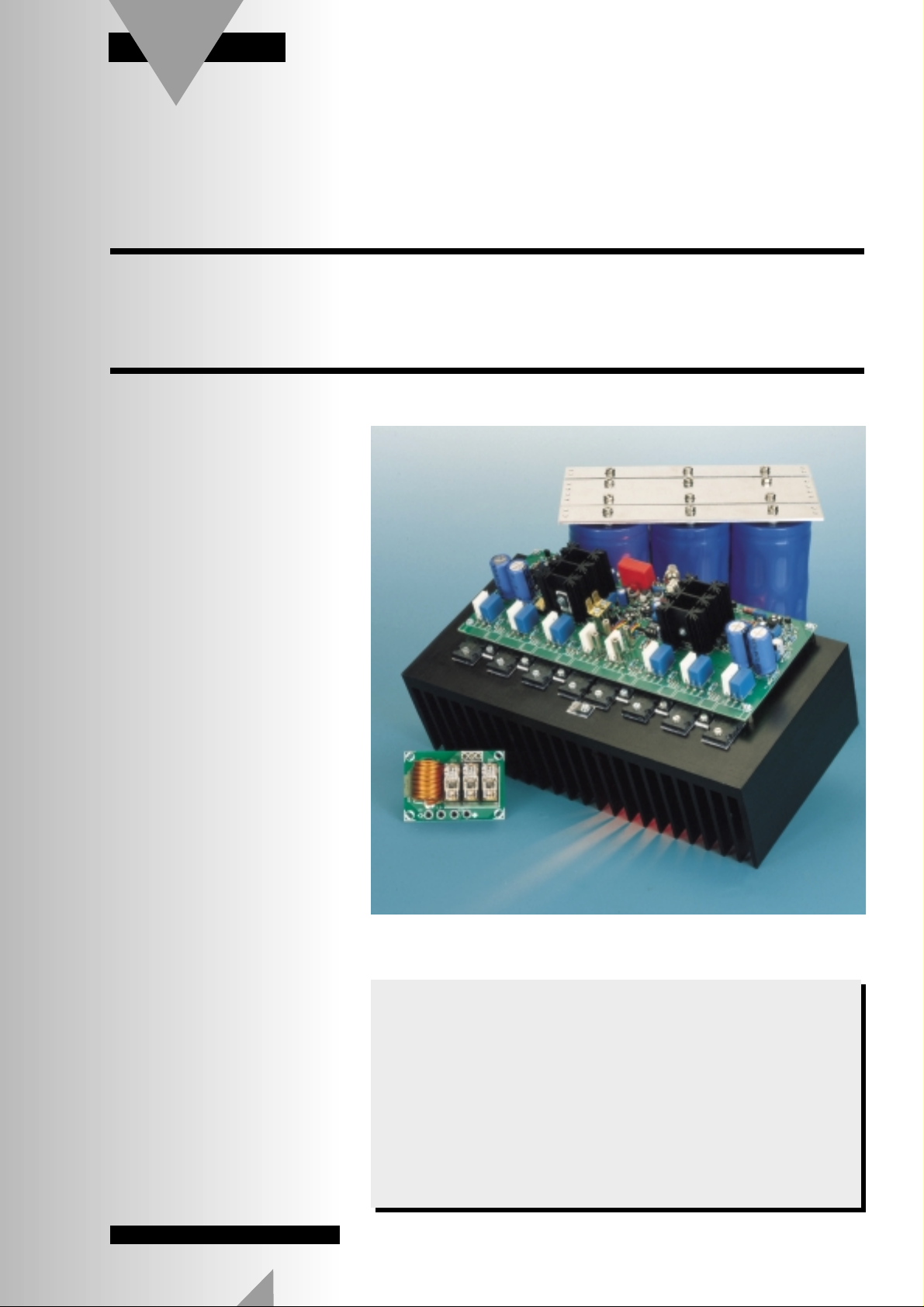

Page 1

Elektor Electronics 2/99

It could be argued

that most of the out-

put amplifiers pub-

lished in this maga-

zine lack power.

Although this is a

debatable point, it

was felt that a true

heavyweight output

amplifier would make

a welcome change for

many constructors.

The Titan 2000 can

produce 300 watts

into 8 Ω, 500 watts

into 4 Ω, and

800 watts into 2 Ω.

For those who believe

that music power is a

reputable quantity, the

amplifier can deliver

2000 watts of this

magical power into

4 Ω.

58

Design by T. Giesberts

Titan 2000

High-power hi-fi and

public-address amplifier

Brief parameters

Sine-wave power output 300 W into 8 Ω; 500 W into 4 Ω; 800 W into 2 Ω

Music power* 2000 W into 4 Ω

Harmonic distortion <0.005%

Slew limiting 85 V µs

–1

Open-loop bandwidth 55 kHz

Power bandwidth 1.5 Hz – 220 kHz

*See text about the validity of this meaningless quantity.

AUDIO & HI-FI

Contents

Page 2

INTRODUCTION

Amplifier output has been a cause of

argument for as long as there have

been audio power amplifiers. For

domestic use, a power rating of

2× 50 W is more than sufficient. With

the volume control at maximum and

the use of correctly matched goodquality loudspeakers, this will provide

a sound pressure level (SPL) equivalent to that of a grand piano being

played forte in the same room.

However, not all amplifiers are

intended for domestic use: many are

destined for discos, small music halls

and other large rooms. But even here,

what power is really required? Since

doubling the amplifier output increases

the SPL by a barely audible 3 dB, it was

felt that 300 watts sine wave power into

8Ωwould appeal to many .

‘ PROGRAMMABLE’

POWER OUTPUT

The amplifier has been designed in

such a manner that its output is ‘programmable’ as it were. With a sine

wave input, it delivers an average

power of 300 W into an 8Ω load,

which should meet the requirements

of all but the power drunk. Compared

with the output of 50 W from a

domestic audio amplifier, this

gives an increase in SPL of

7.5 dB. If even higher outputs are

needed, the load impedance may be

lowered to 4 Ω, which will give an

increase in SPL of 10 dB compared

with a 50 W output.

Although music power is a deprecatory term, since it does not really

give the true power rating of an amplifier, readers may note that the Titan

2000 can deliver 2 kW of this magical

power into 4 Ω. (True power is average

power , that is, the product of the r.m.s. volt-

age across the loudspeaker and the r.m.s.

current flowing into the speaker. The term

music power is generally meaningless,

because to some manufacturers it means the

product of the peak voltage and peak current; to others it means merely double the

true power; and to yet others, even more

disreputable, it means quadrupling the true

power).

However, power is not the only criterion of an amplifier. Low distortion,

good slew limiting, and an extended

power bandwidth, as possessed by the

Titan 2000, are also hallmarks of a good

amplifier.

Power bandwidth denotes the frequency range over which the power

falls to not less than half its maximum

value. This is much more telling than

the frequency response, which is usually measured at a much lower output

level.

Slew limiting is the maximum input

voltage change that can occur in one

59

Elektor Electronics 2/99

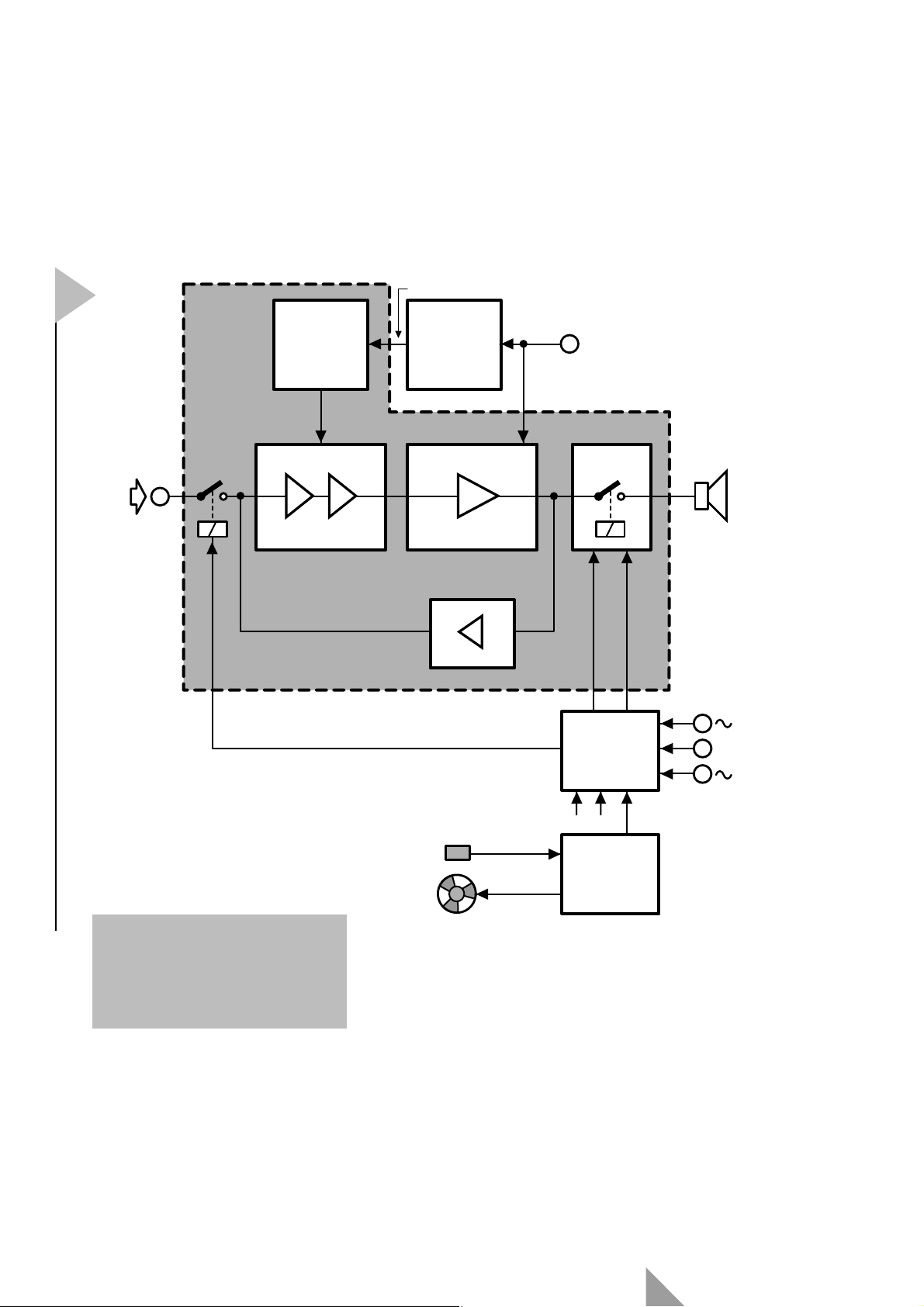

1

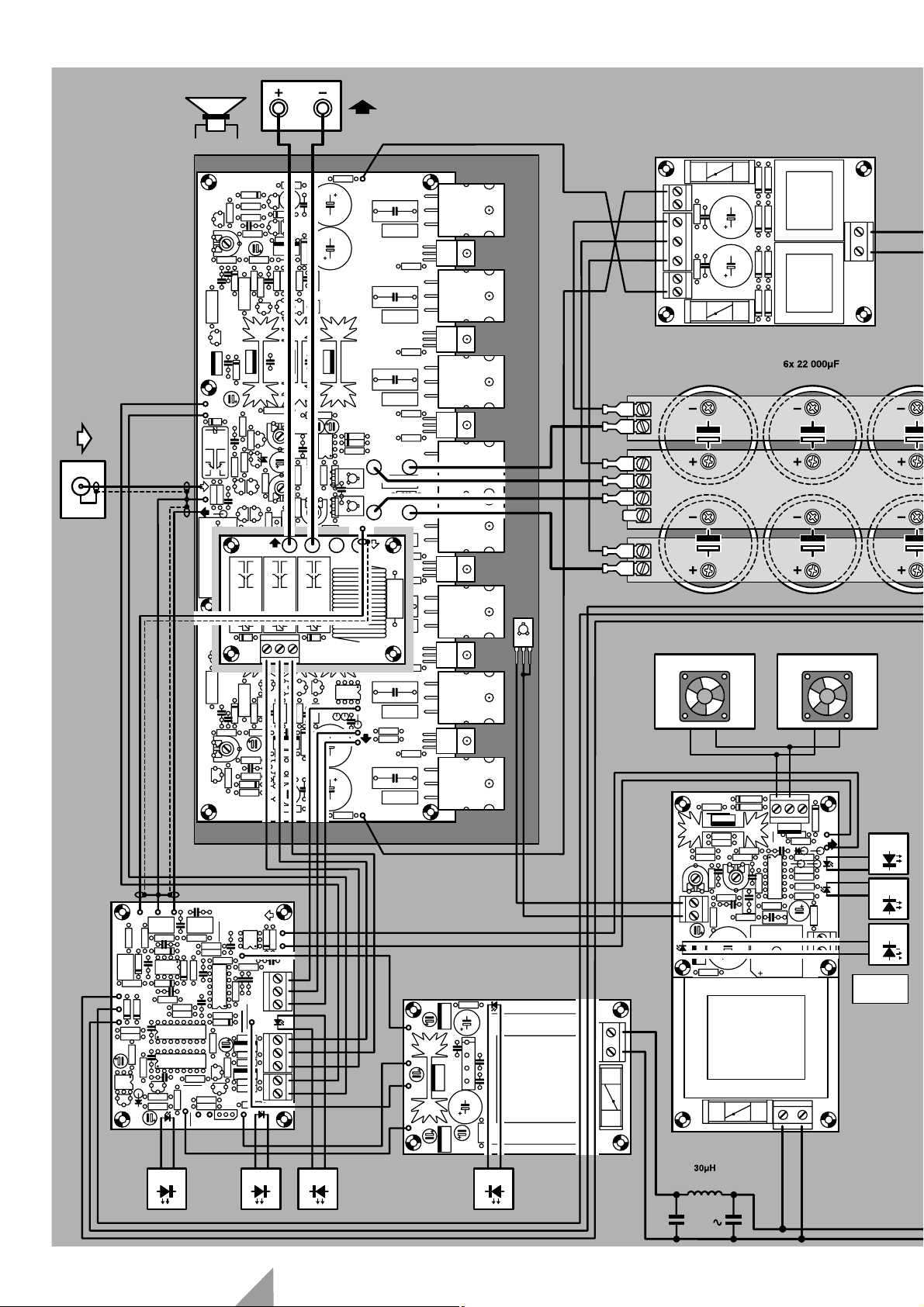

Figure 1. Simplified block diagram of the Titan 2000. The auxiliary power supply, protection

networks and thermal control

are discrete circuits built on discrete PCBs.

