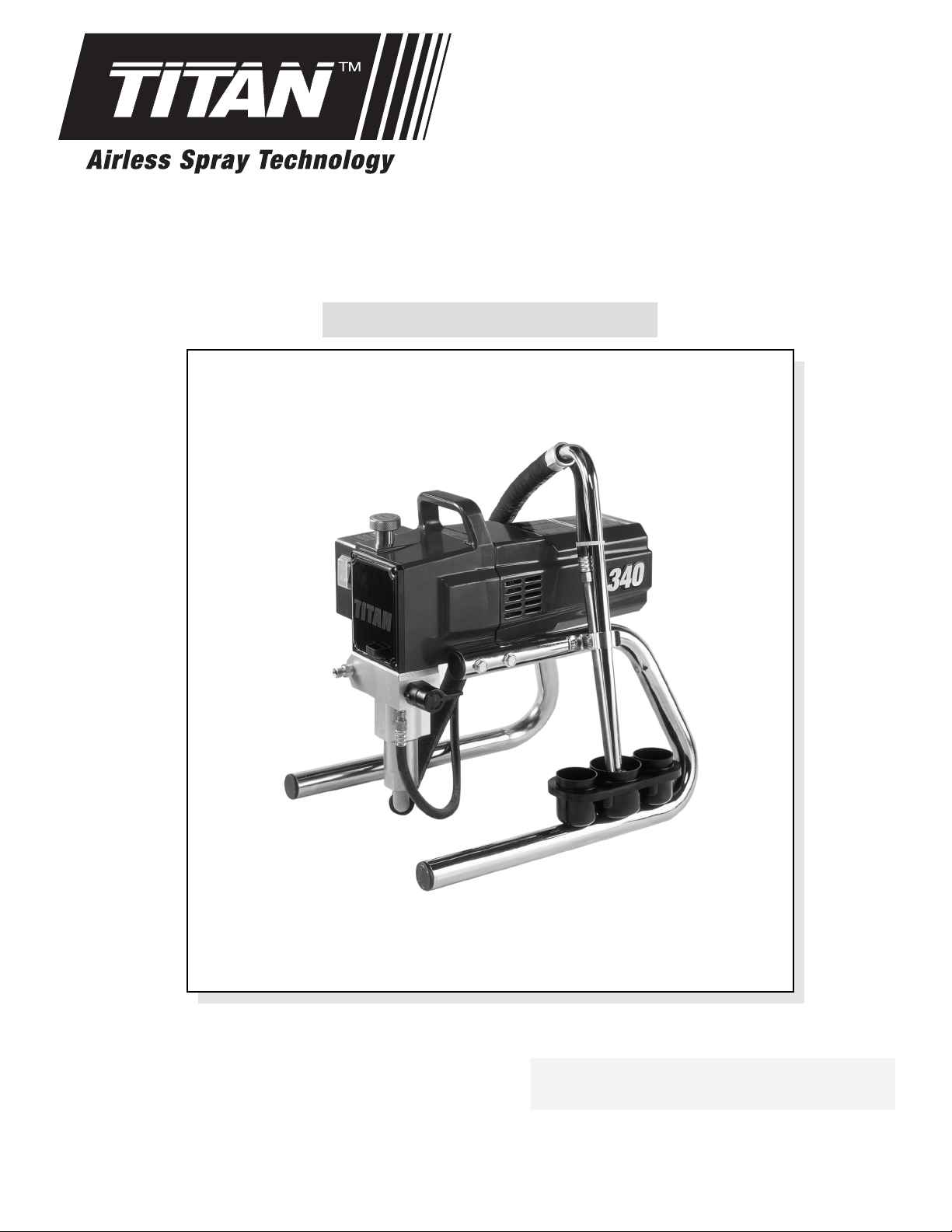

Page 1

Owner’s Manual

For professional use only

Do not use this equipment before reading this manual!

340 Airless Sprayer

International Model

Model Number:

Skid Complete, 230V 704-2115

Skid Complete, 110V 704-2125

Printed in the U. S. A.

NOTE: This manual contains important warnings

NOTE: This manual contains important warnings

and instructions. Please read and retain for

and instructions. Please read and retain for

reference.

reference.

0804 © 2004 Titan Tool Inc. All rights reserved. Form No. 313-2408B

Page 2

Table of Contents

WARNING

CAUTION

WARNING

Safety Precautions.................................................................2

General Description ...............................................................4

Operation ................................................................................4

Setup ....................................................................................4

Preparing to Paint.................................................................4

Painting.................................................................................5

Pressure Relief Procedure ...................................................5

Spraying

Spraying Technique ..............................................................6

Practice.................................................................................6

Cleanup ...................................................................................7

Cleaning the Spray Tip .........................................................7

Maintenance............................................................................8

General Repair and Service Notes.......................................8

Replacing the Motor .............................................................8

Replacing the Motor Brushes ...............................................8

Replacing the Gears.............................................................8

Replacing the Transducer.....................................................9

Replacing the PRIME/SPRAY Valve.....................................9

Servicing the Fluid Section .................................................10

Replacing the Filters ...........................................................11

Troubleshooting ...................................................................12

Parts Listings........................................................................18

Main Assembly....................................................................18

Motor Assembly ..................................................................19

Electrical Schematic ...........................................................19

Gear Box Assembly............................................................20

Suction Set Assembly.........................................................21

Stand Assembly..................................................................21

Fluid Section Assembly ......................................................22

Accessories ........................................................................23

Labels .................................................................................23

Warranty................................................................................24

..................................................................................6

Safety Precautions

This manual contains information that must be read and

understood before using the equipment. When you come to an

area that has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

Attention! Danger of injury by injection!

In case of injury to skin caused by coating materials or

solvents consult a doctor immediately. Inform the doctor of the

type of coating material or cleaning agent with which the injury

was caused.

The operating instructions state that the following points

must always be observed before starting up:

1. Faulty units should not be used.

2. Secure spray gun using the safety catch on the trigger.

3. Ensure that the unit is properly earthed.

4. Check the permissible operating pressures.

5. Check all connections for leaks.

The instructions regarding regular cleaning and

maintenance of the unit must be strictly observed.

Before any work is done on the unit or for every break in

work the following rules must be observed:

1. Release the pressure from the spray gun and hose.

2.

Secure the spray gun using the safety catch on the

trigger.

3. Turn off the motor.

Be safety-conscious!

All local regulations in force must be observed.

In order to ensure safe operation of the airless systems

the safety regulations listed below must be followed:

1. In order to avoid dangers, read the operating instructions

carefully and follow the instructions laid down in them.

2.

Do not use materials with a flash point below 21ºC (70ºF).

3. The use of this unit is prohibited in workshops which are

covered under the explosion prevention regulations.

4. Never spray near sources of ignition; e.g. open flames,

cigarettes — also cigars and pipes are sources of ignition

— sparks, hot wires and hot surfaces, etc.

5. Attention! Danger of injury by injection!

Never point the spray gun at yourself or anyone else.

Never put your fingers or hands into the spray jet. The

very high spraying pressures can cause very serious

injuries. Never use the spray gun without the safety guard.

This symbol indicates a potential hazard that may cause

serious injury or loss of life. Important safety information

will follow.

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to prevent

damage to the equipment or how to avoid causes of minor

injuries will follow.

NOTE: Notes give important information which should

Airless units develop extremely high spraying pressures.

be given special attention.

• Never put your fingers, hands or any other parts of the

body into the spray jet.

Never point the spray gun at yourself or anybody else.

•

• Never use the spray gun without the safety guard.

When installing and removing the tip and during breaks in

work the spray gun must always be secured, so that it

cannot be activated.

6. Wear respiratory equipment when spraying. The operator

must be provided with a protective mask.

In order to prevent work related illness, the manufacturer's

regulations for the materials, solvents, and cleaning

agents used must be observed when preparing, working

with and cleaning the unit. Protective clothing, gloves and,

in certain cases, protective skin cream are necessary to

protect the skin.

7. The spray gun and high pressure hose between the unit

and spray gun must be of a sufficient standard for the

pressure produced in the unit.

The permissible operating pressure for the high-pressure

hose, the manufacturer and date of manufacture must be

indicated by a permanent identification marking on the

hose. Furthermore, it must be constructed so that the

electrical resistance between the connections to the unit

and the spray gun is equal to or less than one megohm.

8. Under certain conditions the flow speed can cause an

electrostatic charge on the unit. This could cause sparks

or flames on discharging. It is, therefore, important that

the unit is always earthed over the electrical installation.

The contact should be made using a shockproof socket

earthed in accordance with the regulations.

2 © Titan Tool Inc. All rights reserved.

Page 3

9. Attention! Please observe the following when working

inside and outside:

No solvent gasses should be carried to the unit. No

solvent gasses should form near the unit. Set up the unit

on the opposite side to the object being sprayed. When

spraying outdoors, take the wind direction into account.

When working indoors there must be sufficient ventilation

to ensure that the solvent gasses are carried away. A

minimum distance of 6.1m (20’) must be observed

between the unit and object being sprayed.

10. Extraction equipment should be installed by the user in

accordance with the local regulations.

11. The objects being sprayed must be earthed.

12. When cleaning the unit, solvent should never be sprayed

into a container with only a small opening (bunghole). An

explosive gas/air mixture is likely to form. The container

must be earthed.

13. Cleaning the unit.

A harsh jet should never be used to spray the unit. In

particular a high-pressure cleaner or high-pressure steam

cleaner should never be used. There is a danger that

water will penetrate into the unit and cause a short-circuit.

14. Pulling the trigger causes a recoil force to the hand that is

holding the spray gun.

The recoil force of the spray gun is particularly powerful

when the tip has been removed and a high pressure has

been set on the airless high-pressure pump. Therefore,

when cleaning without tip set the pressure control valve to

the lowest pressure.

15. The mains plug should always be disconnected from the

socket when work is being carried out on the electrical

components.

16. Work or repairs should only be carried out on electrical

equipment by a trained electrician, even if the work is

described in the operating instructions. No liability will be

accepted for incorrectly installed electrics.

17. Positioning when the ground is uneven.

The front of the unit must point downward so that the

machine does not slip away.

