Page 1

Owner’s Manual

For professional use only

Do not use this equipment

before reading this manual!

SPEEFLO

PowrTex 300DD / 600DD

Texture Sprayers

These sprayers are for

use with water-based

materials only!

Model Numbers:

PowrTex 300DD 600-130

PowrTex 600

Printed in the U.S.A. 0110 • © Titan Tool Inc. All Rights Reserved. Form No. 0528918A

DD 600-140

NOTE: This manual contains important

warnings and instructions. Please

read and retain for reference.

Page 2

Important Safety Information · Read all safety information before

operating the equipment. SAVE THESE INSTRUCTIONS.

This symbol indicates a hazardous situation,

which, if not not avoided could result in death or

serious injury.

HAZARD: ELECTRIC SHOCK HAZARD

May cause severe injury.

• Power cord must be connected to a grounded

circuit. Do not use a 3 to 2 adapter.

• Always unplug cord from outlet and bleed pressure before

working on equipment.

• Never submerge electrical parts.

• Do not expose the spray system to rain. Always store the

spray system indoors.

HAZARD: EXPLOSION HAZARD DUE TO

INCOMPATIBLE MATERIALS

Will cause property damage or severe injury.

PREVENTION:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such

as bleach, mildewcide, methylene chloride and 1,1,1 trichloroethane. They are not compatible with aluminum.

• Contact your coating supplier about the compatibility of

material with aluminum.

HAZARD: DUST INHALATION

Dust or mist created by this sprayer may cause eye, skin,

throat, or respiratory irritation.

• Avoid inhalation of mist or dust. Wear a NIOSH / MSHA

approved respirator when using this equipment or for

anyone entering the work area.

• Maintain proper ventilation to reduce mist / dust exposure.

• NO EATING, DRINKING, OR SMOKING should be

done in the work area to prevent ingesting contaminated

material particles. Workers should wash and clean up

before eating, drinking, and smoking. Articles of food,

drink, or smoking should not be left in the work area where

dust would settle on them.

• Follow all warnings and recommendations provided by the

textured coating manufacturer.

HAZARD: GENERAL

Can cause severe injury of property damage.

• Read all instructions and safety precautions for equipment

and spray material before operating any equipment.

• Comply with all appropriate local, state and national codes

governing ventilation, re prevention and operation.

• This unit is intended for use with water-

based textured materials only. DO NOT

use this sprayer with any ammable or oilbased materials.

• Keep sprayer out of the reach of children.

• Hearing protection is recommended for

extended use.

• Do not operate or spray near children. Keep children

away from equipment at all times.

• Do not leave the sprayer energized or under pressure

while unattended. When the unit is not in use, turn off the

sprayer and relieve the pressure in accordance with the

Pressure Relief Procedure.

• Always follow the Pressure Relief Procedure when

shutting the sprayer down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray nozzles, or preparing for

cleanup.

• This system is capable of producing 100 PSI / 0.69

MPa. Only use replacement parts or accessories that

are specied by the manufacturer and that are rated a

minimum of 100 PSI. This includes spray nozzles, spray

guns, extensions, ttings, and hose.

• Use only manufacturer authorized parts. User assumes all

risks and liabilities when using parts that do not meet the

minimum specications and safety devices of the sprayer

manufacturer.

• Do not overreach or stand on an unstable support.

Certain material overspray can make oors slippery. Keep

effective footing and balance at all times. Wear rubber-

soled shoes.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the

inuence of drugs or alcohol.

• Never modify the pump assembly, air compressor, spray

gun, or any other component of the spray system.

• Check all components of the spray system daily. Repair

or replace any worn or damaged parts immediately.

• Never directly inhale compressed air. Compressed air

may contain toxic vapors.

• Keep hands and other body parts away from the

discharge. For example, do not try to stop leaks with any

part of the body.

• Fittings on the hose, compressor, radiator,

and pump become hot during use. Avoid

skin contact with any ttings when they are

hot. Allow the ttings to cool before touching.

• Know the contents of the material being

sprayed. Read all Material Safety Data

Sheets (MSDS) and container labels provided

with the materials. Follow the material manufacturer’s

safety instructions.

• Do not use the hose as a strength member to pull or lift the

equipment.

• Route hoses away from trafc areas, sharp edges, moving

parts, and hot surfaces.

• Do not kink or over-bend the hose. Hoses can develop

leaks from wear, kinking and abuse.

• Do not expose the hose to temperatures or pressures in

excess of those specied by manufacturer.

• Install the supplied hopper cover onto the hopper before

starting the spray system. When the system is turned on

with only a small amount of material in the hopper, the

hopper cover will prevent material from spraying out of the

hopper.

• Always wear appropriate gloves, eye protection, clothing

and a respirator or mask when spraying.

• Do not aim the gun at or spray any person or animal.

2 © Titan Tool Inc. All rights reserved.

Page 3

Grounding Instructions

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This product is

equipped with a cord having a grounding wire with an appropriate

grounding plug. The plug must be plugged into an outlet that

is properly installed and grounded in accordance with all local

codes and ordinances.

WARNING - Improper installation of the

grounding plug can result in a risk of electric

shock.

If repair or replacement of the cord or plug is

necessary, do not connect the green grounding wire to either

at blade terminal. The wire with insulation having a green outer

surface with or without yellow stripes is the grounding wire and

must be connected to the grounding pin.

Check with a qualied electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt

as to whether the product is properly grounded. Do not modify

the plug provided. If the plug will not t the outlet, have the

proper outlet installed by a qualied electrician.

Use only a 3-wire extension cord that has a 3-blade

grounding plug and a 3-slot receptacle that will

accept the plug on the product. Make sure your

extension cord is in good condition. When using

an extension cord, be sure to use one heavy

enough to carry the current your product will draw.

An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating.

A 12 gauge cord is recommended. If an extension

cord is to be used outdoors, it must be marked with

the suffix W-A after the cord type designation. For

example, a designation of SJTW-A would indicate

that the cord would be appropriate for outdoor use.

Table of Contents

Specications ........................................................................... 3

General Description ................................................................. 4

Operator Controls ..................................................................... 4

Sprayer Controls ................................................................. 4

Spray Gun Controls ............................................................. 4

Operation ................................................................................... 5

Setup ................................................................................... 5

Preparing to Spray .............................................................. 5

Preparing the Spray Material............................................... 6

Spraying .............................................................................. 6

Pressure Relief Procedure .................................................. 6

Spray Gun Operation ............................................................... 6

Using the Spray Gun Controls............................................. 6

Spraying Technique ............................................................ 7

Installing a Texture Nozzle .................................................. 7

Converting the Spray Gun from Non-Bleeder to Bleeder .... 7

Cleanup ..................................................................................... 8

Maintenance .............................................................................. 8

General Repair and Service Notes...................................... 8

Daily Maintenance ............................................................... 8

Replacing the Diaphragms — PowrTex 300DD ................... 9

Replacing the Diaphragms — PowrTex 600DD ................. 10

Replacing the Reversing Valve ......................................... 11

Troubleshooting ..................................................................... 12

Parts Listings .......................................................................... 14

Main Assembly — PowrTex 300DD ................................... 14

Compressor ....................................................................... 15

Main Assembly — PowrTex 600DD ................................... 16

Electrical Schematic .......................................................... 17

Fluid Pump — PowrTex 300DD ......................................... 18

Fluid Pump — PowrTex 600DD ......................................... 19

Motor ................................................................................. 20

PowrTex Gun .................................................................... 21

Texture Nozzle Chart ........................................................ 21

Air Flow Schematic — PowrTex 300DD ................................. 22

Air Flow Schematic — PowrTex 600DD ................................. 23

Accessories ............................................................................ 24

Warranty .................................................................................. 24

Specications

PowrTex 300DD and 600DD Sprayers

Gallons per minute (GPM):

PowrTex 300DD ................ 1.0 (3.8 LPM)

PowrTex 600DD ................ 3.0 (11.4LPM)

Maximum pressure ........................100 PSI (0.69 MPa)

Compressor Size:

PowrTex 300

PowrTex 600DD ................ 2.0 HP, 11.4 Max. CFM

Voltage .........................................100~120V AC, 50/60 Hz

Maximum current consumption .....15 A

Hopper Size (gallons):

PowrTex 300DD ................ 12 (45.4 liters)

PowrTex 600DD ................ 20 (75.7 liters)

Weight:

PowrTex 300DD ................ 97 lbs. (43.9 kg)

PowrTex 600DD ................ 122 lbs. (55.3 kg)

Maximum hose length:

PowrTex 300DD ................ 50’ (15.2 m)

PowrTex 600DD ................ 100’ (30.5 m)

DD ................ 1.5 HP, 8.4 Max. CFM

© Titan Tool Inc. All rights reserved. 3

NOTE: Maximum hose length may vary depending

on the hose diameter and the viscosity of the

material being sprayed.