Contents

regulator

± 78V

T43...T52

voltage amplifier

T1...T10

T15...T26

input stages &

cascode amplifiers

± 85V

auxiliary

power supply

2x 15V

current amplifier

T27...T34

T35...T42

drivers & output stages

offset control

main power

supply

± 70V

heat sink

sensor

fan

protection

circuits

UinU

thermal

control

out

990001 - 12

0

Page 3

60

Elektor Electronics 2/99

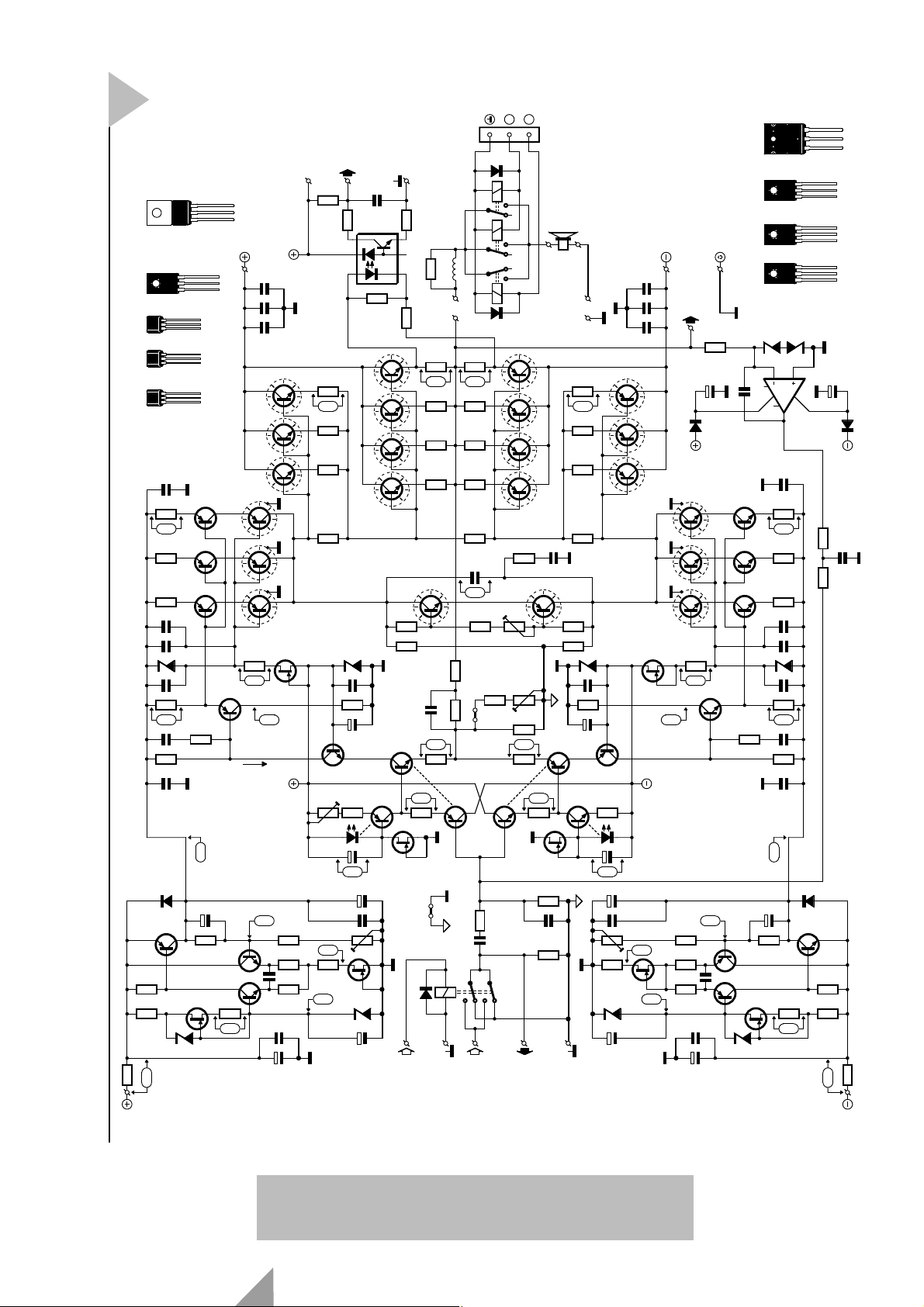

Figure 2. Although the circuit diagram gives the impression of a highly complex design, the amplifier is, in

essence, fairly straightforward.

2

Contents

R56

85V

BF871

BD711

BC550

BF245A BC639

R62

R57

15Ω

BF872

BD712

BC560

BC640

BF256C

R26

R25

R24

D4

R18

R13

T47

330Ω

15k

1V

2R

1R

K1

2SC5359

1M

C24

2µ2 63V

1N4004

T24...T26=MJE340

R17

-39V

T51

2x

15n

T50

D11

220n

100V

470µ

2SA1987

2SC5171

MJE340

BD139

1µ

150Ω

R72

BC

640

T48

30V

2SA1930

MJE350

BD140

D14

2

5

7

1

C19

T18 T19 T20

C23

C22

D6

C11

R20

C5

R15

C18

-78V

C39

15k

BF

245A

1W3

0W5

12V

3

IC1

6

68Ω

0V83 0V83

68Ω

68Ω

270Ω

1V45 1V45

1k00

2µ2

63V

R67

I

+5V

2k2

C42

R78

C

EB

5V

C45

100n

C44

100n

C43

100n

T31

T30

BE

E

B

C

BE

C

S

GD

70V

C

T29...T31=2SC5171

T21...T23=MJE340

3k3

R22

T11

2mA1

63V

T46

BC

639

T45

R58

270Ω

0V36

T29

T23

T22

T21

1W

T13

53V-53V

15V

39V

12k

R64

22Ω

R61

C31

15n

22Ω

R60

C29

220n

C28

470µ 100V

C17

100p

68Ω

T17

68Ω

T16

68Ω

T15

C21

100p

C20

100p

5V6

0W5

C8

100n

270Ω

150Ω

R16

C4

2n2

1k00

C16

100p

+78V

D10

1N4004

C32

2µ2

BD712

15k

R63

2x

BF

245A

T43

D8

30V

1W3

R76

10Ω

R41

38mV32mV

10Ω

R40

10Ω

R39

560Ω

R36

BF256C

D5

R19

T9

P2

250Ω

D1

8V4

5k6

R59

39V

1n

R77

100Ω

6

8

IC2

2

T35...T38=2SC5359

C9

10k

C10

BF871

R5

330Ω

C6

1V71V7

C34

C33

P4

T44

BF256A

D9

C30

100Ω

5

7

6N136

3

2Ω2

R79

100Ω

R74

33Ω

R75

0Ω22

25V

100V

1W3

63V

R48

0Ω22

R47

0Ω22

R46

0Ω22

R45

BD

139

T27

220Ω

R33

22k

R31

1n

C3

T3

5k

22Ω

R12

53mV53mV

22Ω

R4

T7

BF

245A

JP2

D3

1N4148

T38

T37

T36

T35

15V

1W3

100n

1W

100µ

T5

220µ

25V

470µ

220n

39V

47µ

MUTE

D18D19

L1

Re4 Re3 Re2

LS+ LS+

0Ω22

R52

20mV20mV

0Ω22

R51

0Ω22

R50

0Ω22

R49

150Ω

R38

R30RC14

C15

100n

2V24

R34

500Ω

470Ω

P3

470Ω

R11

470Ω

JP1

R10

45mV45mV

T1

R2

C1

Re1

390Ω

R9

T2

562Ω

2µ2

5k

P1

22Ω1

R8

22Ω

R14

R6

V23042-A2003-B101

LS1

T39...T42=2SA1987

T39 T40 T41 T42

C

T28

T4

22Ω

T6

T8

BF

245A

47k

R3

C2

1n

1M

R1

P-IN

T27...T42 on common heatsink

LS- LS-

10Ω

R44

10Ω

R43

10Ω

R42

560Ω

R37

BD

140

220Ω

R35

22k

R32

15V

1W3

D7

C12

100n

10k

1W

R21

C13

25V

100µ

T10

470Ω

R7

C7

C41

C40

P5

5k6

R68

39V

D12

C37

220µ

D2

25V

470µ

220n

47µ

C48

C47

C46

BF872

100V

5k

BF256A

1W3

63V

100n

100n

100n

T32 T33 T34

T14

15V

-30V

T49

-39V

70V

P-LS

R53

C26

D16

T32...T34=2SA1930

15V

T24 T25 T26

1W

BF256C

3k3

R23

35V 35V

T12

12k

R73

22Ω

R70

C38

22Ω

R69

C36

C35

D15

4

100p

R29

R28

R27

100p

100p

5V6

100n

2n2

100p

D13

BD711

270Ω

0V36

E

C

B

990001 - 11

E

C

B

B

C

E

B

C

E

C27

2µ2 63V

OP90G

D17

1N4004

15V

4M7

R54

C25

68n

4M7

R55

0W5

T1, T4, T5, T15...T17 = BC560C

T2, T3, T6, T18...T20 = BC550C

1N4004

T52

330Ω

R71

15k

R66

1V

15Ω

R65

85V

Page 4

microsecond, and to which the amplifier can respond.

DESIGN

CONSIDERATIONS

The Titan 2000 is based on the ‘compact power amplifier’ published in the

May 1997 issue of this magazine. That

was a typical domestic amplifier with a

power output of 50 W into 8 Ω or 85 W

into 4 Ω. The special property of this

fully balanced design was the use of

current feedback instead of voltage

feedback, which resulted in a fastresponding amplifier with a large

open-loop bandwidth. The amplifier

performed well both as regards instrument test and measurements and listening tests. However, to serve as a

basis for the Titan 2000, its output current and drive voltage range had to be

increased substantially.

For a start, the supply voltage has to

be more than doubled, which means

that transistors with a higher power

rating have to be used in the power

supply . The higher supply voltage also

results in larger potential drops across a

number of components, and this

means that dissipation problems may

arise.

The large output current required

for the Titan 2000 makes a complete

redesign of the current amplifier used

in the ‘compact power amplifier’

unavoidable, since that uses insulatedgate bipolar transistors (IGBTs).

Although these are excellent devices,

the large spread of their gate-emitter

voltage makes their use in parallel net-

works next to impossible. To obtain the

requisite output power, the use of parallel networks of symmetrical pairs of

transistors is inevitable.

In view of the foregoing, bipolar

transistors are used in the current

amplifier of the Titan 2000. However,

these cannot be driven as readily as

IGBTs, which means that current drive

instead of voltage drive is used. This

entails a substantial upgrading of the

driver stages and the preceding cascode amplifiers (which also consist of a

couple of parallel-connected transistors). The good news is that the power

transistors in the Titan 2000 are considerably less expensive than IGBTs: an

important factor when eight of these

devices are used.

Finally, the protection circuits have

been enhanced in view of the higher

voltages and currents. The circuits protecting against direct voltages and

short-circuits are supplemented by

networks protecting against overload

and (too) high temperatures. The latter

is coupled to a proportional fan control.

In short, a large part of the Titan

2000 is a virtually new design rather

than a modified one.

BRIEF DESCRIPTION

The block diagram of the Titan 2000 is

shown in Figure 1. The voltage amplifier consists of input stages T

1–T10

, and

cascode amplifiers/pre-drivers T

15–T26

.

The current amplifier is formed by driver transistors T

27–T34

, and output

transistors T35–T42.

The offset control stage prevents

any direct voltage appearing at the

output of the amplifier.

The loudspeaker is linked to the

amplifier by three heavy-duty relays.

The current amplifier operates from

a ±70 V supply, which is provided by

two 50 V mains transformers. To enable

the voltage amplifier to drive the current amplifier to its full extent, it needs

a slightly higher supply voltage to

compensate for the inevitable losses

caused by inevitable voltage drops.

This is accomplished by superimposing

a ±15 V potential from an external

auxiliary supply on to the main ±70 V

supply and dropping the resulting

voltage to ±78 V with the aid of regulator T

43–T52

.

The combined protection circuits

constantly compare the input and output voltage of the amplifier: any deviation from the nominal values leads to

the output relays disconnecting the

loudspeaker and the input relay

decoupling the input signal.

