ventilation systems

Extract Ventilation Unit

Product Manual

EN

CME1 Q Plus

TP300A

TP301A

CME1 Q Plus

with Humidity Sensor

TP300HA

TP301HA

2

Product Overview

Safety and Guidance . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Component Identication . . . . . . . . . . . . . . . . . . . . 5

Packaging Contents. . . . . . . . . . . . . . . . . . . . . . . . . . 6

Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Auto Setback Speed . . . . . . . . . . . . . . . . . . . . 8

Setback Speed . . . . . . . . . . . . . . . . . . . . . . . . . 8

Continuous Speed . . . . . . . . . . . . . . . . . . . . . . 8

Boost Speed with Overrun Timer. . . . . . . . . . 8

Boost Overrun Timer . . . . . . . . . . . . . . . . . . . . 8

Integrated Humidity Sensor. . . . . . . . . . . . . . 8

Installation

Fixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ducting Connections. . . . . . . . . . . . . . . . . . . . . . . . 11

How to Convert Port Cover . . . . . . . . . . . . . . 13

Wiring & Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring Connections Access. . . . . . . . . . . . . . 14

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . 15

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . 16

Commissioning

TP300A & 301A . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Control Parameters . . . . . . . . . . . . . . . . . . . . .17

Commissioning. . . . . . . . . . . . . . . . . . . . . . . . .18

Boost Overrun. . . . . . . . . . . . . . . . . . . . . . . . . .19

Controller Reset . . . . . . . . . . . . . . . . . . . . . . . .19

Hardware Reset . . . . . . . . . . . . . . . . . . . . . . . . 19

TP300HA & TP301HA. . . . . . . . . . . . . . . . . . . . . . . . . 20

Control Parameters . . . . . . . . . . . . . . . . . . . . .20

Commissioning. . . . . . . . . . . . . . . . . . . . . . . . .21

Boost Overrun . . . . . . . . . . . . . . . . . . . . . . . . . 22

Humidity Sensor . . . . . . . . . . . . . . . . . . . . . . . 22

Controller Reset . . . . . . . . . . . . . . . . . . . . . . . .23

Hardware Reset . . . . . . . . . . . . . . . . . . . . . . . . 23

Maintenance

Routine maintenance . . . . . . . . . . . . . . . . . . . . . . . .24

Cleaning Exterior . . . . . . . . . . . . . . . . . . . . . . .24

Cleaning Interior . . . . . . . . . . . . . . . . . . . . . . .24

Access to the Interior for Cleaning . . . . . . . .25

Service Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

IMPORTANT - Fully read this Product Manual to help ensure the ventilation

system is installed, commissioned and used properly

3

Product Overview

Safety and Guidance

Important: read these instructions fully before the installation of this appliance

1. Installation of the appliance must be carried out by a qualied and suitably

competent person and be carried out in clean, dry conditions where dust and

humidity are at minimal levels.

2. The unit must be stored in a clean and dry environment.

3. Do not install the appliance in areas where the following may be present or

occur:

x Excessive oil or a grease laden atmosphere.

x Corrosive or ammable gases, liquids or vapours.

x Ambient temperatures above 40°C or below -5°C.

x Humidity levels above 90% or in a wet environment.

x The appliance is not suitable for installation to the exterior of the dwelling

4. This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

5. Children should be supervised to ensure that they do not play with the

appliance.

6. Ensure that external grilles are located away from any ue outlet, in accordance

with relevant Building Regulations.

7. The unit must not be connected to a tumble drier.

8. The unit must not be connected to a cooker hood.

9. Precautions must be taken to avoid the back-ow of gases into the room from

an open ue appliance.

10. Ensure all ducting is free from debris and blockages before switching on the

unit.

4

Dimensions

This diagram details the overall size of the unit and the additional space required

around the unit to allow for commissioning and future servicing and maintenance.

450

421

355

390

252

550

450

590

Service Void

All dimensions in mm

5

Component Identication

Unit components

Cover

Inlet ring

Scroll

Base

Cover / Scroll / Inlet Ring assembly

6

Packaging Contents

Inspect the unit when taking delivery. Check the unit for damage and that all

accessories have been supplied. The box contains:

CME1 Q Plus Unit x 1.

