clean wheel solutions

GmbH

Service-Hotline: +49 (0) 1805 / 881333-3*

* 0,14Euro/Min from the German landline network / mobile phone charges may vary, max. 0,42 Euro/Min.

BA-RWA301.02 D (21.09.2011)

1

Operating Manual

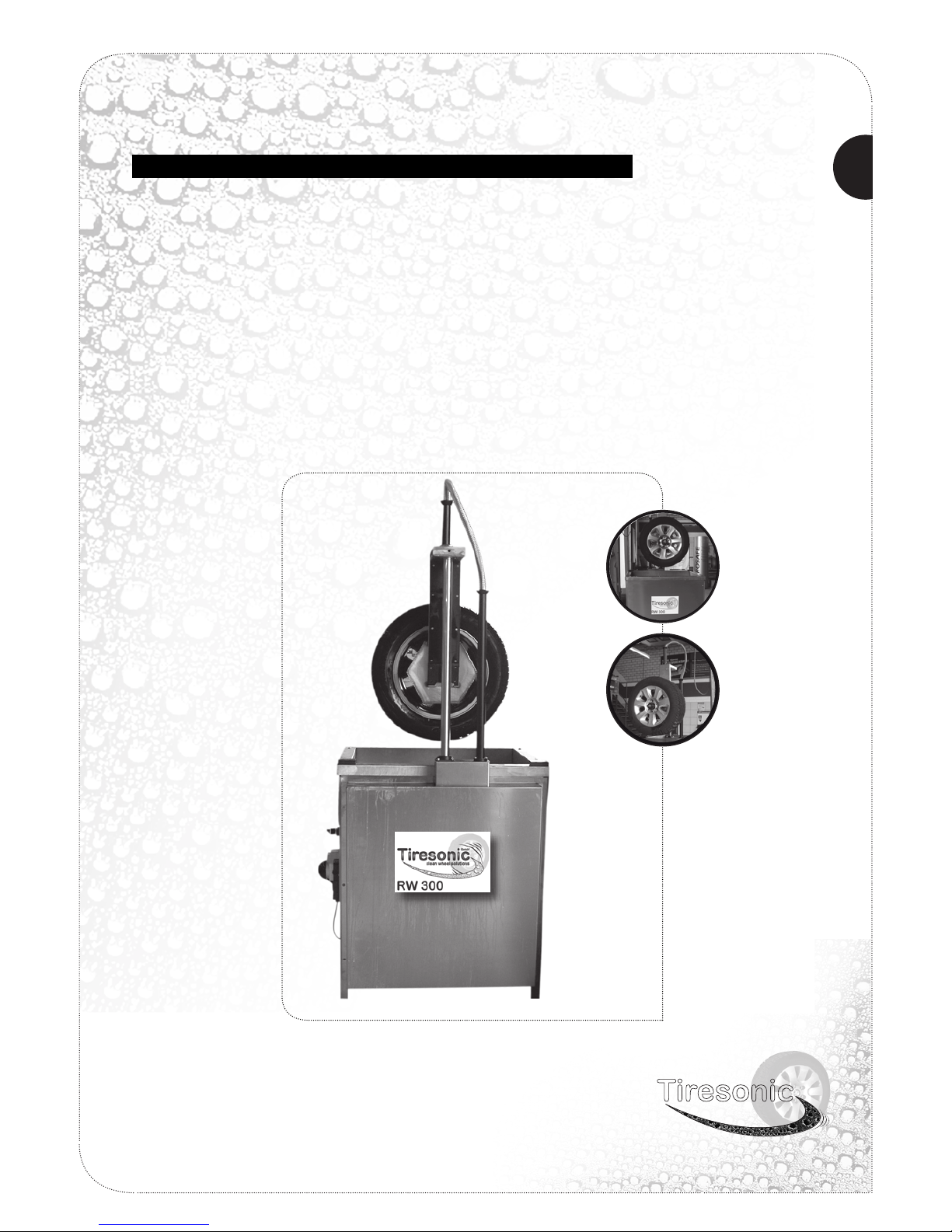

Wheel Washing Machine - Tiresonic RW 301

Rim Washing Machine - Tiresonic FW-301

Operating Manual - Tiresonic GmbH Clean Wheel Solutions

Intern: ..............................

