Tiso SpeedBlade T3.KCD.XV.X Series, T3.KCD.PV.1, T3.KCD.SV.1, T3.KCD.SV.2, T3.KCD.KV.2 Operation Manual

...Page 1

«TiSO-PRODUCTION» LTD

WAIST-HIGH TURNSTILE

«SpeedBlade»

Т3.КСD.ХV.X

OPERATION MANUAL

AUIA177 OM

2018

Page 2

2

CONTENTS

INTRODUCTION .................................................................................................................................. 3

1. DESCRIPTION AND OPERATION................................................................................................. 5

1.1 General Information and Designation ................................................................................ .... 5

1.2 Specifications....................................................................................................................... .... 6

1.3 Configuration and Scope of Delivery ................................................................................... .... 7

1.4 Design and operation ............................................................................................................ .. 10

1.5 Instrumentation, tools and accessories ................................................................................ .. 12

1.6 Description and operation of controllers as integral component of the turnstile.................. .. 12

2 INTENDED USE .............................................................................................................................. 18

2.1 Operation restrictions ........................................................................................................... .. 18

2.2 Layout and installation ........................................................................................................ .. 18

2.3 Preparation for use ................................................................................................................ .. 26

2.4 Contingency actions ............................................................................................................ .. 27

3 MAINTENANCE .............................................................................................................................. 28

3.1 General guidelines ................................................................................................................ .. 28

3.2 Safety Measures ................................................................................................................... .. 28

3.3 Maintenance procedure........................................................................................................ .. 28

4 ROUTINE MAINTENANCE ........................................................................................................... 29

4.1 Possible malfunctions ........................................................................................................... .. 29

4.2 Possible malfunctions ........................................................................................................... .. 29

4.3. “SpeedBlade” turnstile blade initialization procedure ......................................................... .. 30

4.3 Postrepair checkout .............................................................................................................. .. 32

5 TRANSPORTATION AND STORAGE .......................................................................................... 32

5.1 Turnstile storage ................................................................................................................... .. 32

5.2 Turnstile transportation......................................................................................................... .. 32

6 DISPOSAL ........................................................................................................................................ 32

7 MANUFACTURER'S WARRANTY AND TERMS OF WARRANTY MEAINTENANCE ........ 33

Annex А Overall and installation dimensions of the “SpeedBlade” type turnstile T3.KCD.XV.1 ..... 35

Annex B Control panel and connection diagram ................................................................................. 37

Annex C.1 Wiring diagram of the "SpeedBlade" type turnstile ........................................................... 39

Annex D.1 Diagram of the turnstile connection to access control system (ACS) ............................... 40

Annex D.2 Diagram of the turnstile connection to access control system (ACS) ............................... 41

Annex D.3 Diagram of the turnstile connection to fire alarm (FA) ..................................................... 42

Annex D.4 Diagram of the turnstile connection to control panel ....................................................... 43

Page 3

3

INTRODUCTION

This Operation Manual (hereinafter referred to as OM) covers the servo-operated waist-high

turnstile of “SpeedBlade" type (hereinafter referred to as the "turnstile"). The Operation Manual

contains information about design, specifications, installation for proper operation and

maintenance of the turnstile.

This Operation Manual is prepared in compliance with the specification requirements ТU U

31.6-32421280-004:2010.

The turnstile shall be serviced only by the qualified staff having the relevant class of permit

to work with electrical facilities with voltage up to 1000V and scrutinizing this Operation Manual,

obtaining safety instructions and trained for operation and maintenance of the turnstile. Reliability

and durability of the turnstile operation is provided with observation of modes and conditions of

transportation, storage, installation and operation. So, fulfillment of all requirements specified in

this document is mandatory.

The turnstile “SpeedBlade" can be installed either singly or in line. The single turnstile

includes two pedestals (left-hand and right-hand), each of which has one telescopic glass blade.

The turnstile row is provided by installation one more or a number of additional pedestals

equipped with glass blades from both sides reducing costs and saving space.

Depending on the purpose and design features of the turnstile, the following pattern of

reference designation is accepted:

T3. KCD. X V. Х

Floor-standing

X

Number (one and more) of

waist-high turnstile

turnstile access ways

Pedestal with servomotor

KC

Reciprocating mechanism

Double-blade

D

P

Polished stainless steel

S

Brushed stainless steel

K

Painted housing

Example of reference designation of single waist-high turnstile consisting of left-hand and

right-hand pedestals made of brushed stainless steel when the turnstile T3.КСD.SV.1 ТU U 31.632421280- 004:2010 is ordered.

Example of reference designation of double waist-high turnstile consisting of left-hand and

right-hand and one additional pedestals made of polished stainless steel when the turnstile

T3.КСD.РV.2 ТU U 31.6-32421280-004:2010 is ordered.

Due to regular improvement of the product its design can be modified without degradation

of the product features and quality not covered by this Operation Manual.

Page 4

4

WARNINGS TO THE CUSTOMER ON SAFE OPERATION

OF THE TURNSTILE

These warnings are designed for ensuring of safety during operation of the turnstile to

prevent violation of safety characteristics by improper installation or operation. These warnings

are aimed at drawing attention of the customer to safety problems.

GENERAL WARNINGS

The Operation Manual is an integral part of the product and it should be handed over to the

customer. The OM should be kept for later use and consulted for clarifications if required. If the

turnstile is resold, handed over to another owner or transported to another place, make sure that

the OM is enclosed to the turnstile to be used by new owner and/or maintenance staff during

installation and/or operation.

Safety measures and requirements specified in this in this OM must be observed:

– the turnstile must be connected to ground loop prior to operation;

– the turnstile should be connected to AC network with parameters specified in p.1.2

"Specifications";

– inspection, adjustment and repair should be performed only after the turnstile is

deenergized.

After the turnstile is purchased it should be unpacked and its integrity should be checked. In

case of doubt in integrity of the turnstile it should not be used and the customer shall refer to the

supplier or to the manufacturer.

Packing accessories (wooden pallet, nails, clips, polyethylene bags, cardboard etc.) as

potential sources of hazard must be removed to unacceptable place prior to proper use of the

turnstile.

As electric shock protection device the turnstile is related to 01 protection class according to

the GOST (State Standard) 12.2.007.0-75 and is not intended for operation in explosive and firehazardous areas by the “Electrical Installation Code”.

Using of the turnstile for unintended purpose, improper installation, nonobservance of

conditions of transportation, storage, installation and operation specified by this OM, may result in

damage to people, animals or property for which the manufacturer is not responsible.

Page 5

5

1. DESCRIPTION AND OPERATION

1.1 General Information and Designation

1.1.1 Purpose:

The motorized turnstile is designed for pedestrian movement control at access points of

industrial enterprises, banks, stadiums, administrative facilities etc. by access control system (from

magnetic card readers) or manually (from manual control panel).

Traffic flow capacity of the turnstile with personal identification is at least 30 persons per

minute in one direction

1.1.2 Dimensions and weight of the turnstile correspond to the values specified in Table 1.

Table 1

Designation of modification type

Dimensions, mm

Maximum

weight, kg

Н L В

Single

Double

Т3.КСD.PV.1

–

1000

1000

1480

233*

Т3.КСD.SV.1

Т3.КСD.KV.1

–

Т3.КСD.PV.2

2270

339*

Т3.КСD.SV.2

Т3.КСD.KV.2

* When the turnstile with more than two access ways is ordered :

B = 900 · Х + 290 · Y ,

where Х is the number of access ways;

Y – total number of the turnstile pedestrians, pcs.

900 и 500 – width of access way, mm;

290 – width of pedestal body, mm

Example of calculation of B size for Т3.КСD.PV.2 (Double turnstile): B = 900 +500 + 290 ·3= 2270

1.1.3 The turnstile component identification code is specified in Table 2.

Table 2

Description of the

turnstile component

Order code

Dimensions, mm

Maximum

weight, kg

Н L В

Additional pedestal

Т3.КСD.PV

Т3.КСD.SV

Т3.КСD.KV

1000

1000

290

120

Left-hand/right-hand

pedestal

100

1.1.4 The operation condition parameters according to GOST 15150-69 are specified in

Table 3.