The thermal protection circuit monitors the temperature of the heat sink

and, if necessary, switches on a fan. If,

with the fan operating, the temperature approaches the maximum permissible limit, the output relays are

deenergized and disconnect the loudspeaker.

CIRCUIT DESCRIPTION

The circuit diagram of the Titan 2000 is

shown in Figure 2. In spite of the large

number of components, the basic cir-

61

Elektor Electronics 2/99

Contents

Page 5

cuit is straightforward.

As already noted in

the previous paragraph, transistors

T

1–T10

form the input

amplifier, T

11

and T12are buffers, T

13

and T14are current sources, T15–T

26

form the cascode amplifier/pre-driver

stage, T

27–T34

are the driver transistors

in the current amplifier , T

35–T42

are the

output transistors, and T

43–T52

form a

sophisticated supply voltage regulator.

Input amplifier

Strictly speaking, the input amplifier is

formed by transistors T

3–T4

. Cascode

stages T

9–T10

serve merely to enable

the input section handling the high

voltages. These voltages are limited by

zener diodes D

5

and D7, which are part

of the potential divider that also sets

the operating points of T

21–T26

. In

view of the requisite stability, the current through the zener diodes is held

constant by current sources T

13

and

T

14

. Resistors R22and R23limit the

potential across, and thus the dissipation in, these field-effect transistors.

Otherwise, the input section is virtually identical to that of the ‘compact

power amplifier’. The drop across the

emitter resistors of buffers T

1

and T

2

determines the drop across the emitter

resistors of T

3

and T4, and consequently the setting of the operating

point of the overall input section. To

eliminate the influence of temperature

variations, T

1

is thermally coupled to

T

3

and T2to T4.

Since the operating point of buffers

T

1

and T2is critical, current sources T

5

and T6have been added. The reference

for these current sources is provided

by light-emitting diodes (LEDs) D

1

and

D

2

. The current through these diodes

is determined by current sources T

7

and T8. In view of the

requisite stability,

diode D

1

is thermally

coupled to T

5

and D

2

to T6.

Any imbalance of the input stages is

compensated by making the current

through T

5

equal to that through T

6

with potentiometer P2.

Cascode amplifiers/pre-drivers

The large output current of the Titan

2000 necessitates a proportionally

large pre-drive voltage, which is provided by three parallel-connected cascode amplifiers, T

15–T26

. The current

through these amplifiers is arranged at

10–15 mA, but the current feedback

used may cause this level to be appreciably higher. This is the reason that the

transistors used in the T

21–T26

positions are types that can handle currents of up to 50 mA when their collector-emitter voltage is 150V.

The input section is linked to the

cascode amplifiers by buffers T

11

and

T

12

, which results in a lowering of the

input impedance. The arrangement

also enables an increase in the values

of R

13

and R15, which results in a 3 dB

increase in amplification of the input

section.

The function of resistors R

19

and

R

21

is threefold: they limit the dissipation of the buffers; they obviate the

need of an additional voltage to set the

operating point of the buffers; they

limit the maximum current through

the buffers, and thus the cascode

amplifiers, to a safe value.

The open-loop amplification of the

Titan 2000 is determined solely by

those of the input section and cascode

amplifiers. The amplification of the

input section depends on the ratios

R

13

:(R12+R8) and R15:(R14+R8) and,

with values as specified is ×10 (i.e., a

gain of 20 dB).

The amplification of the cascode

amplifiers is determined largely by the

ratio of parallel-connected resistors R

31

and R32and the parallel network of

R

24–R26

. With values as specified, the

amplification is about ×850 (remem-

ber, this is a push-pull design), so that

the overall amplification of input section plus cascode amplifiers is ×8500 (a

gain of close to 80 dB).

Current amplifier

Since one of the design requirements is

that the amplifier is to work with loads

down to 1.5 Ω, the output stages consist of four parallel-connected pairs of

transistors, T

35–T38

and T39–T42. These

transistors have a highly linear transfer

characteristic and provide a direct-current amplification that remains virtually constant for currents up to 7 A.

Like the output transistors, the driver stages need to remain within their

safe operating area (SOA), which

necessitates a threefold parallel network. The transistors used in the driver stages are fast types

(f

T

=200 MHz).

Setting the bias voltage for the requisite quiescent current is accomplished by balanced transistors T

27

and

T

28

. These transistors are mounted on

the same heat sink as the output transistors and driver transistors to ensure

good thermal coupling and current

control. Of course, the current rises

during full drive conditions, but drops

again to its nominal level when the

amplifier cools off. The quiescent current is set to 200 mA with potentiometer P

3

.

Owing to the large output current,

the connection between amplifier output and loudspeaker is not arranged

via a single relay, but via three. Two of

these, Re

3

–Re4, are controlled in synchrony by the protection circuits.

When they are deenergized, their disabling action is delayed slightly to give

the contacts of the third relay , Re

2

, time

to open, which is of importance in a

fault situation.

Input relay Re

1

is switched off in

synchrony with Re

2

to ensure that

there is no input signal by the time Re

3

and Re4are deenergized.

Optoisolator IC

2

serves as sensor for

the current protection circuits. The

light-emitting diode in it monitors the

voltage across R

48–R52

via potential

divider R

74–R75

, so that the positive as

well as the negative output currents

are guarded. The use of an optoisolator prevents earth loops and obviates

compensation of the ±70 V commonmode voltage. The +5 V supply for the

optoisolator is derived from the protection circuits.

Feedback

The feedback loop runs from the out-

62

Elektor Electronics 2/99

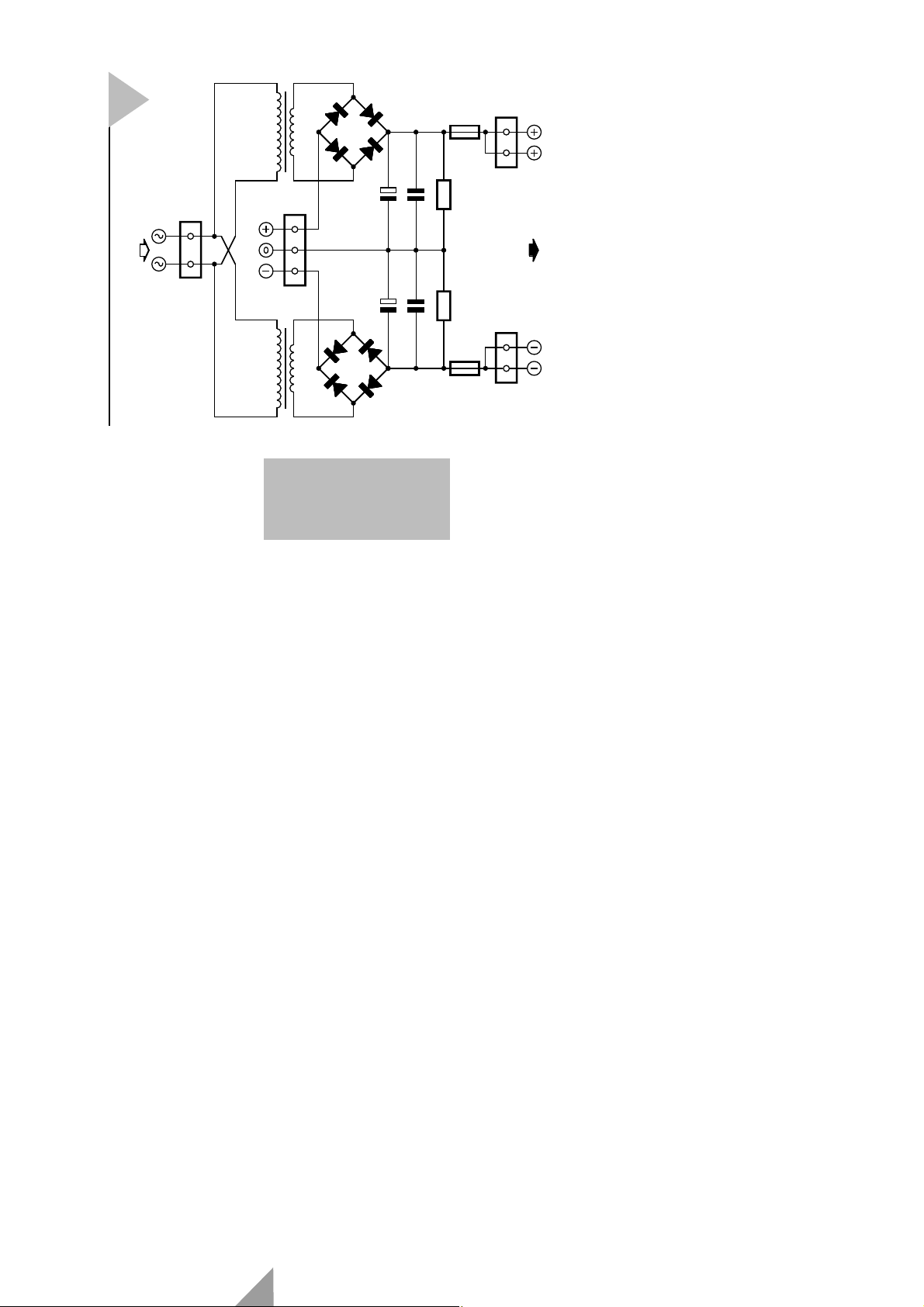

3

Figure 3. Circuit diagram of the requisite

auxiliary power supply.

Contents

K1

12V / 1VA5

70V

Tr1

D3

D4

4x 1N4007

K2

D1

C3

100n

160mA T

R1

1M

D2

C1

470µ

100V

K3

F1

85V

70V

4x 1N4007

Tr2

D5

D6

12V / 1VA5

C4

100n

R2

1M

K4

F2

160mA T

990001 - 13

C2

470µ

100V

D7

D8

85V

Page 6

put of the power stages to the junction

of T

3

and T4via resistors R10and R11.

This is current feedback because the

current through T

3

and T4depends on

the potential across R

8

, which is determined largely by the current through

R

10

and R11. The overall voltage amplification of the output amplifier is determined by the ratio R

8

:(R10+R11).

Compensation

Capacitors C3–C5and resistors R16, R

17

form part of the compensation network required for stable operation.

Low-pass filter R

2–C2

at the input is

essential to prevent fast, that is, highfrequency, signals causing distortion.

This filter is also indispensable for stability’s sake.

Coupling capacitor C

1

is needed

because the available offset compensation network merely redresses the bias

current of the input buffers and is not

intended to block any direct voltages at

the input.

Relay Re

1

at the input enables the

input signal to be ‘switched off’. It

forms part of the overall protection

and in particular safeguards the input

section against overdrive. The overall

protection circuit will be discussed in

detail next month.

Network R

9-P1

is intended specifically for adjusting the common-mode

suppression when two amplifiers are

used in a bridge arrangement. It is

needed for only one of these amplifiers, and may be interconnected or

disabled by jumper JP

1

as needed.

Offset compensation is provided by

integrator IC

1

, which ensures that if

there is any direct voltage at the output

of the amplifier, the operating point of

T

1-T2

is is shifted as needed to keep the

output at earth potential. The operational amplifier (op amp) used draws

only a tiny current (20 µA) and has a

very small input offset (450 µV).

Supply voltage for IC

1

is taken from

the ±15 V line for the input section via

diodes D

16

and D17. This arrangement

ensures that the supply to the IC is

retained for a short while after the

main supply is switched off so that any

interference is smoothed out.

Diodes D

14

and D15safeguard the

input of IC

1

against (too) high input

voltages in fault conditions.

The values of resistors R

54

and R

55

arrange the level of the compensating

current at not more than 1 µA, which is

sufficient to nullify the difference

between the base currents of T

1

and T2.

Regulation

Although current feedback has many

advantages, it also has a serious drawback: poor supply voltage suppression.

This makes it essential for the supply

voltage for the voltage amplifier to be

regulated. In view of the requisite high

symmetrical potential and the fact that

the unregulated voltage that serves as

input voltage can vary substantially

under the influence of the amplifier

load, two discrete low-drop regulators,

T

43–T47

and T48–T52are used.

As mentioned before, owing to

inevitable losses through potential

drops, the supply voltage for the input

section and cascode amplifiers needs to

be higher than the main ±70 V line.

Furthermore, the input voltage to the

regulators must be higher than the

wanted output voltage to ensure effective regulation.

Fortunately, the current drawn by

the voltage amplifier is fairly low

(about 70 mA) so that the input voltage

to the regulators can be increased with

a simple auxiliary supply as shown in

Figure 3. This consists of two small

mains transformers,two bridge rectifiers, D

1–D4

and D5–D8, and the neces-

sary reservoir and buffer capacitors.

The ±15 V output is linked in series

with the ±70 V line to give an unregulated voltage of ±85 V.

The 39 V reference is provided by

zener diode D

9

. This means that the

regulator needs to amplify the reference voltage ×2 to obtain the requisite

output voltage.

The zener diode is powered by cur-

rent source T

43

, to ensure a stable reference, which is additionally buffered

by C

30

.

Differential amplifier T

45-T46

, whose

operating point is set by current source

T

44

, compares the output voltage with

the reference via potential divider

R

63-R64-P4

. This shows that the output

voltage level can be set with P

4

.

Transistor T

47

is the output stage of

the regulator. The output voltage

remains stable down to 0.2 V below the

input voltage.

