Page 1

T&J Models

R/C Model Designs By Jim Young

9356 Wendover Ct.

Brighton, MI 48116

www.tnjmodels.rchomepage.com

Monocoupe 90A

Speed and Comfort for the Common Man

In the late 19020’s , Don A. Luscombe’s Monocoupe introduced affordable and

convenient performance to the light airplane market. Previously, this market was

dominated by large, expensive, open-cockpit biplanes. The Monocoupe was compact and

offered a closed cabin for comfort and convenience. The reverse curve of the fuselage

became one of the signature characteristics of this family of sporty planes. Much lighter

and cleaner than other aircraft of the time, the Monocoupes were also popular for racing.

The longer and wider Model 90 was introduced in 1930, the A version having a 90hp

Lambert R-266 radial engine.

Our Monocoupe is designed for a 30mm outrunner and 3S 3300mAhr flight pack.

Extensive use of laser cutting and self aligning structure provides a straight and light

airframe with operational flaps.

Copyright © 2015 Jim Young and T&J Models

Page 2

Monocoupe 90A

Construction

All of short kits require some level of

modeling and flying experience. We do

not recommend them as a first model to

build or fly.

Additional Materials

The following materials are required to

complete this short kit (list may not be

complete):

(4) 1/16”x3”x36” Balsa Sheet

(2) 1/4” Sq.x48” Balsa

(3+) 1/4” Sq.x36” Balsa

(2) 1/4"x1/2”x36” Balsa

(8) 1/8”x 1/4"x36” Spruce or Basswood

(?) 1/8” Sq.x36” Balsa

(2) 1/8”x3”x36” Balsa

(1?) 3/16” x36” Spruce Dowel

Hardware:

2.75” Light Wheels

Wheel Pant Mounting Hardware

(20) #2 x 3/8” Wood Screws

(4) Robart Medium Hinge Points

1/16” dia. Music Wire

5/32” dia. x 36” Music Wire

1/8” dia. x 36” Music Wire

Initial Preparation

Laminate 4 layers of 1/16” balsa for the

stabilizer and fin outlines. The finished

laminations should be 1/8” thick.

Laminate 4 layers of 1/16” balsa for the

wing tips. The finished laminations

should be approximately 1/2” thick at

the L.E. and may taper to the T.E.

Laminate two sets of main and rear spar

joiners from 1/16” plywood. Mark the

location of R3 on the joiners.

Laminate the strut mount doublers to the

strut mount F10. Glue a 3/16” diameter

magnet into the hole in one of the

doublers.

Laminate the two 1/16” plywood FWs

together.