..............................

Excl. the applicable shipping costs

We hereby order the following items:

Amount Item Price

(please list) (please check) (plus VAT.)

...............

...............

...............

...............

Cleaning agent 5kg

Clamping cone for cars

Clamping cone for trucks

Adapter for 14"-Wheels

40,00€

94,00€

98,00€

48,00€

clean wheel solutions

GmbH

2

FAX to: +49 (0) 1805 / 881333-0*

Delivery Address (Stamp):

Serial Number: ...................................

Year of Construction: .........................

Company:...........................................

Street: ................................................

Place:..................................................

Billing Address:

(if different from delivery address)

Company:................................................

Street: ....................................................

Place:......................................................

Telephone:..............................................

Date: ........................... Signature: ....................................

Order Form / Replacement Part Procurement

Order Form / Replacement Parts Procurement

Tiresonic GmbH

Osterwalder Straße 12

D-87496 Hopferbach

Internet: http://www.tiresonic.de

Telephone +49 (0) 1805 / 881333-3*

Telefax +49 (0) 1805 / 881333-0*

* 0,14Euro/Min from the German landline network / mobile phone charges may vary, max. 0,42 Euro/Min.

Master Copy - Don't Seperate

clean wheel solutions

GmbH

3

i

Index

1. Product Description

2. Operating Range and Intended Use

3. Transport - Storage - Scope of Delivery

Transport and Storage

Shipping-Listing

Transport Damage Report

4. Technical Data

5. Safety Instructions

General Safety Instructions

General Safety Instructions for Wheel Washing Machines

Specific Safety Instructions and Frequently Used Symbols

Safety Instructions Regarding the Cleaning Agent "Tiresonic UR 2.xx“

6. Supply Connection (on-site)

7. Handling and Behavior During Operation

Assembly and Mounting

Overview of Controls

Initial and Follow-up Operation

Preperatory Work

Cleaning Process

8. Adjustments of Operating Parameters

9. Behavior in Case of Failure and Maintenance

10. Customer Service

11. Decleration of Conformity - No. 08 30 07

4

5

6

6

6

7

9

10

10

13

14

15

16

17

17

17

19

19

20

23

26

27

28

Index

clean wheel solutions

GmbH

4

1

Product Description

The wheel washing machine enables ideal cleaning results without pre or post treatment of car wheels

with a diameter of up to 810 mm and width of 400 mm.

The patent registered ultrasonic technology cleans the wheels on the inside and outside in one

operation.

The dirt on the rim and tire is rinsed by rotation during the cleaning process.

The Tiresonic cleaning agent is free of aggressive chemicals and is biodegradable.

The wastwater disposal can take place in an internal sludge container or liquid seperators.

The quick clamping device enables a simple mounting of car wheels.

The mounted tire is effortlessly lifted or lowered by a pneumatically operated hoisting device.

The operation of the Tiresonic RW 301 takes place using the clearly arranged operating console.

1. Product Description

clean wheel solutions

GmbH

2

Operating Range and Intended Use

The wheel washing machine is tested for funktion and durability. It provides efficiency and

safety. It is up to you to use these advantages.

This requires correct operation, proper maintenance and grat care for the washing machine.

Please read the instructions carefully. They contain all the data necessary to keep the wheel

washing machine ready for use at all times.

The wheel washing machine is used for cleaning motor vehicle wheels.

The wheel washing machine is solely designed for car wheels with a maximum diameter of

810 mm and width of 400 mm.

The lifting device is intended solely for lifting wheels with a max. wieght of 60 kg.

When using the wheel washing machine in paint shops or areas with many solvent-based

materials, beware of the risk of explosion.

The wheel washing machine is not explosion-proof standard.

The wheel washing machine is equipped with a safety device that ensures safe operation when

correctly handled.

The wheel washing machine should only be serviced and repaired by factory- trained

personnel.

2. Operating Range and Intended Use

5

clean wheel solutions

GmbH

6

3

Transport and Storage:

The packaged wheel washing machine may only be lifted at the therefore designated points.

