Page 1

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (800) 255-4208 • (651) 426-2993 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

P/N 950-0484 MAC-3 CIRCUIT BOARD REPLACEMENT KIT INSTRUCTIONS

FOR REPLACEMENT ON IN-FORCER MODELS PAI-3,4 WITH CIRCUIT BOARD BUILT IN

Disconnect power supply before making wiring connections to prevent electrical shock and equipment damage.

1. Jumper wire provided must be installed on optional limit location if it is not being utilized.

2. Blue and Yellow wires from Fan Prover must be connected to Auxiliary Prover (3 & 4) contacts.

3. Red wires from High Limit must be connected to Auxiliary Limit (9 & 0) contacts.

4. Gray wires from Alarm Sequencer must be connected to Alarm Sequencer (5 & 6) contacts.

Black and White wires from Alarm Sequencer must be connected to Alarm Sequencer (7 & 8) contacts.

IMPORTANT: Jumper wire must be installed across H & PH terminals when IN-FORCER Fan Prover is wired into Auxiliary Prover (3 & 4)

contacts. It is not necessary to wire the Fan Prover in series with the H & PH terminals as shown in the MAC-3 Instructions enclosed when the

Prover is wired in series with the Auxiliary Prover (3 & 4) contacts. All Fan Provers must be wired in series with the H & PH or Auxiliary Prover

(3 & 4) contacts. Do not put jumper wire across H & PH terminals if Prover circuit is installed across those terminals.

FOR REPLACEMENT ON MAC-3 CONTROLLER

Disconnect power supply before making wiring connections to prevent electrical shock and equipment damage.

1. Jumper wire provided must be installed on optional limit location if it is not being utilized.

2. Jumper wires provided must be installed on Auxiliary Prover terminals (3 & 4) and Auxiliary Limit terminals (9 & 0)

if they are not being utilized.

3. For detailed wiring see MAC-3 Instructions enclosed P/N 8504043.

MAC-3 CIRCUIT BOARD FEATURES

Aux. Limit switch in series with

optional limit on terminal strip

Optional Alarm Sequencer proves Fan

Prover Operation (not limit operation)

Used in conjunction with Optional Alarm

Sequencer

Optional Limit (Spill Switch)

115 VAC Proven “HOT” From Fan Prover

115 VAC Neutral To Inducer / Venter / IN-FORCER

115 VAC “HOT” To Inducer / Venter

/ IN-FORCER motor & Fan Prover

Auxiliary Operation Switch

(i.e. Manual or Gas Pressure)

115 VAC Input From Disconnect Switch

Aux. Prover contacts in series with H & PH

contacts on output terminals

Aux. Motor in parallel with H & N used for

additional Power Venter, Inducer, IN-FORCER

P/N: 8505009 ©2000 TJERNLUND PRODUCTS, INC. ALL RIGHTS RESERVED REV. 08/00

Page 2

REV. A 5/99

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (800) 255-4208 • (651) 426-2993 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

MODEL

MAC-3

MULTIPLE APPLIANCE CONTROL

For Interlocking one Power Venter, Draft Inducer

IN-FORCERTMor Damper with up to three burners

TABLE OF CONTENTS

Cautions ..........................................................................................................................................................................1

Electrical Wiring

Electrical Specifications & Circuit Board Features .....................................................................................................1

Output Power Venter, Draft Inducer, IN-FORCER & Damper Wiring Diagrams ....................................................2, 3

Burner Input Wiring Diagrams ...............................................................................................................................4, 5

Alternative Wiring Diagrams ..................................................................................................................................5, 6

MAC-3 Wired With up to Five Gas Burners and One Power Venter, Draft Inducer or IN-FORCER................5

MAC-3 Wired With a Power Venter or Draft Inducer and a Commercial IN-FORCER ....................................6

MAC-3 Circuit Board Schematic ....................................................................................................................................6

Replacement Parts & Warranty .......................................................................................................................................7

DESCRIPTION

The MAC-3 is used for wiring up to 3 heating appliances with a single Draft Inducer, Power Venter, IN-FORCER or 115V Damper. It

is suitable for both 24 VAC and 115 VAC control systems for gas and oil burners. Plug-in relays must be purchased separately

depending on control system voltage of appliance.

Use Tjernlund part # 950-1040 relay For 24 VAC control systems.

Use Tjernlund part # 950-0480 relay For 115 VAC control systems.

OWNER INSTRUCTIONS, DO NOT DESTROY

!