HAZARD: INJECTION INJURY - A high pressure stream

PREVENTION:

• The maximum operating range of the unit is 20.6 MPa

•

• NEVER allow any part of the body to come in contact with

• NEVER put your hand in front of the gun. Gloves will not

• ALWAYS lock the gun trigger, shut the fluid pump off and

• The tip guard must always be in place while spraying. The

• ALWAYS remove the spray tip before flushing or cleaning

• The paint hose can develop leaks from wear, kinking and

© Titan Tool Inc. All rights reserved. 3

of paint produced by this equipment can pierce

the skin and underlying tissues, leading to

serious injury and possible amputation.

DO NOT TREAT AN INJECTION INJURY AS A

SIMPLE CUT! Injection can lead to

amputation. See a physician immediately.

(3000 PSI) fluid pressure.

NEVER aim the gun at any part of the body.

the fluid stream. DO NOT come in contact with a fluid

stream created by a leak in the fluid hose.

provide protection against an injection injury.

release all pressure before servicing, cleaning the tip

guard, changing tips, or leaving unattended. Pressure will

not be released by turning off the engine. The

PRIME/SPRAY valve must be turned to PRIME to relieve

the pressure. Refer to the PRESSURE RELIEF

PROCEDURE described in this manual.

tip guard provides some protection against injection

injuries but is mainly a warning device.

the system.

abuse. A leak is capable of injecting material into the skin.

Inspect the paint hose before each use.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury. It is important

to treat the injury surgically as soon as possible. DO NOT

delay treatment to research toxicity. Toxicity is a concern

with some coatings injected directly into the blood

stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

HAZARD: EXPLOSION OR FIRE - Solvent and paint fumes

PREVENTION:

• Fire extinguishing equipment must be present and in good

• Use only conductive or earthed high pressure fluid hoses

• The pump must be connected to an earthed object. Use

• When flushing equipment use the lowest possible pressure.

HAZARD: EXPLOSION HAZARD DUE TO INCOMPATIBLE

PREVENTION:

• Do not use bleach.

• Do not use halogenated hydrocarbon solvents such as

HAZARD: GENERAL - May cause property damage or

PREVENTION:

• This high pressure airless pump is designed to be used

• Before each use, check all hoses for cuts, leaks, abrasion

• ALWAYS follow the material manufacturer’s instructions

• Clean up all material and solvent spills immediately.

• Wear ear protection. This unit can produce noise levels

• Wear protective eyewear.

• Do not spray on windy days.

can explode or ignite, causing property damage

and/or severe injury.

working order

for airless applications. Be sure that the gun is earthed

properly through hose connections.

the green earthing wire to connect the pump to a water

pipe, steel beam, or other electrically earthed surface.

methylene chloride and 1,1,1 - trichloroethane. They are

not compatible with aluminum and may cause an

explosion. If you are unsure of a material’s compatibility

with aluminum, contact your coating's supplier.

with manufacturer authorized parts only

pump with parts that do not comply with the minimum

specifications and safety devices of the pump

manufacturer, the user assumes all risks and liabilities.

or bulging of cover, as well as damage or movement of

couplings. If any of these conditions exist, replace the

hose immediately. Never repair a paint hose. Replace it

with another earthed hose.

for safe handling of paint and solvents.

above 85 dB(A).

.

MATERIALS- May cause property damage or

severe injury.

severe injury.

. When using this

Earthing Instructions

This product must be earthed. In the event of an electrical

short circuit, earthing reduces the risk of electric shock by

providing an escape wire for the electric current. This product

is equipped with a cord having an earthing wire with an

appropriate earthing plug. The plug must be plugged into an

outlet that is properly installed and earthed in accordance with

all local codes and ordinances.

DANGER — Improper installation of the earthing plug can

result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not

connect the green earthing wire to either flat blade terminal.

The wire with insulation having a green outer surface with or

without yellow stripes is the earthing wire and must be

connected to the earthing pin.

Check with a qualified electrician or serviceman if the earthing

instructions are not completely understood, or if you are in

doubt as to whether the product is properly earthed. Do not

modify the plug provided. If the plug will not fit the outlet, have

the proper outlet installed by a qualified electrician.

Page 4

Specifications

WARNING

WARNING

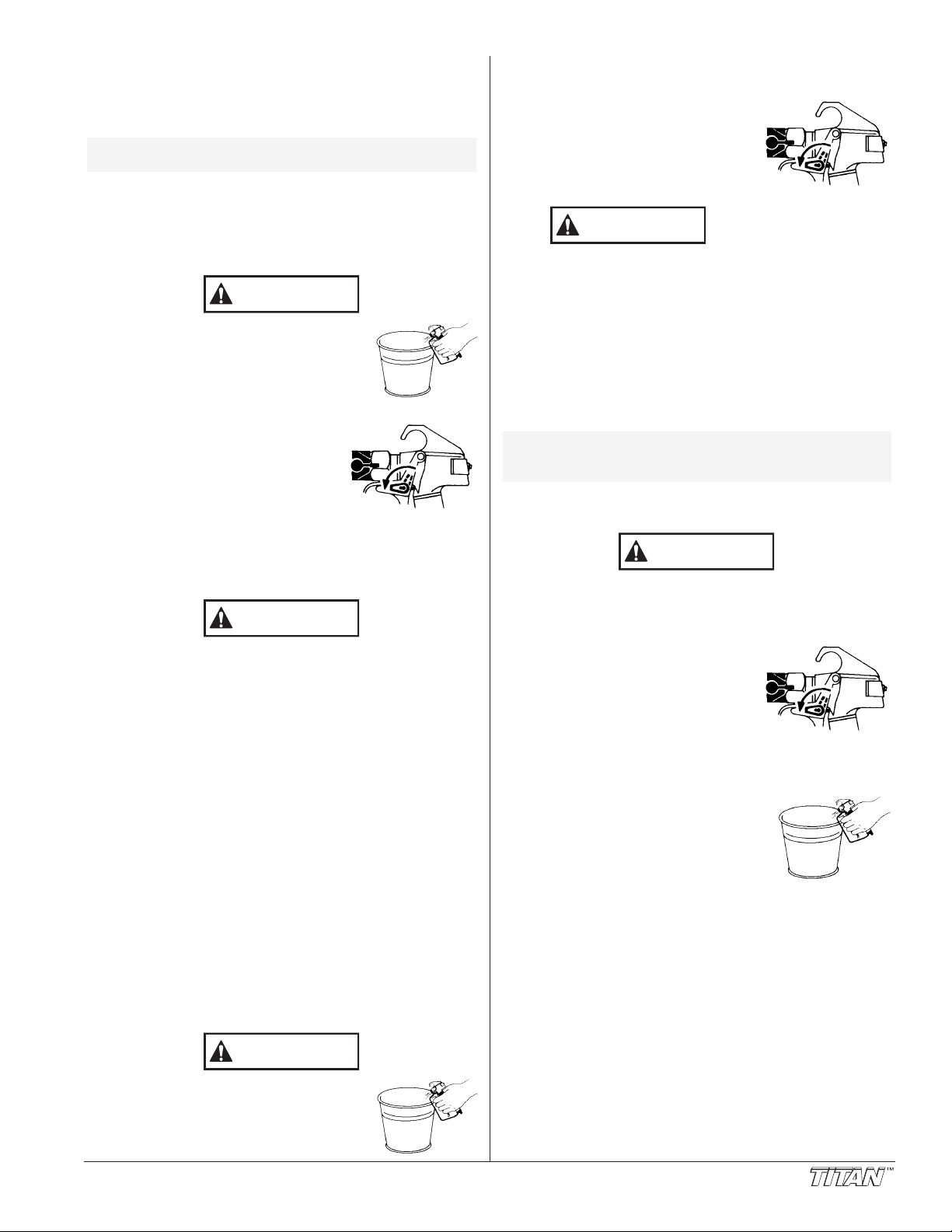

ON/OFF

Switch

Oil Cup

Outlet

Fitting

Fluid

Section

Pressure

Control

Knob

Siphon

Hose

Motor

Return

Tube

Liquid

Holder

and

Drip Cup

PRIME/

SPRAY

Valve

Circuit

Breaker

CAUTION

CAUTION

CAUTION

CAUTION

Liters per minute (LPM) ...................1.5 (0.40 GPM)

Maximum tip sizes ...........................0.019”

Maximum pressure ..........................20.6 MPa (3000 PSI)

Power, 230V unit..............................3/4 HP DC motor, 230V,

Power, 110V unit ..............................3/4 HP DC motor, 110V,

Weight..............................................15.4 kg (34 lbs.)

Maximum hose length......................91.4 m (300’)

Maximum power cord length............91.4 m (300’)

General Description

This airless sprayer is a precision power tool used for spraying

many types of materials. Read and follow this instruction

manual carefully for proper operating instructions,

maintenance, and safety information.

Operation

This equipment produces a fluid stream at extremely high

pressure. Read and understand the warnings in the

Safety Precautions section at the front of this manual

before operating this equipment.

Setup

Perform the following procedure before plugging in the power

cord of an electric unit.

1. Ensure that the suction set and the return hose are

attached and secure.

2. Using a wrench, attach a minimum of 15m (50’) x 10mm

(1/4”) nylon airless spray hose to the unit. Tighten

securely.

3. Attach an airless spray gun to the spray hose. Using two

wrenches (one on the gun and one on the hose), tighten

securely.

NOTE: Do not attach the tip to the spray gun yet.

Make sure all airless hoses and spray guns are electrically

grounded and rated for at least 23 MPa (3300 PSI) fluid

pressure.

50/60 HZ, 4.5 AMP,

1035W

50/60 HZ, 8.8 AMP,

1035W

Remove the tip if it is already attached.

4. Make sure the pressure control knob is turned fully

counterclockwise to its minimum setting.

5. Make sure the ON/OFF switch is in its OFF position.

6. Fill the oil cup with 15g (one tablespoon) of piston seal

lubricant (Piston Lube).

Never operate unit for more than ten seconds without

fluid. Operating this unit without fluid will cause

unnecessary wear to the packings.

7. Make sure the electrical service is correct for the unit.

8. Plug the power cord into a properly grounded outlet at

least 7.6m (25’) from the spray area.

Always use a minimum 12 gauge, three-wire extension cord

with a grounded plug. Never remove the third prong or use

an adapter

.