Page 6

6

Table 3

Operation conditions

For climatic

modification

Parameter value

Ambient temperature

NF4

+ 1 to + 40 °С

Relative humidity

80 % at 20 ºС

Ambient temperature allowable

pressure

84 to 106,7kPa

Transportation temperature range

- 40 to + 50 °С

Storage temperature range

- 5 to + 40 °С

Group of mechanical application

NF4

L3

Altitude above sea level

up to 2000m

Environment

Explosion-proof, does not contain

current-conducting dust, aggressive

gases and vapours in concentration

destroying isolation and metals,

disturbing normal operation of the

equipment installed in turnstiles

Installation site

In enclosed spaces in the absence of

direct impact of precipitations and solar

radiation

Operating position

Vertical, deviation from vertical

position no more than 1º to any side is

tolerated

1.1.5 Reliability indices

– mean time to repair (without delivery time of spare parts, tools and accessories) –

at most 6 hours;

– mean time to failure – at least 1 500 000 accesses;

– mean service life between overhauls – at least 10 years

1.2 Specifications

Key parameters of the turnstile are specified in Table 4..

Table 4

Parameter description

Unit measure

Parameter

value

Minimum traffic flow capacity in single access mode is at least

man/min

30*

Opening/closing time

s

0,8

Maximum width of access way

mm

900 mm

Power supply voltage:

– AC power supply (primary)

V

Hz

100 240

~ 50/60

– DC power supply (secondary)

V

12

Maximum power consumption

W

155*

Index of protection according to EN 60529

-

IP41

* Parameter is multiplied by the number of accesses for the turnstile with the number of access ways more than one

Page 7

7

1.3 Configuration and Scope of Delivery

1.3.1 The turnstile design depends on the number of access ways:

1) For arrangement of single access way the turnstile is a set of left-hand and right-hand

pedestals, each of which has one glass blade (reference designation Т3.КСD.ХV.1);

2) For arrangement of two or more access ways the turnstile is a set of two single blade

pedestals and one or more additional pedestal with two blades (reference designation

Т3.КСD.ХV.Х).

Arrangement of access ways through the turnstile Т3.КСD.ХV.2 is shown in Figure 2.

а) one access way Т3.КСD.ХV.1 b) two access ways Т3.КСD.ХV.2

Fig. 1 – Arrangement of two access ways through the turnstile «SpeedBlade»

1.3.2 Design of the single turnstile of “SpeedBlade” type

1.3.2.1 The base model is a single turnstile consists of two single blade pedestals (left-hand

and right-hand).

The body of each pedestal includes:

– frame;

– base;

– set of side panels;

– top lid;

– actuator with telescopic glass blade;

– two LED displays.

– terminal block;

Page 8

8

– controllers;

– seven access sensors;

– proximity identification card reader*;

– power supply unit.

Optionally the pedestal can be completed with battery*. For the single turnstile a control

panel with power supply unit, automatic circuit-breaker and battery is installed only inside the

pedestal Master on the protected

area side.

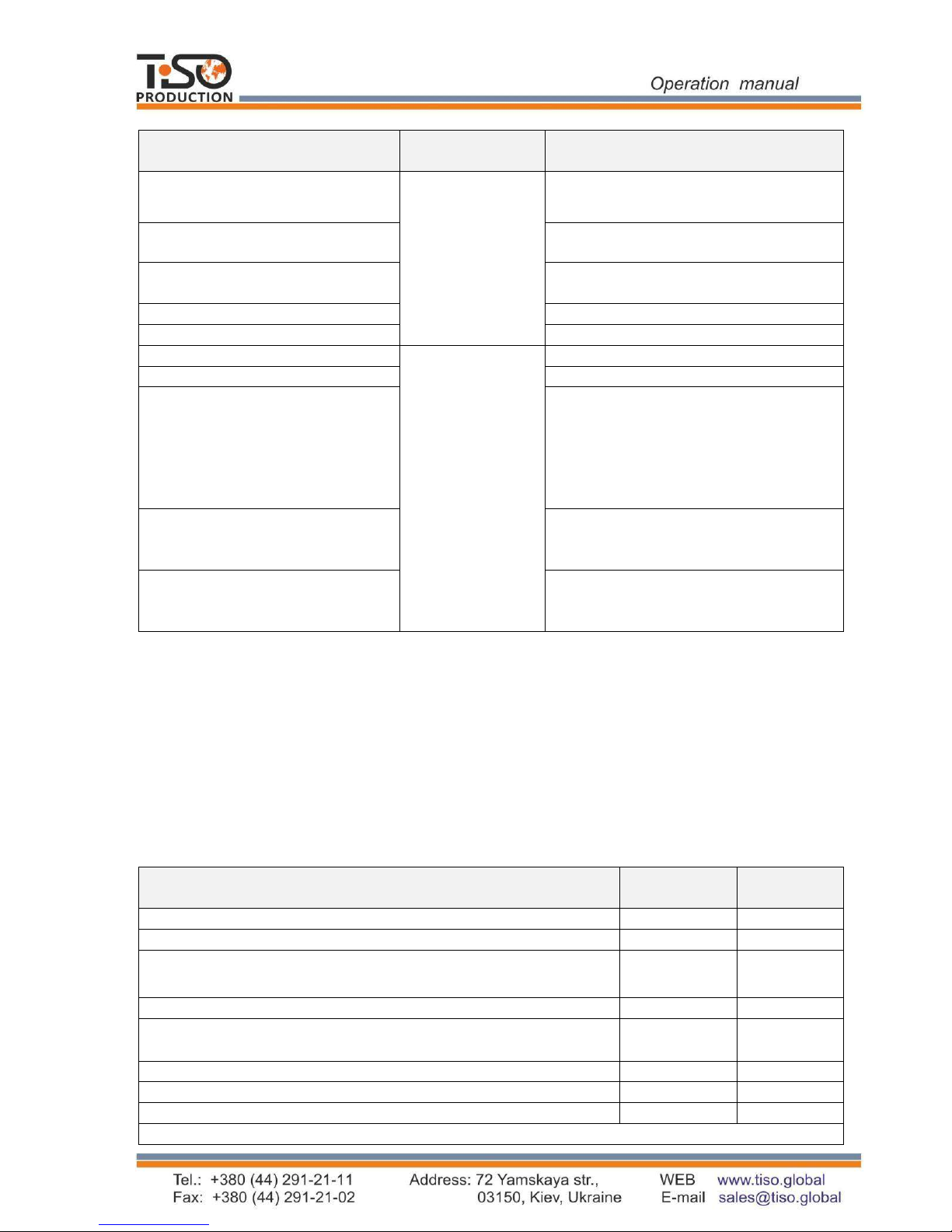

Fig. 2 – Design of the single turnstile of

“SpeedBlade” Т3.КСD.ХV.1 type

1.3.3 Design of the turnstile of “SpeedBlade” type placed in line

The double turnstile is a set of two one-blade pedestals (left-hand and right-hand) and one

additional pedestal with two retractable glass blades. The body of additional pedestal includes:

– frame;

– base;

– set of side panels and doors;

– top lid;

– two actuators with glass blades;

– four LED displays.

There are installed inside additional pedestal;

– two terminal blocks;

– controllers;

– fourteen access sensors;

– two proximity identification card readers;

– power supply unit.

Optionally the additional pedestal can be completed with battery*

It is outside the turnstile scope of supply – to be equipped by customer, when applicable.

1 – location of identification card

readers and LED display;

2 – side LED display;

3 – access sensor;

4 – telescopic glass blade;

5 – turnstile base;

6 – lid;

7 – actuator;

8 – turnstile body.

Page 9

9

Fig. 3 – Design of the double turnstile of “SpeedBlade” type Т3.КСD.ХV.2

1.3.4 Design, overall and installation dimensions of the turnstile are shown in Annex A.

1.3.5 The turnstile material of manufacture is carbon steel subject to painting, brushed

stainless steel or polished stainless steel

1.3.6 Turnstile scope of delivery

The turnstile is delivered in set (a kit of pedestals depending on the number of access ways).

The turnstile is delivered by one or more packages (depending on the customer).

1 – location of identification card

readers and LED display;

2 – side LED display;

3 – access sensor;

4 – telescopic glass blade ;

5 – turnstile base;

6 – lid;

7 – actuator;

8 – turnstile body;

9 - glass blade;

Page 10

10

1.4 Design and operation

1.4.1 General appearance

Fig. 4 – General appearance and design of actuating mechanism of the “SpeedBlade” turnstile

pedestal with blade

1.4.2 Устройство турникета

1.4.2.1 The pedestal body is a set of stainless steel side panels 8,9 and door 10 (See Fig.4),

bottoms of which are rigidly fixed to the base 5 and on the top they are fixed to the frame upper

plate 11. Frame is a set of brackets and posts for fixation of the product components. The

decorative lid 6 is fixed on the body from the top (lid material is optional).

