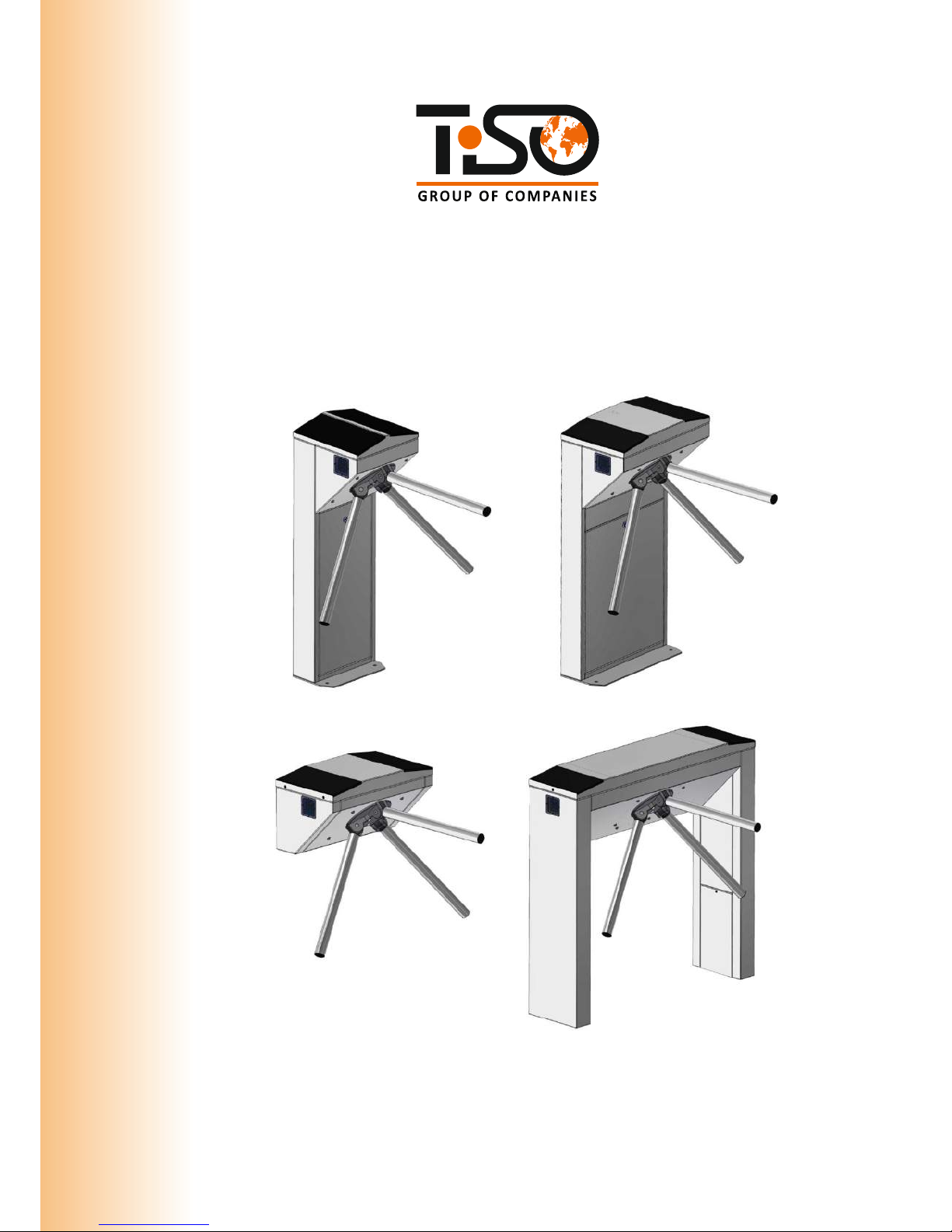

Tiso BASTION-M, TWIX-M, CENTURION-M, SKULL-M Operating Manual

SERVO-OPERATED TRIPOD TURNSTILES

CENTURION-M

BASTION-M

SKULL-M

TWIX-M

OPERATION MANUAL

2018

“TiSO-PRODUCTION” LTD

CONTENTS

INTRODUCTION...........

........................................................................................................................................ 3

1.

DESCRIPTION AND OPERATION.................

................................................................................................. 6

1.1 General Information and Purpose............................................................................................................. 6

1.2 Specifications............................................................................................................................................7

1.3 Configuration and Scope of Delivery....................................................................................................... 7

1.4 Design and Operation .............................................................................................................................10

1.5 Instrumentation, tools and accessories..........................................

......................................................... .13

1.6 Description and operation of controllers as components of the turnstile.............................................. .14

2.

INTENDED USE.....................................................

...........................................................................................24

2.1 Operation restrictions...............................................................................................................................24

2.2 Layout and installation. ...........

................................................................................................................ 24

2.3 Preparation for use ..................................................................................................................

.................. 32

2.4 Contingency actions.................................................................................................................................. 34

3.

MAINTENANCE.............................................

................................................................................................... 34

3.1 General guidelines..................

.................................................................................................................. 34

3.2 Safety measures.................

....................................................................................................................... 35

3.3 Maintenance procedure............................................

................................................................................. 35

4.

ROUTINE MAINTENANCE.............................................................................................................................36

4.1 General guidelines...........

.........................................................................................................................36

4.2 Troubleshooting.................................................

.......................................................................................36

4.3 Postrepair checkout...................................

................................................................................................ 38

5.

TRANSPORTATION AND STORAGE....... .........

............................................................................................ 39

5.1 Turnstile storage.....................

.................................................................................................................. 39

5.2 Turnstile transportation..........................

...................................................................................................39

6. DISPOSAL.................

....................................................................................................................................... .39

7.

MANUFACTURER’S WARRANTY AND TERMS OF WARRANTY MAINTENANCE............................39

Annex А....................................................................................................................................................................41

Annex B: Control panel and connection diagram.........................................

.......................................................... .45

Annex C: Wiring diagram of the servo-operated tripod type turnstile.................................................................

. 47

Annex D 1: Wiring diagram of the turnstile connection to access control system (ACS) in pulse mode...........

....48

Annex D 2: Wiring diagram of the turnstile connection to access control system (ACS) in hold mode................. 49

Annex D 5: Diagram of the turnstile connection to control panel............................................

...

.....

...