Preparing a New Sprayer

If this unit is new, it is shipped with test fluid in the fluid section

to prevent corrosion during shipment and storage. This fluid

must be thoroughly cleaned out of the system with mineral

spirits before you begin spraying.

Always keep the trigger lock on the spray gun in the

locked position while preparing the system.

1. Place the suction tube into a container of mineral spirits

that has a flash point of 60ºC (140ºF) or above.

Place the return hose into a metal waste container.

2.

3. Set the pressure to minimum by turning the pressure

control knob fully counterclockwise.

4. Move the PRIME/SPRAY valve down to the PRIME

position.

5. Turn the unit on by moving the ON/OFF switch to the ON

position.

6. Allow the sprayer to run for 15–30 seconds to flush the

test fluid out through the return hose and into the waste

container.

7. Turn the unit off by moving the ON/OFF switch to the OFF

position.

Preparing to Paint

Before painting, it is important to make sure that the fluid in the

system is compatible with the paint that is going to be used.

NOTE: Incompatible fluids and paint may cause the

Always keep the trigger lock on the spray gun in the

locked position while preparing the system.

1. Place the suction tube into a container of the appropriate

2.

3. Set the pressure to minimum by turning the pressure

4. Move the PRIME/SPRAY valve down to the PRIME

5. Turn the unit on by moving the ON/OFF switch to the ON

4 © Titan Tool Inc. All rights reserved.

valves to become stuck closed, which would

require disassembly and cleaning of the

sprayer’s fluid section.

solvent for the material being sprayed (refer to

recommendations of the material manufacturer). An

example of the appropriate solvent is water for latex paint.

Place the return hose into a metal waste container.

control knob fully counterclockwise.

position.

position.

Page 5

6. Allow the sprayer to run for 15–30 seconds to flush the old

WARNING

WARNING

Trigger lock

in locked position.

WARNING

Trigger lock

in locked position.

WARNING

WARNING

Trigger lock

in locked position.

solvent out through the return hose and into the metal

waste container.

7. Turn the unit off by moving the ON/OFF switch to the OFF

position.

NOTE: Make sure that the spray gun does not have a

8. Move the PRIME/SPRAY valve up to the SPRAY position.

9. Turn the unit on. Make sure the pressure is still set to

10. Unlock the gun by turning the gun trigger lock to the

Ground the gun by holding it against the

edge of the metal container while flushing.

Failure to do so may lead to a static

electric discharge, which may cause a fire.

11. Trigger the gun into the metal waste

12. Lock the gun by turning the gun

13.

14. Check the entire system for leaks.

15. Follow the “Pressure Relief Procedure” in this manual

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for cleanup.

tip or tip guard installed.

minimum with the pressure control knob turned fully

counterclockwise.

unlocked position.

container until the old solvent is gone

and fresh solvent is coming out of the gun.

trigger lock to the locked position.

Set down the gun and increase the

pressure by turning the pressure

control knob slowly clockwise.

If leaks occur, follow the “Pressure

Relief Procedure” in this manual

before tightening any fittings or hoses.

before changing from solvent to paint.

Painting

1. Place the suction tube into a container of paint.

2. Place the return hose into a metal waste container.

3. Set the pressure to minimum by turning the pressure

control knob fully counterclockwise.

4. Move the PRIME/SPRAY valve down to the PRIME

position.

5. Turn the unit on by moving the ON/OFF switch to the ON

position.

6. Allow the sprayer to run until paint is coming through the

return hose into the metal waste container.

7. Turn the unit off by moving the ON/OFF switch to the OFF

position.

8. Remove the return hose from the waste container and

place it in its operating position above the container of

paint.

9. Move the PRIME/SPRAY valve up to the SPRAY position.

10. Turn the unit on.

11. Unlock the gun by turning the gun trigger lock to the

unlocked position.

12. Trigger the gun into the metal waste container until all air

and solvent is flushed from the spray hose and paint is

flowing freely

13. Lock the gun by turning the gun

trigger lock to the locked position.

14. Turn the unit off.

15. Attach tip guard and tip to the gun

as instructed by the tip guard or tip

manuals.

POSSIBLE INJECTION HAZARD. Do not spray without the

tip guard in place. Never trigger the gun unless the tip is

in either the spray or the unclog position.

the gun trigger lock before removing, replacing or

cleaning tip.

16. Turn the unit on.

17.

Increase the pressure by turning the pressure control

knob slowly clockwise and test the spray pattern on a

piece of cardboard. Adjust the pressure control knob until

the spray from the gun is completely atomized. Try to

keep the pressure control knob at the lowest setting that

maintains good atomization.

NOTE: Turning the pressure up higher then needed to

atomize the paint will cause premature tip wear

and additional overspray.

. from the gun.

Always engage

Pressure Relief Procedure

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for cleanup.

1. Lock the gun by turning the gun

trigger lock to the locked position.

2. Turn the unit off by moving the

ON/OFF switch to the OFF position.

3. Set the pressure to minimum by

turning the pressure control knob

fully counterclockwise.

4. Unlock the gun by turning the gun

trigger lock to the unlocked position.

5. Hold the metal part of the gun firmly to

the side of a metal container to ground

the gun and avoid a build up of static

electricity.

6.

Trigger the gun to remove any

pressure that may still be in the hose.

7. Lock the gun by turning the gun trigger lock to the locked

position.

8. Move the PRIME/SPRAY valve down to the PRIME

position.

Ground the gun by holding it against the

edge of the metal container while flushing.

Failure to do so may lead to a static

electric discharge, which may cause a fire.

© Titan Tool Inc. All rights reserved. 5

Page 6

Spraying

Too Thick

Offspray

Arcing Gun at angle

start

stroke

release

trigger

pull

trigger

end

stroke

WARNING

Good spray pattern

Paint tailing pattern

Overlap edges

1st

pass

2nd

pass

3rd

pass

4th

pass

5th

pass

POSSIBLE INJECTION HAZARD. Do not spray without the

tip guard in place. Never trigger the gun unless the tip is

in either the spray or the unclog position. Always engage

the gun trigger lock before removing, replacing, or

cleaning tip.

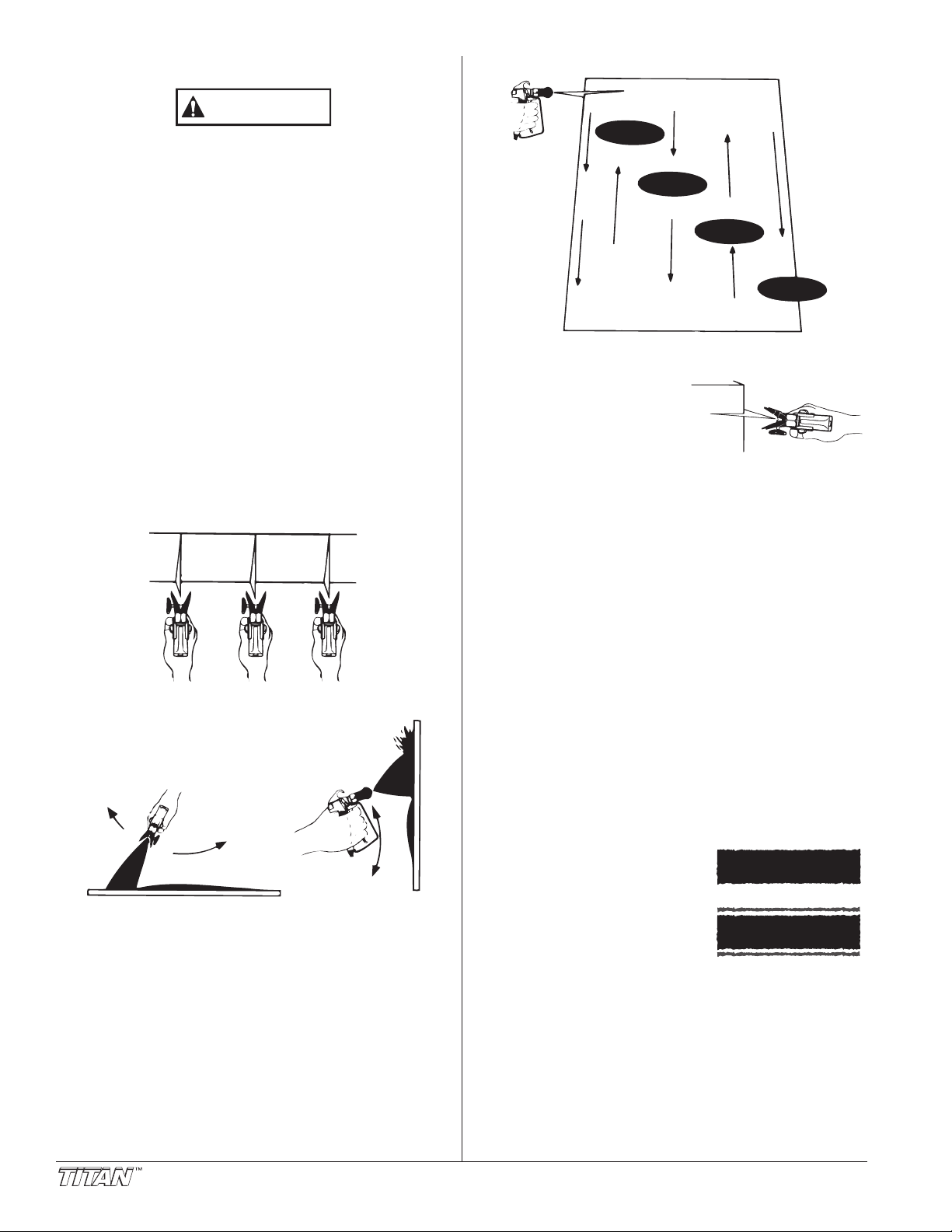

Spraying Technique

The following techniques, if followed, will assure professional

painting results.

Hold the gun perpendicular to the surface and always at equal

distance from the surface. Depending on the type of material,

surface, or desired spray pattern, the gun should be held at a

distance of 30 to 35 cm (12 to 14 inches).

Move the gun either across or up and down the surface at a

steady rate. Moving the gun at a consistent speed conserves

material and provides even coverage. The correct spraying speed

allows a full, wet coat of paint to be applied without runs or sags.

