.

TIP TIG – TIG 500 COMPACT

OPERATING MANUAL

TIP TIG - TIG 500 COMPACT

Operating Manual

Version 1.0 Revision 0

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

INTRODUCTION

Thank you for the trust you have placed in our company and congratulations on buying this highquality TIP TIG product. These instructions will help you familiarize yourself with the product.

Reading the instructions carefully will enable you to learn about the many different features it has to

offer. This will allow you to make full use of its advantages.

Please also note the safety rules to ensure greater safety when using the product. Careful handling

of the product will repay you with years of safe and reliable operation. These are essential

prerequisites for excellent results.

Page 2 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

CONTENTS

1.! GENERAL INSTRUCTIONS 5!

2.! INTENDED USE 6!

2.1! Declaration of conformity 6!

2.2! Welding in environments with increased electrical hazards 6!

2.3! Calibration/Validation 6!

3.! SAFETY RULES 7!

3.1! Explanation of safety symbols 7!

3.2! General safety instructions 7!

4.! GENERAL 10!

4.1! Device concept 10!

4.2! Crane transport 10!

5.! CONTROLS, CONNECTIONS AND MECHANICAL COMPONENTS 11!

5.1! System overview 11!

5.2! Front connection 14!

5.3! Main switch with fuses 15!

5.4! Connection Socket Automation 15!

5.5! Control Panel – Power Source 17!

5.6! Control Panel – Wire Feeder D24B2M1.6 19!

5.7! Control Panel – Wire Feeder Version 2.0 21!

6.! INSTALLATION AND COMMISSIONING 25!

6.1! Before installation and commissioning 25!

6.2! Start-up – Power Source 26!

6.3! Start-up – Wire feeder 29!

7.! WELDING 34!

7.1! Preparation 34!

7.2! Operating modes 35!

7.3! Welding current types (TIG 500AC only) 38!

7.4! MMA welding 39!

7.5! TIG welding 40!

8.! TROUBLESHOOTING, MAINTENANCE AND DISPOSAL 42!

8.1! Troubleshooting 42!

8.2! Care, maintenance and disposal 47!

9.! TECHNICAL DATA 48!

10.! APPENDIX 50!

10.1! Spare part list 50!

Page 3 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

10.2! Wire Feeder 52!

10.3! Wiring Diagram 56!

Page 4 of 58

1. GENERAL INSTRUCTIONS

CAUTION

Read the operating instructions!

The operating instructions provide an introduction to the safe use of the products.

• Read the operating instructions for all system components!

• Observe accident prevention regulations!

• Observe all local regulations!

• Confirm with a signature where appropriate.

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

In the event of queries on installation, commissioning, operation or special conditions at the

installation site, or on usage, please contact your sales partner or our customer service

department on +43 720 303500 or office@tiptig.com.

A list of authorized sales partners can be found at www.tiptig.com.

Liability relating to the operation of this equipment is restricted solely to the function of the

equipment. No other form of liability, regardless of type, shall be accepted. This exclusion of liability

shall be deemed accepted by the user on commissioning the equipment.

The manufacturer is unable to monitor whether or not these instructions or the conditions and

methods are observed during installation, operation, usage and maintenance of the equipment.

An incorrectly performed installation can result in material damage and injure persons as a result.

For this reason, we do not accept any responsibility or liability for losses, damages or costs arising

from incorrect installation, improper operation or incorrect usage and maintenance or any actions

connected to this in any way.

© TIP TIG Automation GmbH, Baumayrweg 5, 4631 Krenglbach, Austria

The copyright to this document remains the property of the manufacturer. Reprinting, including

extracts, only permitted with written approval.

The content of this document has been prepared and reviewed with all reasonable care. The

information provided is subject to change, errors excepted.

Page 5 of 58

2. INTENDED USE

WARNING!

Hazards due to improper usage!

The machine has been constructed to the state of the art and any regulations and

standards applicable for use in industry and trade. It may only be used for the welding

procedures indicated at the rating plate. Hazards may arise for persons, animals and

material objects if the equipment is not used correctly. No liability is accepted for any

damages arising from improper usage!

• ^[3!3QI5>;3<0!;ID0!,</@!?3!ID3H!5<!/5<3!-50[!50D!H3D52<103H!>I6>,D3!1<H!?@!0615<3H!,6!

3]>360!>36D,<<3/b!

• 4,!<,0!5;>6,>36/@!;,H5E@!,6!7,<8360!0[3!3QI5>;3<0b$

WARNING

Hazards due to improper usage!

The machine has been constructed to the state of the art and any regulations and

standards applicable for use in industry and trade. It may only be used for the welding

procedures indicated at the rating plate. Hazards may arise for persons, animals and

material objects if the equipment is not used correctly. No liability is accepted for any

damages arising from improper usage!

• The equipment must only be used in line with its designated purpose and by trained or

expert personnel!

• Do not improperly modify or convert the equipment!

A suitable power source (system component) is required in order to operate the wire feed unit!

For more information refer to the "Warranty registration" brochure supplied and our information

regarding warranty, maintenance and testing at www.ewm-group.com!

The labelled machine complies with the following EC directives in terms of its design and

construction:

WARNING

Hazards due to improper usage!

The machine has been constructed to the state of the art and any regulations and

standards applicable for use in industry and trade. It may only be used for the welding

procedures indicated at the rating plate. Hazards may arise for persons, animals and

material objects if the equipment is not used correctly. No liability is accepted for any

damages arising from improper usage!

• The equipment must only be used in line with its designated purpose and by trained or

expert personnel!

• Do not improperly modify or convert the equipment!

The labelled machine complies with the following EC directives in terms of its design and

construction:

• Low Voltage Directive (LVD)

• Electromagnetic Compatibility Directive (EMC)

• Restriction of Hazardous Substance (RoHS)

In compliance with IEC / DIN EN 60974, VDE 0544 the machines can be used in

environments with an increased electrical hazard.

2.1 Declaration of conformity

The$labelled$machine$complies$with$the$following$EC$directives$and$standards$in$terms$

of$its$design$and$construction:!!

• "#$%&'(&)*!+,-!.,/0123!456370583!9+.4:!

• "#$%&'#&)*!)/3706,;12<3057!=,;>105?5/50@!456370583!9)A=:!!

• "#$$&B(&)*!C3D065705,<!,E!F1G16H,ID!JI?D01<73!9C,FJ:!

!

J01<H16HD!

!

• K)=!B#LM%N$O!"#$"!P67!-3/H5<2!3QI5>;3<0!N!R160!$O!S3/H5<2!>,-36!D,I673D!

• K)=!B#LM%N'O!"#$'!P67!-3/H5<2!3QI5>;3<0!N!R160!'O!P67!D065T5<2!D01?5/5G5<2!

H38573D!

• K)=!B#LM%N$#O!"#$%!P67!-3/H5<2!3QI5>;3<0!U!R160!$#O!)/3706,;12<3057!

7,;>105?5/50@!63QI563;3<0D!

! ! ! ! ! PI2ID0!$V!"#$W!

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXX! ! ! XXXXXXXXXXXXXXXXXXXXXXXXXXXXXX!

YZ623<!R/1D7[V!=)\! ! ! ! ! 4103!,E!437/16105,<!

