Page 1

OWNERS

MANUAL

DO

NOT

USE

EQUIPMENT BEFORE

II

I

READING

FOR

313"" 233

THIS

MANUAL

PROFESSIONAL

USE

ONLY

REV

1i96F

Epic 660ex.

100V Pump Only -702-212 100V Complete -702-213

120V

230V

Pump Only -702-075 120V Complete

Pump Only -

This manual contains important warnings and instructions.

Never operate this unit unless it is properly grounded.

702-1

Please

02 230V Complete -

read

and retain for

reference.

...

702-080

702-1

04

Page 2

Table

Accessories

General Repairs/Service

Maintenance/Service Record

Warnings

Aviso (En

Attention (En Fran9ais)

Notice: Fire

Start-up Procedure

Cleaning Procedure

Flushing Specification

Application Techniques

Airless Tip

Troubleshooting

of

Contents

Espafiol)

or

Selection

Spray Pattern

Airless Gun

Airless Pump

Explosion Hazards

8&9

14&

Parts Drawings &

2

3

4

5

6

7

10

11

12

13

14

Repair Information 16-25

Replacement Labels ............................

Low Rider Frame ................................. 16

Skid Frame .......................................... 17

Electrical Schematics.........................

Motor Housing ..................................... 19

Gear

Box .............................................

Gear

Repair .........................................

On/Off Switch ......................................

Motor Starter, Brushes .........................

Filter Block ...........................................

Pressure Switch ................................... 23

15

Prime Relief

Filter Replacement... ............................

Fluid Section ........................................

Syphon Assembly ................................

Pump Repair ........................................ 25

Valve ...............................

Accessories

Equipment

Stand

17

5 Gallon Swivel Syphon ..... , .................

Stand up Fluid Section ......................... 27

Complete Pumps for

20

Europe, Canada

Specifications ...................................... 28

20

Warranty .............................................. 28

21

21

21

22

23

23

24

24

U.S. Patents: 3,936,002; 4,220,286;

4,457,472; 4,508,268; 4,494,697;

4,500, 119; 4,626,004; 4,611 ,758;

4,744,571; 4,728,213; 4,768,932;

4,755,638; 4,768,929; 4,840,543;

4,908,538; 5,074,467; 5,425,506

Job

History ........................ 26

up

Pump & Frame .....................

& 100v ....................... 27

27

27

LIQUID SHIELD

Cleans and protects spray systems

against rust, corrosion and premature

wear.

of

12

(1

Case

1 Quart 700-889

PISTON

Specially

materials from adhering to the piston

rod, which becomes abrasive to the

upper seals. Piston Lube

down any material that may

accumulate in the wet cup and keep it

from drying.

8

Oz individual

1 Qt individual

Oz, case of 12

8

1 Qt, case of

quart bottles)

SEAL

LUBRICANT

formulated to prevent

12

700:888

will break

700-925

700-926

700-911

700-912

AIRLESS HOSE

I.D.

X Length

1/4" X 25'

1/4" X 50'

3/8"

X 50'

3/16"

X

9'

3/16" X 15'

HIGH PRESSURE SWIVELS

Pressure Rated at 5000 psi

Gun-to-Hose

1/4" NPS (F) x 1/4" NPS (M) 500-428

Hose-to-Hose

1/4" NPS (M) x 1/4" NPS(M) 500-424

FITTINGS

x 1/4" Hose Coupling 490-012

1/4"

1/4"

x 3/8" Hose Coupling 490-016

3/8"

x 3/8" Hose Coupling 490-014

T-Fittings, 1/4" x 1/4" 490-036

Tip Filter Retainer 520-046

1/4" Mx1/4"F Swivel

1/4" Mx3/8"F Swivel

Retaining Nut Adapter 490-007

High Pressure

Fl.

Gauge 730-394

Product No.

316-513

316-505

690-375-50

550-222

550-221

Union 490-005

Union 490-032

2

Page 3

Epic

1

OOV

Pump

Pump

120V

230V Pump

Only

Only

Only

- 702-212

- 702-075

-702-102

1

OOV

Complete

120V

Complete

230V

Complete

Add

P.S.L. here

(Piston Seal Lubricant)

- 702-213

- 702-080

-702-104

Figure 1

G.eneral

WARNING: Before proceeding,

Relief Procedure

follow

injection injury,

shock.

The

sprayer:

Phillips Screwdriver

Needle Nose Pliers

Adjustable Wrench

Rubber

Flat-blade Screwdriver

1/2" Open End Wrench

1.

instructions

2. When disconnecting wires, use needle nose pliers to

separate mating connectors.

all

following tools are needed when repairing this

Before repairing any part of the sprayer, read the

Repair & Service Notes:

follow

outlined

other

warnings

injury

Always

Mallet

unplug

carefully, including all warnings.

on

Page 5. Additionally,

to

reduce

from

moving

the

sprayer before servicing!

3/B"AIIen Wrench

5/16"

Allen Wrench

Allen Wrench

1/4"

Allen Wrench

3/16"

Allen Wrench

1/8"

the Pressure

the

risk

parts

of

or

electric

an

Filter

CAUTION: Never

Pulling

wire.

3.

to

does not operate properly, review the repair procedure to

determine if everything was done correctly. Refer to the

Troubleshooting Charts to help identify other possible

problems.

4.

case solvents are used during cleaning. Always wear

protective eyewear while servicing. Additional protective

equipment may be required depending

cleaning solvent. Always contact the supplier of solvents

for recommendations.

5.

TITAN Airless Sprayer, call TITAN Customer Service

Department at 1-800-526-5362.

3

on

a wire could loosen the connector from the

Test your repair before regular operation of the sprayer

be

sure that the problem is corrected. If the sprayer

Make certain that the service area is well ventilated

If

you

have any further questions concerning your

pull

on a wire

to

disconnect

on

the type

it.

in

of

Page 4

MODEL#

SERIAL#

DATE PURCHASED COMPANY NAME

Titan Tool is

become more efficient and profitable. We feel that if you accurately track the maintenance

in

the business of designing and manufacturing spray systems and accessories that make today's Painting Professional

of

your

equipment

on

this chart it wi''

improve the performance of this valuable tool to help you get the most out of your investment.

The chart is easy

to

follow and to use. The Maintenance Schedule allows for the recording of all your service work and will help you

make sure your unit is always running at peak performance.

Make sure to fill

in

the boxes at the top of this record with the model number, serial number, date purchased and your company

name. This information will be needed to validate your warranty.

Maintenance Schedule

Check Piston Seal Lubricant Level

EPIC 660ex

Gas Engine Models

Change Engine Oil

Date

Every 50 Hours

Clean

Air

Filter Daily

It is extremely important to clean the air filter daily. Consult the Honda Engine Manual supplied with your unit for proper

cleaning instructions.

Air

Filter

Date

Replaced

Date

Date

Electric Motor Models

Check

Brushes

200 Hours

Motor

Every

Date

Date

WEEKLY.

Date Date Date

Date

Date Date Date

Date

Date

Date

Dale

Date

Date

Date

Date

Date

Dale Date

Date Dale Date

Date

Date

· Date

I

Date

Months in

Date

Months in

Date

Months in

Dale

Months in

Date

Months in

Service Center

Service Cost of Repair

Service Center

Service Cost of Repair

Service Center

Service Cost of Repair

Service Center

Service Cost of Repair

Service Center

Service

Cost

of

Repair

Service Performed

Service Performed

Service Performed

Service Performed

Service Performed

Service Record

May Be Copied For Field Use

4

Warranty

Repair

DYes

D No

Warranty

Repair

DYes

D No

Warranty

Repair

DYes

D No

Warranty

Repair

DYes

D No

Warranty

Repair

DYes

D No

I

Page 5

DO NOT USE EQUIPMENT BEFORE READING THIS SECTION

HIGH PRESSURE SPRAY

CAN CAUSE SERIOUS INJURY

Maximum Working Pressure 3000 psi,

An airless spray gun requires that fluid

be introduced to it

Fluids under liigh pressure, from spray

leaks, can penetrate the skin and inject

substantial quantities

the body.

treated, the injury can cause tissue death

or

gangrene and may result in serious,

permanent disability

wounded part. Therefore, extreme

caution must be exercised when using

any airless spray equipment.

ARE

IMMEDIATELY. DO

SIMPLE CUT!

NOTE

the skin is a serious, traumatic injury.

important to treat the injury

soon as possible. Do not delay treatment

to research toxicity. Toxicity is a concern

with some exotic coatings injected

directly into the bloodstream.

Consultation with a plastic surgeon

reconstructive hand surgeon may be

advised.

1) Handle the spray gun

Keep clear of the nozzle. NEVER point

the gun at yourself

NEVER permit any part of

come

either the gun

ALWAYS

lever

spraying.

guard.

2) NEVER attempt to force the flow

fluid backward through the gun with your

finger, hand or hand-held object against

the gun nozzle.

SPRAY

3) NEVER attempt to remove tip,

disassemble or repair equipment without

first doing the

4) Before flushing system, always

If

INJECTED, SEE A PHYSICIAN

TO PHYSICIAN: Injection into

in

contact with the fluid stream of

keep the gun trigger safety

in

a locked position when not

ALWAYS

GUN.

PRESSURE

A.

Set

trigger

B.

Shut

off

C.

Release

and

trigger

D.

Reset

trigger

remove spray tip and adjust fluid

pressure to lowest possible setting.