Port covers x 3.

This Product manual x 1.

Screw Pack x 1.

User Guide x 1.

All shortages or damage must be immediately reported to the supplier.

7

Product Features

Compact low prole unit.

Hidden installation xings.

All duct ports on one level.

Accepts 204mm x 60mm or 110mm x 54mm ducting.

Can be cleaned and serviced without disturbing any ducting.

Straightforward installation.

Versatile volt-free boost and setback switching.

The CME1 Q Plus is controllable by various volt-free switches and sensors. Mains

switching can be achieved by use of the Titon Boxed Relay 5A TP 505.

The following describes the controls and features of the CME1 Q Plus and how they

are controlled. Ensure all controls are adequately labelled, indicating their function

clearly.

Model CME1 Q Plus

Part Number TP300A TP301A TP300HA TP301HA

Complete unit

l

l

2nd Fix Cover / Scroll / Inlet Ring assembly

l l

Auto Setback Speed

l

l

Setback Speed

l l

Continuous Speed

l

Boost Speed

l

Boost Overrun Timer

l

Integrated Humidity Sensor

l l

GB Patent Application No. GB2491516,

EP Patent Application No. EP2242959

8

Auto Setback Speed

Setback Speed is a reduced ventilation rate. Auto Setback Speed is automatically

set at the mid point between minimum possible Continuous Speed and the

selected Continuous Speed. The Auto Setback Speed can be enabled by

connection of a volt-free one-way switch, or combined with the Boost Speed with

the 3 position switch TP 508.

Setback Speed

Setback Speed is a reduced ventilation rate. Setback Speed is congured using

a step-less independent fan control potentiometer. The Setback Speed can be

enabled by connection of a volt-free one-way switch, or combined with the Boost

Speed with the 3 position switch TP 508.

Continuous Speed

Continuous Speed is the normal running speed of the unit. Continuous Speed is

congured using a step-less independent fan control potentiometer.

Boost Speed with Overrun Timer

Boost Speed is an increased speed providing higher extract air ow. Boost Speed

is congured using a step-less independent fan control potentiometer. The Boost

Speed can be triggered by any device which provides a volt-free one-way switch,

such as a PIR, thermostat, humidistat or a standard one-way switch

Boost Overrun Timer

Boost Overrun Timer maintains the Boost Speed for a specic time variable between

0 and 30 minutes. The Boost Overrun Timer time is congured using step-less

independent potentiometer.

Integrated Humidity Sensor

Some units are tted with an Integrated Humidity Sensor. This continuously

monitors the relative humidity (RH) of the extracted air and triggers Boost Speed

when the relative humidity rises over the set threshold. The Humidity Sensor’s

trigger point is variable from 55%RH to 85%RH and is congured using step-less

independent potentiometer.

9

Installation

Fixing

1. The unit must be securely xed to a

smooth at surface, any orientation

is possible.

2. Mark the four xing hole centres

using the Base as a template.

3. Drill holes for xings, use 4mm

Pan Head screws. Always use a

xing type and length suited to

the substrate type. The unit weighs

approximately 5kg.

4. Mount the Base, ensuring it is not

distorted by the xings or mounting

surface.

5. Clip the Motor and Lid assembly to

the Base, ensure that all 6 clips have

engaged.

Tighten screws by hand, DO NOT over

tighten screws or use power tools.

1

2

3

4

5

6

260

260

EXTRACT

PORT

Positions of Clips

10

6. Unscrew the 2 retaining screws that hold on the Cover and remove, retain the

screws.

7. Fit two screws from the Screw Pack

through the preformed holes at the

front of the Inlet Ring to securely x

the Inlet Ring/Scroll assembly to the

Base.

8. Fit one screw from the Screw Pack

through the preformed hole in the

back of the Base. to securely x the

Inlet Ring/Scroll assembly to the

Base.

9. Re-t the Cover using the 2 screws

retained and 1 screw from the

Screw Pack.

11

Ducting Connections

Titon recommend the use of guidance given in the Domestic Ventilation

Compliance Guide 2010 Edition ISBN-978 1 85946 378 9 and

Approved Document Part F 2010 ISBN-978 1 85946 370 3 for all

installations in the United Kingdom.

