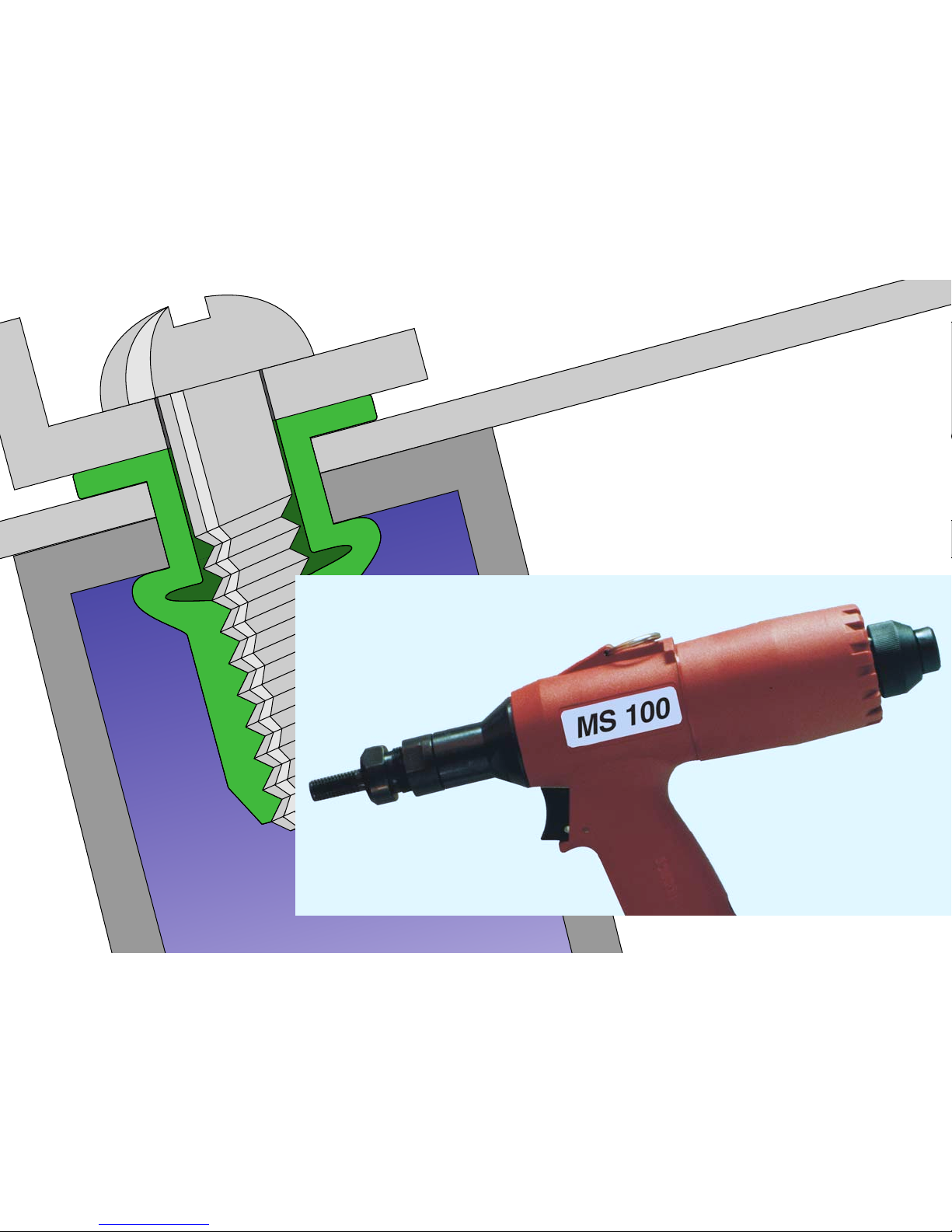

Titgemeyer MS 100 Operating Manual

L

Fastening Technology

Riveting Tool

MS 100

Operating Manual

2

Table of contents

Guiding instructions........................................................... 4

Cautions and instructions in the operating manual .............. 5

Markings on the riveting tool ................................................ 6

Safety instructions ............................................................. 7