Grasping with the lifting truck outside the assigned points may lead to costly repairs.

The wheel washing machine should not be stored outdoors.

The wheel washing machine should only be unpacked at the installation site.

Unpacking

When unpacking the wheel washing machine and the accessories kit, make sure to check for possible

damage in transit which should immediately be reported to the forwarding company and the Tiresonic

company.

All components have to be laid out carefully so that nothing is lost with the disposal of the packaging

materials.

Shipping-Listing

1 x Tire Washing Machine "RW301"

1 x Tank cover

1 x Quick clamping cone for cars

1 x Cleaning agent "UR 2.xx" 5kg for initial filling

1 x CEE connection cablel, 5 m long, 16 A

1 x Compressed air connection hose, 5m

1 x Non-woven abrasive for cleaning the clamping device

Accessories (Optional):

· Cleaning agent "Tiresonic UR 2.xx“ VP (5kg container)

· Clamping cone for cars (as a spare part)

· Clamping cone for transport vehicle

· Adapter for 14"- wheels

· Semi-automatic (Page 21)

Transport - Storage - Scope of Delivery

3. Transport - Storage - Scope of Delivery

clean wheel solutions

GmbH

7

3

IMPORTANT INFORMATION!

for our end customers in case of

TRANSPORT DAMAGE

Delivery:

Please carefully check the goods immediately after delivery in presence of the shipper.

If the goods are damaged, no clean reciept may be given. Note the damage on the shipping papers

as the circumstances require.

Notification of claim:

To ensure a quick and easy settlement of claims, damage taken through transport must be reported to

the Tiresonic-Service-Partner on discovery.

The notification can be made by telephone, in writing or by fax/e-mail and should have the following

content:

· Commission number of the Tiresonic-invoice and date of delivery

· Tire Washing Machine- type and serial number

· Accurate description of damage

(If necessary, use the back of this sheet.)

Damage repair and billing

A regulation of transport damage can only be managed by the Tiresonic company if a notification of

claims is recieved within 3 working days after delivery in one of the above listed ways.

Repairs, replacement part deliveries and billing of transport damage will be carried out by your

Tiresonic-Servicepartner.

Transport - Storage - Scope of Delivery

3. Transport - Storage - Scope of Delivery

* 0,14Euro/Min from the German landline network / mobile phone charges may vary, max. 0,42 Euro/Min.

FAX: +49 (0) 1805 / 881333-0*

clean wheel solutions

GmbH

8

3

Transport - Storage - Scope of Delivery

Wheel Washing Machine

Type

:

Serial number :

delivered by Delivery note no.:

through

Company:

Date :

during

the following damage was recorded:

(exact description of damage)

The package was

delivery

unpacking

damaged

not damaged

Place, Date Customer

3. Transport Damage Report

clean wheel solutions

GmbH

9

4

Technical Data

Size (WxDxH):

Weight (unfilled):

Stainless steel tank:

Water capacity:

Ultrasonic power:

Heating

Driving motor power:

Carrying capacity of the lifting device:

Max. wheel diameter:

Max. wheel width:

Wash programm:

for normally soiled wheels

for heavily soiled wheels

Noise level (machine model "partly insulated") measured in 1m Distance

Noise level (machine model "fully insulated") measured in 1m Distace

Cleaning agent:

Mixing ratio: (according to the water hardness)

approx. 2% dilution (270 l water and 5kg cleaning agent)

The tensides contained in "Tiresonic" are at least 90% biodegradable

according to TensV of WRMG.

Electrical connection:

Compressed air supply:

Fresh water supply:

Waste water disposal:

(in light fluid seperator

workshop floor drain)

All details are subject to technical modification.

880x1040x1800 mm / max. 2550 mm

200 kg

V2A steel sheet 2 mm

270 l

2300 W

Up to 50°C with 4.5 kW

100 W

60 kg

810 mm

400 mm

ca. 120 s

ca. 180 s

83 dB (A)

77 dB (A)

Tiresonic UR 2.xx

3 x 400 V, 16 A (slow acting)

p max. = 10 bar

p min. = 8

Hose

1˝ outlet ball valve

Generally, only original spare parts supplied by the Tiresonic

company should be used!