......................52

Design, overall and installation dimensions of the "BASTION

-M" type turnstile..................................................42

Design, overall and installation dimensions of the "SKULL

-M" type turnstile.......................................................43

Design, overall and installation dimensions of the "TWIX-M" type turnstile.........................................................44

Annex D 3: Wiring diagram of the turnstile connection to fire alarm system (FAS).....................................

..........50

Annex D 4: Wiring diagram of the turnstile connection to fire alarm system (FAS)............................................... 51

Design, overall and installation dimensions of the "СENTURION

-M" type turnstile.............................................41

3

T3. XXX. X X

Waist-high turnstile

Т3

TCC

О without antipanic device

Е with antipanic device

М with electromechanical

antipanic device

TCY

S Brushed stainless steel

P Polished stainless steel

K Painted body

TCG

TYK

INTRODUCTION

This Operation Manual (hereinafter referred to as OM) covers the servo-operated turnstile

(hereinafter referred to as the "turnstile"). The Operation Manual contains information about design,

specifications, installation for proper operation and maintenance of the turnstile.

This Operation Manual is prepared in compliance with the specification requirements ТY

Y 31.6-32421280-

004:2010.

The turnstile shall be serviced only by the qualified staff having the relevant class of permit to work

with electrical facilities with voltage up to 1000 V and scrutinizing

this Operation Manual, obtaining

safety instructions and trained for operation and maintenance of the turnstile.

Reliability and durability of the turnstile operation is provided with observation of modes and

conditions of transportation, storage, installation and operation. So, fulfillment of all requirements

specified in this document is mandatory.

Depending on the turnstile purpose and design features, the following pattern of reference

designation is accepted:

Due to regular improvement of the product its design can be modified without degradation of

the product features and quality not covered by this Operation Manual.

Servo-operated

solid body tripod

(3 barrier rods)

Servo-operated

one-piece elongated body

tripod (3 barrier rods)

Servo-operated

head body tripod

(3 barrier rods)

Servo-operated

corner body tripod

(3 barrier rods)

4

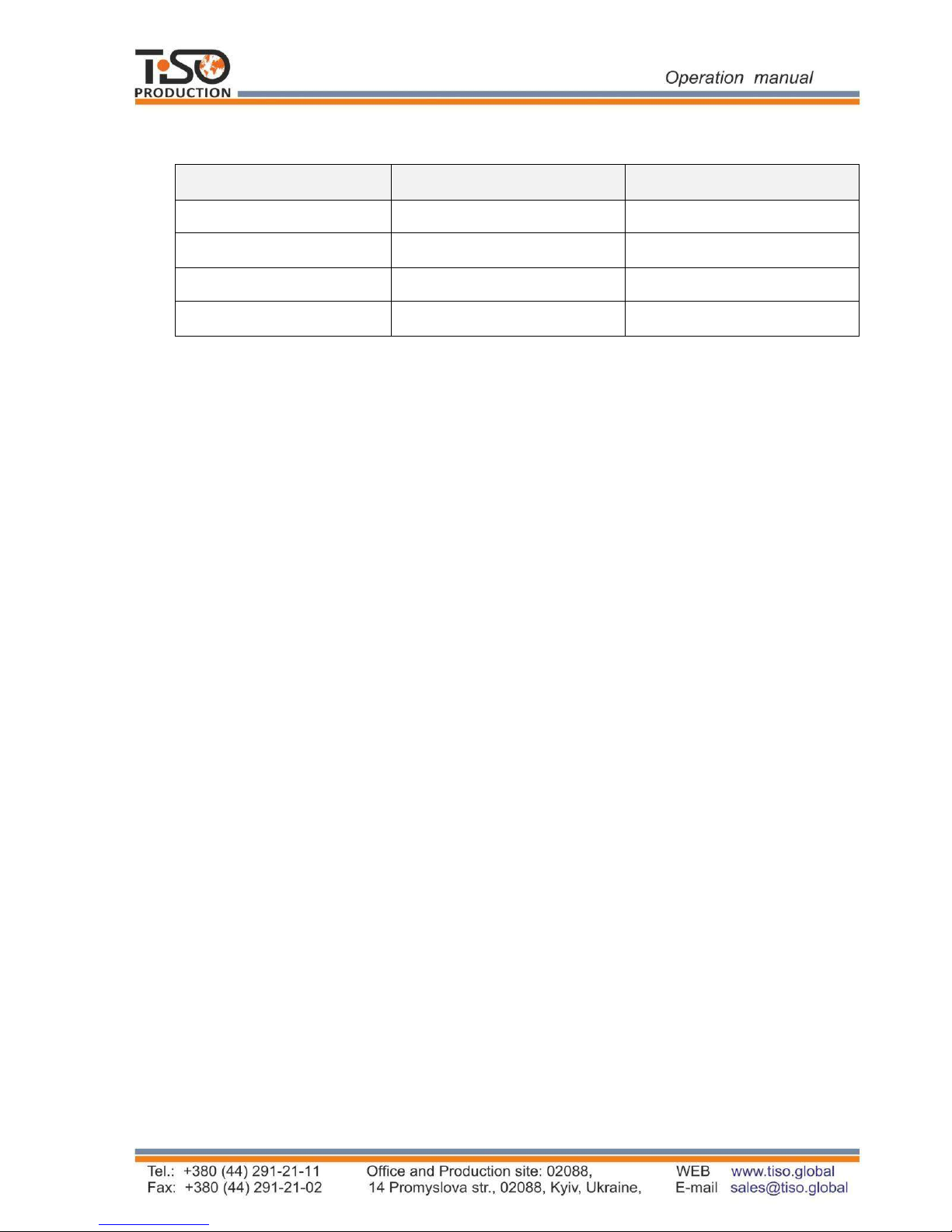

The tripod type turnstile reference designation is given in Table 1.

Table 1

Name Code Designation

CENTURION-M

T3.TCC.ХE

AUIA.095 OM

BASTION-M

T3.TCY.ХE

AUIA.097 OM

SKULL-M

T3.TCG.ХE

AUIA.096 OM

TWIX-M

T3.TYK.ХE

AUIA.137 OM

Example of reference designation of the servo-operated turnstile with solid body of brushed

stainless steel when the turnstile T3.ТСC.SE ТY Y 31.6-32421280-004:2010 is ordered.

5

WARNINGS TO THE CUSTOMER

ON SAFE OPERATION OF THE TURNSTILE

These warnings are designed for ensuring of safety during operation of the turnstile to prevent

violation of safety characteristics by improper installation or operation. These warnings are aimed

at drawing attention of the customer to safety problems.