Basic requirements while dealing with the riveting tool ....... 8

Noise and vibration levels of the MS 100............................. 10

Description of the riveting tool ......................................... 11

Required tools..................................................................... 13

Storing the riveting tool ..................................................... 14

Preparing the riveting tool................................................. 15

Adjusting the riveting tool ................................................. 17

Replace mandrel................................................................... 17

Adjusting stroke (H) .............................................................. 19

Measuring stroke (H) ............................................................ 21

Adjusting length L of the mandrel......................................... 22

Table stroke adjustment dependent on the grip range......... 23

3

Operating the riveting tool................................................. 25

Check function...................................................................... 25

Setting blind rivet nut............................................................ 26

Trigger left-handed rotation manually................................... 28

Maintaining the riveting tool.............................................. 29

Bleeding the hydraulic section.............................................. 29

Refilling hydraulic oil............................................................. 31

Table for torque values ......................................................... 33

Servicing and cleaning the riveting tool .......................... 34

Maintenance intervals ........................................................ 35

Trouble shooting ................................................................. 36

Disposal of the riveting tool .............................................. 39

Technical data ..................................................................... 39

Guarantee ............................................................................ 40

List of parts ......................................................................... 41

Declaration of conformity .................................................. 43

4

Guiding instructions

The legislator prescribes that the user must be well trained for using compressor-driven riveting tools. If desired, the training programme can be

conducted at TITGEMEYER in Osnabrück or directly at the client's place.

This riveting tool is as per the latest technological standards.

Professional and safety conscious operation is a must for the riveting tool

to function safely.

Before using the riveting tool for the first time, read the guiding instructions carefully.

All the procedures necessary for the operation have been described in

these guiding instructions. You may carry out only those procedures,

which have been described here.

In case of obstructions, you may repair only those obstructions, which

have been marked with an O (Operator).

All the illustrations and position-codes in the individual diagrams take

reference from the list of parts in the last pages.

You find a table with the torque values for all screw and thread sizes on

Page 33.

Instruction

Technological level

Reading the guiding instructions

Procedures

Obstructions

Illustrations and position-codes

Table for torque values

5

Guiding instructions

H

E

Cautions and instructions in the operating manual

Please follow the instructions and safety informations.

In this operating manual, some sections have been further illustrated

through diagrams.

Please acquaint yourself well with these diagrams and their meanings:

Caution Hazard of injury! This marking indicates a potential hazard.

Attention Material damage! This marking points at a procedure, which

may cause damage to the riveting tool or the work-piece.

Note This marking indicates useful information

•This point (•) marks every paragraph, which requires you to act by

yourself.

Attention Environmental hazard! This marking indicates a potential

environmental hazard.

