Page 1

Owner’s Manual

Notice d’utilisation

Manual del Propietario

For professional use only

Do not use this equipment before reading this manual!

440i

Airless Sprayer

Model Number:

Complete 700-3000

Printed in the U. S. A.

NOTE: This manual contains important warnings

NOTE: This manual contains important warnings

0707 © 2002 Titan Tool Inc. All rights reserved. Form No. 313-1632, REV E

and instructions. Please read and retain for

and instructions. Please read and retain for

reference.

reference.

EnglishFrançaisEspañol

Page 2

Important Safety Information • Read all safety information before

operating the equipment. Save these instructions.

This symbol indicates a hazardous situation,

which, if not not avoided could result in death or

serious injury.

To reduce the risks of fire or explosion, electrical

shock and the injury to persons, read and understand all instructions included in this manual. Be

familiar with the controls and proper usage of the

equipment.

HAZARD: INJECTION INJURY

A high pressure paint stream produced by this

equipment can pierce the skin and underlying

tissues, leading to serious injury and possible

amputation. See a physician immediately.

DO NOT TREA

CUT! Injection can lead to amputation. See a physician

immediately.

The maximum operating range of the sprayer is 3200 PSI / 22.1

MPa fluid pressure.

PREVENTION:

• NEVER aim the gun at any part of the body.

• Do not aim the gun at, or spray any person or animal.

• NEVER allow any part of the body to touch the fluid stream.

DO NOT allow body to touch a leak in the fluid hose.

• NEVER put your hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS lock the gun trigger, shut the pump off, and

release all pressure before servicing, cleaning the tip or

guard, changing tip, or leaving unattended. Pressure will

not be released by turning off the motor. The

PRIME/SPRAY valve or pressure bleed valve must be

turned to their appropriate positions to relieve system

pressure. Refer to the PRESSURE RELIEF

PROCEDURE described in this manual.

• ALWAYS keep the tip guard in place while spraying. The

tip guard provides some protection but is mainly a

warning device.

• ALWAYS remove the spray tip before flushing or cleaning

the system.

• Paint hose can develop leaks from wear, kinking and

abuse. A leak can inject material into the skin. Inspect

the hose before each use. Do not use hose to lift or pull

equipment.

• NEVER use a spray gun without a working trigger lock

and trigger guard in place.

• All accessories must be rated at or above 3200 PSI / 22.1

MPa. This includes spray tips, guns, extensions, and hose.

• Do not leave the unit energized or under pressure while

unattended. When the unit is not in use, turn off the unit

and relieve the pressure in accordance with the

PRESSURE RELIEF PROCEDURE described in this

manual.

• Verify that all connections are secure before operating the

unit. Unsecured parts may eject at great force or leak a

high pressure fluid stream causing severe injury.

• Always engage the trigger lock when not spraying. Verify

the trigger lock is functioning properly.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury. It is

important to treat the injury as soon as possible. DO

NOT delay treatment to research toxicity. Toxicity is a

concern with some coatings injected directly into the

blood stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

T AN INJECTION INJURY AS A SIMPLE

HAZARD: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other materials can

be harmful if inhaled or come in contact with the body.

apors can cause severe nausea, fainting, or

V

poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be

inhaled. Read all instructions supplied with the

mask to be sure it will provide the necessary

protection.

• Wear protective eyewear

• Wear protective clothing as required by coating

manufacturer.

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite.

Property damage and/or severe injury can occur.

PREVENTION:

Provide extensive exhaust and fresh air introduction to

•

keep the air within the spray area free from accumulation

of flammable vapors. Solvent and paint fumes can

explode or ignite.

• Do not spray in a confined area.

• Avoid all ignition sources such as static electric

sparks, open flames, pilot lights, electrical

appliances, and hot objects. Connecting or disconnecting

power cords or working light switches can make sparks.

Paint or solvent flowing through the equipment is able to

result in static electricity.

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working

order.

• Place pump at least 25 feet (7.62 meters) from the spray

object in a well ventilated area (add more hose if

necessary). Flammable vapors are often heavier than air.

Floor area must be extremely well ventilated. The pump

contains arcing parts that emit sparks and can ignite

vapors.

• The equipment and objects in and around the spray area

must be properly grounded to prevent static sparks.

• Keep area clean and free of paint or solvent containers,

rags and other flammable materials.

• Use only conductive or grounded high pressure fluid hose.

Gun must be grounded through hose connections.

• For electric units — power cord must be connected to a

grounded circuit.

• Always flush unit into a separate metal container, at low

pump pressure, with spray tip removed. Hold gun firmly

against side of container to ground container and prevent

static sparks.

• Follow the material and solvent manufacturer's warnings

and instructions. Know the contents of the paints and

solvents being sprayed. Read all Material Safety Data

Sheets (MSDS) and container labels provided with the

paints and solvents. Follow the paint and solvent

manufacturer’s safety instructions.

• Use extreme caution when using materials with a

flashpoint below 70ºF (21ºC). Flashpoint is the

temperature that a fluid can produce enough vapors to

ignite.

• Plastic can cause static sparks. Never hang plastic to

enclose a spray area. Do not use plastic drop cloths

when spraying flammable materials.

• Use lowest possible pressure to flush equipment.

• Do not spray onto pump assembly.

.

English

2 © Titan Tool Inc. All rights reserved.

Page 3

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

Important Safety Information • Read all safety information before

operating the equipment. Save these instructions.

HAZARD: EXPLOSION HAZARD DUE TO

Will cause property damage or severe injury.

PREVENTION:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such as

• Contact your coating supplier about the compatibility of

HAZARD: GENERAL

Can cause severe injury or property damage.

• Read all instructions and safety precautions before

•

• The United States Government Safety Standards have

• Use only manufacturer authorized parts. User assumes

• All hoses, fittings, and filter parts must be secured before

• Before each use, check all hoses for cuts, leaks, abrasion

• Do not kink or over-bend the hose. Airless hose can

• Do not expose the hose to temperatures or pressures in

• Do not spray outdoors on windy days.

• Wear clothing to keep paint off skin and hair.

• Do not operate or spray near children. Keep children

• Do not overreach or stand on an unstable support. Keep

• Use lowest possible pressure to flush equipment.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the

• For electric units — Always unplug cord from outlet before

• Do not use the hose as a strength member to pull or lift

• Do not lift by cart handle when loading or unloading.

INCOMPATIBLE MATERIALS

bleach, mildewcide, methylene chloride and 1,1,1 trichloroethane. They are not compatible with aluminum.

material with aluminum.

operating equipment.

Follow all appropriate local, state, and national codes

governing ventilation, fire prevention, and operation.

been adopted under the Occupational Safety and Health

Act (OSHA). These standards, particularly part 1910 of

the General Standards and part 1926 of the Construction

Standards should be consulted.

all risks and liabilities when using parts that do not meet

the minimum specifications and safety requirements of the

pump manufacturer.

operating spray pump. Unsecured parts can eject at great

force or leak a high pressure fluid stream causing severe

injury.

or bulging of cover. Check for damage or movement of

couplings. Immediately replace the hose if any of these

conditions exist. Never repair a paint hose. Replace it

with another grounded high-pressure hose.

develop leaks from wear, kinking and abuse. A leak can

inject material into the skin.

excess of those specified by manufacturer.

away from the equipment at all times.

effective footing and balance at all times.

influence of drugs or alcohol.

working on equipment.

the equipment.

Grounding Instructions

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This product

is equipped with a cord having a grounding wire with an

appropriate grounding plug. The plug must be plugged into an

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

Improper installation of the grounding plug

can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not

connect the green grounding wire to either flat blade terminal.

The wire with insulation having a green outer surface with or

without yellow stripes is the grounding wire and must be

connected to the grounding pin.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if you

are in doubt as to whether the product is properly grounded.

Do not modify the plug provided. If the plug will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

IMPORTANT: Use only a 3-wire extension cord that has a

3-blade grounding plug and a 3-slot receptacle that will

accept the plug on the product. Make sure your extension

cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your

product will draw

in line voltage resulting in loss of power and overheating.

A 12 gauge cord is recommended. If an extension cord is

to be used outdoors, it must be marked with the suffix WA after the cord type designation. For example, a

designation of SJTW-A would indicate that the cord would

be appropriate for outdoor use.