GENERAL WARNINGS

The Operation Manual is an integral part of the product and it shall be handed over to the

customer. The OM shall be kept for future use and consulted for clarifications if required. If the

turnstile is resold, handed over to another owner or transported to another place, make sure that

the OM is enclosed to the turnstile to be used by new owner and/or maintenance staff during

installation and/or operation.

Safety measures and requirements specified in this OM must be observed:

–

the turnstile must be connected to ground loop prior to operation;

–

the turnstile to be connected to AC network with parameters specified in paragraph 1.2

"Specifications";

–

inspection, adjustment and repair should be performed only after the turnstile is

deenergized.

After purchasing of the turnstile it should be unpacked and its integrity should be checked. In

case of doubt in integrity of the turnstile it should not be used and the customer should refer to

the supplier or to the manufacturer.

Packing accessories (wooden pallet, nails, clips, polyethylene bags, cardboard etc.) as potential

sources of hazard must be removed to unacceptable place prior to proper use of the turnstile.

As electric shock protection device the turnstile is related to 01 protection class according to

GOST (State Standard) 12.2.007.0-75 and is not intended for operation in explosive and firehazardous areas by the "Rules for design of electrical installations".

Using of the turnstile for unintended purpose, improper installation, nonobservance of conditions

of transportation, storage, installation and operation, specified by this OM, may result in damage

to people, animals or property for which the manufacturer is not responsible.

6

1.

DESCRIPTION AND OPERATION

1.1 General Information and Purpose

1.1.1 Turnstile purpose:

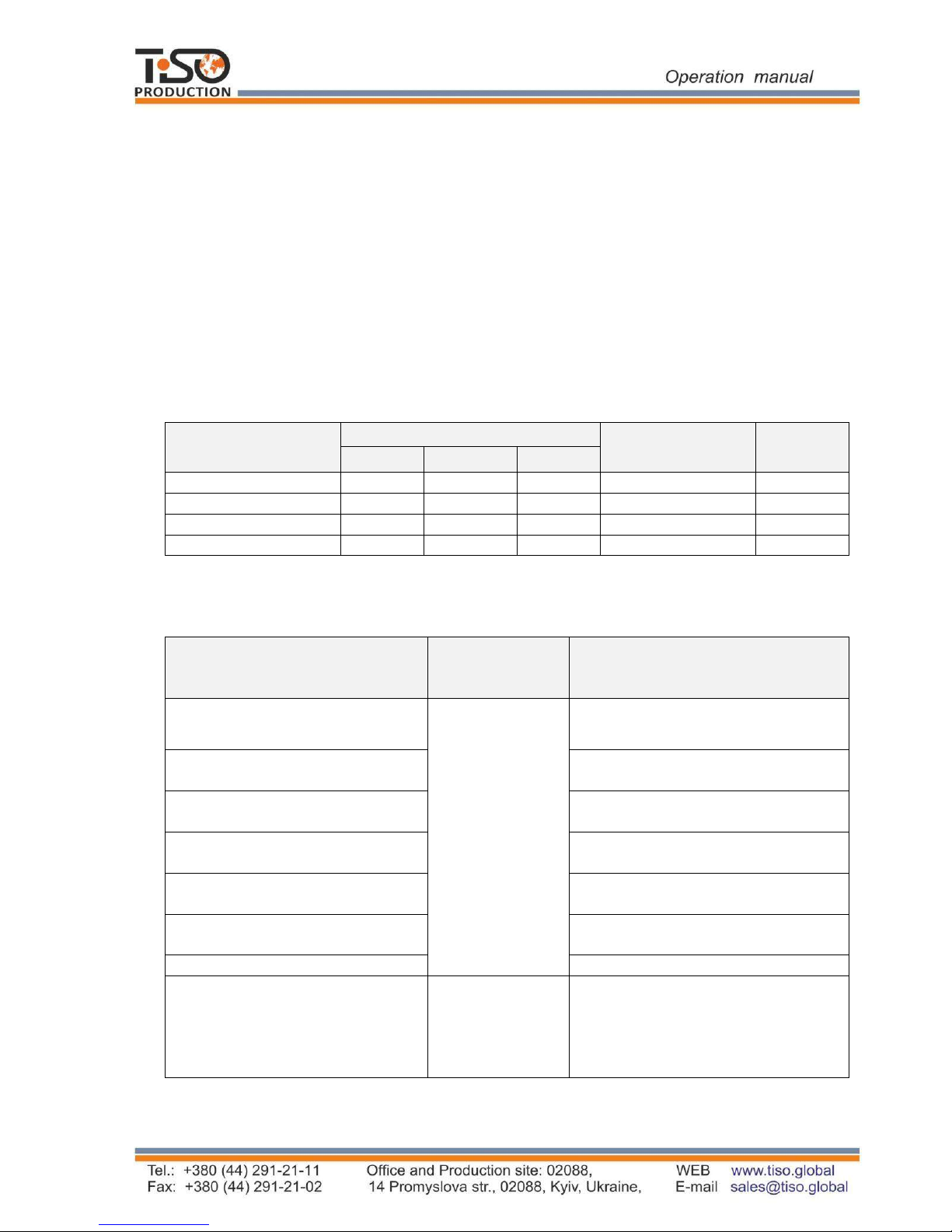

1.1.2 The turnstile dimensions and weight correspond to the values specified in Table 2.

Table 2

Designation of

modification

Dimensions, mm

Pedestal size,

(LхW), m

Max.weight,

kg

Height Length Width

T3.TCC.XE

1000

793

847

324х332

40

T3.TCY.ХE

1000

793

815

524х300

40

T3.TCG.ХE

616

793

833

524х300

30

T3.TYK.ХE

1000

1000

785

1004х270

80

1.1.3 The operation condition parameters according to GOST 15150-69 are specified in

Table 3.

Table 3

Operation

conditions

Ambient air temperature

MC4

+1°С to +40°С

Relative air humidity

Ambient air allowable pressure

Transportation temperature range

Storage temperature range

Group of mechanical application

L3

Altitude above sea level up to 2000 m

Environment MC4

Explosion-proof, does not contain

current-conducting dust, aggressive

gases and vapours in concentration

destroying isolation and metals,

The turnstile is designed for arrangement of individual pedestrian access at access points of

industrial enterprises, banks, stadiums, administrative facilities etc. driven by control signals of

access control system

(from keypad, proximity card readers) or manually (from wire control

panel).