Environmental

hazard

6

Guiding instructions

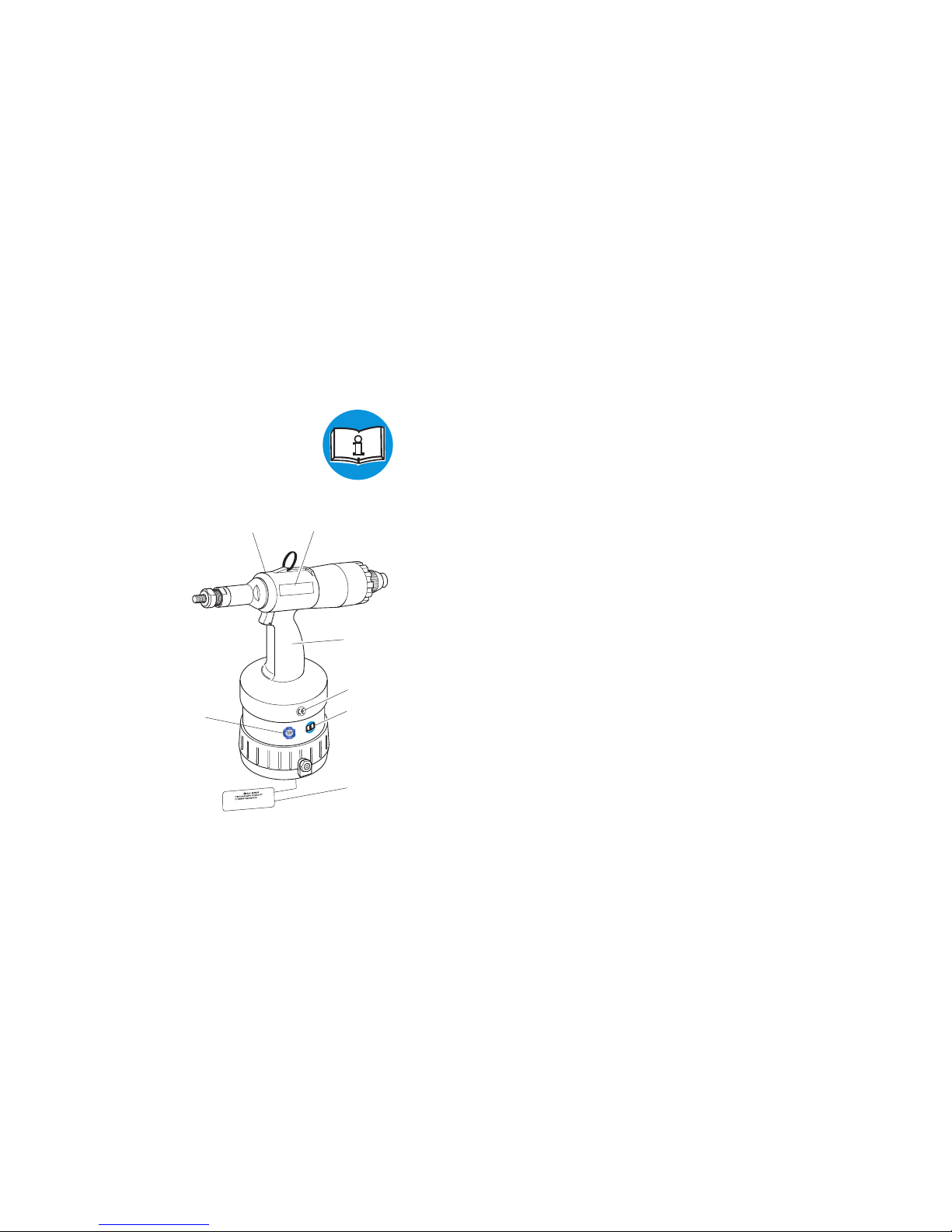

Markings on the riveting tool

This pictogram indicates that you must read the operating manual before

using the riveting tool.

A Marking of the type

B Serial number

C CE-marking

D Instruction for reading the operating manual

E TÜV-Mark (safety checked)

F Name of the manufacturer as well as the value of the maximum

operating pressure

G Supplier

1550355

F

E

C

B

A

G

D

p=

7b

ar

M

S

G

er

MS 100

P

R

O

D

U

C

T

S

E

R

V

I

C

E

Safety instructions

The riveting too has solely been foreseen for the insertion of blind rivet

studs. The riveting tool MS 100 is designed to process blind rivet nuts of

the sizes M8 to M16. If desired, the mandrels can also be supplied with

other thread sizes, e.g. UNC/ UNF.

This riveting tool must be used only as a hand-held device!

The client is fully responsible for any modifications to the riveting tool!

Never throw away or drop the riveting tool!

Please take care that only clean and dry compressed air is let into the

riveting tool. Moisture and dirt can damage the riveting tool. Use only such

compressed air, which falls into class 2 of air quality as per ISO 8573-1.

Caution Hazard of injury because of explosion! Never use the riveting

tool in an atmosphere prone to explosions. Ensure that the

workplace is well lit and clean.

Hazard of injury due to the openly moving compressed air

hose. Connect and lay the compressed air hose properly.

Hazard of injury due to tripping over! Lay the compressed air

hose in such a way that nobody should trip over it.

Attention Material damage! The maximum operating pressure is 7 bar.

For increasing the durability of the riveting tool, it is recommended to fit a compressed air-maintenance unit in the compressed

air hose.