Holding the gun closer to the surface deposits more paint on

the surface and produces a narrower spray pattern. Holding

the gun farther from the surface produces a thinner coat and

wider spray pattern. If runs, sags, or excessive paint occur,

change to a spray tip with a smaller orifice. If there is an

insufficient amount of paint on the surface or you desire to

spray faster, a larger orifice tip should be selected.

Maintain uniform spray stroke action. Spray alternately from

left to right and right to left. Begin movement of the gun before

the trigger is pulled.

Avoid arcing or holding the gun at an angle. This will result in

an uneven finish.

Proper lapping (overlap of spray pattern) is essential to an

even finish. Lap each stroke. If you are spraying horizontally,

aim at the bottom edge of the preceding stroke, so as to lap

the previous pattern by 50%.

For corners and edges, split the

center of the spray pattern on the

corner or edge and spray

vertically so that both adjoining

sections receive approximately

even amounts of paint.

When spraying with a shield, hold it firmly against the surface.

Angle the spray gun slightly away from the shield and toward

the surface. This will prevent paint from being forced

underneath.

Shrubs next to houses should be tied back and covered with a

canvas cloth. The cloth should be removed as soon as possible.

gun extensions are extremely helpful in these situations.

Nearby objects such as automobiles, outdoor furniture, etc.

should be moved or covered whenever in the vicinity of a

spray job. Be careful of any other surrounding objects that

could be damaged by overspray.

Practice

1. Be sure that the paint hose is free of kinks and clear of

objects with sharp cutting edges.

2. Turn the pressure control knob counterclockwise to its to

its lowest setting.

3. Turn the PRIME/SPRAY valve up to its SPRAY position.

4. Turn the pressure control knob clockwise to its highest

setting. The paint hose should stiffen as paint begins to

flow through it.

5. Unlock the gun trigger lock.

6. Trigger the spray gun to bleed air out of the hose.

7. When paint reaches the spray tip, spray a test area to

check the spray pattern.

8. Use the lowest pressure setting

necessary to get a good spray

pattern. If the pressure is set too

high, the spray pattern will be too

light. If the pressure is set too

low, tailing will appear or the

paint will spatter out in gobs

rather than in a fine spray.

6 © Titan Tool Inc. All rights reserved.

Page 7

Cleanup

WARNING

WARNING

CAUTION

WARNING

WARNING

CAUTION

Special cleanup instructions for use with flammable

solvents:

• Always flush spray gun preferably outside and at least one

hose length from spray pump.

If collecting flushed solvents in a one gallon metal

•

container, place it into an empty five gallon container, then

flush solvents.

• Area must be free of flammable vapors.

• Follow all cleanup instructions.

The sprayer, hose, and gun should be cleaned thoroughly

after daily use. Failure to do so permits material to build

up, seriously affecting the performance of the unit.

Always spray at minimum pressure with the gun nozzle tip

removed when using mineral spirits or any other solvent

to clean the sprayer

buildup may result in a fire or explosion in the presence of

flammable vapors.

1. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual.

Remove the gun tip and tip guard and clean with a brush

2.

using the appropriate solvent.

3. Place the suction tube into a container of the appropriate

solvent (refer to recommendations of the material

manufacturer). An example of the appropriate solvent is

water for latex paint.

4. Place the return hose into a metal waste container.

5. Move the PRIME/SPRAY valve down to its PRIME

position.

6. Set the pressure to minimum by turning the pressure

control knob fully counterclockwise.

7. Turn on the unit by moving the ON/OFF switch to the ON

position.

8. Allow the solvent to circulate through the unit and flush

the paint out of the return hose into the metal waste

container.

9. Turn off the unit by moving the ON/OFF switch to the OFF

position.

10. Move the PRIME/SPRAY valve up to its SPRAY position.

11. Turn on the unit.

, hose, or gun. Static electricity

14. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual.

15. Unplug the unit and store in a clean, dry area.

Do not store the unit under pressure.

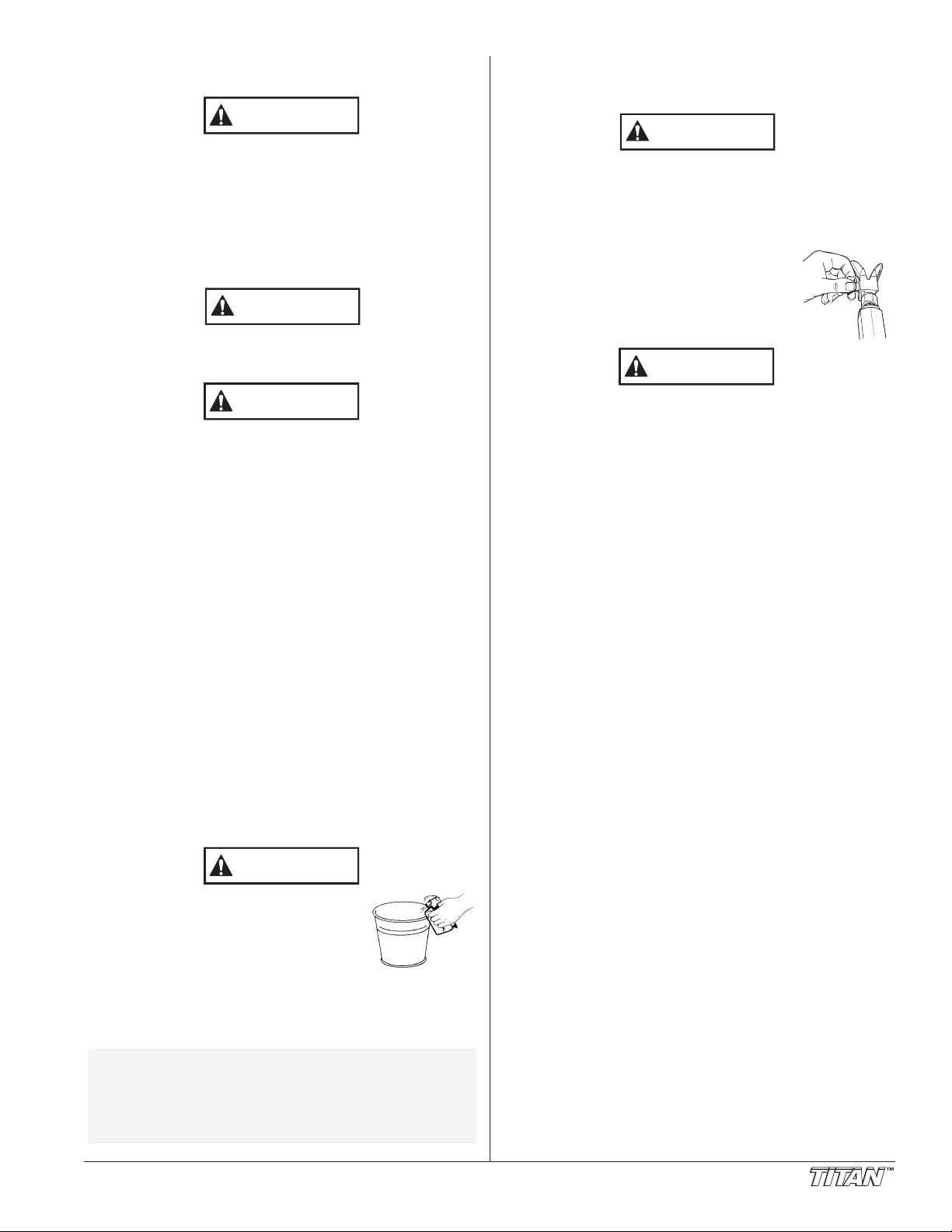

Cleaning the Spray Tip

1. Flush the gun with solvent immediately after the work is

completed.

2. Oil the retractor pins to prevent them from seizing up.

Should the spray tip become clogged, reverse

the spray tip with the lever and pull the trigger.

Once the obstruction comes out of the spray

tip, release the trigger, reverse the spray tip

back to the spray pattern setting, and resume

spraying.

Do not attempt to clean the tip with your finger.

Do not use a needle or other sharp pointed instrument to

clean the tip. The hard tungsten carbide is brittle and can

be chipped.

Ground the gun by holding it against the

edge of the metal container while

flushing. Failure to do so may lead to a

static electric discharge, which may

cause a fire.

12. Trigger the gun into the metal waste

container until the paint is flushed out of the hose and

solvent is coming out of the gun.

Continue to trigger the spray gun into the waste container

13.

until the solvent coming out of the gun is clean.

NOTE: For long-term or cold weather storage, pump

© Titan Tool Inc. All rights reserved. 7

mineral spirits through the entire system.

For short-term storage when using latex paint,

pump water mixed with Titan Liquid Shield Plus

through the entire system (see the Accessories

section of this manual for part number).