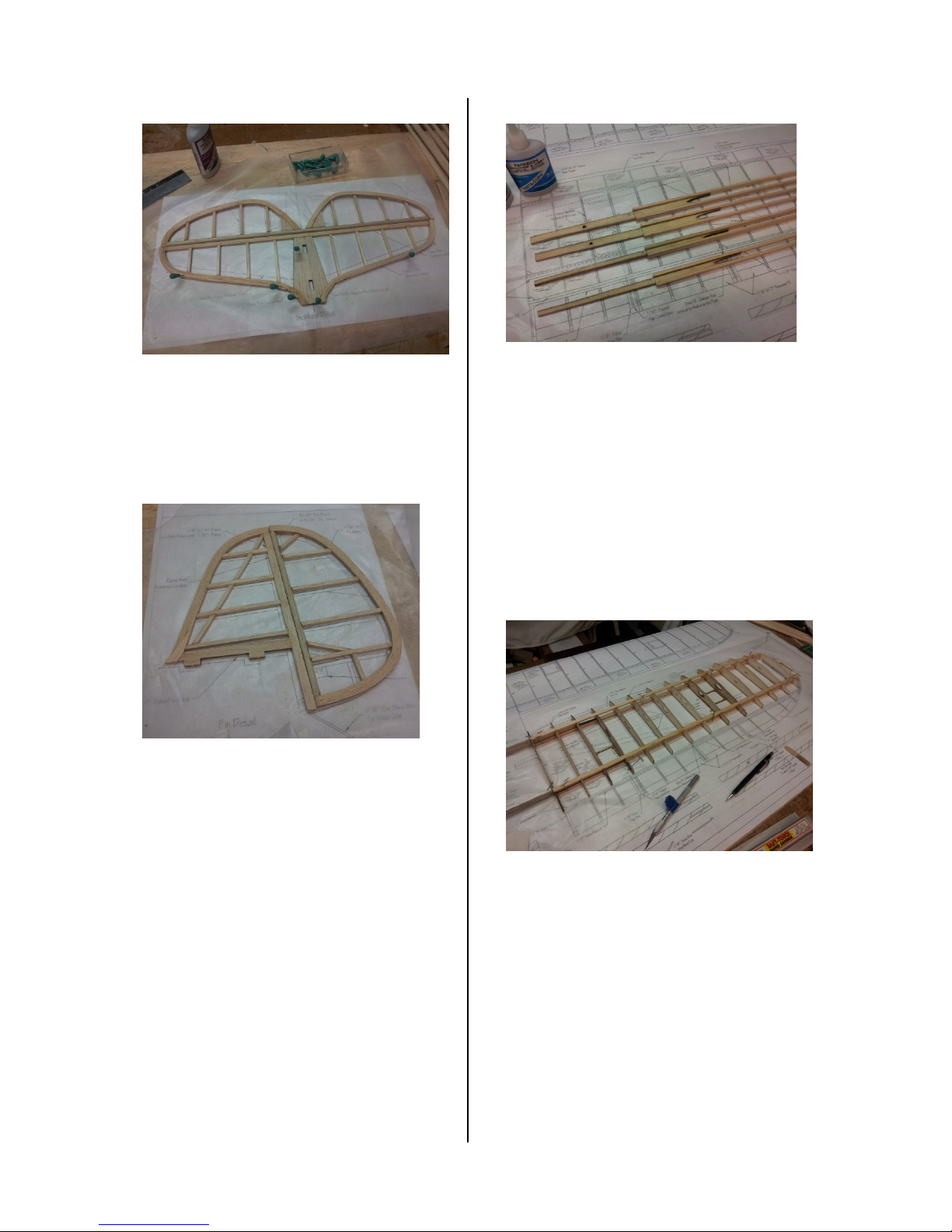

Tail Feathers

The center of the stab and base of the fin

are laser cut. Note that the L.E. of the

fin is offset to the left to give some right

rudder, so make sure the center of the

stab is oriented correctly. Frame up the

stab and fin over the plans with 1/8”

thick stock as shown on the plans. Add

1/32” balsa to the L.E. of the stab and

cap strip the structures with 1/32” balsa.

Page 2 Copyright © 2016 Jim Young and T& J Models

Page 3

Monocoupe 90A

Flip the structures over and cap the other

side with 1/32” balsa. The rudder and

elevator L.E. dowels can be substituted

with rectangular stock for non-scale

hinges.

Glue the 1/16” plywood control horn in

place. Sand the edges round and

temporarily hinge the control surfaces.

Wings

Cut 1/8”x1/4" spruce main spars and

rear spars to length. If you have a

warped spar, use it for the bottom spar

with the warp curving up. Make left and

right spar assemblies with the spar

joiners glued between the spars. For the

right wing, the joiners should be toward

the L.E. and for the left wing the joiners

should be toward the T.E.

Locate the spar assemblies over the

plans. The bottom main spar will be

slightly off the board, so just pin it to

hold it in position. Use the dihedral

gauge to set the angle of R3 and glue in

place. Glue the remaining ribs in place

using the flap and aileron mounts to

space the R6’s and R9’s. Glue the 1/4”

balsa L.E. in place. The 1/8” balsa T.E.

is square to the board from R3 to R8,

and then angled from R8 to the wing tip.