The above documents can be downloaded free from www.planningportal.gov.uk.

Titon recommend that:

1. 204 x 60mm ducting is used for the

connection of the Extract Port to

Outside.

2. 204 x 60mm or 110 x 54mm ducting

is used for connection to the other

ports.

3. A minimum distance of 200mm

between the CME1 Q Plus unit and

any sharp bends in duct work.

4. Ducting should be insulated where

it passes through unheated areas

and voids.

5. Unit should be insulated when

tted in unheated area.

6. Where a duct extends externally above roof level the section above the roof

should be insulated or a condensate trap should be tted just below roof level.

7. Where ducts pass through re barriers, they must be appropriately re stopped

in accordance with the requirements of Part B Building Regulations (England &

Wales).

8. A ducting condensate drain must be tted to vertical Extract Port to Outside

duct work.

9. Condensate drain pipe work must be adequately secured, installed to have

a minimum 5° fall and be insulated if any part of the pipe passes though an

unheated void.

EXTRACT

PORT

Extract Port to Outside

12

10. All insulation to be the equivalent of

at least 25mm of insulating material

with a thermal conductivity

of 0.04 W/(mK).

11. Ducting must be installed in such

a way that resistance to airow is

minimised.

12. Ducting connected to the Extract

Port to Outside must be to the

external air outside the building

envelope.

13. All ducting joints including those

to the CME1 Q Plus unit’s Duct Ports

and Convertible Port Covers must

be permanently connected and

sealed.

14. Do not distort ducting, Convertible

Port Cover or Duct Ports.

15. 204 x 60mm ducting ts inside the

units Duct Ports.

16. 110 x 54mm ducting ts inside the

Convertible Port Cover.

17. Unused extract ports must be tted

with non-converted or undamaged

port covers.

13

How to Convert Port Cover

1. To enable tment of 110 x 54mm

ducting, modify the Convertible

Port Cover by tearing out the ‘rip

strip’.

2. When using the convertible port

cover ensure the tear out section is

completely removed.

14

Wiring & Safety

WARNING: The unit MUST be earthed. All wiring must conform to current I.E.E.

Wiring Regulations and all applicable standards and Building Regulations.

1. Electrical installation of the appliance MUST be carried out by a suitably

qualied competent person.

2. Inspect the appliance. If damaged, it must be replaced by the manufacturer,

their service agent or similarly qualied persons in order to avoid a hazard.

3. The appliance must be connected to a local double pole isolation switch with a

contact separation of at least 3mm. Ideally located adjacent to the unit.

4. CME1 Q Plus is suitable for 230V ~ 50/60Hz single phase with a fuse

rating of 3A.

5. Mains switching can be achieved by use of the Titon Boxed Relay 5A TP 505

Wiring Connections Access

Access to the connections for mains, boost and other volt-free control functions

is via removal of the Cover. Cables must be routed as shown and secured with

clamps provided.