PowrTex Spray Gun

Maximum Operating Pressure ....... 100 PSI (0.69 MPa)

Maximum Air Pressure .................. 100 PSI (0.69 MPa)

Weight ......................................... 2.2 lbs. (1 kg)

Page 4

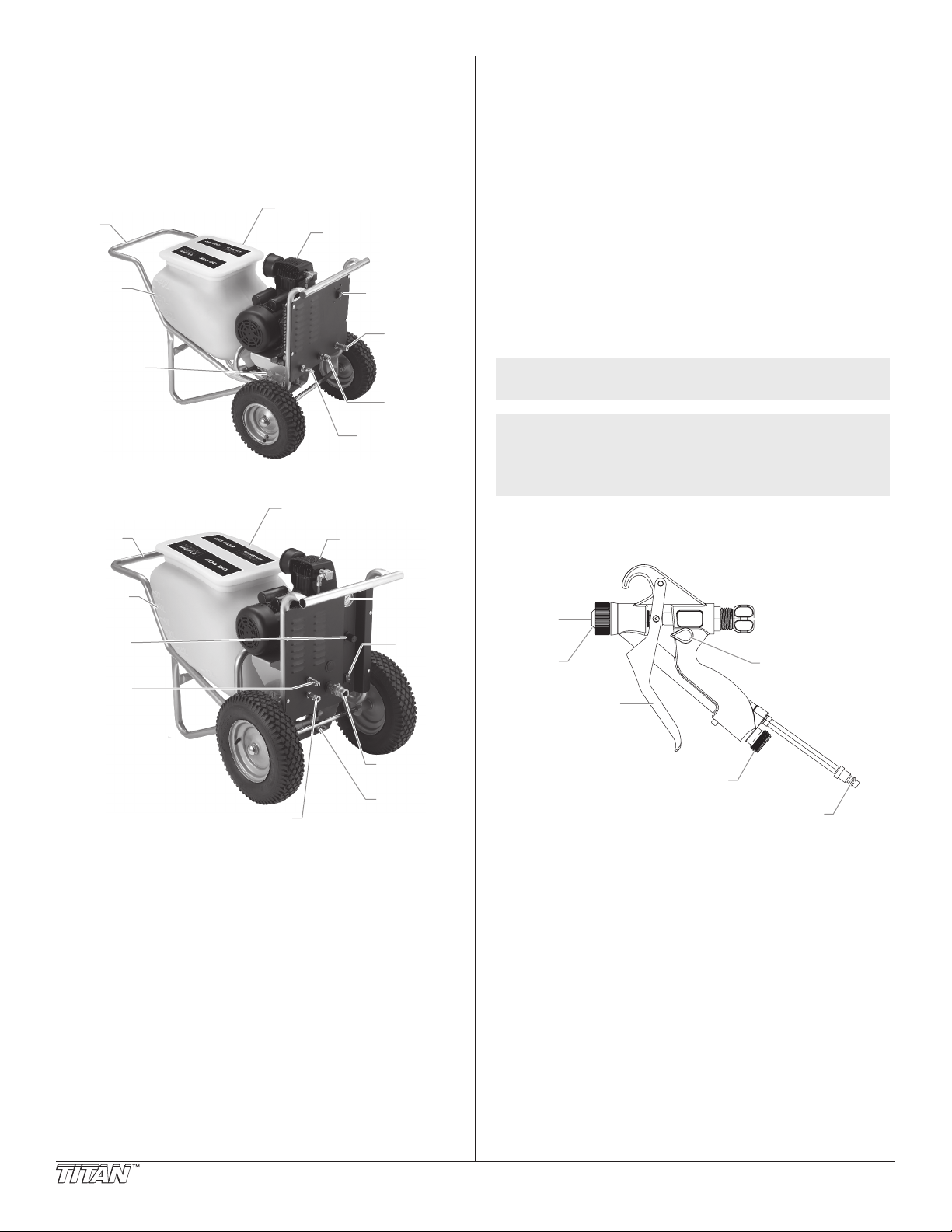

General Description

Hopper w/Cover

Air Compressor

Fluid Outlet

Fitting

Relief

Valve

Air Outlet

Coupling

ON/OFF

Switch

Cart

Material

Level

Indicators

Double

Diaphragm

Pump

Fluid Outlet

Fitting

Double

Diaphragm

Pump

Air Outlet Coupling

Hopper w/Cover

Air Compressor

Fluid

Pressure

Gauge

ON/OFF

Switch

Relief

Valve

Pressure

regulator

Cart

Material

Level

Indicators

Air

Nozzle

Te xture

Nozzle

Trigger

Fluid Adjustment

Knob

Air Adjustment

Valve

Fluid Inlet Fitting

Air Inlet Coupling

and Extension Tube

The PowrTex 300DD and PowrTex 600DD texture sprayers are

precision power tools used for spraying many types of waterbased, textured products from a ready-mixed or powdered

formulation. Read and follow this instruction manual carefully

for proper operating instructions, maintenance, and safety

information.

PowrTex 300DD

Operator Controls

The following section describes the operator controls on PowrTex

sprayer and the PowrTex spray gun.

Sprayer Controls

ON/OFF Switch

The ON/OFF switch controls power to the air compressor.

Moving the ON/OFF switch to the ON position starts the

compressor and begins the ow of air to the spray gun and

double diaphragm pump.

PowrTex 600DD

Fluid Pressure Regulator — PowrTex 600

The uid pressure regulator controls the ow of air to the double

diaphragm pump. Turning the uid pressure regulator clockwise

increases the ow of air to the double diaphragm pump. Turning

the uid pressure regulator counterclockwise decreases the ow

of air to the double diaphragm pump.

NOTE: The recommended setting for most textured

material is 40 – 50 PSI.

NOTE: The double diaphragm pump operates using

air from the air compressor. Any increase to

the setting of the uid pressure regulator to

increase uid volume to the spray gun will also

decrease the air ow to the spray gun.

DD

Spray Gun Controls

Air Adjustment Valve

The air adjustment valve controls the ow of air to the air nozzle

on the spray gun. Moving the air adjustment valve clockwise

4 © Titan Tool Inc. All rights reserved.

toward the vertical position increases the ow of air to the air

nozzle. Moving the air adjustment valve counterclockwise toward

the horizontal position decreases the ow of air to the air nozzle.

When the air adjustment valve is turned fully counterclockwise

to the horizontal position, air ow is completely shut off to the air

nozzle.

Fluid Adjustment Knob

The uid adjustment knob controls the volume of material

owing to the texture nozzle. Turning the uid adjustment knob

clockwise shortens the trigger pull and decreases the volume

of material owing to the texture nozzle. Turning the uid

adjustment knob counterclockwise lengthens the trigger pull and

increases the ow of material to the texture nozzle.