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

K<! 71D3! ,E!I<1I0[,65G3H! 7[1<23DV! 5;>6,>36! 63>156DV! 1<H&,6! >6,[5?503H! ;,H5E57105,<D! -[57[! [183!<,0!

?33<!3]>/5750/@!1I0[,65G3H!?@!^KR!^K_!PI0,;105,<!_;?FV!0[5D!H37/16105,<!D[1//!?3!8,5H3H`!

2.2 Welding in environments with increased electrical hazards

In$compliance$with$IEC$/$DIN$EN$60974,$VDE$0544$the$machines$can$be$used$in$

environments$with$an$increased$electrical$hazard.$$

2.3 Calibration/Validation

S3! [363?@! 7,<E56;! 0[10! 0[5D! ;17[5<3! [1D! ?33<! 03D03H! ID5<2! 71/5?6103H! ;31DI65<2! 3QI5>;3<0V! 1D!

D05>I/103H!5<! K)=&)a! B#LM%V! KJ\&)a! $MBB"V!)a!(#(#%V! 1<H! 7,;>/53D! -50[! 0[3!1H;5DD5?/3! 0,/361<73D`!

C37,;;3<H3H!71/5?6105,<!5<03681/O!$"!;,<0[D!

Page 6 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

WARNING: This symbol indicates that instructions must be followed to avoid

serious personal injury, loss of life, or damage to this equipment. Protect yourself

and others from possible serious injury or death.

READ AND UNDERSTAND INSTRUCTIONS: Read and understand this manual

before operating this equipment. Arc welding can be hazardous. Failure to follow

the instructions in this manual could cause serious personal injury, loss of life, or

damage to this equipment.

ELECTRIC SHOCK CAN KILL: Welding equipment generates high voltages. Do

not touch the electrode, work clamp, or connected work pieces when this equipment

is on. Insulate yourself from the electrode, work clamp, and connected work pieces.

ELECTRICALLY POWERED EQUIPMENT: Turn off input power using the

disconnect switch at the fuse box before working on this equipment. Ground this

equipment in accordance with local electrical regulations.

DANGER! Indicates immediate and real danger. If is not avoided, death or serious

injury will result.

WARNING! Indicates a potentially situation. Death or serious injury may result if

appropriate precautions are not taken.

CAUTION! Indicates a situation where damage or injury could occur. If it is not avoided,

minor injury and/or damage to property may result.

CAUTION

This equipment must be used by qualified personnel. Be sure that all installation, operation,

maintenance and repair procedures are performed only by qualified person. Read and

understand this manual before operating this equipment. Failure to follow the instructions in this

manual could cause serious personal injury, loss of life, or damage to this equipment. Read and

understand the following explanations of the warning symbols. TIP TIG is not responsible for

damages caused by improper installation, improper care or abnormal operation.

3. SAFETY RULES

3.1 Explanation of safety symbols

NOTE! Indicates a risk of flowed and possible damage to the equipment.

IMPORTANT! Indicates tips for correct operation and other particularly useful information. It does

not indicate a potential damaging or dangerous situation.

If you see any of the symbols depicted in the “Safety rules” chapter, special care is required.

3.2 General safety instructions

Page 7 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

ELECTRICALLY POWERED EQUIPMENT: Regularly inspect the input, electrode,

and work clamp cables. If any insulation damage exists replace the cable

immediately. Do not place the electrode holder directly on the welding table or any

other surface in contact with the work clamp to avoid the risk of accidental arc

ignition.

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS: Electric current

flowing through any conductor creates electric and magnetic fields (EMF). EMF

fields may interfere with some pacemakers, and welders having a pacemaker shall

consult their physician before operating this equipment.

CE COMPLIANCE: This equipment complies with the European Community

Directives.

ARTIFICIAL OPTICAL RADIATION: According with the requirements in

2006/25/EC Directive and EN 12198 Standard, the equipment is a category 2. It

makes mandatory the adoption of Personal Protective Equipment (PPE) having filter

with a protection degree up to a maximum of 15, as required by EN169 Standard.

FUMES AND GASES CAN BE DANGEROUS: Welding may produce fumes and

gases hazardous to health. Avoid breathing these fumes and gases. To avoid these

dangers the operator must use enough ventilation or exhaust to keep fumes and

gases away from the breathing zone.

ARC RAYS CAN BURN: Use a shield with the proper filter and cover plates to

protect your eyes from sparks and the rays of the arc when welding or observing.

Use suitable clothing made from durable flame-resistant material to protect you skin

and that of your helpers. Protect other nearby personnel with suitable, nonflammable screening and warn them not to watch the arc nor expose themselves to

the arc.

WELDING SPARKS CAN CAUSE FIRE OR EXPLOSION: Remove fire hazards

from the welding area and have a fire extinguisher readily available. Welding sparks

and hot materials from the welding process can easily go through small cracks and

openings to adjacent areas. Do not weld on any tanks, drums, containers, or

material until the proper steps have been taken to ensure that no flammable or toxic

vapors will be present. Never operate this equipment when flammable gases,

vapors or liquid combustibles are present.

WELDED MATERIALS CAN BURN: Welding generates a large amount of heat.

Hot surfaces and materials in work area can cause serious burns. Use gloves and

pliers when touching or moving materials in the work area.

SAFETY MARK: This equipment is suitable for supplying power for welding

operations carried out in an environment with increased hazard of electric shock.

EQUIPMENT WEIGHT OVER 30kg: Move this equipment with care and with the

help of another person. Lifting may be dangerous for your physical health.

Page 8 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders

containing the correct shielding gas for the process used and properly operating

regulators designed for the gas and pressure used. Always keep cylinders in an

upright position securely chained to a fixed support. Do not move or transport gas

cylinders with the protection cap removed. Do not allow the electrode, electrode

holder, work clamp or any other electrically live part to touch a gas cylinder. Gas

cylinders must be located away from areas where they may be subjected to

physical damage or the welding process including sparks and heat sources.

CAUTION: The high frequency used for contact-free ignition with TIG (GTAW)

welding, can interfere with the operation of insufficiently shielded computer

equipment, EDP centers and industrial robots, even causing complete system

breakdown. TIG (GTAW) welding may interfere with electronic telephone networks

and with radio and TV reception.

NOISE APPEARES DURING WELDING CAN BE HARMFUL: Welding arc can

cause noise with high level of 85dB for 8-hour week day. Welders operating welding

machines are obligated to wear the proper ear protectors /appendix No. 2 for the

Decree of the Secretary of Labor and Social Policy from 17.06 1998 – Dz.U. No. 79

pos. 513/. According to the Decree the Secretary of Health and Social Welfare from

09.07.1996 /Dz.U. No. 68 pos. 194/, employers are obligated to carry examinations

and measurements of health harmful factors.

The manufacturer reserves the right to make changes and/or improvements in design without

upgrade at the same time the operator’s manual.

Page 9 of 58

4. GENERAL

WARNING

Falling equipment can cause death or serious injury.