5) Tighten all fluid connections before

each use. NEVER exceed

this" unit. Make sure that all accessory

hoses, connections, swivels and so forth

can withstand the high pressures which

at

very high pressure.

of

toxic fluid into

not promptly and properly

or

amputation

IF YOU

NOT

or

or

any hose leak.

use a tip safety

THIS IS

following:

RELEASE

pump

fluid

PROCEDURE

safety

in a locked

and

unplug

pressure

TREAT

carefully.

anyone else.

your

NOT

electrical

from

AS

surgically

body to

AN

AIR

position.

entire

system

gun.

safety

in a locked

position.

3000 psi with

of

the

It is

as

or

a

of

cord.

or

A

WARN

develop. NEVER exceed the pressure

rating

of

any component in the system.

6)

WARNING: The paint

develop leaks from wear, kinking, abuse,

etc. A leak is capable of injecting fluid into

the skin, therefore the paint hose should

be

inspected before each use. NEVER

attempt to plug a hose with

your

body, adhesive tape

makeshift device. Do not attempt to

repair a spray hose.

with a new grounded hose. Use only with

hoses that have spring guards. NEVER

use less than

7) Be sure

being used and the object being sprayed

are properly grounded to prevent static

discharge or sparks which could cause

fire

or

explosion. WARNING:

hold the gun against metal container

when flushing system

prevent static discharge. CAUTION:

reduce the risk

expose to rain. Store indoors.

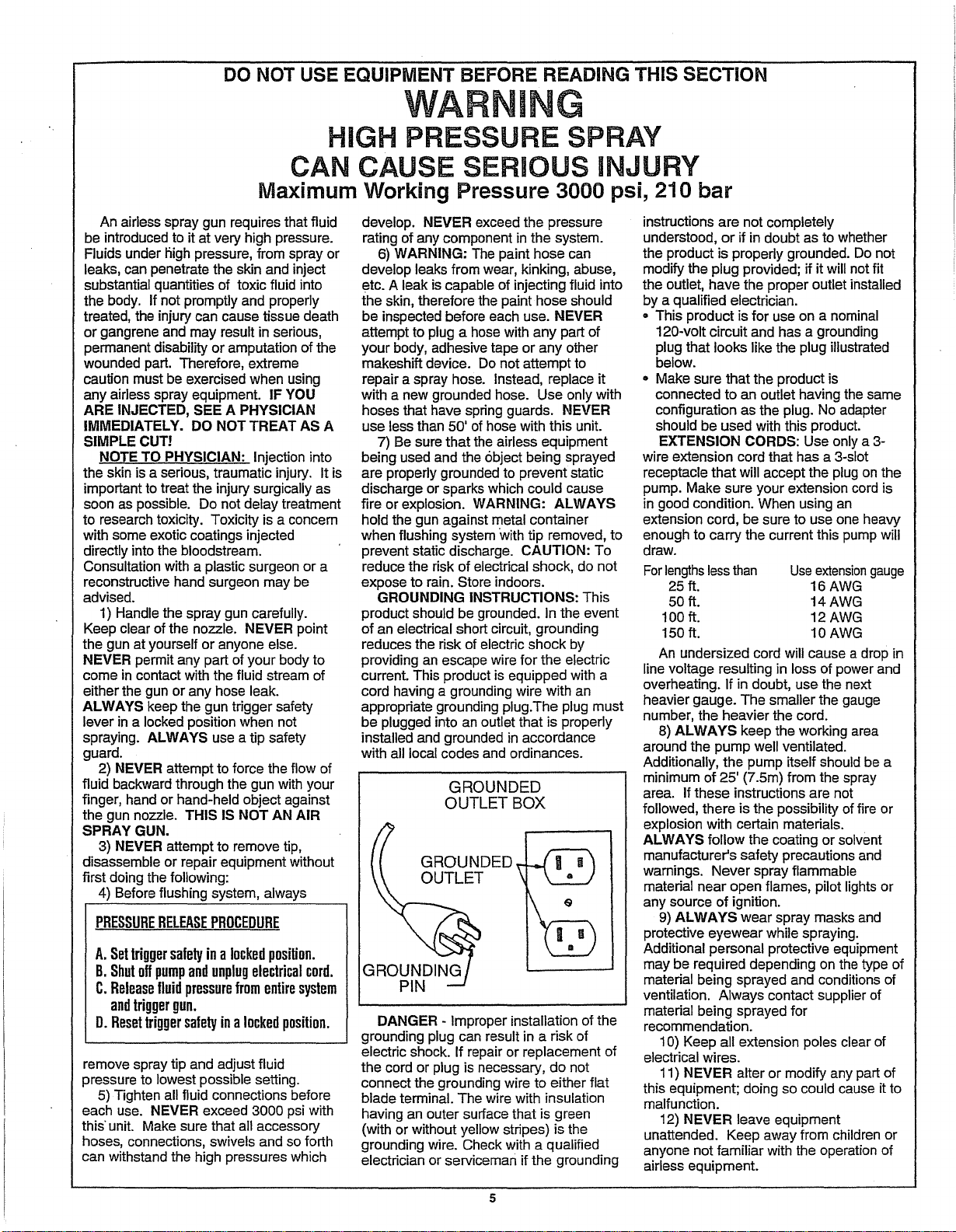

GROUNDING INSTRUCTIONS: This

product should be grounded.

of

an electrical short circuit, grounding

reduces the risk

providing an escape wire for the electric

current. This product is equipped with a

cord having a grounding wire with an

appropriate grounding plug.The plug

be

plugged into an outlet that is properly

installed and grounded in accordance

with all local codes and ordinances.

50' of hose with this unit.

that

of

of

IN

hose

can

any

part

of

or

any

other

Instead, replace it

the airless equipment

ALWAYS

with tip removed, to

electrical shock, do

In the event

electric shock by

To

not

must

GROUNDED

OUTLET BOX

GROUNDED

OUTLET

DANGER - Improper installation of the

grounding plug can result in a risk of

electric shock.

the

cord or plug is necessary,

connect the grounding wire to either flat

blade terminal.

having an outer surface that is green

(with

or

grounding wire. Check with a qualified

electrician

If repair

The

without yellow stripes) is the

or

serviceman if the grounding

or

replacement

do

not

wire with insulation

of

21

0 bar

instructions

understood,

the product is properly grounded. Do not

modify the plug provided; if it

the outlet,

by

a qualified electrician.

• This product is for use on a nominal

120-volt circuit and has a grounding

plug that looks like the plug illustrated

below.

• Make sure that the product is

connected

configuration as the plug. No adapter

should be used with this product.

EXTENSION CORDS: Use only a 3wire extension cord that has a 3-slot

receptacle

pump. Make sure your extension cord is

in good condition. When using an

extension cord, be sure to use one heavy

enough to carry the current this pump

draw.

For

lengths

25ft.

50 ft.

100ft.

150ft.

An

line voltage resulting in loss of power and

overheating.

heavier gauge.

number, the heavier the cord.

8)

around the

Additionally, the pump itself should be a

minimum

area.

followed, there is the possibility of fire

explosion with certain materials.

ALWAYS

manufacturer's safety precautions and

warnings.

material

any source

9)

protective eyewear while spraying.

Additional personal protective equipment

may

material being sprayed and conditions of

ventilation. Always contact supplier of

material being sprayed for

recommendation.

1

0) Keep all extension poles clear of

electrical wires.

11) NEVER alter

this equipment; doing

malfunction.

12) NEVER leave equipment

unattended. Keep away from children

anyone not familiar with the operation

airless equipment.

are

not completely

or

if in doubt as to whether

will not fit

have

the proper outlet installed

to

an outlet having the same

that

will accept the plug on the

will

less

than

undersized cord will cause a drop in

If in doubt, use the next

The

ALWAYS

If these instructions are not

ALWAYS

be required depending on the type

keep the working area

pump

of

25' (7.5m) from the spray

follow the coating

Never

near

open flames, pilot lights

of

ignition.

wear

Use

extension

16AWG

14AWG

12AWG

10AWG

smaller the gauge

well ventilated.

or

solvent

spray flammable

spray masks and

or

modify any part

so

could cause it to

gauge

or

or

of

of

of

or

5

Page 6

NO USE

LA

ROCIADURA A PRESION ALTA

EL

EQUIPO ANTES DE LEER ESTA SECCION

ADVERTENCIA

PUEDE

CAUSAR LESION GRAVE.

Presion de Trabajo Maxima 3000 Iibras

Una

pistola

le

introduzca

liquidos

fugas,

cuerpo

texico.

Ia

lesion

gangrene, y puede

y

permanente o en

lesionada.

precauciones

de

rociadura

EXPUESTO A LA

TO

XI

COS

INMEDIATAMENTE

LA

HERIDA

CORTADURA!

NOTA

t6xicos

traumatica.

quirurgicamente

demore

toxicidad.

trata

de

toxicos

necesaria

un

cirujano

mano.