Add balsa gussets as shown on the plans.

Cut and glue vertical grain sheer webs

between the top and bottom main spars

from R6 to the second R9. Trim the

laminated wing tip to fit and glue in

place. Glue the top sheeting as shown

on the plans. Cap strip the ribs and T.E.

with 1/16”x1/8” balsa.

Page 3 Copyright © 2016 Jim Young and T& J Models

Page 4

Monocoupe 90A

Repeat for the other wing.

The flap and aileron T.E. are 1/16”

basswood. Pin the flap and aileron T.E.

in place. Cut 1/16” cap strips and glue

to the T.E. For the aileron, prop up the

tip at R11 and R12. Glue the 1/8” balsa

flap and aileron L.E. in place. Add the

flap and aileron ribs, and cap them with

1/16” balsa. Remove the flap and

aileron from the board and glue the

1/16” plywood control horns in place

with 1/8” ribs on each side.

The flaps are hinged on the bottom with

the covering material, and the ailerons

are hinged along the top.

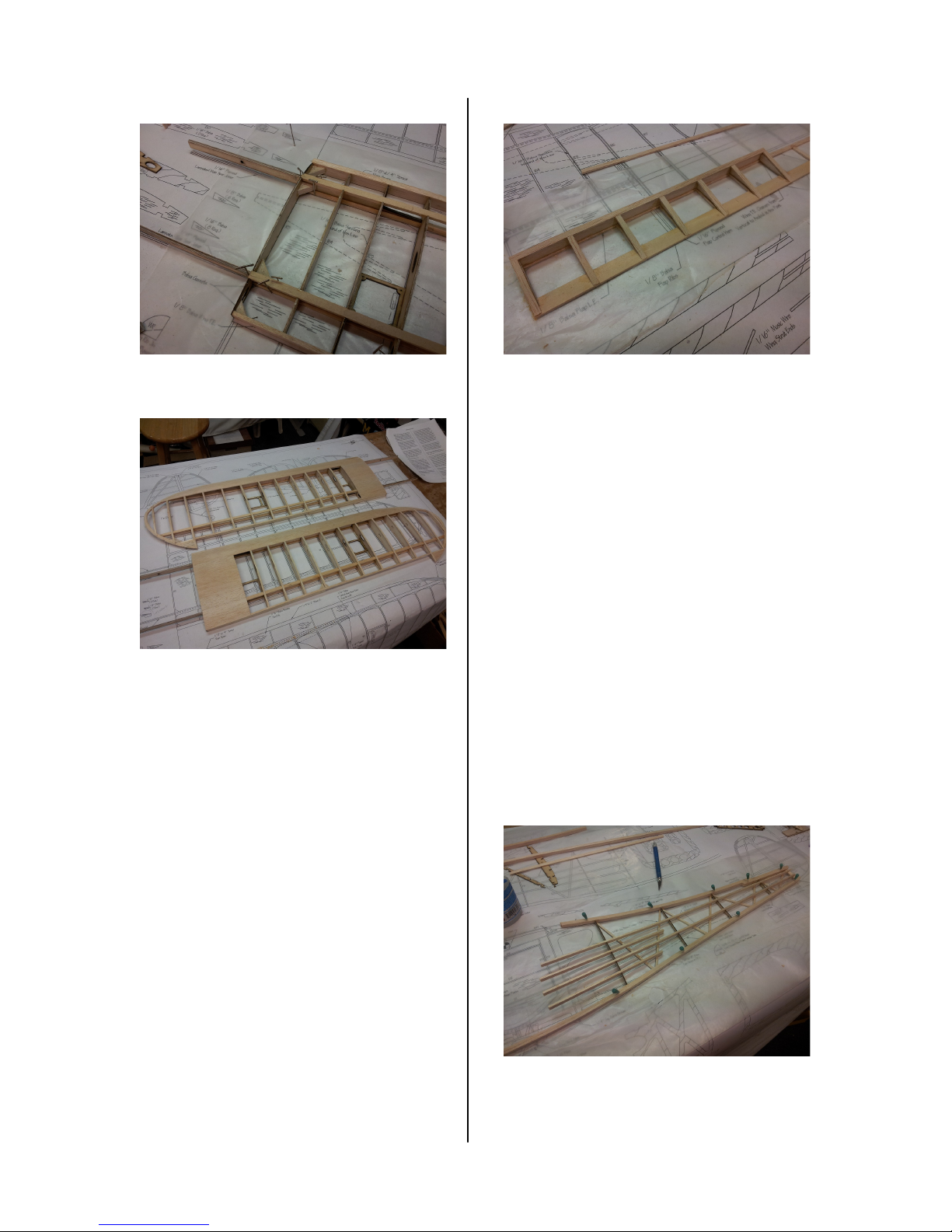

Fuselage

Prepare the top and bottom stringers as

shown on the plans. A separate drawing

of the right side is included so you can

build both sides at once. Using the

fuselage angle gauge, pin F5, F6, F7 and

F8 over the plans. The formers should

angle forward. Glue the 1/4” square and

1/8”x1/4” balsa stringers to the notches

in each former leaving them long enough

to reach forward of F4. Cut and glue

1/8” square balsa cross bracing as shown

on the plans. The cross bracing should

butt up to each former and be glued to

each stringer it crosses.

Page 4 Copyright © 2016 Jim Young and T& J Models

Page 5

Monocoupe 90A

Unpin the structures from the board. Fit

the top and bottom F5, F6, F7, F8 pieces

to mate the two sides. Align the rear

section of the fuselage over the plans

and when satisfied, use thin CA at each

puzzle joint to make them permanent.

Fit F3 and F4 onto the cabin floor. Fit

the F9 assembly and F10 in place on the

fuselage floor. Capture the two landing