Page 5

Operation

3/4” Female

NPT Fitting

300

DD Fluid Hose

Male Quick

Disconnect Fitting

Air Hose

Spray

Gun

Sprayer

1” Female Quick

Disconnect Fitting

600

DD Fluid Hose

Male Quick

Disconnect Fitting

Air Hose

Spray

Gun

Sprayer

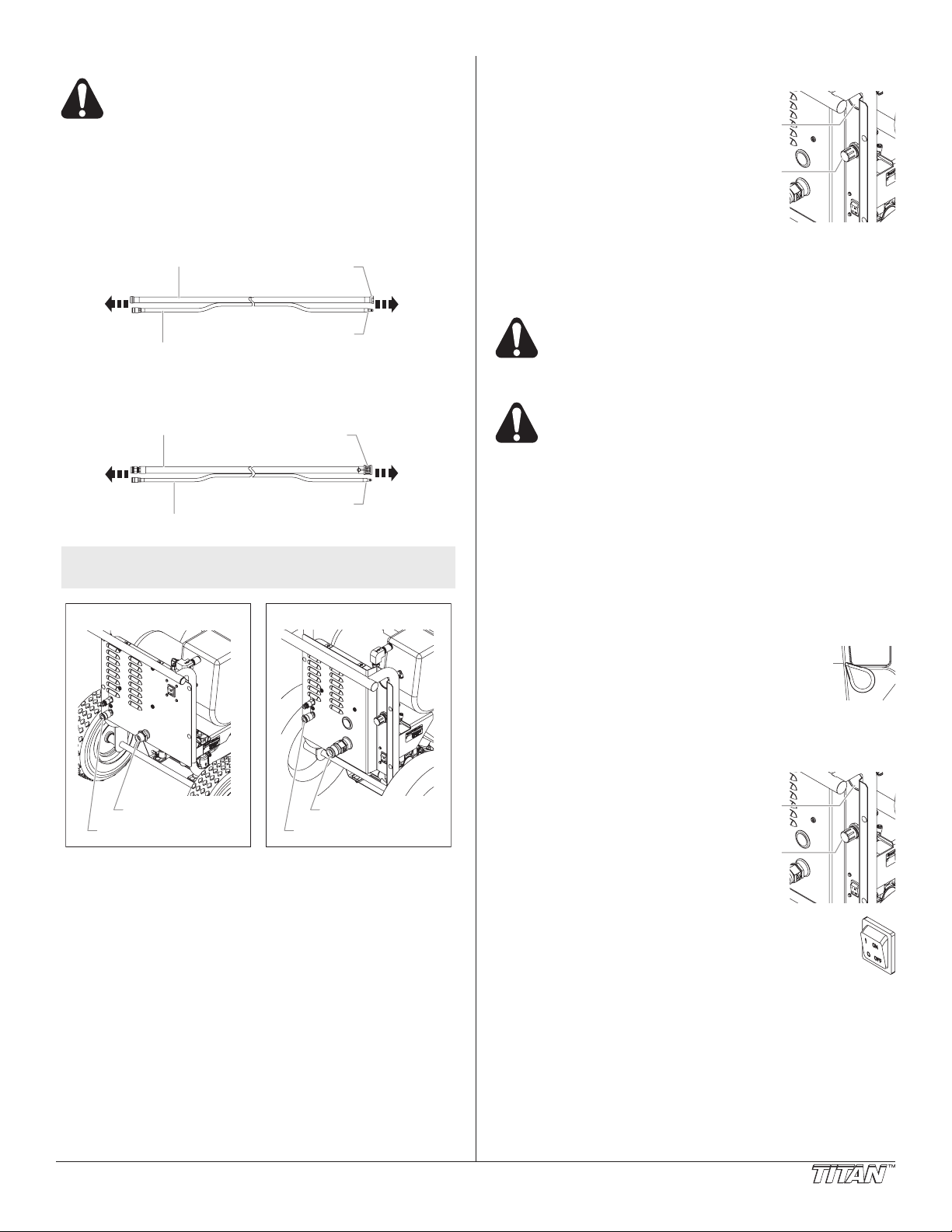

PowrTex 300DD PowrTex 600DD

Fluid Outlet Fitting

Air Outlet Coupling

Fluid Outlet Fitting

Air Outlet Coupling

PowrTex 600DD

Pressure

Gauge

Fluid

Pressure

Regulator

PowrTex 600DD

Pressure

Gauge

Fluid

Pressure

Regulator

Read and understand the warnings at the front of

this manual before operating this equipment.

Setup

Perform the following procedure before plugging in the power

cord of the sprayer.

1. Attach the uid hose to the uid outlet tting on the

sprayer.

a. For the PowrTex 300DD, thread the 3/4” female NPT

tting onto the male uid outlet tting on the sprayer.

b. For the PowrTex 600DD, couple the 1” female quick

disconnect tting to the male uid outlet tting on the

sprayer.

NOTE: The uid hose and air hose included with the

2. Attach the other end of the uid hose to the uid tting on

3. Attach the male quick disconnect tting on the air hose to

4. Attach the female quick disconnect tting on the air hose

5. Install the appropriate texture nozzle for the material

IMPORTANT: Always pull the spray gun trigger when

tightening the nozzle nut. Failure to pull the trigger can

result in damage to the texture nozzle and gun needle

assembly.

sprayer are bonded together for ease of use.

the PowrTex spray gun. Tighten securely.

the air outlet coupling on the sprayer.

to the air inlet coupling on the PowrTex spray gun.

being sprayed (refer to the”Installing a Texture Nozzle”

procedure in the Spray Gun Operation section as well as

the “Texture Nozzle Chart” in the Parts List section of this

manual). While triggering the gun, tighten the nozzle nut

securely.

6. For the PowrTex 600DD

only, make sure the uid

pressure regulator is turned

fully counterclockwise to its

minimum pressure position.

7. Make sure the air lter on

the compressor is clean and

installed.

8. Make sure the electrical

service is 120V, 15 amp

minimum.

9. Plug the power cord into a properly grounded outlet.

IMPORTANT: Always use a minimum 12 gauge, three-wire

extension cord with a grounded plug. Never remove the

third prong or use an adapter.

Be sure to follow the Pressure Relief Procedure

when shutting the sprayer down for any purpose,

including servicing or adjusting any part of the

spray system, changing or cleaning spray nozzles,

or preparing for cleanup.

The air compressor motor is protected from

thermal overload by a thermal protector switch. If

the motor overheats, the thermal protector switch

will shut off the motor automatically. Make sure all

guards and shrouds are in place on the

compressor before pressing the reset switch after

a thermal overload. If this occurs, allow the motor

to cool for 10–15 minutes. Then, press the reset

switch located on the motor housing to restart the

motor.

Preparing to Spray

Use the following procedure to ush the sprayer with water

before spraying begins. This will remove any sediment that may

be in the system.

1. Fill the hopper 1/4 full with water.

2. Move the air adjustment valve on the spray gun

to the half-open (45º) position.

3. For the PowrTex 600DD only, turn the uid pressure

regulator fully counterclockwise to its minimum pressure

position.

4. Turn on the sprayer by

moving the ON/OFF switch to

the ON position.

5. For the PowrTex 600DD

only, turn the uid pressure

regulator clockwise until the

pressure gauge reads 30 PSI.

6. Trigger the spray gun into a

waste container. Continue

holding the trigger open until

the water has emptied from

the hopper.

7. Turn off the sprayer by moving the ON/OFF

switch to the OFF position.

© Titan Tool Inc. All rights reserved. 5

Page 6

Preparing the Spray Material

PowrTex 600DD

Pressure

Gauge

Fluid

Pressure

Regulator

Fluid Adjustment

Knob

Air Adjustment

Valve

The sprayer is designed for use with water-based texture materials

only. Prepare the material to be sprayed according to the

guidelines given by the material manufacturer as a reference point.

Do not use solvent-based materials in the sprayer.

Use of the wrong material can cause a fire and can

seriously damage the sprayer.

The proper mixing of the spray material is very important. Use

clean water only. Mix the material to a smooth consistency

before pouring it into the hopper. The sprayer will not operate if

the material is too thick.

A ow funnel is supplied with the sprayer to help

determine the proper thickness of the spray

material. The material should be mixed to a

smooth consistency that will ow evenly through

the ow funnel.

NOTE: Check the consistency of the material

often. After sitting in the hopper for awhile,

the material may thicken and need to be

thinned with additional water. Using the

provided hopper cover will reduce material

evaporation and help prevent change in material

consistency.

NOTE: When turning the unit on and off in rapid

succession, trigger the gun slightly to relieve

air pressure in the air hose for ease of restart.

Failure to do so may cause the compressor to

stall and trip the thermal protector switch.

Pressure Relief Procedure

Be sure to follow the Pressure Relief Procedure

when shutting the unit down for any purpose,

including servicing or adjusting any part of the

spray system, changing or cleaning spray nozzles,

or preparing for cleanup.

1. Turn off the sprayer by moving the ON/OFF

switch to the OFF position.

2. For the PowrTex 600DD only, turn the uid

pressure regulator fully counterclockwise to its minimum

pressure position.

3. Move the air adjustment valve on the spray gun

to the open (vertical) position.

4. Trigger the gun into a waste container to remove

any air and uid pressure that may still be in the

system.

5. Unplug the sprayer.

Spraying

1. FIll the hopper with the properly mixed spray material as

determined by using the ow funnel.

2. Move the air adjustment valve on the spray gun

to the half-open (45º) position.

3. For the PowrTex 600

pressure regulator fully counterclockwise to its minimum

pressure position.

4. Turn on the sprayer by moving the ON/OFF

switch to the ON position.

5. For the PowrTex 600

pressure regulator clockwise until the pressure gauge

reads 30 PSI.

6. Trigger the spray gun into a waste container. Continue

to trigger the spray gun into the waste container until any

remaining water is ushed from the system and material

begins owing from the gun.