Accessories can be ordered according to the current price list!

If foreign bodies are installede all forms of warranty will become invalid.

i

Note

4. Technical Data

clean wheel solutions

GmbH

10

5

Safety Instructions

General Safety Instructions

Company's duty of care:

The wheel washing machine was built and constructed under consideration of all mandatory harmonised

standards and further technical specifications. It is therefore at the highest level of technology

and offers maximum safety during operation.

However, the machine safety can only be implemented in operational practice if all actions necessary are

taken.The operator of the wheel washing machine is obliged to plan these measures and check

that they are being complied with.

The workplace lighting according to the EU regulations 89/655 EWG must be considered by the

operator. Stability must be guaranteed by a level platform.

The operator must ensure in particular that:

· the wheel washing machine is only used as intended.

· the wheel washing machine is only operated in perfect working condition and the safety

installations are checked regularly for functionality.

· required protective equipment for operating, maintenance and repair personnel is available

and worn.

· the operating manual is complete and legible at all times as well as being available at the site

of operation.

· only qualified and authorized personnel operate, repair and maintain the machine.

· this personell is regularly informed about relevant occupational safety and environmental protection,

as well as knowing the operating manual and particularly the therein determined safety

instructions.

· all safety and warning labels attached to the wheel washing machine are not removed and

completely legible.

Employment

§§

Accident prevention

Regulations

of the

Employers' Liability

Insurance Association

Operating Manual

5. Safety Instructions

clean wheel solutions

GmbH

11

5

Basic safety measures for normal operation:

Only qualified and authorized persons are permitted to operat the wheel washing machine. These

have to know the operating manual and be able to work accordingly!

Before turning on the wheel washing machine ensure that:

· only authoruzed persons are present in the working area of the wheel washing machine.

· no one can be injured by operating the wheel washing machine.

· the wheel washing machine is checked for visible damage before each use and only operated

in perfect condition!

· any defects are reported to your superier immediately!

· all safety installations are funktioning faultlessly before each operating session!

· inspection and service intervals defined in the operating manual are met.

´Basic safety measures for Servicing and maintenance:

Before performing any maintenance or repair work make sure to close off all

access of unauthorized personell to the working area of the wheel washing machine.

Put up signs that call attantion to the maintenance or repair work!

Before performing any maintenance or repair work make sure to unplug power cord.

Before performing any maintenance or repair work make sure to unplug the

power cable. When using permanently installed lines turn the main power switch

off and secure with a padlock. The key to this padlock must be in the hands of

the person performing the maintenance or repair work! When replacing heavy

machine parts only use suitable and flawless lifting devices as well as sling gear!

Make sure to properly dispose environmentally hazardous lubricating, cooling

and cleaning agents!

5. Safety Instructions

Safety Instructions

clean wheel solutions

GmbH

12

5

Safety Instructions

Working on the electrical equipment:

· Only carry out work when the equipment is disconnected from the power supply.

· Repair work on the electrical equipment of the wheel washing machine may only

be performed by a qualified electrician!

· Check electrical equipment regularly!

· Refasten loose connection!

· Replace damaged lines/cables immediately!

· Keep housing provided for electrical equipment closed at all times! access is

limited to authorized personnell with a key and appropriate tools!

· Never clean the housing provided for electrical equipment with a hose pipe!

Note envronmental regulations:

While working at or with the appliance, the legal responsibilities for wast-avoidance

and proper recycling have to be followed.

Especially during installation, repair and maintenance water polluting substances

such as

· greases and oils

· hydraulic oil

· cooling agent

· solvent-based cleaning agents

must not infiltrate the ground nor reach the sewage system.

These substances must be stored, transported and collected in suitable containers

and then disposed of!

5. Safety Instructions

clean wheel solutions

GmbH

13

5

General Safety Instructions for Wheel Washing Machines

The wheel washing machine may only be used to wash car tires complying with the

technical data.

Rims and wheels contaminated with oil and grease must be manually cleaned before

being washed in the wheel washing machine. Other vehicle parts exposed to oil and grease

should under no circumstances be put into the washer - the washing water will lose its

effect!

Only suitably trained staff may operate the machine.