Internal Cable Routing

Cable Access

15

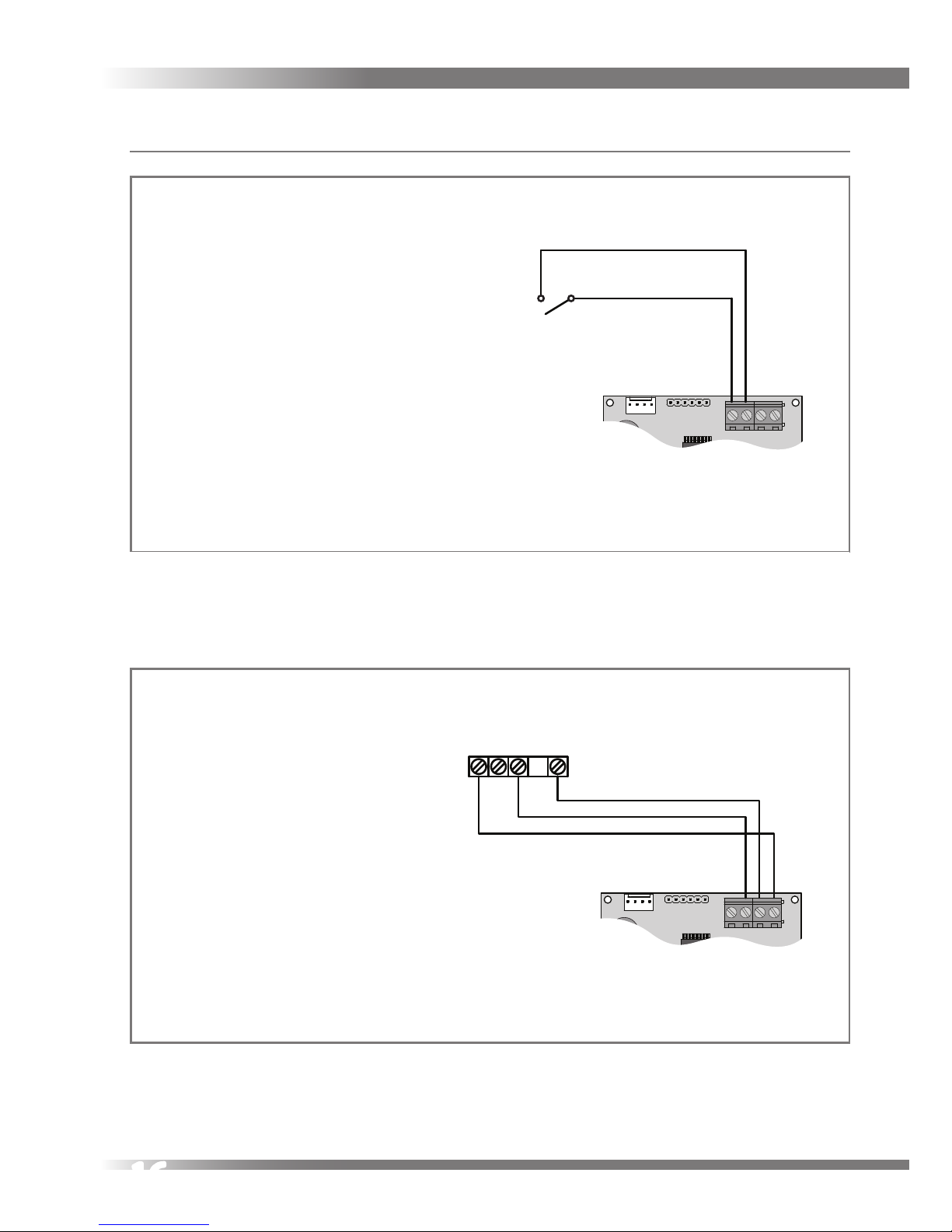

Wiring Diagrams

Double Pole Isolator 3A Fuse

L

N

L

N

Supply Wiring Diagram 230V~50/60Hz EE 141

Volt-free boost switching of unit’s

controller PCB using single-pole

switches TP 502, TP 503, TP 507

and/or TP500 / TP501 Humidistat.

There is no limit to the number of

single pole switches or

humidistats that can used.

TP500 / TP501

1 2 3

Boost switching and External Humidistat connection ref EE 151

16

Wiring Diagrams

Volt-free setback switching of the unit’s

controller PCB using single-pole

latching switch and / or volt-free

normally open relay contacts.

To avoid the unit being inadvertently

left in Setback Mode, it is recommended that only one latching switch

is tted.

Volt-free setback switch or

normally open relay contacts

Setback Switch connection ref EE 152

Three position Rotary Switch TP 508 switching and connection ref EE 153

SWITCH POSITIONS

1 - Setback Speed

2 - Continous Speed

3 - Boost Speed

LU1U2U3

TP 508

Three position rotary switch

17

Commissioning

TP300A & 301A

The fan speeds of the Titon CME1 Q Plus will require adjustment to ensure that the

ow rates achieved provide adequate ventilation. The Titon CME1 Q Plus has 3

standard fan speed settings, Continuous Speed, Boost Speed and Setback Speed.

The Continuous Speed and Boost Speeds are adjustable via Rotary Potentiometers.

Setback Speed is automatically set at the mid point between minimum possible

Continuous Speed and the selected Continuous Speed.

Prior to the rst commission, set the Continuous Speed potentiometer to minimum

by rotating fully anti-clockwise and set the Boost Speed potentiometer to maximum

by rotating fully clockwise.

