Page 1

Operating and Maintenance Instructions

B 13 GB 11/13

VS-32-L

13 0003

Pneumatic

Strapping head

for steel strap

Seal

Important!

Do not throw these instructions away.

The customer agrees to make these

operating instructions understandable

to all operating and service personnel.

Page 2

B 13 GB 07/10

Table of contents

Page

1. Manufacturer details ....................................................................................................................3

2. General ..........................................................................................................................................4

3. Safety regulation ..........................................................................................................................7

4. Life phases of the unit .................................................................................................................9

5. Technical data ........................................................................................................................... 11

5.1. Technical data of the welding unit ..................................................................................... 12

5.2. Finding the time required for a strapping operation .......................................................... 13

5.3. Smallest support with different packing items ................................................................... 14

5.4. Measurements and assembly dimensions VS-32-L ......................................................... 15

5.5. Pneumatic plan equipment (head control system) ............................................................ 16

5.6. Functional time diagram .................................................................................................... 17

5.7. Arrangement and designations ......................................................................................... 18

6. Designations .............................................................................................................................. 19

6.1. Switches and motors ......................................................................................................... 19

6.2. Switches ............................................................................................................................ 21

6.3. Positions of the switches, valves, pressure controllers and motors ................................. 22

7. Functional description .............................................................................................................. 23

7.1. Process description ........................................................................................................... 23

7.1.1. Insertion of strap ..................................................................................................... 23

7.1.2. Feed of strap, medium speed ................................................................................. 23

7.1.3. Strap feed, precise movement ................................................................................ 24

7.1.4. Closing strap gripper 1 ............................................................................................ 24

7.1.5. Transport back of strap ........................................................................................... 24

7.1.6. Tensioning the strap ............................................................................................... 24

7.1.7. Closing strap gripper 2 ............................................................................................ 25

7.1.8. Welding ................................................................................................................... 25

7.1.9. Swivelling the welding station open ........................................................................ 25

7.1.10. Swivelling the welding station back ........................................................................ 25

7.2. Positions on the cam gear ................................................................................................ 26

7.3. Description of the welding operation ................................................................................. 27

8. Adjustments ............................................................................................................................... 28

8.1. Setting switches B1 to B8 ................................................................................................. 28

8.2. Setting the zero position ................................................................................................... 30

8.3. Setting the clamping and opening positions ..................................................................... 30

8.4. Setting the air pressure ..................................................................................................... 31

8.5. Setting the quantity of gas ................................................................................................ 33

8.6. Setting the distance between electrodes .......................................................................... 34

8.7. Setting the torch ................................................................................................................ 35

8.8. Setting the welding parameters ........................................................................................ 36

9. Maintenance ............................................................................................................................... 37

9.1. General ............................................................................................................................. 37

9.2. Maintenance intervals ....................................................................................................... 38

9.3. Check seal ........................................................................................................................ 38

9.4. Lubricating points .............................................................................................................. 39

9.5. Maintenance of the transport unit ..................................................................................... 40

9.6. Maintenance of the clamp guide ....................................................................................... 42

9.7. Maintenance of the cutter ................................................................................................. 44

9.8. Dismounting the torch, replacement of electrode ............................................................. 45

9.9. Dismounting and mounting the clamp............................................................................... 46

9.10. Dismounting and mounting the torch holder ..................................................................... 47

10. Fault detection - remedy ........................................................................................................... 48

11. Declaration of incorporation .................................................................................................... 50

VS-32-L 2

Page 3

B 13 GB 07/10

1. Manufacturer details

TITAN Umreifungstechnik GmbH & Co. KG

Berliner Straße 51 – 55

58332 Schwelm

Deutschland

Tel.: +49 (2336) 808-0

Fax: +49 (2336) 808-208

E-Mail: info@titan-schwelm.de

Web: www.titan-schwelm.de

VS-32-L 3

Page 4

B 13 GB 33/06

2. General

Thank you very much for your confidence in the technology of TITAN

Umreifungstechnik GmbH & Co. KG!

These operating and maintenance instructions are meant to facilitate how to become

acquainted with the strapping machine and apply it as intended. The operating instructions

comprise important information on how the strapping machine can be used safely, as

intended und economically.

The operating instructions must permanently be available at the place the strapping head is

used. They must be read and applied by all staff members working with the strapping head.

Such works especially include operation, troubleshooting and maintenance.

Adjustment and maintenance works may only be performed

by trained technical staff.

Notes on the warning and information symbols:

Caution!

Is used in case of risks threatening life and health.

Attention!

Is used in case of risks which may cause damage to objects.

Note!

Is used for general notes and such notes whose disregard may result

in faults in the course of operations.

The item numbers (…) and designations used in these operating instructions refer to the

spare parts list or documentation on the electrical system.

Copyright © TITAN Umreifungstechnik GmbH & Co.KG 2011 All rights reserved.

The contents of this document must not be duplicated, handed to third parties, published or saved in any form,

neither fully nor partly, without prior written permission by TITAN Umreifungstechnik GmbH & Co.KG.

is a registered trademark of TITAN Umreifungstechnik GmbH & Co.KG.

VS-32-L 4

Page 5

B 13 GB 33/06

The intended use of this strapping head is the bundling, combining and securing of

packing items in strapping machines.

Unintended use!

Strapping material must not be used for the hoisting of loads, this strapping head

may only be used as intended and specified above.

The strapping head VS-32-L meets German and European safety requirements and

complies with the provisions in the following EU directives:

See Declaration of incorporation!

The VS-32-L is the suitable strapping head for medium and heavy packing items;

it does not matter whether those items are steel or stone, wood or glass.

The VS-32-L combines most modern driving and control technology with the state of

the art of patented TIG shield gas welding technology.

All functions are released by solenoid valves. Valves are equipped with actuating

magnets 24 V DC (direct current voltage).

The mains voltage of the VS-32-L head is 400 V 50/60 Hz. The connected load of the

welding unit is 6,6 kVA. Protect by fuse 16 A (slow-blow).

The welding seal can only be opened by means of an appropriate tool (strap scissors or

the like). Sealing strength is at approx. 90 % of the load at rupture of the strap

(depending on strap quality and dimension).

Adjustable strap tension of 4000-20000 N permits a good adaptation of the strapping to

the packing item.

The strapping head can be supplied in the following designs: for strap widths of 19, 25

and 32 mm.

Power and compressed air feed lines have one detachable quick-acting coupling each.

The mechanical joint of the strapping head and the machine is possible at various fitting

surfaces by means of four M16 bolts at the bottom of the drive housing and two of them

at the top. If required, two further M12 bolts on the fitting surface of the holding device

on the right. After the loosening of the four screws and the disconnection of the electric

power and compressed air ports the head can be replaced quickly and without

problems.

VS-32-L 5

Page 6

B 13 GB 07/10

Three compressed air motors and two compressed air cylinder perform all functions of

the strapping head.

Just compressed air being dewatered, filtered and oiled is used. Air pressure

(flow pressure with transport motor being switched on) should be 6 bar. The port cross

section of the feed line must be G 3/4“ or greater.

Air consumption per strapping operation with conduit dimensions amounting to 2000 x

1000 mm is 0,2 to 0,3 m³. Consumption during the transport of strap is

1,25 m³/min. The short-time peak consumption is at 2,5 m³/min.

The argon/welding gas consumption amounts to 2 l per seal. When a 50 l gas bottle

with a filling pressure of 200 bar is used, approx. 5000 seals are possible, in case of

300 bar approx. 7500 seals. The welding electrode can be ground approx. 100 times.

VS-32-L 6

Page 7

B 13 GB 07/10

3. Safety regulation

Read the operating and maintenance instructions before the use of

the strapping machine.