Safety devices should not be replaced.

Necessary repair work must be performed by trained service personell. By unauthorized

modifications to the systemall, liability on the part of the manufacturing company is

extinguished.

Work on the electrical installation may only be carried out by qualified electricians.

The wheel washing machine should not be operated in potentially explosive atmospheres.

If there is a danger of frost the cleaning agent must be removed from the machine.

Only permissible cleaning agent "Tiresonic UR 2.xx" may be used. If other cleaning

agents are used the manufacturing company is exempt from all liabilities.

Safety Instructions

5. Safety Instructions

clean wheel solutions

GmbH

14

5

Safety Instructions

Specific Safety Instructions and Frequently used Symbols

The following operating manual safety instructions point out unavoidable residual risks that may arise

while operating the wheel washing machine.These residual risks include danger for:

· People

· Product

· Environment

The symbals used in this operating manual are primarily intended to call attention to the safety

instructions!

The primary purpose of these safety instructuins is to prevent personal injuries.

The respective safety symbol does not replace the corresponding text. Therefore, always

read the entire text carefully!

When using the ultrasonic mode don't reach into the water bath.

(liquid approx. 50°C hot)

Wear protective PVC gloves.

Use a skin protecting agent before and after operating the wheel washing machine.

Warning of dangerous electrical voltage.

Before opening the controle cabinet make sure the main switch is at „0“ and

secure it from being switched back on again.

(if necessary disconnect the power cord)

During the lifting, lowering and pivoting process no person may remain

in the working area of the wheel dolly! On completing the work process,

swing the pivot arm outside the basin in an upright position.

Dispose sewage through internal sludge tank or light fluid seperator.

This symbol does not refer to any safety instructions but

offers important notes for better understanding of the machine funktions

and its operation.

Wear hearing protection.

Danger of crushing.

i

Hinweis

5. Safety Instructions

clean wheel solutions

GmbH

15

5

Safety Instructions

Safety Instructions Regarding the Cleaning Agent "Tiresonic UR 2.xx"

Safety instructions for the preperation of a 2% cleaning agent solution with

100% cleaning agent (product description Tiresonic UR 2xx)

when handling Tiresonic UR 2.xx pur:

Harmful und irritant substance.

Wear protective PVC gloves.

Wear protective goggles.

Avoid skin and eye contact.

On inhaling atomized spray, eye contact or ingestion, consult a doctor.

Do not allow to enter the drains, surface and ground water. Absorb spilled cleaning

agent with liquid binding materials (sand, turf, saw dust). Wash away residue with

plenty of water. Dispose of in accordance with regulations:

EWC/EAK-Code: 0706 08

5. Safety Instructions

clean wheel solutions

GmbH

16

6

Supply Connection

The electricity supply of the wheel washing machine on-site takes place via a CEE-cable connected

to the electricity network 400 V / 3 phases / 16 A (slow acting).

The socket must have a right-handed rotary field. (DIN VDE 0 100 part 560, point 4.7)

Electrical connections should only be performed by qualified electricians. The

warranty does not cover damage that may occur due to failing to observe the

direction of rotation.

The fresh water is supplied via an external water pipe.

The used cleaning agent is drained via the 1˝ outlet ball valve into the

workshops light fluid seperator (workshop floor drain).

i

Note

6. Supply Connection (on-site)

Caution:

The filled machine is not allowed to be switched off if installed on a site prone to frost.

Alternatively drain the water! Damage due to frost is born by the customer.

i

Note

clean wheel solutions

GmbH

17

7

Handling and Behavior During Operation

Assembly and Mounting

7. Handling and Behavior During Operation

Place the machine in the intended position and align

the tank horizonatally using the integrated bubble

tube.

Mount the cable tube on the back board using the

available screws.

Ensure that the cable tube is not twisted!

It is important to ensure that the cable conduit (a) can move freely

and is not obstructed by other objects.

The cable tube (b) on the back board is not a stop and must not be

mechanically stressed!