• Only use a suitable lifting tackle when transporting devices by crane (e.g. belt with round

slings)

• The lifting tackle must be undamaged and in perfect condition

• Do not transport any other loads by the handle apart from the wirefeeder itself

• Do not hang from the wirefeeder as it is being transported

4.1 Device concept

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

The TIP TIG COMPACT welding system is a

completely digitised, microprocessor

controlled inverter power source with an

included wire feeder and is suitable for wire

spools with max. diameter of 300 mm (11.81

in.).

The power source is generator-compatible. It

is exceptionally sturdy in day-to-day

operation thanks to the protected control

elements and its powder-coated housing.

The function of a TIG pulse arc with a wide

frequency range is available.

The 4-roller drive has good wire-feeding

properties. The wire feeder is also suitable

for long hose packages.

4.2 Crane transport

The TIP TIG FOCUS can be transported by crane at the lifting eyes.

The maximum load-bearing capacity of the lifting eyes is 150 kg (330.69 lbs.)

Before transporting by crane:

- feed out the wire electrode, remove the wire spool

- disconnect the torch hose package and interconnecting hose package from the wire feeder

- if present, unplug the coolant connections

Page 10 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

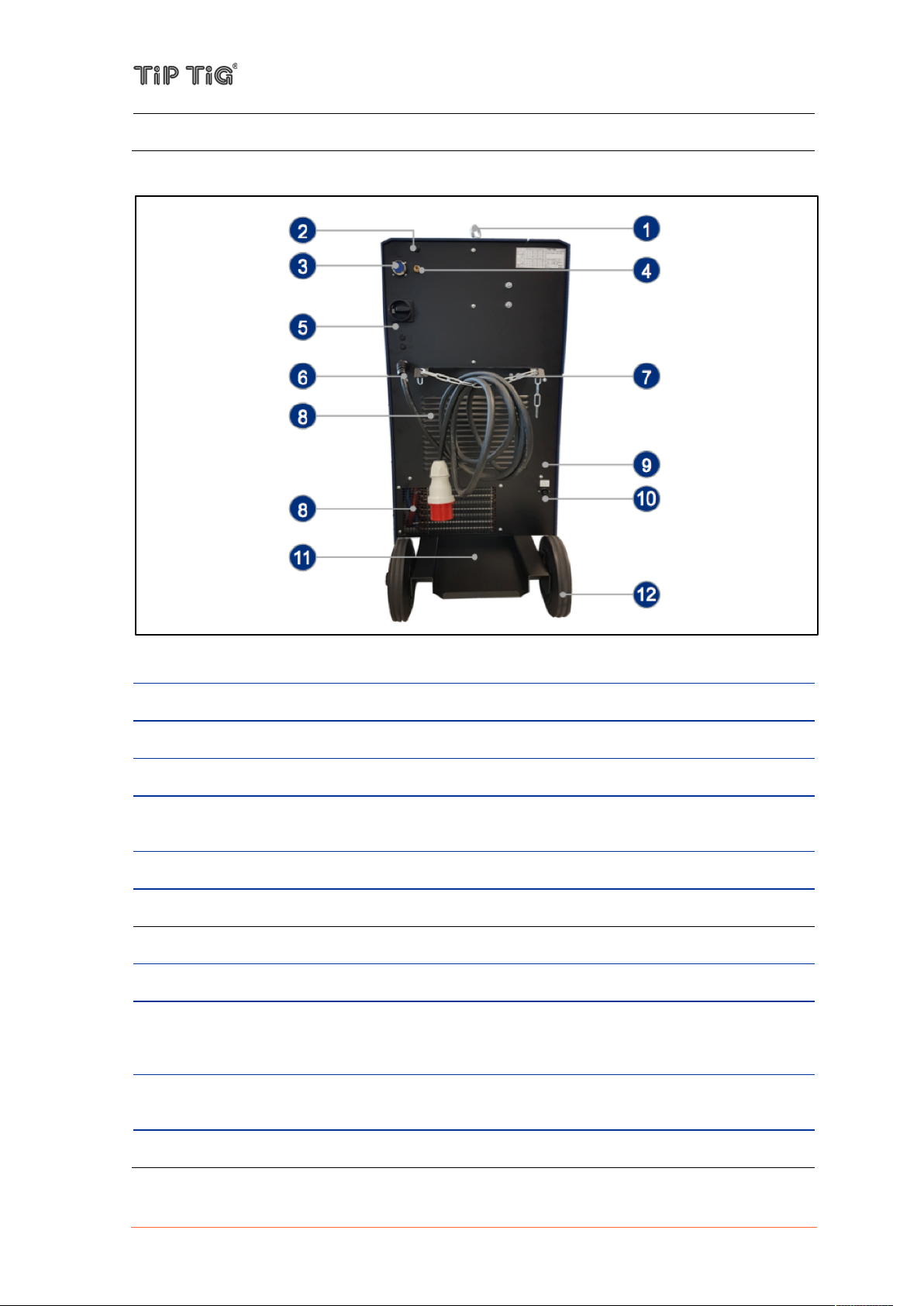

No.

Description

(1)

Transport eyebolt (Lifting lug)

(2)

Control Panel Power Source – See 5.5 Control Panel – Power Source

(3)

Control Panel wire Feeder – See 5.7 Control Panel – Wire Feeder Version 2.0

(4)

Front connection – See 5.2 Front connection

(5)

Wire electrode connection – for connecting the welding torch wire feed

(6)

Transport handle

(7)

Hotwire indicator lamps

Temperature fault indicator (down)

is lit in the case of overheating. It extinguishes after a few minutes when the unit has

cooled down.

Hotwire-on indicator (top)

(1) is lit when there is live operating voltage and the hot wire unit is ready for service,

(2) blinks in case of a fault.

(8)

Connection socket, welding current „+“

for connecting the workpiece lead

(9)

Cooling air inlet

5. CONTROLS, CONNECTIONS AND MECHANICAL COMPONENTS

5.1 System overview

Front of TIP TIG – TIG 500 COMPACT

Page 11 of 58

(10)

Coolant tank with cap

Rear of TIP TIG – TIG 500 COMPACT

No.

Description

(1)

Transport eyebolt (Lifting lug)

(2)

Button gas test

(3)

24 pole connection socket automation – See 5.4 Connection Socket Automation

(4)

Connecting nipple shielding gas

for connecting the shielding gas (G1/4" RH) on the pressure regulator

(5)

Main switch with fuses – See 5.3 Main switch with fuses

(6)

Mains connection cable with plug

(7)

Securing elements for shielding gas cylinder (strap / chain)

(8)

Cooling air outlet

(9)

Hotwire amperage adjustment

for adjusting the amperage setting of the hotwire unit. Adjustment with a flat screw driver.

Adjustment range: 60 – 100 A (Presetting 80 A)

(10)

Connecting socket

Output 230 VAC

(11)

Bracket for shielding gas cylinder

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Page 12 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

(12)

Wheels, fixed castors

No.

Description

(1)

Four roll wire drive

(2)

Clamping levers

for setting the contact pressure of the feed rollers

(3)

Wires pool holder with brake

for holding standard wire spools with max. diameter of 300 mm (11.81 in.) and max.

weight of 15 kg (33.1 lb.)