Read instructions carefully.

Unauthorized individuals are not allowed to use the strapping unit

(machine)

It is urgently required that all safety and warning notes are

followed; we especially refer to the EU Machine Directive.

Before the strapping tool is put in operation, the machine area

must be locked such (protective fences / safety sensors) that

unauthorised individuals cannot get into the danger zone of the

machine.

The operating staff must be instructed precisely and made familiar

with the handling of the unit before operating the unit for the first

time.

The strapping machine may only be positioned and put in

operation in closed and dry rooms.

Operating the machine is appropriate in the temperature range +0

°C to +40 °C.

Do not deposit containers with liquids on the strapping tool or

strapping unit. No liquid must be allowed to penetrate the strapping

tool / strapping unit.

No persons or objects must stay in the area of operation of the unit

(machine) before the latter is put in operation.

Protective installations, covers and linings of the unit (machine)

must be checked before activation. They must neither be loose nor

have been removed.

Do not let your hands get into the channel area and below the

packing items during the strapping operation. Attention! Risk of

squeezing!

VS-32-L 7

Page 8

B 13 GB 07/10

Before the beginning of cleaning works and / or troubleshooting the

strapping head must be put out of operation. Main switch at

position OFF.

Attention! Strap may tear! Do not stand in the alignment of the

strap.

Wear eye and face and hand protection when eliminating fault

strappings

When cutting the strap hold the upper parts firmly

(see figure).

Attention! The lower part of the strap jumps upward.

Consider the strong development of noise during longer

operations. Therefore, protect your health.

Exclusively use original TITAN spare parts! The use of spare

parts not made by TITAN excludes guarantee adjustments and

liability.

In automatic mode attention has to be paid that no squeezing

points may occur between the feeding installations (e.g. roller

conveyors) and the movable strapping unit.

We do not accept liability for alterations to the strapping

machine! Further, warranty/guarantee and these operating

instructions become inapplicable.

For safety regulations applying to

the TIG Inverter shield gas

welding unit see operating

instructions attached. TITANARG

L 250 TI

VS-32-L 8

Page 9

B 13 GB 07/10

4. Life phases of the unit

Transport:

Attention! Do not stay beneath the load during lifting and

depositing. Order individuals standing in the hazardous area to

leave it. Minimum carrying capacity see technical data on page 11.

Putting the unit in operation:

The strapping machine may be put in operation by trained

technical staff only.

Setting, programming:

Setting and programming works related to the strapping unit may

only be performed by trained technical staff.

Operation, modes:

Manual mode:

Manual mode permits the implementation of individual works performed for testing and

troubleshooting. Further, manual mode is applied to take the strapping unit to home position.

Attention! During the touch control of the cam gear there is a risk

of squeezing at the strap guides and the counter plate.

Automatic mode:

Automatic processing of all movements.

In automatic mode attention must be paid that no points with the

risk of squeezing may occur between the feed installations (e.g.

roller conveyors) and the movable strapping unit.

VS-32-L 9

Page 10

B 13 GB 07/10

Cleaning, maintenance, repairs:

Just trained technical staff is allowed to perform maintenance and

repair works on the strapping unit.

Attention! Before beginning with any maintenance work the

relevant staff must disconnect the strapping unit from the power

mains.

Attention! Wear protective glasses when cleaning the unit /

machine with compressed air.

Putting the unit out of operation, disassembly

Attention! When dismounting the strapping machine there is the

risk of squeezing.

Attention! Do not stay beneath the load during lifting and

depositing. Order individuals standing in the hazardous area to

leave it. Minimum carrying capacity see technical data on page 11.

Waste disposal

If packing material is to be disposed of, take it to the relevant

recycling container or admit it to the Dual System.

Should the strapping machine have to be disposed of at the end of its service life, separate

plastic material, steel and aluminium and dispose of such materials separately. In the same

way, motors and electric modules like control system, switches and cables must be admitted

to separate waste disposal. Take such elements to the appropriate waste management.

VS-32-L 10

Page 11

B 13 GB 33/06

5. Technical data

Kind of drive: electro pneumatic, 3 motors and 2 cylinder

Strap conveying speed: 1,7 m/s

Connected load of the

welding unit: 6,6 kVA

Packing steel strap:

- widths: 19, 25, 32 mm

- thicknesses: 0,8-1,0 mm, Megaband to 0,8 mm

Kind of seal: TIG welding seal

Load at rupture of seal: approx. 80-90 % of the load at rupture of

seal (depends of quality, thickness and

surface of strap)

Electrode Ø: d = 2,4 mm ; l = 175 mm ; WS 2 turquoise

Welding gas: welding argon gas 4.6 (Ar. 99,996)

Gas consumption: 2 litre per seal

Gas nozzle: size 6

Sound emission: the sound pressure level acc. to DIN 45635

part 27 is 85 dB (AS)

Min. packing item dimensions:

straight packing item length: min. 150 mm

round packing item Ø: min. 700 mm

Strap tensions: 4000-20000 N adjustable

Air pressure: 5-6 bar flow pressure

Air consumption: approx. 0,2-0,3 m³ per strapping operation

Weight: 200 kg

Dimensions: l 680 x w 580 x h 750 mm

VS-32-L 11

Page 12

B 13 GB 33/06

5.1. Technical data of the welding unit

Welding performance:

Adjusting range, continuous: 80 A / 13,2 V ... 200 A / 18 V

DB 100 % operation-on period: 80 A / 13,2 V

DB 60 % operation-on period: 155 A / 16,2 V

DB 50 % operation-on period: 200 A / 18,0 V

No-op voltage: approx. 15 – 90 V

Mains connection:

Mains voltage: 3 x 400 V 50 / 60 Hz

Continuous / maximum rating: 1,5 / 5,0 kVA

Continuous / maximum current: 2,2 / 7,2 A

Fuse (slow-blow): 16 A

Connecting line: 4 x 1,5 mm² Cu

Power factor cos. phi: 0,9

Dimensions:

Height

(without carrying handles): 333 mm

Width: 287 mm

Depth: 448 mm

Weight: 20,25 kg

Protection: IP 23 Cooling: AF Insulating material class: H

Details of sound emission values:

The welding current source generates a sound level of < 68 dB (A) during no-load

operations and < 68 dB (A) in case of maximum admissible working point at standard

load according to VDE 0544-1 or EN 60974-1. Sound data are measured according to

DIN 45635. Measurements are performed at a distance of 1 m away from the welding

current source.

VS-32-L 12

Page 13

[s]movementpreciseadditionTime+

[m/s]speed transportmax.

[m]lengthonduitC

s8,0+

m/s1,7

m6

( )

]s/m[speedtransport.max

[m]item packing ncecircumfere -[m] lengthconduit

( )

m/s1,7

m4 -m6

]s[momentdownlugtouedadditiontime+

[mm/s]speedensioningtmax.

