TKR Group VAS 6790/2, VAS 6792, VAS 6792/1, VAS 6792/2 Setup And Installation Manual

VAS 6790/2

VAS 6792

VAS 6792/1

VAS 6792/2

Pneumatic/hydraulic

blind riveting tool

BA3

Setup – Installation: Blind riveting tool

Additional information to the instruction manual

BA1 (VAS 6790/2, VAS 6792, VAS 6792/1, VAS 6792/2)

ATTENTION

This supplementary sheet serves as a supplement to the instruction manual BA1

(VAS 6790/2, VAS 6792, VAS 6792/1, VAS 6792/2) and may only be used in

conjunction with it.

Translation of original instruction manual

?

VAS 6790/2

VAS 6792

VAS 6792/1

VAS 6792/2

Pneumatisch hydraulisches

Blindniet-Werkzeug

BA3

Inbetriebnahme – Montage: Blindnietwerkzeug

Zusatzinformation zur Betriebsanleitung BA1

(VAS 6790/2, VAS 6792, VAS 6792/1, VAS 6792/2)

ACHTUNG

Diese Montageanleitung dient als Ergänzung zur Betriebsanleitung BA1

(VAS 6790/2, VAS 6792, VAS 6792/1, VAS 6792/2) und darf nur im Zusammenhang

mit dieser verwendet werden.

Originalbetriebsanleitung

USB-Stick

Owner‘s manual

digital

www.tkr-support.comOwner‘s manual

1. Download current

owner‘s manuals

2. Support

2

Chapter Page

1.

2.

3.

4.

Safety

1.1 Designations 5

Scope of supply

2.1 Scope of Supply and Accessories 6

2.2 Technical specications 9

2.3 Working with the blind riveting tool - basic principles 10

2.4 Maintenance 11

Technical data

3.1 Technical data 12

3.2 Device components 16

Use

4.1 Connecting the high-pressure coupling to the

Compact Booster 18

4.2 Connecting the blind riveting tool

and the Compact Booster 20

4.3 VAS 6792/2, VAS 6792/24: Screwing the extension onto

the blind riveting tool 22

4.4 Replacing the rivet head extension 27

4.5 Removing the extension 28

4.6 Replacing the conical grip 29

4.7 Connecting the spiral hose to the Compact Booster and

hose adapter 32

4.8 Connecting the pneumatic hose to the Compact Booster

and the spiral hose 33

3

4.

Use

4.9 Using the blind riveting tool 34

4.10 Replacing the rivet head 36

4.11 Fitting the ejector 37

4.12 Using with the operating unit 39

4.13 Emptying the mandrel collector 46

4.14 Maintenance and cleaning 47

4.15 Spare parts 50

4.16 Troubleshooting 54

5.

Maintenance / Service

5.1 Disposal BA1, 60

5.2 Warranty BA1, 61

5.3 Declaration of Conformity 62

This instruction manual is protected by copyright. No use is permitted outside the strict limitations of copyright legislation without the consent of the manufacturer. Unauthorized use will

make the oender liable to criminal prosecution. This also applies to the extraction of individual

illustrations and the use of text in the extract form.

4

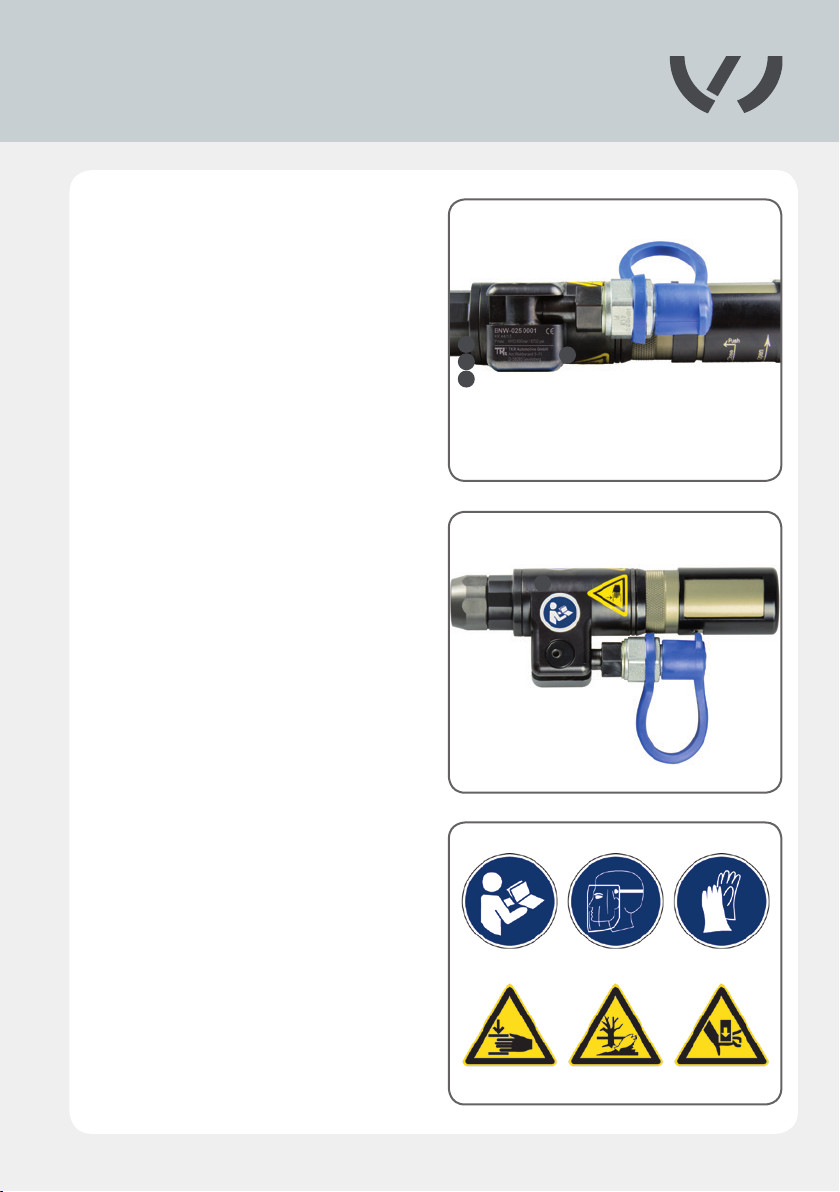

1.1 Designations

Markings on the blind riveting tool

A

B

C

D

see Fig. 1.1.3)