. An undersized cord will cause a drop

© Titan Tool Inc. All rights reserved. 3

English

Page 4

Table of Contents

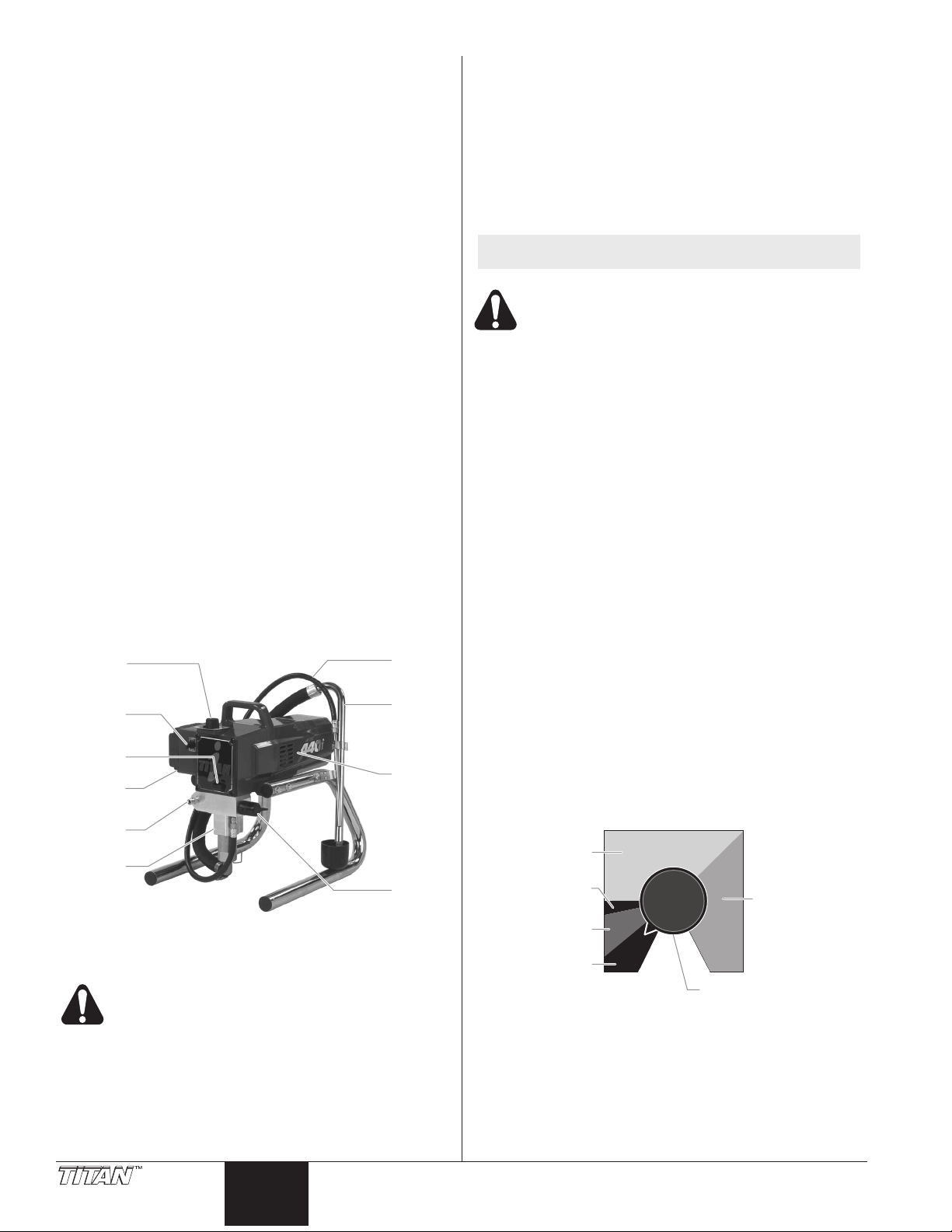

ON/OFF

Switch

Oil Cup

Outlet

Fitting

Fluid

Section

Pressure

Control

Knob

Siphon

Hose

Motor

Return

Tube

PRIME/

SPRAY

Valve

Circuit

Breaker

Clean

Min.

PSI

Max.

PSI

Turbo PulseClean

(red zone)

OFF

(black zone)

Min. – 1800 PSI

(yellow zone)

OFF

(black zone)

1800 – 3200 PSI

(green zone)

Pressure Control Knob

Safety Precautions.................................................................2

General Description ...............................................................4

Operation ................................................................................4

Setup ....................................................................................4

Preparing to Paint.................................................................5

Painting.................................................................................5

Electronic Pressure Control Indicators .................................5

Pressure Relief Procedure ...................................................6

Spraying ..................................................................................6

Spraying Technique ..............................................................6

Practice.................................................................................6

Cleanup ...................................................................................7

Maintenance............................................................................8

General Repair and Service Notes.......................................8

Replacing the Motor .............................................................8

Replacing the Motor Brushes ...............................................8

Replacing the Gears.............................................................8

Replacing the Transducer.....................................................9

Replacing the PRIME/SPRAY Valve.....................................9

Servicing the Fluid Section.................................................10

Replacing the Filters ...........................................................11

Troubleshooting ...................................................................12

Parts Listings........................................................................38

Main Assembly....................................................................38

Motor Assembly ..................................................................39

Gear Box Assembly............................................................40

Fluid Section Assembly ......................................................42

Stand Assembly..................................................................44

Suction Set Assembly.........................................................44

Electrical Schematic ...........................................................45

Accessories ........................................................................46

Warranty................................................................................48

General Description

This airless sprayer is a precision power tool used for spraying

many types of materials. Read and follow this instruction

manual carefully for proper operating instructions,

maintenance, and safety information.

Setup

Perform the following procedure before plugging in the power

cord of an electric unit.

1. Ensure that the suction set and the return hose are

attached and secure.

2. Using a wrench, attach a minimum of 50’ of 1/4” nylon

airless spray hose to the unit. Tighten securely.

3. Attach an airless spray gun to the spray hose. Using two

wrenches (one on the gun and one on the hose), tighten

securely.

NOTE: Do not attach the tip to the spray gun yet.

4. Make sure the pressure control knob is in its OFF position

5.

6.

IMPORTANT: Never operate unit for more than ten

seconds without fluid. Operating this unit without fluid

will cause unnecessary wear to the packings.

7. Make sure the electrical service is 120V, 15 amp

8. Plug the power cord into a properly grounded outlet at

IMPORT

extension cord with a grounded plug. Never remove the

third prong or use an adapter.

Preparing a New Sprayer

If this unit is new, it is shipped with test fluid in the fluid section

to prevent corrosion during shipment and storage. This fluid

must be thoroughly cleaned out of the system with mineral

spirits before you begin spraying.

IMPORTANT: Always keep the trigger lock on the spray

gun in the locked position while preparing the system.

1. Place the suction tube into a container of mineral spirits.

2. Place the return hose into a metal waste container

3. Set the pressure to minimum by turning the pressure

Remove the tip if it is already attached.

Make sure all airless hoses and spray guns are

electrically grounded and rated for at least 3200

psi (21.1 MPa) fluid pressure.

in the black zone.

Make sure the ON/OFF switch is in its OFF position.

Fill the oil cup with one tablespoon of piston seal lubricant

(Piston Lube).

minimum.

least 25’

control knob to the “Min” setting in the yellow zone.

from the spray area.

ANT: Always use a minimum 12 gauge, three-wire

.

Operation

This equipment produces a fluid stream at

extremely high pressure. Read and understand

the warnings in the Safety Precautions section at

the front of this manual before operating this

equipment.

English

4. Move the PRIME/SPRAY valve down to the PRIME

position.

5. Turn the unit on by moving the ON/OFF switch to the ON

position.

6. Allow the sprayer to run for 15–30 seconds to flush the

test fluid out through the return hose and into the waste

container.

7. Turn the unit off by moving the ON/OFF switch to the OFF

position.

4 © Titan Tool Inc. All rights reserved.

Page 5

Preparing to Paint

Trigger lock

in locked position.

Max.

PSI

Clean

Min.

PSI

Pressure

Indicator

Motor Running Indicator

Programmer Port

Programmer Port

Dust Cover

Circuit

Breaker

Blinking Yellow =

0 PSI – priming pressure

Solid Yellow =

priming pressure – 1800 PSI

Solid Green =

1800 PSI – 3200 PSI

Trigger lock

in locked position.

Max.

PSI

Clean

Min.

PSI

Before painting, it is important to make sure that the fluid in the

system is compatible with the paint that is going to be used.

NOTE: Incompatible fluids and paint may cause the

IMPORTANT: Always keep the trigger lock on the spray

gun in the locked position while preparing the system.

1. Place the suction tube into a container of the appropriate

2.

3. Set the pressure to minimum by turning

4. Move the PRIME/SPRAY valve down to

5. Turn the unit on by moving the ON/OFF

6. Allow the sprayer to run for 15–30 seconds to flush the old

7. Turn the unit off by moving the ON/OFF switch to the OFF

NOTE: Make sure that the spray gun does not have a

8. Move the PRIME/SPRAY valve up to the SPRAY position.

9. Turn the unit on.

10. Unlock the gun by turning the gun trigger lock to the

11. Trigger the gun into the metal waste container until the old

12.

13. Set down the gun and increase the

14.

15. Follow the “Pressure Relief Procedure” in this manual

valves to become stuck closed, which would

require disassembly and cleaning of the

sprayer’s fluid section.

solvent. Examples of the appropriate solvent are water for

latex paint or mineral spirits for oil-based paints.

Place the return hose into a metal waste container

the pressure control knob to the “Min”

setting in the yellow zone.

the PRIME position.

switch to the ON position.

solvent out through the return hose and into the metal

waste container.

position.

tip or tip guard installed.

unlocked position.

Ground the gun by holding it

against the edge of the metal

container while flushing. Failure

to do so may lead to a static

electric discharge, which may

cause a fire.

solvent is gone and fresh solvent is coming out of the gun.

Lock the gun by turning the gun

trigger lock to the locked position.

pressure by turning the pressure

control knob slowly clockwise into

the green zone.

Check the entire system for leaks.

If leaks occur, follow the “Pressure

Relief Procedure” in this manual before tightening any

fittings or hoses.

before changing from solvent to paint.

Be sure to follow the pressure relief procedure

when shutting down the sprayer for any purpose,

including servicing or adjusting any part of the

spray system, changing or cleaning spray tips, or

preparing for cleanup.

Painting

1. Place the suction tube into a container of paint.

2. Place the return hose into a metal waste container.

3. Set the pressure to minimum by turning

the pressure control knob to the “Min”

setting in the yellow zone.

4. Move the PRIME/SPRAY valve down to

the PRIME position.

5. Turn the unit on by moving the ON/OFF

switch to the ON position.

6. Allow the sprayer to run until paint is coming through the

return hose into the metal waste container.

7. Turn the unit off by moving the ON/OFF switch to the OFF

.

position.

8. Remove the return hose from the waste container and

place it in its operating position above the container of

paint.

9. Move the PRIME/SPRAY valve up to the SPRAY position.

10. Turn the unit on.

11. Unlock the gun by turning the gun trigger lock to the

unlocked position.

Ground the gun by holding it

against the edge of the metal

container while flushing. Failure to

do so may lead to a static electric

discharge, which may cause a fire.

12. Trigger the gun into the metal waste

container until all air and solvent is flushed from the spray

hose and paint is flowing freely. from the gun.

13. Lock the gun by turning the gun

trigger lock to the locked position.

14. T

urn the unit off.

15. Attach tip guard and tip to the gun

as instructed by the tip guard or tip

manuals.

POSSIBLE INJECTION

HAZARD. Do not spray

without the tip guard in place. Never trigger the

gun unless the tip is in either the spray or the

unclog position. Always engage the gun trigger

lock before removing, replacing or cleaning tip.

16. Turn the unit on.

17

. Increase the pressure by turning the pressure control knob

slowly clockwise toward the green zone and test the spray

pattern on a piece of cardboard. Adjust the pressure control

knob until the spray from the gun is completely atomized.