TIP TIG – TIG 500 COMPACT: operating elements in the machine

Page 13 of 58

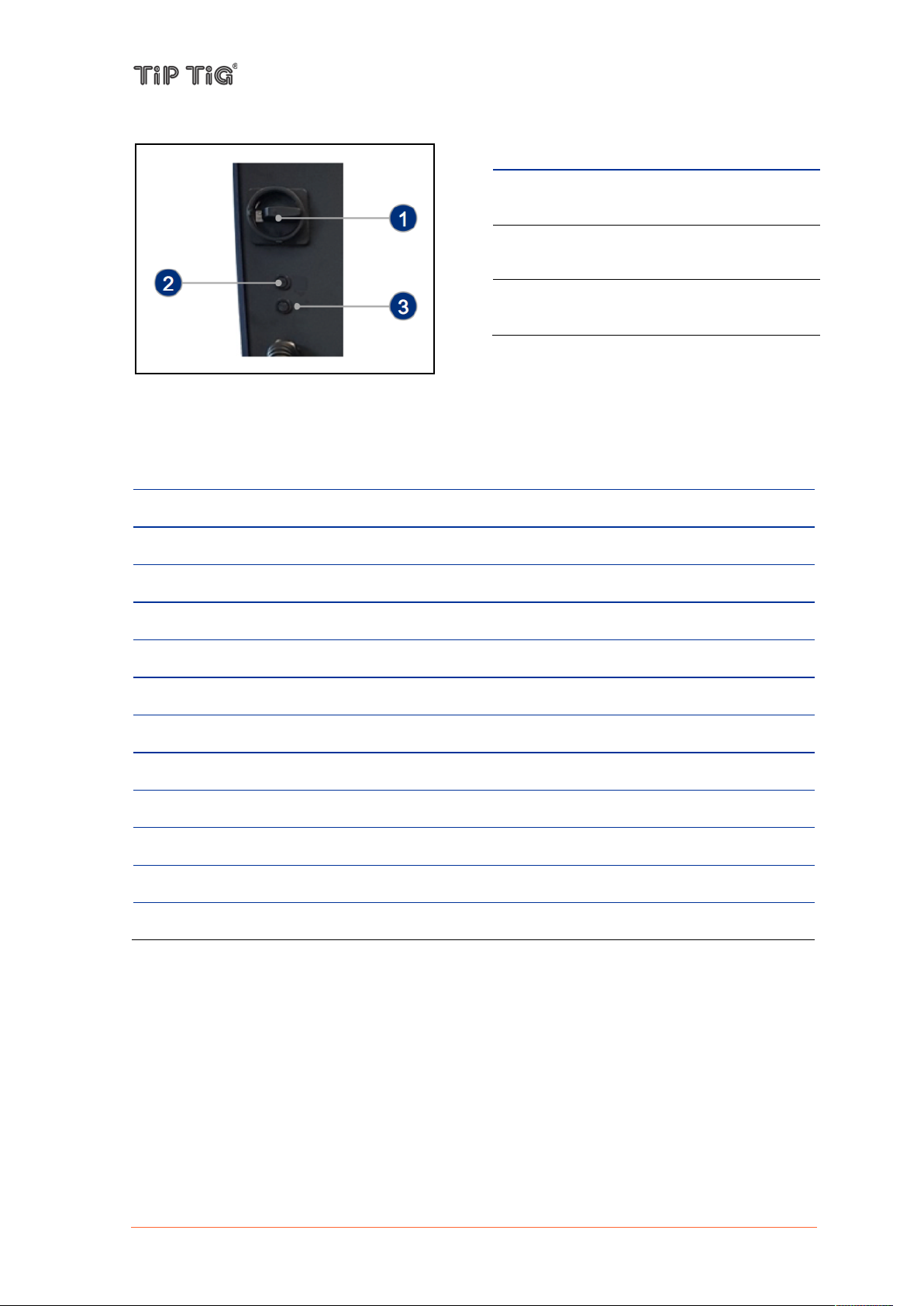

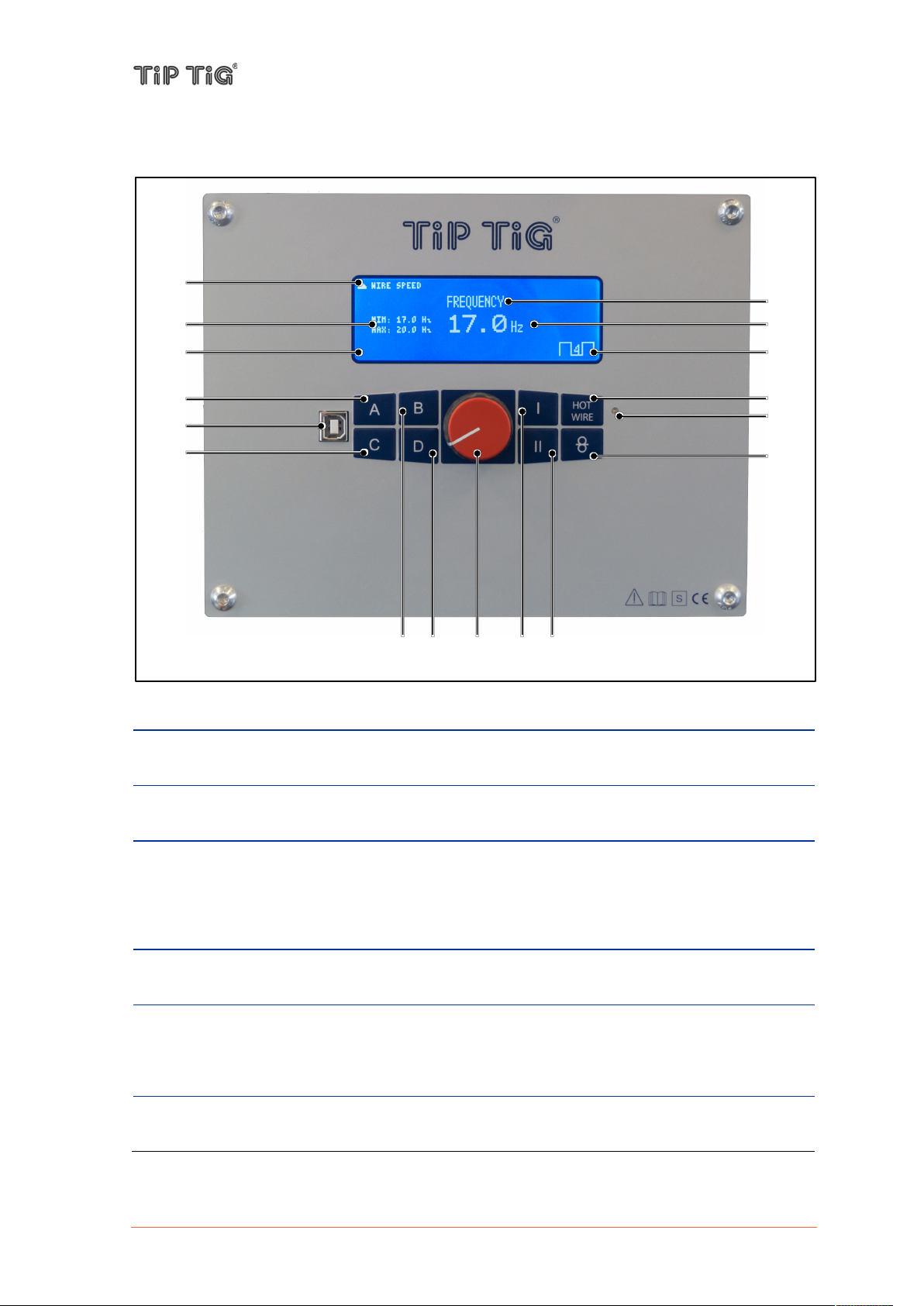

5.2 Front connection

No.