Page 8

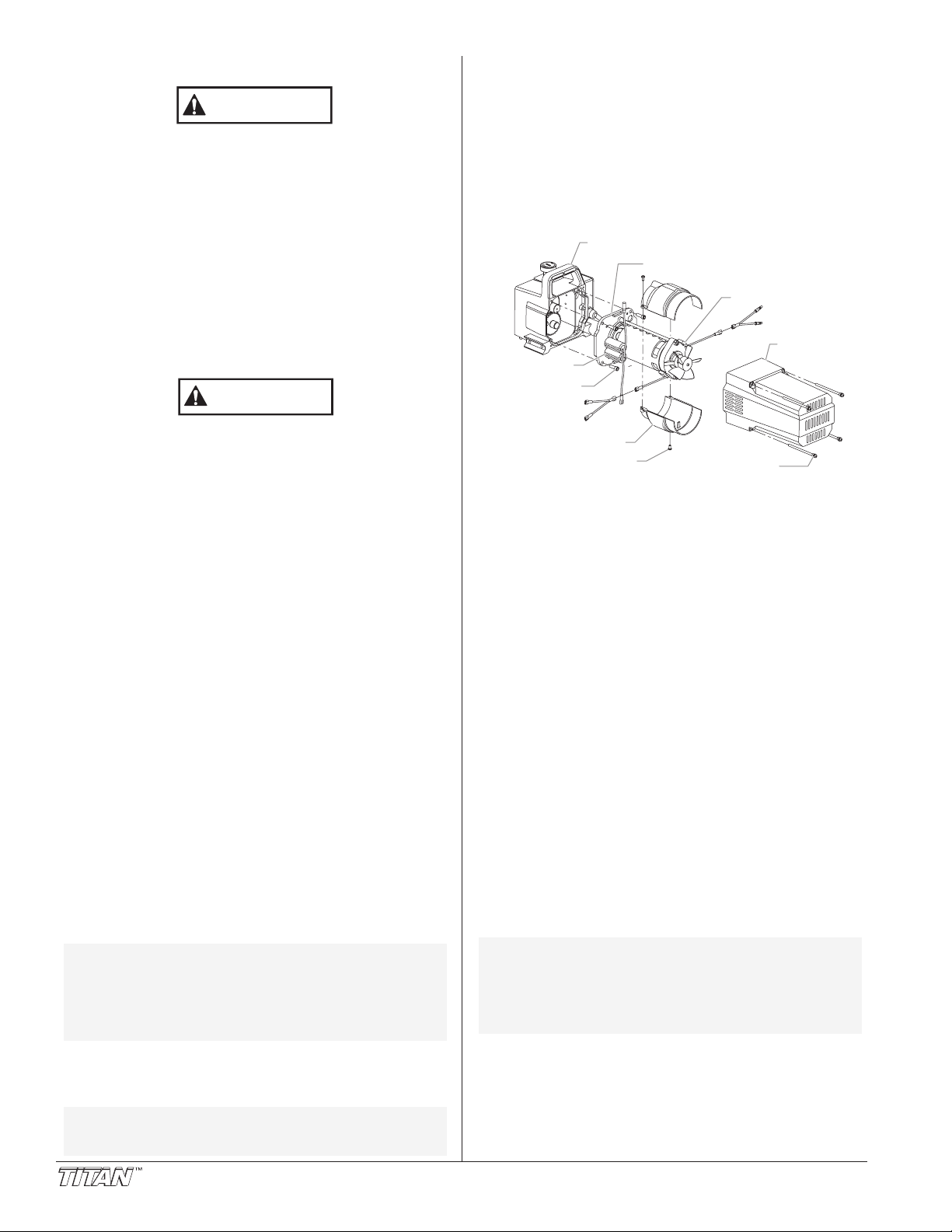

Maintenance

CAUTION

WARNING

BLACK

BLACK

BLACK

RED

RED

RED

Motor Cover

Brush Cover

Motor

Pump Housing

Capacitors

Motor Mounting

Screw

Shroud

Shroud Screw

Motor Cover

Screw

Before proceeding, follow the Pressure Relief Procedure

outlined previously in this manual. Additionally, follow all

other warnings to reduce the risk of an injection injury,

injury from moving parts or electric shock. Always

unplug the sprayer before servicing!

General Repair and Service Notes

The following tools are needed when repairing this sprayer:

1. Before repairing any part of the sprayer, read the

instructions carefully, including all warnings.

Never pull on a wire to disconnect it. Pulling on a wire

could loosen the connector from the wire.

2. Test your repair before regular operation of the sprayer to be

sure that the problem is corrected. If the sprayer does not

operate properly

everything was done correctly. Refer to the Troubleshooting

Charts to help identify other possible problems.

3. Make certain that the service area is well ventilated in

case solvents are used during cleaning. Always wear

protective eyewear while servicing. Additional protective

equipment may be required depending on the type of

cleaning solvent. Always contact the supplier of solvents

for recommendations.

4. If you have any further questions concerning your TITAN

Airless Sprayer, call TITAN:

Customer Service (U.S.) .......................1-800-526-5362

Customer Service (Canada)..................1-800-565-8665

Customer Service (International)...........1-201-337-1240

Replacing the Motor

1. Unplug the unit.

2. Loosen and remove the four motor cover screws.

Remove the motor cover.

3. Disconnect the black and red wires coming from the pump

housing. Disconnect the black and red wires from the

capacitors. Disconnect the black and red wires from the

motor.

4. Remove the capacitors from their mounting clip.

5. Loosen and remove the four motor mounting screws.

6. Pull the motor out of the pump housing.

NOTE: If the motor will not dislodge from the pump

7. With the motor removed, inspect the gears in the pump

housing for damage or excessive wear. Replace the

gears, if necessary.

8. Install the new motor into the pump housing.

NOTE: Rotate the motor fan manually until the

Phillips Screwdriver 3/8" Hex Wrench

Needle Nose Pliers 5/16" Hex Wrench

Adjustable Wrench 1/4" Hex Wrench

Rubber Mallet 3/16" Hex Wrench

Flat-blade Screwdriver 5/32” Hex Wrench

, review the repair procedure to determine if

Fax ................................................1-800-528-4826

Fax ................................................ 1-905-856-8496

Fax ................................................1-201-405-7449

housing:

• Remove the front cover plate.

• Using a rubber mallet, carefully tap on the

front of the motor crankshaft that extends

through the connecting rod.

armature gear engages with the mating gear in

the pump housing.

9. Secure the motor with the four motor mounting screws.

10. Using the double-sided tape and the tie wrap that came

with the new motor, attach the capacitors to the motor.

a. Place the double-side tape on the capacitors, and stick the

capacitors onto the motor. The capacitors should be

positioned in the same spot as they were on the old motor.

b. Wrap the tie wrap around the capacitors and the motor.

11. Reconnect the wires (refer to the electrical schematic in

the Parts List section of this manual).

12. Slide the motor cover over the motor. Secure the motor

cover with the four motor cover screws.

Replacing the Motor Brushes

Perform this procedure using Motor Brush Kit P/N 704-276.

1. Loosen and remove the four motor cover screws.

Remove the motor cover.

2. Loosen and remove the two shroud screws. Remove the

shroud.

3. Using a small screwdriver, pry off the two plastic brush

covers.

4. Disconnect the black and red wires from the motor

brushes. Remove the motor brushes.

5. Install the new motor brushes and snap on the plastic

brush covers.

6. Reconnect the black and red wires from the motor

brushes (refer to the electrical schematic in the Parts List

section of this manual).

7. Position the shroud over the motor fan. Secure the

shroud with the two shroud screws.

8. Slide the motor cover over the motor. Secure the motor

cover with the four motor cover screws.

Replacing the Gears

1. Loosen and remove the four motor cover screws.

Remove the motor cover.

2. Disconnect the black and red wires coming from the pump

housing.

3. Loosen and remove the four motor mounting screws.

4. Pull the motor out of the pump housing.

NOTE: If the motor will not dislodge from the pump

housing:

• Remove the front cover plate.

• Using a rubber mallet, carefully tap on the

front of the motor crankshaft that extends

through the connecting rod.

5. Inspect the armature gear on the end of the motor for

damage or excessive wear. If this gear is completely

worn out, replace the entire motor.

6. Remove and inspect the 2nd stage gear for damage or

excessive wear. Replace if necessary.

7. Remove and inspect the gear and crank assembly for

damage or excessive wear. Replace if necessary.

8 © Titan Tool Inc. All rights reserved.

Page 9

8. Reassemble the pump by reversing the above steps.

CAUTION

WARNING

Front Cover

Pump Housing

Front Cover Screw

2nd Stage Gear

Thrust Washer

Motor

Gear and Crank

Assembly

Armature Gear

Motor Mounting

Screw

Motor Cover

Motor Cover Screw

Gasket

Cam Base

Valve Stem

Pump Block

Valve Housing

Assembly

Valve

Handle

Groove Pin

T-Slot

Pump

Housing

Pump

Block

Pump

Block

Mounting

Screw

Front

Cover

Front

Cover

Screw

Set

Screw

Transducer

Assembly

Transducer O-Ring

During reassembly, make sure the thrust washers is in

place.

NOTE: Refill the gear box with five ounces of

Lubriplate (P/N 314-171).

Replacing the Transducer

Before proceeding, follow the Pressure Relief Procedure

outlined previously in this manual.

other warnings to reduce the risk of an injection injury,

injury from moving parts or electric shock. Always unplug

the sprayer before servicing!

10. Apply a thin film of grease to the transducer o-ring and

12. Thread the set screw into the pump housing and tighten

13. Reassemble the pump by reversing steps 1–6.

Make sure the transducer is aligned properly with the hole

in the pump block during reassembly. Improper alignment

may cause damage to the transducer o-ring.

© Titan Tool Inc. All rights reserved. 9

1. Loosen and remove the four front cover screws. Remove

the front cover.

2. Stop the sprayer at the bottom of its stroke so that the

piston is in its lowest position. Turn off and unplug the

sprayer.

Additionally, follow all

3. Tilt the pump back for easy access to the fluid section.

4. Using a 3/8” hex wrench, loosen and remove the two

pump block mounting screws.

5. Pull the pump block down approximately 1/2” from the

pump housing to clear the transducer.

6. Slide the pump block and piston rod forward until the

piston rod is out of the T-slot on the connecting rod.

7. Using an 1/8” hex wrench, loosen and remove the set

screw from the bottom of the pump housing.

8. Slide the transducer assembly out of the bottom of the

pump housing.

9. Remove the transducer o-ring from the old transducer

11. Install the new transducer assembly into the pump

assembly.

place it into the bottom of the new transducer assembly.

housing.

securely.

Replacing the PRIME/SPRAY Valve

Perform the following procedure using PRIME/SPRAY valve

replacement kit P/N 700-258.

1. Push the groove pin out of the valve handle.

2. Remove the valve handle and the cam base.

3. Using a wrench, loosen and remove the valve housing

assembly.

4. Make sure the gasket is in place and thread the new valve

housing assembly into the pump block. Tighten securely

with wrench.

5. Place the cam base over the valve housing assembly.

Lubricate the cam base with grease and line up the cam

with the pump block.

6. Line up the hole on the valve stem with the hole in the

valve handle.

7. Insert the groove pin into the valve handle and through

the valve stem to secure the valve handle in position.

Page 10

Servicing the Fluid Section

Outlet Valve

Housing

Outlet Valve

Seat

Outlet Valve

Ball

Upper Cage

Upper Seal

Piston Rod

O-Ring

Foot Valve

Housing

Foot Valve

Seat

Foot Valve

Ball

Bushing

O-Ring

Lower Cage

Lower Seal

WARNING

CAUTION

Install lower packings

with raised lip and O-ring

facing up.