Manufacturer‘s identication

Serial number

Production date

Warnings (for complete view

1.1.1

A

C

D

1.1.2

B

E

1.1.3

5

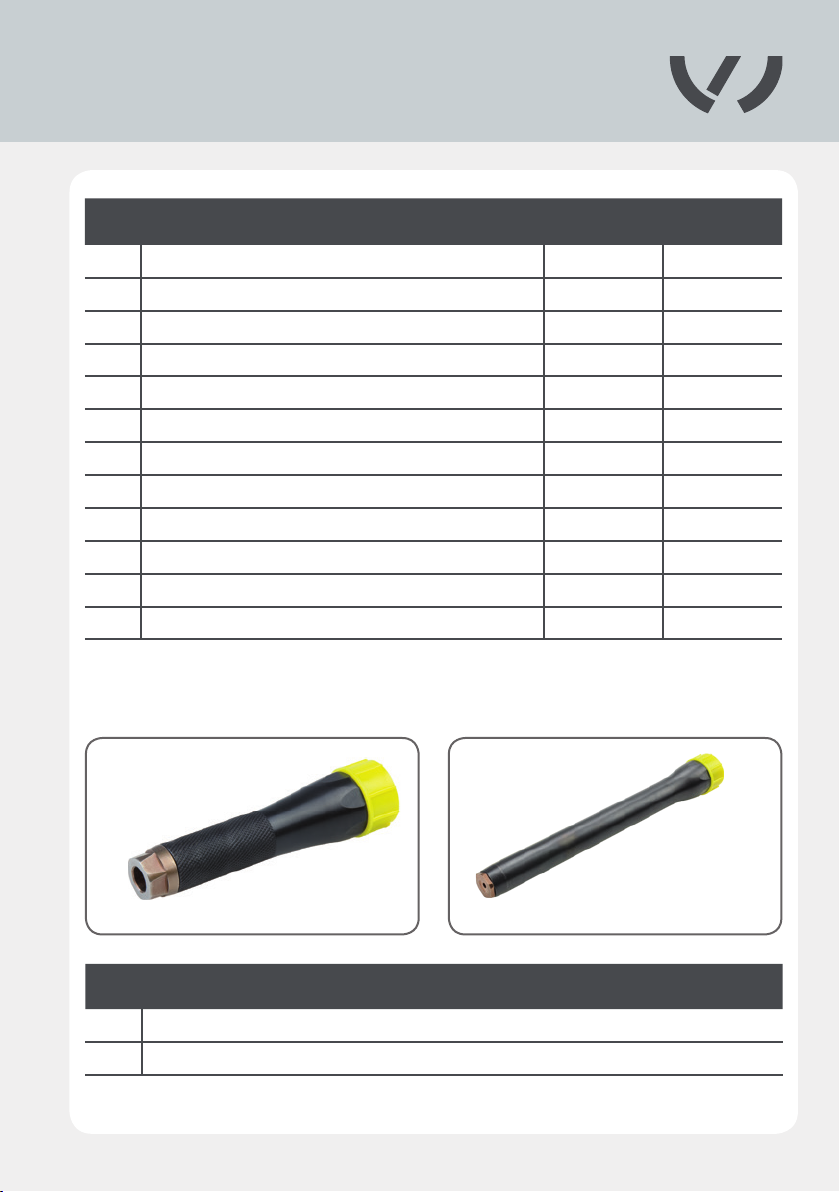

Nietmatrix

PSD-BED-00000125, Vers. 14.12

BA3

VAS 6792/11

Ø 2,0 mm

VAS 6792/13

Ø 3,0 mm

VAS 6792/12

Ø 4,0 mm

VAS 6792/14

Ø 2,6 mm

VAS 6792/10

Ø 3,4 mm

VAS 6792/27

Ø 4,0 – 4,2 mm

Ø 2,0 mm Ø 2,6 mm Ø 3,0 mm

Ø 3,4 mm

Ø 4,0 mm Ø 4,0 – 4,2 mm

Ø 4,0 – 4,2 mm

Ø 3,4 mm

Ø 3,0 mm

Ø 2,6 mm

Ø 2,6 mm

Ø 2,6 mm

Ø 2,6 mm

VAS 6792/15 VAS 6792/17 VAS 6792/19VAS 6792/16 VAS 6792/18 VAS 6792/20

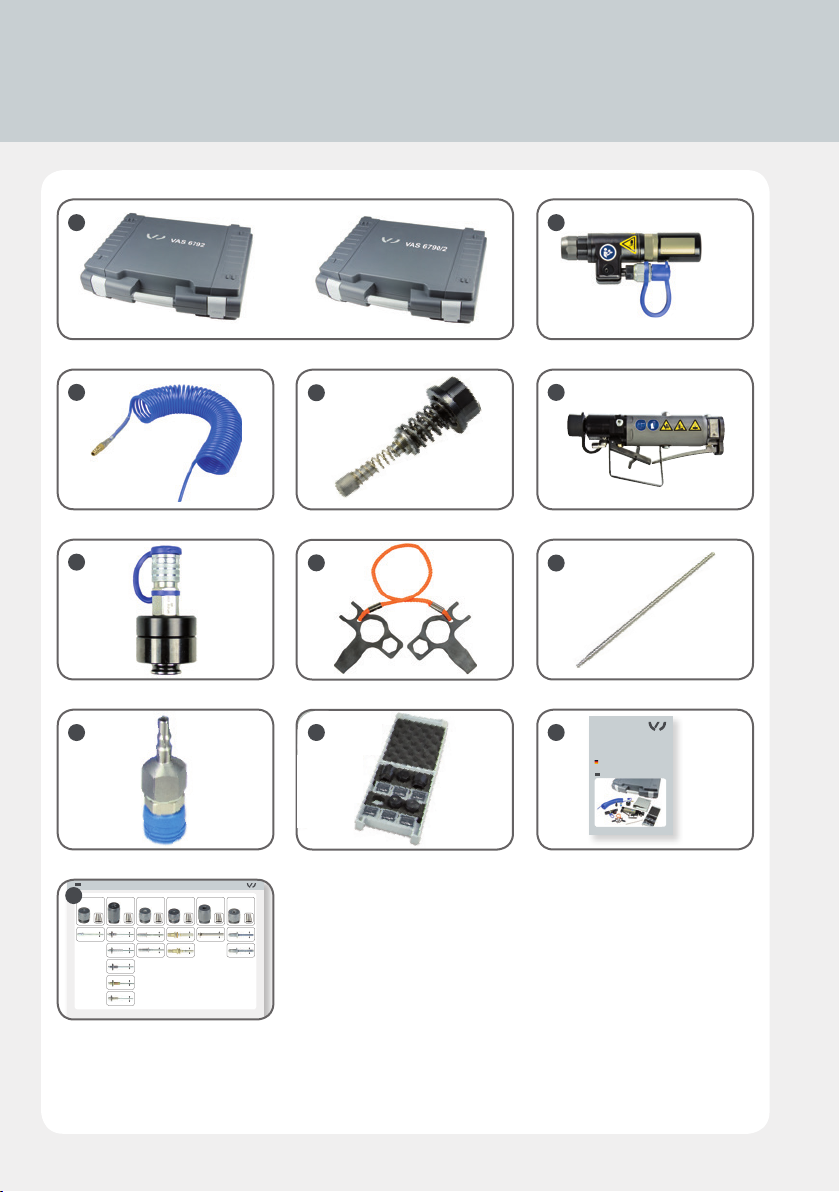

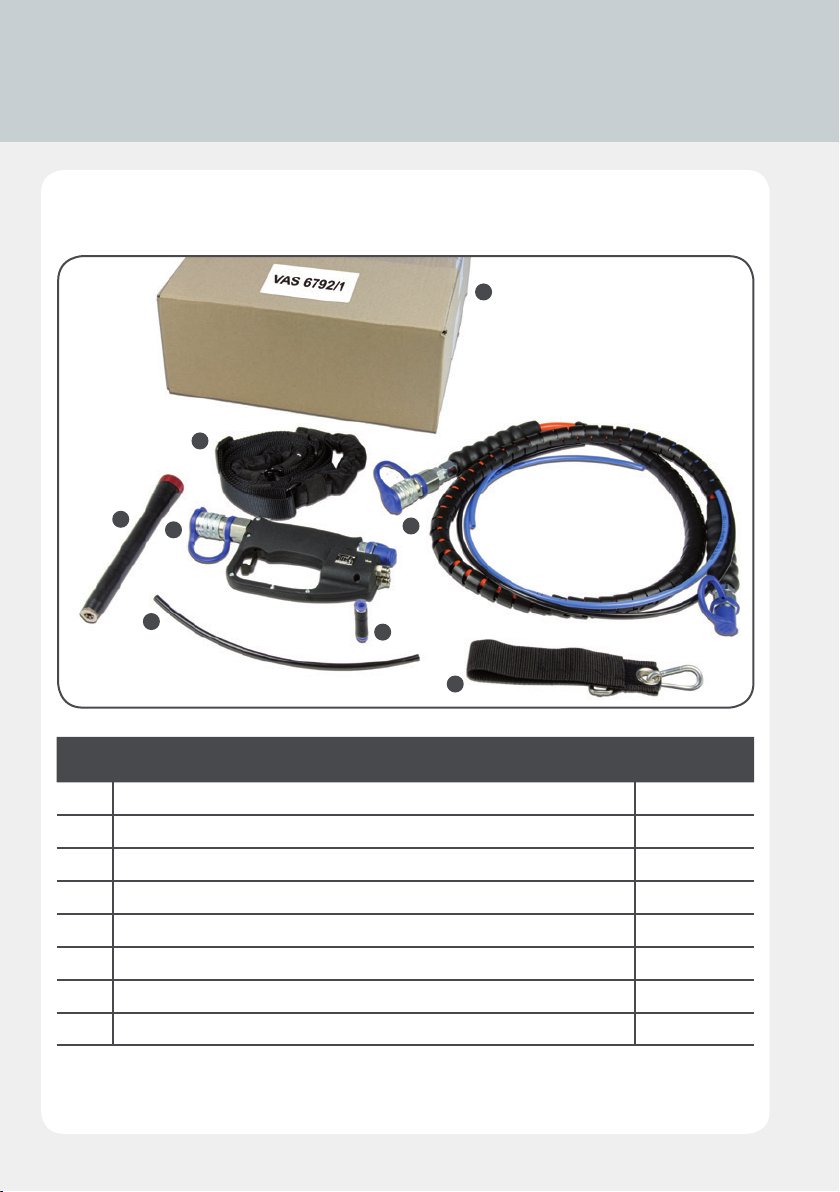

2.1 Scope of Supply and Accessories

A

C E

F

I

D

G

J K

B

H

VAS 6790/2

VAS 6792

VAS 6792/1

VAS 6792/2

Pneumatisch hydraulisches

Blindniet-Werkzeug

Bedienungsanleitung

BA3

L

6

Originalbetriebsanleitung

No. Item VAS 6792 VAS 6790/2

A 1 Case • •

B 1 Blind riveting tool • •

C 1 Spiral hose assembly •

D 1 Ejector •

E 1 Compact Booster •

F 1 High-pressure coupling • •

G 1 Assembly wrench • •

H 1 Assembly aid • •

I 1 Hose adapter •

J 1 Blind rivet set • •

K 1 Instruction manual • •

L 1 Rivet matrix • •

Accessories, optional

VAS 6792/2 VAS 6792/24

No. Item

M Extension, 59 mm

N Extension , 160mm

7

2.1 Scope of Supply and Accessories

Accessories set, optional

V

P

O

R

T

VAS 6792/1

Q

S

U

No. Item VAS 6792/1

O Extension, 160 mm •

P Carrying strap •

Q Hose assembly •

R Operating unit •

S Plug connector •

T Pneumatic hose •

U Supporting belt •

V Cardboard box •

8

