specification ranges.

Improper use may result in such hazards as damage t o t he pr oduc t

or malfunctions that may lead to serious accident s . Local

regulations may restrict the use of this product to below the

contact with product out lets.

Failure to do so may result in burns or other injury from the

Safety considerations continued on next page

172-65694MA-01 (BD800) 25 Jul 2018

3

CAUTION

When disassembling or removing the product, wait until the

injuries or damage.

Before using the product, ensure piping is cleaned and fl ushe d t o

seat.

Be sure to use only the recommended components when

discharge of fluids.

Do not use excessive force when connecting threaded pipes to

which may cause burns or other injury.

Do not place weight on top of t he spanner cap. The product is

spanner cap or injury.

When using the spanner cap, be sure to use heat-resistant

injuries or damage.

Use only under conditions in which no freez e-up will occur.

may cause burns or other injury.

Use only under conditions in which no water hammer will

fluid discharge, which may cause burns or other injury.

internal pressure equals atmospheric pr essur e and t he sur f ace

of the product has cooled to room temperat ur e.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

remove foreign matter.

Failure to observe this precaution may cause leakage from the valve

repairing the product, and NEVER attempt to m odify the

product in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the

the product.

Over-tightening may cause breakage leading to fluid discharge,

not designed to be climbed on by people.

Failure to observe this precaution may result in damage to the

gloves.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

Freezing may damage the product, leading to fluid discharge, which

occur.

The impact of water hammer m ay damage the product, leading to

172-65694MA-01 (BD800) 25 Jul 2018

4

DO NOT use for any other fluids than applicable fluids. DO NOT use for

toxic, flammable or otherwise hazardous fluids. This product is for

intended use only. Improper use may result in such hazards as damage

to the product or malfunctions that may lead to serious accidents.