Description

(1)

Connection socket control lead (7-pole)

for connecting control lead from the welding torch hose package

(2)

Connection socket hot wire

for connecting hot wire power from the welding torch hose package, minus potential

(3)

Connecting nipple coolant return (red)

for connecting coolant return (G3/8" LH) from the welding torch hose package

(4)

Connecting nipple shielding gas

for connecting shielding gas (G1/4" RH) from the welding torch hose package

(5)

Connecting socket, welding current „-“

for connecting TIG welding torch / electrode holder

(6)

Wire electrode connection – for connecting the welding torch wire feed

(7)

Connecting nipple current / coolant supply (blue)

for connecting current / coolant supply (G3/8" RH) from the welding torch hose package

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Page 14 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

No.

Description

(1)

Main switch

Machine on/off

(2)

Fuse F1

T8 A, 230 VAC

(3)

Fuse F2

T8 A, 0 VAC

No.

Configuration

No.

Configuration

A

Current 1

N

Gas on

B

Current 2

P

Gas on

C

Pulse time t1

Q

Arc start

D

Pulse time t2

R

Arc start

E

Soft-start time

S

Ground

F

Soft-down time

T

Uist

G

Spot time

U

GND

H

External mode

V

List J Ground 0V

W

TIPTIG RC 8-2

K

10V

X

TIPTIG RC 8-1

L

I>0 (contact)

Y

NC M I>0 (contact)

Z

NC

5.3 Main switch with fuses

5.4 Connection Socket Automation

With this 24 pol. installation socket, the power source can be commanded with an external control.

Which of these setpoints can be set externally depends on H „External mode“ circuit by means of a

resistor Rx against 10V.

Thus, a very simple and comfortable mode selection is possible.

Page 15 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Mode

Name

Rx

Comment

0

Internal

open

everything internally

1

Pulse 1

1k 1%

I1, I2 internal; t1, t2 external

2

Pulse 2

4k 1%

I1, I2 external; t1, t2 external

3

Footmode

10k 1%

I1 external % from I1 internal

4

Remote 1

22k 1%

I1, I2 external

5

Remote 2

47k 1%

I1 external

6

Remote 3

100k 1%

I1, I2 external; Upslope, Downslope external

7

Spottime

150k 1%

Spottime external

8

Upslope external

220k 1%

Upslope external

9

Pulse 1 +

Footmode

470k 1%

I1, I2 internal; t1, t2 external

I1 external % from I1 internal

The remote control and automation interface provides the following functions:

Mode 1 – Internal Pulsing

The current setting I1 and I2 takes place on the control panel.

The pulse times t1 and t2 can be set externally.

Mode 2 – External Pulsing

The current settings I1 and I2 as well as the pulse times t1 and t2 can be set externally.

Mode 3 – Limitation of welding current

In this mode, generally only 2-Stroke operation is selected.

Externally, the current setpoint can be varied between the minimum and the internal current

setpoint I1.

Mode 4 – Mode 6

In these operating modes, an externally connected potentiometer assumes the function of the

internal I1 setpoint specification on the control panel.

Mode 7 – Spottime function

In the operating mode Spottime, the spot time can be set with an externally connected

potentiometer

Page 16 of 58

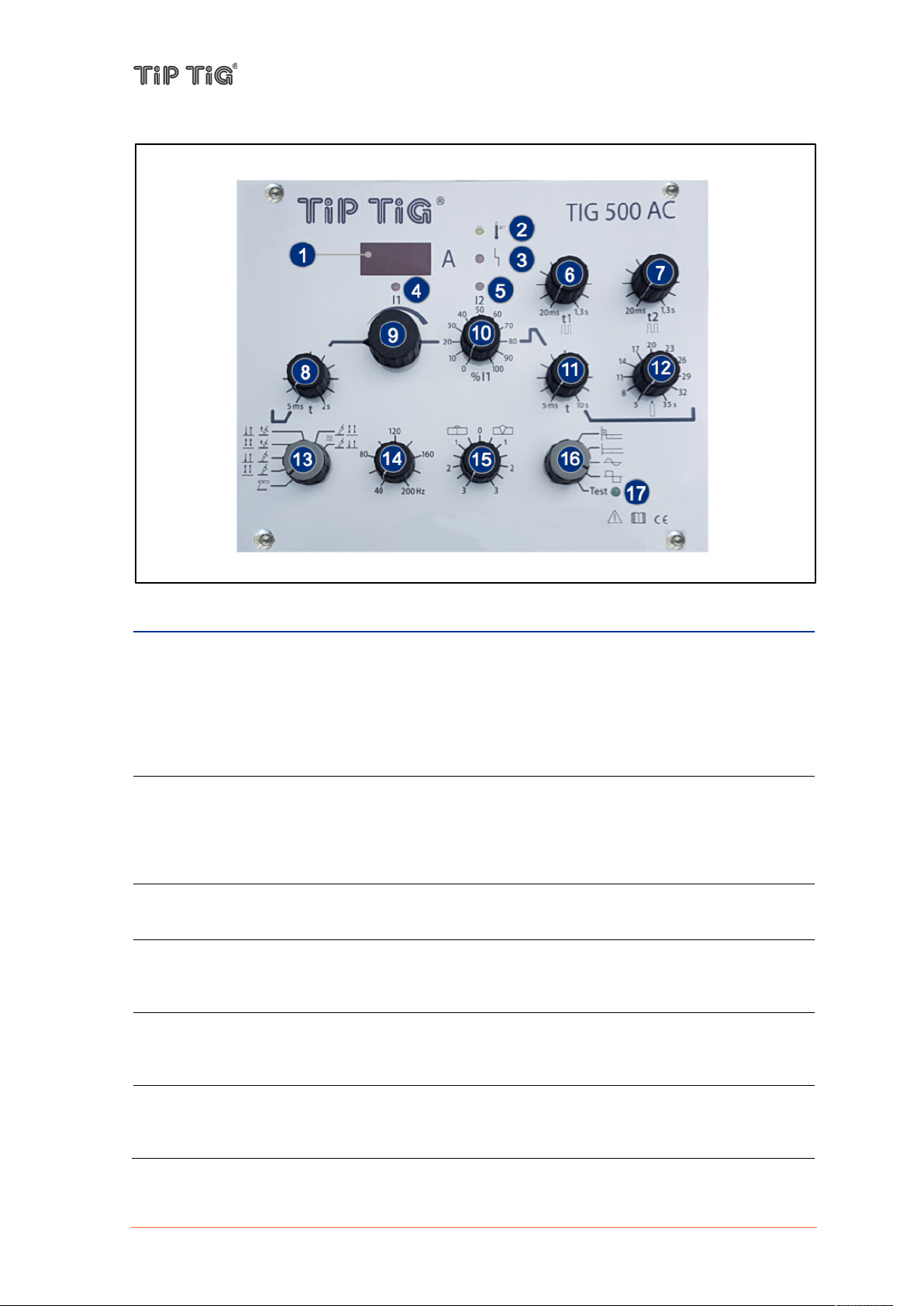

5.5 Control Panel – Power Source

No.