2.2 Technical specications

Travel 20 mm

Setting force 24500 N at 6 bar

Weight 0.8 kg (without hose and operating unit)

Hydraulic operating pressure max. 600 bar

Pneumatic operating pressure 6 bar

Ambient temperature 5 – 50 °C/41 – 122 °F

Prescribed safety clothing

Drive unit Compact Booster

Protective gloves, eye protection, long-sleeved

working clothes, close tting at the neck

The pneumatic/hydraulic blind riveting tool was specially developed for all common

riveting operations on thin sheet metal.

The blind riveting tool must only be used with the pneumatic-hydraulic blind

riveting tool Compact Booster.

The blind riveting tool is connected to the Compact Booster using a high-pressure

coupling.

9

2.3 Working with the blind riveting tool - basic

principles

Risk of injury

Route all supply lines in a manner that prevents people from tripping over them.

Correctly route and attach the compressed air hose. If a compressed air hose whips

around wildly, it could cause severe bodily injury.

Before starting work, check the preset air pressure! Incorrectly set air pressure

could cause equipment damage or bodily injury!

Max. air pressure

Make sure that the maximum permissible operating air pressure of 6 bar / 87 psi

is never exceeded. Check the setting of the pressure regulating valve before each

riveting operation!

Clean compressed air

Make sure that the pressure generator is only supplied with clean and dry compres-

sed air. Moisture and contamination could cause equipment malfunction and/or da-

mage. Only use compressed air of quality class 2 as per ISO 8573-1.