Application as per the purpose

Improper use

Clean and dry compressed air

H

E

7

8

Safety instructions

Basic requirements while dealing with the riveting tool

Caution Follow the prevalent guidelines for the prevention of accidents

in the respective country.

Use only those fittings and hoses, which have been approved

for the operating pressure.

Disconnect the compressed air supply from the riveting tool at

the time of installation or maintenance.

Wear personal safety gear (safety glasses and safety helmet).

Attention Heed the details on the blind rivet nut packaging.

Use the riveting tool only at operating temperatures above 5°C

and 45°C.

Use the prescribed mandrels and nose pieces for each thread

size.

Do not throw away the riveting tool.

H

E

9

Safety instructions

The operator may only carry out the maintenance and repair work described in this operating manual

Maintenance and service work not described in this operating manual

may only be carried out by trained specialists following instruction by

TITGEMEYER on the basis of the service instructions which also exist.

See the address on page 42 for more information on service instructions

and training.

Note The manufacturer accepts no liability for damage resulting from

incorrect repairs or the use of spare parts from other sources

At the time of leaving the workplace, do not leave the riveting tool with

pressure on.

A guarantee is void, if any repair work carried out on the riveting tool has

lead to any damage of the riveting tool.

The riveting tool MS 100 has been checked and manufactured according

to European guidelines. The declaration of conformity can be found on the

second last page.

The riveting tool was additionally tested by TÜV Product Service GmbH

Hanover and certified (TÜV/ Technical Control Board mark) and issued

with the GS sign.

Maintenance and servicing

Service instructions

Guarantee

Declaration of conformity

GS-checked

10

Safety instructions

Noise and vibration levels of the MS 100

The emission sound pressure level at a workplace is L

PAI

= 86dB(A)

according to ISO 10843 and DIN EN ISO 3744.

The main noise is generated by the air motor. Through correct use, the air

motor can be switched off between times, and therefore the noise level

can be lastingly reduced.

Note For safety reasons, however, we recommend the wearing of

ear protection

The effective value measured on acceleration with the handle, as per

ISO/ FDIS 8662-11, is a

hw

<2.5m/s2.