7. Trigger the spray gun into the hopper to circulate material

through the system until a steady stream ows from the gun.

8. Move the air adjustment valve on the spray gun

to the desired position.

9. For the PowrTex 600DD only, adjust the uid

pressure regulator until the material from the gun

ows evenly with no pulsing. Try to keep the uid pressure

regulator at the lowest setting that maintains even, steady ow.

DD only, turn the uid

DD only, turn the uid

Spray Gun Operation

The following section describes how to use the spray gun to

achieve professional results. Remember that practice and

experimentation with the controls, nozzle size, and spraying

technique is the best way to nd the desired spray pattern.

Using the Spray Gun Controls

The controls on the spray gun provide the opportunity to adjust

and ne tune the spray pattern for the different spray materials

that can be used. Make adjustments on the gun and then test

the spray pattern on a piece of cardboard or test surface.

Adjusting the Air Flow

Start spraying with the air adjustment valve turned fully clockwise

(vertical) in the open position. If necessary, turn the air adjustment

valve counterclockwise until a good spray pattern is achieved.

Turning the air adjustment valve counterclockwise will decrease

air ow through the gun and increase material output.

Turning the air adjustment valve clockwise will increase air ow

through the gun and decrease material output.

NOTE: For the PowrTex

10. Test the spray pattern on a

6 © Titan Tool Inc. All rights reserved.

600DD only, the

recommended

working pressure

setting for the uid

pressure regulator

is 40–50 PSI. It is

recommended not to

exceed 80 PSI.

piece of cardboard. Fine tune the spray pattern using

the uid adjustment knob and air adjustment valve on the

spray gun. Refer to the “Spray Gun Operation” section for

detailed information on gun adjustments.

Adjusting the Fluid Volume

Start spraying with the uid adjustment knob positioned to allow

minimum trigger pull. This will create minimum uid volume

owing to the texture nozzle when the trigger is pulled. If

necessary, turn off the sprayer, relieve system pressure, release

the lock nut, and turn the uid adjustment knob counterclockwise

to increase the uid volume owing to the texture nozzle.

Another way to adjust uid volume on the gun is to change the

size of the texture nozzle. A smaller nozzle will decrease the

uid volume. A larger nozzle will increase the uid volume.

Refer to the “Texture Nozzle Chart” in the Parts List section of

this manual for information on nozzle sizes and uses.

Page 7

NOTE: For the PowrTex 600DD only, uid volume

Te xture Nozzle

Nozzle Nut

Air Shut-Off

Valve

Bleed Screw

Adjustment

Spring

Fluid

Adjustment

Knob

Wrench flats

on air trip rod

also can be adjusted using the uid pressure

regulator on the sprayer.

Please note that the double diaphragm pump

operates using air from the air compressor.

Any increase to the setting of the uid pressure

regulator to increase uid volume to the spray gun

will also decrease the air ow to the spray gun.

Spraying Technique

Hold the gun 18 to 30 inches from the surface. Squeeze the

trigger slowly and move the gun in a circular pattern. Consistent,

steady movement will prevent material buildup, runs, and sags.

NOTE: Pressure builds up in the system when the spray

gun is not triggered. Aim the gun away from the

spray surface when initially triggering the gun and

work toward the spray surface. This will prevent

material surge onto the spray surface. Keep the

gun moving and avoid repeated triggering of the

gun once spraying has begun.

Proper lapping (overlap of spray pattern) is essential to an even

nish. Lap each stroke. If you are spraying horizontally, aim

at the bottom edge of the preceding stroke, so as to lap the

previous pattern.

Maintain uniform spray stroke action. Spray alternately from left

to right and right to left. Begin movement of the gun before the

trigger is pulled.

Holding the gun closer to the surface deposits more material on

the surface and produces a narrower spray pattern. Holding the

gun farther from the surface produces a thinner coat and wider

spray pattern.

Converting the Spray Gun from NonBleeder to Bleeder

If preferred, the spray gun can be converted from a non-bleeder

to a bleeder setup. Non-bleeder setup means that when the

trigger is released, the air ow from the air nozzle stops. Bleeder

setup means that air ow is continuous from the air nozzle

whether the trigger is pulled or released.

NOTE: In bleeder setup, the removal of the bleed screw

from the air valve seal causes the air supply to

be on at all times when the air hose is attached

to the gun.

To convert a spray gun to bleeder setup:

1. Perform the “Pressure Relief Procedure” outlined in the

Operation section of this manual.

2. Remove the uid hose and air hose from the spray gun.

3. Turn the uid adjustment knob counterclockwise until it

threads off of the gun body. The adjustment spring inside

the uid adjustment knob will release once the knob is off

off the threads.

Installing a Texture Nozzle

Use the following procedure to install a different size texture

nozzle onto the spray gun.

1. Perform the “Pressure Relief Procedure” outlined in the

2. While triggering the gun, remove the nozzle nut from the

NOTE: Always pull the spray gun trigger when tightening

3. Remove the existing texture nozzle from the inside of the

4. Place the new texture nozzle inside the nozzle nut.

5. While triggering the gun, thread the nozzle nut onto the

NOTE: For information on texture nozzle sizes and their

© Titan Tool Inc. All rights reserved. 7

Operation section of this manual.

front of the spray gun by turning it counterclockwise.

the nozzle nut. Failure to pull the trigger can

result in damage to the texture nozzle and texture

shaft assembly.

nozzle nut.

front of the spray gun by turning it clockwise. Tighten

securely.

recommended uses, refer to the “Texture Nozzle

Chart” in the Parts List section of this manual.

4. Using a pliers, hold the air trip rod

rmly at the wrench ats between the

back of the trigger and the gun body.

This will prevent the air trip rod from

turning during the removal of the bleed

screw.

5. Using a Phillips screwdriver, remove

the bleed screw from the back of the

air shut-off valve inside the gun body.

Store the screw in a safe place.

6. Make sure the adjustment spring is in

position inside the uid adjustment knob.

7. Pushing rmly, thread the uid adjustment knob clockwise

onto the gun body.

8. To position the uid adjustment knob:

a. Trigger the gun while turning the uid adjustment knob.

b. When the trigger pull starts to shorten, back off the uid

adjustment just until full trigger pull is allowed.

Page 8

Cleanup

PowrTex 600DD

Pressure

Gauge

Fluid

Pressure

Regulator

Te xture Shaft Assembly

Adjustment Spring

Fluid

Adjustment

Knob

Te xture

Nozzle

Nozzle Nut

Oil

Proper cleaning of the sprayer and spray gun after each use is

the most important step toward maintaining the performance of

the spray system.

IMPORTANT: The sprayer, fluid hose, and gun should be

cleaned thoroughly after daily use. Failure to do so permits

material to build up, seriously affecting the performance of

the sprayer.

Do not allow material to dry inside the hopper, pump, hoses,

or spray gun.

NOTE: Leave the spray gun attached to the air hose and

the compressor running at all times during spray

system cleanup. This will prevent material backup

into the air nozzle and texture shaft assembly.

26. Replace the hopper onto the cart and uid inlet assembly.

Use the cart handles as guides to position the hopper

down onto the uid inlet assembly.

27. Pour approximately 12 ounces of water into the hopper to

keep the sprayer wet when not in use.

NOTE: For long-term or cold weather storage, pour

straight Liquid Shield Plus into the hopper to

prevent freezing (see the Accessories section of

this manual for part number).

IMPORTANT: Water or material remaining in unit when

temperatures are below freezing can damage motor and/or

delay pump startup. Do not allow unit to freeze.

28. Store the sprayer indoors in a clean, dry area.

1. Move the air adjustment valve on the spray gun

to the half-open (45º) position.

2. For the PowrTex 600DD only, turn the uid

pressure regulator fully counterclockwise to its

minimum pressure position.

3. Turn on the sprayer by

moving the ON/OFF switch to

the ON position.

4. For the PowrTex 600DD

only, turn the uid pressure

regulator clockwise until the

pressure gauge reads 30 PSI.

5. Trigger the spray gun into

a waste container until all

remaining material is ushed

from the hopper and uid

hose.

6. Turn off the sprayer by moving the ON/OFF

switch to the OFF position.

7. Fill the hopper 1/2 full with clean water.

8. Clean the inside of hopper using a brush and rags.

9. Turn on the sprayer.

10. Trigger the spray gun into a waste container. Continue

holding the trigger open until the water has emptied from

the hopper.

11. Turn off the sprayer.

12. Fill the hopper full with clean water.

13. Turn on the sprayer.

14. Trigger the spray gun into a waste container until half the

water in the hopper is gone.