10

Always disconnect the riveter from the compressed air when leaving your

workstation!

Warranty

The manufacturer accepts no liability for damage or injury caused by improper re-

pair or use of foreign replacement parts.

Incorrect usage of the blind riveting tool that leads to equipment damage invali-

dates the warranty.

The compressed air supply must be disconnected from the equipment before

any adjustment or maintenance work is performed.

2.4 Maintenance

The tool‘s hydraulic system, pneumatic control systems, hoses and couplings

must all be kept free of dirt and other contamination. Foreign bodies in the

hydraulic uid or in the control air will cause the tool system to malfunction.

All maintenance and service work on the blind riveting tool must only be per-

formed with the pressure generator disconnected.

Under normal circumstances, maintenance of the blind riveting tool is restricted to

4.16

regular cleaning and replacement of the conical grips.

All other necessary maintenance work and/or repairs must be performed by the ma-

nufacturer or properly trained personnel only.

The user must only perform the maintenance and repair measures outlined in this

instruction manual.

Maintenance and repair work not covered in this instruction manual may only be

performed by professionals who have been correctly trained by TKR. For further in-

formation on servicing and training, please contact us at our Service address:

TKR Spezialwerkzeuge GmbH

Service

Am Waldesrand 9-11

D-58285 Gevelsberg (Germany)