[mm]engthlTensioning

s5,0+

mm/s350

mm80

B 13 GB 04/13

5.2. Finding the time required for a strapping operation

Example: Strap cross section 32 x 0,8 mm

Conduit size 1,5 x 1,5 m

Size of packing item 1,0 x 1,0 m

F1 Strap feed =

=

F2 Clamping strap = fixed time = 0,3 s

F3 Strap return =

Head forward = e.g. = 2,0 s

F4 Tensioning strap =

=

F5 Clamping, cutting = fixed time = 0,6 s

F6 Sealing = selected = 1,5 s

Switching = = 0,5 s

Ignition = = 0,2 s

Sealing = selected = 1,5 s

Cooling = selected = 1,7 s

F7 Seal, released = fixed time = 1,3 s

F8 Head backward,

retraction = selected = 1,0 s

= 4,3 s

=

= 0,7 s

= 1,2 s

Total time Σ 16,8 s

VS-32-L 13

Page 14

150

150

>15

160

For small packing units,

design R

B 13 GB 26/06

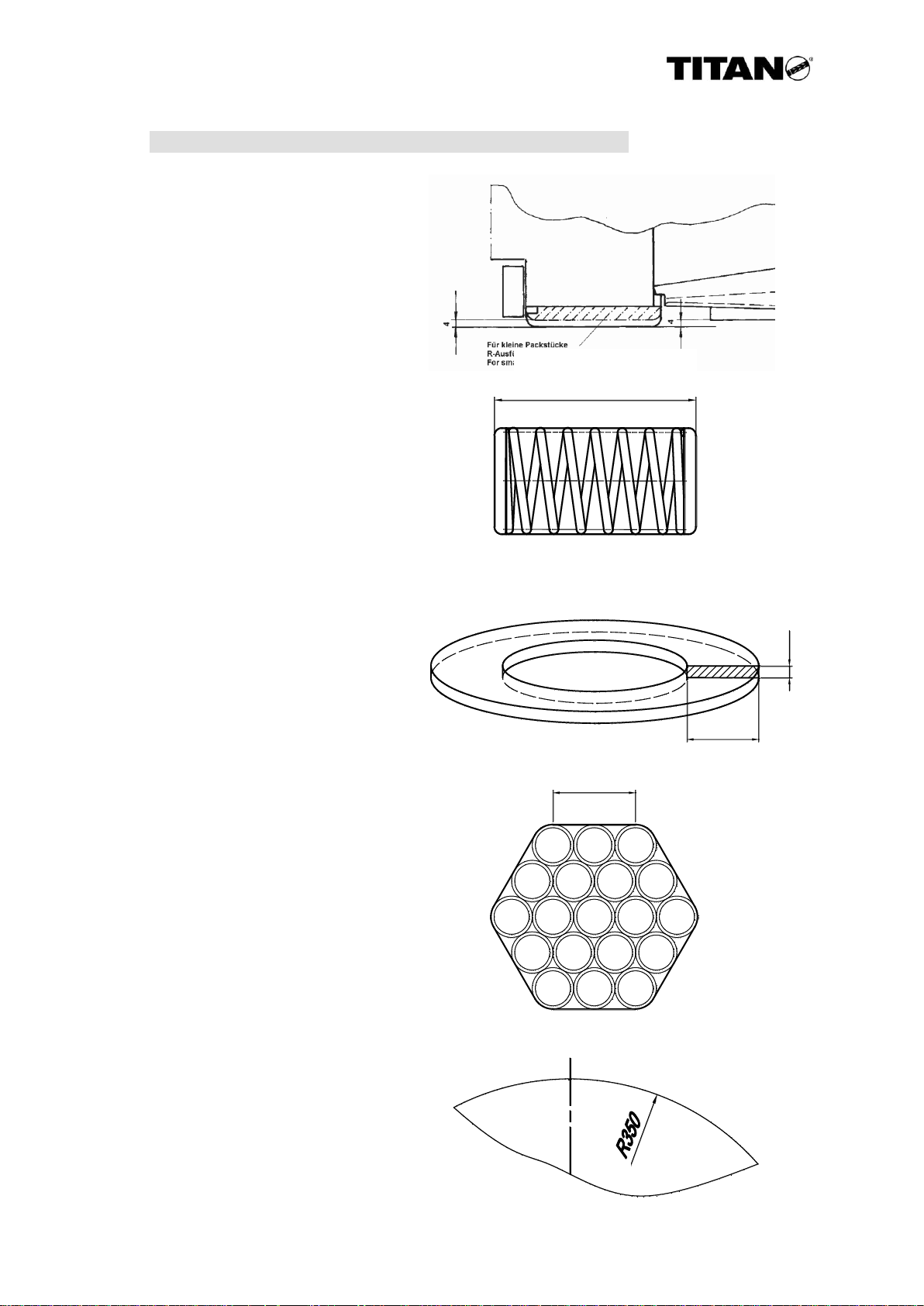

5.3. Smallest support with different packing items

VS 32-L | VS 32-R

Expansive packing item:

180 mm | 150 mm

Slit coil:

180 mm | 150 mm

Hexagon pipe bundle:

-- | 160 mm

Round packing item:

Ø 800 mm | Ø 700 mm

VS-32-L 14

Page 15

XX XXX

Free space to

swivel the welding

station open

425

310

245

80

140

55

Channel

outlet

35

Free space

for SEK 01

25

325

4

40

30

22

50

65

77

300 68

750

600

Modular dimension 680mm

160

30

Middle strap

575

38

50

110 110

5

115

140

Multi-functional

block

41

Head deactivation

Channel

intake

Multi-functional

block

405

Intake of strap

140

Free space

for assembly

counterroller

130 15

M16

20

100

80

755150

Welding

torch

M12

80

Middle seal

Gas port

Control cable

Welding current

235

M16

Welding and

electric console

SEK 01

B 13 GB 33/06

5.4. Measurements and assembly dimensions VS-32-L

VS-32-L 15

Page 16

B 13 GB 11/13

Blowing device

Welding station

throttled

A

B

Quick-acting

coupling Microspray oiler

Pos. 635

(Pos. 636)

Pos. 690 Pos. 700

2/2 distribution control valve

5/3 distribution control valve

5/2 distribution control valve

3/2 distribution control valve Machine maintanence unit

Multi-functional block

Pressurre control valve

Pos. 620,

632, 653,

680

Pos. 600

Pos. 845

Pos. 710

DR1

Pos. 569

DR2

DR3

Lift cylinder

transport slide

Pressing cylinder

tensioning rocker Transport motor

tensioning motor

Sealing motor

Z 1

Z2

M1

M2

M3

5.5. Pneumatic plan equipment (head control system)

VS-32-L 16

Page 17

t8

Y15

B15

Y1 Y2 prec.

t5

0,5 s

Commutation

rapid

B7

Y5

Y16

t3

F8

0

K

B3

0

W

B4

F

0

K

Pos.

F

Y6

precise

B1-B2

B1 - Strap stopping switch

B2 - Counter switch

B3 - Zero position

B4 - Position switch K-W-F

B7 - Head before packing item

B8 - Head on packing item

B14 - Start precise movement

B15 - Head at the rear

B16 - Head at the front

Y1 - Air valve, medium speed (adjustable)

Y2 - Air valve, fast speed

Y3 - Transport motor forward

Y4 - Transport motor backward

Y5 - Sealing motor

Y6 - Tensioning motor

Y10 - Gas valve

Y15 - Blowing device

Y16 - Tensioning rocker pressed

rapid v = 1,7 m/s

Y2, Y3

B14

Y1

mean

B3

B4

t4 min. 8 s after-flow

Y5

Pos.

F

F7

Pos.

W

W

K

F

0

B3

Pos.

0

F1

Strap feed

t5

Welding

Clamping

cutting

Tensioning

strap

Strap return

head forward

Clamping

strap

t1 - Tensioning strap OFF

t3 - Cooling time sealing

t4 - Gas after-flow

t5 - Sealing time

t6 - Welding flow

t7 - if B14 does not exist

t8 - Air-cleaning device

t9 - Overlapping of strap

t10 - Strap circulation check

prec.

precise

Y5

B4

Y4

B8

B16

Y6

Y2

B2

Gas pre-flow

Y10

rapid mean precise

Y5

B2

B4

Pos.

W

F2

Pos.

0

0

F

B4

K

K

F3

Pos.

K

F4

F5

K

Pos.

K

F

0

F6

B4

W

Pos.