15. Turn off the sprayer.

16. While triggering the gun, remove the nozzle nut and

texture nozzle from the spray gun and place in a bucket of

clean water.

17. Turn on the sprayer.

18. Trigger the spray gun into the hopper to circulate the water

through the system for a few minutes.

19. Trigger the spray gun into a waste container until the

water has emptied from the hopper and uid hose.

20. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual.

21. Disconnect the uid hose and air hose from the spray gun.

Perform the “Cleaning the Spray Gun” procedure in this

section of this manual.

22. Perform the “Cleaning the Fluid Hose” procedure in this

section of this manual.

23. Disconnect the uid hose and air hose from the sprayer.

Coil up the hoses and store in a dry area.

24. Lift the hopper off of the uid inlet assembly and the cart.

Use the cart handles as guides while lifting the hopper.

25. Clean out the one-way valve assembly at the bottom of

the hopper thoroughly.

8 © Titan Tool Inc. All rights reserved.

Cleaning / Lubricating the Spray Gun

Use the following procedure to clean the spray gun once it has

been removed from the uid hose and air hose.

1. If not already removed from the spray gun, remove the

nozzle nut and texture nozzle from the front of the gun body.

2. Turn the uid adjustment knob counterclockwise until it

threads off of the gun body. The adjustment spring inside

the uid adjustment knob will release once the knob is off of

the threads.

3. Remove the texture shaft assembly from the gun body.

To remove the texture shaft assembly:

a. From the front of the gun, push on the air nozzle at the

front of the texture shaft assembly until the back of the

texture shaft assembly is accessible at the rear of gun.

b. Pull the texture shaft assembly out of the rear of the

gun body.

4. Clean all components of the the spray gun completely

using water, a soft brush, and a rag.

a. Clean the nozzle nut and texture nozzle.

b. Clean the uid adjustment knob and adjustment spring.

c. Clean the texture shaft assembly.

d. Clean out the uid and air passageways inside the gun.

The uid and air passageways may be rinsed clean by

spraying with a garden hose.

5. Oil the texture shaft assembly using Titan Piston Lube

(refer to the Accessories section for P/N). Apply several

drops of Piston Lube in each location shown in the above

illustration.

NOTE: Failure to lubricate the indicated areas on the

texture shaft assembly could cause the air valve

to become clogged. A clogged air valve will

cause a bad spray pattern.

6. Reassemble the spray gun.

Page 9

Cleaning the Fluid Hose

Lubricate

Use the following procedure to clean the uid hose once the

spray gun has been removed pressure has been relieved as

described in the Cleanup procedure.

1. Remove the uid hose from the uid outlet tting on the

front panel of the sprayer.

2. Insert the cleaning cylinder into the uid outlet

tting. Refer to the Accessories section of this

manual for ordering information on the cleaning

cylinder.

3. Reattach the uid hose to the uid outlet tting.

4. Fill the hopper 1/4 full with clean water.

5. For the PowrTex 600

regulator fully counterclockwise to its minimum pressure

position.

6. Plug in the sprayer.

7. Hold the open end of the uid hose over a waste container.

8. Turn on the sprayer

9. For the PowrTex 600DD only, turn the uid pressure

regulator clockwise until the pressure gauge reads 30 PSI.

10. Allow the pump to push the cleaning cylinder through the

uid hose and out into the waster container. Retrieve the

cleaning cylinder from the waster container for future use.

11. Continue to run the pump until the remaining water has

emptied from the hopper and uid hose.

12. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual.

DD only, turn the uid pressure

Never pull on a wire to disconnect it. Pulling on a

wire could loosen the connector from the wire and

can cause an electric shock.

2. Test your repair before regular operation of the sprayer

to be sure that the problem is corrected. If the sprayer

does not operate properly, review the repair procedure

to determine if everything was done correctly. Refer to

the Troubleshooting Charts to help identify other possible

problems.

3. If you have any further questions concerning your TITAN

Airless Sprayer, call TITAN:

Customer Service (U.S.) .....................1-800-526-5362

Fax .............................................1-800-528-4826

Customer Service (Canada) ...............1-800-565-8665

Fax ..............................................1-905-856-8496

Daily Maintenance

Perform the following maintenance procedures daily too keep the

sprayer operating in good condition.

1. Check hoses for damage.

2. Check all ttings to make sure they are tight.

3. Clean the air lter on the compressor.

4. Apply a light lm of multi-purpose grease to the outer

diameter of the pump inlet tube (see below).

Cleaning the Fluid Inlet Assembly

The uid inlet assembly between the hopper and the double

diaphragm pump may need to be cleaned out periodically.

1. Perform the “Pressure Relief Procedure” outlined in the

Operation section of this manual.

2. Lift the hopper off of the uid inlet assembly and the cart.

Use the cart handles as guides while lifting the hopper.

NOTE: The hopper does not need to be empty before

3. Remove any sediment from inside the uid inlet assembly.

4. Using a garden hose, ush the uid inlet assembly with

5. Replace the hopper onto the cart and uid inlet assembly.

removing it from the cart. The one-way valve

assembly inside the hopper prevents spray

material from leaking when the hopper is removed.

water.

Use the cart handles as guides to position the hopper

down onto the uid inlet assembly.

Maintenance

Before proceeding, follow the Pressure Relief

Procedure outlined previously in this manual.

Additionally, follow all other warnings to reduce

the risk of an injection injury, injury from moving

parts or electric shock. Always unplug the sprayer

before servicing!

General Repair and Service Notes

The following tools are needed when repairing this sprayer:

Phillips Screwdriver Adjustable Wrenches

Needle-nosed pliers Channel Lock

7/16 Hex Wrench

1. Before repairing any part of the sprayer, read the

instructions carefully, including all warnings.

Replacing the Diaphragms —

PowrTex 300

Use the following procedure to replace the product diaphragms

and support diaphragms in the double diaphragm pump of the

PowrTex 300

1. Perform the Cleanup procedure outlined in this manual.

Do not add water to the hopper for storage purposes as

described at the end of the procedure.

2. Lift the hopper off of the uid inlet assembly and the cart.

Use the cart handles as guides while lifting the hopper.

3. Remove the air line from the tting at the top of the pump.

4. Remove the four lock nuts and carriage screws that

secure the pump to the cart.

5. Remove the double diaphragm pump from the cart by

sliding it straight toward the back of the sprayer until the

uid pipe is free of the front panel.

6. Place the pump upside down on a waste container to

allow any remaining uid to drain.

7. Once the pump is empty, place it on a at surface.

DD

DD.

© Titan Tool Inc. All rights reserved. 9

Page 10

Manifold Screw

Support

Diaphragm

Pump Motor

Manifold

Nut

Suction Manifold

Outer

Diaphragm

Disk

Delivery Manifold

Diaphragm

Cover

Diaphragm

Cover

Nut

Diaphragm

Cover

Screw

Product

Diaphragm

pump. Make sure the manifold is positioned in the same

Manifold Screw

Diaphragm

Pump Motor

Manifold

Nut

Suction Manifold

Delivery Manifold

Diaphragm Cover

Screw

Diaphragm

Cover

Nut

Diaphragm

Cover

Outer Diaphragm

Disk

orientation as it was before it was removed.

25. Carefully slide the pump back into position on the cart.

Make sure to align the uid pipe with the appropriate hole

on the front plate before positioning the pump.

26. Using the four lock nuts and carriage screws, secure the

pump to the cart.

27. Reattach the air line from the radiator manifold to the

tting on the pump.

28. Replace the hopper onto the cart and uid inlet assembly.

Use the cart handles as guides to position the hopper

down onto the uid inlet assembly.

Replacing the Diaphragms —

8. Remove the four manifold nuts, screws, and washers

9. Remove the four manifold nuts, screws, and washers that

10. Remove the six diaphragm cover nuts, screws, and

11. Using two wrenches, hold the nut on one of the outer

12. Remove the product diaphragm and support diaphragm

13. Pull the opposite side diaphragm assembly that is still

14. Place the shaft into a vice. Use caution when securing the

15. Using a wrench, loosen and remove the remaining outer

16. Remove the remaining product diaphragm and support

17. Place one of the new support diaphragms followed by

18. Remove the shaft with the assembled diaphragm

19. Lubricate the shaft with grease and slide it through the

20. Place the remaining new support diaphragm followed

21. Using two wrenches, hold the nut on the opposite outer

22. Using the six diaphragm cover nuts, screws, and washers

23. Using the four manifold nuts, screws, and washers,

24. Using the four manifold nuts, screws, and washers,

10 © Titan Tool Inc. All rights reserved.

that secure the delivery manifold to the top of the pump.