63

Elektor Electronics 2/99

Current-feedback

In an amplifier using voltage feedback (Figure a), the differential voltage at its inputs is multiplied by the open-loop

amplification. The feedback loop forces the output voltage to a level that, divided by network R

1-R2

, is equal to the

input voltage.

Whereas an amplifier with voltage feedback has high-impedance inputs, an amplifier with current feedback (Figure

b) has an high-impedance and a low-impedance input. Its input stage consists of a buffer with unitary gain between

the inverting and non-inverting inputs. Essentially, the inverting input is the low-impedance input. The buffer is followed by an impedance matching stage that converts the output current of the buffer into a directly proportional output voltage.

The current feedback loop operates as follows. When the potential at the non-inverting input rises, the inverting input

will also rise, resulting in the buffer current flowing through resistor R

1

. This current, magnified by the impedance

matching stage, will cause the output

voltage of the amplifier to rise until the

output current flowing through resistor R

2

is equal to the buffer current through R1.

The correct quiescent output voltage can

be sustained by a very small buffer current. The closed-loop amplification of the

circuit is determined by the ratio

(1+R

2

):R1.

A interesting property of an amplifier

with current feedback is that the closedloop bandwidth is all but independent of

the closed-loop amplification, whereas

that of an amplifier with voltage feedback

becomes smaller in inverse proportion to

the closed-loop amplification – a relation

known as the gain-bandwidth product.

Contents

U

in

A(s)

ab

U

out

U

in

R2

R1

R2

A

= 1 +

v

R1

R1

R(s)

A

=1

v

I

R2

A

= 1 +

v

R2

R1

990001 - 14

U

out

Page 7

65

Elektor Electronics 2/99

Resistor R57and diode D8protect T

43

against high voltage during switch-on,

while D

10

prevents current flowing

through the regulator in the wrong

direction.

Capacitors C

31

and C32enhance the

rate of operation of the regulator.

Network R

56-C28-C29

provides

additional smoothing and r.f. decoupling of the ±85 V lines.

NEXT MONTH

Next month’s second and concluding

instalment of this article will describe

details of the protection circuits, the fan

control, and the construction of the

amplifier. The instalment will also

include detailed specifications and performance characteristics.

[990001-1]

Contents

Page 8

Elektor Electronics 3/99

SIX FUNCTIONS

The integrated protection network consists of six sub-circuits:

• power-on delay

• transformer voltage sensor

• temperature sensor

• current sensor

• direct-current sensor

• overdrive sensor

The power-on delay ensures that the

relays in the amplifier are energized

50–100 milliseconds after the supply

has been switched on to prevent

switch-on clicks.

The transformer voltage sensor

reacts to the cessation of the secondary

voltage of the mains transformers to

prevent switch-off clicks and crackles.

The temperature sensor responds to

excessive heat sink temperatures, but it

should be noted that this works only in

This second of four

parts deals primarily

with the protection

network incorporated

in the amplifier. This

indispensable net-

work safeguards the

amplifier and the

loudspeakers con-

nected to it against all

kinds of error that

may arise. The net-

work is an indepen-

dent entity with its

own power supply.

32

Design by T. Giesberts

Titan 2000

Part 2: protection network

INTRODUCTION

As mentioned briefly in Part 1, extensive and thorough protection is a must

in an amplifier of this nature. It may

well be asked why this is so: is there

such a likelihood of mishaps arising?

Or is the amplifier so vulnerable? On

the contrary: extended tests on the

prototype have shown that the Titan

2000 is a very stable and reliable piece

of equipment. In fact, unusual means

had to be used to actuate the protection circuits during these tests, since

not any standard test prompted the

amplifier into an error situation.

The extensive protection is necessary because by far the largest number

of mishaps occur owing to actions by

the user, not because of any shortcomings in the amplifier. For example, the

most robust and reliable amplifier can

not always cope with extremely high

overdrive or overload conditions.

Correction. In last month’s first part

of this article, it was stated erroneously that the article consists of

two parts, whereas in fact it will be

described in four parts.

AUDIO & HI-FI

Contents

Page 9

conjunction with the fan drive, which

is reverted to later in this article.

The current sensor monitors the

output current, while the direct-current and overdrive sensors form a

combined circuit that monitors differences between the input and output

signals, and reacts to excessive directcurrent levels or distortion. This circuit

is the most important and ‘intelligent’,

but also the most complex of the six.

All sensors, when actuated, react in

the same way: they cause the output

relays and the mute relay at the input

of the amplifier to be deenergized

immediately. This action causes the

input signal and the

output load to be disconnected from the

amplifier. After the fault

causing the sensor

action has been

removed or remedied, the relevant

protection circuit is disabled, whereupon the amplifier relays are reenergized after a short delay.

When the protection network is

actuated, a red LED lights to indicate

an error. When the fault has been

removed or remedied, the red LED

remains on, but a yellow LED flashes

to indicate that the amplifier will be

reenabled shortly. The red LED then

goes out, shortly followed by the yellow, whereupon a green LED lights to

indicate that all is well.

COMMON SECTION

AND POWER

- ON DELAY

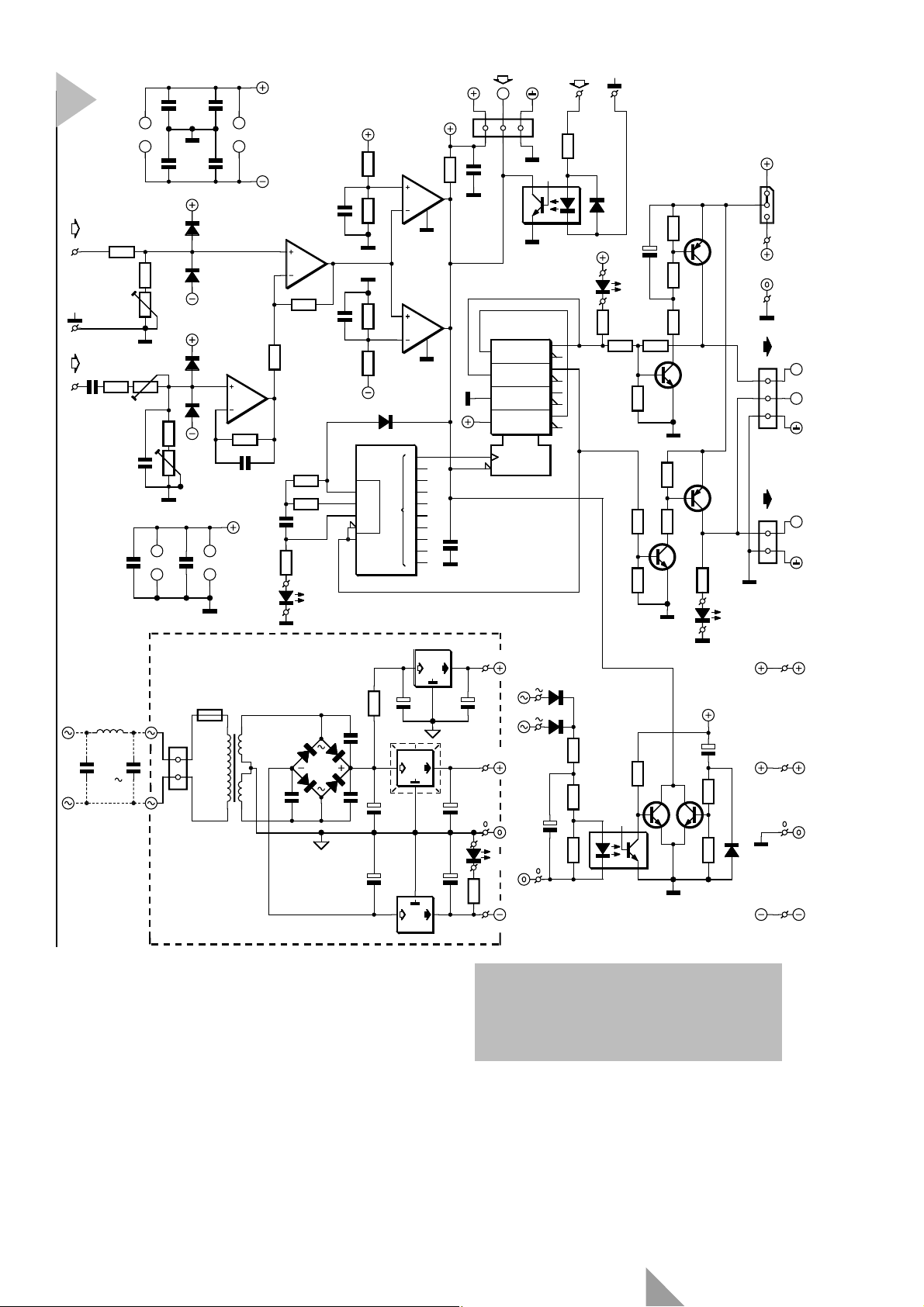

The circuit of the integrated protection

network, including the +5 V and ±12 V

power supplies, is shown in Figure 4.

33

Elektor Electronics 3/99

V

V

4

Figure 4. The protection network consists of six sensor circuits each of which

causes the input and output relays of

the amplifier to be deenergized when a

fault occurs.

Contents

LSP

input

C1

100n

R1

R5

680Ω

30µH

2x 100n

250V

100k

IC1

P2

C2

C16

100n

8

4

500Ω

R2

1k05

1n

16

IC3

P1

250Ω

8

C12

100n

C13

100n

R6

820k

K4

P3

500k

12V

12V

12V

12V

C17

100n

C14

100n

C15

100n

D1

2x

BAT82

D2

D3

2x

BAS45A

D4

16

IC4

8

F1

50mA T

Tr1

3

2

5V

2x 15V

8VA

IC2

IC1a

R7

11

6

1M

12V

12V

C3

100n

IC1 = OP249GP

IC2 = LM319

5

IC1b

6

R4

10k0

R3

10k0

1

R14

2M2

R13

470k

C7

470n

R15

1k

D6

EARLY

B80C1500

C26

47n

temp

I

11

12

13

IC2a

IC2b

3

4

5

6

7

8

9

5V

R12

C6

2k2

100n

12

3

7

8

4

5

12

13

5V

7

5

4

6

14

13

15

1

2

3

C8

100n

9

1

12V

R8

47k

4

R9

C4

100n

7

C5

100n

11

10

9

12

12V

RCX

RX

CX

CT=0

IC3

470Ω

R10

470Ω

R11

47k

CTR14

!G

D5

+

5

9

10

1N4148

CT

74HC4060

IC4

74HC175

1D

C1

R

5

4

K1

IC5

4N35

R16

4k7

126

D7

R19

47k

R24

47k

47k

R25

R20

2M7

C9

4µ7

63V

R23

4k7

2k2

R22

R21

2k2

T1

BC

R27

4k7

4k7

R26

T3

BC

547B

547B

T2

T4

R28

BD

140

BD

140

3k9

D9

ON

1N

4148

5V

D8

ERROR

R17

1k

2

3

7

6

10

11

15

14

R18

47k

Vre

12V

JP1

Vre Ext.

K2

K3

int

ext

2R

1R

mute

IC9

12V

+5V

5V

+5V

+12

+12V

4µ7

C18

4µ7

63V

C19

4µ7

63V

C22

63V

+12V

+5V

D13

R35

3k3

+5V

+12V

POWER

50V

50V

D10

D11

C10

10µ

63V

2x

1N4007

R32

15k

R31

15k

R30

3k3

IC6

126

4N35

R29

47k

5

4

5V

C11

47µ 25V

BC

547B

R34

T6

100k

R33

D12

100k

1N4001

T5

2x

7805

R36

C23

22Ω

47µ

C20

1000µ

25V

C21

470µ

25V

25V

IC7

7812

IC8

C24

47n

B1

C25

47n

7912

–12V

–12V

–12V

12V

–12

990001 - 2 - 11

Page 10

The network is linked to the input

and output of the amplifier via terminals ‘input’ and ‘LSP ’ respectively (to

terminals ‘P-IN’ and ‘P-LS’ on the

amplifier board).

Terminals ‘50 V≈’ are connected to

the secondary windings of the mains

transformers.

The three output relays and the

mute relay in the amplifier are linked

to the protection network via K

2

, and

K

3

respectively.

The current sensor is connected to

the output of optoisolator IC

2

in the

amplifier (‘I->’ on the amplifier board)

via K

1

.

The terminals marked ‘temp’ are

intended to be linked to the output of

the fan control circuit.