W

Head

backward

swivelling in

Releasing

seal

W

B 13 GB 36/09

5.6. Functional time diagram

VS-32-L 17

Page 18

D

C

B

B 13 GB 36/09

5.7. Arrangement and designations

The strapping head comprises the following main assembly units (see fig. 1).

A: Transport and tensioning unit:

The transport and tensioning unit transports the strap.

When being returned the strap is drawn narrowly around the packing item and

tensioned according to the tensioning force preset.

B: Welding station:

The welding station (sealing unit) is a cam controlled unit. It clamps the ends of

the strap, cuts the strap and forms the seal by means of the welding torch.

C: Multi-functional block:

The multi-functional block is equipped with pneumatic control elements being

required to adjust all speeds and strap tensions on the strapping head.

D: Welding and electric console:

Device to feed the torches with welding gas and welding current; it also comprises

the electrical units for the direct gas flow and current flow control (e.g. solenoid

valve etc.), further the electrical link between the strapping head and the machine

control system.

A

Fig. 1: Main assembly units

VS-32-L 18

Page 19

B 13 GB 33/06

6. Designations

6.1. Switches and motors

Actuating magnets:

( The designations of the magnets on the valves have been taken from the pneumatic

diagram in section 5.6 and the functional time diagram in section 5.5)

Air valve, medium speed (adjustable) Y1

Air valve, fast speed Y2

Transport motor forward Y3

Transport motor backward Y4

Sealing motor Y5

Tensioning motor Y6

Transport slide Y7

Gas valve Y10

Head forward Y13 on the machine

Head backward Y14 on the machine

Blowing device Y15

Tensioning rocker pressed Y16

Control elements:

Strap stop switch B1

Counter switch B2

Zero position B3

Stop position K-W-F B4

Head before packing item B7

Head on packing item B8

Service switch strap insertion B9

Service switch seal B10

Start precise movement B14 in the conduit

Head at the rear B15 on the machine

Head at the front B16 on the machine

Accumulator full B17 on the machine

Accumulator empty B18 on the machine

End of strap B19 on the machine

Motors:

Transport motor M1

Tensioning motor M2

Sealing motor M3

Cylinder:

Lift cylinder transport slide Z1

Pressing cylinder tensioning rocker Z2

VS-32-L 19

Page 20

B 13 GB 11/13

Pressure control valves:

Main maintenance unit (fast speed) DR1

On the multi-functional block:

Pressure controller (precise motion) DR2

Pressure controller (medium speed) DR3

Time elements:

Tensioning strap OFF t1

Ignition ON t2

Cooling time t3

Further flow of gas t4

Sealing time t5

Welding flow t6

Start precise movement t7 if B14 not available

Cleaning burner cell t8

Monitoring time strap overlapping t9

Monitoring operating time:

Feed / Return / Tensioning / Welding / Seal

VS-32-L 20

Page 21

0

F

K

W

B4

B1

F

W

0

K

B3

0

F

K

W

B4

B2

B4

B2

B3

B1

B7

B8

B9 / B10

B 13 GB 33/06

6.2. Switches

B1 OFF Strap stop switch

B2 ON/OFF Counter switch

B3 OFF 0- position switch

B4 OFF Terminal switch

pos. K, W, F

B7 OFF Head before

packing item

B8 OFF Head on packing

item

B9 TOUCH- Strap insertion

CONTROL

B10 TOUCH Sealing

CONTROL

Switch functions:

B1: Precise movement for strap overlapping has been started. Counter switch B2

and safety timer t9 are activated.

B2: Identifies stop of strap and switches off precise movement after strap

overlapping has been effected. It also switches from transport back to

tensioning and from tensioning to sealing.

B3: Monitors the zero position (start position) of the cam gear.

B4: Stops the cam gear at the relevant positions. K (clamping), W (welding) and F

(releasing).

B7: Signals head before packing item. Switches machine movement “Head forward”

to precise movement and – after release of seal – activates the precise

movement at the cam gear for movement to 0-position.

B8: Signals head on packing item. Starts the fast transport back or strap tensioning.

B9: Lifts the transport rocker during insertion of strap.

B10: Actuates the welding station (sealing motor). Cam gear positions can be

approached individually.

VS-32-L 21

Page 22

Y10

B9

B10

B3/B4

B1

B7

Y1

Y16

DR2

Y7

M3

DR3

Y6

Y5

Z2

Y15

B8

Z1

Y2

M2

B2

Y3

Y4

M1

B 13 GB 33/06

6.3. Positions of the switches, valves, pressure controllers and motors

VS-32-L 22

Page 23

306

B9

B10

B 13 GB 33/06

7. Functional description

7.1. Process description

7.1.1. Insertion of strap

Before the insertion of the strap into

the TITAN strapping head type

VS-12-L attention must be paid that

the beginning of the strap has been

cut cleanly and sprightly. The

beginning of the strap is then inserted

into the guide rolls (306) until the

resistance of the conveying roller

(392) is sensed.

Following that, switch B9 on the

SEK01 is actuated, which then

triggers the lifting cylinder Z1 and the

transport rocker. Then the strap can

be slipped further.

After releasing switch B9 the rocker

lowers down and the strap is clamped

between conveying roll and counter

roller (420); therefore, it is ready for

the feed of the strap.

Should strap be inserted from a

greater distance, a switch for the lifting

of the conveying rocker has to be

provided at the machine!

Caution!

Use protective gloves when inserting strap.

7.1.2. Feed of strap, medium speed

At the tone of the start signal the 5/3-port directional control valve Y3 is selected.

The transport motor M1 is switched on and transports the strapping material

through the conduit system at 1,7 m/s, until the strap stop B1 is reached.

Simultaneously, a timer is processed (strap circulation control) which interrupts

the transport of strap when the maximum strap transporting time is exceeded

(breakaway of strap or resistances in the conduit).

Before the strapping head is reached switch B14 in the conduit is triggered: it

switches off the transport of strap fast movement Y2 and switches on medium

speed Y1.

The medium speed can be set on the pressure controller DR3.

Note!

When readjusting the medium section, the setting of the strap

tension is altered!

Fig. 2: Insertion of strap.

Fig. 3: Service switch strap B9.

VS-32-L 23

Page 24

B 13 GB 33/06

7.1.3. Strap feed, precise movement

The transport motor M1 then operates at reduced speed-mean speed Y1, until the

strap stop lever (87) has been reached which actuates the limit switch B1 and

again reduces the precise movement.

Simultaneously, counter switch B2 is activated. Switch B2 counts the pulses at

the transport shaft (385) prespecified and switches off the precise movement

during the transport of the strap after the strap overlapping has been completed.

In addition, a monitoring timer t9 is processed for strap overlapping. The

beginning of the strap is then found in the sealing sector.

7.1.4. Closing strap gripper 1

After the number of pulses prespecified has been reached, the solenoid valve Y5

of the sealing motor M3 is switched on, the sealing motor turns 50° and closes the

gripper (1671). During that operation switch ring 1 (55) leaves the zero position of

the sealing unit and the limit switch B3 (zero position = casing pitch and feather

key groove same level). Then after 50°, switch ring 2 (52) occupies Pos. K at

switch B4.

Then the beginning of the strap is secured against retraction. In most strapping

situations that position is chosen as stand-by position. From that position the

strapping head can be moved to the packing item.

A switching slide with two switches then sends the signal “Head before packing

item“ B7 to the control system, then, when the movement continues, it signals

"Head on packing item" B8.

7.1.5. Transport back of strap

With switch B8 (head on packing item) being assigned the 5/3-port control valve

Y4 is switched on for the transport back of the strap. The transport back remains

in operation until the strapping sling is around the packing item and the transport

motor M1 has applied a pretension of approx. 1800 N to the strap.