Function

(1)

Welding data display (3-digit)

displays the current value of the welding current as well as error messages:

- In normal operation, the welding current is displayed.

- If a fault occurs in the cooling system, the welding process is switched off and the

message "H2O" flashes together with (2) Overheat Indicator

- In the event of a mains or inverter fault as well as overheating, the display flashes "- - -"

and the welding process is switched off.

(2)

Overheat Indicator

lights up when the power source has overheated and turned off (for example, due to the

duty cycle being exceeded). It extinguishes when the unit is cooled down and is ready

for welding.

If there is a lack of water, the display flashes.

(3)

Inverter Fault Indicator

lights up if there is a mains under voltage or a defect in the welding inverter.

(4)

Welding Current I1 Indicator

lights up when welding current I1 is active. With TIG pulses, this corresponds to the

pulse current phase.

(5)

Welding Current I2 Indicator

lights up when welding current I2 is active. With TIG pulses, this corresponds to the

basic current phase.

(6)

Pulse Time t1 Rotary Knob

for setting the pulse time t1, while welding current I1 is active during TIG pulses. (Range:

20ms - 1.3sec.)

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Page 17 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

(7)

Pulse Time t2 Rotary Knob

for setting the pulse time t2, while welding current I2 is active during TIG pulses. (Range:

20ms - 1.3sec.)

(8)

Soft Start (Upslope) Rotary Knob

for setting the soft-start time, in which the welding current is increased to the set value.

(Range: 5ms - 2sec.). In 2-stroke mode, the welding current starts in the minimum, in 4cycle mode with the starting current (20% of the welding current I1)

(9)

Welding Current I1 Rotary Knob

for adjusting the welding current I1:

- Setting range TIG: 4A - 500A

- Setting range MMA: 15A - 400A

(10)

Welding Current I1 Rotary Knob

for adjusting the welding current I2 (range: 0% - 100%). In 2-stroke operation, the

welding current starts in the minimum, in 4-stroke operation with the starting current

(20% of the welding current I1). The maximum adjustable welding current I2 always

corresponds to the set value of I1. This welding current is used as a base current during

pulsing.

(11)

Soft Down (Downslope) Rotary Knob

for setting the soft-down time (range: 5ms - 10sec.) at which the welding current is

reduced from the set value to min.

(12)

Gas Post-Flow Time Rotary Knob

for adjusting the gas post-flow time during TIG welding (range: 5sec - 35sec.). If started

but not welded, the gas post-flow time does not expire.

(13)

Operating Mode Rotary Knob

for setting the operating mode, see 7.2 Operating modes:

- MMA

- TIG 4-Stroke

- TIG 2-Stroke

- TIG Liftarc 4-Stroke

- TIG Liftarc 2-Stroke

- TIG Pulse 4-Stroke

- TIG Pulse 2-Stroke

(14)

Frequency Rotary Knob (AC only)

for adjusting the frequency of the AC arc (range: 40Hz - 200Hz)

(15)

Balance Rotary Knob (AC only)

for adjusting the balance of the AC arc (range: 80:20 - 20:80). As a result, either a deep

penetration or a high cleaning effect can be set.

(16)

Welding Current Type / S-Test Rotary Knob (AC only)

for setting the welding current type, see 7.3 Welding current types (TIG 500AC only):

- DC welding with pulse start

- DC welding

- AC welding sinus (soft)

- AC welding rectangle (hard)

- S-Test

(17)

S-Test indicator (AC only)

lights up when the Current Type / S-Test Rotary Knob is set to S-Test mode and the

inverter is operating correctly, see 7.1.1 S-Test (AC only)

Page 18 of 58

5.6 Control Panel – Wire Feeder D24B2M1.6

No.

Function

(1)

Display

shows the current figure of the selected parameter

(2)

Parameter selection button

for selecting the parameters listed below (5)

(3)

Adjusting button -

for negative adjustment of the selected parameter (5)

(4)

Adjusting button +

for positive adjustment of the selected parameter (5)

(5)

Parameter indicator

shows which parameter is selected:

- Wire Feeding Speed

- Frequency Control

- Start Delay

- Wire Retract

- Spot Time

(6)

Mode button

for selecting the desired mode (7)

(1)

(2)

(3)

(4)

(5)

(7)

(6)

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Page 19 of 58

(7)

Mode indicator

shows which mode is selected:

- 4-Stroke

- 2-Stroke

- Lead Voltage 0-10 V

- Spot Function

- Program Load

- Program Save

Wire Feeding Speed

Display value multiplied by 0,0635 is the wire feed speed in m/min

or display value multiplied by 2,5 is the wire feed speed in IPM

(WIRE FEED SPEED = 0,0635*Display value)

Example: Factor 100 = 6,35 m/min or 250 IPM

For more information please go to Appendix 9.2.1 or visit

https://www.tiptig.com/english/support/

Frequency Control

The value is as shown as factor

For all applications use 230 = 17 Hz

Start Delay

The value is as shown as factor (optional)

Useful for track weld

Wire Retract

The value is as shown as factor (optional)

Is an option – normally not used

Spot Time

The value is as shown as factor (optional)

Only for spot weld

To use spot time it's needed to adjust the mode spot function

4-Stroke

Generally select 4-Stroke mode for hand welding

2-Stroke

2-Stroke mode mostly used for tack welding

Lead Voltage 0-10 V

optional

Spot Function

optional

Program Load

optional

Program Save

optional

CAUTION

The wire feed speed may have a variation of ± 10%. It depends

on the settings of the feed roll tensioner (see 5.5 (2)) and the

quality of the wire.!