1)

Maneje

Mantengase

apunte

NUNCA

se

ponga

Ia

pistola o de

SIEMPRE

pistola

utilice

2)

JAMAS

Ia

pistola

objeto

de

Ia

pistola,

PISTOLA

3)

JAMAS

desarmar o reparar

antes

PROCEDIMIENTO DE

DESCOMPRESION

rociadora

liquido a presion

bajo

presion

pueden

penetrar

cantidades

Si

no

se

puede

causar

Por

lo

estrictas

sin

POR

COMO

PARA

en

Ia

piel

Es

importante

eltratamiento

La

toxicidad

Ia

penetracion

en

Ia

corriente

Ia

consulta

especialista

Ia

alejado

Ia

pistola

permita

en

contacto

alguna

mantenga

mientras

el

protector

intente

hacia

atras

sostenido

ya

DE

ROCIADURA

intente

con

los

pasos

sin

alta,

de

en

Ia

considerables

atiende

rapida y apropiadamente,

muerte

resultar

Ia

amputaci6n

tanto,

hay

al

usar

aire.

Sl

USTED

PENETRACION

INYECCION,

AL

MEDICO.

Sl

FUERA

EL

MEDICO:

es

una

herida

mas

pronto

para

es

asunto

de

sanguinea.

con

uh

en

de

Ia

usted u otra

parte

con

fuga

trabado

este

rociando.

de

seguridad

forzar

con

el

Ia

mano

NOSE

quitar

el

equipo

siguientes:

tratar

ciertos

Ia

rociadura

boquilla.

alguna

el

de

lo

pistol a de

hacia

que

no

con

que

A. Coloque el seguro de

en posicion trabada.

B. Apague

tambh~n

C.

Descargue

de

sistema

D.

Vuelva a trabar el seguro.

4)

Antes

boquilla

liquido

5)

Ajuste

uso.

JAMAS

cuadrada

todas

las

Ia

bomba y desconecte

el cable de electricidad.

Ia

presion del

todo

el

y de Ia pistola.

de

lavar

el

mas

esta

sistema,

bajo

posible.

las

conexiones

3000

unidad.

conexiones,

Iibras

de

rociadura y ajuste

al

valor

todas

supere

con

mangueras,

aire

requiere

muy

alta.

Ia

rociadura o de

piel e inyectar

de

liquido

del

tejido

en

incapacidad

de

que

invesligar

el

dedo,

TRATA

Ia

Ia

emplear

cualquier

HA

EST

DE

CONSUL

iNO

UNA

MERA

La

penelraci6n

seria

y

Ia

herida

posible.

Ia

serio

cuando

revestimientos

Puede

cirujano

plastico

reconstruccion

con

JAMAS

persona.

de

su

chorro

de

Ia

manguera.

el

seguro

SIEMPRE

de

Ia

boquilla.

flujo

delliquido

Ia

mano o un

contra

Ia

DE

DE

A1RE.

boquilla

haber

Ia

pistola

ni

sin

llquido

siempre

Ia

presion

antes

por

Asegurese

pulgada

de

arliculaciones

que

Los

en

o

seria

parte

equipo

ADO

TE

TRATE

No

que

cuidado.

cuerpo

liquido

de

Ia

boquilla

UNA

cumplido

quite

del

de

cada

que

giratorias y demas

se

en

condiciones

se

las

el

de

se

sea

o

de

de

por

Ia

presentan.

presion

sistema.

6)

puede

desgaste,

pueden

que

inspeccionada

intente

cuerpo o con

elemento

manguera

con

Utilice

resorte.

15,2 m con

INSTRUCCIONES

TIERRA:

En

caso

proporciona

electrica y reduce

El

producto

un

alambre y de

enchufe

Ia

debidamente

tierra,

codigos y ordenanzas

PELIGRO -La

enchufe

de

choque

emplazar

alambre

terminales

aislamiento

amarillas,

Consulte a un

no

comprende

conexi6n a tierra o si

producto

No

modifique

producto;

un

electricista

tomacorriente

•

Este

un

esta

de

JAMAS

de

cualquier

ADVERTENCIA:

presenter

inyectar

Ia

manguera

obturar

una

solamente

JAMAS

de

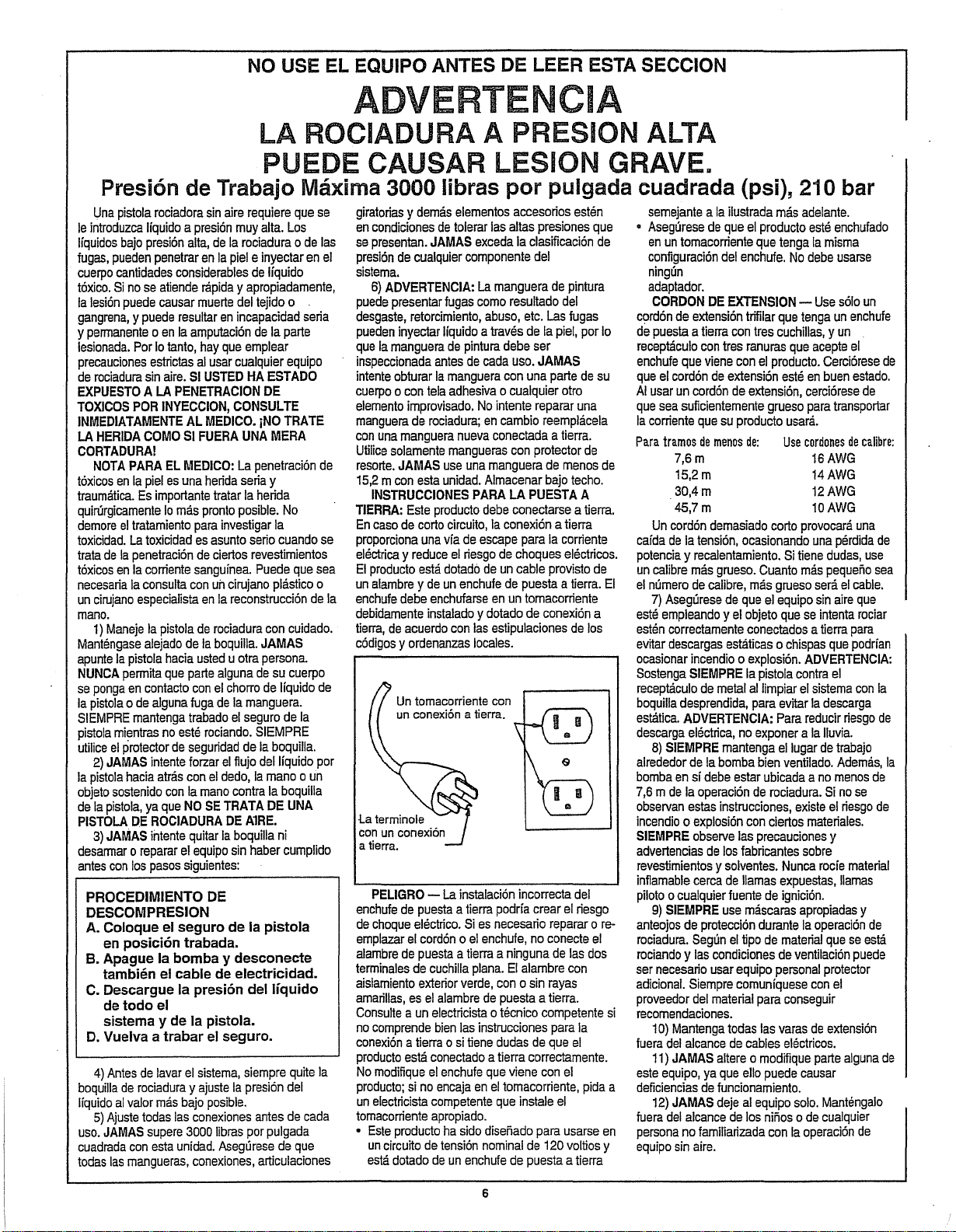

Un tomacorriente con

un conexi6n a tierra.

producto

circuito

dotado

fugas

retorcimienlo,

liquido a traves

antes

Ia

tela

improvisado.

de

rociadura;

manguera

use

esta

unidad.

Este

producto

de

corto

una

via

esta

dotado

un

debe

enchufarse

instalado y dotado

acuerdo

de

puesta a tierra

electrico.

el

cordon o el

de

puesta a tierra a ninguna

de

cuchilla

exterior

es

el

alambre

electricista o tecnico

bien

esta

conectado a tierra

el

enchufe

si

no

encaja

competente

apropiado.

ha

de

tension

de

por

elementos

tolerar

componente

de

pintura

manguera

adhesive o cualquier

nueva

mangueras

una

circuito,

de

el

riesgo

enchufe

con

instalacion

Si

verde,

las

sido

un

enchufe

accesorios

las

altas

exceda

Ia

clasificacion

La

manguera

como

resultado

abuso,

etc.

de

debe

de

cada

uso.

con

una

No

intente

en

cambio

conectada a tierra.

con

manguera

Almacenar

PARA

LA

PUESTA

debe

conectarse a tierra.

Ia

conexion a tierra

escape

para

de

choques

de

un

cable

de

puesta a tierra.

en

un

tomacorriente

las

locales.

es

plana.

instrucciones

tiene

en

de

estipulaciones

incorrecta

podria

necesario

enchufe,

nominal

no

El

alambre

con o sin

de

puesta a tierra.

dudas

correctamente.

que

viene

el

tomacorriente,

que

instale

disefiado

de

de

puesta a tierra

presiones

del

Las

Ia

ser

JAMAS

reparar

reemplacela

protector

de

bajo

conexion

crear

conecte

competente

de

con

para

120

pulgada cuadrada (psi), 210 bar

esten

que

de

de

pintura

del

fugas

piel,

por

parte

de

su

otro

una

de

menos

techo.