WARNING

Install properly and

DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

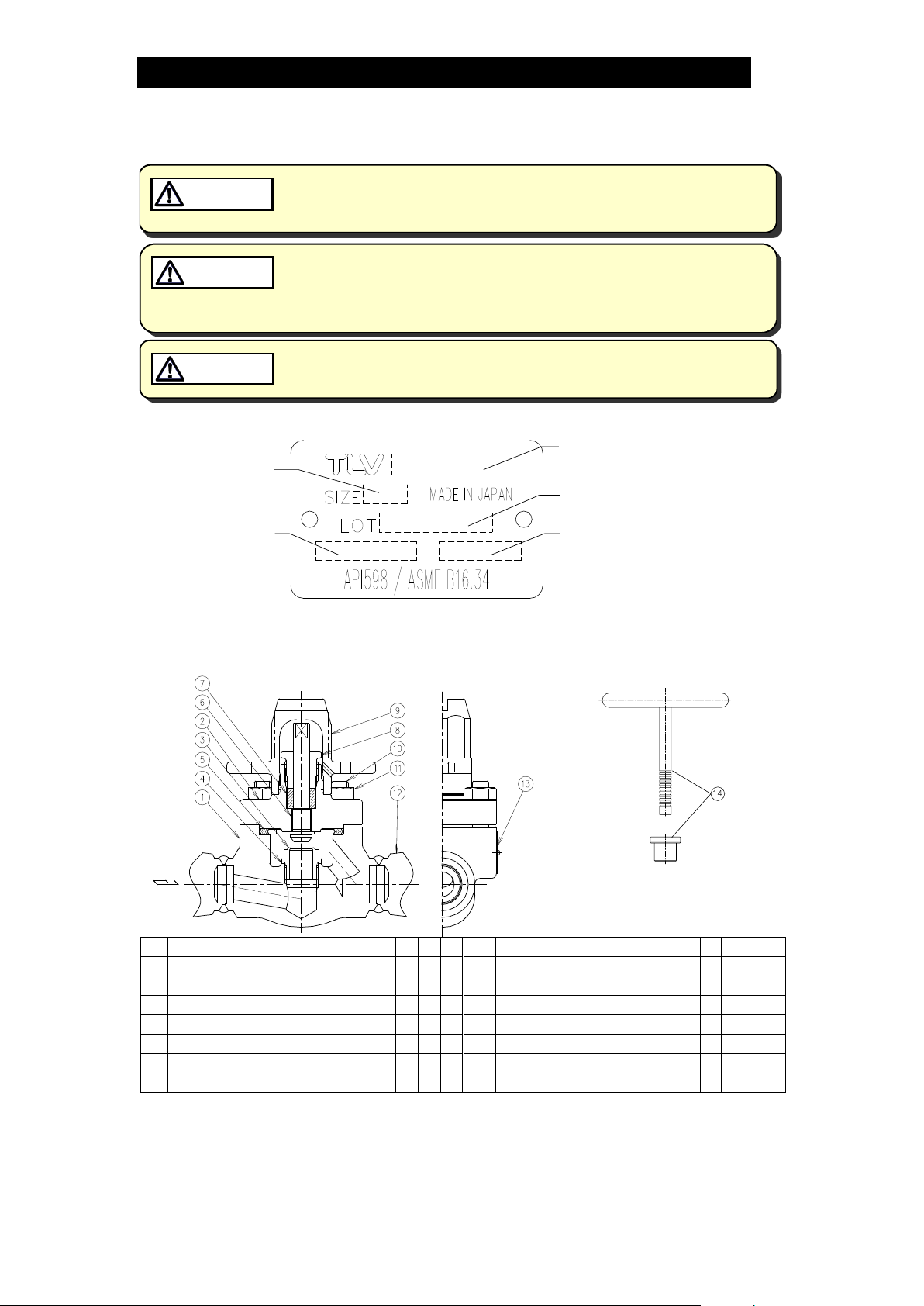

Model

Production Lot No.

Max. Operating Pressure (PMO) /

Max. Operating Temperature (TMO)

Nominal Diameter

Valve Class/

Body Material

No.

Name

M*

R*

G*

T*

No.

Name

M*

R*

G*

T* 1 Body

8

Gland Holder

2

Bonnet

9

Spanner Cap

3

Valve Seat

10

Bonnet Bolt

4

Valve Seat Gasket

11

Bonnet Nut

5

Bonnet Gasket

12

Flange/Socket

6

Valve Stem

13

Nameplate

7

Gland Packing

14

Gland Packing Removal Tool

Specifications

Refer to the product nameplate for detailed specifications.

Configuration

NOTE: Gland packing removal

tool is available on request.

Consult TLV for details.

*Replacement parts are available only in the following kits:

M = Maintenance kit

R = Repair kit

G = Gland packing

T = Gland packing removal tool

172-65694MA-01 (BD800) 25 Jul 2018

5

DO NOT use for any other fluids than applicable fluids. DO NOT use for

toxic, flammable or otherwise hazardous fluids. This product is for

intended use only. Improper use may result in such hazards as damage

to the product or malfunctions that may lead to serious accidents.

WARNING

Before using the product, ensure piping is cleaned and flushed to

remove foreign matter. Failure to observe this precaution may cause

leakage from the valve seat.

CAUTION

Install properly and

DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Do not use excessive force when connecting threaded pipes to the

product. Over-tightening may cause breakage leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Installation

Installation, inspection, maintenance, repair s, disas sem bly, adjustment and valve

opening/closing should be carried out only by trained maintenance per s onnel.

1. When t he pr oduct is shipped from the fact ory, the valve stem is positioned in the

lowest, valve-closed position.

2. Before installation, be sure to remove all protective seals.

3. Before installing the product, open the inlet valve and blow out the piping to

remove any piping scraps, dirt and oil. Close the inlet valve after blowdown.

4. Install the product so the arrow on the body is pointing in the dir ection of flow.

5. Install outlet piping.

If there is a problem, deter mine the cause using the “Troubleshooting” section in this

manual.

172-65694MA-01 (BD800) 25 Jul 2018

6

DO NOT use for any other fluids than applicable fluids. DO NOT use for

toxic, flammable or otherwise hazardous fluids. This product is for

intended use only. Improper use may result in such hazards as damage

to the product or malfunctions that may lead to serious accidents.

WARNING

Install properly and

DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

When using the spanner cap, be sure to use heat

-resistant gloves

.

Disassembling or removing the product when it is hot or under pressure

may lead to discharge of fluids, causing burns, other injuries or damage.