For climatic

modification

Parameter value

80 % at 20 ºС

84 to 106,7kPa

- 40°С to + 50°С

+ 5°С to + 40°С

7

Continued Table 3

1 2 3

disturbing normal operation of the

equipment installed in turnstiles

Installation site

In enclosed spaces in the absence of

direct impact of precipitations and

solar radiation

Operating position

Vertical, deviation from vertical

position no more than 1º to any side

is acceptable

1.1.5 Reliability indices:

– mean time to repair (without delivery time of spare parts, tools and accessories) – at most

6 hours;

– mean time to failure – at least 1 500 000 accesses;

– mean service life between overhauls – at least 10 years.

1.2 Specifications

The key parameters of the turnstile are specified in Table 4.

Table

4

Parameter description

Unit measure

Parameter

value

Minimum traffic flow capacity in free access mode

man/min.

60

Minimum traffic flow capacity in single access mode

man/min.

25

Maximum access way width

mm

600 mm

Power supply voltage:

–

AC power supply (primary)

V

Hz

100 240

~ 50/60

–

DC power supply (secondary)

V

12

Maximum power consumption

W

55

Index of protection according to EN 60529

-

IP41*

1.3 Configuration and Scope of Delivery

1.3.1 The servo-operated waist-high turnstile design includes the following key

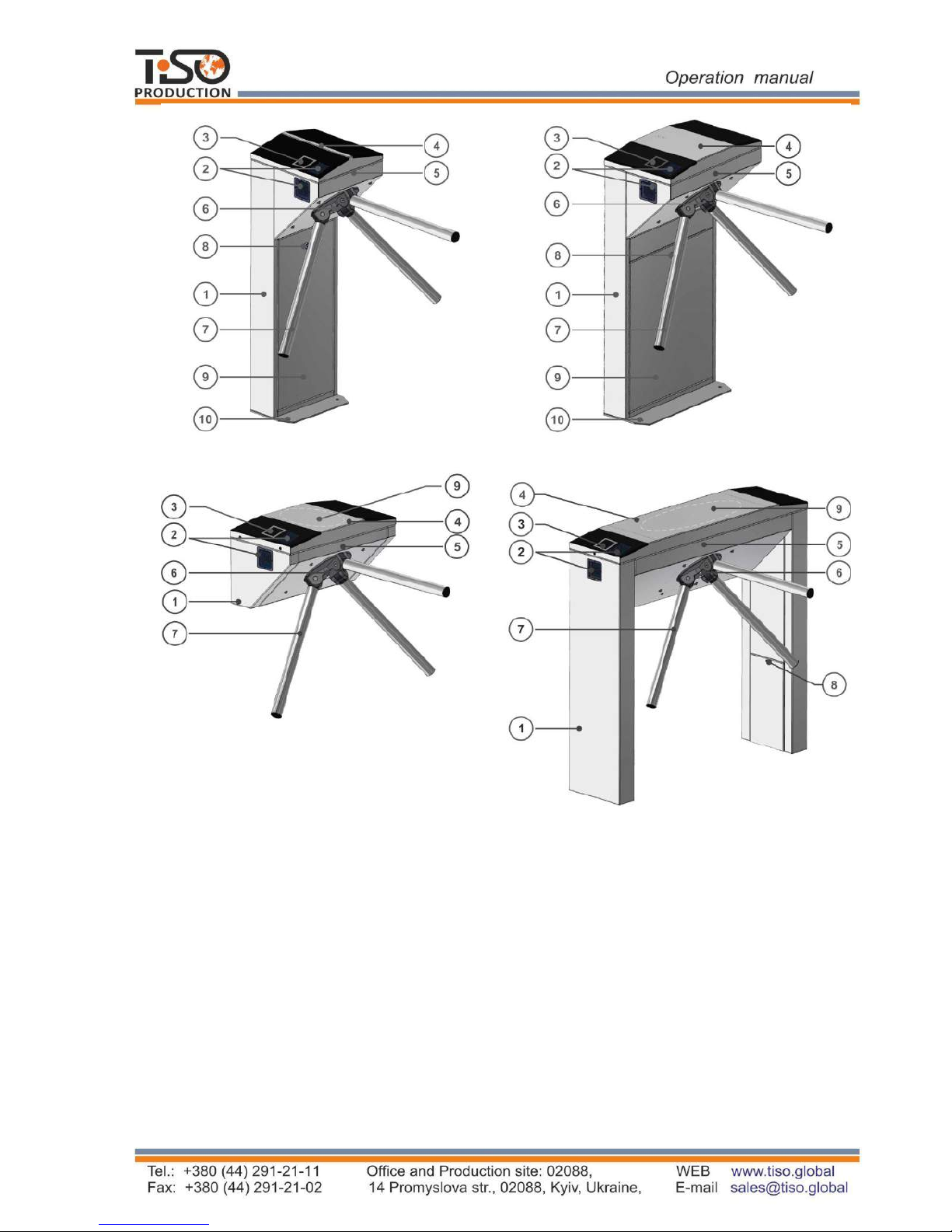

devices and components (See Fig.1):

Design, overall and installation dimensions of the turnstile are shown in Annex A.