Phone: +49 23 32 666 07 - 0

Fax: +49 2332 666 07 - 941

E-Mail: info@tkrgroup.com

Download-Service

www.tkr-support.com

11

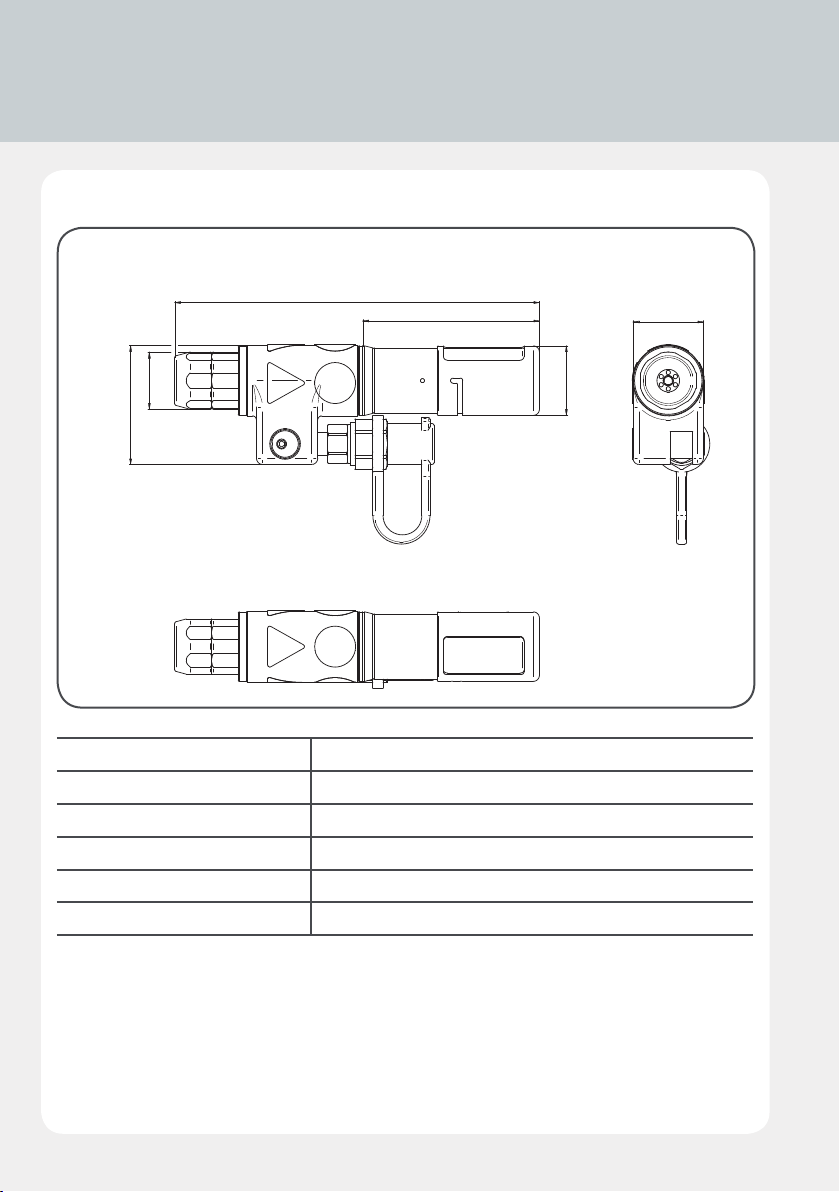

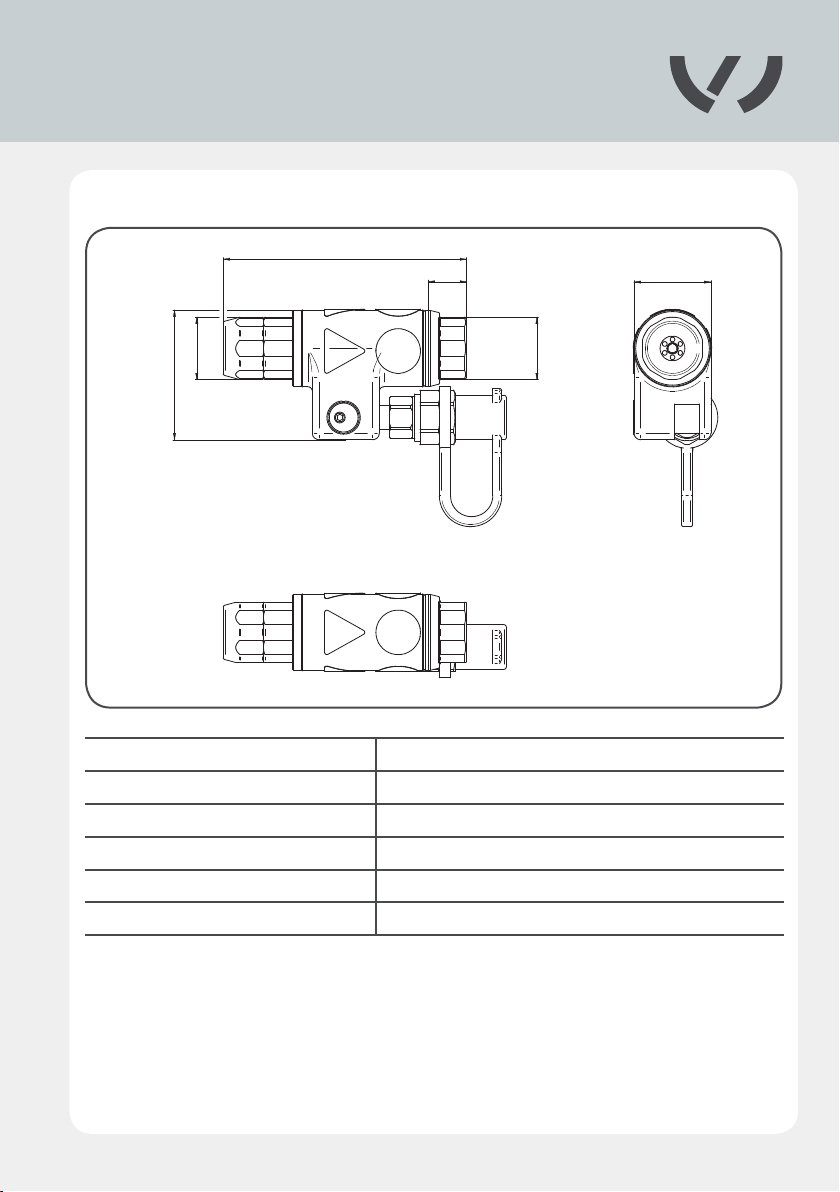

3.1 Technical data

Blind riveting tool with mandrel collector

3.1.1

179

28

O

58

Overall length 179 mm

Length of mandrel collector 87 mm

Height 58 mm

Width 35 mm

Ø Mandrel collector 34 mm

Ø Rivet head 28 mm

87

34

O

35

12

Blind riveting tool with ejector

3.1.2

28

58

109

Overall length 109 mm

Length of ejector 17 mm

Width 35 mm

Height 58 mm

Ø Ejector 38 mm

Ø Rivet head 28 mm

17

28

O

35

13