Try to keep the pressure control knob at the lowest setting

that maintains good atomization.

NOTE: Turning the pressure up higher then needed to

atomize the paint will cause premature tip wear

and additional overspray.

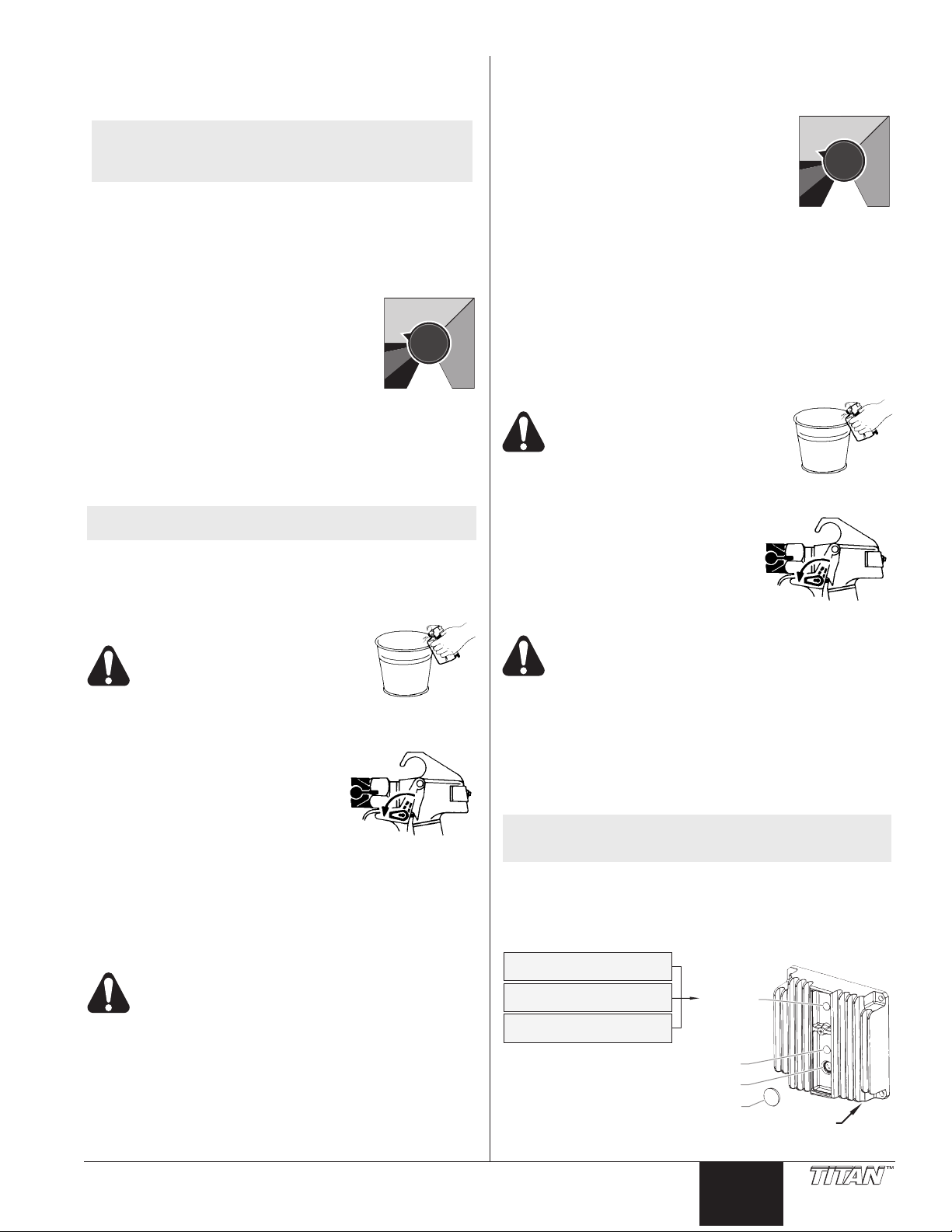

Electronic Pressure Control Indicators

The following is a description of the indicators on the electronic

pressure control.

© Titan Tool Inc. All rights reserved. 5

English

Page 6

Pressure Indicator

Trigger lock

in locked position.

Too Thick

Offspray

Arcing Gun at angle

start

stroke

release

trigger

pull

trigger

end

stroke

The pressure indicator shows the current operating pressure of

the sprayer. It has three different indications: blinking yellow,

solid yellow, and solid green.

Blinking Yellow

When the pressure indicator is blinking yellow, the sprayer is

operating between 0 and 200 PSI.

indicator means:

• The sprayer is plugged in and turned “ON”

• The sprayer is at priming pressure (little or no pressure)

• It is safe to move the PRIME/SPRAY valve between

positions

• It is safe to change or replace the spray tip

NOTE: If the pressure indicator begins blinking yellow

Solid Yellow

When the pressure indicator is solid yellow, the sprayer is

operating between 200 and 1800 PSI.

indicator means:

Solid Green

When the pressure indicator is solid green, the sprayer is

operating between 1800 and 3200 PSI. A solid green pressure

indicator means:

when the pressure control knob is set at a

higher pressure and the PRIME/SPRAY valve is

in the SPRAY position, either the spray tip is

worn or the sprayer is in need of service/repair.

• The sprayer is at the proper pressure setting for spraying

stain, lacquer, varnish, and multi-colors

• If the pressure indicator goes to solid yellow when the

pressure is set so that it starts at solid green, it indicates

one of the following:

a. Tip Wear Indicator — when spraying with latex or at

high pressure the solid yellow appears. This means

the tip is worn and needs to be replaced.

b. Tip Too Large — when a tip that is too large for the

sprayer is put in the gun, the pressure indicator will turn

from solid green to solid yellow.

c. Fluid Section Wear — if a solid yellow pressure

indicator appears when using a new tip and the

pressure is set at maximum, service may be required

(worn packings, worn piston, stuck valve, etc...).

• The sprayer is at the proper pressure setting for spraying

oil-based and latex house paints

The sprayer is operating at peak performance at a high

•

pressure setting

A

blinking yellow pressure

solid yellow pressure

A

Motor Running Indicator

The Motor Running indicator is on when the motor is

commanded to run. This indicator is used by service centers

to troubleshoot motor problems.

5. Hold the metal part of the gun firmly to

the side of a metal container to ground

the gun and avoid a build up of static

electricity.

6. Trigger the gun to remove any

pressure that may still be in the hose.

7. Lock the gun by turning the gun trigger lock to the locked

position.

8. Move the PRIME/SPRAY valve down to the PRIME

position.

Spraying

POSSIBLE INJECTION HAZARD. Do not spray

without the tip guard in place. Never trigger the

gun unless the tip is in either the spray or the

unclog position. Always engage the gun trigger

lock before removing, replacing, or cleaning tip.

Spraying Technique

The following techniques, if followed, will assure professional

painting results.

Hold the gun perpendicular to the surface and always at equal

distance from the surface. Depending on the type of material,

surface, or desired spray pattern, the gun should be held at a

distance of 12 to 14 inches (30 to 35 cm).

Move the gun either across or up and down the surface at a

steady rate. Moving the gun at a consistent speed conserves

material and provides even coverage. The correct spraying

speed allows a full, wet coat of paint to be applied without runs

or sags.

Holding the gun closer to the surface deposits more paint on

the surface and produces a narrower spray pattern. Holding

the gun farther from the surface produces a thinner coat and

wider spray pattern. If runs, sags, or excessive paint occur,

change to a spray tip with a smaller orifice. If there is an

insufficient amount of paint on the surface or you desire to

spray faster, a larger orifice tip should be selected.

Maintain uniform spray stroke action. Spray alternately from

left to right and right to left. Begin movement of the gun before

the trigger is pulled.

Avoid arcing or holding the gun at an angle. This will result in

an uneven finish.

Pressure Relief Procedure

1. Lock the gun by turning the gun

trigger lock to the locked position.

2. T

ON/OFF switch to the OFF position.

3. Turn the pressure control knob

counterclockwise to its OFF position

in the black zone.

4. Unlock the gun by turning the gun

trigger lock to the unlocked position.

Be sure to follow the pressure relief procedure

when shutting the unit down for any purpose,

including servicing or adjusting any part of the

spray system, changing or cleaning spray tips, or

preparing for cleanup.

urn the unit off by moving the

English

Proper lapping (overlap of spray pattern) is essential to an

even finish. Lap each stroke. If you are spraying horizontally,

aim at the bottom edge of the preceding stroke, so as to lap

the previous pattern by 50%.

6 © Titan Tool Inc. All rights reserved.

Page 7

For corners and edges, split the

Good spray pattern

Paint tailing pattern

Overlap edges

1st

pass

2nd

pass

3rd

pass

4th

pass

5th

pass

Min.

PSI

Max.

PSI

Clean

center of the spray pattern on the

corner or edge and spray vertically

so that both adjoining sections

receive approximately even

amounts of paint.

When spraying with a shield, hold it firmly against the surface.

Angle the spray gun slightly away from the shield and toward

the surface. This will prevent paint from being forced

underneath.

Shrubs next to houses should be tied back and covered with a

canvas cloth. The cloth should be removed as soon as

possible. Titan gun extensions are extremely helpful in these

situations.

Nearby objects such as automobiles, outdoor furniture, etc.

should be moved or covered whenever in the vicinity of a

spray job. Be careful of any other surrounding objects that

could be damaged by overspray.

Practice

1. Be sure that the paint hose is free of kinks and clear of

objects with sharp cutting edges.

2. Turn the pressure control knob counterclockwise to its to

its lowest setting.

3. Turn the PRIME/SPRAY valve up to its SPRAY position.

4. Turn the pressure control knob clockwise to its highest

setting. The paint hose should stiffen as paint begins to

flow through it.

5. Unlock the gun trigger lock.

6. Trigger the spray gun to bleed air out of the hose.

7. When paint reaches the spray tip, spray a test area to

check the spray pattern.

8. Use the lowest pressure

setting necessary to get a

good spray pattern. If the

pressure is set too high, the

spray pattern will be too light.

If the pressure is set too low,

tailing will appear or the paint

will spatter out in gobs rather

than in a fine spray.