Fig. 5 - Turnstile status display

1 – устройство считывания

идентификационных карт и

световое табло индикации;

2 – световое табло индикации;

3 – датчики прохода;

4 – телескопическая

стеклянная створка;

5 – основание турникета;

6 – крышка;

7 – привод;

8,9 – боковая панель;

10 – двери;

11 – верхняя пластина рамы;

12 – упор;

13 – тяга;

14 – рычаг;

15 – вал поворота створки;

16 – кронштейн;

17 – стойка рамы;

18 – ремень;

19 – магнитный датчик;

20 – кулиса;

Page 11

11

1.4.2.2 The turnstile’s status (Fig. 5) is displayed by the LEDs 1,2, installed on the pedestal

frame elements. Constantly lit blue LED means the turnstile initial state. In case of attempt of

unauthorized access red LED starts blinking and sound signal is generated. When opening

command is received, signal is transformed to green arrow from the side of authorized access. If

unauthorized access is attempted when blades are open, the blades will close if there is no any

obstacle in the blade movement area.

1.4.2.3 Seven infrared sensors 3, located on the turnstile side panels from access side, are

designed for detection of the turnstile access, preventing closing of blades during pedestrian

access in immediate proximity to them and minimizing potential for injury during the turnstile

access.

1.4.2.4 Blade 4 is made from 10 mm thick tempered glass and is located in the middle of the

pedestal body, pivotally connected with actuator. Each blade is actuated by separate servomotor.

Additional pedestal is equipped with two servomotors (one per each access way), while margin

pedestals (left-hand and right-hand) are equipped with one servomotor.

1.4.2.5 In case of 230V main power failure the turnstile blades will remain in the position in

which they were, and the turnstile operation will be maintained from battery (if available).

1.4.2.6 The pedestal crank-and-rocker mechanism, shown in Figure 5, provides reciprocal

movement of the pedestal telescopic glass blade.

1.4.2.7 Inside the turnstile body the panels are fixed on which controllers, power supply

unit, battery and terminal blocks to be connected to 230V mains and control devices are located.

Controllers РСВ.201.01.00.00 control the turnstile motors analyzing signals from magnetic

sensor, and provide motor overload protection. Controllers analyze infrared sensors, receive

control commands from peripherals (control panel, ACS etc.), control LED displays and generate

feedback signals for ACS.

1.4.2.8 External control panel has the following functions: single entry and single exit, entry

and exit LOCK, free entry and exit

1.4.3 Principle of operation

1.4.3.1 Access cycle:

1. In the initial state the turnstile glass blades are located perpendicular to the body block

access.

2. The turnstile is opened for access in the direction "А" or "В" after the appropriate

command from ACS or control panel is issued.

3. Green arrow is lit on LED display and glass blades go fully to slots, i.e. they open. A

pedestrian is able to access through the turnstile freely.

4.After pedestrian exit from control area, the "closed" mode is set until next access. Blue

LED is lit. Blades are reliably closed preventing attempts of unauthorized access.

More detailed description of the turnstile operation modes is given in section 1.6

"Description and operation of controller as an integral component of the turnstile".

1.4.3.2 12V DC power voltage is provided by power supply unit.

1.4.3.3 In case of mains power supply failure, the turnstile is automatically switched to

power supply from 12V, 7A•h battery (optional), which ensures the turnstile's operation within 2

hours.

1.4.3.4 The turnstile wiring and connection diagrams are shown in Annex C.

Page 12

12

1.5 Instrumentation, tools and accessories

Dedicated tools are not required for the turnstile installation (multi-purpose measurement

instrumentation and installation tools are sufficient).

1.6 Description and operation of controllers as integral component of the turnstile

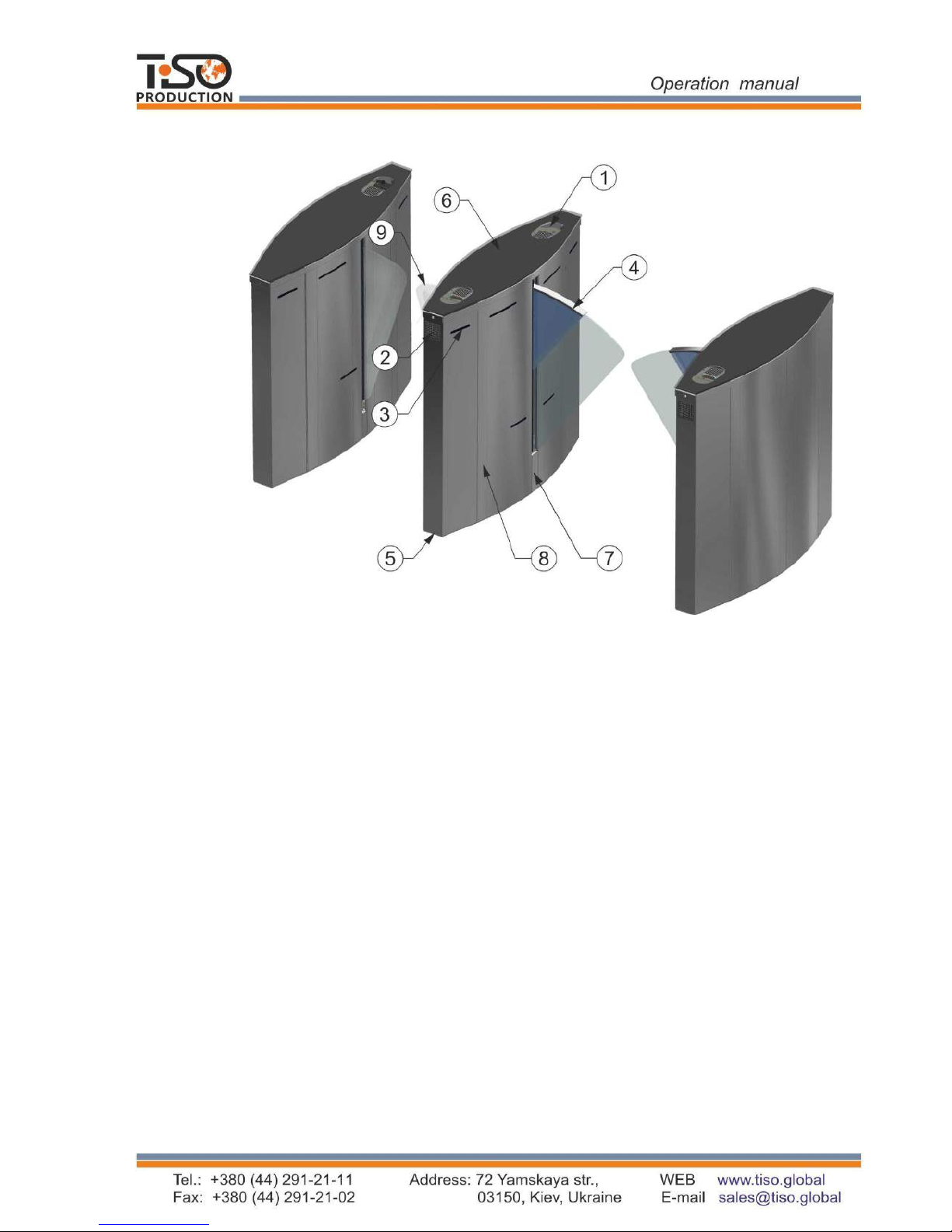

1.6.1 Controller AUIA.206.21.20.00

1.6.1.1 Appearance of controller AUIA.206.21.20.00 is shown in Figure 6.

1.6.1.2 Description of operation

The controller provides algorithm of operation of the whole turnstile. It is assembled on the

120 х 80 mm size card from foil-clad textile laminate, on which electronic components and

terminals for connection to other turnstile units as well as for connection to control peripherals

(ACS, control panel etc.) are located.

The controller generates signal for 7 infrared transmitters and picks up signal from 7

infrared receivers that enables to detect human (or object) presence in the turnstile access area

with high probability. Furthermore, the controller controls light and sound indication, receives

commands from control panel using interface RS-485, picks up commands and generates report

signals for ACS via signal inputs and outputs as well as controls operation of motor controllers

(РВС.201.01.00.00).

The controller and therefore the turnstile can be in the following modes:

"INITIAL STATE".

"SINGLE ACCESS IN THE DIRECTION А".

"SINGLE ACCESS IN THE DIRECTION B".

"SINGLE ACCESS IN BOTH DIRECTIONS".

"FREE ACCESS IN THE DIRECTION А".

"FREE ACCESS IN THE DIRECTION B".

"FREE ACCESS IN BOTH DIRECTIONS".