Noise level

Vibration level

11

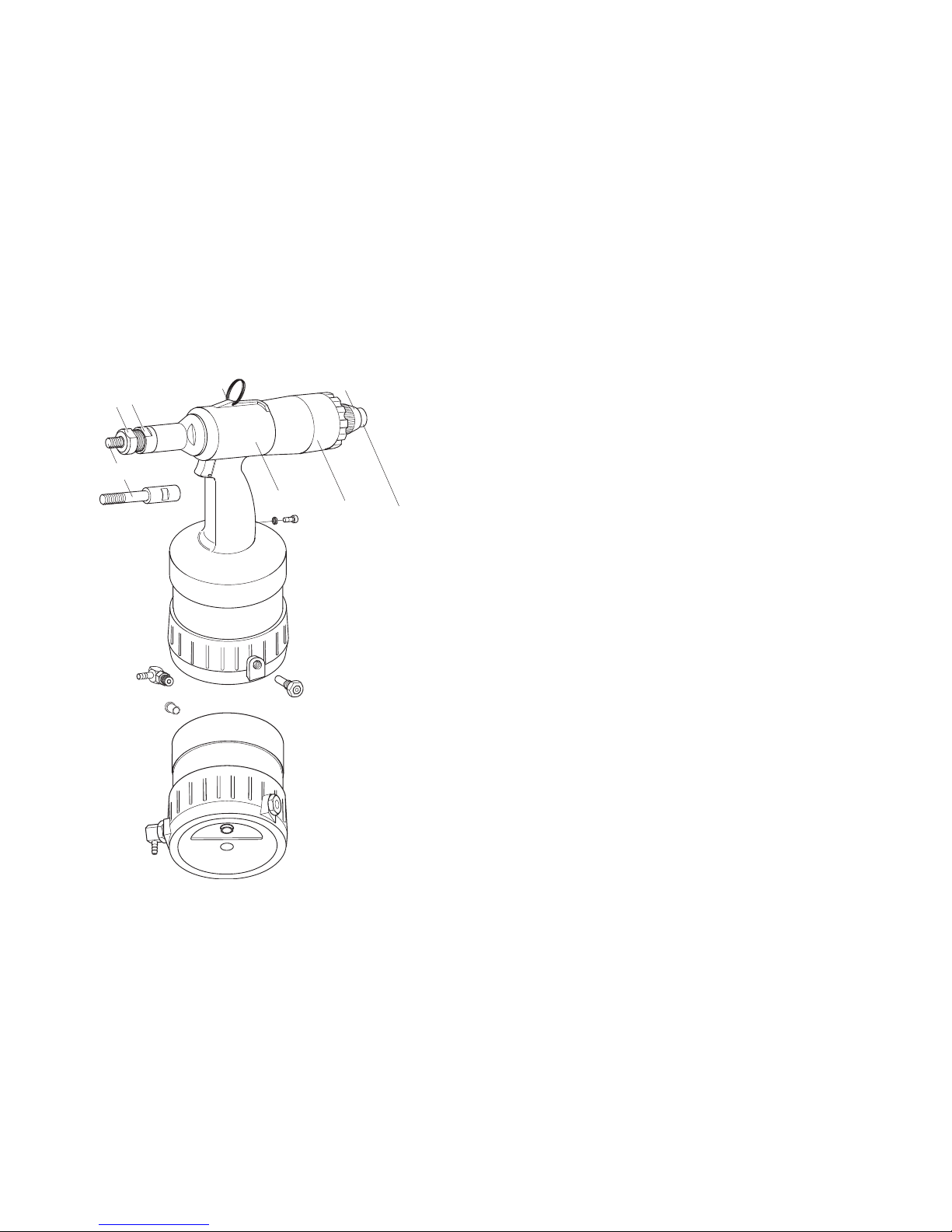

Description of the riveting tool

The riveting tool MS 100 is pneumatically - hydraulically actuated and has

an air motor.

It consists of the following operation-related components:

1 Nose piece for threads M8, M10, M12 and M16

2 Lock nut for fixing the nose pieces

3 Mandrel for threads M8, M10, M12 and M16 of

blind rivet nuts

4 Hang-up eyelet for hanging up on a hook whenever

stationary

5 Hydraulic the pneumatic and the hydraulic

housing units are located in the hydraulic housing

6 End cap is a complete unit enabling the switching of

the rotation of the air motor to left-handed

rotation

6.1 Adjustment screw is used for adjusting the end stop for the

automatic switching to the left-handed rotation

6.2 Button manually release the left-handed rotation

1

2

3

4

5

6

6.1

6.2

12

Description of the riveting tool

Note The socket head screw (7) and the O-ring (8) are screwed tightly

into the grip. The socket head screw (7) must not be loosened,

else the hydraulic oil will leak.

7 Socket locking for the hydraulic oil system

head screw Opening serves as an oil inlet

8 O-Ring Sealing of the hydraulic oil system

9 Safety valve (Brass) In case of very high pressures

approx. 8 bar or more), it opens, and lets the

air out.

10 Plug serves the purpose of protection of the

thread and also against dirt

11 Swivel- serves as the connection for compressed air

joint hoses (operating pressure 6 bar)