gear wires with the two F11 fuselage

keels. Fit the cabin ceiling F3A in place.

Making sure each piece is square and

fully inserted in its slot, glue the forward

fuselage structure together. Fit and glue

F1, F1A, F1B, F1C and F2 to the

fuselage. Glue the FW assembly in

place. Add 1/4” balsa doublers to F3.

Bend the forward landing gear from

5/32” music wire and the rear gear from

1/8” music wire.

Bind the landing gear together with fine

wire and solder.

Page 5 Copyright © 2016 Jim Young and T& J Models

Page 6

Monocoupe 90A

Assemble the forward spar box making

sure it is wide enough to fit both main

wing spars. Assemble the rear spar box

to F4, again making sure the rear spars

will fit. Fit the forward spar box to the

cabin ceiling and use the R2’s to

position it. Use epoxy to glue the

forward spar box in place. Glue R1,

F4A’s, and F5A’s in place.

Glue the door frame pieces D1 through

D9 in place using 1/64” plywood to

space them.

Sheet the forward portion of the fuselage

with 1/16” balsa. Glue 1/4” balsa L.E.

to the fronts of the R2. Sheet the center

of the wing from the forward spar box to

the L.E. Add 1/16” balsa cap strips to

the tops of the R2’s, F4A’s, and F5A’s.

Glue the front and rear fuselage together.

The F5A’s and F11’s key on to F6.

Page 6 Copyright © 2016 Jim Young and T& J Models

Page 7

Monocoupe 90A

Glue SC to front of F1 and sand to

shape.

Cut the door free and hinge each with

two Robart hinge points.

Laminate 8 pairs of C4 from 1/8” balsa.

Assemble the cowl structure. Plank the

cowl with 1/16” or 3/32” balsa. Glue the

cowl rings on the front and sand smooth.

Two layers of 1/8” balsa are sanded to

shape for the engine crankcase.

Glue together and laminate the three

cowl rings CR1, CR2, and CR3.

A template (7 cylinder, equally spaced)

is provided for the cowl blisters. Cowl

blisters can be sanded prior to or after

gluing in place. The cowl is held in

place with three screws through C1 into

the firewall.