Control Parameters

All volt-free switch inputs are disabled when the Program / Run Header Link is

in the Program position.

All speed control potentiometers are disabled when the Program / Run Header

Link is in the Run position.

The unit needs to be powered up for the commissioning settings to be stored.

Continuous Speed

Boost Speed

Boost Overrun Timer

Program / Run Header Link

Continuous Speed

Boost Speed

Boost Overrun Timer

Control Identication

18

Commissioning

1. Remove Program / Run Header Link

and place in the Program Position,

tted over both pins. The CME1

Q Plus will automatically switch

between Continuous Speed and

Boost Speed when adjusting the

respective potentiometer.

2. Rotate Continuous Speed

adjustment potentiometer to

achieve required continuous air

ow.

3. Rotate Boost Speed adjustment

potentiometer to achieve required

boost air ow.

4. Return Program / Run Header Link

to Run Position, tted to one pin, to

exit commissioning.

After commissioning the Program / Run

Header Link must be placed in the

Run position.

Alternatively the Program / Run Header

Link can be completely removed to

‘lock’ the commissioned settings.

Header Link in Program position

Header Link in Run positions

Run

Continuous

Boost

Boost Overrun Timer

Extract

Supply

1

2

3

4

5

6

7

8

Commissioning Pot positions

19

Boost Overrun

Boost Overrun Timer is variable between

0 and 30 minutes. Rotate potentiometer

to change overrun time. Boost Overrun

Timer adjustment can be done at any

time without the need to move the

Program / Run Header Link.

Controller Reset

Following a controller reset the ventilation system will need to be fully recommissioned. The unit will need to be powered up during the reset procedure.

1. Place the Program / Run Header Link in the Run Position

2. Rotate the Continuous Speed and Boost Speed adjustment fully clockwise.

3. Place Program / Run Header Link in the Program Position.

4. Rotate the Continuous Speed adjustment potentiometer fully anti clockwise.

Hardware Reset

Certain conditions (repeated supply interruptions etc.) can activate the automatic

motor protection mode. Where by the fan motors are prevented from operating.

This requires a hardware reset to return the unit to normal operating mode, to

achieve this power to the unit should be switched o for 5 minutes, restoring

the power after this time will reset the hardware of both the motor and PCB.

Commissioning settings are not aected during a hardware reset.

Boost Overrun Pot positions

Boost

Overrun

Timer

Program

Switch

Run

Continuous

Boost

Boost Overrun Timer

Extract

Supply

Potentiometers

ExtractSupply

BoostCont

1

2

3

4

5

6

7

8

0

30

15

20

TP300HA & TP301HA

The fan speeds of the Titon CME1 Q Plus will require adjustment to ensure that the

ow rates achieved provide adequate ventilation. The Titon CME1 Q Plus has 3

standard fan speed settings, Continuous Speed, Boost Speed and Setback Speed.

All speeds are adjustable via Rotary Potentiometers.

Control Parameters

All volt-free switch inputs are disabled when the Program / Run Header Link is

in the Program position.

All speed control potentiometers are disabled when the Program / Run Header

Link is in the Run position.

Boost Overrun Timer & Humidity Sensor adjustment can be done at any time

without the need to move the Program / Run Header Link

The unit needs to be powered up for the commissioning settings to be stored.

Program / Run

Header Link

Continuous Speed

Boost Speed

Humidity Sensor

Boost Overrun Timer

Setback Speed

21

Commissioning

1. Remove Program / Run Header

Link and place in the Program

Position, tted over both pins. The

CME1 Q Plus will automatically

switch between Setback Speed,

Continuous Speed and Boost Speed

when adjusting the respective

potentiometer.

2. Rotate the Speed adjustment

potentiometer to achieve required

air ow for each speed.

3. Return Program / Run Header Link

to Run Position, tted to one pin, to

exit commissioning.

After commissioning the Program / Run

Header Link must be placed in the

Run position.

Alternatively the Program / Run Header

Link can be completely removed to

‘lock’ the commissioned settings.