12 Trigger — starts right-handed rotation

— triggers a riveting action

— stops left-handed rotation

13 Nose cap covered mandrel

15 Stroke is used to adjust the stroke

adjustment screw

7 Socket head closes the opening to pull back the

screw in device pneumatic rod

floor

7

8

12

13

9

10

11

15

7

13

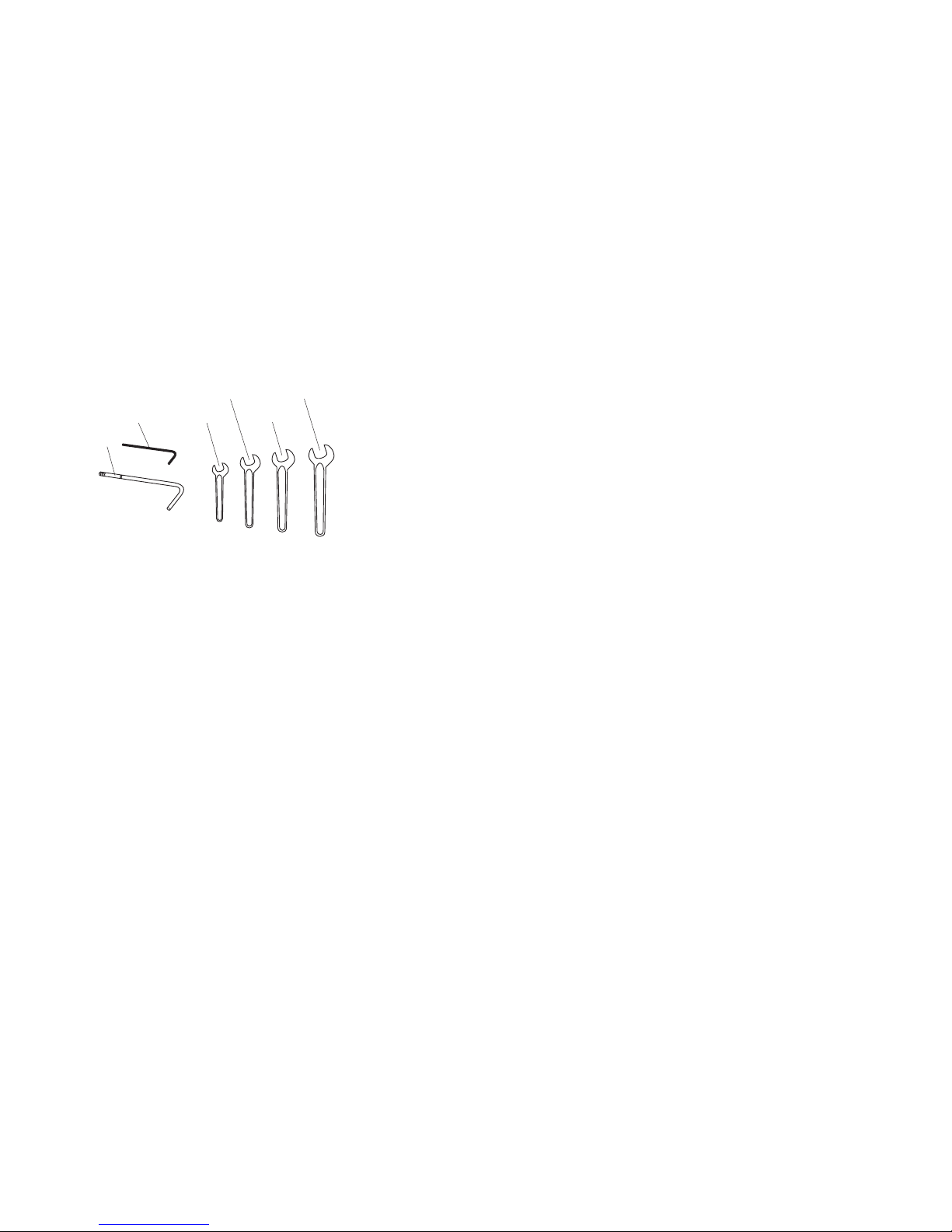

Required tools

You will require the following tools for all installation, servicing and maintenance work.

Tools

— Crank (18)

— Wrench

1

SW13, SW17, SW27, SW30

— Internal hex key (19) SW4

1

No delivery possibility

SW13

SW17 SW30

19 SW27

18

14

Storing the riveting tool

Until first use

If you do not use the riveting tool immediately, store it inside the original

packing, dry and dust-free.

Long term storage after usage

Clean nose piece (1), lock nut (2), mandrel (3) and lubricate with acid-free

grease. Screw out the swivel joint (11) and close the opening with a

plug (10). If possible, store all pieces in the original packing.

After long-term storage

After long-term storage (about 3 years), change the hydraulic oil before

re-use.

A hydraulic oil change may only be carried out by trained specialist with

the help of the service instructions. For further information regarding

service instructions and training, please see the address on page 42.

10

11

1

2

3

Loading...

Loading...