Remove the delivery manifold.

secure the suction manifold to the bottom of the pump.

Remove the suction manifold.

washers that secure each of the two diaphragm covers

to the pump motor. Remove the diaphragm covers from

each side of the pump motor.

diaphragm disks while using the other wrench to loosen

and remove the opposite outer diaphragm disk.

that were released by the removal of the rst outer

diaphragm disk.

assembled to the shaft out of the pump motor.

shaft in the vice so that the shaft is not damaged.

diaphragm disk.

diaphragm from the shaft.

a new product diaphragm onto the shaft. Thread the

corresponding outer diaphragm disk into the shaft and

tighten securely.

assembly from the vise.

pump motor.

by the remaining new product diaphragm onto the shaft.

Thread the corresponding outer diaphragm disk into the

shaft.

diaphragm disk while using the other wrench to tighten the

remaining outer diaphragm disk securely.

on each, reassemble the two diaphragm covers to each

side of the pump motor. TIghten the nuts securely.

reassemble the suction manifold to the bottom of the

pump. Make sure the manifold is positioned in the same

orientation as it was before it was removed.

reassemble the delivery manifold to the top of the

PowrTex 600

Use the following procedure to replace the diaphragms in the

double diaphragm pump of the PowrTex 600DD.

1. Perform the Cleanup procedure outlined in this manual.

Do not add water to the hopper for storage purposes as

described at the end of the procedure.

2. Lift the hopper off of the uid inlet assembly and the cart.

Use the cart handles as guides while lifting the hopper.

3. Remove the air line from the elbow at the top of the pump.

4. Remove the uid outlet tting from the front panel. This

will allow the uid pipe to slide out of the front panel during

removal of the pump.

5. Remove the four lock nuts and carriage screws that

secure the pump to the cart.

6. Remove the double diaphragm pump from the cart by

sliding it straight toward the back of the sprayer until the

uid pipe is free of the front panel.

7. Place the pump upside down on a waste container to

allow any remaining uid to drain.

8. Once the pump is empty, place it on a at surface.

9. Remove the four manifold nuts, screws, and washers

that secure the delivery manifold to the top of the pump.

Remove the delivery manifold.

10. Remove the four manifold nuts, screws, and washers that

secure the suction manifold to the bottom of the pump.

Remove the suction manifold.

11. Remove the six diaphragm cover nuts, screws, and

washers that secure each of the two diaphragm covers

to the pump motor. Remove the diaphragm covers from

each side of the pump motor.

DD

Page 11

12. Using two wrenches, hold the nut on one of the outer

Pressure Side Cover

Pressure Gasket

Reversing Valve

Reversing Valve

Screw

Pressure Cover

Nut

Pressure Cover

washer

Reversing Valve

Gasket

diaphragm disks while using the other wrench to loosen

and remove the opposite outer diaphragm disk.

13. Remove the diaphragm that was released by the removal

of the rst outer diaphragm disk.

14. Pull the opposite side diaphragm that is still assembled to

the shaft out of the pump motor.

15. Place the shaft into a vice. Use caution when securing the

shaft in the vice so that the shaft is not damaged.

16. Using a wrench, loosen and remove the remaining outer

diaphragm disk.

17. Remove the remaining diaphragm from the shaft.

18. Place one of the new diaphragms onto the shaft. Thread

the corresponding outer diaphragm disk into the shaft and

tighten securely.

19. Remove the shaft with the assembled diaphragm from the

vise.

20. Lubricate the shaft with grease and slide it through the

pump motor.

21. Place the remaining new diaphragm onto the shaft.

Thread the corresponding outer diaphragm disk into the

shaft.

22. Using two wrenches, hold the nut on the opposite outer

diaphragm disk while using the other wrench to tighten the

remaining outer diaphragm disk securely.

23. Using the six diaphragm cover nuts, screws, and washers

on each, reassemble the two diaphragm covers to each

side of the pump motor. TIghten the nuts securely.

24. Using the four manifold nuts, screws, and washers,

reassemble the suction manifold to the bottom of the

pump. Make sure the manifold is positioned in the same

orientation as it was before it was removed.

25. Using the four manifold nuts, screws, and washers,

reassemble the delivery manifold to the top of the

pump. Make sure the manifold is positioned in the same

orientation as it was before it was removed.

26. Carefully slide the pump back into position on the cart.

Make sure to align the uid pipe with the appropriate hole

on the front plate before positioning the pump.

27. Using the four lock nuts and carriage screws, secure the

pump to the cart.

28. Replace the uid outlet tting onto the front panel.

29. Reattach the air line from the radiator manifold to the

tting on the pump.

30. Replace the hopper onto the cart and uid inlet assembly.

Use the cart handles as guides to position the hopper

down onto the uid inlet assembly.

Replacing the Reversing Valve

Use the following procedure to replace the reversing valve in the

double diaphragm pump.

1. Remove the pump from the sprayer as described in the

corresponding “Replacing the Diaphragms” procedure in

this section.

2. Remove the four manifold nuts, screws, and washers

that secure the delivery manifold to the top of the pump.

Remove the delivery manifold.

3. Remove the four nuts and washers from the screws that

secure the pressure side cover to the motor. Pull the

pressure side cover off of the screws.

4. Remove the four valve screws that secure the reversing

valve to the motor. Remove the reversing valve.

5. Using a jet of compressed air, blow out the inside of the

motor.

6. Making sure the reversing valve gasket is positioned

properly, position the new reversing valve inside

the motor. Make sure that the shoe is in the “end of

stroke” position (both vertically and horizontally) before

assembling the valve.

7. Using the four valve screws, secure the reversing valve to

the motor.

8. Place the pressure side cover onto the four screws that

secure it to the motor. Secure the pressure side cover

using the four washers and nuts. Tighten securely.

9. Using the four manifold nuts, screws, and washers,

reassemble the delivery manifold to the top of the

pump. Make sure the manifold is positioned in the same

orientation as it was before it was removed.

10. Replace the pump onto the sprayer as described in the

corresponding “Replacing the Diaphragms” procedure in

this section.

© Titan Tool Inc. All rights reserved. 11

Page 12

General

Problem

Spray too coarse

Troubleshooting

Cause

1. Improperly mixed material

2. Fluid pressure too high (600DD only)

3. Not enough air

4. Texture nozzle too large

5. Fluid volume set too high on gun

Solution

1. Thin the material and mix well.

2. Turn the uid pressure regulator counterclockwise to

decrease uid pressure (600DD only).

3. Turn the gun air adjustment valve clockwise to

increase air ow.

4. Change to a smaller nozzle.

5. Turn the uid adjustment knob clockwise to decrease

uid volume.

Spray too ne

Material volume too low

Too much material at start of stroke

Double diaphragm pump is working,

but no material is owing

Material output decreases during

operation

Material output decreases during

operation and completely stops

Material is surging at the gun

1. Improperly mixed material

2. Too much air

3. Fluid volume set too low on gun

4. Fluid pressure too low (600DD only)

1. Texture nozzle too small

2. Fluid pressure too low (600DD only)

3. Material too thick

1. Trigger pull too fast

1. Hopper is empty

2. Fluid inlet assembly is clogged

1. Partial obstruction in uid inlet assembly

2. Slight variation in material consistency

(viscosity)

1. Complete obstruction in uid inlet

assembly

2. Strong variation in material consistency

(viscosity)

1. Material too thick.

1. Thicken the material and mix well.

2. Turn the gun air adjustment valve counterclockwise

to decrease air ow.

3. Turn the uid adjustment knob counterclockwise to

increase uid volume.

4. Turn the uid pressure regulator clockwise to

increase uid pressure (600DD only).

1. Change to larger nozzle.

2. Turn the uid pressure regulator clockwise to

increase uid pressure (600DD only).

3. Thin the material and mix well.

1. Refer to the “Spray Gun Operation” section in this

manual.

1. Fill the hopper with properly mixed material.

2. Remove hopper and clean uid inlet assembly.

1. Remove hopper and clean uid inlet assembly.

2. Re-mix material to a smooth, even consistency.

1. Remove hopper and clean uid inlet assembly.

2. Re-mix material to a smooth, even consistency.

1. Thin the material and mix well.

Spray Gun

Problem

Material will not ow from gun

Gun will not shut off

Fluid adjustment knob won’t move

No air through gun when pulling

trigger

Cause

1. Material too thick

2. Not enough air

3. Fluid volume set too low

4. Texture nozzle too small

5. Gun is plugged

1. Worn texture nozzle or air nozzle

2. Texture nozzle retaining nut not tightened

securely

3. Debris in the gun passages

1. Material dried in threads

1. Air nozzle passage packed with material

2. Two-stage texture shaft assembly not

functioning properly

Solution

1. Thin the material and mix well.

2. Turn the gun air adjustment valve clockwise to

increase air ow.