As mentioned earlier, the action of

each sensor results in the deenergizing

of the output and mute relays in the

amplifiers. This implies that the outputs of the the various sensor circuits

are interlinked. This is effected by combining the open-collector outputs of

these circuits into a wired OR gate with

R

12

functioning as the common pullup resistance. The combined output

signal serves to reset a number of

34

Elektor Electronics 3/99

-12V

~

~

Parts lists

Protection network

Resistors:

R

1

, R33, R34= 100 kΩ

R

2

= 1.05 kΩ

R

3

, R4= 10.0 kΩ

R

5

= 680 Ω

R

6

= 820 kΩ

R

7

= 1 MΩ

R

8

, R11, R18, R19, R24, R25, R29= 47 kΩ

R

9

, R10= 470 Ω

R

12

, R21, R22= 2.2 kΩ

R

13

= 470 kΩ

R

14

= 2.2 MΩ

R

15

, R17= 1 kΩ

R

16

, R23, R26, R27= 4.7 kΩ

R

20

= 2.7 MΩ

R

28

= 3.9 kΩ

R

30

, R35= 3.3 kΩ

R

31

, R32= 15 kΩ

R

36

= 22 Ω

P

1

= 250 Ω, multiturn preset (upright)

P

2

= 500 Ω, multitun preset (upright)

P

3

= 500 kΩ, multiturn preset (upright)

Capacitors:

C

1

, C3= 0.1 µF

C

2

= 0.001 µF

C

4

, C5, C6, C8, C12–C17=0.1 µF,

ceramic

C

7

= 0.47 µF

C

9

, C18, C19, C22= 4.7 µF, 63 V, radial

C

10

= 10 µF, 63 V, radial

C

11

, C23= 47 µF, 25 V, radial

C

20

= 1000 µF, 25 V, radial

C

21

= 470 µF, 25 V, radial

C24–C26= 0.047 µF, ceramic

Semiconductors:

D

1

, D2= BAT82

D

3

, D4= BAS45A

D

5

, D7= 1N4148

D

6

, D8, D9, D13= 3 mm high-efficiency

LED

(yellow, red, green, green respectively)

D10, D11= 1N4007

D

12

= 1N4001

T

1

, T3, T5, T6= BC547B

T

2

, T4= BD140

Integrated circuits:

IC

1

= OP249GP (Analog Devices)

IC

2

= LM319N

IC

3

= 74HC4060

IC

4

= 74HC175

IC

5

, IC6= 4N35

IC

7

= 7812

IC

8

= 7912

IC

9

= 7805

Miscellaneous:

JP

1

= 2.54 mm pin strip and pin jumper

K

1

, K2= 3-way terminal block, pitch

5mm

K3= 2-way terminal block, pitch 5 mm

K

4

= 2-way terminal block, pitch 7.5 mm

B

1

= bridge rectifier, rectangular, Type

B80C1500

F

1

= fuse, 50 mAT and fuse holder

Tr

1

= mains transformer, 15 VA, with

2×15 V secondary

Heat sink (for IC

7

) = e.g. Fischer

SK104, 50 mm

Mains interference filter

Figure 5. The printed-circuit

board of the overall protection network.

Contents

+12V

0

+5V

D8

+5V

0

Vre

ext

int

+12V

D9

H8

H7

H4

C11

H3

C18

T5

C19

C22

R34

R25

JP1

R28

mute

R17

R24

IC8

IC7

R33

T3

K3

T6

D12

R26

C8

C21

C20

IC6

R18

R27

IC9

C26

T4

R29

R21

R35

B1

R20

C23

IC4

T1

R30

R22

C25

C24

R36

C10

C17

T2

R19

R31

R23

C9

R32

IC3

D13

TR1

~

~

0

R2

D10

D11

C13

C16

D1

R4

R13

R14

C12

C7

C5

D5

R15

IC2

R8

C15

C14

0

T

K2

D6

2R

I

P1

D2

D4

IC1

C3

D3

R3

R10

R9

R11

R12

-12V

+

K1

IC5

R16

C6

T

R1

R6

R7

R5

D7

temp

K4

F1

C4

H5

50mAT

H6

H2

LSP

P3

T

input

C1 C2

P2

990001-2

990001-2

(C) ELEKTOR

H1

990001-2

(C) ELEKTOR

Page 11

D-type bistables (flipflops), contained in

IC

4

, which are interconnected to form a

shift register. Note that D-type bistables

are essential since these can be set and

reset in a defined manner.

The outputs of IC

4

are used to drive

two level converters, T

1-T2

and T3-T

4

respectively, which bridge the difference between the 5 V level of the logic

ICs and the 12 V supply for the relays.

Jumper JP

1

enables a different, external

supply voltage (V

RE

) to be used if 12 V

relays are not employed.

Transistors T

1

and T2drive Re1and

Re

2

, which are the first to be energized

(synchronously). On switch-off, capacitor C

9

ensures that T2remains on for

some milliseconds longer during

which period Re

3

and Re4are deener-

gized (see Part 1).

The power-on delay, which also

operates after a fault situation, is more

complex than usual. To start with, after

the supply voltage us switched on,

input CLR of IC

4

is held low (active)

for a few seconds by the circuit around

T

6

. When, after this period, CLR is

made high by R

12

–which happens

only when there is no error situation

(any longer)–the internal oscillator of

IC

3

is enabled via D5. This results after

a few seconds in a clock pulse appearing at the CLK input of IC

4

, where-

upon Q

4

goes high. The period

between the oscillator being enabled

and the appearance of

the first clock pulse is

not defined since,

owing to the presence

of T

6

, a power-on reset is purposely not

provided. To ensure a minimum delay

in the energizing of Re

1

and Re2in

spite of this, a high level is clocked into

Q

4

after IC3has been enabled. The precise moment at which this happens

varies, therefore, only when the supply

voltage is switched on for the first time.

A period of IC

3/Q3

later, Q1of IC

4

goes high, whereupon Re1and Re2are

energized. After another period, Q

2

of

IC

4

becomes high, whereupon Re3and

Re

4

are energized. At the same time,

IC

3

is disabled since its reset is inter-

linked with Q

2

of IC4.

The red LED, D

8

, in parallel with Q

1

of IC4lights when the relays in the

amplifier are not energized, either

because the amplifier is (not yet)

switched on, or owing to an error .

The yellow LED, D

6

, is linked to the

output of the oscillator in IC

3

, causing

it to flash until IC

4

is clocked.

The green LED, D

9

, is connected in

parallel with Re

3

and Re4, so that it

lights only when the amplifier is fully

switched on.

TRANSFORMER

VOLTAGE SENSOR

The 50 V≈ secondary voltages of the

mains transformers in the amplifier are

rectified by diodes D

10

and D11, and

smoothed by R30-R31-R32-C10. The values of these components ensure that

the LED in optoisolator IC

6

lights sufficiently to hold the associated photo

transistor on. This transistor pulls the

base of T

5

to ground, causing T5to cut

off. When the secondary voltages fail,

T

5

is switched on immediately via R29,

whereupon the D-type bistables in IC

4

are reset.

Use is made of an optoisolator purposely to avoid any risk of earth loops

between the supply return and the

ground of the protection network,

which is linked to the input ground of

the amplifier.

TEMPERATURE SENSOR

The temperature sensor works in a

manner similar to that of the transformer voltage sensor . The optoisolator

in this circuit is IC

5

, which, in contrast to

IC

6

, is normally cut off and comes on

only when the heat sink becomes

excessively hot.

The sensor reacts to the fan control

circuit switching the fan speed to maximum (because the heat sink is getting

too hot). A comparator in the fan control circuit then toggles, whereupon

IC

5

is actuated via the ‘temp’ input and

resets the D-type bistables in IC

4

. This

situation changes only after the heat

sink has cooled down to an acceptable

temperature (although the fans may

still be rotating).

CURRENT SENSOR

To nullify high common-mode voltages

and to prevent any risk of earth loops,

the current sensor also uses an optoisolator, IC

2

(Figure 5). However, this is

not located on the protection board,

but directly at the output of the amplifier.

The values of the relevant components cause the sensor to be actuated

when the output current is about 40 A.

This may appear a very large current,

but this is due entirely to the specified

requirement that the amplifier must be

capable of delivering 60 V into a load

of 1.5 Ω without the protection circuit

being actuated. The current level may

be lowered to some extent by increasing the value of R

74

in the amplifier.

Output resistor R

78

is in parallel

with R

12

by linking terminals ‘I’, ‘+5 V’

and ground on the amplifier board to

K

1

on the protection board via three

lengths of insulated, stranded circuit

wire twisted together. This arrange-

35

Elektor Electronics 3/99

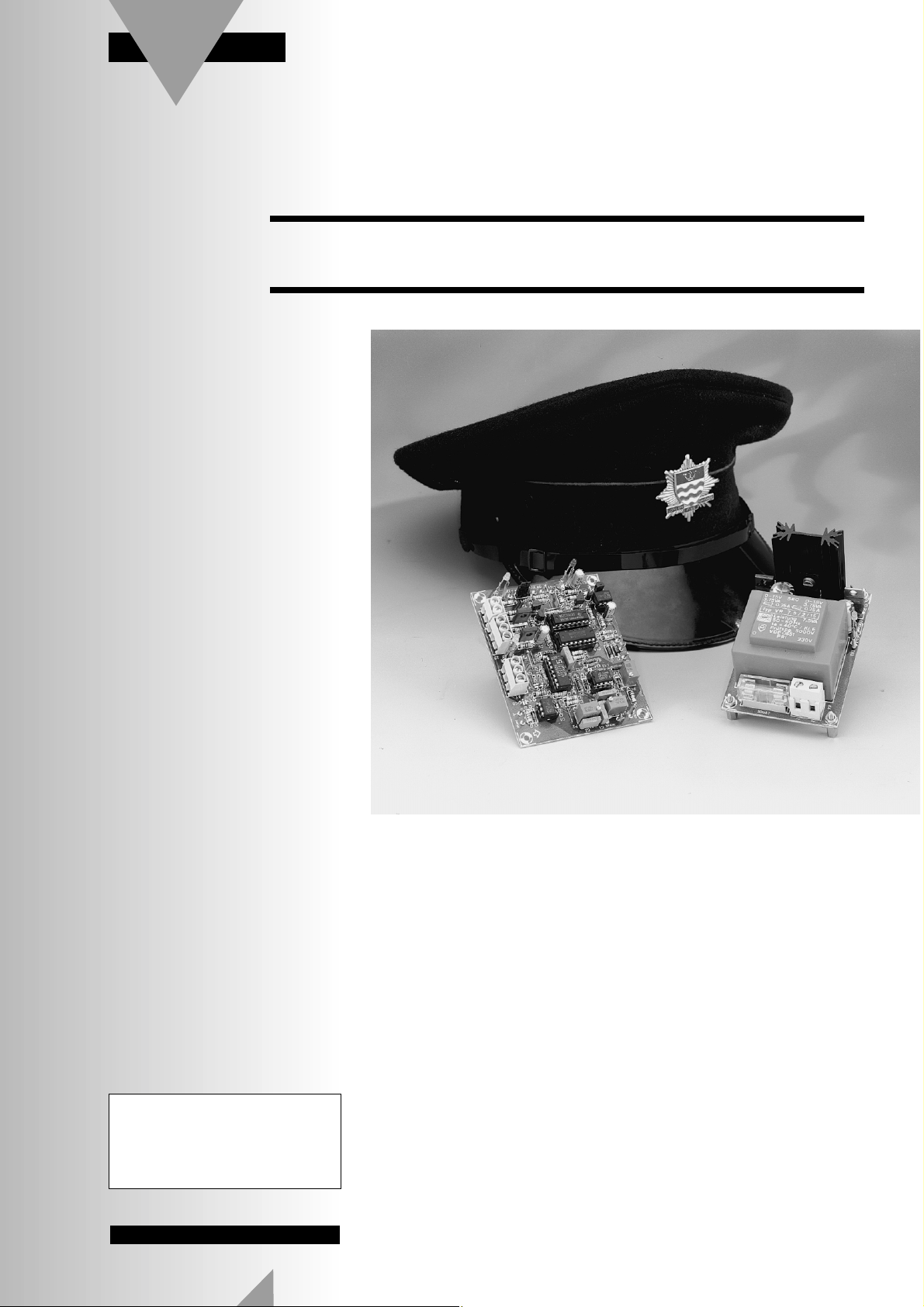

Figure 6. Completed prototype of the protection

network.

Contents

Page 12

37

Elektor Electronics 3/99

ment ensures a low impedance to any

interference and a high reaction speed.

DIRECT- CURRENT AND

OVERDRIVE SENSOR

The d.c. and overdrive sensor constantly compares the input and output

signals of the amplifier and reacts

when the difference between the two

is too great. The comparison is effected

with the aid of operational amplifier

IC

1

which has a very low bias current

and a very low offset. It is, of course,

essential that during the comparison of

the two signals by differential amplifier

IC

1b

the differences in phase and transit times do not lead to error detection.

At the same time, the voltage amplification (×43) of the amplifier must be

taken into account.

The amplification is compensated

by potential divider R

1-R2-P1

at input

LSP. The potentiometer is a multiturn

type to ensure accurate adjustment.

The phase difference is compen-

sated by the circuit based on IC

1a

. The

transit at high and low cut-off points

is simulated by first-order networks

that can also be adjusted very accu-

rately with multiturn potentiometers P

2

and P3.

The inputs of IC

1a

and IC

1b

are protected by diodes. Since any

leakage current of these diodes, combined with the high input impedance

(≈ 1MΩ) of IC

1a

, might lead to an

appreciable offset, and therefore to an

unwanted error detection, the diodes,

D

3

and D4, are special types with a

leakage current of only 1 nA.

The output of differential amplifier

IC

1b

is monitored by a window com-

parator formed by IC

2a

and IC2b. The

value of the components used in

potential dividers R

8-R9

and R10-R

11

ensures that the protection circuit is

actuated when the direct voltage

reaches a level of ±5 V or the distortion

becomes 2.5 per cent. Such distortion

will normally be the result of overdrive, but the circuit reacts equally well

to oscillations or other spurious signals

that cause too large a difference to be

detected.

CONSTRUCTION AND

SETTING UP

The integrated protection network is

best built on the printed-circuit board

shown in Figure 5. Populating this

board should not present any undue

difficulties, but it should be noted that

diodes D

6

, D8, D9and D13, are not

located on the board, but are linked to

it via flexible, stranded circuit wire.

They are fitted to the front of the enclosure.

Jumper JP

1

will normally be in position ‘intern’ unless relays with a coil

voltage other than 12 V are used.