A

Ia

corriente

electricos.

provisto

de

a

de

los

del

el

riesgo

reparar o re-

el

de

las

dos

con

rayas

para

Ia

que

el

el

pida

el

usarse

voltios

semejante a Ia

•

Asegurese

en

configuraci6n

ningun

adaplador.

CORDON

cordon

lo

de

puesta a tierra

receptaculo

enchufe

que

el

AI

usar

que

sea

Ia

corriente

Para

de

Un

cafda

potencia y recalentamiento.

un

El

en

y

calibre

el

numero

7)

este

esten

evitar

ocasionar

Sostenga

receptaculo

boquilla

estatica.

descarga

8)

alrededor

bomba

7,6 m de

observan

incendio o explosion

SIEMPRE

advertencies

revestimientos y solventes.

inflamable

piloto o cualquier

9)

anleojos

rociadura.

rociando y las

ser

necesario

adicional.

proveedor

si

recomendaciones.

1

0)

Iuera

11)

este

a

deficiencies

12)

fuera

persona

equipo

de

un

tomacorriente

DE

de

extension

con

que

viene

cordon

un

cordon

suficientemente

que

tramos

de

7,6m

15,2m

.

30,4

m

45,7m

cordon

demasiado

de

Ia

tension,

mas

de

calibre,

Asegurese

empleando y el

correctamente

descargas

incendio o explosion.

SIEMPRE

de

desprendida,

ADVERTENCIA:

electrica,

SIEMPRE

de

Ia

en

si

debe

Ia

operacion

estas

observe

de

cerca

SIEMPRE

de

proteccion

Segun

usar

Siempre

del

Mantenga

del

alcance

JAMAS

equipo,

ya

de

JAMAS

del

alcance

no

familiarizada

sin

aire.

ilustrada

que

del

EXTENSION-

tres

de

extension

su

menos

grueso.

de

estaticas o chispas

metal

mantenga

bomba

instrucciones,

los

de

fuente

use

condiciones

material

todas

altere o modifique

que

funcionamiento.

deje

mas

el

producto

que

tenga

enchufe.

con

con

de

producto

ocasionando

que

no

estar

las

fabricantes

llamas

el

tipo

equipo

comuniquese

de

ello

al

de

No

trifilar

que

Ires

cuchillas, y un

ranuras

que

el

producto.

este

extension,

grueso

usara.

de:

Use

corto

Si

Cuanto

mas

grueso

el

equipo

objeto

que

conectados a tierra

Ia

pistola

allimpiar

para

evitar

Para

exponer a Ia

ellugar

bien

ventilado.

ubicada a no

de

rociadura.

con

ciertos

precauciones

Nunca

expuestas,

de

ignicion.

mascaras

durante

de

material

de

ventilaci6n

personal

para

conseguir

las

varas

cables

electricos.

puede

equipo

los

solo.

nifios o de

con

Ia

adelante.

este

enchufado

Ia

misma

debe

usarse

Use

solo

tenga

acepte

en

cerciorese

para

cordones

16AWG

14AWG

12

10AWG

provocara

una

tiene

mas

sera

sin

se

ADVERTENCIA:

contra

el

sistema

Ia

reducir

existe

materiales.

sobre

apropiadas

Ia

operacion

con

de

parte

causar

operacion

un

un

enchufe

el

Cerciorese

buen

estado.

de

transporter

de

calibre:

AWG

una

perdida

dudas,

use

pequeiio

el

cable.

aire

que

intenta

rociar

para

que

podrian

el

con

descarga

riesgo

lluvia.

de

trabajo

Ademas,

menos

Sino

se

el

riesgo

y

rocfe

material

llamas

y

de

que

se

esta

puede

protector

el

extension

alguna

Mantengalo

cualquier

de

de

de

sea

Ia

de

Ia

de

de

de

6

Page 7

NE PAS UTILISER LE MATERIEL AVANT D' A VOIR

LU

CETTE SECTION

ATTENTION!

LES PULVERISATEURS A HAUTE PRESSION PEUVENT

Le

liquide

introduit

pulverisateur

extremement

pression,

fuite

peau

liquide

traitee

voulue,

provoquer

donner

voire a !'amputation

prudence

!'utilisation

EN

MEDECIN

LA

D'UNE

Une

lesion

trailer

perdez

!'injection.

cas

certains

d'un

chirurgie

conseillee.

a

vers

autre

de

liquide

quelconque

TOUJOURS

lorsque

Veillez a TOUJOURS

surete a Ia

liquide

votre

du

PISTOLET

aucune

pompe

surpression.

demonter

l'appareil

suivante:

enlevez

en

quelconque,

et

d'injecter

toxique

promptement

Ia

lesion

Ia

lieu a de

extreme

de

CAS

D'INJECTION,

IMMEDIATEMENT.

BLESSURE

SIMPLE

REMARQUE A L'INTENTION

injection

traumatique

chirurgicalement

pas

de

II

s'agit

d'injection

revetements

chirurgien

reconstructive

1)

Maniez

l'ecart

de

Ia

aucune

personne.

votre

corps

s'echappant

au

vous

buse

2)

N'essayez

dans

main

ou

pistole!.

CET

PULVERISATEUR A AIR.

piece

non

equipee

3)

N'essayez

ou

avant

PROCEDURE

DE

PRESSION

A. Verrouillez

B. Arretez

cordon electrique.

C.

Delestez

systeme

du

pistolet.

D.

Reverrouillez Ia surete de

. detente.

4)

Avant

de

toujours

dans

sans

air

doit

elevee.

provenance

dans

causae

necrose

serieux

materiel

COMME

COUPURE!

penetrant

temps a rechercher

directe

plasticien

le

pistole!

buse.

partie

Ne

entrer

niveau

le

levier

n'etes

JAMAIS

le

pistole!

d'un

APPAREIL

de

JAMAIS

de

reparer

d'avoir

Ia

Ia

et

proceder

Ia

l'etre a pression

Les

liquides a haute

du

sont

capables

d'importantes

l'organisme.

et

avec

de

des

tissus

handicaps

du

membre

s'impose

de

pulverisation

CONSULTEZ

S'IL

Ia

peau

grave

qu'il

aussitot

Ia

d'un

risque a envisager

dans

exotiques.

ou

de

avec

N'en

dirigez

de

votre

laissez

en

contact

du

pistole!

du

flexible.

de

surete

pas

occupe a pulveriser.

utiliser

du

pistolet.

de

au

moyen

objet

maintenu

materiel

sans

d'une

d'enlever

accompli

DE

DELESTAGE

Ia

surete de

pompe et debranchez le

pression dans tout le

appuyez

au

buse

de

PROVOQUER

DE

SERIEUSES LESIONS

Pression de travail maxi male: 3000

un

pistole!

pulverisateur

de

penetrer

quantites

Si

elle

toute

!'attention

Ia

sorte

peut

ou

Ia

permanents,

atteint.

done

lors

NE

TRAITEZ

S'

AGISSAIT

DU

constitue

est

important

que

possible.

Ia

toxicite

le

circuit

sanguin

La

consultation

d'un

specialists

Ia

main

peut

soin.

Maintenez-vous

JAMAIS

corps

ou

JAMAIS

soupape

vers

aucune

avec

ou

d'une

Verrouillez

de

Ia

detente

un

dispositif

refouler

le

de

votre

centre

N'EST

PAS

air

avec

de

Ia

Ia

procedure

Ia

sur

Ia

rinc;:age

du

pulverisation

ou

d'une

Ia

de

n'est

gangrene

Une

de

sans

air.

UN

MEDECIN

une

de

de

en

de

de

etre

Ia

buse

aucune

partie

le

flux

de

fuite

de

flux

de

doigt,

Ia

buse

UN

N'utilisez

une

buse,

de

detente.

detente

Ia

systeme,

et

reglez

pas

et

PAS

:

Ne

Ia

de

Ia

pression

au

5)

hydrodynamique

depassez

pression

flexibles

sont

bien

pressions

capacite

du

systeme.

d'electrocution,

6)

produire

de

l'usure,

auxquels

injections

par

Ia

d'inspecter

N'essayez

votre

corps,

fortune.

flexible

un

nouveau

n'utiliser

securite a ressort

15,2 m de

7)

et

que

Ia

terre,

d'electricite

de

provoquer

ATTENTION:

centre

systeme,

JAMAIS

de

flammes

source

INSTRUCTIONS

produit

d'un

court-circuit

le

risque

fuite

pour

pourvu

fiche

appropriee

etre

branchee

a

Ia

terre

codes

DANGER

terre

peut

electriques.

niveau

Serrez

bien

JAMAIS,

de

3000

accessoires,

capables

prevues.

de

pression

DANGER : Afin

ATTENTION : Des

voie

doigt

Assurez-vous

n'exposez

le

long

du

des

torsions,

il

est

eventuellement

de

liquide

de

telles

le

flexible

JAMAIS

ou

de

de

ruban

adhesif

N'essayez

de

pulverisation ; remplacez-le

flexible

que

les

flexibles

flexible

I'

objet a peindre

de

fac;:on a eviler

statique

un

Tenez

un

recipient

apres

en

de

substanc~s

nues,

d'allumage.

doit

etre

mis a Ia

de

chocs

le

courant

d'un

cordon

de

sur

adequatement

et

reglements

BOX

-

La

provoquer

Si

le

le

plus

taus

avant

psi.

de

Ne

flexible

tout

pas

N'utilisez

avec

incendie

en

avoir

lampes

Rangez a l'interieur.

electrique,

electriques

une

PRISE

A LA

pose

cordon

Iaible

les

raccords

chaque

avec

Assurez-vous

raccords,

nominale

dans

fuites.

avant

d'obturer

autre

mis a Ia

que

ou

TOUJOURS

DE

electrique.

possedant

mise a Ia

locaux.