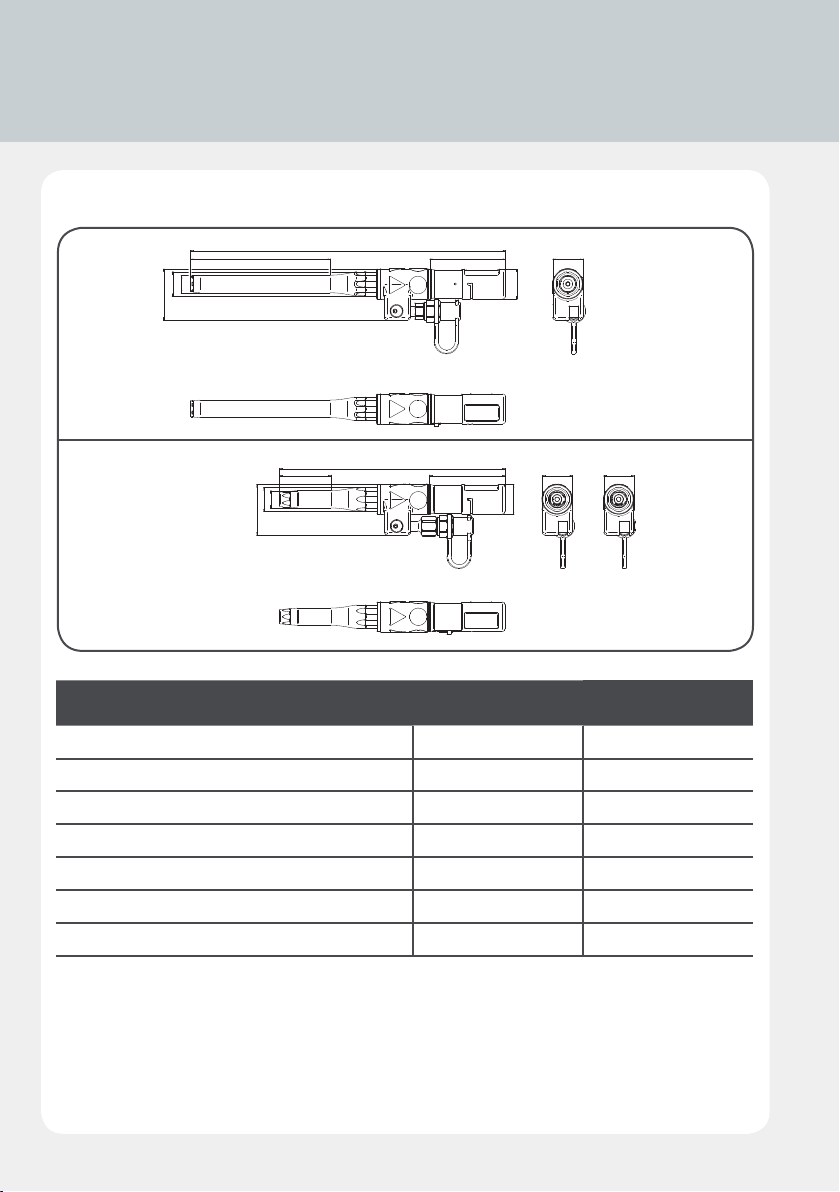

58

360

260.2

35

3.1 Technical data

Blind riveting tool with mandrel collector and extension

3.1.3

28

20

O

O

87160

35

34

O

VAS 6792/24

59

28

20

O

O

58

87

35

34

O

VAS 6792/2

VAS 6792/24 VAS 6792/2

Overall length 360 mm 260.2 mm

Height 58 mm 58 mm

Ø Rivet head 20 mm 20 mm

Width 35 mm 35 mm

Length of straight housing 160 mm 59 mm

Length of mandrel collector 87 mm 87 mm

Ø Mandrel collector 34 mm 34 mm

14

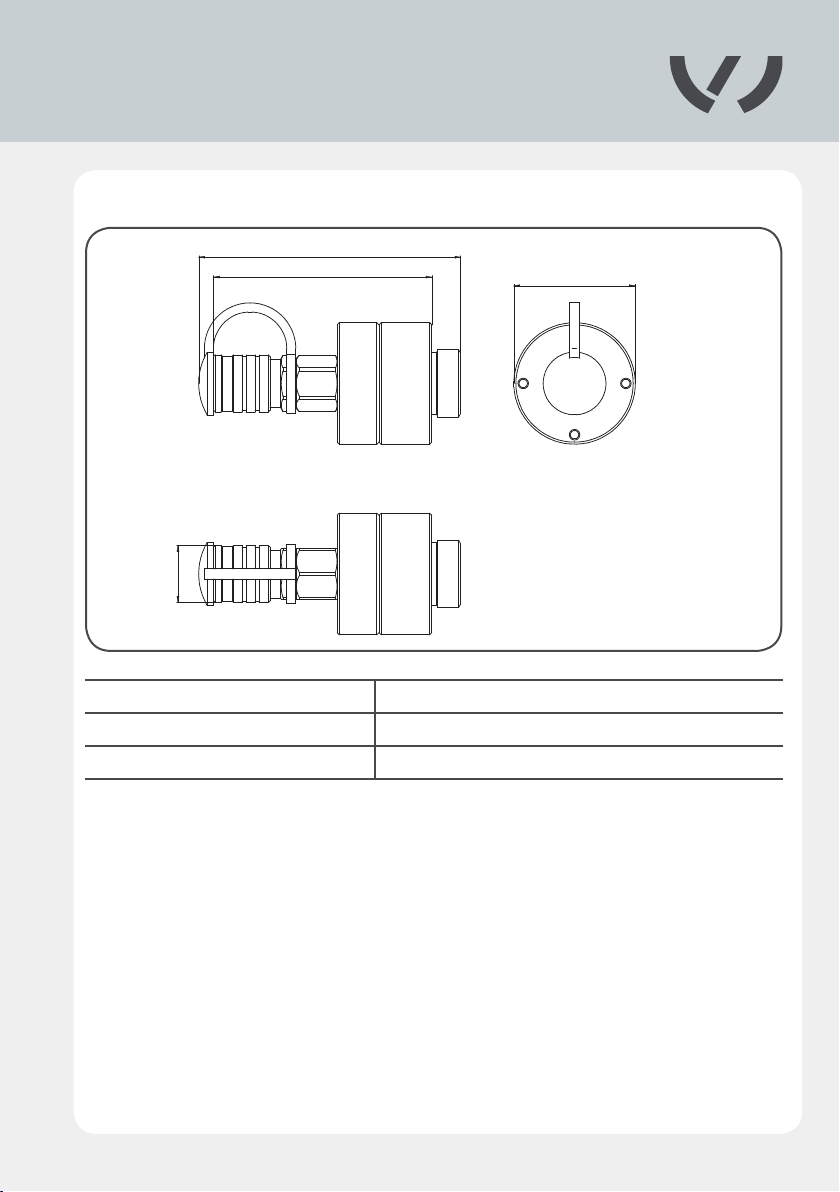

High-pressure coupling

3.1.4

27.2O

125

104

Length 125 mm

Ø Coupling 58 mm

Ø Connection 27 mm

O58

15

Q

O

Q

O

R

S

U

Q

F

Q

U