Connect to power supply and pessurized air.

a

b

clean wheel solutions

GmbH

Button: "Up"

Button: "Down"

Button: "Clamp" / "<!>"

Overview of Controls

Display

Rotary Potentiometer

for Menu Selection

Button: "Heating ON"

Button: "Timer" / "<=>"

Control-LED: Water Level Too Low

Control-LED: OK

Control-LED: Heating Active

Button: "Heating Off"

Button: "Washing Duration"

Heating Modes

Note: After switching on the machine, the heating is always active!

Heating always active

Activate by pressing <Heating On>

Heating always off

Activate by pressing<Heating OFF>

Heating activated by timer

Activate by pressing <Timer>

18

7

Handling and Behavior During Operation

7. Handling and Behavior During Operation

clean wheel solutions

GmbH

19

7

Handling and Behavior During Operation

Reinigungsmittel "Tiresonic UR 2.xx"

Harmful and irritant

substance!

Pay attention to safety

instructions!

When filling with the

cleaning agent, wear

personal protective

equipment!

the Ultrasonic oscillators must be covered with liquid during operation!

If the water level is too low, the ultrasonic mode will not function

and the yellow water level lamp will light up.

Initial and Follow-up Operation

Preparatory work:

Turn the main switch to ON ( I ).

Press the <Open> button.

The stroke unit will now move up.

A message will then appear '<Lift up>'.

During the lifting, tilting and lowering operation, no one should

stand in the range of operation of the wheel dolly.

It is necessary to check that the wheel dolly runs straight up

and doesn't turn to the side (if so, correct the alignment of the

machine).

Fill the cleaning tank with cold or pre-heated water

to above the level sensor.

Add 5 Kg cleaning agent "Tiresonic UR 2.xx“ for a new filling

and dissolve completely by stirring.

No cleaning agent should remain on the tank floor!

The cleaning tub will automatically be heated to operating

temperature (ex factory approx. 50°C).

The machine is now ready for operation.

min

max

7. Handling and Behavior During Operation

clean wheel solutions

GmbH

20

7

Handling and Behavior During Operation

Initial and Follow-up Operation

Cleaning Process:

Clamping the wheel

Put the pneumatically driven wheel dolly in the lowest position

with the button <Down> (this is the operating position for

clamping and removing the wheel).

(The wheel dolly will automatically stop in the lowest position.)

Release the support shaft by pressing <Clamp> .

Remove the clamping cone from the supporting shaft of the

clamping device.

Use the plastic cone (Pos. 1) of the quick clamping device (for

car wheels with centre hole centering).

Push the wheel onto the support shaft as far as possible.

Mount the cone with the small diameter onto the supporting

shaft and snap the bayonet catch into place by slightly rotating

clockwise.

To tightly clamp the wheel, hold <Clamp> pressed for 2

seconds.

If the button is released before the 2 seconds have passed,

the supporting shaft will open for safety reasons.

7. Handling and Behavior During Operation

clean wheel solutions

GmbH

21

7

Handling and Behavior During Operation

Initial and Follow-up Operation

Immersing the wheel into the cleaning bath

Vie button control drive the pneumatically

driven wheel dolly into its uppermost position.

(the wheel dolly will automatically stop

in the uppermost position)

Rotate the supporting arm in center above

the cleaning bath by hand.

Using button control lower the pneumatically driven

supporting arm of the wheel dolly and the

mounted wheel completely into the stainless

steel bath, filled with cleaning agent.

(The wheel dolly will automatically stop in

washing position.)

The light barrier protects against bruising and

crushing.

7. Handling and Behavior During Operation

clean wheel solutions

GmbH

22

7

Handling and Behavior During Operation

Initial and Follow-up Operation

Starting cleaning

Press the "60s" button for lightly soiled,

"120s" button for normally soiled and

"180s" button for heavily soiled rims.

The washing program will now run automatically. The material and environmentally friendly

ultrasonic cleaning technology, combined with the wheel rotation ensure extremely clean wheels

without additional manual work. It is also an active contribution to environmental protection.

Caution: Good washing results only

with setpoint temperature and degassed water!

After completing the ultrasonic cleaning process,

the clean wheel will automatically be lifted out of

the washing bath. Let the wheel drip off and swing

outwards by hand. By pressing the button <Down>

move into the lowest position and wind down the

wheel.