8

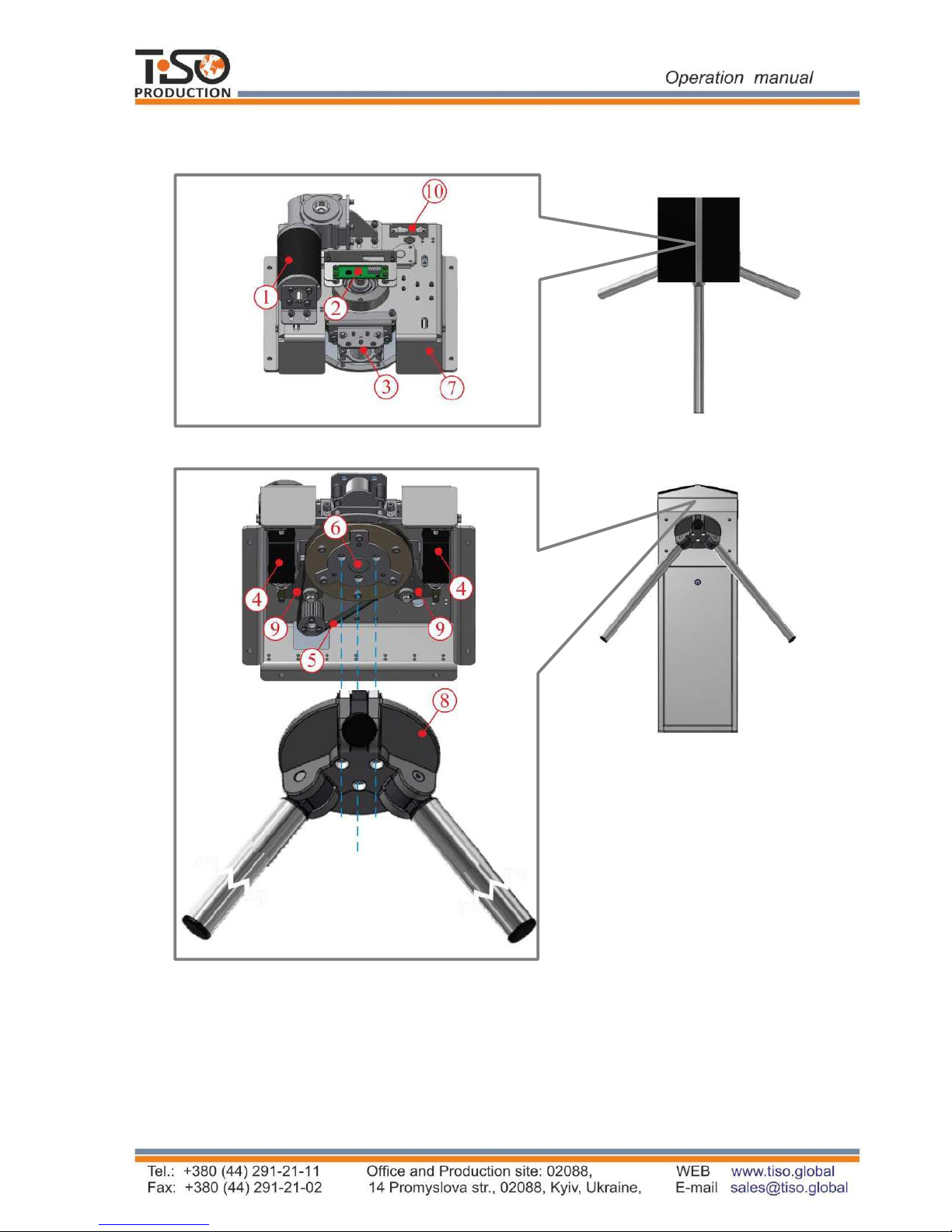

Fig. 1 – Turnstile general appearance

The turnstile modifications are manufactured from:

– polished stainless steel (reference designation T3.TCC.PE).

– brushed stainless steel (reference designation T3.TCC.SE).

– carbon steel painted in any colour according to RAL (reference designation T3.TCC.КE);

The turnstile basic modification is made of brushed stainless steel.

CENTURION-M

BASTION-M

SKULL-M

TWIX-M

1 - turnstile rack;

2 - LED display;

3 - card reader location;

4 - upper lid;

5 - control mechanism;

6 - hub;

7 - barrier rod;

8 - lock door;

9 - control panel;

10 - footing.

9

1.3.2

Turnstile scope of delivery

(standard):

Tripod turnstile

Control panel

Anchors (4 pcs.)

Data sheet

Battery (capacity 4 Ah)

1

For convenience of delivery the turnstile

is supplied ready-to-install with

dismounted barrier rods (See Fig.2).