3.2 Device components

3.2.1

2

1

5

4

3

6

7

8

9

A

10

B

11

C

12

G

16

E

14

D

13

S

18

O

19

Q

20

F

15

I

17

16

21

R

T

22

23

U

No. Title

1 Blind riveting tool

2 Front ejector

3 Assembly wrench

4 Assembly aid

5 High-pressure coupling

6 Spiral hose

7 Compact Booster

8 Hose adapter

9 Blind rivet set

10 Protection cover

11 Protection cover

12 Extension rod

13 Rivet head

14 Extension casing

15 Mandrel collector

16 Conical grip

17 Ejector

18 Plug connector

19 Extension 160 mm

20 Hose package

21 Operating unit

22 Pneumatic hose

23 Supporting belt

17

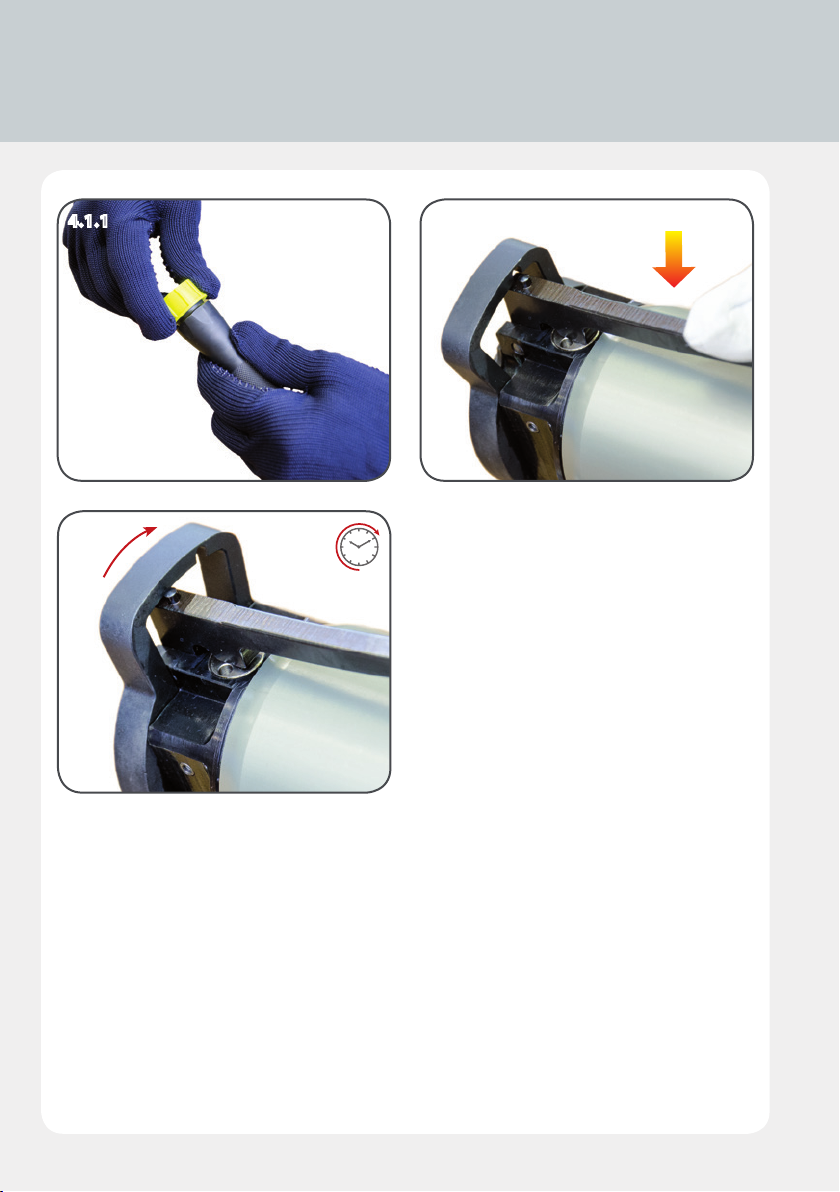