Recognize this symbol as an indication of important Safety Information!

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED, LICENSED

SERVICE PERSONNEL FOR PROPER INSTALLATION, ADJUSTMENT AND

OPERATION OF THIS UNIT. READ THESE INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO FOLLOW

THESE INSTRUCTIONS MAY RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRI CAL SHOCK, CARBON MONOXIDE POISONING, EXPLOSION, OR PERSONAL

INJURY OR PROPERTY DAMAGE.

PLEASE READ CAREFULLY AND KEEP ON JOB

SITE FOR FUTURE REFERENCE.

Copyright © 1999, Tjernlund Products, Inc. All rights reserved. P/N 8504043

Page 3

CAUTIONS

1. Failure to install, maintain and/or operate the MAC-3 in accordance with manufacturer’s instructions may result in conditions that

can produce bodily injury and property damage.

2. The safety interlock and system operation performance checks must be performed on each appliance interlocked with the

MAC-3 in accordance with the Power Venter, Draft Inducer, IN-FORCER or Damper installation instructions.

ELECTRICAL

All wiring from the MAC-3 to the appliance must be appropriate Class 1 wiring as follows: installed in rigid metal conduit, intermediate conduit,

rigid non-metallic conduit, electrical metallic tubing, Type MI Cable, Type MC Cable or be otherwise suitably protected from physical damage.

The disconnect means and circuit protection are to be provided by the installer of this device.

SEQUENCE OF OPERATION OF MAC-3 INTERLOCKED WITH 24 VAC & 115 VAC APPLIANCE CONTROL CIRCUITS

The circuit board of the MAC-3 is designed for a simple three wire interlock with up to three separate burners. Upon a call for heat the “hot”

leg of the burner circuit is intercepted and routed to the MAC-3 terminal strip. The MAC-3 is activated, the power venter, draft inducer,

IN-FORCER or damper starts. The proving switch makes and the intercepted “hot” leg is returned to the burner circuit, allowing the burner to

fire. Plug-in relays must be purchased separately depending on control system voltage of appliance.

