TJEP LB-18 T-NUT Operation And Maintenance Manual

- 1 -

1

OPERATION and MAINTENANCE MANUAL

MODEL : TJEP LB-18 T-NUT

NAILER

DRIVES 11,5-18MM (7/16”-3/4”) T-NUTS

,!

WARNING:

BEFORE OPERATING THIS TOOL, ALL OPERATORS SHOULD STUDY MANUAL

TO UNDERSTAND AND FOLLOW THE SAFETY WARNINGS AND INSTRUCTIONS.

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE. IF

YOU HAVE QUESTIONS, CONTACT YOUR DISTRIBUTOR.

- 2 -

2

INTRODUCTION

The pneumatic tools is a precision-built tool, designed for high speed, high volume

fastening. These tools will deliver efficient, dependable service when used correctly, and

with care. As with any fine power tool for best performance the manufacture’s

instructions must be followed. Please study this manual before operating the tool and

understand the safety warning and cautions. The instructions on installation, operation

and maintenance should be read, carefully, and the manual kept for reference. NOTE:

Additional safety measures may be required because of your particular application of

the tool. Contact your representative or distributor with any questions concerning the

tool and its use.

INDEX

INTRODUCTION…………………………..……………………………………………….….1

SAFETY INSTRUCTIONS………………………………………………………………….…2

AIR SYSTEMS……………………………………………………………………………….…5

TOOL INSTALLATION……………………………………………………………………..…7

TOOL LOADING….……………………………………………………………………………8

TOOL OPERATION…………………………………………………………………………….9

MAINTENANCE…………………………………………………………………………….….10

OPERATOR TROUBLESHOOTING…………………………………………………………14

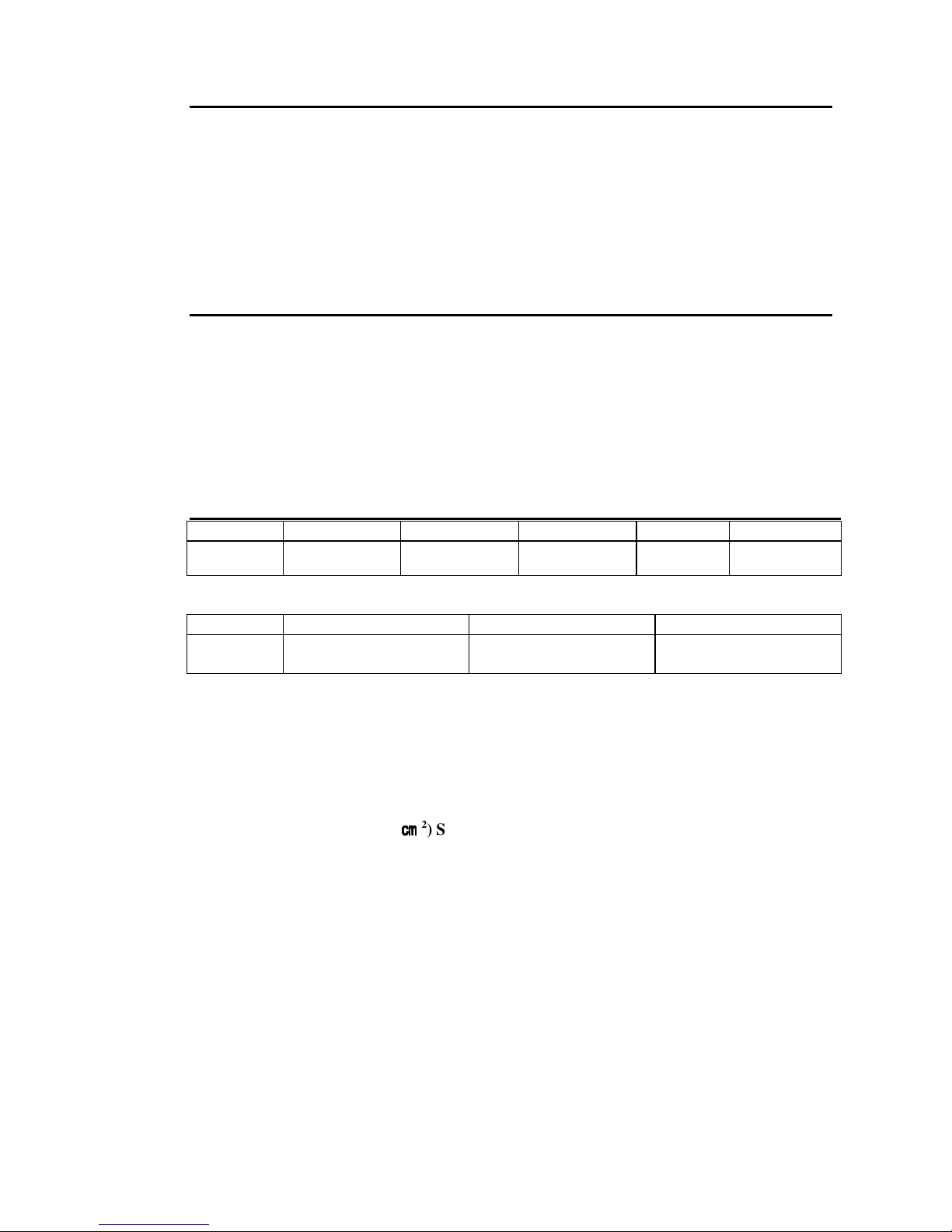

TOOL SPECIFICATIONS

MODEL LENGTH WIDTH HEIGHT WEIGHT CAPACITY

TJEP LB-18

322 mm

(12 11/16“)

403mm

(15 7/8“)

81mm

(3 3/16“)

3.2kg

(7,1lbs)

13 T-NUTS

FASTENER SPECIFICATIONS:

MODEL T-NUT SIZE DIAMETER BARREL LENGTH

TJEP LB-18

23×21mm

(7/8”

×13/16”)

M6, M8, M10

(1/4”, 5/16”, 3/8”)

11,5-18mm

(7/16”-3/4”)

TOOL AIR FITTING

This tool uses a 1/4” N.P.T male plug. The inside diameter should be .200”(5mm) or larger.

The fitting must be capable of discharging tool air pressure when disconnected from the

air supply.

OPERATING PRESSURE