Page 7 Copyright © 2016 Jim Young and T& J Models

Page 8

Monocoupe 90A

Final Assembly

The wing struts are laser cut from 1/16”

plywood and are faced on both sides

with 1/32” balsa. Bend 1/16” music

wire as shown on the plans. Notch the

bottom spars between the R9’s to clear

the Z-bend. Glue the strut mounts in

place.

Insert the wings into the fuselage.

Temporarily insert the music wire ends

into the struts and install to the wing and

fuselage. The outboard ends of the struts

can be trimmed as necessary. Rough up

the music wire bits and apply slow cure

epoxy to them. Reassemble the struts

making sure the wing is not twisted.

Use balsa or filler to make the fillet

around the landing gear and wing struts.

The wing is held in place by a pin or

screw inserted through the spar box and

spars.

The wheel pants are laminated from 1/8”

balsa. The bottom edge of each piece

should align around the wheel opening.

Sand to shape and install mounting

hardware of your choice.

Glue the tail feathers in place.

Page 8 Copyright © 2016 Jim Young and T& J Models

Page 9

Monocoupe 90A

Assemble the elevator push rod as

shown on the plans and install. Use

plastic tubes as guides for the rudder

pull-pull cables.

Any iron on covering is suitable. The

Prototype is covered with 21st Century

Painted Fabric. There are plenty of

classic color scheme possible. The

windshield is cut from clear plastic from

the template on the plans.

The prototype is flying with a Scorpion

3020-16 spinning a 12x6 Xoar wooden

prop, a Castle Creations Phoenix 45

ESC, and a 3S 3300mAhr LiPo pack.

Since there are 6 servos, a separate

switching BEC is used to power the

radio.

The recommended servos are HS-65 for

the elevator, rudder, and flaps. The

ailerons can be HS-45’s or HS65s.

Recommended control throws are:

Ailerons: +/- 3/8”

Flaps: 45 degrees

Elevator: +/- 3/8”

Rudder: +/- 1”

Flap to Elevator Mix: 20% down

Flying

The Monocoupe 90A is not a hard plane

to fly but it is not a trainer being a tail

dragger. Take offs require rudder input

to keep it tracking straight. Once in the

air you’ll find that it can do basic

aerobatics including loops, rolls, and

stall turns. The rudder is very effective,

and the roll rate is typical for a high

wing plane.

The stall is very gentle, and depending

on the elevator throws non-existant.

The flaps are not necessary, but add

another element of flight to experiment

with. Without elevator input, deploying

the flaps will cause the ‘coupe to nose

up, so down elevator is needed to

maintain level flight. I have the flaps

setup on a flight mode switch with the

elevator trim separate for each mode.

This allows for quick setup of the

elevator compensation for flaps. As you

deploy the flaps in the different flight

modes, simply add down elevator trim to

maintain level flight. When the flaps are

retracted, the elevator trim returns to

normal flight mode trim setting.

Page 9 Copyright © 2016 Jim Young and T& J Models

Page 10

Monocoupe 90A

With the flaps at half or full, flybys are

very slow. Just make sure to throttle

back up before fully retracting the flaps.

Landings can be performed with or

without flaps. I like to keep a little

power on all the way to touch down

since it seems to help the roll out.

Page 10 Copyright © 2016 Jim Young and T& J Models

Page 11

Monocoupe 90A

Disclaimer

Jim Young and T&J Models accept no responsibility for crash damage and/or loss of kits, engines, accessories, etc.

incurred during operation or building of a Jim Young and T&J Model’s radio-controlled model. In most cases it is very

difficult or impossible to determine whether crash damage was actually due to radio equipment failure or to operator error.

It is impossible to guarantee product compatibility for product recommendations. We provide information and suggestions

to the best of our abilities based on the information available to us at the time. We are unable to guarantee successful

outcomes.