A prototype of the completed pro-

tection board is shown in Figure 6.

All input and output terminals of

the board are clearly marked with the

same symbols as shown in Figure 4.

Most interconnections can be made in

thin, stranded hook-up wire to

DEF61-12, but the input and output

links (‘input’ and ‘LSP’) must be

screened audio cable.

Although the power supply for the

protection network can be fitted on the

same board, the relevant section may

be cut off and fitted elsewhere. Of

course, the supply lines must then be

linked to the relevant terminals on the

protection board via insulated,

stranded hook-up wire.

The power supply is straightforward. From the secondary output of

the specified mains transformer, Tr

1

, a

symmetrical ±12 V supply is obtained

with the aid of regulators IC

7

and IC8.

From the same secondary, a +5 V supply for the digital circuits is obtained

with the aid of regulator IC

9

. Since the

relays are fed by the +12 V line, regulator IC

7

must be fitted on a heat sink.

To ensure that the protection network is not actuated by interference on

the mains supply , it is advisable to precede the power supply by a suitable

noise filter. This may be made from a

30 µH choke and two 0.1 µF, 300 V≈

capacitors as shown in dashed lines in

Figure 4.

The network is set up by maximizing the common-mode suppression

7

Parts lists

Auxiliary power supply

Resistors:

R

1

, R2= 1 MΩ

Capacitors:

C

1

, C2= 470 µF, 100 V, radial

C

3

, C4= 0.1 µF, 100 V, pitch 7.5 mm

Semiconductors:

D

1–D8

= 1N4007

Miscelleneous:

K

1

= 2-way terminal block, pitch 7.5

mm

K

2

= 3-way terminal block, pitch

7.5 mm

K

3

, K4= 2-way terminal block, pitch

5mm

Tr

1

, Tr2= mains transformer, 1.5 VA,

with 12 V secondart

F

1

, F2= fuse, 160 mAT, and fuse

holder

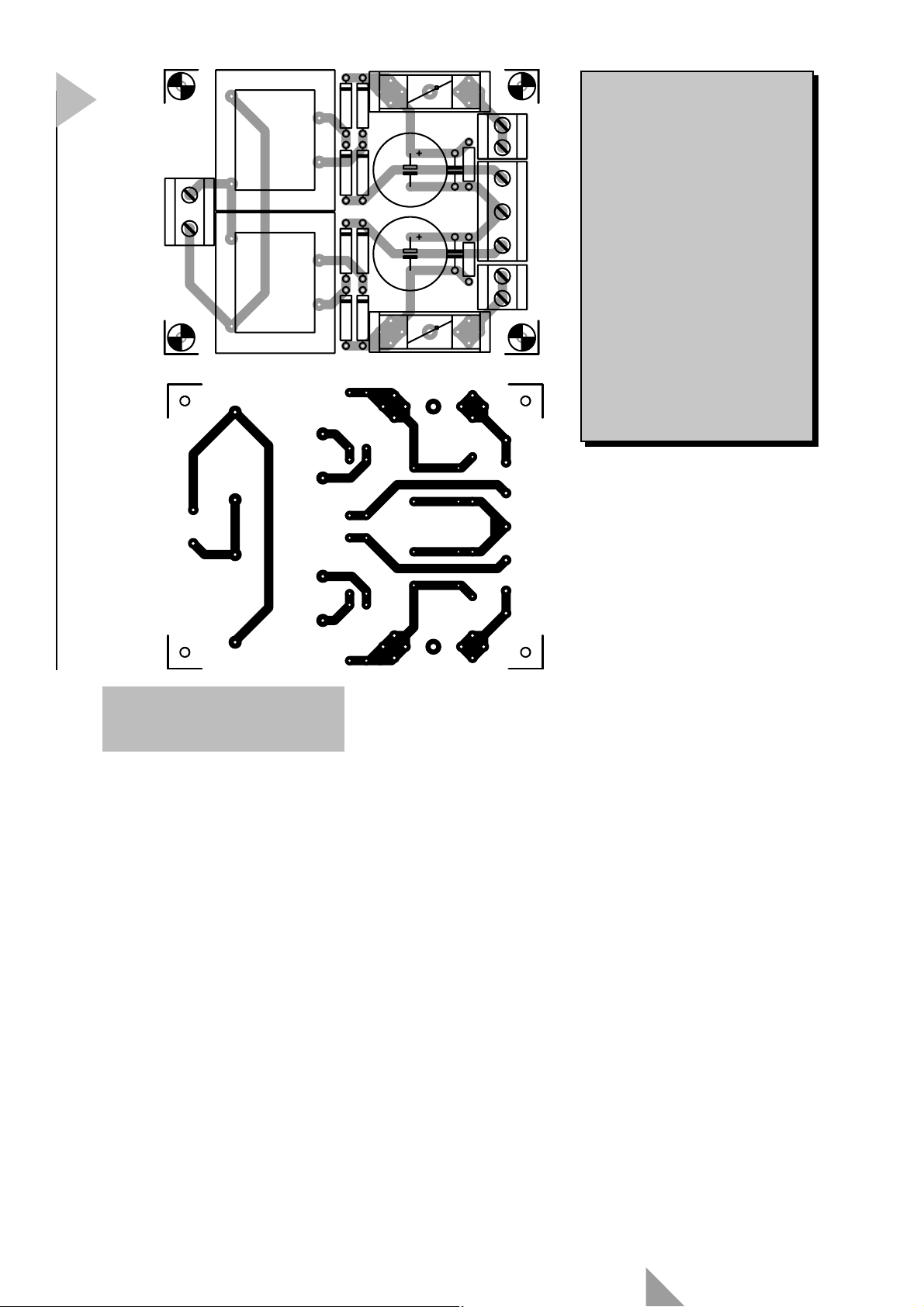

Figure 7. Printed-circuit board

for the auxiliary power supply

described in Part 1.

Contents

H1

990001-3

990001-3

(C) ELEKTOR

K1

~~

H2

(C) ELEKTOR

990001-3

TR1

TR2

H4

D1

D2

F1

0.16AT

C1

D3

D4

D5

D6

C2

F2

D7

D8

0.16AT

C3

+++

K2 K3K4 R1R2

C4

0

---

H3

Page 13

38

Elektor Electronics 3/99

9

with the aid of an oscilloscope or a

multimeter with sufficient bandwidth.

Measurements need to be made at

1 kHz, 20 kHz, and 20 Hz. The opencircuit amplifier is driven as far as possible by a suitable sine-wave generator

or CD player with a test CD.

With a signal of 1 kHz, set P

1

for

minimum sign al at the output of IC

1b

,

follow this with a signal of 20 kHz and

adjusting P

2

, and finally, with a signal

of 20 Hz, by adjusting P

3

. Since the settings influence one another to some

extent, the potentiometers should be

set a couple of times, perhaps also at

some different audio frequencies.

POWER SUPPLY

The auxiliary power supply described

in Part 1 is best constructed on the

printed-circuit board shown in Fig-

ure 7. The mains voltage is linked to

K

1

, the ±70 V to K2and the +85 V and

–85 V lines to K

3

and K4respectively.

Since all currents are low level, the

wiring may be made in thin, insulated,

stranded hook-up wire. A completed

prototype board is shown in Figure 8.

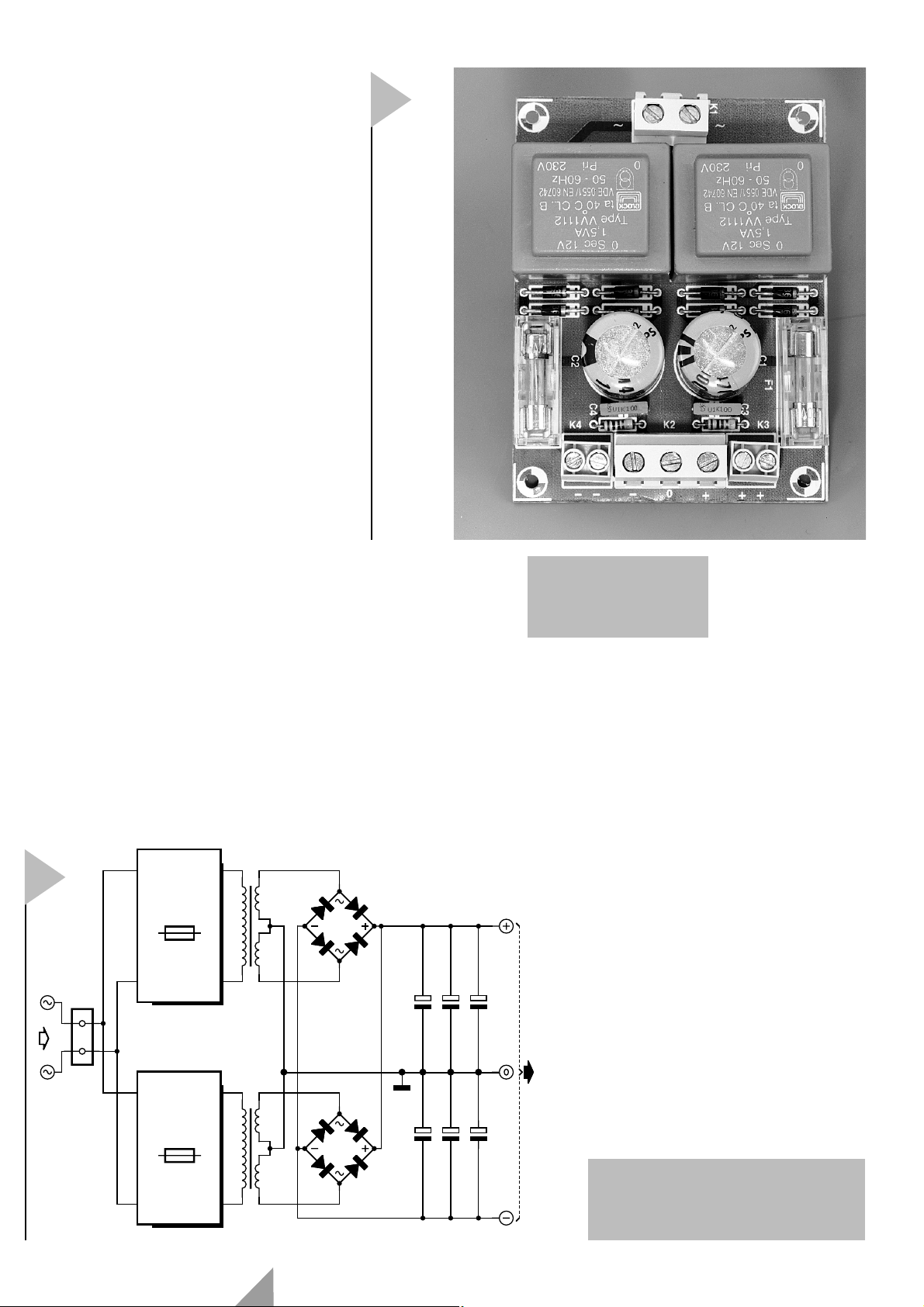

The main supply for the amplifier is

a straightforward, unregulated type,

providing an output of ±70 V. Its circuit diagram is shown in Figure 9.

Since the specified requirements

call for a 2 Ω load, the supply must be

rated at 1000 VA, which necessitates

two toroidal transformers. To prevent

unforeseen equalizing currents, the

dual secondaries are not linked in parallel, but are individually connected to

a bridge rectifier. The outputs of the

rectifiers can be connected in parallel

without any problem. The rectifiers

need to be mounted on a suitable heat

sink such as a Type SK01.

It should be clear that the wiring of

the power supply must

allow for the large output currents of the

amplifier. In the prototype, the electrolytic

capacitors are linked by 3 mm thick

strips of aluminium. The remainder of

the wiring should be in insulated,

high-current wire to BS6231 with a

conductor size of 50/0.25 mm (2.5 mm

2

)

or better. The use of car-type connectors is recommended.

Note that the power supply as

described is intended for use with a

mono(phonic) amplifier that can deliver

800 W into 2 Ω and

should remain stable

with loads of 1.5 Ω. If

you are certain that you will always

use 4 Ω or 8 Ωloads, the power supply

requirements may be relaxed to some

extent. A reasonable relaxation is the

use of 2×50V/300 VA transformers and

10,000 µF/100 V smoothing capacitors.

The rating of the primary fuses may

then be reduced to 1.5 AT.

MAINS

- ON DELAY

The use of a mains-on delay is recommended when heavy loads are to be

switched on, as in the case of the present amplifier. Such a delay circuit

switches on the mains to the load gradually to ensure that the switch-on current remains within certain limits and to

prevent the mains fuses from blowing.

The most recently published (in this

magazine) mains-on delay is found in

the July/August 1997 issue (p. 74),

whose circuit diagram is reproduced in

Figure 10. Its printed-circuit board is

readily connected with the primary

windings of the two mains transformers. The board is not available readymade, however, and its diagram is,

therefore, reproduced in Figure 11.