Header Link in Program position

Header Link in Run position

Continuous Speed

Boost Speed

Humidity Sensor

Boost Overrun Timer

Setback Speed

1

2

3

4

5

6

7

8

Commissioning Pot positions

22

Boost Overrun

Boost Overrun is variable between

0 and 30 minutes. Rotate potentiometer

to change overrun time. Boost Overrun

adjustment can be done at any time

without the need to move the Program /

Run Header Link.

Humidity Sensor

The Humidity Sensor’s trigger point is

variable from 55%RH to 85%RH. Rotate

potentiometer to change trigger point.

Humidity Sensor adjustment can be

done at any time without the need to

move the Program / Run Header Link.

Boost Overrun Pot positions

Program / Run

Header Link

1

2

3

4

0

30

15

55% 85%

70%

Humidity Sensor Pot positions

Program / Run

Header Link

1

2

3

4

5

6

7

8

55% 85%

70%

23

Controller Reset

Following a controller reset the ventilation system will need to be fully recommissioned. The unit will need to be powered up during the reset procedure.

1. Place the Program / Run Header Link in the Run Position

2. Rotate the Setback, Continuous and Boost Speed adjustment potentiometers

fully clockwise.

3. Place Program / Run Header Link in the Program Position.

4. Rotate the Setback Speed potentiometer fully anti clockwise and the

Continuous Speed adjustment potentiometer to the mid position.

Hardware Reset

Certain conditions (repeated supply interruptions etc.) can activate the automatic

motor protection mode. Where by the fan motors are prevented from operating.

This requires a hardware reset to return the unit to normal operating mode, to

achieve this power to the unit should be switched o for 5 minutes, restoring

the power after this time will reset the hardware of both the motor and PCB.

Commissioning settings are not aected during a hardware reset.

24

Maintenance

Routine maintenance

All ventilation units require periodic maintenance. Routine maintenance must

only be carried out by a suitably qualied and competent person. The CME1 Q Plus

must be periodically cleaned internally. The maximum time between cleaning will

depend on the local environment. Titon recommend the unit be cleaned every

3 – 4 years at a minimum.

In the event of any queries please contact the system installer.

WARNING: The unit uses a 230V ~ supply and contains rotating mechanical

parts. ISOLATE the unit from mains power supply and allow sucient time for

all moving parts to stop before undergoing any Servicing or Maintenance.

Cleaning Exterior

For best results use a clean cloth and warm water with a mild detergent solution.

Do not use solvents or abrasive cleaners.

Cleaning Interior

For best results use a clean damp cloth and mild detergent. Do not use solvents or

abrasive cleaners. When cleaning the interior ensure that the humidity sensor does

not get wet, dust with a dry cloth.

Humidity Sensor

25

Access to the Interior for Cleaning

To gain access to the interior of the unit

for cleaning –

1. Unscrew the 3 retaining screws that

hold on the Cover and remove

2. Remove the 4 Scroll retaining

screws.

3. Using a at bladed screw driver,

un-clip Scroll from Inlet Ring by

disengaging the 3 retaining clips.

Ensure that the Scroll is supported

and does not strain the cables.

26

4. Remove the 3 retaining screws

5. Using a at bladed screwdriver,

un-clip the Inlet Ring from Base by

disengaging the 4 retaining clips.

6. Carefully remove dust from the

unit and fan blades using a vacuum

cleaner.

7. Wipe with damp cloth and mild

detergent.

8. Check xing screws.

9. Assembly is the reverse of the

preceding instructions.

10. Ensure all fasteners are secure

before returning power to the unit.

Tighten screws by hand, DO NOT over

tighten screws or use power tools.

After servicing, always complete the

service record.

2

1

4

3

1

2

Positions of Clips

27

Service Record

Serviced by Company Name Date Notes

DO 5177 iss01 Feb 2013

MARKETING DIVISION

International House, Peartree Road , Stanway, Colchester, Essex CO3 0JL

Tel : +44 (0) 1206 713800 Fax : +44 (0) 1206 543126

Email : ventsales@titon.co.uk Web : www.titon.com

©2013 TITON

In the event of any queries please contact the system installer. Ensure this

booklet is passed to the householder once installation and commissioning of

the ventilation system is complete. This Product Manual must be kept in the

Home Information Pack and used as a Service Record.

Installed by

Loading...

Loading...