CAUTION

Spanner Cap

Figure A

Valve Stem

Figure B

Operation

Removing the Spanner Cap

Remove the spanner cap by turning it counter-clockwise.

Adjusting the Valve Aperture

Place the spanner cap as shown in Figure A, adjust t he valve aperture by turning the

valve stem. The adjustment can also be made by using t he nar row open end of the

spanner cap as shown in Figure B.

NOTE: The valve stem is in a fully closed position when shipped from the f ac t or y and

is tightened to a specific torque. Depending on the environment in which the product

is installed, the valve stem may be difficult to adjust. In such a cas e, us e an

adjustable wrench or socket wrench to adjust t he valve stem. This will make the

valve steam easy to adjust with the spanner cap.

NOTE: The valve stem can also be

adjusted with an adjustable wrench,

socket wrench, etc.

Distance across flats: 7 mm (

9

/32 in)

Restoring the Spanner Cap

Once the adjustment is made, replace t he spanner cap.

This prevents unintentional change of the valve aperture. As the valve stem is

covered by the spanner cap, it is protected ag ainst rainwater or foreign matt er,

reducing the likelihood of the valve stem stick ing.

172-65694MA-01 (BD800) 25 Jul 2018

7

Spanner Cap

Hole

Wire/

Steel Wire

Piping

3.5

3

2.5

2

1.5

1

0.5

0

0

1

2

3 4

5

3.5

3

2.5

2

1.5

1

0.5

0

0

1

2

3 4

5

3.5

3

2.5

2

1.5

1

0.5

0

0

1

2

3 4

5

Cv(US)

No. of turns*

Cv(UK)

KV

No. of turns*

No. of turns*

*No. of turns of the valve stem is based on the fully closed position

Preventing Erroneous Operation of the Valve Stem

The product is equipped with a function that prevents erroneous operation of the

valve. A hole in the spanner c ap allows the spanner cap t o be fixed by passing a

wire/steel wire and tightening it around the piping or flange as shown below.

Restricting movement of the s panner cap prevents the valve from being operated

erroneously.

Relation between CV / Kvs Values and No. of Turns of the Valve Stem

172-65694MA-01 (BD800) 25 Jul 2018

8

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Do not place weight on top of the spanner cap. The product is not

designed to be climbed on by people. Failure to observe this precaution

may result in damage to the spanner cap or injury.

CAUTION

When using the spanner cap, be sure to use heat-resistant gloves.

Disassembling or removing the product when it is hot or under pressure

may lead to discharge of fluids, causing burns, other injuries or damage.

CAUTION

Spanner Cap

Spanner Cap

Spanner Wrench

Valve Stem

Gland Holder

Blow hole

Maintenance

Periodic Inspection

Periodic inspection for the following points is recommended at least twice per year:

・ Leakage when the valve is fully closed

・ Leakage from the gland holder

The spanner cap has a blow hole at the bottom. Fluid jets

from the hole when there is leakage from the gland.

Take safety precautions when perf or ming this inspection.

・ Leakage from the bonnet gasket

Retightening of the Gland Section

The gland holder can be retightened. When fluid leaks from the gland section,

retighten the gland holder by following the steps below. Make sure that the valve is in

the fully closed position when tightening the gland section.

1. Remove the spanner cap by turning it counter-clockwise.

2. Tighten the gland holder.

The gland holder can be tightened with the spanner c ap as well as a spanner

wrench with a distance across flats of 22 mm (

7

/

in). Tighten as necessar y.

8

172-65694MA-01 (BD800) 25 Jul 2018

9

NOTE: Once leakage from the upper part of the gland holder has stopped, do not

tighten any further. Make sure that the valve stem can still turn after the

gland holder is tightened. Contact TLV if leakage does not st op even after

retightening.

3. After retightening is complete, replace the spanner cap.

172-65694MA-01 (BD800) 25 Jul 2018

10

NEVER apply direct heat to the float. The float may explode due to

increased internal pressure, causing accidents leading to serious injury

or damage to property and equipment.

WARNING

Use hoisting equipment for heavy objects (weighing approximately

20 kg (44 lb) or more). Failure to do so may result in back strain or other

injury if the object should fall.