MfSE A LA

un

emploi.

cet

appareil,

resister

metallors

articulations,

aux

depassez

non

cet

sont

toute

prise

TERRE

inappropriee

JAMAIS

d'aucun

de

reduire

pas a Ia

fuites

risquent

de

peinture

des

rudes

soumis.

Ia

peau

sont

II

est

done

chaque

une

!uite a I'

membre

ou

de

tout

plus

de

terre.

munis

de

JAMAIS

appareil.

le

materiel

adequatement

toute

decharge

etincelle

ou

une

explosion.

du

ate

Ia

buse.

inftammables a proximite

temoin

ni

MISE A LA

terre.

Dans

Ia

mise a Ia

en

assurant

Ce

un

fil

terre.

qui

est

conforrnement a tous

TERRE

MISE

risque

de

ou

Ia

fiche

possible.

du

que

hautes

pluie.

traitements,

usage.

de

autre

reparer

Veillez

dispositifs

sans

le

rinc;:age

Ne

d'aucune

TERRE : Ce

!'hypothese

produit

de

La

posee

de

chocs

doit

systeme

Ne

une

taus

les

etc.

Ia

composant

tout

risque

de

se

sous

l'effet

Les

possibles

important

aide

de

votre

moyen

un

pluto!

par

a

de

moins

de

air

utilise

mis

susceptible

pistole!

du

vaporisez

terre

reduit

un

fil

est

terre

avec

fiche

doit

et

mise

les

Ia

fiche

etre

repare

psi -21 0 bar

ou

remplace,

l'une

une

(avec

Consultez

service

parfaitement

si

vous

produit

Ia

fiche

faites

competent

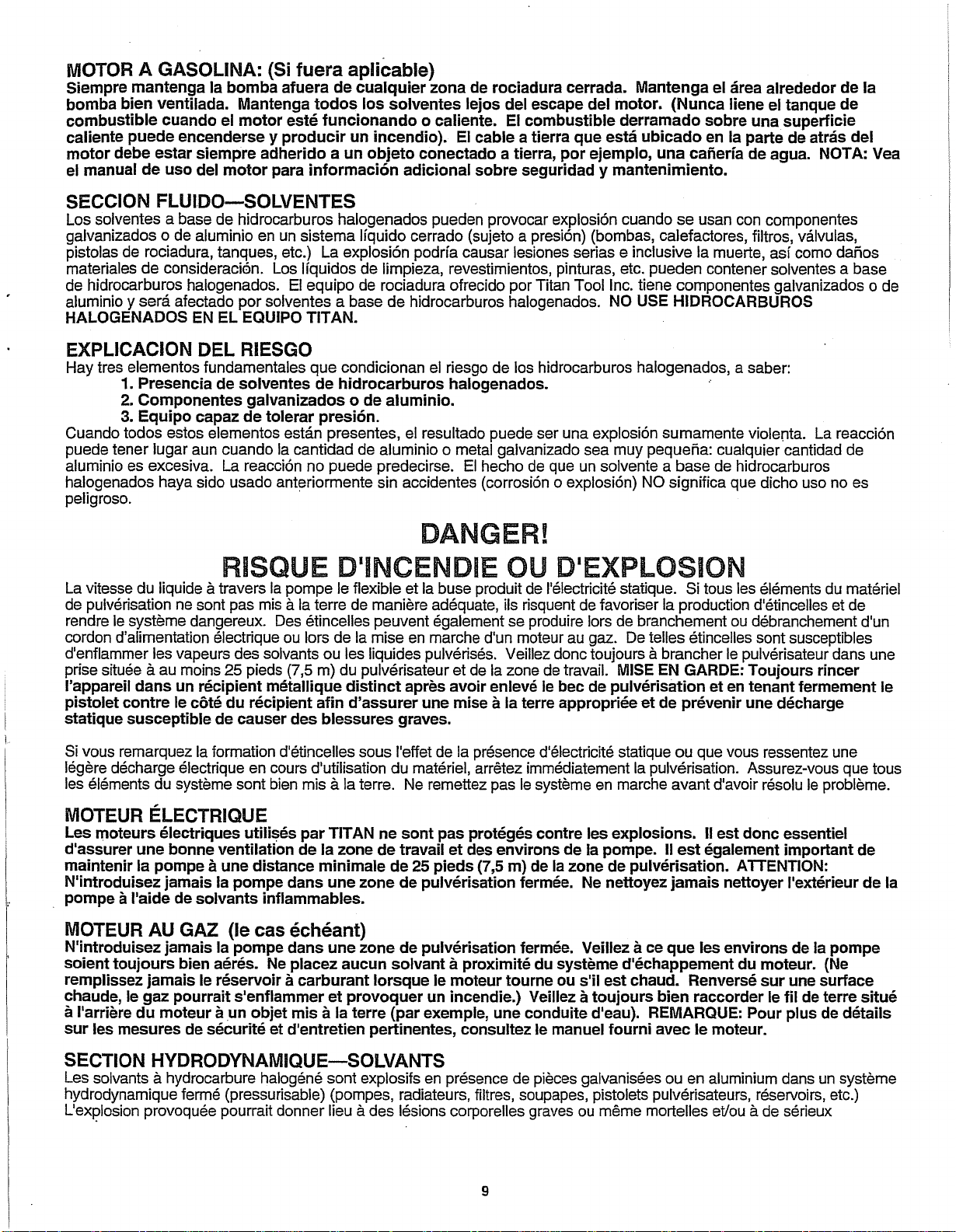

•

etc.

a

Ce

a

tension

terre

•

S'assurer

prise

Aucun

produit..

CORDONS

uniquement

de

pourvu

et

une

Ia

pompe.

rallonge

cordon

suffisamment

que

Pour

de

moins

15,2

30,4

45,7m

Un

de

tension

perle

doute,

puissant

calibre

de

de

8)

pas

essentiel

zone

egalement

distance

pulverisation.

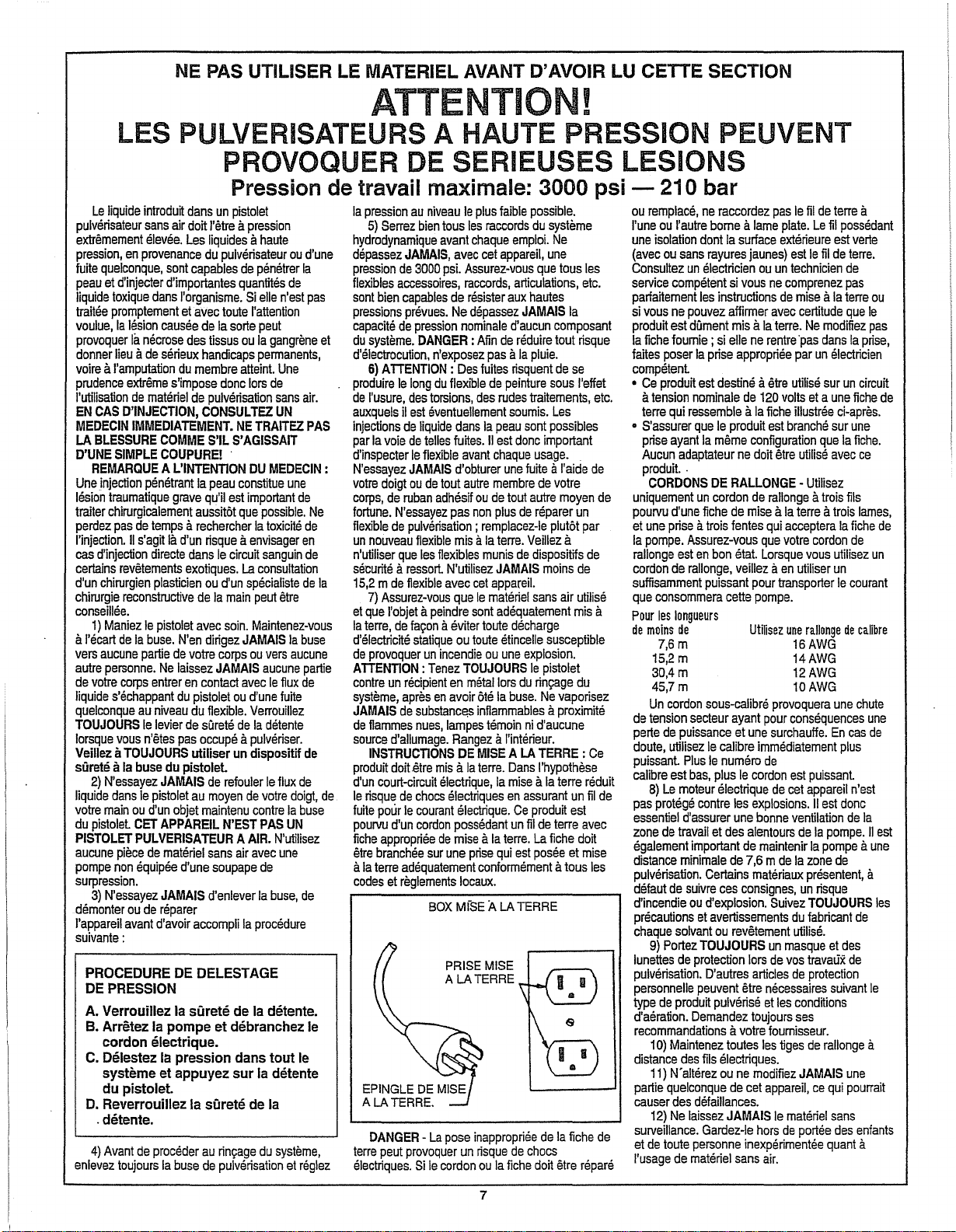

defaut

d'incendie

precautions

chaque

9)

lunettes

pulverisation.