Fig.2. – Tripod turnstile scope of delivery

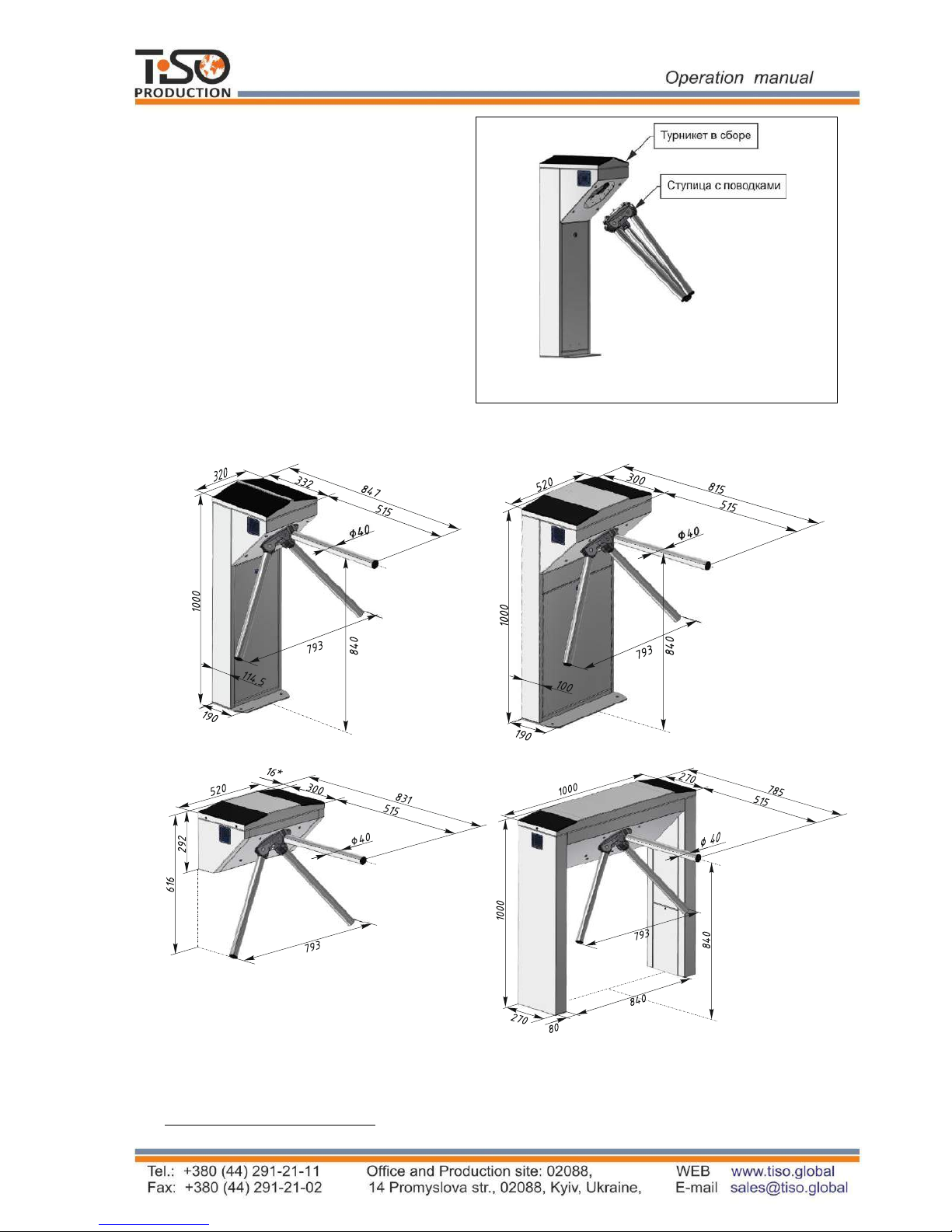

1.3.3 The turnstile design, overall and installation dimensions (See Fig.3)

Fig. 3 - Tripod turnstile dimensions

1

Is not included in the turnstile scope of delivery - to be equipped by the custoner, if appropriate

CENTURION-M BASTION-M

SKULL-M

* Carrier sleeve size

TWIX-M

Turnstile assembly

Hub with barrier rods

10

1.4 Design and operation

1.4.1

Turnstile design

1.4.1.1 The

turnstile body is a metalware, which footing 10 (See Fig.1) is installed on an even

surface

by means of Redibolt anchors. The turnstile status is displayed by LED display boards 2,

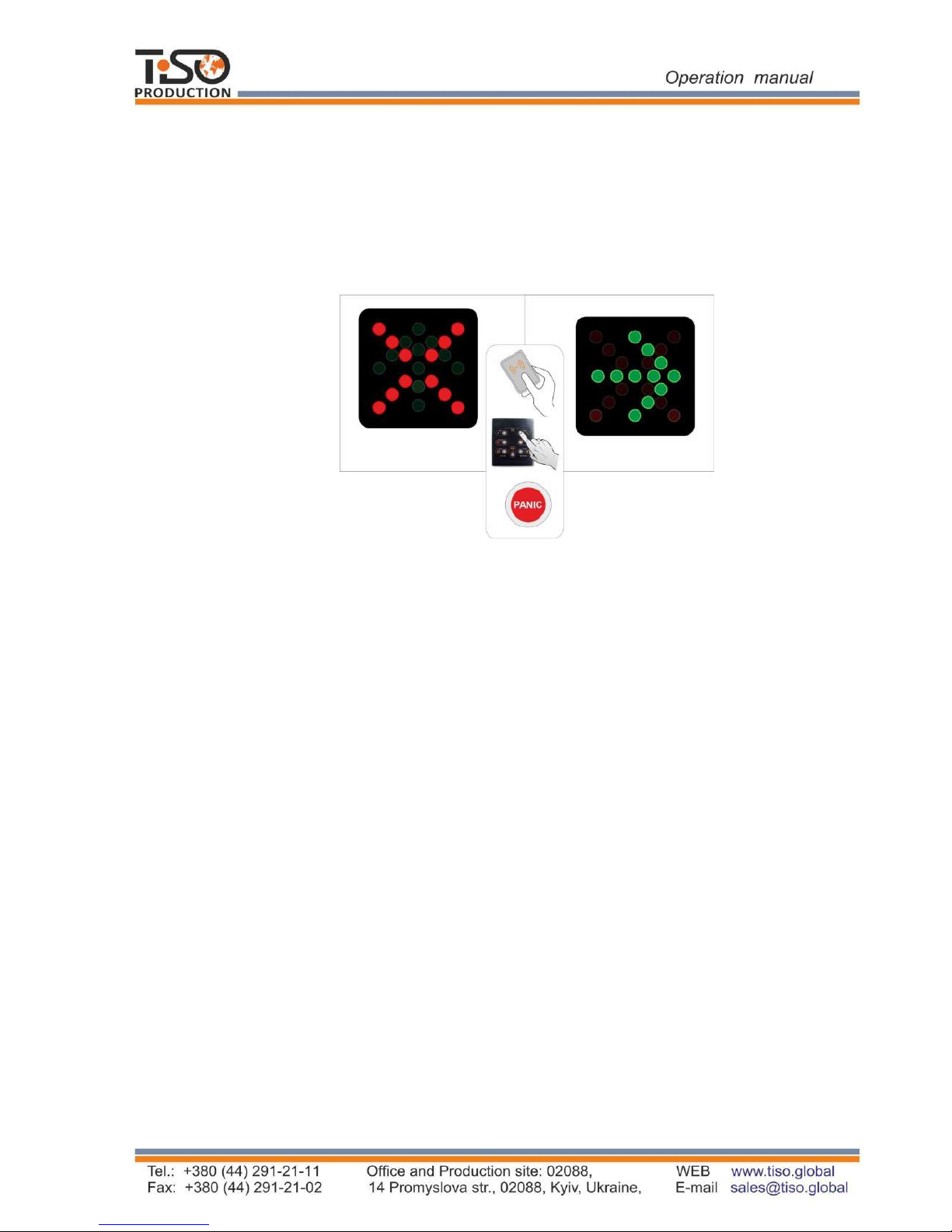

built in the turnstile body. The turnstile initial state is indicated by constantly lit red LED (See

Fig.4): the turnstile access is locked in both directions.

Fig. 4 - Turnstile status LED display

1.4.1.2 The control mechanism 5 (See Fig.1) is installed at the top of the body. The hub 6

with

barrier

rods 7, securely fixed to its levers by crimping method, is installed on the control

mechanism shaft. One of three barrier rods is positioned horizontally barring the turnstile access.

1.4.1.3 The plates, on which power supply unit, controllers, terminal blocks for connection to 220

V network and control panel are mounted, are fixed inside the turnstile post 1 (See Fig.1) under the

removable

door 8 (for the turnstiles CENTURION-M and BASTION-M) or removable lid 4 (for

the turnstiles TWIX and SKULL). Controller controls the turnstile motor analyzing signals from

speed and position sensors as well as provides the motor protection against overloads. Receiving

control commands from peripherals (control panel, ACS etc.) the controller controls LED displays

and generates feedback signals for ACS (Access Control System).