Cleanup

Special cleanup instructions for use with

flammable solvents:

• Always flush spray gun preferably outside and at least one

hose length from spray pump.

• If collecting flushed solvents in a one gallon metal

container, place it into an empty five gallon container, then

flush solvents.

• Area must be free of flammable vapors.

• Follow all cleanup instructions.

IMPORTANT: The sprayer, hose, and gun should be

cleaned thoroughly after daily use. Failure to do so

permits material to build up, seriously affecting the

performance of the unit.

Always spray at minimum pressure with the gun

nozzle tip removed when using mineral spirits or

any other solvent to clean the sprayer, hose, or

gun. Static electricity buildup may result in a fire

or explosion in the presence of flammable vapors.

1. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual.

2. Remove the gun tip and tip guard and clean with a brush

using the appropriate solvent.

Place the suction tube into a container of the appropriate

3.

solvent. Examples of the appropriate solvent are water for

latex paint or mineral spirits for oil-based paints.

4. Place the return hose into a metal waste container.

5. Move the PRIME/SPRAY valve down to its PRIME

position.

6. Set the pressure to Turbo PulseClean by

turning the pressure control knob to its

CLEAN position in the red zone.

7. Turn the unit on by moving the ON/OFF

switch to the ON position.

8. Allow the solvent to circulate through the

unit and flush the paint out of the return

hose into the metal waste container.

9. Turn the unit off by moving the ON/OFF switch to the OFF

position.

10. Move the PRIME/SPRAY valve up to its SPRAY position.

11. Turn the unit on.

Ground the gun by holding it

against the edge of the metal

container while flushing.

Failure to do so may lead to a

static electric discharge, which

may cause a fire.

12. Trigger the gun into the metal waste container until the

paint is flushed out of the hose and solvent is coming out

of the gun.

13. Continue to trigger the spray gun into the waste container

until the solvent coming out of the gun is clean.

NOTE: For long-term or cold weather storage, pump

14. Follow the “Pressure Relief Procedure” found in the

15. Unplug the unit and store in a clean, dry area.

IMPORT

mineral sprits through the entire system.

For short-term storage when using latex paint,

pump water mixed with Titan Liquid Shield

through the entire system (see the Accessories

section of this manual for part number).

Operation section of this manual.

ANT: Do not store the unit under pressure.

© Titan Tool Inc. All rights reserved. 7

English

Page 8

Motor Cover

Brush Cover

Motor

Motor Mounting Screw

Pump Housing

Capacitors

Shroud

Shroud Screw

Motor Cover Screw

BLACK

BLACKBLACK

REDRED

BLACK

RED

RED

Maintenance

Before proceeding, follow the Pressure Relief

Procedure outlined previously in this manual.

Additionally, follow all other warnings to reduce

the risk of an injection injury, injury from moving

parts or electric shock. Always unplug the

sprayer before servicing!

General Repair and Service Notes

The following tools are needed when repairing this sprayer:

Phillips Screwdriver 3/8" Hex Wrench

Needle Nose Pliers 5/16" Hex Wrench

Adjustable Wrench 1/4" Hex Wrench

Rubber Mallet 3/16" Hex Wrench

Flat-blade Screwdriver 5/32” Hex Wrench

1. Before repairing any part of the sprayer, read the

instructions carefully, including all warnings.

IMPORTANT: Never pull on a wire to disconnect it. Pulling

on a wire could loosen the connector from the wire.

2. Test your repair before regular operation of the sprayer to

be sure that the problem is corrected. If the sprayer does

not operate properly

determine if everything was done correctly

Troubleshooting Charts to help identify other possible

problems.

3. Make certain that the service area is well ventilated in

case solvents are used during cleaning. Always wear

protective eyewear while servicing. Additional protective

equipment may be required depending on the type of

cleaning solvent. Always contact the supplier of solvents

for recommendations.

4. If you have any further questions concerning your TITAN

Airless Sprayer, call TITAN:

Customer Service (U.S.) .......................1-800-526-5362

Fax ................................................1-800-528-4826

Customer Service (Canada)..................1-800-565-8665

Fax ................................................ 1-905-856-8496

Customer Service (International)...........1-201-405-7520

Fax ................................................1-201-405-7449

Replacing the Motor

1. Unplug the unit.

2. Loosen and remove the four motor cover screws.

Remove the motor cover.

3. Disconnect the black and red wires coming from the pump

housing. Disconnect the black and red wires from the

capacitors. Disconnect the black and red wires from the

motor.

4. Remove the capacitors from their mounting clip.

5. Loosen and remove the four motor mounting screws.

6. Pull the motor out of the pump housing.

NOTE: If the motor will not dislodge from the pump

7. With the motor removed, inspect the gears in the pump

8. Install the new motor into the pump housing.

NOTE: Rotate the motor fan manually until the

9. Secure the motor with the four motor mounting screws.

housing:

• Remove the front cover plate.

• Using a rubber mallet, carefully tap on the

front of the motor crankshaft that extends

through the connecting rod.

housing for damage or excessive wear. Replace the

gears, if necessary.

armature gear engages with the mating gear in

the pump housing.

, review the repair procedure to

English

. Refer to the

10. Push the capacitors into their clip on the new motor.

11. Reconnect the wires (refer to the electrical schematic in

the Parts List section of this manual).

12. Slide the motor cover over the motor. Secure the motor

cover with the four motor cover screws.

Replacing the Motor Brushes

Perform this procedure using Motor Brush Kit P/N 704-276.

1. Loosen and remove the four motor cover screws.

Remove the motor cover.

2. Loosen and remove the two shroud screws. Remove the

shroud.

3. Using a small screwdriver, pry off the two plastic brush

covers.

4. Disconnect the black and red wires from the motor

brushes. Remove the motor brushes.

5. Install the new motor brushes and snap on the plastic

brush covers.

6. Reconnect the black and red wires from the motor

brushes (refer to the electrical schematic in the Parts List

section of this manual).

7. Position the shroud over the motor fan. Secure the

shroud with the two shroud screws.

8. Slide the motor cover over the motor. Secure the motor

cover with the four motor cover screws.

Replacing the Gears

1. Loosen and remove the four motor cover screws.

Remove the motor cover.

2. Disconnect the black and red wires coming from the pump

housing.

3. Loosen and remove the four motor mounting screws.

4. Pull the motor out of the pump housing.

NOTE: If the motor will not dislodge from the pump

housing:

• Remove the front cover plate.

• Using a rubber mallet, carefully tap on the

front of the motor crankshaft that extends

through the connecting rod.

5. Inspect the armature gear on the end of the motor for

damage or excessive wear. If this gear is completely

worn out, replace the entire motor.

6. Remove and inspect the 2nd stage gear for damage or

excessive wear. Replace if necessary.

7. Remove and inspect the gear and crank assembly for

damage or excessive wear. Replace if necessary.

8. Reassemble the pump by reversing the above steps.

During reassembly, make sure the thrust washers is in

place.

NOTE: Refill the gear box with five ounces of

Lubriplate (P/N 314-171).

8 © Titan Tool Inc. All rights reserved.

Page 9

RED

BLACK

Front Cover

Pump Housing

Front Cover Screw

2nd Stage Gear

Thrust Washer

Motor Mounting

Screw

Gear and Crank

Assembly

Armature Gear

Motor

Motor Cover

Motor Cover Screw

Gasket

Cam Base

Valve Stem

Pump Block

Valve Housing

Assembly

Valve

Handle

Groove Pin

T-Slot

Pump

Housing

Pump

Block

Pump

Block

Mounting

Screw

Front

Cover

EPC

Mounting

Screw

Electronic

Pressure

Control

(EPC)

Front

Cover

Screw

Set Screw

Transducer

Assembly

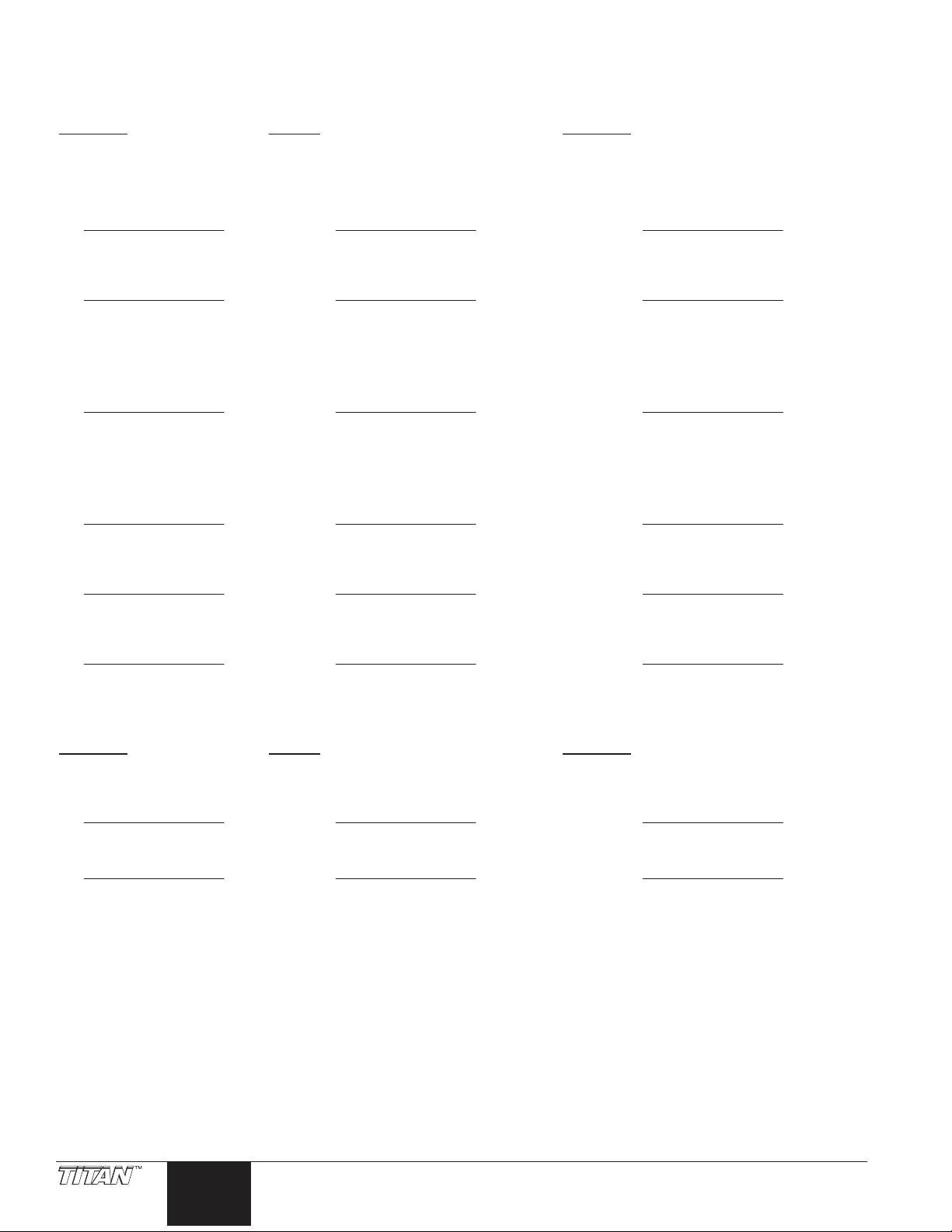

Replacing the Transducer

1. Loosen and remove the four front cover screws. Remove

the front cover.