personnelle

type

d'aeration.

recommandations a votre

1

distance

11)

partie

causer

12)

surveillance.

et

de

I'

usage

ne

ou

isolation

ou

ne

est

poser

produit

qui

ayant

d'une

prise a trois

de

consommera

les

raccordez

I'

autre

borne a lame

dent

sans

rayures

un

electricien

competent

les

instructions

pouvez

dument

foumie ; si

Ia

prise

est

destine a etre

nominale

ressemble a Ia

que

le

Ia

meme

adaptateur

DE

un

cordon

fiche

Assurez-vous

est

en

bon

rallonge,

puissant

longueurs

de

7,6m

m

m

cordon

sous-calibre

secteur

de

puissance

utilisez

le

Plus

le

est

bas,

Le

protege

de

Portez

de

0)

quelconque

toute

plus

moteur

centre

d'assurer

travail

et

important

minimale

Certains

de

suivre

ou

d'explosion.

et

avertissements

solvant

ou

TOUJOURS

de

protection

D'autres

peuvent

produit

pulverise

Demandez

Maintenez

des

fils

N"

alterez

des

defaillances.

Ne

laissez

Gardez-le

personne

de

materiel

electrique

Ia

si

affirrner

mis a Ia

elle

produit

RALLONGEde

fentes

cette

ayant

calibre

numero

des

de

ces

revetement

!cutes

electriques.

ou

de

JAMAIS

pas

le

plate.

surface

exterieure

jaunes)

est

ou

un

vous

appropriee

de

ne

etat.

veillez a en

et

le

les

une

de

consignes,

etre

ne

inexperimentee

sans

technicien

ne

comprenez

de

mise a Ia

avec

certitude

terre.

ne

rentre

·pas

par

utilise

120

volts

fiche

illustree

est

branche

configuration

doit

etre

utilise

de

rallonge a trois

mise a Ia

Utilisez

une

alentours

7,6 m de

lors

cet

terre a trois

qui

acceptera

que

votre

Lorsque

utiliser

pour

transporter

pompe.

une

16AWG

14AWG

12

10AWG

provoquera

pour

consequences

surchauffe.

immediatement

de

cordon

est

de

cet

explosions.

bonne

ventilation

de

maintenir

Ia

materiaux

articles

toujours

modifiez

un

Suivez

du

utilise.

un

masque

de

vos

de

necessaires

et

les

conditions

ses

foumisseur.

les

tiges

JAMAIS

appareil,

le

materiel

hors

de

portee

air.

fil

de

terre

Le

le

Ne

eta

Utilisez

cordon

vous

rallonge

AWG

puissant

appareil

II

Ia

zone

presentent,

TOUJOURS

fabricant

travalix

protection

de

ce

a

fil

possedant

est

verte

fil

de

terre.

de

pas

terre

que

modifiez

dans

Ia

un

Ia

prise,

electricien

sur

un

circuit

une

fiche

ci-apres.

sur

une

que

Ia

fiche.

avec

ce

fils

lames,

Ia

fiche

de

utilisez

un

le

courant

de

calibre

une

chute

En

cas

plus

n'est

est

done

de

Ia

pompe.

pompe a une

de

risque

de

et

des

de

suivant

rallonge

une

qui

pourrait

sans

des

enfants

quant

a

ou

le

pas

un

une

de

II

est

a

les

le

a

de

de

7

Page 8

FIRE OR EXPLOSION HAZARD

Static electricity is created by the high velocity of fluid through the pump, hose and tip.

is not properly grounded, sparking may occur and the system may become hazardous.

in

plugging

fluids being sprayed. Always plug the sprayer into

flush

of

the container

injury.

If you experience any static sparking or slight shock while using this equipment, stop spraying immediately. Check the

entire system for proper grounding.

or unplugging a power supply cord, or starting a gas engine. Sparks

an

outlet at least 25' away from the spray area. WARNING: Always

the

unit

into

a separate metal container

to

assure

proper

grounding

Do

not use the system again until the problem has been corrected.

with

and

the

spray

prevent

tip

static

removed

discharge

and

which

If

every part of the spray element

Sparking may also occur when

can

ignite fumes from solvents or the

the

gun

held

could

firmly

cause

against

serious

the

bodily

side

ELECTRIC MOTOR

The electric

around

WARNING:

any

flammable solvents.

the

motors

pump

Always

used

by

TITAN are

well ventilated. Additionally,

keep

pump

outside

not

explosion

of

any

proof.

the

pump

enclosed

Therefore,

itself

should

spray

area. Never clean

it

be a

is

essential

minimum

the

to

keep

of

25'

exterior

the

from

of

working

the

the

pump

spray

area

area.

with

GAS ENGINE {Where Applicable)

Always

solvents

hot

object, i.e.

keep

pump

away

surface can

water

outside

from

engine exhaust. (Never

ignite

pipe. NOTE: Refer

of

any

and cause a fire.)

enclosed

Always

to

engine

spray

area. Keep area

fill

the

fuel

attach

owner's

tank

while

ground

manual

around

the

wire

for

additional

engine

located

pump

well ventilated. Keep all

is

running

on rear

safety and service

of

engine

or

hot. Fuel

spilled

to a grounded

information.

on a

FLUID SECTION-SOLVENTS

Halogenated Hydrocarbon solvents can cause an explosion when used with aluminum or galvanized components

closed

serious injury, death and/or substantial property damage. Cleaning agents, coatings, paints, etc. may contain .

Halogenated Hydrocarbon solvents. Titan Tool

and will

TITAN EQUIPMENT.

(pre~surizable)

be

affected by Halogenated Hydrocarbon solvents.

fluid system (pumps, heaters, filters, valves, spray guns, tanks, etc.). The explosion could cause

Inc. spray equipment includes aluminum or galvanized components

DO

NOT USE HALOGENATED HYDROCARBONS

in

IN

a

EXPLANATION OF THE HAZARD

There are three key elements to the Halogenated Hydrocarbon (HHC) solvent hazard. These elements are:

1. The presence

Aluminum

2.

3.

Equipment

all three elements are present, the result can

When

with very little aluminum or galvanized metal: any amount of aluminum is too much. The reaction is unpredictable. Prior

use of

an

HHC solvent without incident (corrosion or explosion) does NOT mean that such use is safe.

of

HHC solvents.

or

galvanized parts.

capable

of

withstanding

pressure.

be

an extremely violent explosion. The reaction can

be

sustained

PELIGRO DE INCENDIO 0 EXPLOSION

La

alta velocidad del lfquido a traves de

componente del equipo de rociadura no esta conectado a tierra correctamente pueden producirse chispas y

se

vuelve peligroso. Tambien pueden producirse chispas al enchufar o desenchufar cables electricos o

funcionamiento un motor a gasolina. Las chispas pueden encender los vapores provenientes de los solventes o

lfquidos rociados.

rociadura. ADVERTENCIA: Lavar siempre Ia unidad en un recipiente metalico separado, habiendo

boca del

correcta y evitar

Si

ocurren chispas

immediate. Verifique que

hasta que

rociador

el

Siempre conecte

y teniendo Ia pistola firmemente

Ia

descarga estatica

de

electricidad estatica o

el

sistema

problema haya sido resuelto.

MOTOR ELECTRICO:

Los

motores

area de trabajo alrededor de Ia bomba bien ventilada. Ademas, Ia

minima de 25 pies (7.5 m) del area de rociadura. ADVERTENCIA: Mantener siempre Ia bomba afuera de

cualquier

electricos utilizados

area de rociadura cerrada. Nunca

Ia

bomba, manguera y

el

rociador a un enchufe ubicado a no menos de 25 pies

contra

que

podrfa

si

en

su

totalidad este conectado a tierra correctamente. No vuelva a usar

por

TIT AN

sufre

no

son

limpie

causar

un

shock electrico ligero mientras usa

a prueba

el

Ia

el

lesion

exterior

boquilla produce electricidad

lado

del recipiente para asegurar

corporal

de

explosion.

de

Ia

grave.

bomba

bomba

Por

lo

tanto, es esencial mantener el

misma

debe estar a

con solventes inflamables.

de

el

equipo, deje de rociar de

estc:Hica.

al

distancia de

una

una

Si algun

el

sistema

poner

en

de

los

Ia

zona

de

quitado

puesta a tierra

distancia

el

sistema

Ia

8

Page 9

MOTOR

Siempre

bomba

combustible

caliente

motor

el manual

A GASOLINA: (Si

mantenga

bien

ventilada. Mantenga

cuando

puede

debe

estar

de

Ia

bomba

el

encenderse y

siempre

uso

del

motor

fuera

afuera

motor

este

producir

adherido a un

para

informacion

aplicable)

de

cualquier

todos

los

solventes

funcionando

un

incendio).

objeto

zona de rociadura cerrada. Mantenga

lejos del escape del

o caliente. El

El cable a tierra

conectado

adicional

sobre

combustible

a tierra,

seguridad y

por

motor.

derramado

que

esta

ubicado

ejemplo,

mantenimiento.