70 to 110 p.s.i. (4,9 to 7,8kg/

2

) Select the operating pressure within this range for best

fastener performance.

DO NOT EXCEED THIS RECOMMENDED OPERATING PRESSURE.

NOISE CHARACTERISTIC VALUES IN ACCORDANCE WIT Enxxl:

A-weighted single-event sound pressure level at operator’s :LPA,2s= 89 dBA

A-weighted single-event sound power lever :LWA,1s= 98 dBA

A-weighted single-event surface sound pressure level :LPA,1s,1m= 85 dBA

VIBRATION CHARACTERISTIC VALUES IN ACCORDANCE WITH ISO 8662;

PART11:

Weighted root mean square acceleration: 3,01 m/s

2

- 3 -

3

SAFETY INSTRUCTIONS

SAFETY FIRST

These safety instructions provide information necessary for safe

operation of pneumatic tools. DO NOT attempt to operate the tool until

you read and understand all safety precautions and manual instructions.

WEAR EYE AND HEARING PROTECTION

Always wear hearing and eye protection devices, including side

shields when operating or working in the vicinity of a tool.

THE TOOL MUST BE USED ONLY FOR THE PURPOSE

FOR WHICH IT WAS DESIGNED

Do not throw the tool on the floor; strike the housing in any way or

the tool as a hammer to knock material into place.

NEVER ENGAGE IN HORSEPLAY WITH THE TOOL

The tool is not a toy so do not use it like one. Never engage in

horseplay with the tool or point it at yourself or any person, even if

you think it is not loaded.

NEVER ASSUME THE TOOL IS EMPTY

Check the magazine for fasteners that may be left in the tool. Even if

you think the tool is empty or disconnected never point it at anyone

or yourself. Unseen fasteners could fire the tool.

NEVER CLAMP THE TRIGGER IN A LOCKED OR

OPERATING POSITION

The trigger of the tool must never be tampered with; disabled or

clamped in a locked or operating position since this will cause the

tool to driver a fastener any time the work contacting element is

depressed.

DO NOT LOAD FASETNERS WITH THE AIR LINE

CONNECTED, OR WITH THE TOOL TRIGGER OR

WORK CONTACTING ELEMENT DEPRESSED

When loading fasteners into the tool, make sure to disconnect the air

line and not to depress the trigger or work contacting element.