When handling wet wheels

wear hand protection!

Use suitable gloves made of PVC!

Use a skin protecting

agent before and after

washing a wheel.

Extras: Semiautomatic

The semiautomatic mode allows the machine to be

operated by using only one button. To simplify operation,

the button is installed at knee height.

Here, the steps of procedure are systematically and

automatically performed as follows:

wheel clamping - wheel lifting - lowering of wheel and start

of cleaning - wheel lifted out of the water - wheel lowered clamping device loosened.

7. Handling and Behavior During Operation

clean wheel solutions

GmbH

Button: "Up"

Button: "Down"

Button: "Clamp" / "<!>"

Overview of controls

Display

Rotary Potentiometer

for Menu Selection

Button: "Heating ON"

Button: "Timer" / "<=>"

Control-LED: Water Level Too Low

Control-LED: OK

Control-LED: Heating Active

Button: "Heating OFF"

Button: "Washing Duration"

23

8

Adjustmens of Operating Parameters

8. Adjustments of Operating Parameters

Heating Modes

Note: After switching on the machine, the heating is always active!

Heating always active

Activate by pressing <Heating ON>

Heating always off

Activate by pressing <Heating OFF>

Heating activated by teimer

Activate by pressing <Timer>

clean wheel solutions

GmbH

24

Water temperature setpoint

Press and hold the <Heating ON> button for 5 seconds.

The display will show:

Water temperature: 45°C

End < = > Save < !>

Set the desired water temperature with the potentiometer (recommended: 45.0°C).

By pressing <Clamp> the water temperature will be saved and the menu exited.

By pressing <Timer> the menu will be exited without saving.

Washing duration 60 s

A variable washing duration can be assigned to the 60 s button.

Press and hold the <60 s> button for 5 seconds

The display will show:

Washing Duration 1 : 60 s

End < = > Save < !>

Set the desired wash duration using the potentiometer.

By pressing <Clamp> the water washing duration will be saved and the menu exited.

By pressing <Timer> the menu will be exited without saving.

Time and switching time

Press and hold the <Timer> button for 5 seconds

The display will show:

Tim e o ld: 09 : 1 9:56

Time new: 09:19:56

The hours of the line "Time new“ are flashing.

Set the hours using the potentiometer and save with the <Clamp> button.

By pressing <Timer> the menu "time" will be exited without saving.

The minutes of the line "Time new“ are flashing.

Set the minutes using the potentiometer and save with the <Clamp> button.

By pressing <Timer> the menu "time" will be exited without saving.

8

Adjustmens of Operating Parameters

8. Adjustments of Operating Parameters

clean wheel solutions

GmbH

25

The seconds of the line "Time new“ are flashing.

Set the seconds using the potentiometer and save with the <Clamp> button.

By pressing <Timer> the menu "time" will be exited without saving.

The display will show:

Sw. t i m e. On Off

09:00 18:30

The hours of the switching time ON are flashing.

Set the hours using the potentiometer and save with the <Clamp> button.

By pressing <Timer> the menu "switching time" will be exited without saving.

The minutes of the switching time ON are flashing.

Set theminutes using the potentiometer and save with the <Clamp> button.

By pressing <Timer> the menu "switching time" will be exited without saving.

The hours of the switching time OFF are flashing.

Set the hours using the potentiometer and save with the <Clamp> button.

By pressing <Timer> the menu "switching time" will be exited without saving.

The minutes of the switching time OFF are flashing.

Set theminutes using the potentiometer and save with the <Clamp> button.

By pressing <Timer> the menu "switching time" will be exited without saving.

Resetting the wheel counter for bath tank cleaning

Switch off the machin.

Press and hold the <60 s> button and switch on machine simultaneously.

The display will show:

Cle a n i ng: XX X Wheels

End <=> S ave < ! >

Using the turn potentiometer, the desired number of wheels until the next cleaning can be adjusted.

Default settings are 150 wheels.

Finally confirm with the <Clamp> Button or cancel without saving by pressing <Timer>.

8

Adjustmens of Operating Parameters

8. Adjustments of Operating Parameters

clean wheel solutions

GmbH

26

Maintenance

Failure

Maintenance as needed:

· Clean light barrier

· Remove dirt from the quick clamping device for

wheel fitting using the abrasive cloth enclosed.