4.1 Connect the high-pressure coupling to the

Compact Booster

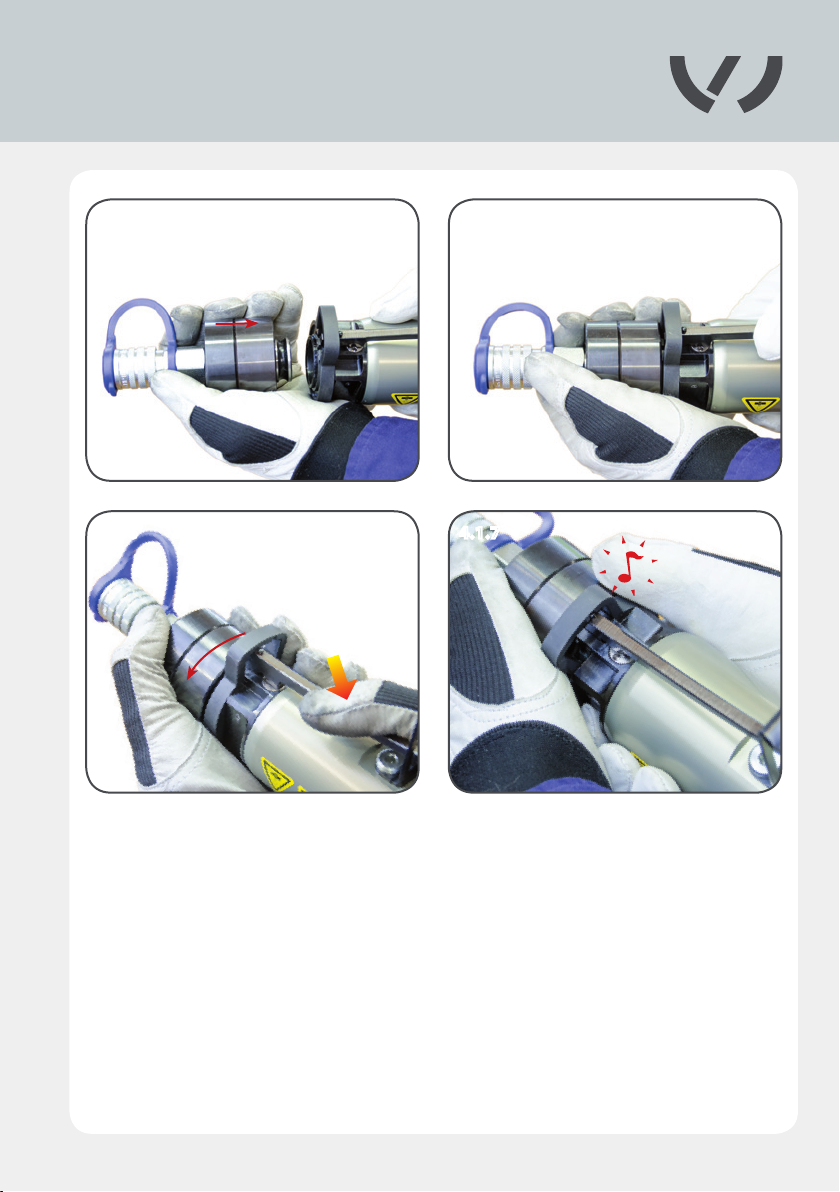

4.1.1 4.1.2

4.1.3

4.1.1 – 4.1.3

Press the lever on the Compact Booster to

turn the locking mechanism clockwise.

18

4.1.4 4.1.5

4.1.6 4.1.7

4.1.4 – 4.1.7

Insert the high-pressure coupling straight into the seating on the Compact Booster and turn

the locking mechanism counterclockwise until it engages.

19

4.2 Connecting the blind riveting tool and the

Compact Booster

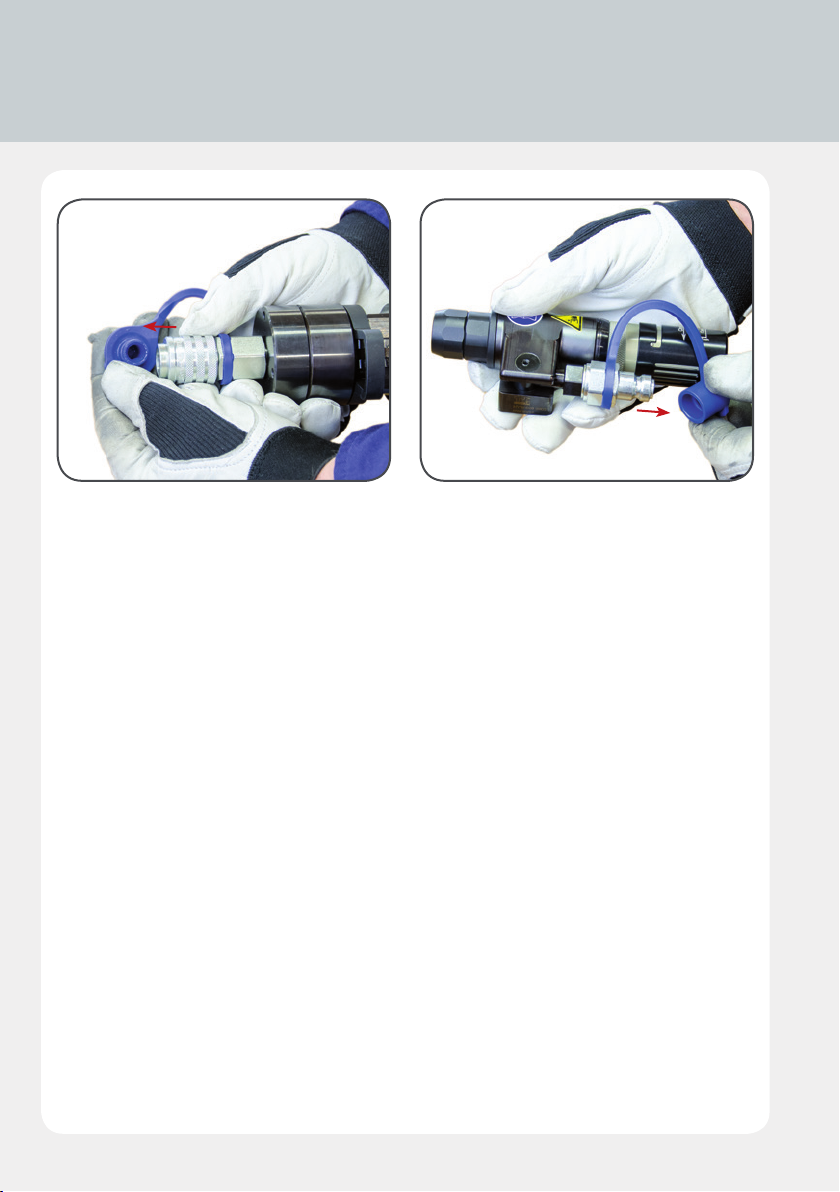

4.2.1 4.2.2

4.2.1/4.2.2

Remove the protective caps from the high-pressure coupling and the blind riveting tool.

20

Loading...

Loading...