3. Turn the uid adjustment knob counterclockwise to

increase uid volume.

4. Change to larger nozzle.

5. Remove texture nozzle and clean gun

1. Perform the “Pressure Relief Procedure” and replace

the worn parts.

2. Tighten the nozzle nut securely.

3. Perform the “Pressure Relief Procedure”, remove

texture nozzle and clean gun.

1. Soak and clean well.

1. Clean the texture shaft passage.

2. Clean the texture shaft assembly.

12 © Titan Tool Inc. All rights reserved.

Page 13

Air Compressor

Problem

Compressor does not start

Troubleshooting

Cause

1. Loose wiring

2. Motor shut off due to thermal overload

Solution

1. Check the wiring connections

2. Wait 10—15 minutes, then press the reset switch on

the motor housing

Low air pressure

Relief valve is releasing prematurely

Excessive dust formation

Air leaks at ttings

Excessive noise

Compressor is over-heating

1. Loose ttings.

2. Air lter is clogged

1. Defective relief valve

1. Air lter is clogged

1. Fittings are not tight enough

1. Loose valve

2. Piping is loose

3. Carbon or foreign materials on piston

4. Worn bearings

1. Air leaks in the system

2. Valve has carbon buildup, is worn, or

damaged

1. Check all ttings along the air ow line. Tighten if

necessary.

2. Clean or replace the air lter.

1. Replace relief valve.

1. Clean or replace the air lter.

1. Tighten the ttings where air can be heard escaping.

Check the ttings with a soapy water solution, if

necessary.

1. Inspect valve for damage and replace if necessary.

2. Check connections and tighten as necessary

3. Contact an authorized Titan service center.

4. Contact an authorized Titan service center.

1. Locate and tighten the ttings where air can be heard

escaping. Check the ttings with a soapy water

solution, if necessary.

2 Inspect valve and clean, repair, or replace, if

necessary.

© Titan Tool Inc. All rights reserved. 13

Page 14

10

31

32

33

34

38

30

40

41

43

44

39

42

35

36

37

18

30

11

12

13

16

17

18

19

21

22

23

25

26

27

28

29

24

20

14

15

7

6

5

3

2

1

4

3

8

9

Parts List

Main Assembly — PowrTex 300DD (P/N 600-130)

14 © Titan Tool Inc. All rights reserved.

Page 15

Item Part # Description Quantity

1

3

2

1 600-477 Tank and cover .........................................1

2 858-601 Nut ............................................................4

3 770-601 Flat washer ...............................................8

4 600-463 One-way assembly

(includes items 2, 3, and 5........................1

5 858-636 Screw ........................................................4

6 600-464 Fluid inlet assembly, PowrTex 300

7 600-376 Compressor screw, long ...........................2

8 600-478 Air compressor .........................................1

9 600-375 Compressor screw, short ..........................2

10 600-421 Nipple .......................................................1

11 600-372 Elbow ........................................................1

12 600-373 Compression connector............................1

13 600-379 Copper tubing ...........................................1

14 600-479 Radiator (includes item 21).......................1

15 600-371 Nipple .......................................................1

16 600-358 Street elbow..............................................1

17 600-359 Elbow ........................................................1

18 600-246 Fitting ........................................................2

19 600-370 Manifold ....................................................1

20 600-245 Plug ..........................................................1

21 ---------- Screw ........................................................4

22 600-009 Front panel ...............................................1

23 600-178 Relief valve ...............................................1

24 600-385 Screw ........................................................1

DD .......1

Item Part # Description Quantity

25 600-252 Air outlet coupling .....................................1

26 600-354 Screw ........................................................4

27 600-142 Fluid outlet tting ......................................1

28 600-215 Grommet ...................................................1

29 600-217 Carriage bolt .............................................4

30 600-216 Lock nut ....................................................8

31 770-712 Carriage bolt .............................................4

32 600-480 Pump, Zip 52 ............................................1

33 600-094 Fluid pipe ..................................................1

34 600-231 Strain relief ...............................................2

35 600-109 Switch box ................................................1

36 704-229 Ground screw ...........................................1

37 704-380 ON/OFF Switch ........................................1

38 600-481 Cart frame .................................................1

39 600-177 Lock nut ....................................................4

40 600-185 Wheel .......................................................2

41 870-004 Washer .....................................................2

42 800-019 Cap ...........................................................2

43 800-007 Axle ...........................................................1

44 800-011 Spacer ......................................................1

45 600-257 Power cord (not shown)............................1

46 600-345 Air tubing (not shown, refer to

Air Flow Schematic — PowrTex 300

600-482 Cart assembly complete

(includes items 38, and 40–44)

DD) ...1

Air Compressor

(P/N 600-478, PowrTex 300DD •

P/N 600-484, PowrTex 600DD)

Labels

Part # Description

0524934 Hopper cover label — PowrTex 300DD

0524935 Hopper cover label — PowrTex 600DD

0524936 Gun label, right side

0524937 Gun label, left side

313-2717 Fluid label

313-2723 Material ow adjustment label —

PowrTex 600DD only

313-2776 Warning label

0276808 Warning label —Burn Hazard

Item Part # Description Quantity

1 600-466 Valve kit ....................................................1

2 600-468

600-469

3 600-467 Air lter kit .................................................1

© Titan Tool Inc. All rights reserved. 15

Thermal protector, 15 A, PowrTex 300DD

Thermal protector, 18 A, PowrTex 600DD ...1

...1

Page 16

1

2

3

3

5

7

8

10

11

12

13

14

15

16

17

18

19

21

22

23

24

25

27

26

28

29

30

31

32

33

34

20

9

4

36

37

38

39

40

41

42

43

44

45

38

35

46

47

35

48

49

51

50

6

Main Assembly — PowrTex 600DD (P/N 600-140)

16 © Titan Tool Inc. All rights reserved.

Page 17

Item Part # Description Quantity

WHITE

GREEN

GREEN

BLACK

WHITE

BLACK

Compressor

Ground screw

at switch box

Ground

screw at

switch box

ON/OFF

Switch

Power

Cord

1 600-483 Tank and cover .........................................1

2 858-601 Nut ............................................................4

3 770-601 Flat washer ...............................................8

4 600-463 One-way assembly

(includes items 2, 3, and 5........................1

5 858-636 Screw ........................................................4

6 600-465 Fluid inlet assembly, PowrTex 600

DD .......1

7 600-377 Compressor screw, long ...........................2

8 600-484 Air compressor .........................................1

9 600-375 Compressor screw, short ..........................2

10 600-421 Nipple .......................................................1

11 600-372 Elbow ........................................................1

12 600-373 Compression connector............................1

13 600-374 Copper tubing ...........................................1

14 600-479 Radiator(includes item 22)........................1

15 600-371 Nipple .......................................................1

16 600-358 Street elbow..............................................1

17 600-359 Elbow ........................................................1

18 600-246 Fitting ........................................................1

19 600-370 Manifold ....................................................1

20 600-248 Elbow ........................................................1

21 600-146 Front panel ...............................................1

22 ---------- Screw ........................................................4

23 600-168 Pressure gauge ........................................1

24 600-353 Mounting nut .............................................1

25 600-178 Relief valve ...............................................1

26 600-385 Screw ........................................................1

27 600-252 Quick disconnect coupling ........................1

28 600-355 Plug ..........................................................1

29 600-136 Fluid outlet tting ......................................1

Item Part # Description Quantity

30 600-138 Bushing.....................................................1

31 600-214 Grommet ...................................................2

32 600-354 Screw ........................................................4

33 704-380 ON/OFF Switch ........................................1

34 600-218 Carriage bolt .............................................4

35 600-216 Lock nut ....................................................8

36 770-712 Carriage bolt .............................................4

37 600-485 Pump, Zip 80 ............................................1

38 600-250 Elbow ........................................................3

39 600-025 Fluid pipe ..................................................1

40 600-249 Elbow ........................................................1

41 600-095 Pressure regulator ....................................1

42 600-231 Strain relief ...............................................2

43 600-245 Plug ..........................................................1

44 600-109 Switch box ................................................1

45 704-229 Ground screw ...........................................1

46 600-486 Cart frame .................................................1

47 600-177 Lock nut ....................................................4

48 600-184 Wheel .......................................................2

49 870-004 Washer .....................................................2

50 800-019 Cap ...........................................................2

51 800-007 Axle ...........................................................1

51 600-257 Power cord (not shown)............................1

52 600-351 Air tubing, 1/4” O.D. (not shown, refer to

Air Flow Schematic — PowrTex 600

DD) ...1

53 600-346 Air tubing, 3/8” O.D. (not shown, refer to

Air Flow Schematic — PowrTex 600

DD) ...2

600-487 Cart assembly complete

(includes items 46 and 48–51))

Electrical Schematic

NOTE: All electrical work should be performed

by an authorized service center.