Install upper packing

with raised lip and O-ring

facing down.

O-Ring

O-Ring

Raised Lip

Raised Lip

Connecting

Rod

Retainer

Nut

Piston

Guide

Upper

Packing

Pump

Block

Lower

Packings

Pump Block

Mounting

Screw

Piston Rod

T-Slot

Transducer

O-ring

Use the following procedures to service the valves and repack

the fluid section. Perform the following steps before

performing any maintenance on the fluid section.

1. Loosen and remove the four front cover screws. Remove

the front cover.

2. Stop the sprayer at the bottom of its stroke so that the

piston is in its lowest position. Turn off and unplug the

sprayer.

Before proceeding, follow the Pressure Relief Procedure

outlined previously in this manual.

other warnings to reduce the risk of an injection injury,

injury from moving parts or electric shock. Always

unplug the sprayer before servicing!

3. Unscrew the return hose assembly from the pump block.

Remove the retaining clip that holds the suction set in the

4.

foot valve. Pull the suction set out of the foot valve.

5. Tilt the pump back for easy access to the fluid section.

Servicing the Valves

The design of Titan's fluid section

allows access to the foot valve and

seat as well as the outlet valve and

seat without completely

disassembling the fluid section. It

is possible that the valves may not

seat properly because of debris

stuck in the foot valve seat or outlet

valve seat. Use the following

instructions to clean the valves and

reverse or replace the seats.

1. Using a wrench, loosen and

remove the foot valve housing

from the pump block.

2. Clean out any debris in the foot valve housing and

examine the valve housing and seat. If the seat is

damaged, reverse or replace the seat.

3. Using a 3/4" socket wrench, loosen and remove the outlet

valve housing from the piston rod.

Additionally, follow all

Repacking the Fluid Section

1. Remove the foot

valve and outlet

valve assemblies

using the steps in

the “Servicing the

Valves” procedure

above.

2. Using 3/8” a hex

wrench, loosen

and remove the

two pump block

mounting screws.

3. Pull the pump

block down

approximately 1.5

cm (1/2”)” from the

pump housing.

4. Slide the pump

block and piston

rod forward until

the piston rod is

out of the T-slot on

the connecting

rod.

5. Slide the piston

rod out through

the bottom of the

pump block

6. Loosen and remove the retainer nut and piston guide from

the pump block.

7. Remove the upper and lower packings from the pump

block.

8. Clean the pump block and install the new upper and lower

packings. Refer to the illustration below for proper

packing orientation.

NOTE: Always service the

4. Clean out any debris and

examine the valve housing and

seat. If the seat is damaged,

reverse or replace the seat.

5. Remove, clean, and inspect the

upper cage and upper ball. Replace if they are worn or

damaged.

6. Reassemble the valves by reversing the steps above.

outlet valve with the

piston rod attached to

the pump. This will

prevent the piston rod

from rotating during

disassembly of the

outlet valve.

9. Inspect the piston rod for wear and replace if necessary.

10. Reassemble the outlet valve assembly into the piston rod.

Tighten the outlet valve housing with a wrench until secure.

NOTE: Use the T-slot on the connecting rod to hold

Never use a wrench on the piston itself. This could cause

damage to the piston and cause leakage.

11. Insert the piston guide into the retainer nut. Thread the

12.

NOTE: Coat the piston guide tool and the piston rod

13. Using a wrench, tighten the retainer nut securely.

14. Slide the top of the piston rod into the T-slot on the

10 © Titan Tool Inc. All rights reserved.

the piston rod in position while securing the

outlet valve housing.

retainer nut into the pump block until it is hand tight.

Slide the piston guide tool (included in the repacking kit)

over the top of the piston rod and insert the piston rod

through the bottom of the pump block. Using a rubber

mallet, tap the bottom of the piston rod lightly until the

piston rod is in position in the pump block.

with grease before inserting them into the

pump block.

connecting rod.

Page 11

15. Position the pump block underneath the pump housing

Pump Block

Seal

Filter

Filter Housing

CAUTION

Gun Body

Handle Seal

Filter

Handle

and push up until it rests against the pump housing.

Make sure the transducer is aligned properly with the hole

in the pump block during reassembly

may cause damage to the transducer o-ring.

16. Thread the pump block mounting screws through the

pump block and into the pump housing. Tighten securely.

17. Reassemble the foot valve assembly into the pump block.

18. Insert the elbow on the suction set into the bottom of the

foot valve. Position the retaining clip into the foot valve to

secure the suction set assembly.

19. Thread the return hose into the pump block and tighten

securely.

20. Place the front cover on the pump housing and secure in

position using the four front cover screws.

21. Turn on the sprayer by following the procedure in the

“Operation” section of this manual and check for leaks.

NOTE: Repacking kit P/N 730-401 is available. For

best results use all parts supplied in this kit.

. Improper alignment

Replacing the Filters

Pump Filter

1. Loosen and remove the filter housing.

2. Turning clockwise, unscrew the filter from the pump block.

NOTE: Left-handed threads require turning the filter

3. Inspect the seal. Based on inspection, clean or replace

4. Turning counterclockwise, thread the new or cleaned filter

5. Slide the filter housing over the filter and thread it into the

clockwise to remove. If the filter breaks off in

the pump block, use a small wood screw to

remove.

the seal.

into the pump block.

pump block until secure.

Gun Filter

1. Move the gun trigger lock to the unlocked position.

2. Loosen and remove the handle assembly from the gun

head.

3. Turning clockwise, unscrew the filter from the gun head.

NOTE: Left-handed threads require turning the filter

clockwise to remove.

4. Turning counterclockwise, screw the new or cleaned filter

into the gun head.

5. Make sure the handle seal is in position and thread the

handle assembly into the gun head until secure.

6. Move the gun trigger lock to the locked position.

NOTE: For more detail, part number information, and

assembly drawings at larger scale, please see

the LX-80IIProfessional Airless Gun Owner's

Manual (P/N 313-2293).

© Titan Tool Inc. All rights reserved. 11

Page 12

Problem

The unit will not run.

Troubleshooting

Cause

1. The unit is not plugged in.

2. Tripped breaker.

3. The pressure is set too low (pressure

control knob set at minimum setting

does not supply power to unit).

4. Faulty or loose wiring.

5. Excessive motor temperature.

6. ON/OFF switch is defective.

Solution

1. Plug the unit in.

2. Reset the breaker.

3. Turn the pressure control knob clockwise to

supply power to the unit and increase the

pressure setting.

4. Inspect or take to a Titan authorized service

center.

5. Allow motor to cool.

6. Replace the ON/OFF switch.

The unit will not prime.

The unit will not build or

maintain pressure.

1. The PRIME/SPRAY valve is in the

SPRAY position.

2. Air leak in the siphon tube/suction set.

3. The pump filter and/or inlet screen is

clogged.

4. The siphon tube/suction set is clogged.

1. The spray tip is worn.

2. The spray tip is too large.

3. The pressure control knob is not set

properly.

4. The pump filter, gun filter, or inlet

screen is clogged.

5. Material flows from the return hose

when the PRIME/SPRAY valve is in the

SPRAY position.

6. Air leak in the siphon tube/suction set.

7. There is external fluid leak.

8. There is an internal fluid section leak

(packings are worn and/or dirty, valve

balls are worn).

9. Worn valve seats

10. Motor powers but fails to rotate

1. Rotate the PRIME/SPRAY valve clockwise

to the PRIME position.

2. Check the siphon tube/suction set

connection and tighten or re-tape the

connection with PTFE tape.

3. Remove the pump filter element and clean.

Remove the inlet screen and clean.

4. Remove the siphon tube/suction set and

clean.

1. Replace the spray tip following the

instructions that came with the spray gun.

2. Replace the spray tip with a tip that has a

smaller orifice following the instructions that

came with the spray gun.

3. Turn the pressure control knob clockwise to

increase the pressure setting.

4. Remove the pump filter element and clean.

Remove the gun filter and clean. Remove

the inlet screen and clean.

5. Clean or replace the PRIME/SPRAY valve.

6. Check the siphon tube/suction set

connection and tighten or re-tape the

connection with PTFE tape.

7. Check for external leaks at all connections.

Tighten connections, if necessary.

8. Clean the valves and service the fluid

section following the “Servicing the Fluid

Section” procedure in the Maintenance

section of this manual.

9. Reverse or replace the valve seats

following the “Servicing the Fluid Section”

procedure in the Maintenance section of

this manual.

10. Take unit to a Titan authorized service

center.

Fluid leakage at the upper end

of the fluid section.

1. The upper packings are worn.

2. The piston rod is worn.

12 © Titan Tool Inc. All rights reserved.

1. Repack the pump following the “Servicing

the Fluid Section” procedure in the

Maintenance section of this manual.

2. Replace the piston rod following the

“Servicing the Fluid Section” procedure in

the Maintenance section of this manual.

Page 13

Problem

Excessive surge at the spray

gun.

Troubleshooting

Cause

1. Wrong type of airless spray hose.

2. The spray tip worn or too large.

3. Excessive pressure.

Solution

1. Replace hose with a minimum of 15m (50’)

x 10mm (1/4”) grounded textile braid airless

paint spray hose.

2. Replace the spray tip following the

instructions that came with the spray gun.

3. Rotate the pressure control knob

counterclockwise to decrease spray

pressure.

Poor spray pattern.

The unit lacks power.

1. The spray tip is too large for the

material being used.

2. Incorrect pressure setting.

3. Insufficient fluid delivery.

4. The material being sprayed is too

viscous.

1. The pressure adjustment is too low.

2. Improper voltage supply.

1. Replace the spray tip with a new or smaller

spray tip following the instructions that

came with the spray gun.

2. Rotate the pressure control knob to adjust

the pressure for a proper spray pattern.

3. Clean all screens and filters.

4. Add solvent to the material according to the

manufacturer's recommendations.

1. Rotate the pressure control knob clockwise

to increase the pressure setting.

2. Connect the input voltage to the proper

voltage for the unit.

© Titan Tool Inc. All rights reserved. 13

Page 14

Consignes de sécurité

AVERTISSEMENT

ATTENTION

AVERTISSEMENT

Ce manuel contient des informations qu'il faut lire et

comprendre avant d'utiliser l'appareil. En cas d'accès à une

zone comportant l'un des symboles suivants, faire très

attention et veiller à respecter les mises en garde.