8

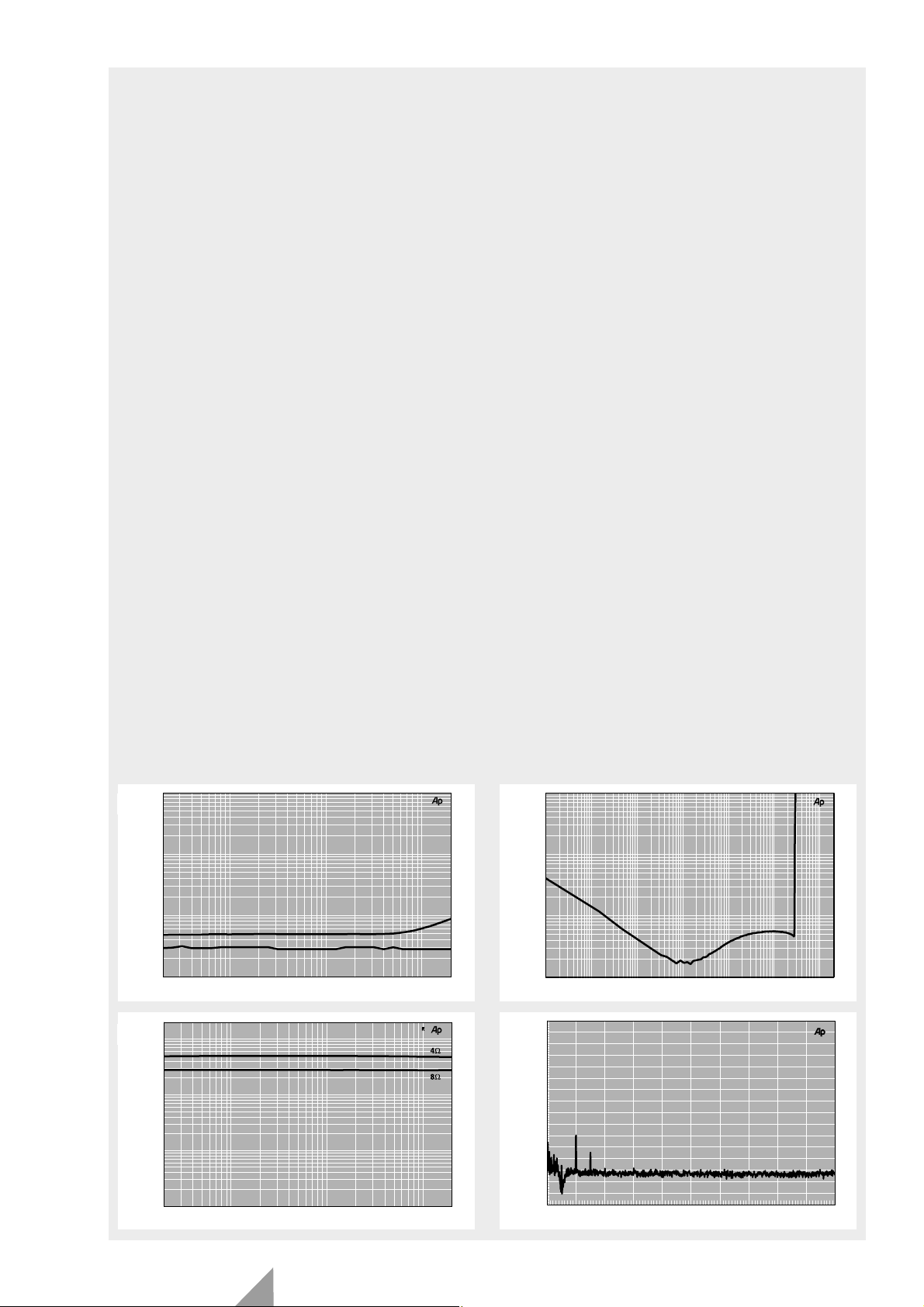

Figure 8. The auxiliary

power supply is small

enough to fit in most

enclosures.

Figure 9. The main power supply for

the amplifier is a heavy-duty entity

in which the six capacitors are particularly impressive.

Contents

mains

power-on

delay

2A5 T

e.g. 974078 - 1

mains

power-on

delay

2x 50V

500VA

2x 50V

500VA

200V / 35A

200V / 35A

6x 22000µ / 100V

70V

1000VA

e.g. 974078 - 1

2A5 T

990001 - 2 - 12

70V

Page 14

39

Elektor Electronics 3/99

The delay arranges for the load,

that is, the Titan 2000, to be switched

on in two stages. In the first of these,

the switch-on current is limited by

series network R

4–R7

. After the delay

determined by capacitors C

2

and C3,

the series network is shorted by a relay

contact, whereupon the full current

flows between K

1

and K2.

Relay Re

1

can switch up to 2000 VA.

Its supply voltage is obtained from the

mains with the aid of rectifier B

1

,

capacitor C

1

and resistor R3.

Since the amplifier power supply

uses two mains transformers, two

mains-on delay circuits are needed.

Fuse F

1

functions as a primary

mains fuse for the amplifier.

Capacitor C

1

is a metallized paper

type intended especially for use with

mains voltage applications.

Bear in mind that the circuit is

linked directly to the mains supply and

thus carries lethal voltages.

Next month’s third instalment of

this article deals with the construction

of the amplifier, a few other practical

matters, and some measurements.

[990001-2]

Figure 10. The mains-on delay ensures that the

switch-on current remains within certain limit. Two of

these delays are required for each Titan 2000.

Figure 11. Printed-circuit board for the mains-on delay

circuit, which is not available ready made.

Parts lists

Mains-on delay circuit

Resistors:

R

1

, R2= 470 kΩ

R

3

= 220 Ω

R

4–R7

= 10 Ω, 5 W

Capacitors:

C

1

= 0.33 µF, 300 V a.c.

C

2

, C3= 470 µF, 40 V

Miscellaneous:

K

1

, K2= 2-way terminal block, pitch

7.5 mm

B1= bridge rectifier, round, Type

B250C1500

Re

1

= relay, coil 12 V, 1200Ω; contact

rating 250 V, 8 A

F

1

= see text

10

11

Contents

R1

K1

470kR2470k

C1

330n

*

250V

zie tekst

*

see text

*

voir texte

*

siehe Text

*

F1

R3

220Ω

*

~

B1

C3

470µ

40V

Re1

B250C1500

Re1 = V23057-B0006-A201

(250V / 8A)