(Nunca

una

caiieria

el

area alrededor

liene el tanque

sobre

una

superficie

en Ia parte

de

de agua. NOTA: Vea

atras

de

de

del

Ia

SECCION FLUIDO-SOLVENTES

Los solventes a base de hidrocarburos halogenados pueden provocar explosion cuando se usan con componentes

en

un

galvanizados o de aluminio

pistolas de rociadura, tanques, etc.) La explosion podrfa causar lesiones serias e inclusive

materiales de consideraci6n. Los llquidos de limpieza, revestimientos, pinturas, etc. pueden contener solventes a base

de hidrocarburos halogenados.

aluminio y

HALOGENADOS

sera afectado por solventes a base de hidrocarburos halogenados. NO USE HIDROCARBUROS

EN

EL EQUIPO TITAN.

sistema trquido cerrado (sujeto a presion) (bombas, calefactores, filtros, valvulas,

Ia

muerte, asf como daiios

El

equipo de rociadura ofrecido por Titan Tool Inc. tiene componentes galvanizados o de

EXPLICACION DEL RIESGO

Hay tres elementos fundamentales que condicionan

de

capaz

solventes

galvanizados

de

tolerar

1. Presencia

2.

Componentes

3.

Equipo

Cuando todos estos elementos estan presentes,

puede tener

aluminio es excesiva. La reaccion no puede predecirse.

halogenados haya sido usado anteriormente sin accidentes (corrosion o explosion)

peligroso.

Iugar aun cuando Ia cantidad de aluminio o metal galvanizado sea muy pequeiia: cualquier cantidad de

de

hidrocarburos

o de

presion.

el

riesgo de los hidrocarburos halogenados, a saber:

halogenados.

aluminio.

el

resultado puede ser una explosion sumamente violenta. La reaccion

El

hecho

de

que

un

solvente a base de hidrocarburos

NO signifies que dicho uso

noes

DANGER!

RISQUE o•INCENDIE

La

vitesse du liquide a travers

ne

de pulverisation

rendre

cordon

d'enflammer les vapeurs des solvants ou les

prise situee

l'appareil

pistolet

statique

Si

Iegere decharge electrique

les

le systeme dangereux.

d'alimentation electrique

a

dans

contre

susceptible

vous remarquez

elements du systeme sont bien mis a

sont pas mis a

au

moins 25 pieds (7,5 m) du pulverisateur et

un

recipient metallique

le cote

de

Ia

formation d'etincelles sous l'effet de

MOTEUR ELECTRIQUE

Les

moteurs

d'assurer

maintenir Ia pompe a

N'introduisez jamais Ia

pompe

MOTEUR

N'introduisez jamais

soient

remplissez

chaude, le

toujours

a l'arriere

sur

les mesures de securite et d'entretien pertinentes, consultez le manuel

electriques

une

bonne ventilation de Ia zone

a l'aide de

AU

GAZ (le cas echeant)

bien aeres.

jamais

gaz

pourrait s'enflammer

du

moteur a un

une

solvants

Ia

le reservoir a

Ia

pompe le flexible et

Ia

terre de maniere adequate, ils risquent de favoriser

Des

etincelles peuvent egalement se produire lors de branchement

ou

lors de

du

recipient

causer

pompe

pompe

des

en

cours d'utilisation du materiel, arretez immediatement

utili~es

distance

objet

par

dans

inflammables.

dans

Ne

placez

carburant

mis

Ia

mise

liquides pulverises. Veillez done toujours a brancher

distinct

afin

d'assurer

blessures

Ia

terre. Ne remettez pas

TIT AN

minimale

une

zone

une

zone de pulverisation fermee. Veillez a ce

aucun

lorsque

et

provoquer

a Ia terre (par exemple,

Ia

buse produit de l'electricite statique.

en

marche d'un moteur

apres

avoir

une mise a Ia terre appropriee

graves.

Ia

ne

sont

pas

de

travail

de

de

solvant a proximite

et

25

pieds

pulverisation fermee. Ne nettoyez

le

moteur

un incendie.) Veillez a

OU

de

Ia

zone

enleve le bee de pulverisation

presence d'electricite statique ou que vous ressentez une

le

systeme

proteges contre les

des

environs

(7,5 m) de

du

tourne ou s'il

une

conduite d'eau). REMARQUE:

o·exPLOSION

Si

tous les elements du materiel

Ia

production d'etincelles et de

ou

debranchement d'un

au

gaz.

De

telles etincelles sont susceptibles

le

pulverisateur dans une

de

travail. MISE EN GARDE:

et

de prevenir

Ia

pulverisation. Assurez-vous que tous

en

marche avant d'avoir resolu

explosions.

de

Ia pompe. II

Ia

zone de pulverisation. ATTENTION:

systeme d'echappement

est

toujours

fourni

est

jamais

que

les

chaud. Renverse

bien

raccorder le

avec le moteur.

Toujours

et

en tenant fermement le

une

II

est

done essentiel

egalement important

nettoyer l'exterieur

environs

du

moteur. (Ne

sur

Pour

rincer

decharge

le

problema.

de Ia

pompe

une surface

fil

de terre

plus

de

details

de

de

situe

Ia

SECTION HYDRODYNAMIQUE-SOLVANTS

Les solvants a hydrocarbure halogens sont explosifs

hydrodynamique

L'exl?losion provoquee pourrait donner lieu

ferme (pressurisable) (pompes, radiateurs, filtres, soupapes, pistolets pulverisateurs, reservoirs, etc.)

a des lesions corporelles graves

en

presence de pieces galvanisees

ou

meme mortelles et/ou a de serieux

9

ou

en

aluminium dans

un

systeme

Page 10

degfds materiels. Certains produits d'entretien, revetements, peintures et autres liquides contiennent

hydrocarbure halogens.

composB;.nts,galvanises

HALOGENES DANS

Les

appareils pulverisateurs

sensibl§ls

LE

MATERIEL TITAN. .

aux solvants a hydrocarbure halogens. N'EMPLOYER

de

Ia

Titan Tool

Inc.

comportent des pieces

PAS

des

solvants a

en

aluminium et

D'HYDROCARBURES

des

EXPLICATION DU RISQUE

Le danger que presentent

1. La presence de solvants a hydrocarbure halogene

2.

La

presence de pieces en aluminium ou galvanisees

3. Un materiel capable de supporter des pressions elevees

La

combinaison

en presence d'une quantite minime d'aluminium

deja trop.

La

aucun incident (corrosion

de

ces

reaction est imprevisible. Toute utilisation anterieure de solvant a hydrocarbure halogens n'ayant donne lieu a

les

solvants a hydrocarbure halogene se caracterise par trois elements

trois elements peut donner

ou

explosion)

NE

CONSTITUE NULLEMENT

lieu a une

ou

de

explosion extremement violente.

metal

galvanise.

En

un

fait,

signe

Ia

moindre trace d'aluminium

de

securite.

cles:

La

reaction

peut se produire

en

constitue

HALOGENATED SOLVENTS

DEFINITION - Any hydrocarbon solvent containing any

Consult your material supplier to determine whether your solvent or coating contains Halogenated Hydrocarbon Solvents.

of

the elements as listed below: J

SOLVENTES HALOGENADOS

DEFINICION - Cualquier solvente a base de hidrocarburos que contenga cualquiera de estos elementos:

EJEMPLOS (lista parcial):

Consulte

Ia

informacion suministrada por

contiene solventes

su

proveedor

de

materiales para determinar

de

Hidrocarburos Halogenados.

si

un

solvente o revestimiento

SOLVANTS HALOGENES

DEFINITION-- Tout solvant a hydrocarbure contenant l'un des elements suivants:

EXEMPLES (liste incomplete):

Pour determiner

si

vos solvants

ou

revetements contiennent des solvants a hydrocarbure halogens, consultez votre

foumisseur.

Fluorine (F) "-fluor-" Chlorine (CI) "-chloro-

11

SOLVENTS:

SOLVENTS:

tetrachloride

dichloride

Iodine (I) 11-lodo-

METHYLENE

DICHLOROMOETHANE

Monochlorobenzene

Orthodichlorobenzene

Perchloroethylene

TRICHLOROETHANE

Trichloroethylene

Monochlorotoluene

EXAMPLES

(not

all-inclusive):

FLUOROCARBON

·

Dichlorofluoromethane

Trichlorofluoromethane

BROMINATED

Ethylene

Methylene

Methyl

dibromide

bromine

SOLVENTS:

SOLVENTS:

chlorobromide

Bromine (Br) "-bromo-

IODINATED

N-butyl

iodide

Methyl

iodide

Ethyl

iodide

Propyl

iodide

CHLORINATED

. .

Carbon

Chloroform

Ethylene

START-UP PROCEDURE

WARNING:

label

on

IMPORTANT: Whenever starting or cleaning this

this sprayer for

Do not operate dry.