"LOCK OF ACCESS IN THE DIRECTION А".

"LOCK OF ACCESS IN THE DIRECTION B".

"LOCK OF ACCESS IN BOTH DIRECTIONS".

«"ALARM".

"INITIAL STATE"

The turnstile is in this mode during energization and after completion of the turnstile access,

if during access the mode is not changed to "LOCK", "FREE" or "ALARM". In this mode red

LED is constantly lit on both LED boards, sound indication is OFF, access is locked by blades.

"SINGLE ACCESS"

The turnstile goes to this mode when command "SINGLE ACCESS A/B" comes from control

panel via interface RS-485 or when signal inputs "INP1" ("ACCESS А TO BE OPENED") or/and

"INP5" ("ACCESS B TO BE OPENED") are closed on common wire (terminal "GND"). In this

case if command comes via interface RS-485, the access start waiting time is 5 sec. and when

signal inputs are short circuited the turnstile will wait for access start while input is closed. Green

arrow is lit on LED display from the side of authorized access and red cross is lit from the side of

denied access. Glass blades go to pedestal slots clearing access. Pedestrian is able to access

through the turnstile. If access start time is up and access is not started (the first IR barrier in the

direction of movement was not locked), the turnstile returns to "INITIAL STATE". If within the

above time period access is started, controller generates the signal "ACCESS IS OCCUPIED"

Page 13

13

(outputs "OUT1" or/and "OUT2") and starts tracing position and direction of pedestrian

movement in the turnstile access way, analyzing 6 IR barriers. As soon as pedestrian is behind the

blades line they close, the controller generates the signal "DETECTION OF ACCESS" of 0,3

second duration (outputs "OUT3" or "OUT4") and LED display is switched from green to red.

After the pedestrian turnstile access the controller removes the signal "ACCESS IS OCCUPIED"

and returns to "INITIAL STATE".

Fig. 6 – Appearance and configuration of controller AUIA.206.21.20.00

"FREE ACCESS"

The turnstile goes to this mode either upon command "FREE ACCESS А/В" arrived via

interface RS- 485 from control panel or if during "SINGLE ACCESS" initiated by signal on input

"INP1" ("ACCESS А TO BE OPENED") or/and "INP2" ("ACCESS B TO BE OPENED") at the

end of 0,3 sec. after the signal "DETECTION OF ACCESS А" or "DETECTION OF ACCESS B"

is removed by controller, the signal on the relevant input "INP1" or "INP2" was not removed. In

this mode glass blades go to the turnstile pedestal slots, green arrow is blinking on LED display

from the side of authorized access. Thus every turnstile access is traced and the signal

"DETECTION OF ACCESS" of 0,3 second duration is generated to the relevant output («OUT3»

or "OUT4").

In this state the turnstile will be until arrival of command "CANCELLATION OF FREE

ACCESS" via interface RS-485 or until removal of signals from "INP1" or/and "INP2" depending

on the cause of switching to the free access mode.

1 - ON - when command is issued, the turnstile will

open for 5 seconds;

- OFF - when command is issued, the turnstile will

open for the time set in ACS;

2 - ON - Outputs OUT1-5 will be NC;

- OFF - Outputs OUT1-5 will be O;

3 - 5 - Not usable;

6 - Free access mode setting when blades are normally

closed is possible by closing IN1 and IN2. Signal on

IN1 or IN2 must be more than 6500 ms to set free

access;

- ON - Activation of free access mode when blades

are normally closed;

- OFF - Deactivation of free access mode when blades

are normally closed;

7 - ON - Activation of free access mode A when blades

are normally closed;

Blades will be open when the first IR sensor is

crossed;

- OFF - Deactivation of free access mode A when

blades are normally closed;

Blades will be open all the time;

8 - ON - Activation of free access mode B when blades

are normally closed;

Blades will be open when the first IR sensor is crossed;

- OFF - Deactivation of free access mode B when

blades are normally closed;

Blades will be open all the time;

Page 14

14

"LOCK OF ACCESS"

The turnstile switches to this mode only upon command "LOCK OF ACCESS А/В" arrived

via interface RS-485 from control panel.

Thus red LED is blinking from the side of locked access, glass blades are closed (if the

turnstile is not open for free or single access from opposite side), controller does not respond to

signals of inputs "INP1" ("ACCESS А TO BE OPENED") or/and «INP2» ("ACCESS B TO BE

OPENED") respectively.

The lock mode prevails over single and free access mode. It means that access can be locked

at any time, thus, if within the blade closing area there is no any obstacle they will be closed. The

controller will be in this mode until arrival of command "CANCELLATION OF ACCESS

LOCK" via interface RS-485 from control panel.

"ALARM"

The turnstile switches to this mode from any above mentioned mode in case of unauthorized

access attempts. In this case red LED is frequently blinking (4 times per second), siren alarm is

generated on control panel and output "OUT5" is activated on the controller board. If the turnstile

was opened, then blades would be closed if there were no obstacles in the closing area. The

turnstile will return to the mode preceding the "ALARM" mode as soon as causes of this mode

disappear. In this case the output "OUT5" will go to passive state, siren alarms on control panel

will be off and blades and light indication will be set according to the current mode.

The purpose of the controller contacts intended for connection to peripherals is specified in

Table 5.

Table 5

№

Connec

tor/cont

act

Description

Directio

n

Designation

Signal description and

parameters

1 2 3

4

5

ХТ4/1

INP1

(«TO BE OPENED

A»)

ENTRY

Command "TO BE

OPENED FOR SINGLE

/ FREE ACCESS"

1) logical «0» (02,2)

V;

2) logical «1» (3 5)

V;

3) active level of

signal (factory setting)

logical «0»

4) voltage on open

input < 5 V

ХТ4/2

INP2

(«TO BE OPENED

B»)

ENTRY

ХТ4/3

INP3

(«PANIC»)

ENTRY

Command "SWITCHING

TO PANIC STATE"

ХТ4/4

INP4

ENTRY

Not applicable

ХТ4/5

INP5

ENTRY

ХТ4/6

INP6

ENTRY

ХТ4/7

GND

COMMON WIRE

ХТ3/1

GND

COMMON WIRE

ХТ3/2

OUT1

(«ACCESS A IS

OCCUPIED»)

EXIT

Signal is generated from

the moment of blocking

of the first IR barrier in

the direction of

movement and is

removed after

cancellation of the latter

1) type of output –

open collector;

2) peak voltage on

privacy key 55V;

3) peak current of

public key 100mA;

4) resistance of public

key (5 7) Ohm;

5) active level of

ХТ3/3

OUT2

(«ACCESS B IS

OCCUPIED»)

EXIT

Page 15

15

Continued Table 5

1 2 3

4

5

ХТ3/4

OUT3

(«DETECTION OF

ACCESS А»)

EXIT

Signal appears during

barring of the second last

IR barrier and continues

0,2 sec.

signal (Factory

setting) – logical «0»

(connection on GND)

ХТ3/5

OUT4

(«DETECTION OF

ACCESS В»)

EXIT

ХТ3/6

OUT5 («ALARM»)

EXIT

Output is active in case

of unauthorized access

attempt

ХТ5/1

POW

«+» power supply

1)Power supply

voltage 12V;

2)Consumption

current < 150 mA

ХТ5/2

B1

It is used for data

transmission via serial

port. It is used for

connection of control

panel.

Interface RS-485

ХТ5/3

A1

Interface RS-485

ХТ5/4

GND

COMMON WIRE

ХТ1/1

BUZ

Output for connection of

audible alarm. The output

is active in case of

unauthorized access

1) type of output –

open collector;

2) peak voltage on

privacy key 60V;

3) peak current of

public key 250mA;

4) resistance of public

key (0,48640) Ohm;

5) active level of

signal (Factory

setting) – logical «0»

(connection on GND)

ХТ1/2

B2

It is used for data

transmission via serial

port.

Interface RS-485

ХТ1/3

A2

Interface RS-485

ХТ2/1

+ 12V

«+» power supply

(energization of

controller)

1) Power supply

voltage 12V;

2) Consumption

current < 150 mA

ХТ2/2

+ 12V

ХТ2/3

GND (common)

«-» power supply

(common wire)

ХТ2/4

GND (common)

1.6.2 Turnstile controller РСВ.201.01.00.00

1.6.2.1 Appearance of controller РСВ.201.01.00.00 is shown in Figure 7.

Page 16

16

Fig. 7 – Appearance of controller РСВ.201.01.00.00

1.6.2.2 Description of operation

The controller is designed to control DC motor, intended to move the turnstile blades, and

electromagnetic brake installed on motor shaft. Control is performed based on the signals coming

from magnetic sensor as well as from motor current sensor. Control commands come to inputs

"IN1" and "IN2" from the controller AUIA.206.21.20.00.