2. Stop the sprayer at the bottom of its stroke so that the

piston is in its lowest position. Turn off and unplug the

sprayer.

Before proceeding, follow the Pressure Relief

Procedure outlined previously in this manual.

Additionally, follow all other warnings to reduce

the risk of an injection injury

parts or electric shock. Always unplug the

sprayer before servicing!

3. Tilt the pump back for easy access to the fluid section.

4. Using a 3/8” hex wrench, loosen and remove the two

pump block mounting screws.

5. Pull the pump block down approximately 1/2” from the

pump housing to clear the transducer

6. Slide the pump block and piston rod forward until the

piston rod is out of the T-slot on the connecting rod.

7. Loosen and remove the four electronic pressure control

(EPC) mounting screws.

8. Pull back the EPC for access to the transducer plug-in.

9. Unplug the transducer connection from EPC board

location “JP3” (refer to the electrical schematic in the

Parts List section of this manual).

10. Using an 1/8” hex wrench, loosen and remove the set

screw from the bottom of the pump housing.

11. Slide the transducer assembly out of the bottom of the

12. Install the new transducer assembly into the pump

13. Thread the set screw into the pump housing and tighten

14. Plug the transducer connection into the EPC board at

15. Reassemble the pump by reversing steps 1–8.

IMPORTANT: Make sure the transducer is aligned

properly with the hole in the pump block during

reassembly. Improper alignment may cause damage to

the transducer gasket.

pump housing.

housing.

securely.

location “JP3” (refer to the electrical schematic in the

Parts List section of this manual).

, injury from moving

.

Replacing the PRIME/SPRAY Valve

Perform the following procedure using PRIME/SPRAY valve

replacement kit P/N 700-258.

1. Push the groove pin out of the valve handle.

2. Remove the valve handle and the cam base.

3. Using a wrench, loosen and remove the valve housing

assembly.

4. Make sure the gasket is in place and thread the new valve

housing assembly into the pump block. Tighten securely

with wrench.

5. Place the cam base over the valve housing assembly.

Lubricate the cam base with grease and line up the cam

with the pump block.

6. Line up the hole on the valve stem with the hole in the

valve handle.

7. Insert the groove pin into the valve handle and through

the valve stem to secure the valve handle in position.

© Titan Tool Inc. All rights reserved. 9

English

Page 10

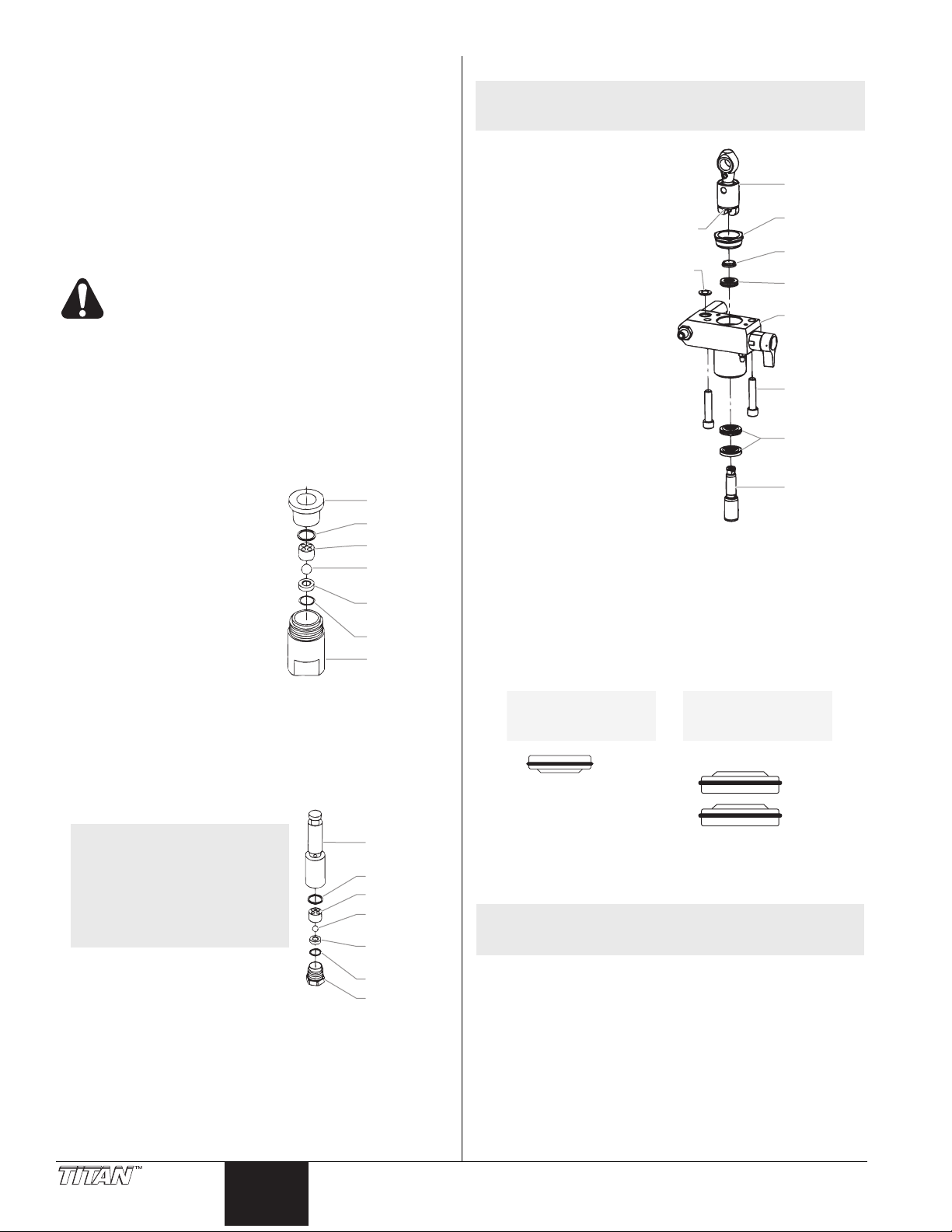

Servicing the Fluid Section

Outlet Valve

Housing

Outlet Valve

Seat

Outlet Valve

Ball

Upper Cage

Upper Seal

Piston Rod

O-Ring

Foot Valve

Housing

Foot Valve

Seat

Foot Valve

Ball

Bushing

O-Ring

Lower Cage

Lower Seal

Install lower packings

with raised lip and O-ring

facing up.

Install upper packing

with raised lip and O-ring

facing down.

O-Ring

O-Ring

Raised Lip

Raised Lip

Connecting

Rod

Retainer

Nut

Piston

Guide

Upper

Packing

Pump

Block

Lower

Packings

Pump Block

Mounting

Screw

Piston Rod

T-Slot

Transducer

Gasket

Use the following procedures to service the valves and repack

the fluid section. Perform the following steps before

performing any maintenance on the fluid section.

1. Loosen and remove the four front cover screws. Remove

the front cover.

2. Stop the sprayer at the bottom of its stroke so that the

piston is in its lowest position. Turn off and unplug the

sprayer.

Before proceeding, follow the Pressure Relief

Procedure outlined previously in this manual.

Additionally, follow all other warnings to reduce

the risk of an injection injury

parts or electric shock. Always unplug the

sprayer before servicing!

3. Unscrew the return hose assembly from the pump block.

4. Remove the retaining clip that holds the suction set in the

foot valve. Pull the suction set out of the foot valve.

ilt the pump back for easy access to the fluid section.

5. T

Servicing the Valves

The design of Titan's fluid section

allows access to the foot valve and

seat as well as the outlet valve and

seat without completely

disassembling the fluid section. It

is possible that the valves may not

seat properly because of debris

stuck in the foot valve seat or outlet

valve seat. Use the following

instructions to clean the valves and

reverse or replace the seats.

1. Using a wrench, loosen and

remove the foot valve housing from the pump block.

2. Clean out any debris in the foot valve housing and

examine the valve housing and seat. If the seat is

damaged, reverse or replace the seat.

3. Using a 3/8" hex wrench, loosen and remove the outlet

valve housing from the piston rod.

, injury from moving

Repacking the Fluid Section

NOTE: The factory-installed packings are black in

color. The replacement packings in the

packing replacement kit are white.

1. Remove the foot

valve and outlet

valve assemblies

using the steps in

the “Servicing the

Valves” procedure

above.

2. Using 3/8” a hex

wrench, loosen

and remove the

two pump block

mounting screws.

3. Pull the pump

block down

approximately 1/2”

from the pump

housing.

4. Slide the pump

block and piston

rod forward until

the piston rod is

out of the T-slot

on the connecting

rod.

5. Slide the piston rod out through the bottom of the pump

block

6. Loosen and remove the retainer nut and piston guide from

the pump block.

7. Remove the upper and lower packings from the pump

block.

8. Clean the pump block and install the new upper and lower

packings. Refer to the illustration below for proper

packing orientation.

