Tiresonic FW-301, RW 301 Operating Manual

clean wheel solutions

GmbH

Service-Hotline: +49 (0) 1805 / 881333-3*

* 0,14Euro/Min from the German landline network / mobile phone charges may vary, max. 0,42 Euro/Min.

BA-RWA301.02 D (21.09.2011)

1

Operating Manual

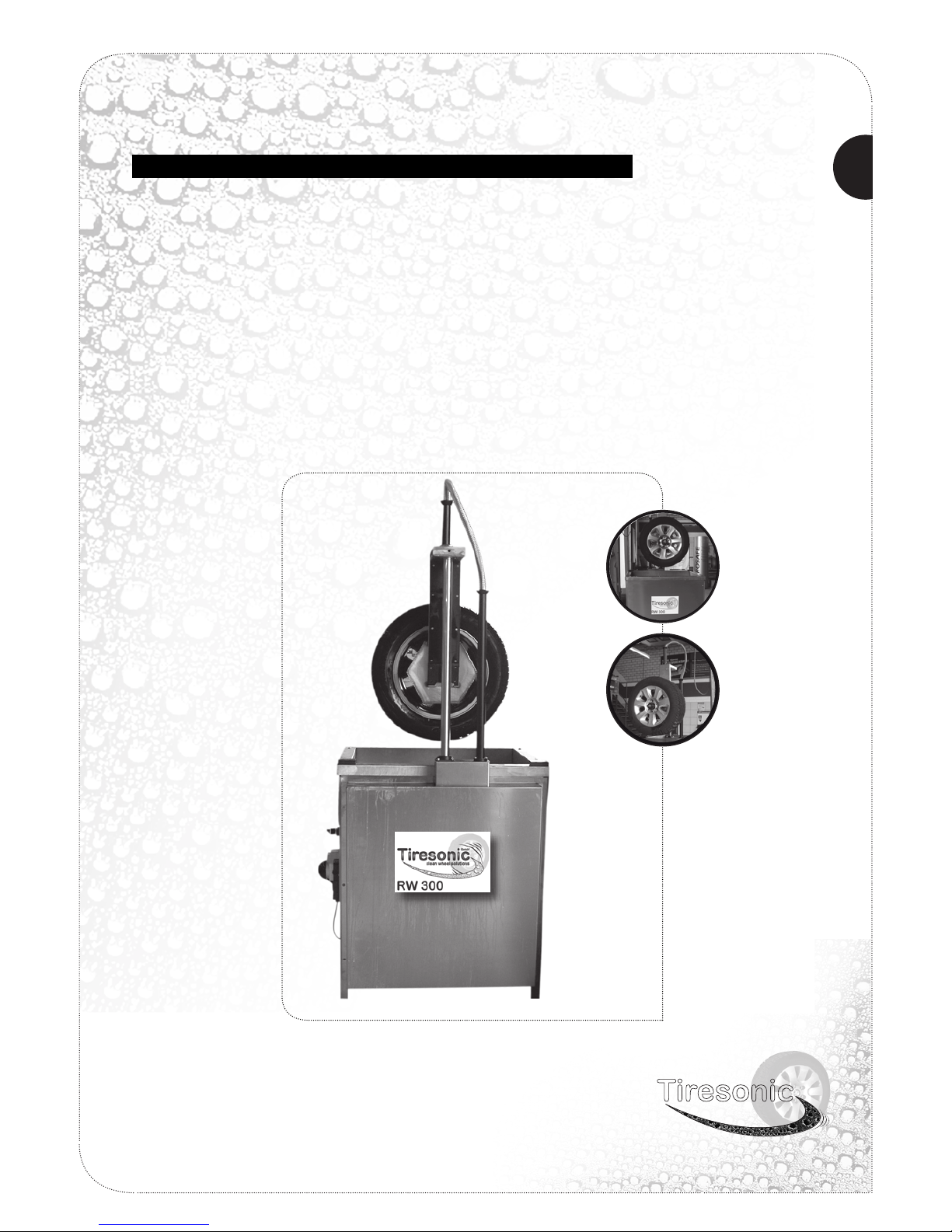

Wheel Washing Machine - Tiresonic RW 301

Rim Washing Machine - Tiresonic FW-301

Operating Manual - Tiresonic GmbH Clean Wheel Solutions

Intern: ..............................