When the motor is in operation, counter switch B2 being screwed in the motor

flange (529) scans the speed of the motor (approx. 540 1/min = 1080) over two

surfaces on the transport shaft (385). A pulse monitoring device in the electronic

control switches off the motor when being at a standstill and starts the tensioning

operation.

After the transport back of the strap the valve air-cleaning device Y8 is switched

on for a short time t8 = approx. 0,5 s to remove abrasive and combustion residues

from the sealing cell.

7.1.6. Tensioning the strap

When the transport motor M1 is switched off, valve Y6 of the tensioning motor M2

and, simultaneously, the short stroke cylinder (314) of the rocker (330) over valve

Y16 are switched on. The rocker is lowered down to the strap and tensions it

around the packing item until the nominal value preset stops the tensioning motor.

The adjustable strap tension can be between 4000 and 20000 N. It can at the

multi-functional module (569) see chapter 8.4 being adjusted. The tension

pressures achieved can be read on the pressure gauge installed.

VS-32-L 24

Page 25

B 13 GB 33/06

7.1.7. Closing strap gripper 2

After reaching and maintaining the strap tension the solenoid valve Y5 is selected.

The sealing motor M3 moves 105° and moves switch ring 2 (52) to pos. W.

The clamping (47) grips both straps; simultaneously, gas valve Y10 is switched

on. Then, the strap fed is cut and pressed flexibly by means of the welded torch

holder (59). The closed strap gripper 2 is signalled via switch ring 2 by means of

switch B4. Simultaneously, a timer element t1 is processed which switches off the

tensioning motor M2 after the cutting and pressing of the strap.

7.1.8. Welding

After reaching pos. W the TIG automatic torches are ignited consecutively and

seal both ends of the strap. If no ignition of the first welding point, the 2

nd

welding

point will be set and the 1st will be repeated.

Welding time t5 and welding intensity t6 can be set in the control electronics.

Usually, a welding time of 1 to 1,5 s each at an intensity of current of approx. 160

A is satisfactory. The quantity of gas at the welding station should be set to 10

l/min (for setting see section 8.5). The time of the gas after-flow was set to 8 s by

the manufacturer.

The tip of the electrode should project 2 mm out of the gas nozzle. The distance

between electrode and strapping material should be 3 mm (for setting, see

sections 8.6 and 8.7).

7.1.9. Swivelling the welding station open

When the straps have been welded, the solenoid valve Y5 is switched on, the

sealing motor runs 160° to pos. F. In that situation switch ring 2 is assigned to

switch B4. The welding station swivels open by the curve (14) and releases the

welding seal.

7.1.10. Swivelling the welding station back

When the seal applies to the packing item, the strapping head can be moved to its

initial position. Simultaneously, the strapping material is retracted from the cutting

area. The sealing motor M3 is switched on and operates until the 0 position of

the head has been reached. The tensile springs (116) close the welding station.

Switch ring 1 (55) then occupies switch B3.

- A new strapping cycle may begin. -

VS-32-L 25

Page 26

160°

0

F

W

B3 = OFF

B4 = ON

B3 = OFF

B4 = ON

F

50°

Pos. F

Welding station swung open,

retracting strap from cutting area

Pos. W

Gripper 2 closed,

keeping tension of strap, pressing,

cutting and sealing the straps

105°

K

W

B3 = OFF

B4 = ON

K

W

F

0

B3 = ON

B4 = OFF

F

0

K

0

K

W

Pos. K

Gripper 1 closed,

beginning of strap secured against retraction,

strap return, tensioning of strap

0-position

Welding station closed,

cutters and clamps lifted,

strap feed

B 13 GB 26/06

7.2. Positions on the cam gear

VS-32-L 26

Page 27

B 13 GB 33/06

7.3. Description of the welding operation

The TIG welding method is the tungsten inert gas welding method. This is a contactfree welding method. It must not be mixed with the so-called spot welding (with contact

electrode).

The weld is made contact-free by the electric arc under argon shield gas. This is a

commercial shield gas with a degree of purity of 99,996 % (argon 4.6).

Weld gas consumption amounts to 2 litre per seal argon gas. Therefore, a 50-l gas

bottle permits approx. 5000 welding seals.

A high-frequent ignition current ignites the electric arc via an initiating electrode.

The latter is made of tungsten. Each electrode is identified by a colour on the head and

can therefore be ordered according to DIN by each merchant. The electrode used in

the VS 32-L is of the type WS 2 turquoise with the dimensions Ø 2,4 x 175 mm.

The consumption of the electrode must be compensated for.

Note! Preventive maintenance

Replace electrode before the beginning of shift or after 1000

welding operations at the latest or sharpen it.

The electrode can be ground up to 100 times. Up to approx. 1000 welding spots can be

affected for application between the grinding operations.

The electrode should be provided with 2 grinding angles. An obtuse tip of approx. 70°

and a slim tip of approx. 15 °. Angles being too obtuse provide good ignitability, but it is

their disadvantage that they are consumed too quickly which in turn increases ignition

distance. Sharpening the ignition needle should be done by means of a TITAN-Sharp

grinder.

TITAN holds patents for the TIG welding system in strapping machines Europe and

North America.

The TIG welding method permits the welding of all bright or blued surfaces. In this

context it is important that the surface is not polluted strongly.

Note! Painted strapping material

Galvanised or zinc dust painted strap cannot (!) be welded. The

same applies to zinc portions in paints used.

VS-32-L 27

Page 28

85

71

B3

B4

B1

1

529

446

385

B 13 GB 26/06

8. Adjustments

8.1. Setting switches B1 to B8

B1 Strap stopping switch:

Switch B1 should be set such that the gap between pusher (71) and switch (85) is

max.1 mm.

B2 Counter switch:

Switch B2 (446) is screwed into transport rocker (529) such that the gap between shaft

(385) and switch is 1 mm and fixed by a locknut.

VS-32-L 28

Page 29

572

B7

987

992

B8

B 13 GB 26/06

B3 B7 Limit switches:

All switches are with fixed values. Setting is not required.

B8 Head on packing item:

Switch (992) has a fixed dimension to the switching slide (572). Setting the switching

length at holder 2 (987) in the axial direction of the slide is possible.

The switching length between B7 "Head before packing item" and B8 "Head on packing

item" can be set to max. 115 mm.

VS-32-L 29

Page 30

F

W

0

K

B3

Partial axis

55

53

26 23

52

195

3

2

1

Curve flank

29

53

32

B 13 GB 26/06

8.2. Setting the zero position

The zero position of the welding station is set up such that the feather key (26) of the

driving shaft (23) is parallel to the partial axis of the bearing shell. The contact surface

of the switch ring (55) is assigned to switch B3 (195). The thread pin (53) of switch ring

2 (52) is also parallel to the partial axis.

8.3. Setting the clamping and opening positions

If the thread pin (53) of the triple switch ring (52) is also found on the partial axis, the

subsequent clamping and opening positions are correct as well.

The toothed wheel (18) of the opening curve must be plugged such that the cam roller

(32) fits closely to the radius of the opening curve (14). The curve flank is then vertical

to the partial axis. Positions 1 to 3 are engraved on the toothed wheel (29) and can be

controlled there.

52

14

18

VS-32-L 30

Page 31

ungeölte Druckluft

geölte Druckluft

Oiled air

Unoiled air

DR 3

DR 2

Y1

Y2

B 13 GB 11/13

8.4. Setting the air pressure

The optimum result is obtained by three pressure settings.