High

pressure device, thoroughly

the sprayer.

more

than I 0 seconds without

read

fluid,

and

understand

sprayer,

this

can

always

cause

the

warning

reduce

unnecessary wear

engine

section

or motor

located

to

the

11

11

CHLORIDE

in

speed.

packings.

or

the

owner's

Additionally,

manual

never operate

and

the

Step 1: Before

A.

Tighten suction

not install

they

are

guard.

overpressurization, causing a component

you

plug

in

the power

and

return

tip

yet,

or

remove

electrically grounded

This

is

to

reduce

the

cord

to

the

electrical outlet or start

hoses,

if installed. WARNING:

risk

then

install a minimum

and

rated

for at

least

of

serious bodily injury caused

rupture.

If

you

3000

10

the

of

50'

are

supplying your

psi

(21 0 bar)

by

gas

engine,

of

nylon

airless spray

own

working

static sparking

do

the

hoses

pressure,

and

fluid

following:

hose

and

and

spray

and

that

injection

airless

gun,

the

gun

or

gun.

be

has

Do

sure

a tip

Page 11

B.

Preset pressure control by turning the pressure control knob counterclockwise

C.

Place on-off switch in the off position.

D.

Be sure to fill the Wet Cup 1/3 full with Piston Seal Lubricant.

Step

2E: ELECTRIC MOTOR

A.

Check electrical service. Be sure it is 120V 15 amp minimum

B.

Plug electrical cord into a grounded outlet that is at least 25' from the spray area.

extension

prong

C.

If a secondary hose and gun is not installed be sure the plug is secure.

D.

Place the suction tube into container containing mineral spirits.

Step

2G:

GAS

ENGINE {Where

A.

Check

supplied.

B.

Fill

the

could cause a fire. Close the black fuel shut off lever located under the

air cleaner.

C. If a secondary hose and gun is not installed, be sure the plug is secure.

D.

Place the suction tube into container containing mineral spirits.

E.

Open the fuel shut off lever by pushing it

F.

Move the throttle lever

G. Close the engine choke lever, located beneath the air cleaner.

H.

Tum the engine switch on.

prime position.

I.

Pull the starter rope. Holding the frame with one hand, pull the rope

rapidly and firmly. Continue to hold the rope as you let it return.

return rope until. engine starts.

or

the

gas

cords

use

an

engine

tank.

Use

are a

three

wire, 12

adaptor.

oil

Be sure the engine

unleaded

Never

Applicable)

level. For instructions refer to the engine manual

high

aW?Y

from fuel tank.

Tum

gauge

exceed 150'

is

quality

pressure relief prime valve down to

minimum

of

cool. Refueling a hot engine

gasoline.

in

the direction of the arrow.

cord

extension

andthat

with a grounded

cord.

outlet is properly grounded.

Pull and

to

lowest setting.

Make

certain

plug.

Never

Remove Tip end Safety Guard

that

remove

Lock position

when flushing

all

third

Step

3: Flush oil out

mineral spirits before you begin to spray.

A.

Pour 1/2 gallon mineral spirits into a metal container and insert syphon and return tube.

B.

Tum

cycle for approximately

Then

Step

4:

Prepare the paint according to manufacturer's recommendations. Remove any skin that

Strain the paint through a fine nylon mesh bag to remove particles that could clog spray tip.

Step

5: Place syphon and return tubes into paint container.

down for priming.

Step

6:

Tum

sprayer on and tum up pressure slightly. Let circulate on prime until

Step

7: Hold gun firmly against a metal container, disengage trigger lock and trigger gun against side of container. Then,

while gun is triggered, tum the pressure relief valve to the spray position. Keep the gun triggered until

forced out of the system and the paint flows freely. Release the trigger and engage gun safety lock; set gun down

while unit pressurizes.

Step

8: Check

Step

9: Turn off sprayer and relieve pressure by turning pressure relief prime knob to prime.

Step

10:

With gun trigger lock engaged, install tip and guard as instructed in separate tip

Step

11:

Tum

of

new paint pump: Oil is used by the factory for testing and protection. It is necessary to flush out with

pressure relief prime valve down to prime position and tum unit on. Increase pressure slightly. Let solvent

30 seconds. Then tilt syphon tube above container and let the sprayer pump itself dry.

tum

unit off. If you are going to use water based paints, repeat procedure using water.

may

have formed and stir.

Tum

pressure relief priming knob, located on side of pump,

no

bubbles filter up through the paint.

for

leaks

..

If any leaks occur, follow the proper pressure relief procedure before tightening.

or

gun manual.

sprayer on and rotate the pressure relief prime valve to the spray position.

all the air is

Step

12: Test on cardboard to check spray pattern. Adjust pressure just until the spray from gun is completely atomized.

CLEANING PROCEDURE

WARNING:

High

Always

away

from

pressure

clean

using

the

device-

low

sprayer. Never clean

Follow

pressure,

with

all

the

safety

the

spray

exterior

warnings

tip

removed.

of

the

11

located

pump

on

sprayer

Always

while

the

and

in

flush

into a separate

pump

is

the

owner's

plugged

in

manual.

metal

or

container

operating.

Page 12

PRESSURE

Step

1 : Engage trigger safety lock on gun.

Step

2:

Tum

off pump and release fluid pressure by turning the pressure relief prime valve located on the side of pump

down.

LOW

PRESSURE CLEANING PROCEDURE:

Step

3: Remove tip and let soak clean,

setting.

Step

4:

Tum

the pump on. Tilt syphon ·tube above paint container, allowing the sprayer

tube.

Step

5: Have available container of hot soapy water if spraying latex (or suitable solvent for oil base paints). Do not clean

with mineral spirits if using latex

Step

6: Place syphon tube into container with hot soapy water

Step

7:

To

save paint still

of metal paint container. Be careful of splashing. When cleaning solution appears, shut off gun and place gun

separate metal container. Repeat process if spraying with two guns.

Step

8: Trigger gun and let cleaning solution circulate for approximately 2-3 minutes, then

Step

9:

Tum

prime valve down and remove suction tube from cleaning container.

Tum

unit on and allow sprayer to pump dry.

RELEASE

in

PROCEDURE:

in

a small container of solvents

paint as this will make jelly.

or

spray hose, tum prime valve up to spray position, then carefully trigger gun into and against side

or

water. Adjust fluid pressure to lowest possible

to

pump itself dry through the return

solvents. Let circulate for 2-3 minutes, then tum unit off.

tum

unit off.

in

a

Step

1 0: Take a clean container of water

with water, pump a small amount

corrosion.

Step

11: Take suction tube out

Step

12: Check filter on pump and gun. Clean

Step

13: Remove spray tip from solvent, clean with a soft bristle brush and store in a dry place.

of

container and let sprayer run itself dry.

or

solvent and using low pressure pump through system until clear. If cleaning

of.

mineral spirits or

or

replace.

TIT

AN

LS-1

0 solution through pump. This will protect against

FLUSHING SPECIFICATIONS

1.

New

Changing

2.

3.

Changing

Changing

4.

5.

Storage:

Sprayer:

A.

B.

A. Water-Base Paint: Flush with water, then mineral spirits and leave the pump, gun and hose filled with mineral

spirits.

prime valve to spray position. .

B.

to prime to relieve pressure and leave open. Return prime valve to spray position.

Oil is used by the factory for testing and protection. It

If spraying water-base paint, flush with mineral spirits followed by water.

If spraying oil-base paint, flush with mineral spirits only.

from

water-base

from

oil-base

colors:

To

Oil-Base Paint: Flush with mineral spirits. Shut off and unplug the sprayer, turn the pressure relief prime valve

Flush with a compatible solvent such

assure proper performance and long life, always clean the sprayer thoroughly before storing.

Shut off and unplug the sprayer and turn pressure relief prime valve to prime to relieve pressure. Return

to

oil-base: Flush with water, then mineral spirits.

to

water-base: Flush with mineral spirits, then water.

as

water or mineral spirits.

is

necessary to flush unit before spraying.

6.

Start-Up

After

Storage:

A. Water-Base Paint: Flush out mineral spirits with water.

B. Oil-Base Paint: Flush out the mineral spirits with the material to be sprayed.

in

Always dispose of mineral spirits

a proper way.

12

Page 13

The

following

painting

Hold

the

distance

surface

distance

Move

the

steady

rate.

material

speed

allows a full

or

sags.

techniques,

results.

gun

perpendicular

from

the

or

desired

of

12

to

gun

either

Moving

and

provides

surface.

spray

14

inches.

across

the

even

wet

coat

if

followed,

to

the

Depending

pattern,

gun

the

or

up

at a consistent

coverage.

of

paint

APPLICATION TECHNIQUES

will

assure

surface

on

gun

and

down

The

to

be

and

always

the

type

should

the

speed

correct

applied

professional

at

equal

of

material,

be

held

at

surface

at

a

conserves

spraying

without

runs

a

Maintain uniform spray stroke action. Spray alternately from left

to

right and right to left. Begin movement of the gun before the

trigger is pulled.

Proper Technique

Holding

the

surface

gun

farther

wider

spray

change

there

is

desire

to

the

gun

closer

and

produces a narrower

from

the

pattern.

to a spray

an

insufficient

spray

faster, a larger

1st 2nd 3rd 4th

PASS

to

the

surface

If

runs,

sags

tip

with a smaller

amount

OVERLAP

EDGES

PASS

surface

deposits

spray

pattern.

produces a thinner

or