Display values

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Modes

Page 20 of 58

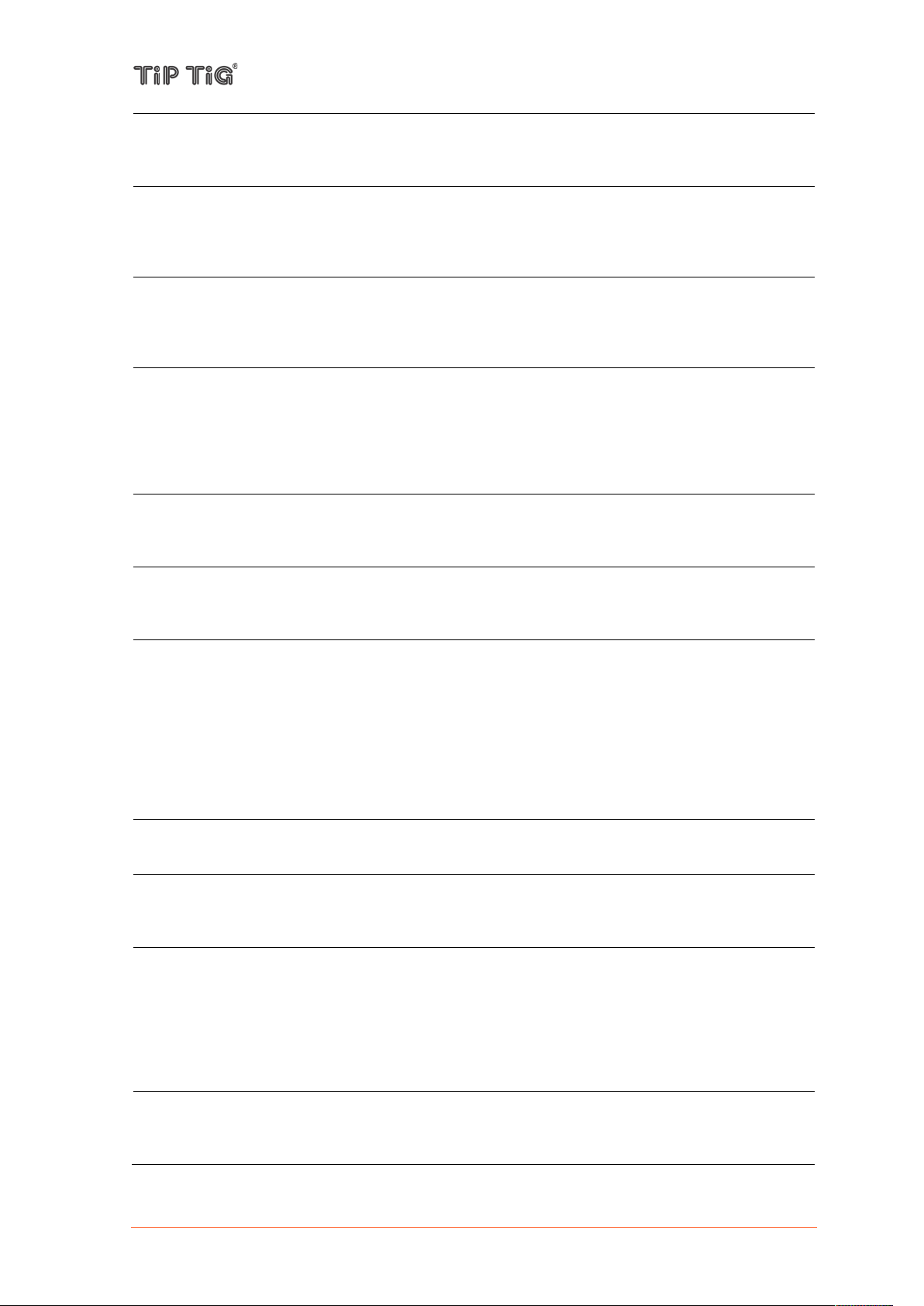

5.7 Control Panel – Wire Feeder Version 2.0

No.

Function

(1)

Menu (parameter) forecast up/down

shows which parameter will be selected when switching menu up/down

(2)

Parameter range indicator

shows min. and max. value of the selected parameter

(3)

Menu (parameter) indicator

shows which parameter is selected:

- Wire speed

- Frequency

- Weld amps

(4)

Parameter

shows the current value and unit of the selected parameter

(5)

Mode indicator

shows which mode is selected:

- 2-Step

- 4-Step

(6)

A – Menu (parameter) up button

switching menu up

(1)

(7)

(3)

(4)

(2)

(9)

(5)

(14)

(16)

(6)

(8)

(10)

(12)

(13)

(11)

(1)

(15)

Display – Parameters and Modes

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Page 21 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

(7)

Software update port

to update provided TIP TIG software

(8)

C – Button not assigned

button is not assigned in this software version

(9)

B – Menu (parameter) down button

switching menu down

(10)

D – Button not assigned

button is not assigned in this software version

(11)

Rotary knob

to adjust the selected parameter (parameter positive adjustment – rotate clockwise /

parameter negative adjustment – rotate counter-clockwise)

(12)

I – Mode button

for selecting the desired mode (5)

(13)

II – Settings button

press and hold for 3 seconds to enter settings menu

(14)

HOT WIRE button on/off

for switching hot wire on/off

(15)

Hot wire indicator

shows if hotwire is switched on (green) or off (no light)

(16)

OIO – Wire inching button

potential- and oscillation-free inching of the wire through the hose package to the

welding torch

Page 22 of 58

Display – Settings menu

No.

Function

(1)

Software version

indicates the installed software version number

(2)

Settings menu

highlights the selected parameter and its value

- Weld amps (on/off)

- Weld amps max

- Weld amps offset

- Automation (on/off)

- Remote control (on/off)

- Up/Down (Wire/Amps)

- Language (EN/DE/CN)

- Invert colors (on/off)

(3)

A – Menu (parameter) up button

switching menu line up

(4)

B – Menu (parameter) down button

switching menu line down

(5)

Rotary knob

to adjust the selected parameter value (parameter value positive adjustment – rotate

clockwise / parameter value negative adjustment – rotate counter-clockwise)

(6)

II – Settings button

press and hold for 1 second to exit settings menu

(2)

(1)

(4)

(3)

(6)

(5)

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Page 23 of 58

Display values

WIRE SPEED

Display value multiplied by 0,0657+0,17 is the wire feed speed in

m/min!

(WIRE FEED SPEED = 0,0657*Display value+0,17)

Example: Factor 100 = 6,74 m/min or 265,35 IPM

For more information please go to Appendix 9.2.2 or visit

https://www.tiptig.com/english/support/

2-Step

2-Stroke mode mostly used for tack welding

4-Step

Generally select 4-Stroke mode for hand welding

CAUTION

The wire feed speed may have a variation of ± 10%. It depends

on the settings of the feed roll tensioner (see 5.5 (2)) and the

quality of the wire.!

Modes

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Page 24 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

WARNING

Incorrect operation or shoddy workmanship can cause serious injury or damage. All work

described in this document must only be carried out by trained and qualified personnel. All

functions described in this document must only be used by trained and qualified personnel.

Do not carry out any of the work or use any of the functions described until you have fully

read and understood the following documents:

• this document

• all the operating instructions for the system components, especially the safe!ty rules

6. INSTALLATION AND COMMISSIONING

6.1 Before installation and commissioning

Safety

Utilization for intended purpose

The power source is intended exclusively for TIG and MMA welding. Utilization for any other

purpose, or in any other manner, shall be deemed to be not in accordance with the intended

purpose. The manufacturer shall not be liable for any damage resulting from such improper use.

Proper use also includes:

- following all the information in the operating instructions

- carrying out all the specified inspection and servicing work

Ambient conditions

The machine must not be operated in the open air and must only be set up and operated on a

suitable, stable and level base!

- The operator must ensure that the ground is non-slip and level and provide sufficient lighting

for the place of work.

- Safe operation of the machine must be guaranteed at all times.

Unusually high quantities of dust, acid, corrosive gases or substances may damage the equipment.

- Avoid high volumes of smoke, vapor, oil vapor and grinding dust!

- Avoid ambient air containing salt (sea air)!