All of the products sold by Jim Young and T&J Models are intended for retail consumption by our customers and are not

intended for resale. We reserve the right not to sell to resellers. Any consequences arising out of the resale of

merchandise purchased from Jim Young and T&J Models is the responsibility of the seller, not Jim Young and/or T&J

Models. Jim Young and T&J Models may revoke the ordering privileges of customers commercially reselling our products.

Model airplane performance claims typically apply to density altitudes under 3,000 feet above sea level. If you will be

flying your airplane above this, additional considerations such as motor power, choice of propeller and aircraft weight

should be taken into consideration.

Additional policies may exist. Policies are not limited to those on this page. Call with any questions

Waiver and Release from Liability

I HEREBY ACKNOWLEDGE that I understand that flying model aircraft is an extremely dangerous activity and may result

in injury and or death, even when practiced by a competent pilot using proper equipment. I further acknowledge that I am

aware of and understand the types of hazards and dangers, both real and hidden, involved in flying model aircraft and

accept any and all of the risks of possible injury or death. I understand that the model aircraft products manufactured and

distributed by Jim Young and T&J Models have not been designed, manufactured or tested to meet any federal or state

government air-worthiness standards or regulations. I understand that flying model aircraft is an extremely demanding

activity requiring exceptional levels of attention, judgment, maturity, and self discipline, requiring me to make a conscious

and continual commitment to my own safety and the safety of those around me. In particular, I understand that gusty

winds or turbulence may interfere with even an expert pilot's ability to safely control flying mode aircraft and thereby cause

it to crash.

I HEREBY RELEASE, AGREE TO HOLD HARMLESS AND INDEMNIFY Jim Young and T & J Models and their agents

and employees for any and all liability for any loss, damage, injury or death to myself or to any other person or property

resulting from the use of these products and I further agree to waive, and not make any claim or file any suit based upon

negligence, breach of warranty, contract or other legal theory. This release, agreement to hold harmless and to indemnify

shall be binding upon me, my legal representatives, heirs, legatees and assigns as well as upon all who may be

dependent upon or entitled to my services, consortium or support. Should I breach this agreement by filing any such suit

or making any such claim, I will pay all attorney's fees and costs of the released parties. I agree that this release shall be

governed by and construed in accordance with the laws of the State of Michigan. All disputes and matters whatsoever

arising under, in connection with or incident to this agreement shall be litigated, if at all, in and before a court located in

the State of Michigan, USA, to the exclusion of the courts of any other state or country. If any part, article, even

paragraph, sentence or clause of this agreement is not enforceable, the effected provisions shall be curtailed and limited

only to the extent necessary to bring it within the requirements of the law and the remainder of the agreement shall

continue in full force and effect.

I VOLUNTARILY ASSUME all risks, known and unknown, of any injuries, personal or financial or of wrongful death,

however caused, if caused in part or in whole by the action, inaction or negligence of any of the released parties named

above to the fullest extent of the law. I represent that I am at least 18 years of age and I acknowledge that I have read this

agreement, fully understand the potential dangers of engaging in flying model aircraft products from Jim Young and T&J

Models and am fully aware of the legal consequences of accepting this agreement. I understand and agree that this

document is legally binding and will preclude me from recovering monetary damage from the above listed entities and or

individuals, whether specifically named or not, for personal injury, bodily injury, property damage, wrongful death or any

other personal or financial injury sustained by me in connection with the use of any model aircraft product from Jim Young

and T&J Models.

Copyright

All content of this manual including text, graphics, logos of Jim Young and T&J Models brands, the selection and

arrangement thereof are copyright Jim Young and T&J Models. ALL RIGHTS RESERVED and are protected to the full

extent of U.S. and International copyright laws. Any other use of this material --including reproduction, modification,

distribution, or re-publication--without the prior written permission of Jim Young and T&J Models is strictly prohibited.

Page 11 Copyright © 2015 Jim Young and T&J Models

Loading...

Loading...