© Titan Tool Inc. All rights reserved. 17

Page 18

1

5

4

6

9

10

11

12

13

14

7

8

2

3

15

2

16

17

Fluid Pump — PowrTex 300DD (P/N 600-480)

Item Part # Description Quantity

1 600-475 Screw (torque to 44 in./lbs.)......................4

2 600-417 Washer ...................................................20

3 600-409 Delivery manifold ......................................1

4 600-422 Motor ........................................................1

5 600-413 Support diaphragm ...................................2

6 600-412 Product diaphragm ...................................2

7 600-410 Outer diaphragm disk (torque to 9 ft./lbs.) 2

8 600-411 Diaphragm cover ......................................2

Item Part # Description Quantity

9 600-420 Nut ............................................................8

10 600-423 Fluid valve unit..........................................4

11 600-408 Suction manifold .......................................1

12 600-439 Screw, self-tapping ...................................1

13 600-424 Ground lug ................................................1

14 600-414 Screw ........................................................4

15 600-416 Nut (torque to 44 in./lbs.) ........................12

16 600-418 Screw ......................................................12

17 600-501 O-ring (also included in item #10).............4

18 © Titan Tool Inc. All rights reserved.

Page 19

1

5

4

8

9

10

11

6

7

2

2

3

12

13

14

16

15

17

18

Fluid Pump — PowrTex 600DD (P/N 600-485)

Item Part # Description Quantity

1 600-414 Screw (torque to 30 in./lbs.)......................4

2 600-417 Washer .....................................................8

3 600-427 Delivery manifold ......................................1

4 600-434 Motor ........................................................1

5 600-430 Diaphragm ................................................2

6 600-428 Outer diaphragm disk (torque to 9 ft./lbs.) 2

7 600-429 Diaphragm cover ......................................2

8 600-416 Nut ............................................................8

9 600-435 Fluid valve unit..........................................4

Item Part # Description Quantity

10 600-426 Suction manifold .......................................1

11 600-431 Screw ........................................................4

12 600-433 Nut (torque to 49 in./lbs.) ........................12

13 600-437 Washer ...................................................12

14 600-432 Screw ......................................................12

15 600-502 O-ring (also included in item #9)...............4

16 600-440 Screw ........................................................1

17 600-436 Washer .....................................................1

18 600-424 Ground lug ................................................1

© Titan Tool Inc. All rights reserved. 19

Page 20

1

2

3

14

12

13

15

16

17

4

5

6

7

8

9

10

11

Motor (P/N 600-422, PowrTex 300DD • P/N 600-434, PowrTex 600DD)

Item Part # Description Quantity

1 600-444 Pressure side cover ..................................1

2 600-449 Pressure cover gasket ..............................1

3 600-455 Reversing valve (includes items 2 and 4) . 1

4 600-448 Reversing valve gasket ............................1

5 600-441 Feeler pin ..................................................2

6 600-453 Lip gasket, small .......................................2

7 600-454 Lip gasket, large .......................................2

8 600-445 Bushing guide ...........................................2

9 600-443 Shaft .........................................................1

Item Part # Description Quantity

10 600-460 Inner diaphragm disk,PowrTex 300

600-442 Inner diaphragm disk,PowrTex 600

DD ......2

DD

11 600-452 Screw ........................................................6

12 600-416 Nut (torque to 44 in./lbs.) ..........................4

13 600-425 Contact washer.........................................4

14 600-451 Screw ........................................................4

15 600-450 Silencer .....................................................1

16 600-446 Discharge side cover ................................1

17 600-419 Screw ........................................................4

20 © Titan Tool Inc. All rights reserved.

Page 21

PowrTex Gun (P/N 600-400)

1

2

3

4

5

6

7

8

9

10

12

13

14

15

18

19

16

11

17

20

21

22

24

25

26

27

28

30

31

29

10

15

23

Nozzle

Size

Nozzle

Part #

Application Air Flow Fluid Pressure

(PowrTex 600DD only)

600-1001/8”

Round

Orifice

3/16”

Round

Orifice

1/4”

Round

Orifice

5/16”

Round

Orifice

Fog High

Medium to high

Low

Low to medium

600-105 Coarse simulated acoustics

Splatter coat

Knockdown

Medium

Low to medium

Low

High

Medium to high

High to medium

600-107

Orange peel

600-106Fine to medium simulated acoustics

Splatter coat

High

Low to medium

Low to medium

Medium to high

Flat

Pattern

0524465 Orange peel

Fine to medium simulated acoustics

Coarse simulated acoustics

Splatter coat

Knockdown

High

Medium to high

Medium to high

High

High

Medium

Low to medium

Low

Low to medium

Low to medium

Item Part # Description Quantity

1 600-055 Fluid adjustment knob ...........................1

2 600-057 Adjustment spring .................................1

3 600-054 Air valve seal .........................................1

4 600-077 Air trip rod .............................................1

5 600-079 O-ring ....................................................1

6 600-052 Texture shaft .........................................1

6 600-053 Air nozzle ..............................................1

8 600-069 Plug .......................................................1

9 9822550 Retaining ring ........................................1

10 931-014 O-ring ....................................................2

11 9812322 Lock nut ................................................1

12 580-506 Belleville washer ...................................1

13 600-475 Flat washer ...........................................1

14 600-068 Washer ..................................................1

15 600-096 Shoulder screw .....................................2

16 600-100 Texture nozzle, 5/16” ............................1

600-105 Texture nozzle, 1/8”

600-107 Texture nozzle, 3/16”

600-106 Texture nozzle, 1/4”

17 600-066 Nozzle nut .............................................1

18 600-050 Gun body ..............................................1

19 600-051 Trigger ...................................................1

20 600-080 Spring ....................................................1

21 600-078 Air shut-off valve ...................................1

22 9805384 Screw ....................................................1

23 194-113 O-ring ....................................................1

24 700-201 Viton o-ring ............................................1

25 600-061 Trigger mounting block .........................1

26 600-097 Retainer screw ......................................1

27 600-099 Shaft spring seal ...................................1

28 600-098 Washer ..................................................1

29 600-203 Air adjustment knob ..............................1

30 600-202 Whip hose assembly .............................1

31 581-088 Trigger pin .............................................1

Texture Nozzle Chart

© Titan Tool Inc. All rights reserved. 21

600-462 Texture shaft assembly

(includes items 3–7, 20-22, and 24)

600-461 O-ring and seal kit (includes items 5, 10,

23, 24 and 27)

Page 22

Gun Air Line

From radiator outlet side

To radiator inlet side

Relief Valve

Manifold

Radiator

Compressor

To double

diaphragm pump

From compressor

Double Diaphragm Pump

= Air Flow

Key

Air Tubing

(not shown)

Air Flow Schematic — PowrTex 300DD

22 © Titan Tool Inc. All rights reserved.

Page 23

= Air Flow

Key

To double

diaphragm pump

To pressure

regulator

Double Diaphragm Pump

Compressor

From compressor

Gun Air Line

From radiator outlet side

To pressure gauge

To radiator inlet side

Relief Valve

Manifold

Radiator

Pressure

Gauge

Pressure

Regulator

3/8” Air Tubing

(not shown)

3/8” Air Tubing

(not shown)

1/4” Air Tubing

(not shown)

Air Flow Schematic — PowrTex 600DD

© Titan Tool Inc. All rights reserved. 23

Page 24

Accessories

United States Sales & Service

1770 Fernbrook Lane

Minneapolis, MN 55447

www.titantool.com

200 Trowers Road, Unit 7B

Woodbridge, Ontario L4L 5Z8

Phone:

Fax:

1-800-526-5362

1-800-528-4826

Phone:

Fax:

1-800-565-8665

1-800-856-8496

Canadian Branch

1770 Fernbrook Lane

Minneapolis, MN 55447

Phone:

Fax:

1-201-337-1240

1-201-405-7449