..............................

Excl. the applicable shipping costs

We hereby order the following items:

Amount Item Price

(please list) (please check) (plus VAT.)

...............

...............

...............

...............

Cleaning agent 5kg

Clamping cone for cars

Clamping cone for trucks

Adapter for 14"-Wheels

40,00€

94,00€

98,00€

48,00€

clean wheel solutions

GmbH

2

FAX to: +49 (0) 1805 / 881333-0*

Delivery Address (Stamp):

Serial Number: ...................................

Year of Construction: .........................

Company:...........................................

Street: ................................................

Place:..................................................

Billing Address:

(if different from delivery address)

Company:................................................

Street: ....................................................

Place:......................................................

Telephone:..............................................

Date: ........................... Signature: ....................................

Order Form / Replacement Part Procurement

Order Form / Replacement Parts Procurement

Tiresonic GmbH

Osterwalder Straße 12

D-87496 Hopferbach

Internet: http://www.tiresonic.de

Telephone +49 (0) 1805 / 881333-3*

Telefax +49 (0) 1805 / 881333-0*

* 0,14Euro/Min from the German landline network / mobile phone charges may vary, max. 0,42 Euro/Min.

Master Copy - Don't Seperate

clean wheel solutions

GmbH

3

i

Index

1. Product Description

2. Operating Range and Intended Use

3. Transport - Storage - Scope of Delivery

Transport and Storage

Shipping-Listing

Transport Damage Report

4. Technical Data

5. Safety Instructions

General Safety Instructions

General Safety Instructions for Wheel Washing Machines

Specific Safety Instructions and Frequently Used Symbols

Safety Instructions Regarding the Cleaning Agent "Tiresonic UR 2.xx“

6. Supply Connection (on-site)

7. Handling and Behavior During Operation

Assembly and Mounting

Overview of Controls

Initial and Follow-up Operation

Preperatory Work

Cleaning Process

8. Adjustments of Operating Parameters

9. Behavior in Case of Failure and Maintenance

10. Customer Service

11. Decleration of Conformity - No. 08 30 07

4

5

6

6

6

7

9

10

10

13

14

15

16

17

17

17

19

19

20

23

26

27

28

Index

clean wheel solutions

GmbH

4

1

Product Description

The wheel washing machine enables ideal cleaning results without pre or post treatment of car wheels

with a diameter of up to 810 mm and width of 400 mm.

The patent registered ultrasonic technology cleans the wheels on the inside and outside in one

operation.

The dirt on the rim and tire is rinsed by rotation during the cleaning process.

The Tiresonic cleaning agent is free of aggressive chemicals and is biodegradable.

The wastwater disposal can take place in an internal sludge container or liquid seperators.

The quick clamping device enables a simple mounting of car wheels.

The mounted tire is effortlessly lifted or lowered by a pneumatically operated hoisting device.

The operation of the Tiresonic RW 301 takes place using the clearly arranged operating console.

1. Product Description

clean wheel solutions

GmbH

2

Operating Range and Intended Use

The wheel washing machine is tested for funktion and durability. It provides efficiency and

safety. It is up to you to use these advantages.

This requires correct operation, proper maintenance and grat care for the washing machine.

Please read the instructions carefully. They contain all the data necessary to keep the wheel

washing machine ready for use at all times.

The wheel washing machine is used for cleaning motor vehicle wheels.

The wheel washing machine is solely designed for car wheels with a maximum diameter of

810 mm and width of 400 mm.

The lifting device is intended solely for lifting wheels with a max. wieght of 60 kg.

When using the wheel washing machine in paint shops or areas with many solvent-based

materials, beware of the risk of explosion.

The wheel washing machine is not explosion-proof standard.

The wheel washing machine is equipped with a safety device that ensures safe operation when

correctly handled.

The wheel washing machine should only be serviced and repaired by factory- trained

personnel.

2. Operating Range and Intended Use

5

clean wheel solutions

GmbH

6

3

Transport and Storage:

The packaged wheel washing machine may only be lifted at the therefore designated points.

Grasping with the lifting truck outside the assigned points may lead to costly repairs.

The wheel washing machine should not be stored outdoors.