Settings must be affected on the following pressure controllers:

DR 1 Pressure controller on the machine

(Main controller)

DR 2 Pressure controller on the

multi-functional block

DR 3 Pressure controller on the multi-

functional block

1. The pressure controller DR 1 is found on the maintenance unit of the machine.

The maintenance unit provides for the quality of the compressed air. It filters water, oil

aerosols as well as dirt and rust particles from the air and provides the entire machine

with sufficient air pressure. It should be able to discharge oiled and unoiled air.

In case of high level differences between

the maintenance unit and the strapping

head or a hose being longer than 5 m a

separate oiler (700) has to be installed

near the head.

If the machine is without air supply, the maintenance unit-depending on the installation

position of the head must be attached directly to the head or immediately near it

Port cross section: min. 3/4“

Air pressure: 6 bar flow pressure

DR 1 can be set at an impact pressure of 6,0 to 7,0 bar.

Effects of that setting on the strapping head:

The pressure preset results in

Max. strap tension,

the fastest strap feed speed

Selection via speed valve Y2 in the multi-functional block and related consumer valve

Y3, Y4 to Y6.

This setting makes for the speed of the sealing process (Welding station).

VS-32-L 31

Page 32

B 13 GB 33/06

2. The pressure controller DR 2 is found on the multi-functional block. It is set to a

jamming pressure of 1,5 - 2 bar, readable at its manometer.

The pressure preset results in the minimum strap tension, feed and sealing speeds.

Selection directly via consumer valves, Y3, Y4 to Y6.

Main functions:

Precise movement pulse counting

Slow partial feed of strap

Slow return of strap during movement of head “Head on packing item“ B8

3. The pressure controller DR 3 is found on the multi-functional block. It is used to

set all speeds and strap tensions between minimum and maximum.

Selection via speed valve Y1 on the multi-functional block and the relevant consumer

valve Y6.

The main function is the setting of the strap tension.

Pressure is set at the pressure control valve with valve Y1 being activated and read on

its pressure gauge. The blow-off noise of the secondary ventilation can be heard on the

small pressure control valve DR 2, as long as Y1 is selected. This is no problem.

The speed valve Y1 can be activated in manual mode (emergency actuation) or

switched on via the control system.

Note!

Check the flow pressure at the tapping point. Flow pressure

exceeding 6 bar results in increased wear at the compressed air

motors. Pressure being too low results in reduced output.

VS-32-L 32

Page 33

Fig. 4: Pressure reducer

including flow rate meter

B 13 GB 26/06

8.5. Setting the quantity of gas

The SV-32-L strapping head comprises a plant for central gas supply, which in turn

comprises a pressure control station and a pressure reducer incl. flow rate meter.

The pressure control station including accessories can be obtained in two designs. The

operation of the head can be designed by means of a gas cylinder or a group of two

with a maximum feed pressure of 200 or 300 bar.

The closed circuit pressure (working pressure) has been controlled by the manufacturer

to 5 bar on the main pressure reducer. That pressure cannot be controlled on the

pressure reducer. In case of decreasing cylinder pressure the working pressure and

therefore the shield gas consumption remain constant.

The quantity of gas required for a welding operation should amount to 10 litres per

minute. It is set on the flow rate meter via the second pressure reducing valve (fig. 4).

That pressure reducer including flow rate meter should be mounted near the head of

the machine.

If the quantity of shield gas is too low (quantity of gas < 10 l/min), the weld metal bead

may be affected by pores.

Set the quantity of gas via the setscrew

of the pressure reducer.

Important:

For safety regulations, mounting

instructions and commissioning of the

central gas feed system see operating

instructions (Fa. Everwand & Fell

GmbH) attached.

All plant sectors must be kept free of oil and grease!

All mounting works deviating from the mounting instructions may

only be performed by an authorised specialised company or the

manufacturer. Otherwise, any manufacturer’s guarantee as well as

all claims within the scope of the product liability act will expire.

Caution!

Gas bottles are to be protected against dangerous heating up (over

50°C) by heating elements or open flames. Bottles at a wellventilated place store and against falling down secure.

VS-32-L 33

Page 34

1.

2.

3.

4.

668

560

666

669

B 13 GB 26/06

22-0.5

8.6. Setting the distance between electrodes

The igniting electrode sharpened (see sketch) should project 2 mm out of the ceramic

gas nozzle (668).

Setting is performed as follows:

1. Manually unscrew the gas nozzle (668).

2. Detach the tensioning sleeve casing (666) by

means of torch wrench (560).

3. Insertion of the igniting electrode (669) into the

tensioning sleeve casing. The electrode should

project approx. 30 mm. Manually screw in casing.

4. Use the torch wrench preset to slip the electrode

into the casing to size and screw it.

5. Manually screw the gas nozzle firmly.

VS-32-L 34

Page 35

176

VS 32

VS 12

60

505

61

273

B 13 GB 05/10

8.7. Setting the torch

The torch including holding device is set as follows:

Slip torch (505) including electrode into the setting gauge included (273) into the scope

of supply until the electrode is in contact with the bottom of the gauge. Slip holder (60)

onto the torch till it reaches the stop of gauge VS 32 and then screw it by means of

cylinder screw (61).

Note!

If the clamping sleeve housing, the clamping sleeve or the welding

electrode will be exchanged separately, the adjusting of the burner

has to be controlled. Due to the modified constellation it is possible

that the distance between welding electrode and support of the

burner change.

VS-32-L 35

Page 36

Strap cross

section

in [mm]

Sealing time

t5

in [s]

Welding current

t6

in [A]

Welding time

total

in [s]

19 x 0,8

1,0

160

2,7

19 x 1,0

1,5

180

3,7

25,4 x 0,8

1,0

165

2,7

25,4 x 1,0

1,5

180

3,7

31,75 x 0,8

1,0

170

2,7

31,75 x 0,9

1,3

180

3,3

31,75 x 1,0

1,5

190

3,7

B 13 GB 26/06

8.8. Setting the welding parameters

The settings specified depend on strength and surface of the strapping material.

Painted strap!

Galvanised or zinc dust painted strap cannot (!) be welded.

VS-32-L 36

Page 37

B 13 GB 26/06

9. Maintenance

9.1. General

Regular and careful maintenance provides for the permanent readiness for operation of

the strapping head of the type VS-32-L. The strapping head must always be kept clean.

Always keep strap guidance's and sealing sector free of pollution and foreign

substances.

The kind of packing material and its surroundings are decisive for

the cleaning intervals. Main attention has to be paid for abrasive

material originating from work with steel strap; that may result in

malfunctions.

For cleaning only use environmentally friendly cleaning agents

which neither damage plastic materials nor the painting on the

machine.

All parts must be checked at regular intervals and replaced when

worn out. Parts worn out affect the sealing strength and have

influence on the transport security of the packing item.

Attention!

Disregarding that note may result in faults and injuries.

Only use original TITAN spare parts!

The use of spare parts not manufactured by TITAN excludes

guarantee and liability.

Caution!

In case of maintenance works on live parts of the strapping head

the main switch of the control system must be set to position “0“

and secured.

Tool inspection!

Perform a daily visual inspection of the outside of the unit. The early detection of

damaged parts extends the life of the unit. Replace all damaged parts immediately

with Original TITAN spare parts.

VS-32-L 37

Page 38

1)

2)

3)

4)

Clamp 2

slides

Cutting edge

(upper strap)

Clamp 1

OK

Cutting

mark by

cutter

Job

Interval

Daily

Weekly

Monthly

Every 6

months

1. Check seal (see section 9.3).

2. Before the beginning of shift

sharpen or replace igniting

electrode.

3. Check of pressure gauge on gas

installations: check flow rate and

cylinder contents.

4. Clean and check transport and

tensioning wheel tooting.

5. Check clamps and cutters and clean

them by means of brush and apply

grease.

6. Completely dismount, check and

clean welding station.

7. Check valves and screwing’s for

leaks.