Table 6

№

Connector

/contact

Descriptio

n

Direction

Designation

Signal description and

parameters

X1/1

IN1

ENTRY

«TO BE OPENED A»

1) logical “0”

(0 1,7) V; 2)

2) logical “1”

(3,7 5) V; 3)

3) active level of signal

– logical “0”;

4) voltage on open input

≤ 5 V

X1/2

IN2

ENTRY

«LOCK»

X1/3

IN3

ENTRY

Not applicable

X1/4

IN4

ENTRY

To be connected to

microswitch

X1/5

IN5

ENTRY

To be connected to

magnetic sensor

X1/6

IN6

ENTRY

X1/7

IN7

ENTRY

X1/8

IN8

ENTRY

Page 17

17

Continued Table 6

1 2 3

4

5

X1/9

GND

“-“ power supply

(common wire)

X1/10

GND

X1/11

GND

X1/12

+5 V

EXIT

Not applicable

X2/1

GRN1

EXIT

Not applicable

X2/2

RED1

EXIT

Not applicable

X2/3

GRN2

EXIT

Not applicable

X2/4

RED2

EXIT

Not applicable

X2/5

-MG1

EXIT

Not applicable

1) type of output –

open collector;

2) peak voltage on

privacy key 50V;

3) peak current of

public key 5A

X2/6

+MG1

EXIT

Not applicable

X2/7

-MG2

EXIT

Not applicable

X2/8

+MG2

EXIT

Not applicable

X2/9

MOT1

EXIT

Connection of motor

1) voltage (10 ÷ 27)V;

2) current ≤ 4 А

X2/10

MOT2

EXIT

X2/11

GND

“-“ power supply

(common wire)

X2/12

+24 V

ENTRY

“+” power supply

(energization of controller)

1) voltage (10 ÷ 27)V;

2) current ≤ 4 А

Х3

Х3

ENTRY/

EXIT

Communication port

1) logical “0” (0 ÷ 1)V;

2) logical “1” (3,5 ÷ 5) V

Page 18

18

2 INTENDED USE

2.1 Operation restrictions

2.1.1The turnstile must be used in the environment specified in p. 1.1.4 of this document

subject to the specifications listed in section 1.2.

IT IS FORBIDDEN:

1) TO MISUSE THE TURNSTILE (See Section 1 "DESCRIPTION

OPERATION");

2) TO USE THE TURNSTILE UNEARTHED;

3) TO USE HEATING PIPES AND RADIATIONS AS WELL AS PIPES

CENTRALOF WATER SUPPLY FOR EARTHING;

4) TO REPAIR AND ADJUST WITHOUT DEENERGIZATION.

5) TO RELOCATE THE OBJECTS EXCEEDING THE ACCESS WAY

THROUGWIDTH THE TURNSTILE ACCESS AREA;

6) TO JERK AND IMPACT ANTICROSSING BLADES, LED DISPLAY OR

PAROTHERSOF THE PRODUCT, WHICH MAY CAUSE THEIR

MECHANICAL DISTORTION OR DAMAGE;

2.1.2 It is forbidden to use the turnstile:

– at the presence of mechanical rattle in movable parts of the turnstile;

– when metalwork of the turnstile and its components and accessories are mechanically

damaged.

2.1.3 List of special conditions of operation

Mean time of the turnstile access (in single access mode) equals to 2 sec.

Escape door, portal or pedestrian gate can be installed near the turnstile to increase the

turnstile traffic flow capacity in case of emergency.

IMPORTANT:

THE MANUFACTURER WARNS OF THE NECESSITY TO KEEP THE

MANUFACTURER’S SEALS ON THE TURNSTILE COMPONENTS!

2.2 Layout and installation

2.2.1 The turnstile and components of the scope of supply to be delivered to installation site

in factory packing. The turnstile to be unpacked only on installation site.

2.2.2 Preparation of the turnstile for installation (dismounting) and commissioning to be

performed according to this OM with mandatory observation of safety measures according to in p.

2.1 and general electrical safety code.

WARNING:

The turnstile damage occurred during transportation is not covered by the

manufacturer’s warranty obligations

2.2.3 Safety measures:

Installation to be performed only by the persons briefed on safety and studied this

manual;

Only serviceable tools to be used during the turnstile installation;

Connection of all cables to be performed only when power supply is OFF;

Page 19

19

Cables to be laid in compliance with electric code;

The turnstile to be installed by at least 2 installers.

2.2.4 Tools and accessories to be used (Fig.8):

puncher;

concrete drills (according to diameter of anchors included in the turnstile scope of

delivery);

extension cord;

kit of end and pin wrenches;

kit of hexagons;

kit of screwdrivers;

hammer;

multimeter (tester);

measuring tape;

marker;

pliers, side cutters;

builder's level.

Fig. 8 - Tools and accessories for layout and installation

Page 20

20

2.2.5 General layout of the “SpeedBlade” turnstile access ways

Fig. 9 – “SpeedBlade” type turnstile layout options

2.2.6 Installation procedure.

The turnstile installation procedure is as follows:

1) The package integrity to be checked prior to unpacking. If package is damaged, then

damages to be fixed (picture to be taken, damage report to be made);

2) The turnstile to be unpacked and inspected for defects and damages as well as

completeness to be checked according to the turnstile data sheet;

WARNING:

When the turnstile damages are detected or in case of shortage of delivery

installation work to be stopped and the turnstile supplier to be referred to.

3) Turnstile disassembly and redeployment:

The turnstile removal from pallet (See Figure 10). The turnstile U-shape door to be taken off

to access fixation holes and terminal blocks:

- End screws to be unscrewed and table board to be removed (View А);

- Two frame screws to be loosened and removed and the turnstile door to be taken off (View

B);

Page 21

21

- Two frame screws to be loosened and removed at the bottom of the turnstile frame base

(View С);

- The turnstile to be removed from pallet;

Fig. 10 – Turnstile removal from pallet

4) Make sure that the turnstile installation area is ready as follows:

The site surface to be flat and horizontal;

Thickness of concrete blinding coat under the site to be at least 150 mm.

WARNING:

The turnstile is fixed by means of Redibolt (with jacket and screw) included in the

scope of delivery.

5) The turnstile fixation holes to be marked on the site surface according to Figure 11. The

turnstile itself, located upright at the installation site, can be used as a template.

Page 22

22

IMPORTANT! Pedestals are linked by control line optical sensor system requiring

accurate positioning of pedestals. The relative position of pedestals and vertical

position of the turnstile to be respected.

Fig. 11– Installation dimensions of “SpeedBlade” type turnstile

6) The relevant holes to be drilled on the surface according to the marking due to

diameter of anchors (12×120М10) for the turnstile fixation.

7) Anchor jackets to be inserted into the prepared holes

WARNING:

The turnstile installation and fixation to be performed only after all electric

cables to be connected to the turnstile are pulled

8) The following cables to be run to the turnstile installation site:

Power supply cable 230 V ~;

Control panel connection cable;

Access Control System connection cables, if it is available;

Cables between pedestals (Figure 15 and 16);

Cables to be run in corrugated or metal pipes.

Page 23

23

Fig. 12 – Cable entries between the turnstile†

†

Master («SpeedBlade»-1 )– pedestal

Slave («SpeedBlade» -1)- pedestal

Master/Slave («SpeedBlade» -2 ) – double blade pedestal

Page 24

24

Fig. 14 – Fixation points by means of

anchors

Fig. 15–Connection of power supply cable

9) The length of cable free ends to be at least 1 m

to provide cable entry, termination and connection to

the relevant terminals in the turnstile post.

10) The cable outlet point to be aligned with the

hole on the turnstile mounting plate.

11) The turnstile to be installed upright at the

prepared location.

12) Cables to be pulled through available access

holes in the turnstile post bottom end part by reclining

the turnstile.

13) Fixation holes at the turnstile bottom plate to

be aligned with prepared surface holes.

14) The turnstile to be fixed by means of anchors

included in the scope of delivery (Fig. 14).