C2

470µ

40V

R4

10Ω

5W

R5

10Ω

5W

R6

10Ω

5W

R7

10Ω

5W

K2

974078 - 11

~~~~

H3

F1

K1

R4

C1

R2

H4

974078-1

R1

R3

974078-1

B1

C3

R5

R6

RE1

H2

OUT

K2

R7

C2

H1

974078-1

Page 15

Elektor Electronics 4/99

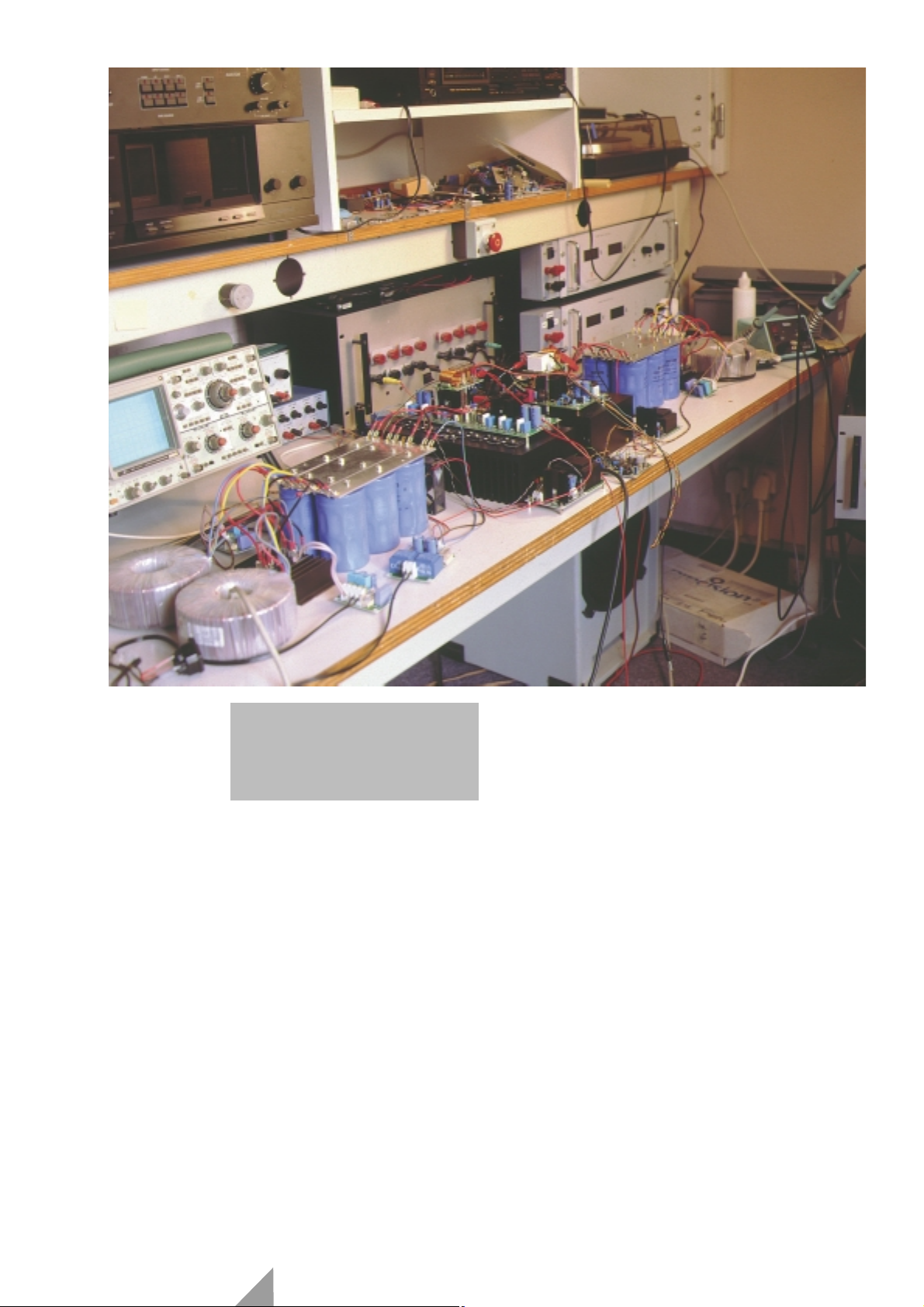

INTRODUCTION

It is clear from the first two parts of this

article that the Titan 2000 is a complex

unit that needs to be constructed and

wired up with with great care to

ensure the specified performance. For

that reason, the construction notes will

be more detailed than is usual with

projects in this magazine. It is assumed

that the protection network and auxiliary power supply have already been

built and tested.

MOTHER BOARD

It must be borne in mind that in the

case of a fast power amplifier like the

Titan 2000, with a gain/bandwidth

product of about 0.5 GHz, the board

must be an integral part of the circuit.

The mother board is therefore

designed together with the remainder

of the circuit. The length of the tracks,

the area of the copper pads, the positions of the decoupling capacitors, and

other factors, are vital for the proper

and stable operation of the unit. Constructors who make their own boards

are therefore advised to adhere strictly

to the published layout.

Owing to the power requirements,

the various stages are parallel configurations. When these are mounted on

the heat sinks, a fairly large parasitic

capacitances to earth ensue. This is

because for reasons of stability all seven

heat sinks must be strapped to earth. It

This third of four parts

deals primarily with

the construction of the

amplifier and ends

with a brief resume of

its performance and

specifications. Let the

constructor beware,

however: the Titan

2000 is not an easy

project and certainly

not recommended for

beginners in elec-

tronic construction.

40

Design by T. Giesberts

Titan 2000

Part 3:

construction and setting up

AUDIO & HI-FI

Contents

Page 16

41

Elektor Electronics 4/99

T13 T14

Parts lists

It is regretted that, owing to circumstances beyond our control, component codings in the various sections

have been duplicated. Consequently,

the mother board, protection network

board, and auxiliary power supply

board contain many components

with the same identification (R

1-R36

,

C

1-C26

, D1-D12, T1-T6, IC1-IC2, JP1,

K

1

).

Amplifier

Resistors:

R

1

, R53= 1 MΩ

R

2

= 562 Ω

R3= 47 kΩ

R4, R6, R12, R14, R60, R61, R69, R70=

22 Ω

R5, R62, R71= 330 Ω

R7, R34= 470 Ω

R8= 22.1 Ω

R9= 390 Ω

R10, R11= 470 Ω, 5 W

R13, R15= 1.00 kΩ

R16, R17, R38= 150 Ω

R18, R20, R58, R67= 270 Ω

R19, R21= 10 kΩ, 1 W

R22, R23= 3.3 kΩ, 1 W

R24–R29= 68 Ω

R30= see text

R31, R32= 22 kΩ

R33, R35= 220 Ω

R36, R37= 560 Ω

R39–R44= 10 Ω

R45–R52= 0.22 Ω, inductance-free

R54, R55= 4.7 MΩ

R56, R65= 15 Ω

R57, R63, R66, R72= 15 kΩ

R59, R68= 5.6 kΩ

R64, R73= 12 kΩ

R74, R76, R77= 100 Ω

R75= 33 Ω

R78= 2.2 kΩ

R79= 2.2 Ω, 5 W

P1, P4, P5= 4.7 kΩ (5 kΩ) preset

P2= 250 Ω, preset

P3= 500 Ω, preset

Capacitors:

C1= 2.2 µF, metallized polyester

(MKP)

C2, C3, C42= 0.001 µF

C4, C5= 0.0022 µF

C6, C7= 220 µF, 25 V, radial

C8, C9, C11, C12, C15= 0.1 µF

C10, C13= 100 µF, 25 V, radial

C14= see text

C16–C23= 100 pF, 100 V

C24= 1 µF, metallized polypropylene

(MKT)

C25= 0.68 µF

C26, C27, C32, C39= 2.2 µF, 63 V,

radial

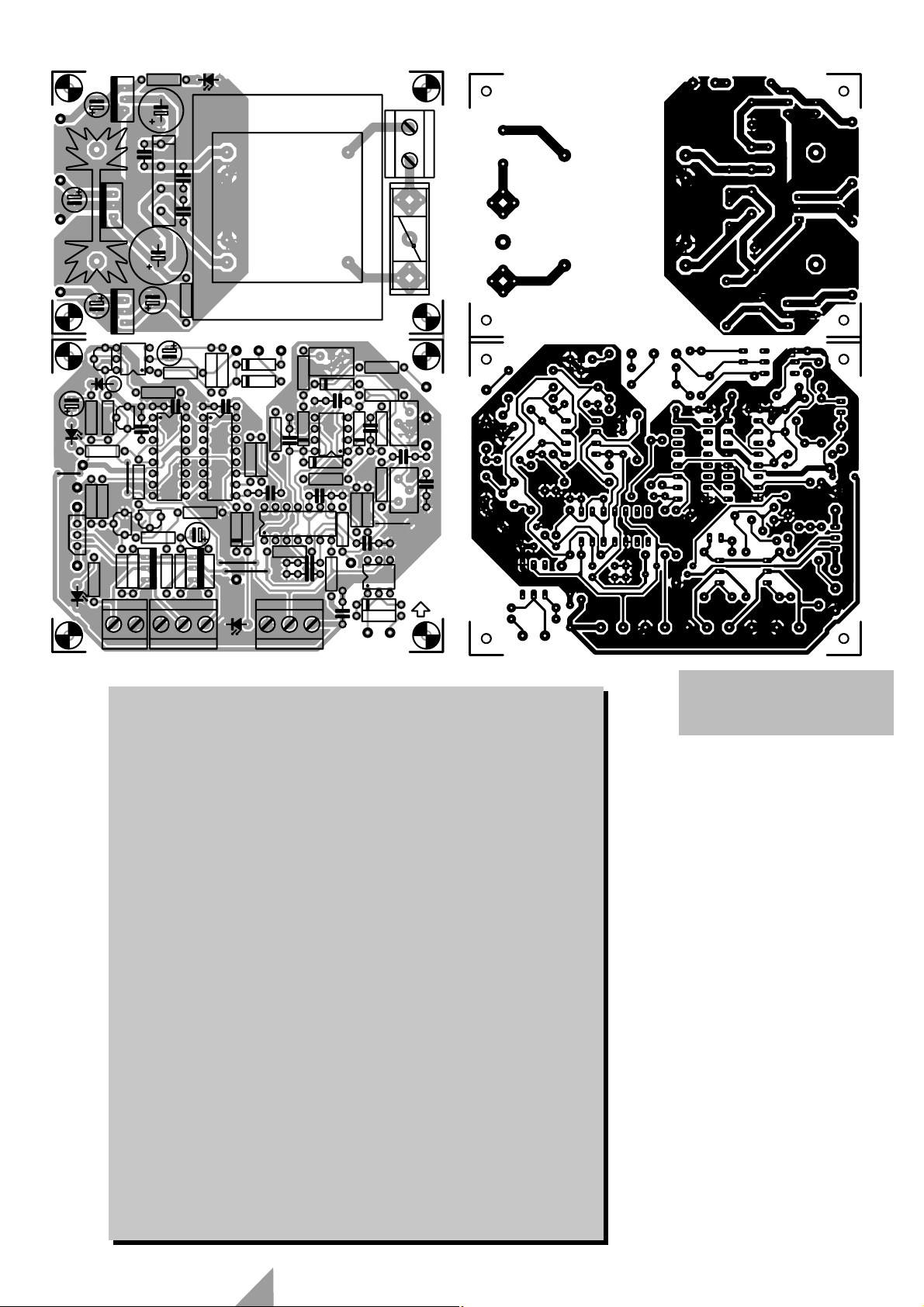

Figure 12. The double-sided printed-circuit board is intended to be combined with the

heat sink into a single entity. Before that can be done, however, the section for the output

relay and the inductor must be cut off the main section.

Contents

T

R79

T9

P4 P5

T10

H16

H15

H4

C8

R22 R23

H11 H12

D3

RE1

R1R2R3

P-IN

C11

H3

T49

T44

T

C10

LS+

C16

C9

mute

C18

R68

R59

C31

D4

D5

C25

R55

C2

D7

D6

C38

C32

R19

R54

R4

T1T2T3 T4

R6

C1

C13

C12

R21

C39

D11

D8

R58

R61

D2

R69

R70

R67

R60

1R

L1

K1

T

H14

D18D19

RE4

RE3

RE2

R13

LS-

C30

T43

D9

T45

R62

T47 T48

R63R64

C4

R18

R26

R16 R17

T11

C20

R57

T17

C33

T46

R25

C29

D10

T16

R24

C21

LS+

C17

T15

OUT2

T21T22T23

R56

990001-1

(C) ELEKTOR

C28

C34 C35

990001-1

H13

++

C43

C46

C44

R45

R49

H1

T35

T29

R39

T39

T32

R42

R46

-

R50

+

R47

R51

R48

R52

R38

R36

R40

R37

R43

R41

R44

T36

T30

T40

T37

T33

T41

T31

T38

T34

T42

H2

D16

P2

T7

R5

D1

T5

R12

P1

JP1

R14

T6

C7

R7

T8

C22

T12

C5

R15

R20

R29

R72R73

T52

T51

R71

D12

D17

P3

JP2

R27

C23

C19

R34

T18

C27

D15

IC1

D14

R53

LS+

C41

C42

+5V

R78

I

T27 T28

OUT1

P-LS

T

0 0

C47

H17H18

C45

R74

R75

C48

--

R77

R33

C15

R35

LS-

R11

T24T25T26

IC2

R76

R65

C26

C24

C6

R31 R32

R9

R8

C14

R30

C3

R10

T19

T20

R28

C40

D13

T50

C36

R66

C37

Page 17

42

Elektor Electronics 4/99

990001-1

Contents

(C) ELEKTOR

Page 18

is, of course, of paramount importance

that these capacitances are as small as

feasible. For this reason, it is vital that

in the thermal coupling of T

21–T34

1.5 mm thick ceramic—not mica—isolating washers are used. Mica washers

may , however, be used with the output

transistors since parasitic capacitances

there are of no significance.

The component and track layouts

of the mother board are shown in Fig-

ure 12. It will be seen that the board

consists of two sections: the mother

board proper and the output-relay

board. The latter must be cut off before

any other work is done. Later, when it

is built up, it is mounted on the mother

board with the aid of four 50 mm long

metal spacers in such a way that the

LS– and LS+ terminals on the two

boards are above each other. The spacers also provide the electrical link

between the boards.

The completed relay board is

shown in Figure 13. Inductor L

1

is

made from a doubled-up length of

1.5 mm enamelled copper wire wound

in two layers of eight turns each

around a 16 mm former (such as a

piece of PVC pipe). After the coil has

been wound, the PVC pipe is removed

and the four windings connected in

parallel. See Figure 14.

Ignoring the drivers and output

transistors for the moment, the construction of the mother board is traditional. As always, great care must be

taken during the soldering and placing

of components. Do not forget the thermal coupling of T

1-T3

, T2-T4, D1-T5,

D

2-T6

, T45-T46, and T50-T51, as already

pointed out in Part 1. Also, T

21–T23

and

T

24–T26

must be mounted on a heat

sink, and isolated from it by means of

a ceramic washer. When this is done, fit

the composite heat sinks on the board,

and link them to earth.

The input signal and the ±85 V

supply lines are linked to the board via

standard solder pins.

For connecting the ±70 V supply

lines and the relay board, 3 mm screw

holes are provided. Metal spacers are

to be fixed to these and cable connectors to the top of the spacers.

MAIN HEAT SINK

When the mother board has been completed, and carefully checked, as far as

described, it and the drivers and output transistors, T

27–T42

, must be

mounted on the main heat sink. This is

a 150 mm high Type SK157 from Fischer with a thermal resistance of

0.25 K W

–1

. This is admittedly a very

tedious job. It is vital that all requisite

fixing holes are drilled accurately in the

heat sink and preferably tapped with

3 mm thread. The template delivered

with the ready-made board is almost

indispensable for this work.

When the holes have been drilled

(and, possibly, tapped) transistors T

27

and T28should be fitted first (this is

important because they become inaccessible after the board has been fitted).

They must be located as close as possible to the output transistors and not in

the position indicated on the board.

Again, the template makes all this clear.

Their terminals must then be extended

with the aid of short lengths of equipment wire, which are later fed through

the relevant holes on the board and

soldered to the board via, for instance,

a three-way pin header.

The terminals of the drivers and

output transistors must be bent at right

angles: those of the former at the point

where they become thinner and those

of the latter about 5 mm from the body

of the device. When this is done, screw

all transistors loosely to the heat sink,

not forgetting the isolating washers. If it

is intended to use fan cooling, the requisite temperature sensor—that is, a

Type BD140 transistor— should also be

attached to the heat sink at this stage.

The template does not show a location

for the sensor, but it seems sensible to

fit it at the centre close to T

37

or T40.

The next step is to fit all ten spacers

to the heat sink: these should all be

10 mm long. In the prototype, spacers

with a 3 mm screwthread at one end

were used. Two of the spacers merely

provide additional support for the

relay board and another two form the

electrical link between the negative

supply line and the heat sink.

When all this work is done, the

board should look more or less like that

in Figure 15. Note that because of tests

later on, there are, as yet, no ceramic

isolating washers fitted on the prototype.

The next, and most tedious, step is

to combine the board and heat sink. It

is, of course, vital that all spacers are

exactly opposite the relevant fixing

holes and—even more tedious—that

the terminals of all transistors are

inserted into the correct mounting

holes. Bear in mind that the metal

43

Elektor Electronics 4/99

C28, C34, C35, C41= 470 µF, 100 V,

radial

C29, C33, C36, C40= 0.22 µF, 100 V

C30, C37= 47 µF, 63 V, radial

C31, C38= 0.015 µF

C43–C48= 0.1 µF, 630 V

Inductors:

L1= see text

Semiconductors:

D1, D2= LED, red, flat

D3, D18, D19= 1N4148

D4, D6= zener, 5.6 V, 500 mW

D5, D7= zener, 15 V, 1.3 W

D8, D11= zener, 30 V, 1.3 W

D9, D12= zener, 39 V, 1.3 W

D10, D13, D16, D17= 1N4004

D14, D15= zener, 12 V, 500 mW

T1, T4, T5, T15–T17= BC560C

T2, T3, T6, T18–T20= BC550C

T7, T8, T43, T48= BF245A

T9= BF871

T10= BF872

T11, T50, T51= BC640

T12, T45, T46= BC639

T13, T14= BF256C

T21–T23= MJE350

T24–T26= MJE340

T27= BD139

T28= BD140

T29–T31= 2SC5171 (Toshiba)

T32–T34= 2SA1930 (Toshiba)

T35–T38= 2SC5359 (Toshiba)

T39–T42= 2SA1987 (Toshiba)

T44, T49= BF256A

T47= BD712

T52= BD711

Integrated circuits:

IC1= OP90G

IC2= 6N136

Miscellaneous:

JP1, JP2= 2.54 mm, 2-way pinstrip

and pin jumper

K1= 3-way terminal block, pitch 5 mm

Re1= relay, 12 V, 600 Ω

Re2–Re4= relay, 12 V, 16 A, 270 Ω

Heat sink for T21–T26= 38.1 mm,

11 K W–1(Fischer Type SK104-STC;

TO220)

Heat sink for drivers/output transistors,

150 mm, 0.25 K W–1, Fischer Type

SK157

Ceramic isolation washers for T21–T34:

Fischer Type AOS220

Mica isolating washers for T35–T

42

PCB Order no 990001-1 (see Readers

Services towards end of this magazine)

Contents

Page 19

spacers for linking –, +,

LS+, and LS–, are

already on the board.

As the terminals of the

output transistors are

slightly longer than

those of the drivers, it may be possible

to do this work in two stages: output

transistors first and drivers second. It

may prove necessary to turn one or

more of the transistors slightly, which

is the reason that the fixing screws

have not yet been tightened. When all

terminals are correctly inserted, these

screws must, of course, be tightened

firmly.

The final step is to fix the relay

board on the spacers that form the link

for the LS– and LS+ terminals.

SETTING UP

Before the amplifier module can be

taken into use, presets P

2–P5

must be

set as required. Preset P

1

is intended

only for possibly adjusting the balance

in case of a bridge configuration.

Start by turning P

3

(the quiescentcurrent control) fully anticlockwise and

P

2

, P4, and P5, to their centre position.

Check the outputs of the power supply

and auxiliary power supply and, if

these are correct, link the +70 V line to

pins ‘+’ and ‘0’, the –70 V line to ‘–’

and ‘0’, the +85 V line to ‘++’ and the

-85 V line to ‘--’. For absolute safety, link

the ±70 V lines temporarily via a 10 Ω,

5 W resistor.

Next, set P

4

and P5for voltages of

+78 V and –78 V respectively at the

cases of transistors T

47

and T52respec-

44

Elektor Electronics 4/99

Figure 13. Illustrating

how the relay board is

mounted on the

mother board with the

aid of spacers.