1.4.1.4 The external control panel (See Annex B) has the following functions: single entry access,

single exit access; entry locking, exit locking; free entry access, free exit access, panic.

11

1.4.1.3 The tripod turnstile control mechanism design is shown in Figure 5.

Top view

Front view

6 – hub shaft; 1 – gear motor;

2 – position sensor; 7 – mechanism body;

3 – antipanic device; 8 – hub with barrier rods;

9 – stop catches; 4 – locking solenoid;

5 – driving belt; 10 – mechanism connectors;

Fig. 5 – Turnstile actuating mechanism

12

1.4.3 Turnstile principle of operation

1.4.3.1 Turnstile operation modes:

1) single access in the direction “A” or “B”;

2) locking;

3) free access in the direction “A” or “B”.

4) "PANIC" mode

1.4.3.2 In the initial state, when the turnstile is deenergized, barrier rods are locked

from rotation and access is barred.

1.4.3.3 Green arrow in the intended direction is lit on LED display and barrier rods are unlocked

when access permission command in the direction “A” or “B” comes to controller. Servomotor is

actuated and turns barrier rods in the appropriate direction when a barrier rod is manually gently

pushed in the intended direction. After the turnstile pedestrian access barrier rods continue to

smoothly turn forward (turn additionally) gradually slowing down and when the relevant angle is

reached they are locked by means of two stop catches of the actuating mechanism.

The mechanism powerful controllable ratchet system does not allow to return a barrier rod in the

opposite direction (against the movement in which the access was started) after rotation to 30 º,

60 º, 90 º, 120º.

In case of need for emergency human evacuation from building rooms, the turnstile goes to

"PANIC" mode and provides free access in both directions by means of antipanic device.

The antipanic device (See Fig. 6) is automatically activated when the turnstile is deenergized

(Failsafe), and in this case a barrier rod can't be returned to its initial position during the active

panic mode.

Barrier rod is dropped and access way is cleared when the "PANIC" button is pushed on control

panel and hold for more than 7 seconds or when signal is sent to the relevant input (in1) of the

turnstile controller.

А) "Standby" mode B) "Panic" mode

Fig.6 – Turnstile operation in "PANIC" mode

More detailed description of the turnstile operation modes is given in section 1.8 "Description

and operation of controller as a component of the turnstile”.

1.4.3.4

The turnstile 12V

DC power voltage is provided by power supply unit.

1.4.3.5

The turnstile wiring diagram is shown in Annex C.

1.5

Instrumentation, tools and accessories

Dedicated tools

are not required for installation of the turnstile (multi-purpose

measurement instrumentation and installation tools are sufficient

(See Fig. 8)

).

Fig. 8 -

Tools and accessories for installation

p

uncher

;

concrete drills

(

according to diameter of anchors included in the turnstile scope of delivery

)

;

extension cord

;

kit

of end

and pin

wrenches

;

kit of hexagons

;

kit

of screwdrivers

;

hammer

;

multimeter (tester)

;

measuring tape

marker

;

pliers, side cutters

;

builder's level.

13

After

the signal

is deactivated from the input (

in1

) or deactivation of the panic mode from control

panel, a barrier rod is automatically re

set

to its initial position.

Before turning on the power and turning off the panic, you need to manually check the verticality of

the barrier rod (if necessary, lower the leash manually to the stop). After full recovery - check the

blocking of all three barrier rods.

Fig.7 - Deactivation of the "PA

NICA" mode and restoration of the leash to the starting position

b) The positions of the restored rod

in the

"Standby"mode

"PANIC" mode before restoring

a) The positions of the rod in the

14

1.6 Description and operation of controllers as components of the turnstile

1.6.1 Motorized mechanism controller РСВ.201.01.00.00

The controller is designed for acquisition of commands from the turnstile controller

PCB.112.21.20.00 and generation of signals controlling motor and the motorized mechanism

locking solenoids.