NOTE: Always service the

4. Clean out any debris and

examine the valve housing and

seat. If the seat is damaged,

reverse or replace the seat.

5. Remove, clean, and inspect the upper cage and upper

ball. Replace if they are worn or damaged.

6. Reassemble the valves by reversing the steps above.

outlet valve with the

piston rod attached to

the pump. This will

prevent the piston rod

from rotating during

disassembly of the

outlet valve.

English

9. Inspect the piston rod for wear and replace if necessary.

10. Reassemble the outlet valve assembly into the piston rod.

Tighten the outlet valve housing with a wrench until

secure.

NOTE: Use the T-slot on the connecting rod to hold

the piston rod in position while securing the

outlet valve housing.

IMPORTANT: Never use a wrench on the piston itself.

This could cause damage to the piston and cause leakage.

11. Insert the piston guide into the retainer nut. Thread the

retainer nut into the pump block until it is hand tight.

12.

Slide the piston guide tool (included in the repacking kit)

over the top of the piston rod and insert the piston rod

through the bottom of the pump block. Using a rubber

mallet, tap the bottom of the piston rod lightly until the

piston rod is in position in the pump block.

10 © Titan Tool Inc. All rights reserved.

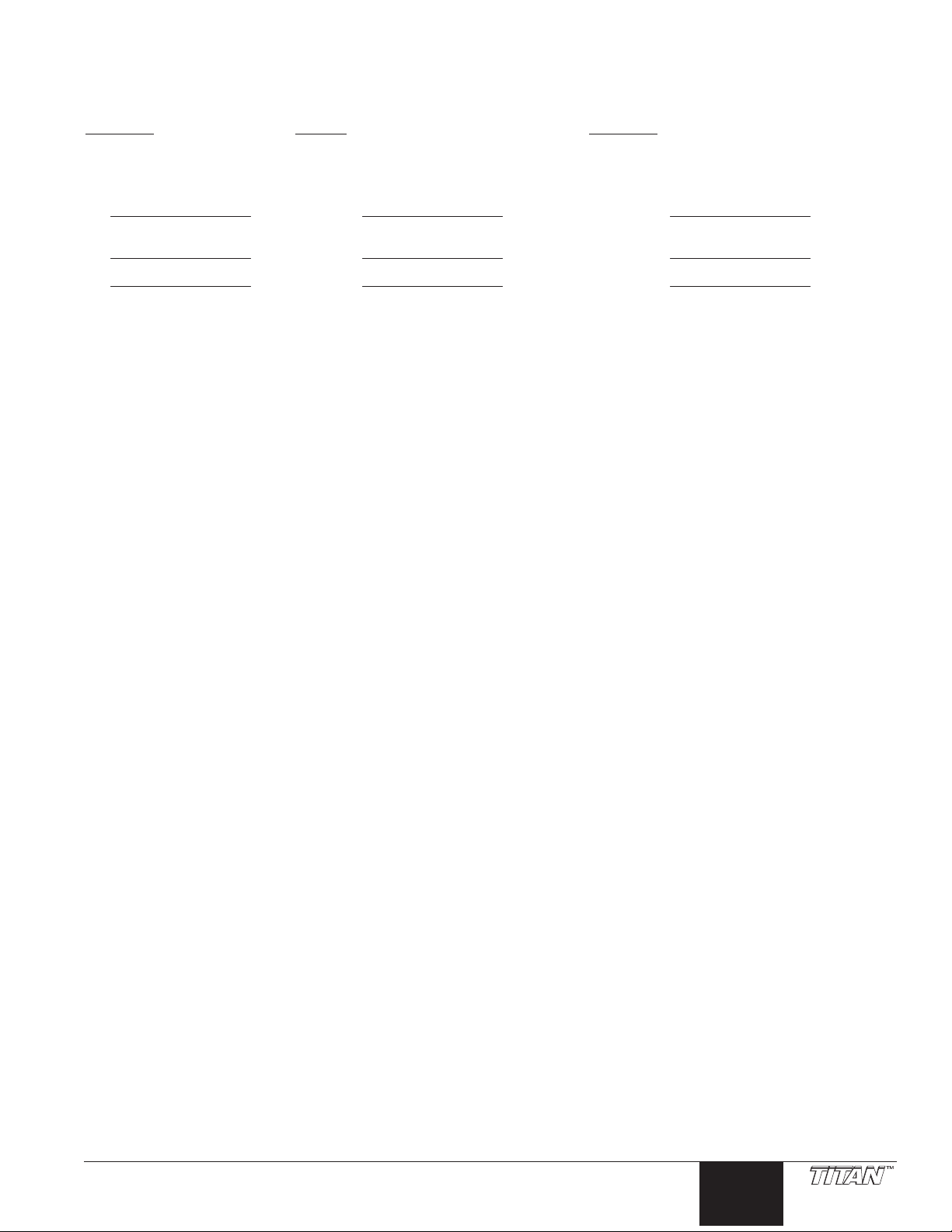

Page 11

Pump Block

Seal

Filter

Filter Housing

NOTE: Coat the piston guide tool and the piston rod

Gun Body

Handle Seal

Filter

Handle

13. Using a wrench, tighten the retainer nut securely.

14. Slide the top of the piston rod into the T-slot on the

15. Position the pump block underneath the pump housing

IMPORTANT: Make sure the transducer is aligned

p

roperly with the hole in the pump block during

reassembly. Improper alignment may cause damage to

the transducer gasket.

16. Thread the pump block mounting screws through the

17. Reassemble the foot valve assembly into the pump block.

18. Insert the elbow on the suction set into the bottom of the

19. Thread the return hose into the pump block and tighten

20. Place the front cover on the pump housing and secure in

21. Turn on the sprayer by following the procedure in the

NOTE: Repacking kit P/N 730-401 is available. For

with grease before inserting them into the

pump block.

connecting rod.

and push up until it rests against the pump housing.

pump block and into the pump housing. T

foot valve. Position the retaining clip into the foot valve to

secure the suction set assembly.

securely.

position using the four front cover screws.

“Operation” section of this manual and check for leaks.

best results use all parts supplied in this kit.

ighten securely.

Gun Filter

1. Move the gun trigger lock to the unlocked position.

2. Loosen and remove the handle from the gun body.

3. Turning clockwise, unscrew the filter from the gun body.

NOTE: Left-handed threads require turning the filter

clockwise to remove.

4. Turning counterclockwise, screw the new or cleaned filter

into the gun body.

5. Make sure the handle seal is in position and thread the

handle into the gun body until secure.

6. Move the gun trigger lock to the locked position.

Replacing the Filters

Pump Filter

1. Loosen and remove the filter housing.

2. Turning clockwise, unscrew the filter from the pump block.

NOTE: Left-handed threads require turning the filter

clockwise to remove. If the filter breaks off in

the pump block, use a small wood screw to

remove.

3. Inspect the seal. Based on inspection, clean or replace

the seal.

4. Turning counterclockwise, thread the new or cleaned filter

into the pump block.

5. Slide the filter housing over the filter and thread it into the

pump block until secure.

NOTE: For more detail, part number information, and

assembly drawings at larger scale, please see

the LX-80 Professional Airless Gun Owner's

Manual (P/N 313-012).

© Titan Tool Inc. All rights reserved. 11

English

Page 12

Airless Sprayer

Troubleshooting

Problem

Electric motor won't run

Sprayer won’t prime

Insufficient material flow

Sprayer will not maintain

pressure

Not enough pressure

Cause

1. Unit unplugged or circuit fuse blown

2. Pressure setting too low

3. Brushes on motor are worn

4. Electric motor burned out

5. Switch defective

6. Circuit breaker on sprayer tripped

1. Air in line

2. Insufficient pressure

3. Clutch worn or damaged (gas models)

1. No paint

2. Siphon strainer clogged

3. Sprayer/gun filter clogged

4. Sprayer will not prime, material too

heavy

5. Engine not tuned properly (gas)

6. Worn clutch (gas models)

1. Air leak in system

2. Air leak in siphon tube

3. Inlet valve not seating

4. Worn packings

5. Dirty or worn ball valves

6. Worn valve seats

7. Worn prime valve

1. Pressure setting too low

2. Plugged filters

3. Spray tip too big or worn

4. Engine or motor rpm too low (gas)

Solution

1. Check

2. Increase

3. Replace

4. Replace

5. Replace

6. Reset the breaker

1. Check siphon tube O-Ring and/or let paint

circulate in prime position

2. Increase pressure

3. Replace

1. Check supply

2. Clean

3. Clean & replace

4. Thin material

5. Tune engine

6. Service

1. Tighten connections

2. Tighten, check for leaks

3. Service or clean

4. Replace

5. Clean or replace

6. Reverse

7. Replace

1. Increase

2. Clean or replace

3. Change or replace

4. Increase throttle

Excessive surge at spray gun

Paint leaks into oil cup

Airless Gun

Problem

Spitting gun

Gun will not shut off

Gun does not spray

1. Wrong type of hose

2. Spray tip too big or worn

3. Excessive pressure

1. Worn out packings

Cause

1. Air in system

2. Dirty gun

3. Needle assembly out of adjustment

4. Broken or chipped seat

1. Worn or broken needle & seat

2. Needle assembly out of adjustment

3. Dirty gun

1. No paint

2. Plugged filter or tip

3. Broken needle in gun

1. Replace with a minimum 50' grounded

nylon braid high pressure hose

2. Change or replace

3. Decrease pressure and engine speed

1. Replace

Solution

1. Inspect connections for air leaks

2. Disassemble and clean

3. Inspect and adjust

4. Inspect and replace

1. Replace

2. Adjust

3. Clean

1. Check fluid supply

2. Clean

3. Replace

English

12 © Titan Tool Inc. All rights reserved.