The wheel washing machine should only be unpacked at the installation site.

Unpacking

When unpacking the wheel washing machine and the accessories kit, make sure to check for possible

damage in transit which should immediately be reported to the forwarding company and the Tiresonic

company.

All components have to be laid out carefully so that nothing is lost with the disposal of the packaging

materials.

Shipping-Listing

1 x Tire Washing Machine "RW301"

1 x Tank cover

1 x Quick clamping cone for cars

1 x Cleaning agent "UR 2.xx" 5kg for initial filling

1 x CEE connection cablel, 5 m long, 16 A

1 x Compressed air connection hose, 5m

1 x Non-woven abrasive for cleaning the clamping device

Accessories (Optional):

· Cleaning agent "Tiresonic UR 2.xx“ VP (5kg container)

· Clamping cone for cars (as a spare part)

· Clamping cone for transport vehicle

· Adapter for 14"- wheels

· Semi-automatic (Page 21)

Transport - Storage - Scope of Delivery

3. Transport - Storage - Scope of Delivery

clean wheel solutions

GmbH

7

3

IMPORTANT INFORMATION!

for our end customers in case of

TRANSPORT DAMAGE

Delivery:

Please carefully check the goods immediately after delivery in presence of the shipper.

If the goods are damaged, no clean reciept may be given. Note the damage on the shipping papers

as the circumstances require.

Notification of claim:

To ensure a quick and easy settlement of claims, damage taken through transport must be reported to

the Tiresonic-Service-Partner on discovery.

The notification can be made by telephone, in writing or by fax/e-mail and should have the following

content:

· Commission number of the Tiresonic-invoice and date of delivery

· Tire Washing Machine- type and serial number

· Accurate description of damage

(If necessary, use the back of this sheet.)

Damage repair and billing

A regulation of transport damage can only be managed by the Tiresonic company if a notification of

claims is recieved within 3 working days after delivery in one of the above listed ways.

Repairs, replacement part deliveries and billing of transport damage will be carried out by your

Tiresonic-Servicepartner.

Transport - Storage - Scope of Delivery

3. Transport - Storage - Scope of Delivery

* 0,14Euro/Min from the German landline network / mobile phone charges may vary, max. 0,42 Euro/Min.

FAX: +49 (0) 1805 / 881333-0*

clean wheel solutions

GmbH

8

3

Transport - Storage - Scope of Delivery

Wheel Washing Machine

Type

:

Serial number :

delivered by Delivery note no.:

through

Company:

Date :

during

the following damage was recorded:

(exact description of damage)

The package was

delivery

unpacking

damaged

not damaged

Place, Date Customer

3. Transport Damage Report

clean wheel solutions

GmbH

9

4

Technical Data

Size (WxDxH):

Weight (unfilled):

Stainless steel tank:

Water capacity:

Ultrasonic power:

Heating

Driving motor power:

Carrying capacity of the lifting device:

Max. wheel diameter:

Max. wheel width:

Wash programm:

for normally soiled wheels

for heavily soiled wheels

Noise level (machine model "partly insulated") measured in 1m Distance

Noise level (machine model "fully insulated") measured in 1m Distace

Cleaning agent:

Mixing ratio: (according to the water hardness)

approx. 2% dilution (270 l water and 5kg cleaning agent)

The tensides contained in "Tiresonic" are at least 90% biodegradable

according to TensV of WRMG.

Electrical connection:

Compressed air supply:

Fresh water supply:

Waste water disposal:

(in light fluid seperator

workshop floor drain)

All details are subject to technical modification.

880x1040x1800 mm / max. 2550 mm

200 kg

V2A steel sheet 2 mm

270 l

2300 W

Up to 50°C with 4.5 kW

100 W

60 kg

810 mm

400 mm

ca. 120 s

ca. 180 s

83 dB (A)

77 dB (A)

Tiresonic UR 2.xx

3 x 400 V, 16 A (slow acting)

p max. = 10 bar

p min. = 8

Hose

1˝ outlet ball valve

Generally, only original spare parts supplied by the Tiresonic

company should be used!

Accessories can be ordered according to the current price list!

If foreign bodies are installede all forms of warranty will become invalid.

i

Note

4. Technical Data

Loading...

Loading...