Ce symbole avertit d'un danger potentiel pouvant infliger des

blessures graves ou la mort. Il est suivi d'une consigne de

sécurité importante.

Ce symbole avertit d'un risque potentiel pour vous ou pour

l'appareil. Il est suivi d'une information importante sur la façon

d'éviter les dommages à l'appareil ou de vous protéger des

blessures superficielles.

NOTE: Les notes donnent des indications importantes

Les appareils sans air comprimé génèrent des pressions

de pulvérisation très élevées.

Attention! Danger de blessure par injection!

En cas de blessure de la peau provoquée par des produits de

revêtement ou des solvants, consulter immédiatement un

médecin. Communiquer au médecin la nature du produit de

revêtement ou du solvant qui a provoqué la blessure.

Les instructions d'utilisation précisent qu'il faut toujours

observer les consignes suivantes avant démarrage:

1. Ne pas utiliser d'appareils défectueux.

2.

3. Veiller à ce que l'appareil soit bien relié à la terre.

4. Contrôler les pressions d'utilisation acceptables.

5. Vérifier qu'aucun raccord ne comporte de fuite.

Les consignes concernant le nettoyage et l'entretien

périodique doivent être suivies avec rigueur.

Avant chaque intervention sur l'appareil ou pour chaque

arrêt du travail, les règles suivantes doivent être respectées:

1. Libérer la pression dans le pistolet et le flexible.

2. Bloquer le pistolet Wagner avec le cran de sûreté de la

3. Arrêter le moteur.

Toutes les réglementations locales en vigueur doivent être

respectées.

Pour garantir la sécurité d'utilisation des systèmes sans

air les réglementations de sécurité suivantes doivent être

suivies:

1. Pour éviter les dangers, lire attentivement les consignes

qui doivent être prises très au sérieux.

• Ne jamais mettre les doigts, les mains ou une quelconque

partie du corps dans le jet de pulvérisation.

• Ne jamais diriger le pistolet vers vous ou vers une autre

personne.

• Ne jamais utiliser le pistolet sans sa sécurité.

Bloquer le pistolet Wagner avec le cran de sûreté de la

gâchette.

gâchette.

Soyez attentifs à la sécurité!

d'utilisation et suivez les recommandations qui s'y trouvent.

2. N'employez pas des produits de revêtement avec un point

d'éclair au-dessous de 21ºC (70ºF)

3. L'utilisation de cet appareil est interdite dans les ateliers

soumis aux règlements contre les explosions.

4. Ne jamais pulvériser près d'une source d'inflammation;

par exemple flammes nues, cigarettes (les cigares et les

pipes sont également des sources d'inflammation),

étincelles, fils chauds, surfaces chaudes, etc...

5. Attention! Risque de blessure par injection!

Ne jamais pointer le pistolet vers vous-mêmes ou une

personne quelconque.

Ne jamais mettre les doigts ou la main dans le jet de

pulvérisation. Les très hautes pressions de pulvérisation

peuvent provoquer des blessures très graves. N'utiliser

jamais le pistolet sans sa protection.

Pour le montage ou démontage de la tête de pulvérisation

ou lors des pauses dans le travail, le pistolet doit toujours

être verrouillé, de façon à ce qu'il ne puisse être activé.

6. Porter un équipement respiratoire pour pulvériser. Un

masque de protection doit être fourni à l'opérateur.

De façon à prévenir les maladies professionnelles, les

consignes du fabricant de produits, solvants, et agents

nettoyants doivent être respectées lors de la préparation,

de l'utilisation ou du nettoyage de l'appareil. Des gants et

vêtements de protection et, dans certains cas, une crème

protectrice sont nécessaire pour protéger la peau.

7. Le pistolet et le flexible haute pression entre l'appareil et le

pistolet doivent avoir des spécifications permettant de

supporter la pression produite par l'appareil.

La pression de fonctionnement admissible par le flexible,

le nom du fabricant et la date de fabrication doivent être

indiqués par un marquage d'identification permanent sur

le flexible. En outre, il doit être conçu de telle façon que

la résistance électrique

8. Dans certaines conditions, la vitesse du flux peut

provoquer une charge électrostatique dans l'appareil, ce

qui peut provoquer des étincelles ou des flammes de

décharge. Il est donc important que l'appareil soir relié en

permanence à la terre de l'installation électrique. Le

contact doit se faire par l'intermédiaire d'une douille antichoc mise à la terre conformément aux réglementations.

9. Attention! Observer les précautions suivantes lors de

travaux intérieurs ou extérieurs:

Des vapeurs de solvant ne doivent pas être dirigées vers

l'appareil. Des vapeurs de solvant ne doivent pas se

former autour de l'appareil. Placer l'appareil dans le sens

opposé de l'objet à pulvériser. Lors de pulvérisations à

l'extérieur, tenir compte de la direction du vent. Lors d'un

travail à l'intérieur, prévoir une ventilation suffisante pour

assurer l'évacuation des vapeurs de solvant. Une

distance minimale de trois mètres doit être respectée

entre l'appareil et l'objet à peindre.

10. L'utilisateur doit installer un appareillage d'évacuation

conforme aux règlements en vigueur.

11. Les objets à peindre doivent être reliés à la terre.

12. Lors du nettoyage de l'appareil, ne jamais pulvériser de

solvant dans un récipient avec une petite ouverture

(comme une bonde). La formation d'un mélange explosif

air/gaz est probable. Le récipient doit être relié à la terre.

13. Nettoyage de l'appareil.

Ne jamais se servir d'un jet haute pression pour nettoyer

l'appareil. En particulier de jamais utiliser un nettoyeur

haute pression ou à vapeur. Il y a risque de pénétration

d'eau dans l'appareil ce qui peut provoquer un court-circuit.

Français

14 © Titan Tool Inc. Tous droits réservés.

Page 15

14. L’action sur la gâchette produit une force de recul sur la

main tenant le pistolet.

La force de recul du pistolet est particulièrement élevée

avec buse démontée et réglage maximum de la pompe

Airless à haute pression. Pour cette raison, en cas de

nettoyage sans buse, régler la pompe à la pression

minimum.

15. Les fiches doivent toujours être déconnectées des prises

d'alimentation électrique lors d'une intervention sur les

composants électriques.

16. Seul un électricien agréé doit réparer ou intervenir sur un

appareil électrique, même si le travail est décrit dans la

notice d'utilisation. Aucune responsabilité ne sera

acceptée en cas d'installation électrique incorrecte.

17. Placement de l'appareil sur un sol irrégulier.

L'avant de l'appareil doit être orienté vers le bas, pour que

la machine ne puisse glisser loin de l'utilisateur.

DANGER: BLESSURE PAR INJECTION - Un jet de

MESURES PREVENTIVES:

• La pression de service maximale du fluide dans l'appareil

•

• NE JAMAIS mettre une quelconque partie du corps en

• NE JAMAIS placer la main devant le pistolet. Les gants

• TOUJOURS verrouiller la gâchette du pistolet, fermer la

• Pendant la pulvérisation, toujours vérifier que la protection

• TOUJOURS retirer la protection de buse avant de rincer

• Le flexible d'alimentation en peinture peut fuir par suite

AVERTISSEMENT AU MEDECIN:

Une injection sous-cutanée est un accident traumatique.

Il est important de traiter la blessure de façon

chirurgicale aussitôt que possible. NE PAS RETARDER

le traitement pour des recherches de toxicité. La

toxicité n'est un risque qu'en cas d'injection de certains

enduits directement dans le flux sanguin. Il est

conseillé de consulter un chirurgien plasticien ou un

chirurgien des mains.

peinture sous haute pression produit par cet

appareil peut perforer la peau et les tissus

sous-jacents et provoquer des blessures

graves pouvant conduire à une amputation.

NE PAS TRAITER UNE BLESSURE PAR

INJECTION COMME UNE SIMPLE COUPURE!

Une perforation de la peau peut conduire à

une amputation. Consulter immédiatement

un médecin.

est de 20.6 MPa (3000 PSI).

NE JAMAIS diriger le pistolet vers une quelconque partie

du corps.

contact avec le jet de liquide. NE JAMAIS se mettre au

contact d'un jet de liquide provenant du flexible

d'alimentation en liquide.

n'offrent pas de protection contre une blessure par

injection.

pompe à liquide et décompresser l'appareil lors de son

entretien, du nettoyage de la protection de buse, du

remplacement de la buse de pulvérisation ou si l'appareil

reste sans surveillance. L'arrêt du moteur n'élimine pas la

pression. Le bouton AMORCAGE/PULVERISATION doit

être mis sur AMORCAGE pour libérer la pression. Se

reporter à la PROCEDURE DE DECOMPRESSION

décrite dans ce manuel.

de buse est en place. La protection de buse offre une

certaine protection contre les blessures par injection mais

sa principale fonction est préventive.

ou de nettoyer l'appareil.

d'usure, de vrillage ou de mauvais traitements. Une fuite

peut injecter du produit sous la peau. Vérifier le flexible

avant chaque utilisation.

DANGER: EXPLOSION OU INCENDIE – Les vapeurs de

MESURES PREVENTIVES:

• Toujours avoir un extincteur en état de fonctionner à

• Utiliser uniquement des flexibles haute pression

• La pompe doit être connectée à un objet mis à la terre.

•

DANGER: RISQUE D'EXPLOSION PAR INCOMPATIBILITE

MESURES PREVENTIVES:

• Ne pas utiliser d'eau de Javel.

• Ne pas utiliser de solvants aux hydrocarbures halogénés

DANGER: GENERALITES – Peut provoquer des

MESURES PREVENTIVES:

• Cette pompe à haute pression sans air comprimé est

• Vérifier, avant toute utilisation, que les flexibles ne

• Ne jamais pulvériser quand il y a du vent.

• Porter des lunettes de protection.

solvant ou de peinture sont explosives et

inflammables et peuvent causer des dommages

matériels et/ou corporels sérieux.

portée de la main.

conducteurs ou reliés à la terre pour les utilisations sans

air comprimé. S'assurer que le pistolet est bien relié à la

terre par l'intermédiaire du flexible.