Page 13

Spray Patterns

Troubleshooting

Problem

Tails

Heavy centered pattern

Distorted pattern

Pattern expanding and

contracting (Surge)

Cause

1. Inadequate fluid delivery

2. Fluid not atomizing

3. Insufficient velocity

4. Material too cohesive

5. Tip worn past sprayer capacity

1. Worn tip

2. Tip may be chipped

1. Plugged, worn or chipped tip

1. Leak in suction tube

2. Not enough hose

3. Tip too large or worn

Patents

These products are covered by one or more of the following U.S. patents:

4,500,119 4,768,929

Solution

1. Increase pressure

2. Change to smaller tip

3. Clean gun and pump filters

4. Reduce viscosity

5. Replace

1. Replace

2. Replace

1. Clean or replace

1. Tighten

2. Use a minimum of 50' (15m) of 1/4" high

pressure hose

3. Replace with a new or

smaller tip

© Titan Tool Inc. All rights reserved. 13

English

Page 14

Importantes consignes de sécurité • Lire toutes ces consignes

avant d’utiliser l’appareil. Garder ces consignes.

Indique une situation à risque, laquelle, si elle n'est pas

évitée, peut entraîner des blessures graves, voire la

mort.

Pour réduire les risques d’incendie ou d’explosion, de

choc électrique et de blessure, vous devez lire et

comprendre les directives figurant dans ce manuel.

Familiarisez-vous avec les commandes et l’utilisation

adéquate de l’équipement.

DANGER : INJECTION CUTANÉE

Le jet de haute pression produit par cet appareil peut

transpercer la peau et les tissus sous-jacents, causant des

blessures graves pouvant entraîner l'amputation.

NE PAS TRAITER CE TYPE DE BLESSURE COMME UNE SIMPLE

COUPURE! Une amputation peut en résulter

CONSULTER UN MÉDICIN SUR-LE-CHAMP.

La pression maximale de ce pulvérisateur est d’environ 3 200 PSI /

22,1 MPa.

MESURES PRÉVENTIVES :

• Ne pas pointer le pistolet vers une partie du corps.

•

Ne pas pointer le pistolet vers une personne ou un animal; ne

pas pulvériser non plus de produit dessus.

NE JAMAIS mettre une partie du corps devant le jet de produit.

•

NE JAMAIS toucher les fuites du flexible de pulvérisation.

• NE JAMAIS mettre la main, même gantée, devant le pistolet (les

gants n’offrent aucune protection contre les blessures par

injection).

• TOUJOURS verrouiller la détente, arrêter la pompe et relâcher toute

la pression avant d’effectuer la maintenance de l’appareil ou de le

laisser sans surveillance, d’en nettoyer le protège-embout ou

l’embout, ou de remplacer ce dernier. La pression ne sera pas

relâchée par le simple arrêt du moteur; pour ce faire, on doit se servir

du bouton PRIME/SPRAY (se reporter à la section COMMENT

LIBÉRER LA PRESSION, du présent manuel).

• TOUJOURS s'assurer que le protège-embout est en place avant de

pulvériser. Il est cependant à noter que, s’il assure une certaine

protection, ce dispositif joue surtout un rôle préventif.

• TOUJOURS retirer l’embout avant de vidanger ou de nettoyer

l’appareil.

• TOUJOURS inspecter le flexible avant de commencer; celui-ci

peut présenter des fuites attribuables à l’usure, à une flexion

excessibe ou à un traitement abusif, lesquelles fuites présentent

des risques d’injection cutanée. Ne pas utiliser le flexible pour

soulever ou tirer l’équipement.

• NE JAMAIS utiliser de pistolet sans verrou de détente et protègedoigts.

• Tous les accessoires (pistolets, embouts, rallonges, flexibles etc.)

doivent pouvoir subir une pression nominale de 3 200 PSI / 22,1

MPa ou plus.

• Ne laissez pas l’appareil sous tension ou sous pression quand vous

vous en éloignez. Quand vous n’utilisez pas l’appareil, éteignez-le

et libérez la pression conformément aux instructions COMMENT

LIBÉRER LA PRESSION, du présent manuel.

• Vérifiez que toutes les connexions sont bien serrées avant

d’utiliser l’appareil. Toute pièce qui n’est pas fixée solidement

risque d’être projetée violemment ou d’entraîner la fuite d’un jet

de liquide à une pression extrêmement élevée, ce qui pourrait

causer des blessures graves.

• Verrouillez toujours la détente quand vous ne pulvérisez pas.

Vérifiez que le verrou de la détente fonctionne correctement.

REMARQUE À L’INTENTION DES MÉDECINS :

Les injections cutanées sont des lésions traumatiques; il

importe donc de les traiter sans délai. On NE DOIT PAS retarder

ce traitement sous prétexte de vérifier la toxicité du produit en

cause, celle-ci n’étant conséquente que dans le cas d’injection

directe de certains produits dans le système sanguin. Il pourrait

s’avérer nécessaire de consulter un plasticien ou un spécialiste

en chirurgie reconstructive de la main.

. ON

DOIT

DANGER : ÉMANATIONS DANGEREUSES

Certains produits (peintures, solvants, insecticides ou autres)

peuvent être nocifs s’ils sont inhalés ou entrent en contact

avec l’organisme. Les émanations de ces produits peuvent

provoquer de graves nausées, évanouissements ou

empoisonnements.

MESURES PRÉVENTIVES :

• Se servir d’un masque ou d’un respirateur s’il y a

risque d’inhalation (lire toutes les directives concernant

ces dispositifs afin de s’assurer qu’ils offrent la

protection requise).

• Porter des lunettes de protection.

• Porter les vêtements de protection prescrits par le fabricant du

produit utilisé.

DANGER : EXPLOSION OU INCENDIE

Les émanations de certains produits peuvent exploser ou

s’enflammer, et risquent d’entraîner des dommages matériels

ou de graves blessures.

MESURES PRÉVENTIVES :

• S’assurer que l’aire de travail est dotée de moyens d’évacuation

d’air vicié et d’introduction d’air frais pour éviter l’accumulation de

vapeurs inflammables. Les vapeurs dégagées par la peinture ou

les solvants peuvent provoquer une explosion ou s’enflammer.

• Ne pas pulvériser de produit dans un endroit clos.

• Ne pas travailler près de sources d’ignition (décharges

électrostatiques ou étincelles provoquées par le

branchement/ débranchement d’appareils ou la

commutation d’interrupteurs, d'appareils électriques, flammes

nues, veilleuses, objets chauds, etc.). La peinture ou le solvant

s’écoulant dans l’équipement peut générer de l’électricité statique.

• Ne pas fumer dans l’aire de travail.

• L

’aire de travail doit être munie d’un extincteur en bon état de

marche.

• Prévoir un espace d’au moins 7.62 mètres entre la pompe et

l’objet à pulvériser s’ils sont dans la même pièce bien ventilée

(rallonger le flexible au besoin). Les vapeurs inflammables étant

souvent plus lourdes que l’air, l’espace au-dessus du plancher

doit être particulièrement bien aéré. La pompe contient des

pièces qui produisent des arcs et émettent des étincelles pouvant

enflammer les vapeurs.

• Les appareils et objets à l’intérieur ou à proximité de l’aire de

travail doivent être adéquatement mis à la terre pour éviter les

décharges électrostatiques.

• Veillez à ce que la zone soit propre et exempte de contenants de

peinture ou de solvant, chiffons ou autres matériaux

inflammables.

• Les flexibles dont on se sert doivent être conçus pour subir les

pressions élevées et faits de matériaux conducteurs ou mis à la

terre adéquatement; le pistolet sera mis à la terre par le biais de

ses raccords aux flexibles.

• Pour les appareils électriques — Le cordon d’alimentation doit

être branché à un circuit trifilaire.

• L’appareil doit toujours être vidangé à basse pression, embout

retiré, dans un contenant métallique distinct. Tenir le pistolet

contre la paroi du contenant de manière à mettre ce dernier à la

terre et à prévenir les décharges électrostatiques.

• Toujours respecter les mises en garde et les directives du

fabricant des produits et solvants utilisés. On doit connaître les

produits contenus dans les peintures et solvants qu'on pulvérise.

Lire les fiches techniques santé-sécurité (FTSS) et les étiquettes

des contenants fournies avec les peintures et solvants. Suivres

les consignes de sécurité du fabricant de peinture et de solvant.

• S’entourer de toutes les précautions possibles lorsqu’on utilise

des produits ayant un point d’éclair inférieur à 21°C (70°F). Le

point d'éclair est la température à laquelle le liquide peut créer

suffisamment de vapeurs et s'enflammer.

• Le plastique est générateur de décharges électrostatiques; ne

jamais en suspendre pour fermer une aire de travail ou en utiliser

en guise de toile de protection lorsqu’on pulvérise un produit

inflammable.

• Se servir de la pression la plus basse possible pour vidanger

l’appareil.

• Ne pas pulvériser de produit sur la pompe.

Français

14 © Titan Tool Inc. Tous droits réservés.

Page 15

Importantes consignes de sécurité • Lire toutes ces consignes

Prise de terre

Goupille de mise à la terre

Couvercle du boîtier de prise de terre

avant d’utiliser l’appareil. Garder ces consignes.

DANGER : EXPLOSION CAUSÉE PAR DES PRODUITS

INCOMPATIBLES

Ce type d’explosion peut entraîner des dommages matériels

ou des blessures graves.

MESURES PRÉVENTIVES :

• Ne pas utiliser de produits contenant du chlore ou du javellisant.

• Ne pas utiliser de solvants à base de halons comme l’eau de

javel, les agents antimoisissure, le chlorure de méthylène et le

trichloroéthane-1-1-1, lesquels ne sont pas compatibles avec

l’aluminium.

• Communiquer avec le fournisseur du produit concerné pour en

connaître la compatibilité avec l’aluminium.

DANGER : GÉNÉRALITÉS

D’autres dangers peuvent entraîner des dommages matériels ou des

blessures graves.

• Lire toutes les directives et consignes de sécurité avant d’utiliser

l’appareil.

• Observer tous les codes locaux, provinciaux, d’état et nationaux

régissant la ventilation, la prévention des incendies et le

fonctionnement de l’appareil.

• Aux États-Unis, le gouvernement a adopté des normes de

sécurité en vertu de l’Occupational Safety and Health

Le cas échéant, on doit les consulter, notamment les parties 1910

des normes générales et 1926 des normes de construction.