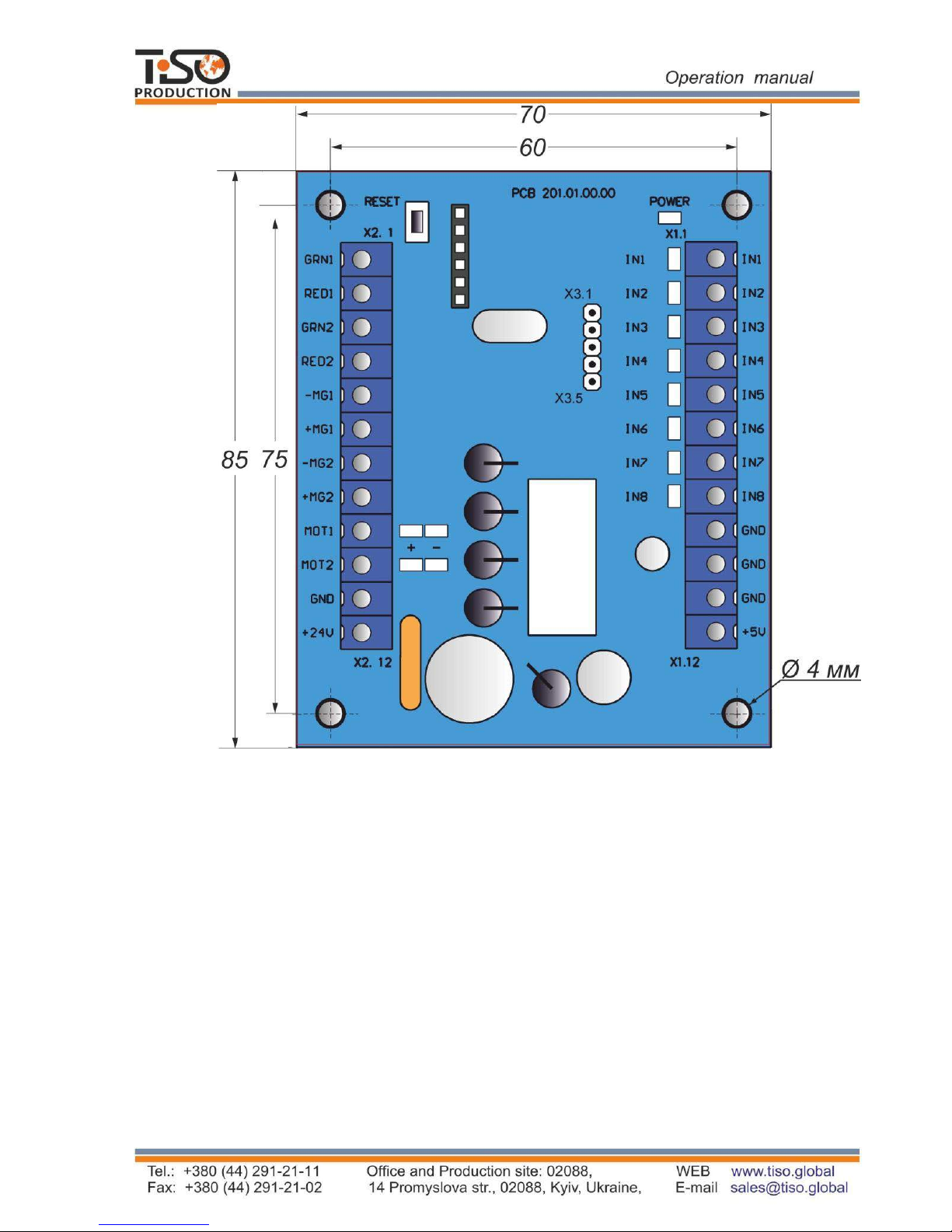

1.6.1.1 The controller is assembled on the (85 х 70mm) board, on which electronic components

and connectors for external connections are mounted.

13 LEDs are installed on the controller board. Their purpose is as follows:

Table 5

Parameter description Parameter value

Number of inputs 2

Number of outputs 4

Type of inputs logical

Type of outputs «GRN1», «RED1», «GRN2», «RED2» open collector

Logical «1» voltage

(3,7 5) V

Logical «0» voltage

(0 1,7) V

Maximum peak voltage applied to inputs «IN1»÷« IN8»

15 V

Peak voltage switched by outputs «GRN1», «RED1», «GRN2»,

«RED2»

30 V

Peak current switched by outputs «GRN1», «RED1», «GRN2»,

«RED2»

2 А

Peak voltage switched by outputs «-MG1», «-MG2»

50 V

Peak current switched by outputs «-MG1», «-MG2»

5 A

Peak voltage switched by outputs «MOT1», «MOT2»

27 V

Peak current switched by outputs «MOT1», «MOT2»

≤ 4 А

Controller supply voltage

(10 27) V

Consumption current when outputs «MOT1» and «МОТ2» are OFF

≤0,15 А

Climatic modification and location category according to GOST

15150-69

MC4

The controller appearance is shown in Figure 9.

/('VLQGLFDWHFRQGLWLRQRILQSXWV³,1ª ©,1´

"32:(5"/('LQGLFDWHVDYDLODELOLW\RIVXSSO\YROWDJH9

/('VLQGLFDWHFRQGLWLRQRIRXWSXWVIRUmotor FRQQHFWLRQ

WHUPLQDOV DUH LQVWDOOHG RQ ERDUG RI WKHP DUH GHVLJQHG IRU H[WHUQDO FRQQHFWLRQV WKH

UHVW DUH GHVLJQHGIRUFRQQHFWLRQWRWKHWXUQVWLOHXQLWVRUDUHVWDQGE\

1.6.1.2 7HFKQLFDOIHDWXUHV

7KHFRQWUROOHUWHFKQLFDOIHDWXUHVDUHVKRZQLQ7DEOH5.

15

Fig. 9 – Appearance of the motorized mechanism controller РСВ.201.01.00.00

1.6.1.3 Description of controller operation

The controller controles the turnstile DC motor and the turnstile mechanism locking solenoids

according to the logic entered into program depending on incoming commands, rotor position,

rotation speed and motor current. It provides rotor locking in initial state, maintaining rotor

rotation speed in access mode as well as motor protection in emergency situations. Control

commands are issued from the turnstile controller PCB.112.21.20.00 via communication port

"Х3".

The purpose of the controller contacts, designed for connection to peripherals, is specified in

Table 6.

Table 7

Connector/

contact No

Designation

Direction

Purpose

Signal parameters and

description

X1/1 IN1

X1/2 IN2

X1/3 IN3

X1/4 IN4

ENTRY Not applicable

ENTRY Not applicable

ENTRY Selection of turnstile type

ENTRY Not applicable

X1/5 IN5 ENTRY

Connection of rotor position

sensor

X1/6 IN6 ENTRY

X1/7 IN7 ENTRY

X1/8 IN8 ENTRY

X1/9 GND

X1/10 GND

X1/11 GND

X1/12 +5 V

X2/1 GRN1

X2/2 RED1

X2/3 GRN2

X2/4 RED2

EXIT Not applicable

EXIT Not applicable

EXIT Not applicable

EXIT Not applicable

EXIT

Not applicable

X2/5 -MG1 EXIT

Connection of locking

solenoid winding

X2/6 +MG1 EXIT

Connection of locking solenoid

winding (cathode of protective

diode )

X2/7 -MG2

EXIT

X2/8 +MG2 EXIT

X2/9 MOT1 EXIT

Motor connection

X2/10 MOT2 EXIT

X2/11 GND

X2/12 +24 V ENTRY

Х3 Х3

ENTRY /

EXIT

«-» power supply

(common wire)

«-» power supply

(common wire)

Communication port

«+» power supply

(controller energization)

1)

(0 y 1,7) 9;

2) ORJLFDO «1»

(3,7 y 5) 9;

3) DFWLYHOHYHORIVLJQDO

– ORJLFDO «0»;

4) YROWDJHRQRSHQ

LQSXW ≤ 5 9

ORJLFDO «0»

W\SHRIRXWSXW±RSHQ

FROOHFWRU

SHDNYROWDJHRQ

SULYDF\NH\±9

SHDNFXUUHQWRISXEOLF

NH\±$

1) YROWDJH

(10 ÷ 27) 9;

2) FXUUHQW ≤ 4 А

1) YROWDJH

(10 ÷ 27) 9;

2) FXUUHQW ≤ 4 А

1)

(0 1) V;

2)

logical «1»

(3,5 5) V

logical «0»

1.6.2

Turnstile controller РСВ.112.21.20.00

The controller is designed for acquisition of control commands from peripherals (control panel,

access control system etc.), generation of feedback signals, the turnstile LED display control and

the motorized mechanism controller control.

Connection of locking solenoid winding

Connection of locking solenoid winding

(

cathode of protective diode )

Loading...

Loading...