CAUTION

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Part

During Disassembly

During Reassembly

Spanner Cap

Unscrew and remove from the bonnet

Screw onto the bonnet

Bonnet Nut

Remove with a socket wrench

Consult the table of tightening torques

and tighten to the proper torque

Bonnet

Pull up and remove

Align the embossed lettering on the

bonnet and body and reattach

Part

During Disassembly

During Reassembly

Gland Holder

Remove with a socket wrench

Consult the table of tightening torques

and tighten to the proper torque

Valve Stem

Replace only when necessary;

Unscrew from the bonnet

Screw into the bottom part of the

bonnet

Gland Packing

Replace only when necessary;

Packing” section for replacement

Reassemble as shown in the

section

Part

During Disassembly

During Reassembly

Bonnet

Gasket

Remove the gasket and clean

sealing surfaces

Replace with a new gasket

Valve Seat

Replace with a socket wrench only

when necessary

Consult the table of tightening torques

and tighten to the proper torque

Valve Seat

Gasket

Remove the gasket and clean

sealing surfaces

Replace with a new gasket; coat

surfaces with anti-seize

Disassembly/Reassembly

Use the following procedures to remove component s. Use the same procedures in

reverse to reassemble. (Installation, inspection, maintenance, repairs, disassembly,

adjustment and valve opening/closing should be carr ied out only by trained

maintenance personnel.)

Disassembly/Reassembly of the Body/Bonnet Section

NOTE: When assembling the bonnet to the body, tighten the bonnet nuts, making sure that

the valve stem is seated on the valve seat with no built-up of rust and scale.

When tightening the bonnet nuts, tighten all of them evenly and gradually to the proper

torque to avoid uneven tightening. When the secondary side of the product is open to

the atmosphere, visually check whether fluid is leaking on the secondary side.

Contact TLV in the event leakage does not stop.

Disassembly/Reassembly of the Bonnet Section

see the “Replacing the Gland

“Replacing the Gland Packing”

Disassembly/Reassembly of the Body Section

172-65694MA-01 (BD800) 25 Jul 2018

11

Torque

Distance Across Flats

N⋅m

(lbf⋅ft)

mm

(in)

Bonnet Nut

80

(59)

17

(21/32)

Gland Holder

60

(44)

22

(7/8)

Valve Seat

80

(59)

21

(13/16)

NOTE:

-Coat all threaded portions with anti-seize.

If drawings or other special documentation were supplied for the

torque given there takes precedence over values shown here.

(1 N⋅m ≈ 10 kg⋅cm)

Gland Holder

Bonnet

Valve Stem

Removal Tool (B)

Removal Tool (A)

Gland

Packing

Removal Tool (A)

Gland Packing

Plastic Mallet

Removal Tool (A)

Table of Tightening Torques

Part Name

-

Replacing the Gland Packing

1. Remove the valve stem then the gland holder from the bonnet.

2. Insert gland packing removal tool (A) into the bonnet, then screw removal tool (B) into

removal tool (A).

When removal tools (A) and (B) are inserted to the bonnet, the gland packing is caught by

the tip of removal tool and can be removed by lifting up the removal tool. Make sure to

remove dust and scale from inside the bonnet.

3. Reinsert the valve stem into the bonnet, then insert new gland packing into the bonnet.

Align the gland packing so that the stickers face each other. After the gland packing is

inserted, place removal tool (A) on top of the gland packing, and push the gland packing

into position by tapping on removal tool (A) with a plastic mallet. Remove removal tool (A),

replace the gland holder and tighten it to the proper torque.

172-65694MA-01 (BD800) 25 Jul 2018

12

Spanner Cap

Bonnet Nut

Gland Holder

Gland Packing*

Bonnet

Valve Stem

Bonnet Gasket

Valve Seat

Valve Seat Gasket

Bonnet Bolt

Body

Exploded View

*Inlaid in the bonnet

172-65694MA-01 (BD800) 25 Jul 2018

13

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure m

ay lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Turn the valve stem

counter- clockwise

Scale is scraped off the valve seat

when turning the valve stem back

clockwise

Cleaning is complete if no

leakage occurs after closing the

valve again

Turn the valve stem counter-

clockwise again

Scale

Cleaning the Valve Seat Section

When scale adheres to the valve seat section, sealing is inhibited, causing fluid

leakage that af fects the work environment.