15) Turnstile connection:

a) Power supply cable ~230 V to be connected

(Fig. 15):

- Phase (L) to be connected to circuit breaker;

- Neutral (N) to be connected to terminal ~230

V (N);

- Earth (РЕ) to be connected to earthing

terminal (РЕ).

b) Control panel cable to be connected to

terminals (Fig.16):

- P (Power) – control panel power supply

+12V;

Fig.13 – Cable entries Master and Slave pedestals

Page 25

25

Fig.16 – Connection of control panel

communication cable to terminals PCB

- G (GND) – common wire of control

panel;

- A (RSA) – RSA wire of control panel

link;

- B (RSB) – RSB wire of control panel

link;

c) The turnstile to be earthed, power supply

cable to be connected the turnstile

according to wiring diagrams (See

Annex B).

d) Proximity card readers to be installed, if

access control system (ACS) is available.

The turnstile door and side pieces (Fig.17)

to be installed at their fixation locations and table

board to be fixed with screws.

Fig. 17– Body installation on the turnstile frame

16) Installation of proximity card reader upon the availability of access control system

(ACS)

- The turnstile table board to be removed;

- Screws to be unscrewed and acrylic to be removed;

- Maximum size of the card reader to be installed is not more than 80x80x25 mm (See Fig.18);

- Acrylic to be secured with screws in previous position;

- The turnstile table board to be installed and secured with screws in previous position.

Door

Frame base

Page 26

26

Fig. 18 - Installation of card reader

2.3 Preparation for use

2.3.1 Commission guidelines

Prior to the turnstile energization:

1) make sure of proper connection and good condition of all connecting cables;

2) clear the turnstile blade opening area from foreign particles.

When mains cable of power supply unit is connected to the network, the turnstile actuating

mechanism is energized. Blades are locked from opening.

The turnstile is set in initial state: entry and exit LED displays are blue.

2.3.2 Required inspections

2.3.2.1 When the turnstile is commissioned it is necessary to perform inspections specified

in Table 7. During inspections the wiring diagram according to Annex C and the control panel

according to Appendix B to be used.

Table 7

Operation Mode

Mode Setting

LED Display

1

2

3

1.Turnstile is

closed in both

directions (initial

state)

–

Blue LED is lit

2. Single access in

one direction

"SINGLE" button to be pushed

for access in chosen direction

(“A” or “B”)

Green arrows of authorized single

access in chosen direction is lit and

blue LED display in opposite

direction is lit

3. Single access in

both directions

Both "SINGLE" buttons to be

pushed for access in both

directions (“A” and “B”)

Green arrows of single access in

both directions are lit

Page 27

27

Continued Table 7

1

2

3

4. Free access in

one direction

"FREE" button to be pushed for

access in chosen direction(“A” or

“B”)

Green arrow of authorized free

access in chosen direction is lit

and blue LED display in opposite

direction is lit

5. Free access in

both directions

Both "FREE" buttons to be

pushed for access in both

directions (“A” and “B”)

Green arrows of authorized free

access in both directions are lit

6. Single access in

one direction and

free access in

opposite direction

"SINGLE" button to be pushed

for access in chosen direction

(“A” or “B”) and "FREE" button

to be pushed for access in

opposite direction

Green arrow of authorized single

access in chosen direction is lit and

green arrow of authorized free

access in opposite direction is lit

7. Single access in

one direction and

locked access in

opposite direction

"SINGLE" button to be pushed

for access in chosen direction

(“A” or “B”) and "LOCK" button

to be pushed for locking access in

opposite direction

Green arrow of authorized single

access in chosen direction is lit and

red LED display of locked access is

lit

8. Free access in

one direction and

locked access in

opposite direction

"FREE" button to be pushed for

access in chosen direction (“A” or

“B”) and "LOCK" button to be

pushed for locking access in

opposite direction

Green arrow of authorized free

access in chosen direction is lit and

red LED display of locked access in

opposite direction is lit

9. Locked access in

one direction

"LOCK" button to be pushed for

locking access in chosen direction

(“A” or “B”)*

Red LED of locked access in one

chosen direction is lit

10. Locked access

in both directions

Both "LOCK" buttons to be

pushed for locking access in both

directions (“A” and “B”)**

Red LED of locked access in both

directions is lit

11. Activation of

“Panic” mode

“PANIC” button to be pushed and

hold for at least 5 s***

Green arrows of authorized free

access in both direction is lit

* In this case other control panel buttons of single and free access in selected direction are

locked;

**In this case all control panel buttons of single and free access in both directions are locked

2.3.2.2 Upon completion of the turnstile satisfactory inspection it is ready for long-term

operation.

2.4 Contingency actions

For emergency human escape (in case of fire, acts of God etc.) and ensuring free access the

turnstile to be unlocked from control panel by issuing the relevant command. For full opening of

access way an “PANIC” function to be used.

Page 28

28

In case of the mains power failure the turnstile automatically switches to power from the

backup battery (optional). If the mains power is not recovered and battery is discharged, the glass

blades are fully put manually to the turnstile pedestal slots to make access way free.

3 MAINTENANCE

3.1 General guidelines

3.1.1 Commissioning and subsequent maintenance of the turnstile to be performed only by

the staff being in charge of the turnstile.

3.1.2 The turnstile to be serviced only by the staff having the relevant electrical safety

qualification level according to the national requirements.

3.1.3 The turnstile to be installed and operated only by the qualified safety briefed staff

having the relevant class of permit to work with electrical facilities with voltage up to 1000V,

being aware of this OM, the turnstile design and principle of operation.

3.2 Safety Measures

3.2.1 During maintenance of the turnstile the relevant safety measures according to p. 2.1 to

be observed.

IT IS FORBIDDEN:

TO USE DEFECTIVE APPLIANCES, TOOLS, FUSES, INSTRUMENTATION

THE SERVICE LIFE OF WHICH HAS EXPIRED

3.2.2 When instrumentations are prepared for operation it is necessary to strictly comply

with the safety requirements specified in the instrumentation instruction manuals.

3.3 Maintenance procedure

3.3.1 The turnstile maintenance includes preventive measures which are taken according to

the established frequency to maintain the turnstile in operational condition, decreasing of

component wearing and prevention of faults and malfunctions.

3.3.2 Daily and periodic maintenance of the turnstile are recommended.

Normally the daily maintenance is carried out before the beginning of operation or during

operational timeout and includes visual inspection of the turnstile body and, if required,

troubleshooting of mechanical damages, surface corrosion and contamination.

IT IS FORBIDDEN:

TO USE ABRASIVE AND CHEMICALLY ACTIVE SUBSTANCES DURING

CLEANING OF CONTAMINATED EXTERNAL SURFACES OF THE

TURNSTILE.

The recommended stainless steel detergents are given in Table 8.

Page 29

29

Table 8

Detergent description

Manufacturer

Country of origin

Stainless steel cleaning spray “Stainless

Steel Cleaner And Polish”

3M

Group of European

companies

Cleaning fluid “Well Done”

Well Done

Hungary

Stainless steel products and other metals

cleaner “XANTO STEEL 3in1”

XANTO

United Kingdom

«Dr.BECKMANN»

Dr.Beckmann

Germany

Cleaning solution “Reinex

Edelstahlreiniger”

Reinex

Germany

Cleaning spray “Stainless steel cleaner”

Onish

United Kingdom

3.3.3 Periodic maintenance for the purpose of defect detection and remedy is performed at

least twice a year and includes as follows:

visual inspection of the turnstile body, actuating mechanism and other

components for absence of external damages (corrosion, warps and other

mechanical defects and pollutions);

visual inspection of connecting, network and earthing cable condition;

verification of the turnstile performance;

during manual control in the modes specified in Table 7 or when identification

cards are used;

verification of reliability of the turnstile screw joints and earthing connections;

4 ROUTINE MAINTENANCE

4.1 Possible malfunctions

Possible malfunctions of the turnstile and their remedies are listed in Table 10.

ВНИМАНИЕ: IMPORTANT:

INSPECTION, CLEANING, REPAIR OF THE TURNSTILE COMPONENTS

TO BE PERFORMED ONLY AFTER THE TURNSTILE IS DEENERGIZED !!

4.2 Possible malfunctions

Possible malfunctions of the turnstile and their remedies are listed in Table 9.

Table 9

Symptom

Possible cause

Remedy

1

2

3

Turnstile does not

operate when

energized

There is no mains power

supply.

Idle power cable.

Power supply unit is out of

order.

AC power to be recovered.

Power supply cable to be connected.

Power supply unit to be replaced..

Blade does not open

Belt is damaged.

Magnetic sensor is adjusted

improperly.

Magnetic sensor is out of

order.

Magnetic sensor to be replaced.

Belt to be replaced.

Magnetic sensor to be adjusted or

PCB to be replaced.