Utiliser le fil de terre vert pour relier la pompe à un tuyau

d'eau, à une poutre métallique ou à une autre surface

électriquement mise à la terre.

Lors du rinçage de l'appareil, utiliser la pression minimale.

DES MA

dommages matériels ou corporels sérieux.

comme le chlorure de méthylène et le trichloroéthane-1-1-

1. Ces produits sont incompatibles avec l'aluminium et

peuvent provoquer une explosion. En cas de doute sur la

compatibilité du produit avec l'aluminium, prendre contact

avec votre fournisseur de peinture.

dommages matériels ou corporels sérieux.

conçue pour être utilisée uniquement avec des pièces

agréées par le fabricant. Toute utilisation de l'appareil

avec des pièces ne répondant pas aux normes techniques

et aux dispositifs de sécurité de base du fabricant de la

pompe se fera aux risques et périls de l'utilisateur.

présentent pas de coupures, de fuites, de traces d'usure

ni de renflement de la gaine, ainsi que des raccords

endommagés. Si le flexible a subi l'un des dommages

précités, le remplacer immédiatement. Ne jamais réparer

un flexible d'alimentation en peinture. Le remplacer par

un autre flexible relié à la terre.

TERIAUX – Peuvent être à l'origine de

Directives de mise à la terre

Cet appareil doit être relié à une terre. En cas de court-circuit,

la mise à la terre réduit le risque de choc électrique en

fournissant une ligne de fuite au courant électrique. Cet

appareil est fourni avec un câble d'alimentation muni d'un fil de

terre et d'une fiche appropriée. La fiche doit être reliée à une

prise correctement installée et mise à la terre selon les normes

et règlements locaux.

DANGER – Une installation inadéquate de la prise de terre

peut être la cause d'un choc électrique.

S'il est nécessaire de réparer ou de remplacer le câble ou la

fiche, ne pas connecter le fil vert de mise à la terre à l'une des

bornes à broches plates. Le fil comportant un isolant vert,

avec ou sans lignes jaunes est le fil de terre et doit être

connecté à la broche de terre.

Contrôler avec un électricien qualifié ou un technicien que les

directives de mise à la terre sont entièrement comprises ou en

cas de doute, que le raccordement de l'appareil à la terre est

ef

ficace. Ne pas modifier la fiche qui est fournie. Si la fiche

ne s'adapte pas à la prise, demander à un électricien qualifié

d'installer une prise appropriée.

© Titan Tool Inc. Tous droits réservés. 15

Français

Page 16

Precauciones de Seguridad

ADVERTENCIA

PRECAUCION

ADVERTENCIA

Este manual contiene información que tiene que leerse y

entenderse antes de utilizar el equipo. Cuando se encuentre

en una área que tenga uno de los siguientes símbolos, esté

muy atento y asegúrese que tiene en cuenta la seguridad.

Estos símbolos indican un peligro potencial que puede causar

graves daños o pérdidas humanas. A continuación se explica

información importante para la seguridad.

Estos símbolos indican un peligro potencial para usted o para

su equipo. A continuación se explica información que puede

prevenir daños en el equipo o cómo evitar las causas que

provocan daños menores.

NOTA: Las notas dan información importante que

Las unidades sin aire desarrollan presiones de

pulverización extremadamente altas.

¡Atención! ¡Peligro de lesiones por inyección!

En caso de lesiones en la piel causadas por materiales de

revestimiento o solventes, consultar a un médico

inmediatamente. Informar al médico del tipo de material de

revestimiento o agente de limpieza con el que se causó la lesión.

Las instrucciones de empleo señalan que deben

observarse siempre los siguientes puntos antes de

empezar:

1. No deben utilizarse las unidades averiadas.

2. Asegurar la pistola pulverizadora utilizando el pasador de

3. Asegurarse de que la unidad está puesta a tierra

4. Comprobar las presiones operativas permisibles.

5. Comprobar todas las conexiones para ver si existen fugas.

Deben observarse estrictamente las instrucciones

referentes a la limpieza y mantenimiento regular de la

unidad.

Antes de realizar ningún trabajo en la unidad o cuando se

tome un descanso en el trabajo, deben observarse las

siguientes normas:

1. Aliviar la presión de la pistola pulverizadora y de la

2.

3. Apagar el motor.

tendría que ser considerada con especial

atención.

• Nunca poner los dedos, las manos ni ningún otro

miembro del cuerpo en la boquilla del pulverizador

• Nunca apuntar la pistola pulverizadora a uno mismo ni a

ninguna otra persona.

• Nunca utilizar la pistola pulverizadora sin la protección de

seguridad.

seguridad en el disparador.

correctamente.

manguera.

Asegurar la pistola pulverizadora utilizando el pasador de

seguridad en el disparador.

¡Ser precavido!

.

Deben observarse todas las ordenanzas locales en vigor.

Para asegurar un funcionamiento seguro de los sistemas

sin aire deben seguirse las normas de seguridad que se

listan a continuación:

1. Para evitar peligros, leer detalladamente las instrucciones

de empleo y seguir las instrucciones que se indican en las

mismas.

2. No utilice los materiales de revestimiento con un punto de

inflamación debajo de 21ºC (70ºF).

3. Se prohíbe el uso de esta unidad en talleres que estén

bajo ordenanzas de prevención de explosiones.

4. Nunca operar cerca de fuentes de combustión, v.gr.:

llamas abiertas, cigarrillos, cigarros y pipas, chispas,

alambres al rojo vivo, superficies calientes, etc.

5. ¡Atención! ¡Riesgo de lesiones por inyección!

Nunca apuntar la pistola pulverizadora a uno mismo ni a

otras personas.

Nunca poner los dedos o las manos en la boquilla del

pulverizador. Las presiones de pulverización que son muy

altas pueden ocasionar lesiones muy graves. Nunca

utilizar la pistola pulverizadora sin la protección de

seguridad.

Al instalar y extraer la puntera y durante los descansos en el

trabajo, la pistola pulverizadora debe estar siempre

bloqueada, de forma que no pueda activarse.

6. Usar equipo respiratorio al pulverizar. El operario debe

estar provisto con una mascarilla protectora.

Para evitar enfermedades profesionales, deben

observarse las regulaciones del fabricante con respecto a

los materiales, solventes y agentes de limpieza utilizados

al preparar, trabajar con y limpiar la unidad. Para proteger

la piel es necesario usar ropa protectora, guantes y, en

algunos casos, crema protectora de la piel.

7. La pistola pulverizadora y la manguera de alta presión

entre la unidad y las pistola pulverizadora debe ser de un

estándar suficiente para la presión producida en la

unidad.

En la manguera debe indicarse con una marca de

identificación permanente la presión operativa permisible para

la manguera de alta presión, el fabricante y la fecha de

fabricación de la misma. Además, debe estar construida de

tal forma que la resistencia eléctrica entre las conexiones a la

unidad y la pistola pulverizadora sea igual a o inferior a un

megaohmio.

8. En ciertas condiciones la velocidad del caudal puede

causar una carga electroestática en la unidad. Esto puede

causar chispas o llamas en la descarga. Por lo tanto, es

importante que la unidad esté siempre puesta a tierra

sobre la instalación eléctrica. El contacto debe realizarse

usando un receptáculo a prueba de sacudidas puesto a

tierra conforme a las regulaciones.

9. ¡Atención! Observar las siguientes indicaciones al trabajar

en el interior y al aire libre:

No deben llevarse gases de solventes a la unidad. No

deben formarse gases de solventes cerca de la unidad.

Instalar la unidad en el lado opuesto al objeto que se vaya a

pulverizar. Cuando se pulverice al aire libre, tener en cuenta

la dirección del viento. Al trabajar en el interior, asegurarse

de que haya suficiente ventilación para la extracción de los

gases de solvente. Debe observarse una distancia mínima

de 3 m entre la unidad y el objeto que se esté pulverizando.

10. El usuario debe tener instalado un equipo de extracción

conforme a los reglamentos locales.

11. Los objetos que se estén pulverizando deben estar

puestos a tierra.

12. Al limpiar la unidad, no pulverizar nunca solventes en un

envase que tenga una abertura pequeña (piquera). Puede

formarse una mezcla explosiva de gas/aire. El envase

debe estar puesto a tierra.

Español

16 © Titan Tool Inc. Todos los derechos reservados.

Page 17

13. Limpieza de la unidad.

Nunca debe utilizarse una boquilla gruesa para pulverizar

la unidad. En particular, nunca debe utilizarse un

limpiador de alta presión o limpiador a vapor de alta

presión. Hay peligro de que el agua penetre en la unidad

y cause un cortocircuito.

14. El apriete del disparador ejerce una fuerza de retroceso

en la mano, con la que se dirige la pistola de

pulverización.

La fuerza de retroceso de la pistola de pulverización es

especialmente elevada con la boquilla desmontada y la

bomba de alta presión Airless ajustada a presión elevada.

Por esa razón, para la limpieza sin boquilla, ajustar la

válvula reguladora de presión a la graduación más baja.

15. La clavija principal debe estar siempre desconectada del

receptáculo cuando se esté trabajando en los

componentes eléctricos.

16. El trabajo o reparaciones en el equipo eléctrico debe ser

llevado a cabo solamente por un electricista especializado,

incluso si el trabajo se describe en las instrucciones de

operación. No se aceptará responsabilidad alguna por una

instalación eléctrica incorrecta.

17. Posicionamiento cuando el suelo está desnivelado.

La parte delantera de la unidad debe señalar hacia abajo

para que la máquina no pueda resbalar.

PELIGRO: LESIONES POR INYECCION - Un chorro de

PREVENCION:

• La gama operativa máxima de la bomba es una presión

•

• NUNCA permitir que ninguna parte del cuerpo entre en

• NUNCA poner la mano delante de la pistola. Los guantes no

• Bloquear SIEMPRE el disparador de la pistola, apagar la

• La protección de la puntera debe estar siempre en su lugar

• Extraer SIEMPRE la puntera de pulverización antes de

• La manguera de pintura puede desarrollar fugas por

NOTA AL MEDICO: La inyección en la piel es una lesión

traumática, por ello es importante tratar la lesión

quirúrgicamente tan pronto como sea posible. NO

retrasar el tratamiento para investigar la toxicidad. La

toxicidad está vinculada con algunos revestimientos