Use Tjernlund part # 950-1040 relay For 24 VAC control systems

Use Tjernlund part # 950-0480 relay For 115 VACcontrol systems

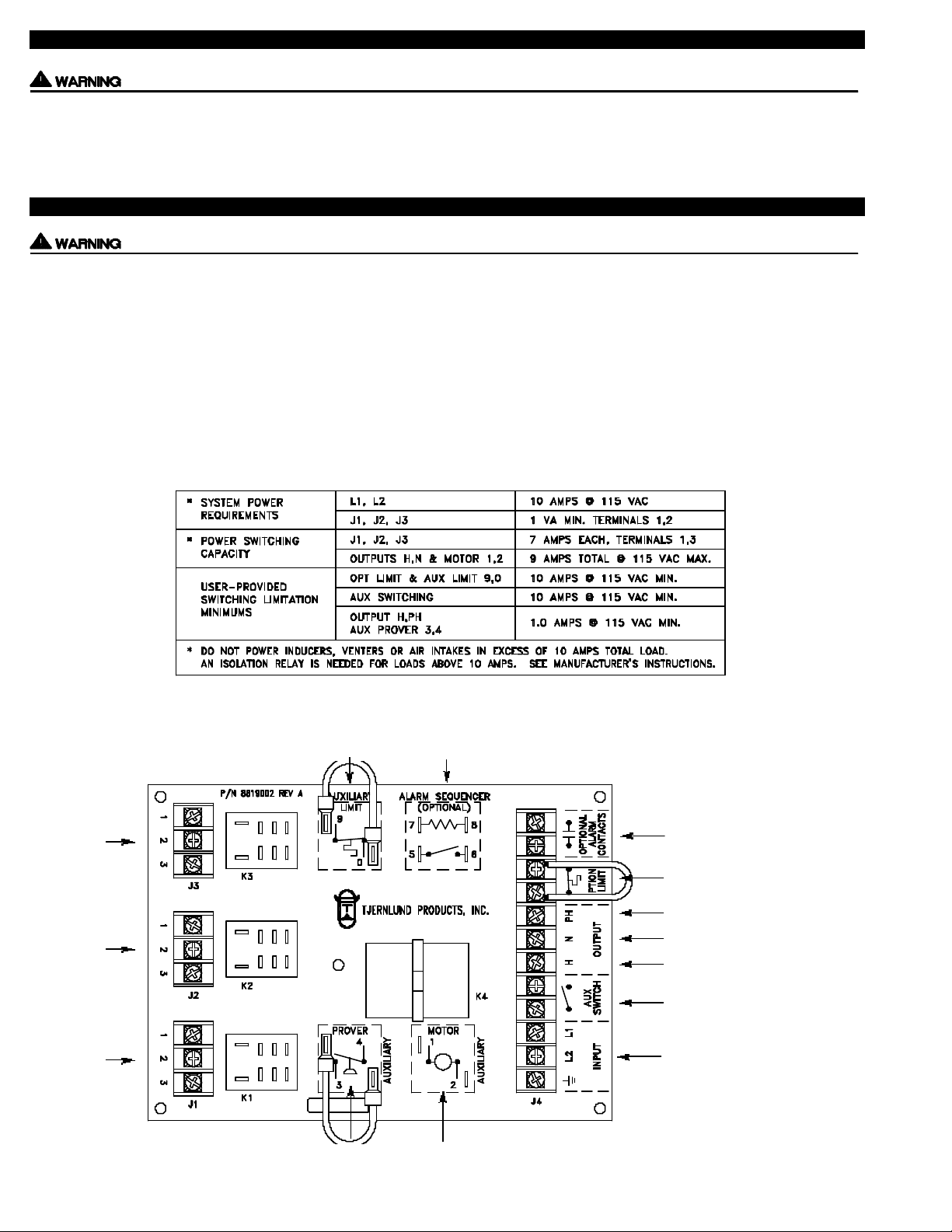

ELECTRICAL SPECIFICATIONS TABLE

Appliance # 3

Interlock

Appliance # 2

Interlock

Appliance # 1

Interlock

MAC-3 CIRCUIT BOARD FEATURES

Aux. Limit switch in series with

optional limit on terminal strip

Optional Alarm Sequencer proves Fan

Prover Operation (not limit operation)

Used in conjunction with Optional Alarm

Sequencer

Optional Limit (Spill Switch)

115 VAC Proven “HOT” From Fan Prover

115 VAC Neutral To Inducer / Venter / IN-FORCER

115 VAC “HOT”To Inducer / Venter

/ IN-FORCER motor & Fan Prover

Auxiliary Operation Switch

(i.e. Manual or Gas Pressure)

115 VAC Input From Disconnect Switch

Aux. Prover contacts in series with H &PH

contacts on output terminals

Aux. Motor in parallel with H &N used for

additional Power Venter, Inducer, IN-FORCER

1

Page 4

OUTPUT POWER VENTER, DRAFT INDUCER, IN-FORCER & DAMPER WIRING WITH THE MAC-3

2

When wiring the MAC-3 with a Tjernlund Power Venter without a post-purge Timer/Relay only the Fan Proving Switch and motor

leads are utilized for wiring. If you are wiring with a post purge Timer/Relay see wiring on bottom of page 2. Our HSUL Series,

GPAK-J/1 Series and Commercial HS-3,4,5 Series utilize our part # 950-1040 relays which can be plugged into the MAC-3 for 24V

control systems. The HSUL-Series, GPAK-J/1 Series and model HS-5 include one part # 950-1040 relay. The models HS-3 and

HS-4 include two part # 950-1040 relays.

MAC-3 WIRED WITH A TJERNLUND POWER VENTER, DRAFT INDUCER, IN-FORCER OR 115V DAMPER

WITHOUT A POST-PURGE (VENTER MOTOR LESS THAN 9 AMPS)

MAC-3 WIRED WITH A TJERNLUND HST, GPAK-T SERIES POWER VENTER OR DRAFT INDUCER

WITH A 950-1067 POST-PURGE TIMER/RELAY (VENTER MOTOR LESS THAN 4.4 AMPS)

NOTE: The WHITE/BROWN wire from terminal 5 of the Timer/Relay is

ORANGE in the GPAK-T Series. The ORANGE wire from terminal 4 of

the Timer/Relay is BLUE in the GPAK-T Series.

Page 5

MAC-3 WIRED WITH A TJERNLUND MODEL SS1 OR SS2 SIDESHOT® VENT SYSTEM

MAC-3 WIRED WITH A POWER VENTER, DRAFT INDUCER OR IN-FORCER WITH A MOTOR GREATER THAN 9 AMPS

TJERNLUND MODELS INCLUDE THE XL DRAFT INDUCER, HS-5 POWER VENTER & PAI-7 IN-FORCER

3

Page 6

BURNER INPUT WIRING WITH THE MAC-3

The diagrams included with these instructions depict two burners interlocked with the MAC-3 . To wire a third burner to the MAC-3,

purchase the proper control voltage plug-in relay and wire according to the diagram suited for that application.