Proper connection of ACS to input output terminals on controller board

Page 30

30

Continued Table 8

1

2

3

Turnstile does not obtain

actuation signal from ACS.

to be checked. Availability of

actuation signal from ACS to be

checked.

Blade knocks

Magnetic sensor to be

checked.

Magnetic sensor to be adjusted or

PCB to be replaced.

Control panel sends

sound signal

"communication"

Control panel is out of

contact with controller

Wires to be checked.

Control panel to be checked.

Controller to be checked.

LED display is out of

order

No contact with controller.

Wires are damaged.

LED display is out of order

Wires to be checked.

LED display to be checked.

LED to be replaced.

Continuous sound

signal when turnstile

is open

Infrared sensors don’t see

each other.

Infrared sensors are out of

order.

Plexiglas to be cleaned from dust.

Infrared sensors to be checked.

Infrared sensors to be replaced if they

are out of order.

Blade stays in

semiopen position

Magnetic sensor is out of

order.

Mechanism jamming.

Blade opening to be checked

manually turning off power supply.

Mechanism components to be

checked.

Sensor adjustment to be checked.

Blade remains open

Magnetic sensor is out of

order.

Mechanism jamming

“FREE ACCESS” mode is

set.

Infrared sensors are out of

order

Blade opening to be checked

manually turning off power supply.

Mechanism components to be

checked.

Sensor adjustment to be checked

Blade slow opening

Mechanism jamming.

Infrared sensors don’t see

each other.

Infrared sensors are out of

order.

Magnetic sensor to be

checked.

Check manually whether it operates

or not. Mechanism components to be

checked. Magnetic sensor to be

adjusted or PCB to be replaced

Magnetic sensor to be adjusted or

PCB to be replaced.

Wires to be checked.

4.3. “SpeedBlade” turnstile blade initialization procedure

Initial setting of the blade zero position at the first activation of the turnstile

1) Turnstile to be deenergized;

2) Motor to be disconnected from PCB 201terminal: MOT1 (Fig.7);

3) Blade to be set in the required zero position ((Fig.19 and (Fig.20);

4) The turnstile to be energized;

5) Zero position setting button on magnetic sensor board to be pushed and hold for at

least 1 second, then to be released (make sure that the button pressure force does not

bend the board);

6) After the button on the magnetic sensor board is released the zero position LED to be

lit;

Page 31

31

7) Presence of signals of rotation

anglechanging, speed and zero position on

controller PCB 201 - terminals: IN5, IN6,

IN7, IN8. During blade opening and

closing:

- IN5, IN6 – should exchange winks.

- IN7 – is lit brightly if the blade is not

moved or is moved slowly. Brightness is

decreased if blade is rotated rapidly.

- IN8 – to be lit in just set zero position;

8) Turnstile to be deenergized;

9) Motor to be connected to PCB 201,

terminals MOT1;

10) The turnstile to be energized;

11) Turnstile operation to be checked

12) New zero position setting is completed

Magnetic sensor and magnet gap control.

Normal gap is 1mm

• If LED is lit then gap is too large or too small.

Initial position (Zero) display

• If LED is lit then magnet is in initial (zero)

position.

Magnetic sensor operation display

• If it is blinking then magnetic sensor is in order.

• If it is lit or not lit then magnetic sensor is out of

• order.

Magnetic sensor

Zero position setting button

Fig. 20 – Magnetic sensor board PCB 730.01

Power supply LED

Fig. 19 – Turnstile blade in zero position

(access way is open)

Page 32

32

4.3 Postrepair checkout

The turnstile performance is checked after repair according to p. 2.3.2 of this OM.

5 TRANSPORTATION AND STORAGE

5.1 Turnstile storage

It is forbidden to subject the turnstile to jerks and impacts during storage. Transportation

trolleys to be used for handling of the turnstile. In storage facilities there should not be aggressive

gases and vapours causing metal corrosion.

Air temperature during storage should not be below +50° С and above +40° С and relative

air humidity should not be more than 80% at the temperature 20° С.

5.2 Turnstile transportation

The ready-to-install turnstile to be transported according to the transportation regulations

related to the relevant mode of transport, such as:

– in railway or special containers;

– in closed vehicles;

– waterborne (in ship’s hold) .

Air temperature during transportation should not be below -40°С and above +50°С.

After transportation or storage of the turnstile at negative temperatures or increased

humidity the turnstile to be kept indoor with normal climatic conditions without original packing

within 12 hours before commissioning:

1) ambient temperature: + 15°С to +35°С;

2) relative humidity: 45% to 80 %;

3) atmospheric pressure: 84,0 to 106,7kPa (630-800 mm Hg).

6 DISPOSAL

The turnstile design does not contain materials environmentally hostile and hazardous to

health and special measures are not required for its disposal.

Page 33

33

7 MANUFACTURER'S WARRANTY AND TERMS OF WARRANTY

MEAINTENANCE

7.1. The manufacturer guarantees good state and declared quality of the turnstile if

conditions of transportation, storage, installation and operation are observed by the consumer

7.2. The warranty period of the turnstile from the date of sale is 12 months unless otherwise

specified by agreement.

7.3 During warranty period the Manufacturer undertakes to perform repair or replacement

within 10 days (at the discretion of the Manufacturer) of the failed turnstile or its parts having

proven factory defects (not due to nonobservance of storage, transportation, installation and

operation conditions specified by this OM) preventing further use of the turnstile.

7.4 The Manufacturer does not bear responsibility and warranty liabilities for the turnstile

damage due to nonobservance of the requirements specified by this OM and in case of the turnstile

unintended use.

7.5 Warranty liabilities of the Manufacturer are valid only if sections 3, 4, 5 of this

DATASHEET and warranty coupon are completed as well as the relevant signatures and seals are

available. The turnstile to be repaired only by the authorized service center of the manufacturer

with use of exclusively original spare parts. Warranty liabilities don’t include free-of-charge

arrival of technical staff to the Customer for repair.

7.6 The relationships between the Manufacturer and the Customer under warranty liabilities

are regulated by the applicable law of Ukraine, concluded purchase contracts and these warranty

obligations.

Page 34

34

Manufacturer:

"TiSO-PRODUCTION" LTD

72 Yamskaya str., 03150 Kiev, Ukraine

Tel.: +38 (044) 291-21-11

Tel../Fax: +38 (044) 291-21-02

E-mail: sales@tiso.global

WEB www.tiso.global

Our equipment complies with requirements of the European Standards:

EN 60335-1:2002, EN 61000-6-1:2007; EN 61000-6-3:2007;

EN 61000-4-2:2009; EN 61000-4-3:2006;

EN 61000-4-4:2004; EN 61000-4-5:2006; EN 61000-4-11:2004

and is in conformity with requirements of the following EC Directives:

2004/108/EC; 2006/95/ EC; 2006/42/ EC

The company is certified acc. to -EN ISO 9001:2015 certificate No. HU14 / 7373.03.

QR-code to be used to download the Operation Manual via Internet

Page 35

Annex А

(mandatory)

Overall and installation dimensions of the “SpeedBlade” type turnstile T3.KCD.XV.1

Fig.А.1 – Single turnstile (right-hand and left-hand pedestal (Master and Slave))

Page 36

Continued Annex А

Overall and installation dimensions of the “SpeedBlade” type turnstile T3.KCD.XV.2

Fig.А.2 – Double turnstile (right-hand, right-hand/left-hand and left-hand pedestal (Master, Master

/ Slave and Slave))

Page 37

37

Annex B

(mandatory)

Control panel and connection diagram

1 – control panel body;

5 – "FREE ACCESS" mode control button

2 – "SINGLE ACCESS" mode control

button

6 – "PANIC" mode control button

3 – front plate;

7 – access direction LED display;

4 – "LOCK" mode control button;

8 – controller connection terminals

Fig. B.1 – Control panel AUIA.114.02.00.00

Page 38

38

Continued Annex B

Control panel and connection diagram

Fig. B.2 – Connection diagram of control panel AUIA.114.02.00.00

Page 39

Annex C.1

(mandatory)

Wiring diagram of the "SpeedBlade" type turnstile

"A"

X1

M1

A2

"G"

"B"

"P"

AA2

X1

M1

X1

AA4

"A"

"P"

"N"

"L"

A1

XS2

A1

XT1

XT1

X2

"B"

"G"

"PE"

XS3

XS1

A3

X1

AA5

213

XS22

К СЕТИ 220В

X1

4

3

1

2

8

7

5

4

2

1

9

6

3

+-

M

2

1

321

+

XP1

+

-

AUIA.205.14.05

BD3

КС ИСТЕМЕ УПРАВЛЕНИЯ ДОСТУ ПОМ

10

9

7

6

4

3

1

8

5

2

6

5

3

2

7

4

1

XT3

10

9

7

6

4

3

1

8

5

2

XS25

10

9

7

6

4

3

1

8

5

2

XS6

220V50Hz(N)