8. Check and clean compressed air

maintenance unit. Refill oiler with

oil.

9. Apply grease to gear unit and

bearings.

B 13 GB 33/06

9.2. Maintenance intervals

9.3. Check seal

To achieve best sealing strength the weld should be checked regularly for its

appearance. The following figure shows seals of different quality:

1) Bad welding.

2) Good welding.

3) Bad welding.

4) Sliding at clamp 2, cutting edge of upper strap is not positioned

at the cutting mark, therefore loose strapping.

VS-32-L 38

Page 39

B 13 GB 26/06

9.4. Lubricating points

All bearings installed are provided with a long-term lubrication which requires

republication once or twice a year. All sliding surfaces of the welding station require

lubrication. The gear unit, the ball and needle bearings of the compressed air motors

must be lubricated with grease on the lubricating nipples every six months.

The following greases can be used:

Shell Retinax AM

Mobilgrease Special

DEA Molytex Grease EP 2

Esso Multipurpose fat

Aral Multipurpose fat F

Molykote BR2 Plus extends the lubrication intervals.

Important!

This head may only be used in connection with a compressed air maintenance unit

comprising a pressure reducer, water separator and oiler. It cleans the compressed air,

removes condensation water and permanently supplies the motors with the quantities

of oil required. On its upper side the oiler is set by means of screwdrivers such that

each strapping operation makes a drip of oil drop in the inspection glass. Cw turning

causes more oil, ccw turning less.

Attention!

In no case the strapping head may be operated without oil in the

oiler, since that would immediately result in the destruction of the

compressed air motors.

During the entire operation the compressed air motors must be operated with filtered

and oiled compressed air. As to quantity per 1 m³ air approx. 3 to 5 drips are required,

this corresponds to 0,12-0,2 g/m³. Primarily, lubricating oil should be unalloyed mineral

oil. It must be fluid and free of resin and acid.

A viscosity of 2-4 °E at 50°C (12-30cSt) has been found successful (for further

temperature ranges see viscosity table). Motor temperatures of -30 to +100 °C are

admissible. However, in case of ambient temperatures of below +5 °C there is the risk

of icing. In that case dried air or icing-inhibiting lubricants (e.g. "Killfrost Anti Eis") are

recommended.

Caution!

Wear breathing mask when using antifreeze agents.

VS-32-L 39

Page 40

B 13 GB 26/06

The following oils can be used:

Esso D 32 -10 to +30°C

D 100 +25 to +55°C

CL 320 +45 to +75°C

DEA Aries 32 -25 to +20°C

Aries 100 0 to +50°C

Shell Tonna Oil R32 -10 to +30°C

Tonna Oil R100 +25 to +55°C

Mobil Almo 525 -20 to +20°C

Almo 527 0 to +30°C

Almo 528 more than +15°C

9.5. Maintenance of the transport unit

The maintenance and inspection of the transport (392) and tensioning (3401) wheels

should be performed every week. After the disassembly the tooting must be freed of

wax and paint residues by means of a wire brush.

Worn-out wheels require replacement.

The counter rollers (352) and (420) and the strap guidance’s (4261) and (4251) should

be checked once a month and free of paint, dirt and wax residues.

Dismounting and mounting

The following tool is required for mounting and dismounting operations:

hexagon socket screw key SW 5, 6 and 8 mm, slotted screw driver.

Unscrewing the protecting ledges (1042/1172) and the flap backside (5691).

Loosening the fastening screw (372) of the retention pin (522) and removal at the

pin heel. Swinging out the counter bearing elements (3481/3491), simultaneously

lifting the tensioning motor (430). The counter roller (352) and the strap guidance

have canned then are cleaned (fig. 5 to 8).

When loosening the 2 fastening screws of the rocker cover (334) the latter can be

removed by means of its handle (400) and the tensioning wheel (3401) found

below can be dismounted. The tensioning wheel is linked to the driving shaft via a

feather key and can be removed towards the front (figs. 9 to 10).

The transport wheel (392) is secured by means of a safety disk (394). It can be

loosened by means of a screwdriver or pincers, and the transport wheel can be

removed towards the front. The counter roller (420) found below and the

guidance’s (4251/4261) can then be cleaned (fig. 11).

Mounting is performed in the reverse order.

Slightly lubricate all parts (exc. screws).

VS-32-L 40

Page 41

Fig. 6: Loosen flap

Fig. 7: Remove retention

Fig. 8: Swing out counter

bearing elements.

Fig. 5: Remove

protective ledge.

Fig. 9: Remove rocker

Fig. 10: Dismount

wheel.

1042

522

5691

3481

334

3401

392

B 13 GB 26/06

backside.

cover.

pin.

tensioning

VS-32-L 41

Fig. 11: Dismount transport wheel.

Page 42

Die

1671 /

1672 /

1673

Guide

1711 /

1712 /

1713

Side jaw on

the right

1691 /

1692 /

1693

Flap on

the left

1741 /

1742

Cutting edge,

sharp edges

Clamping edge

R0.5 rounded

Cutting plate

B 13 GB 04/13

9.6. Maintenance of the clamp guide

During checks and maintenance of the clamp guide special attention must be paid to

the clamping and cutting edges of the cutting plate. They should have sharp edges or

have a slight radius of max. 05 mm. Strongly rounded edges cause the slipping of the

strap during the tensioning operation or a strong formation of burr during cutting.

Check die (1671), side jaws (1691 / 1701), guide (1711) and flaps (1731 / 1741) for

wear and replace elements, if required. Further, paint, wax and dirt residues on the

strap guidance positioned inside must be removed.

When strapping material is welded, residues of burnt wax and paint particles which

might impair the readiness of ignition of the electrode are formed on the base plate.

Those residues must be removed from the base plate by means of a wire brush

regularly (once a month) (fig. 16).

Dismounting and mounting

The following tool is required for dismounting and mounting operations:

Hexagon socket screw keys SW 5 and 8 mm.

Loosening of the upper 2 fastening screws (184/186) of the protecting ledges

(1042/1172); slip the protecting ledges aside. Relieve the pressure springs (158)

by loosening the threaded pins (159) (fig. 12).

Loosening the sealing screw (166) and extraction of the lock (562). Loosening the

supporting strip (4) and base plate (1) (figures 13 to 14).

Then the clamp guide can be removed from the sealing unit (fig. 15). If required,

the cutting plate acc. to section 9.7 can be dismounted.

Mounting is performed in the reverse order.

VS-32-L 42

Page 43

Fig. 12: Relieving pressure springs.

Fig. 13: Loosening cylinder screw.

Fig. 14: Remove seal.

Fig. 15: Remove clamping guidance.

Fig. 16: Cleaning base plate.

4 1

166

562

1721

1

159

B 13 GB 33/06

VS-32-L 43

Page 44

116

Cutting edge

Cutter

581

B 13 GB 04/13

9.7. Maintenance of the cutter

The cutting edge of the cutter must be checked regularly in the same way as it is done

with the clamping or stationary cutter edges. If that edge is notch or broken, it must be

replaced.

Attention!

Broken cutter edges may cause faults in strap feed and return

motions. The beginning of the strap is bent!

Dismounting and mounting operations

The following tools are required for dismounting and mounting operations:

Spring hooks, hexagon socket screw keys SW 6.

To dismount the cuter relieve the pressure springs (116) by means of spring

hooks (fig. 17).

The sealing unit can now be tilted open and the cutter guidance can be removed

from the clamp guide by the loosening of the cheese-head screw (fig. 18).

Mounting is performed in the reverse order.

580 /

Fig. 17: Sealing unit tilted open.

Fig. 18: Dismounting cutter guide.

VS-32-L 44

Page 45

Fig. 20: Remove torch holder.