Restore sealing performance and eliminate fluid leakage by following the steps

described below.

The figure below illustrates scale accumulation bet ween the valve seat and valve

stem resulting in the valve not being able to f ully clo s e.

1. Remove the spanner cap.

2. Turn the valve stem counter-clockwise one to two times.

3. Turn the valve stem clockwise (right rot ation) until it cannot be turned any further .

4. Repeat steps 2 and 3 two to three times. When the secondar y side of the product

is open to the atmosphere, visually check whether fluid is leaking on the

secondary side after performing step 3.

5. When no fluid is leaking and the valve closes fully, cleaning is com plet e.

If leakage still occurs, repeat steps 2 and 3 another two to three times.

172-65694MA-01 (BD800) 25 Jul 2018

14

NEVER apply direct heat to the float. The float may explode due to

increased internal pressure, causing accidents leading to serious injury

or damage to property and equipment.

WARNING

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Problem

Cause

Remedy

Fluid is leaking from

The valve stem is not tightened

・

Place the spanner on the flat

・

(16 N⋅m (12 lbf⋅ft)

The sealing surfaces of the valve

those surfaces

Clean the valve seat and valve

TLV)

Fluid is leaking

section

The gland holder is loosened

Retighten the gland holder, clean

TLV)

The valve stem

does not move

The valve stem is clogged with

rust and scale

Clean or replace with a new valve

stem

Fluid is leaking from

Fluid is leaking from between

and scale

Replace with new gasket(s)

Improper tightening torques were

used

Tighten to the proper torque

The valve stem and

Water hammer has occurred

Check whether the valve stem

・ Check and correct the piping

Troubleshooting

When the produc t fails to operate properly, use the f ollowing table to locat e the

cause and remedy.

the outlet (even)

when the valve is

closed

sufficiently

surfaces of the valve stem and

tighten it to the proper torque

(16 N⋅m (12 lbf⋅ft)

Tighten the spanner cap with a

spanner to the proper torque

from the gland

a place other than

the outlet

the valve seat

frequently become

damaged

seat and valve stem are damaged

or clogged with rust and scale

(erosion, corrosion, etc.), clean

・

the bonnet and body

・ Gasket deterioration or damage

・ The gasket sealing surfaces of

the body and bonnet are

damaged or clogged with rust

stem; if leakage does not stop after

cleaning, replace with a new valve

seat and/or valve stem (contact

or replace with new parts (contact

・

is over-tightened; if the valve

stem is deteriorated or

damaged, replace with a new

valve seat and/or valve stem

(contact TLV)

NOTE: When replacing parts with new, use the parts list for reference, and replace with parts

from the maintenance kit, repair kit, etc. Please note that replacement parts are only

available as part of a replacement parts kit.

172-65694MA-01 (BD800) 25 Jul 2018

15

Product Warranty

1. Warranty Period

One year following product delivery.

2. Warranty Coverage

TLV CO., LTD. warrants this pr oduct to the or i g i nal pur c haser to be free

from defective materials and wor kmans hip. Under thi s warranty, the product

will be repaired or r epl aced at our opt ion, without charge for parts or l abor .

3. This product warranty will not apply to cosmetic defects, nor to any

product whose exterior has been damaged or defaced; nor does it apply in

the following cases:

1) Malfunctions due to improper installation, use, handling, etc., by other

than TLV CO., LTD. authorized service representatives.

2) Malfunctions due to dirt, scale, rust, etc.

3) Malfunctions due to improper disassembly and reassembly, or

inadequate inspection and maintenance by other than TLV CO., LTD.

authorized service representatives.

4) Malfunctions due to disasters or forces of nature.

5) Accidents or malfunctions due to any other cause beyond the control of

TLV CO., LTD.

4. Under no circumstances will TLV CO., LTD. be liable for consequential

economic loss damage or consequential damage to property.

* * * * * * *

For Service or Technical Assistance:

Contact your representative or your regional office.

Manufacturer

881 Nagasuna, Noguchi

Kakogawa, Hyogo 675-8511, JAPAN

Tel: 81-(0)79 - 427 - 1800

172-65694MA-01 (BD800) 25 Jul 2018

Loading...

Loading...