Use Tjernlund part # 950-1040 relay For 24 VAC control systems

Use Tjernlund part # 950-0480 relay For 115 VAC control systems

MAC-3 WIRED WITH UP TO THREE 24V GAS APPLIANCES

MAC-3 WIRED WITH UP TO THREE 115 VOLT GAS APPLIANCES

4

Page 7

MAC-3 WIRED WITH UP TO THREE OIL BURNERS WITH R8184G CONTROLS - BURNER MOTOR LESS THAN 7 AMPS

MAC-3 WIRED WITH UP TO FIVE 24V GAS BURNERS AND ONE POWER VENTER, DRAFT INDUCER OR IN-FORCER

5

Page 8

MAC-3 WIRED WITH A POWER VENTER OR DRAFT INDUCER AND A COMMERCIAL IN-FORCER

MAC-3 CIRCUIT BOARD WIRING SCHEMATIC

6

Page 9

LIMITED PARTS WARRANTY AND CLAIM PROCEDURE

Tjernlund Products, Inc. warrants the components of its products for one year from date of installation. This warranty covers defects

in material and workmanship. This warranty does not cover normal maintenance, transportation or installation charges for replacement parts or any other service calls or repairs. Products that are tampered with, damaged, or defective due to malfunctioning appliances are not covered under this warranty. This warranty DOES NOT cover the complete MAC-3 if it is operative, except for the

defective part.

Tjernlund Products, Inc. will issue credit or provide a free part to replace one that becomes defective during the one year warranty period. If the part is over 18 months old, proof of date of the installation in the form of the contractor sales/installation receipt is necessary

to prove the unit has been in service for under one year. All receipts should include the date code of the MAC-3 to ensure that the defective component corresponds with the complete unit. This will help preclude possible credit refusal.

1.) If unable to determine faulty component, contact your Tjernlund distributor or Tjernlund Products Technical Customer Service

Department at 1-800-255-4208 for troubleshooting assistance.

2.) After the faulty component is determined, return it to your Tjernlund distributor for replacement. Please include MAC-3 date

code component was taken from. If MAC-3 date code is older than 18 months you will need to provide a copy of the original installation receipt to your distributor. Credit or replacement will only be issued to a Tjernlund distributor after the defective part has been

returned prepaid to Tjernlund.

REPLACEMENT PARTS COVERED BY WARRANTY

24 Volt Relay 950-1040

115 Volt Relay 950-0480

4PDT Isolation Relay 950-0481

Alarm Sequencer 950-0478

Circuit Board only 950-0484

WHAT IS NOT COVERED

Product installed contrary to our installation instructions

Product that has been altered, neglected or misused

Product that has been wired incorrectly

Any freight charges related to the return of the defective part

Any labor charges related to evaluating and replacing the defective part

TJERNLUND LIMITED ONE YEAR WARRANTY

Tjernlund Products, Inc. warrants to the original purchaser of this product that the product will be free from defects due to faulty material or workmanship for a period of (1) year from the date of original purchase or delivery to the original purchaser, whichever is earlier. Remedies under this warranty are limited to repairing or replacing, at our option, any product which shall, within the above stated warranty period, be returned to Tjernlund

Products, Inc. at the address listed below, postage prepaid. THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON

THE FACE HEREOF, AND TJERNLUND PRODUCTS, INC. EXPRESSLY DISCLAIMS LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF THIS PRODUCT. THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES AND NO AGENT

IS AUTHORIZED TO ASSUME FOR US ANY LIABILITY ADDITIONAL TO THOSE SET FORTH IN THIS LIMITED WARRANTY. IMPLIED WARRANTIES ARE LIMITED TO THE STATED DURATION OF THIS LIMITED WARRANTY. Some states do not allow limitation on how long an implied

warranty lasts, so that limitation may may not apply to you. In addition, some states do not allow the exclusion or limitation of incidental or consequential damages, so that above limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you may also have

other rights which may vary from state to state. Send all inquires or products requiring warranty work to Tjernlund Products, Inc. 1601 9th Street, White

Bear Lake, MN 55110-6794. Phone (651) 426-2993 • (800) 255-4208 • Fax (651) 426-9547.

7

Loading...

Loading...