Fig. 19: Detach clamp spring.

63

505

59

S1

B 13 GB 33/06

9.8. Dismounting the torch, replacement of electrode

Before the beginning of a shift or at least once a day the tungsten electrode

(d = 2,4 mm; l = 175 mm; WS 2 turquoise) must be sharpened or replaced.

Replacement should be done when the electrode is l ≤ 50 mm.

Dismounting and mounting:

Turn the main switch S1 on the automatic welding

unit L 250 TI to position “0“ and secure it.

Loosen clamp spring (63) and remove the torch

(505) from the torch holder (59) (fig. 19 to 20).

Manually unscrew the gas nozzle (668).

Detach the tensioning sleeve casing (666) by means of torch wrench (270).

Remove igniting electrode (669) and sharpen it by means of TITAN-SHARP.

Insertion of the igniting electrode (669) into the tensioning sleeve casing. The

electrode should project approx. 30 mm. Manually screw in casing.

Use the torch wrench preset to slip the electrode into the casing to size and screw

it (also see section 8.6).

Manually screw the gas nozzle firmly.

Punch out spiral pins (94) out of the cutter (97) by means of pin punches and slip

cutter out of the cutting plate (1751 / 1752).

Mounting is performed in the reverse order.

VS-32-L 45

Page 46

33

116

48 47

B 13 GB 26/06

9.9. Dismounting and mounting the clamp

To dismount the clamps relieve tension springs (116) by means of spring hooks.

Swing out sealing unit. Unscrew cover (33) and swing out clamp holder (45) incl.

clamp (47) (fig. 21). Remove bolts (48) and clamp holder incl. clamp from the

sealing unit.

After the check or the replacement slip the clamp including holder onto the rocker

(37) and link it to the bolt. Fasten cover and close sealing unit. Slightly lubricate all

sliding surfaces. Finally suspend the tension springs.

Fig. 21: Swinging out sealing unit.

Fig. 22: Remove linking bolts.

VS-32-L 46

Page 47

Fig. 25: Dismount pressure springs.

116

33

66

67

59

B 13 GB 26/06

9.10. Dismounting and mounting the torch holder

To dismount the torch holder (59) relieve tension springs (116) by means of

spring hooks. Dismount torch (505). Swing out sealing unit. Move torch holder to

welding position pos. W by manual actuation of Y5. Unscrew cover (33).

Attention!

When removing the cover pay attention to the pretension of the

pressure springs (67).

Remove bar (66) with screw M4. Move torch holder to zero position pos. 0 by

means of manual actuation of Y5. Dismount pressure springs (67). Swing out

torch holder by means of pusher (42) and detach link with bolt (48). Remove torch

holder from sealing unit.

Mounting is performed in reverse order. Slightly lubricate torch holder on the

sliding surfaces.

Fig. 23: Swing out sealing unit.

Fig. 24: Remove bar.

Fig. 26: Swing out torch holder.

VS-32-L 47

Page 48

Fault

Cause

Remedy

The strap is not transported

into the conduit system.

The strap is not found between

transport wheel (392) and counter

roller (420).

Insert strap again.

See section 7.1.1

The sealing unit is not at 0 position.

Set up zero position again.

See section 8.2

The sealing unit is opened.

Set up zero position again or

eliminate clamping point.

The strap does not reach

strap stopping switch B1.

Offset at the transition points in the

conduit (bordering).

Align transition points.

The strap does not arrive at

the sealing unit.

The 0 position is not correct.

The die (1671) has been lowered

partially.

Readjust zero position.

See section 8.2.

Transport wheel (392) worn out or

clogged with wax or dirt.

Cleaning or replacement of

the transport wheel.

See section 9.5

Strap overlapping is too

short / too long.

Time t9 for precise movement during

strap feed too short.

Extend time.

Time t9 for precise movement during

strap feed too short.

Reduce time.

Transport motor (432) runs too slowly.

Motor runs dry, refill oil in

pressure oiler.

Pressure variations in compressed air

circuit.

Provide for constant

pressure.

The switching pulse from

transport to tensioning does

not materialise.

Counter switch B2 defective.

Change / replace inductive

switch (446).

Strap tension is too low.

Tension wheel (3401) slippery.

Change / replace tension

wheel. See section 9.5

Closing clamp t1 overlapping time and

tension motor off is too short; before

the straps are clamped, the tension

motor switches off. Strap tension is

relieved.

Extend overlapping timer t1.

Strap tension reduced too much.

Increase pressure at pressure

controller DR3.

See section 8.4

B 13 GB 33/06

10. Fault detection - remedy

VS-32-L 48

Page 49

Fault

Cause

Remedy

The strap tears at the

clamping edge during

tensioning operation.

Strap tension chosen too high.

Reduce pressure at pressure

controller DR3.

See section 8.4

The strap is not cut.

Cutter has too much cutting air.

Reduce cutting air.

See sections 9.7

Cutter is blunt or broken.

Replace cutter.

See section 9.7

The sealing unit does not

open.

Strap is squeezed.

Manually cut strap. Provide

zero position.

The head is not detached

from the packing item

Cutter broken.

Manually cut strap. Move

head to initial position. Repair

of cutter.

See section 9.7

Torch is not ignited.

Gas feed interrupted.

Open gas cylinder.

Gas valve Y10 (216)

defective.

Feed hose (954 or 974) bent.

Repair bend.

Welding facility not switched on.

Set main switch S1 to

switching position “I“.

Electrode defective.

Sharpen or replace electrode.

See sections 8.6 u. 9.8

Welding spot too small.

Welding timer t5 too short.

Extend welding time t5.

Welding current t6 too low.

Increase welding current t6.

Welding spot too large.

Welding time t5 too long.

Reduce welding timer t5.

Welding current t6 too high.

Reduce welding current.

Welding spot not welded

through.

Welding time and welding current too

short / low.

Increase Welding time and

welding current.

Welding spot with hole.

Welding current too high. Paint coat

on strapping material to thick.

Reduce welding current t6.

Replace strapping material.

B 13 GB 33/06

VS-32-L 49

Page 50

B 13 GB 07/10

11. Declaration of incorporation

VS-32-L 50

Page 51

Das TITAN

Gesamtprogramm

Umreifungsgeräte

für Stahl- und

Kunststoffband

Umreifungsmaschinen

und Aggregate

für Stahl- und

Kunststoffband

Ballenumreifungssysteme

für Stahl- und

Kunststoffband

Crimpsysteme

Stanzverbinder

Verpackungsband

aus Stahl- und

Kunststoffband

Verschlusshülsen

Zubehör

The TITAN

range of products

Strapping tools

for steel and plastic strap

Strapping machines and

aggregates

for steel and plastic strap

Baling systems

for steel and plastic strap

Crimp systems

Strip joining devices

Strapping

Steel and plastic strap

Seals

Accessories

La gamme

de produits TITAN

Appareils de cerclage

pour feuillard d’acier et

plastique

Machines et têtes de

cerclage

Pour feuillard d’acier et

plastique

Systèmes de cerclage de

balles

Pour feuillard d’acier et

plastique

Systèmes crimp

Système d’agrafage de

bobines

Feuillard d’emballage

Acier et plastique

Chapes

Accessoires

TITAN Umreifungstechnik GmbH &

Co. KG

Postfach 440, 58317 Schwelm

Berliner Straße 51-55, 58332

Schwelm

Telefon: +49 (0) 23 36 / 8 08-0

Telefax: +49 (0) 23 36 / 8 08-208

E-Mail: info@titan-schwelm.de

www.titan-schwelm.de

Technische Änderungen vorbehalten

Subject to technical alterations

Sous réserve de modifications

techniques

Loading...

Loading...