QF1( 6A)

Кабель

Заземление

XT1

Жгут№2

213

XS19

213

XS21

213

XS20

AA3

213

XS23

213

XS26

213

XS24

Жгут№1

XS8

2

1

ВЕДОМАЯС ТОЙКА

321

+

XP1

+

-

AUIA.205.14.05

BD1

321

+

XP1

+

-

AUIA.205.14.05

BD2

321

+

XP1

+

-

AUIA.205.14.05

BD5

321

+

XP1

+

-

AUIA.205.14.05

BD6

53241

XS10

43152

+5V

OUT

GND

XP1

GND

+5V

AUIA.205.14.06

BL2

43152

+5V

OUT

GND

XP1

GND

+5V

AUIA.205.14.06

BL3

53241

XS11

XS7

B4

2 G

1

3 R

+12v

HL2

53241

XS13

53241

XS14

43152

+5V

OUT

GND

XP1

GND

+5V

AUIA.205.14.06

BL6

43152

+5V

OUT

GND

XP1

GND

+5V

AUIA.205.14.06

BL5

6

5

3

2

7

4

1

XT1

АЮИА.114.02.00.00

ПУЛЬТУПРАВЛЕНИЯ

2

1

2

1

AA2.XT1

2.Элементыподсветк иHL1, HL2 устанавливаютсяпо требованиюзаказчика.

B4

2 G

1

3 R

+12v

HL1

ВЕДУЩАЯСТОЙКА

Провод заземленияот

ведущейстойки

К клемме заземления

ведомойстойки

5

3

2

4

1

B

A

SH

GND

+12v

AA1

1.К оличестводатчиков BL,BD можетбыть

измененов зависимостиот исполнения турникета.

321

+

XP1

+

-

AUIA.205.14.05

BD4

321

+

XP1

+

-

AUIA.205.14.05

BD7

53241

XS9

53241

XS12

53241

XS15

43152

+5V

OUT

GND

XP1

GND

+5V

AUIA.205.14.06

BL1

43152

+5V

OUT

GND

XP1

GND

+5V

AUIA.205.14.06

BL4

43152

+5V

OUT

GND

XP1

GND

+5V

AUIA.205.14.06

BL7

+-

M

GB1

X2

12

10

9

7

6

4

3

1

11

8

5

2

1GND

X3

12+24V

10MOT 2

9MOT1

7-MG2

6+MG1

4RED2

3GRN2

1GRN1

X1

2RX

118GND

+MG2

52-MG1

RED1

+5V

GND

GND

IN7

IN6

IN4

IN3

IN1

GND

IN8

IN5

IN2

Контроллер

PCB201.01.00.00

A2

+5V

B143

1

5

2

6

5

3

2

4

2

1

B2

GND

A12

6

3

7

4

1

4

1

3

3

XT1

3

1

XP5

1

3

2

XP3

9

6

3

XP2

10

8

7

5

4

2

1

GND

POW

XT5

IN5

IN2

OUT5

OUT4

OUT2

OUT1

XT3

GND

+12V

+12V

2

2

1

2

4

3

XP4

1

8

7

4

5

2

1

9

6

3

XP1

IN6

IN3

GND

IN4

XT4

IN1

OUT3

GND

XT2

RED2

+12V

+12V

AUX2

AUX1

IROUT 8

IROUT 5

IROUT 2

IRIN8

IRIN7

IRIN5

IRIN4

IRIN2

IRIN1

GRN2

BUZ

RED1

AUX3

GRN1

GND

IROUT 7

IROUT 6

IROUT 3

IROUT 4

IROUT 1

OUTCOM

CUROUT

IRIN6

IRIN3

КОНТРОЛЛЕР

АЮИА.206.21.20.00

X2

12

10

9

7

6

4

3

1

11

8

5

2

1GND

X3

12+24V

10MOT 2

9MOT1

7-MG2

6+MG1

4RED2

3GRN2

1GRN1

X1

2RX

118GND

+MG2

52-MG1

RED1

+5V

GND

GND

IN7

IN6

IN4

IN3

IN1

GND

IN8

IN5

IN2

Контроллер

PCB201.01.00.00

+V

B-

B+

N

NC

L

8

6

5

3

2

XT1

4

71COM

ИСТОЧНИКПИТАНИЯ

AD-155A

10

9

7

6

4

3

1

XP1

8

2

5

OUT2

OUT1

IN2

IN1

OUT3

IN3

GND

485_B

485_A

+12V

PCB.205.01.05.00

HL4

10

9

7

6

4

3

1

XP1

8

2

5

OUT2

OUT1

IN2

IN1

OUT3

IN3

GND

485_B

485_A

+12V

PCB.205.01.05.00

HL3

33

30

9-3

10-2

31

5

3

2

4

1

XS31

5

4

2

1

ZERO 3

ANGLE 2

GND

+12V

3 ANGLE 1

XP1 PCB .01730

B2

32

6 6

SPEED

77 7

SET ZERO IN

67

68

70

69

59-3

58-3

5

3

2

4

1

X5S

5

4

2

1

ZERO 3

ANGLE 2

GND

+12V

3 ANGLE 1

XP1 PCB .01730

B1

6 6

SPEED

77 7

SET ZERO IN

13467

9

10

28-2

131516

IROUT1

IROUT4

IROUT7

+++

+

111

1

222

2

ВВВ

В

CUR

AUX3

2

5

23-2

8

14

IROUT3

IROUT5

IROUT2

GGG

NNN

DDD

IROUT6

RSA2

IROUT8

AUX2

RSB2

AUX1

XP1

XP2

Провода к ведомо й стойке

9

1357246

8

8653274

1

RJ1

RJ2

XS1

PCB 715.001

XP31324

GND

XS2

XT21324

6564636160

59

-

1

5754506266

59-455

8

8

-

-

1

1

555156

52

IROUT1

IROUT4

IROUT7

+++

+

111

1

222

2

ВВВ

В

CUR

AUX3

IROUT3

IROUT5

IROUT2

GGG

NNN

DDD

IROUT6

RSA2

IROUT8

AUX2

RSB2

AUX1

XP1

XP2

9

1357246

8

8653274

1

RJ1

RJ2

XS1

PCB 715.001

XP3

132

4GND

XS2

XT21324

Провода к ведущей стойке

747574-1

75-1

63

65

64

72

67

68

69

70

58-2

58-3

58-6

71

75

74

58-1

59-1

59-2

59-3

Page 40

Annex D.1

(mandatory)

Diagram of the turnstile connection to access control system (ACS)

inp1- " TO BE OPENED A" in pulse mode. When command is issued

the input is activated for 5 sec.

inp2- " TO BE OPENED B" in pulse mode. When command is issued

the input is activated for 5 seconds.

3 «PANIC»inp -

GND- "-" of power supply (common wire)

out3- DETECTION OF ACCESS A« »

out - « »4 DETECTION OF ACCESS B

}

ACS

Door contact 2

Relay 1

Relay 2

Door contact

2

In1 and IN2 with 5

sec. delay

Page 41

41

Annex D.2

(mandatory)

Diagram of the turnstile connection to access control system (ACS)

inp1- " TO BE OPENED A" in pulse mode. When command is issued

the input is activated for 5 sec.

inp2- " TO BE OPENED B" in pulse mode. When command is issued

the input is activated for 5 seconds.

inp3- "PANIC"

GND - "-" of power supply (common wire)

out3- DETECTION OF ACCESS A« »

out - « »4 DETECTION OF ACCESS B

}

ACS

Relay

1

Relay 2

In1 and IN2 with 5

sec. delay

Page 42

42

Annex D.3

(mandatory)

Diagram of the turnstile connection to fire alarm (FA)

inp1- " TO BE OPENED A" in pulse mode. When command is issued

the input is activated for 5 sec.

inp2- " TO BE OPENED B" i n pulse mode. When command is issued

the input is activated for 5 seconds.

inp3- "PANIC"

GND- "- " of power supply (common wire)

Аout3- DETECTION OF ACCESS« »

out - « »4 DETECTION OF ACCESS B

}

Relay 1

In1 and IN2 with 5

sec. delay

Fire alarm

Page 43

43

Annex D.4

(mandatory)

Diagram of the turnstile connection to control panel

5 4 3 2 1

P

B

A

G

Loading...

Loading...