• N’utiliser que les pièces autorisées par le fabricant; les utilisateurs

qui choisiront d’utiliser des composants dont les caractéristiques

techniques et les exigences en matière de sécurité sont

inférieures devront en assumer tous les risques et responsabilités.

• Tous les raccords, les tuyaux et les bouchons de remplissage

doivent être fixés solidement en place avant d’utiliser la pompe

de pulvérisation. Toute pièce qui n’est pas fixée solidement

risque d’être projetée violemment ou d’entraîner la fuite d’un jet

de liquide à une pression extrêmement élevée, ce qui pourrait

causer des blessures graves.

• Avant chaque utilisation, examiner tous les flexibles afin de

confirmer l’absence de coupures, de fuites, d’abrasions ou de

renflements. Vérifier également l’intégrité des raccords. Remplacer

sans délai les pièces qui semblent présenter des défectuosités. Ne

jamais tenter de réparer un flexible; remplacer ceux qui font défaut

par des modèles haute pression, avec mise à la terre.

•. Ne faites pas de nouer avec le tuyau et ne le tordez pas trop. Le

tuyau à vide peut présenter des fuites suite à l’usure, les nouer

ou les mauvais traitements. Une fuite risque d’injecter du produit

dans la peau.

•. N’exposez pas le tuyau à des températures ou des pressions

supérieures à celles spécifiées par le fabricant.

• Ne pas pulvériser à l’extérieur par grands vents.

• Porter des vêtements aptes à protéger la peau et les cheveux du

produit utilisé.

• Ne pas utiliser le pistolet ou ne pas pulvériser de produits en

présence d’enfants à proximité. Éloigner les enfants de

l’équipement en tout temps.

• Ne pas s'étirer ni ne travailler sur un support instable. Toujours

garder les deux pieds au sol pour rester en équilibre.

• Se servir de la pression la plus basse possible pour vidanger

l’appareil.

• Rester vigilant et faire attention à ce que l'on fait.

• Ne pas se servir de l'équipement en cas de fatigue ou si vos

aptitudes sont affaiblies par la consommation de drogues ou de

boissons alcoolisées.

• Pour les appareils électriques — Débranchez toujours le cordon

électrique de la prise avant de travailler sur l’équipement.

• N’utilisez pas le tuyau pour tirer ou soulever l’équipement.

• Ne pas soulever par la poignée de chariot en chargeant ou en

déchargeant.

Act (OSHA).

Instructions de mise à la terre

Cet appareil doit être mis à la terre. La mise à la terre réduit

les risques d'électrocution lors d'un court-circuit en permettant

au courant de s'écouler par le fil de mise à la terre. Cet

appareil est muni d'un cordon électrique avec fil de mise à la

terre ainsi que d'une fiche de terre. La fiche doit être branchée

sur une prise installée correctement et mise à la terre

conformément à la réglementation et aux codes en vigueur.

Le fait de ne pas brancher correctement la

fiche trifilaire de l’appareil peut entraîner

des risques de choc électrique.

Si on doit réparer ou remplacer le cordon ou la fiche, ne pas

raccorder le fil de terre à la borne des broches plates (lames)

de cette dernière. Ce fil, normalement vert (avec ou sans

rayures jaunes), doit être relié à la broche de terre.

Consulter un technicien ou un électricien qualifié à défaut de

comprendre l’ensemble des présentes directives ou en cas

d’incertitude quant à la mise à terre de l’appareil. Ne pas

modifier la fiche de l’appareil; si elle ne s’adapte pas dans la

prise voulue, faire remplacer cette dernière par un électricien

qualifié.

IMPORTANT : Utiliser uniquement une rallonge à trois fils

munie d'une fiche de terre dans une prise secteur mise à

la terre correspondant au type de fiche de l'appareil.

S'assurer que votre rallonge est en bon état. Lorsque

vous utilisez une rallonge, assurez-vous qu'elle soit d'un

calibre suffisant pour supporter l'intensité du courant

requise par l'appareil. Une rallonge trop mince entraîne

une chute de tension, une diminution de l'intensité et une

surchauffe. Une rallonge de calibre 12 est recommandée.

Si vous devez utiliser une rallonge à l’extérieur, celle-ci

doit comprendre la marque W

indiquant le type de cordon. Par exemple, la désignation

SJTW-A indique que le cordon est conçu pour être utilisé

à l’extérieur.

après la désignation

-A

© Titan Tool Inc. Tous droits réservés. 15

Français

Page 16

Table des matières

Commutateur

Cuvette

de lubrifiant

Raccord

Section

des

liquides

Bouton de

régulation de

la pression

Flexible

de siphon

Moteur

Flexible

de retour

AMORÇ

VAP ORISATION

Soupape

AMORÇAGE/

VAPORISATION

Disjoncteur

Clean

Min.

PSI

Max.

PSI

Nettoyage par

pulsations

(Turbo PulseClean,

zone rouge)

Arrêt

(OFF, zone noire)

Min. – 1 800 lb/po2

(Min, zone jaune)

1 800 à 3 200 lb/po2

(zone verte)

Arrêt

(OFF, zone noire)

Bouton de régulation

de pression

Consignes de sécurité.........................................................14

Description générale............................................................16

Fonctionnement ...................................................................16

Vérifications préliminaires...................................................16

Préparation avant de peindre .............................................17

Peinture ..............................................................................17

Indicateurs de pression ......................................................18

Procédure de décompression.............................................18

Vaporisation..........................................................................18

Technique de vaporisation ..................................................18

Essais préliminaires............................................................19

Nettoyage ..............................................................................19

Maintenance..........................................................................20

Généralités concernant la maintenance.............................20

Remplacement des filtres ...................................................20

Remplacement du moteur ..................................................21

Remplacement des balais de moteur.................................21

Remplacement des engrenages.........................................21

Remplacement du transducteur .........................................21

Remplacement de la soupape AMORÇAGE/VAPORISATION..22

Maintenance de la section des liquides..............................22

Dépannage ............................................................................23

Listes de pièces ...................................................................38

Vue d’ensemble...................................................................38

Moteur.................................................................................39

Boîte d’engrenages.............................................................40

Section des liquides............................................................42

Support ...............................................................................44

Bloc d’aspiration .................................................................44

Schéma de raccordement électrique..................................45

Accessoires ........................................................................46

Garantie.................................................................................48

Description générale

Ce vaporisateur à dépression est un outil électrique de

précision servant à atomiser divers types de matériaux. On

doit lire et suivre attentivement les directives apparaissant

dans ce manuel pour savoir comment l’utiliser et le maintenir

en bon ordre, et ce, en toute sécurité.

Vérifications préliminaires

On doit procéder aux étapes suivantes avant de brancher le

cordon d’alimentation de l’appareil.

1. S’assurer que le flexible et le bloc d’aspiration soient

solidement fixés.

2. Fixer un flexible de vaporisation à tresse de Nylon, conçu

pour les appareils à dépression, et mesurant au moins 15

mètres (50 pi).

3. Fixer un pistolet à dépression au flexible de vaporisation;

ne pas fixer l’embout au pistolet tout de suite (le retirer s’il

est déjà fixé).

S’assurer que tous les flexibles et pistolets à

dépression soit mis à la terre et conçus pour

accepter des pressions de liquide d’au moins 3

200 lb/po2 (22,1 MPa).

4. S’assurer que le bouton de régulation de pression soit à la

p

osition OFF (zone noire).

5. S’assurer que le commutateur soit à la position OFF.

6. Verser 15 ml (une cuillère à table) de lubrifiant pour joint

de piston (Piston Lube) dans la cuvette.

IMPORTANT : Ne jamais faire fonctionner l’appareil sans

liquide pendant plus de 10 secondes, ce qui pourrait user

inutilement les tampons graisseurs.

7. S’assurer que l’alimentation électrique soit d’au moins 15

A

à 120 V

8. Brancher le cordon d’alimentation dans une prise

adéquatement mise à la terre située à une distance d’au

moins 7,5 m (25 pi) de la surface à vaporiser.

IMPORTANT : Les rallonges utilisées doivent être trifilaires,

de calibre 12 et dotées d’une fiche à broche de MALT

doit jamais retirer cette troisième broche ou utiliser un

adaptateur.

Préparation d’un nouveau vaporisateur

Si cet appareil est neuf, il contient encore un liquide d’essai

mis en usine pour le protéger de la corrosion en cours

d’expédition ou d’entreposage. Ce liquide doit être

complètement éliminé au moyen d’essence minérale avant

que l’appareil puisse être utilisé.

IMPORTANT : La détente du pistolet doit toujours être

verrouillée lorsqu’on procède à ces vérifications

préliminaires.

1. Mettre le flexible d’aspiration dans un contenant

d’essence minérale.

2. Mettre le flexible de retour dans un contenant de purge

métallique.

3. Régler la pression au minimum en mettant le bouton de

régulation à la position Min (zone jaune).

.

; on ne

Fonctionnement

Cet appareil produit un jet à très haute pression;

avant de le faire fonctionner, il est donc essentiel

de lire et de comprendre les avertissements

formulés dans la section Consignes de sécurité à

l’avant de ce manuel.

Français

4. Abaisser la soupape AMORÇAGE/VAPORISATION à la

position PRIME.

5. Mettre l’appareil en marche en mettant le commutateur à

la position ON.

6. Laisser le vaporisateur fonctionner pendant 15 à 30

secondes pour évacuer le liquide d’essai par le flexible de

retour, jusqu’au contenant de purge.

7. Arrêter l’appareil en mettant le commutateur à la position

OFF

16 © Titan Tool Inc. Tous droits réservés.

Page 17

Préparation avant de peindre

Détente verrouillée.

Max.

PSI

Clean

Min.

PSI

Détente verrouillée.

Max.

PSI

Clean

Min.

PSI

Avant de peindre, il est important de s’assurer que le liquide

dans l’appareil est compatible avec le produit à utiliser.

NOTA: L’incompatibilité liquide/produit peut provoquer

IMPORTANT : La détente du pistolet doit toujours être

verrouillée lorsqu’on procède à ces vérifications

préliminaires.

1. Mettre le flexible d’aspiration dans un contenant de

2. Mettre le flexible de retour dans un contenant de purge

3.

4. Abaisser la soupape AMORÇAGE/