Clean (see picture on the right) and check for free movement.

-> For repurchase: 3M-Scotch-Brite grinding/polishing fleece

grain size 280

After approx. 150 to 180 washes or in case of decreasing efficiency

· Dispose of cleaning water (through light fluid seperator)

· Clean stainless steel tub. Remove residual sediments and refill with new cleaning agent

(approx. 2% solution: In 270 l water 5 kg cleaning agent "Tiresonic UR 2.xx")

On completing the cleaning, make sure to reset the counter for the cleaning of the tub (see

page 24).

In general, when errors occur contact the customer service!

(Service-Hotline: +49 (0) 1805 / 881333-3*)

9

Behavior in Case of Failure and Maintenance

If abnormal errors occur while operating the wheel washing machine, disconnect

electricity, take out of service, secure against unauthorized usage and contact

the customer service. All repairs must be performed by trained personnel.

i

Note

Assuming normal use, the wheel washing machine should be maintenanced annually

by the customer service.

9. Behavior in Case of Failure and Maintenance

i

Note

* 0,14Euro/Min from the German landline network / mobile phone charges may vary, max. 0,42 Euro/Min.

EWR - Messgeräte GmbH

Beim Hammerschmied 7

88299 Leutkirch

clean wheel solutions

GmbH

27

10

Notes on repair services and spare parts acqusition

Manufacturer's customer service

Tiresonic GmbH

Osterwalder Straße 12

D-87496 Hopferbach

Telephone +49 (0) 1805 / 881333-3*

Telefax +49 (0) 1805 / 881333-0*

E-Mail: info@tiresonic.de

Internet: www.tiresonic.de

Operating hours:

Mo - Thu: 700 - 14

00

Fri: 700 - 12

00

* 0,14Euro/Min from the German landline network / mobile phone charges may vary, max. 0,42 Euro/Min.

Suppliers customer service:

(please enter stamp or signature)

Company:

Street:

Place:

Telephone:

Customer Service

10. Customer Service

clean wheel solutions

GmbH

28

11

Decleration of Confirmity No. 08 30

Hiermit erklärt Tiresonic als Hersteller, in alleiniger Verantwortung, dass nachstehend bezeichnete Maschine in

Konzeption und Bauart den grundlegenden Sicherheits- und

Gesundheitsanforderungen den hier genannten EG-Richtlinien entspricht.

Bei Änderungen an der Maschine, die nicht mit uns abgestimmt und genehmigt wurde, verliert diese Erklärung ihre

Gültigkeit.

Bezeichnung:

RW 301

Maschinentyp:

Radwaschmaschine

EG-Richtlinien:

· 98/37/EG für Maschinen

· 2004/108/EG für Elektromagnetische Verträglichkeit

· 73/23/EG für Niederspannung

DIN EN-Normen:

· EN 60204 Teil 1

· EN 60439 - 1

· VDE 701, VDE 702

Technische Dokumentation:

· Entwicklungs- und Konstruktionsunterlagen

· Gefahren- und Risikoanalyse

· Sicherheitsgerechte Bedienungsanleitung

· Installationsanleitung

Hopferbach 30th August 2007

Betriebsleitung / Operations Manager

Herewith Tiresonic declares as a manufacturer its sole

responsibility to ensure that the equipment named hereafter

meets the safety and health regulations both in design and

construction required by the EG Guidelines stated below.

This declaration becomes invalid if any changes are made

to the equipment that were not discussed and approved by

Tiresonic beforehand.

Description:

RW 301

Machine type:

Wheel washing machine

EG-guidelines:

· 98/37/EEC for machines

· 2004/108/EEC for electro-magnetic compatibility

· 73/23/EEC for low voltage

DIN EN-Standards:

· EN 60204 Part 1

· EN 60439 - 1

· VDE 701, VDE 702

Technische Dokumentation:

· Design and construction documents

· Danger and risk analysis

· Operating manual based on established safety regulations

· Installation instruction

11. Declaration of Conformity No. 08 30 07

Loading...

Loading...