- 4 -

4

SAFETY INSTRUCTIONS

OPERATE THE TOOL ONLY ON A WORKPIECE

The tool should be operated only when it is in contact with the work

piece. Even then you should be careful when fastening thin material

or working near the edges and corners of the work piece since the

fasteners may drive through or away from the work piece.

DO NOT DISABLE OR REMOVE THE WORK

CONTACTING ELEMENT

This tool is equipped with a safety mechanism, called a work

contacting element, to help prevent accidental firing. Never tamper

with, disable or remove the work contacting element. Do not use the

tool unless the work contacting element is working properly. The

tool could fire unexpectedly.

DISCONNECT THE TOOL WHEN NOT IN USE

Always disconnect the tool from the air line when it is not used or

when you leave the work area. The tool should never be left

unattended because people who are not familiar with the tool might

handle it and injure themselves or others.

CARRY THE TOOL ONLY BY THE HANDLE

Always carry the tool by the handle only. Never carry the tool by the

air hose or with the trigger depressed since you could drive a

fastener unintentionally and injure yourself or someone else.

DO NOT WEAKEN THE TOOL HOUSING

The tool housing is a pressure vessel and should never be weakened

by having your company’s name, area of work or anything else

stamped or engraved into its surface.

DISCONNECT THE TOOL WHEN PERFORMING

REPAIRS AND CLEARING JAMS

Never attempt to clear a jam or repair a tool unless you have

disconnected the tool from the air line and removed all remaining

fasteners from the tool.

- 5 -

5

SAFETY INSTRUCTIONS

ALWAYS USE THE PROPER FITTING FOR THE TOOL

Only MALE pneumatic type air connectors should be fitted to the

tool, so that high pressure air in the tool is vented to atmosphere as

soon as the air line is disconnected.

NEVER install FEMALE quick disconnect couplings on the tool.

Female couplings will trap high pressure air in the tool when the air

line is disconnected, leaving the tool charged and able to drive at

least one fastener.

DO NOT EXCEED THE MAXIMUM RECOMMENDED

AIR PRESSURE

Operate the tool only at the recommended air pressure. Do not

exceed the maximum air pressure marked on the tool. Be sure the

air pressure gauge is operating properly and check it at least twice a

day.

Never use any bottled air or gases such as oxygen to operate the tool

since they could cause the tool to explode.

KEEP THE TOOL CLEAN AND LUBRICATED

Clean the tool at least daily and lubricate as required. Never operate

a dirty or malfunctioning tool.

USE ONLY RECOMMENDED PARTS AND FASTENERS

Use only parts and fasteners specifically designed and recommended

for use in the tool and for the work to be done. Using unauthorized

parts and fasteners or modifying the tool in any way creates

dangerous situations. Replace all missing parts-refer to tool

schematic for correct placement and part number.

,! DANGER

,!

Failure to follow any of the above instructions could result

in severe personal injury to tool user and bystanders or cause

damage to tool and property.

- 6 -

6

AIR SYSTEMS

For air-powered tools to work their best, the air supply system must be

properly installed and maintained regularly. A drawing in this section

shows a properly installed air supply system. Handy checklists for

installing and maintaining air supply systems follow.

INDOOR AIR SYSTEM INSTALLATION BE CERTAIN

THAT:

All pipes supplying air have a large enough inside diameter to

ensure adequate air supply.

The main supply pipe slopes down, away from the compressor

(1/16 inch per foot).

Air storage is provided along lengthy air lines.

Pipe line branch outlets are at the top of the main pipe line.

Cut-off valves are provided at each branch pipe line throughout

the system.

Water legs extend from the bottom of each branch line.

A refrigerant-type dryer is installed on the system.

Air hoses are kept as short as practical.

A regular maintenance program is followed.

QUTDOOR AIR SYSTEM INSTALLATION BE CERTAIN

THAT:

A moisture trap and a filter/regulator/lubricator are installed at

the compressor.

Air hoses and fittings are large enough so that air flow not

restricted. Minimum hose size is 3/8 inch ID, with 1/2 inch ID hose

used for any application over 25 feet.

Air hoses are not longer than 150 feet.

Loading...

Loading...