In operation

Temperature range of the ambient air:

- -25 °C to +40 °C

Relative air humidity:

- Up to 50% at 40 °C

- Up to 90% at 20 °C

Transport and storage

Storage in an enclosed space, temperature range of the ambient air:

- -30 °C to +70 °C

Relative air humidity:

- Up to 90% at 20 °C

Page 25 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

WARNING

A electric shock can be fatal. If the machine is plugged into the mains supply during

installation, there is a high risk of very serious injury and damage. Do not carry out any

work on the device unless:

• the mains switch is in the „O“ position,!

• the device is unplugged from the mains.

Machine cooling

Insufficient ventilation results in a reduction in performance and equipment damage.

- Observe the ambient conditions!

- Keep the cooling air inlet and outlet clear!

- Observe the minimum distance of 0.5 m from obstacles!

Mains Connection

The devices are designed to run on the mains voltage shown on the respective rating plates. If your

version of the device does not come with mains cables and plugs ready-fitted, these must be fitted

in accordance with national regulations and standards. For details of fuse protection of the mains

lead, please see the Technical Data.

NOTE! Inadequately dimensioned electrical installations can cause serious

damage. The incoming mains lead and its fuse must be dimensioned to suit the local power supply.

The technical data shown on the rating plate applies.

Generator-powered operation

The power source is generator-compatible, provided that the maximum apparent power delivered

by the generator is at least 10 kVA.

NOTE! The voltage delivered by the generator must never exceed the upper or

lower limits of the mains voltage tolerance range. Details of the mains voltage tolerance are given

in the "Technical data" section.

6.2 Start-up – Power Source

Safety

General

This section describes how to commission the power source:

- for the main TIG welding application,

- with reference to a standard configuration for a TIG welding device.

The standard configuration consists of the following system components:

- power source

- TIG manual welding torch

- pressure regulator

- gas cylinder

- gas cylinder holder

The steps set out below provide an overview of how to commission the power source. For detailed

information about the individual steps, please refer to the operating instructions for the system

components.

Page 26 of 58

6.2.1 Welding torch cooling system

Coolant

Temperature range

KF 23E (Standard)

-10 °C to +40 °C

KF 37E

-20 °C to +10 °C

CAUTION

Coolant mixtures!

Mixtures with other liquids or the use of unsuitable coolants result in material damage and

renders the manufacturer's warranty void!

• Only use the coolant described in this manual (overview of coolants).

• Do not mix different coolants.

• When changing the coolant, the entire volume of liquid must be changed.

Insufficient frost protection in the welding torch coolant!

Depending on the ambient conditions, different liquids are used for cooling the welding

torch.Coolants with frost protection (KF 37E or KF 23E) must be checked regularly to ensure

that the frost protection is adequate to prevent damage to the machine or the accessory

components.

• The coolant must be checked for adequate frost protection with a frost protection tester.

• Replace coolant as necessary if frost protection is inadequate!

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

NOTE! The disposal of coolant must be carried out according to official regulations and

observing the relevant safety data sheets.Coolant must not be disposed of together with

household waste.Coolant must not be discharged into the sewerage system. Recommended

cleaning agent: water, if necessary with cleaning agent added.

List of coolants

The following coolants may be used:

Adding coolant

The unit is supplied ex works with a minimum level of coolant.

- Unscrew and remove the coolant tank sealing cover.

- Top up coolant, close sealing cover again.

NOTE! After the initial filling, wait for at least one minute when the machine is switched

on so that the hose package is filled with coolant completely and without bubbles. With frequent

changes of torch and during the initial filling process, the cooling unit tank should be topped up as

necessary.

need to vent the coolant circuit. In this case the welding machine will automatically shut down the

coolant pump and signal an error, Rectifying faults.

NOTE! If there is less coolant in the coolant tank than the minimum required, you may

Page 27 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

WARNING

If gas cylinders topple over, there is a risk of very serious injury and damage.

• Place gas cylinders on a solid, level surface in such a way that they remain stable

• Secure gas cylinders to prevent them from toppling over: fix the safety strap at the same

height as the top part of the cylinder

• Never fix the safety strap around the neck of the cylinder

Follow the gas cylinder manufacturer's safety instructions.

6.2.2 Connecting the gas cylinder

1. Secure the gas cylinder

2. Take the protective cap off the gas cylinder

3. Briefly open the gas cylinder valve to remove any dust or dirt

4. Check the seal on the pressure regulator

5. Screw the pressure regulator onto the gas cylinder and tighten it

When using a TIG welding torch with an integral gas connector:

6. Use the gas hose to connect the pressure regulator to the shielding gas connection on the rear

of the power source

7. Tighten the union nut on the gas hose

When using a TIG welding torch with no integral gas connector:

6. Connect the TIG welding torch gas hose to the pressure regulator

6.2.3 Establishing a ground (earth) connection to the workpiece

1. Move the mains switch to the O position

2. Plug the grounding (earthing) cable in and latch it

3. Use the other end of the grounding (earthing) cable to establish a connection to the workpiece

6.2.4 Connecting the welding torch

1. Move the mains switch to the O position

2. Plug in the TIG welding torch cable and latch it by turning it clockwise

3. Plug the welding torch control plug into the torch control connection and latch it

4. Equip the welding torch in accordance with the welding torch operating instructions

Only when using a water-cooled torch:

5. Plug in the welding torch water connections to the water flow (blue) and return (red)

connections.

Page 28 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

WARNING

Incorrect operation or shoddy workmanship can cause serious injury or damage. All work

described in this document must only be carried out by trained and qualified personnel. All

functions described in this document must only be used by trained and qualified personnel.

Do not carry out any of the work or use any of the functions described until you have fully

read and understood the following documents:

• this document

• all the operating instructions for the system components, especially the safety rules

6.3 Start-up – Wire feeder

Safety

Prerequisites

When commissioning the wire-feed unit, the following requirements must be met:

- Wire-feed unit connected to the power source using the interconnection hose package

- Welding torch connected to wire-feed unit

- Feed rollers inserted in the wire-feed unit

- Wire spool or basket-type spool and adapter inserted in the wire-feed unit

- Wire electrode threaded in

- Feed roller contact pressure set

- Brake adjusted

- All covers closed, all side panels in place, all protection devices intact and in their proper place

General

The wire-feed unit is started by pressing the torch trigger (for manual applications) or by means of

a welding start-up signal (for automatic applications).

Page 29 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

WARNING

An electric shock can be fatal. Before starting the work described below:

• turn the power source mains switch to the „0“ position

• disconnect the power source from the mains

• ensure that the power source remains disconnected from the mains until all work has

been completed

WARNING

An electric shock can be fatal. Before starting the work described below:

• turn the power source mains switch to the „0“ position

• disconnect the power source from the mains

• ensure that the power source remains disconnected from the mains until all work has

been completed

CAUTION

Risk of injury from springiness of spooled wire electrode. When inserting the wire spool/basket-

type spool, hold the end of the wire electrode firmly to avoid injuries caused by the wire

electrode springing back.

CAUTION

Risk of injury from falling wire spool/basket-type spool. Ensure that the wire spool/basket-type

spool and basket-type spool adapter are always seated securely on the wire spool holder.

6.3.1 Inserting/replacing feed rollers

Safety

General information

In order to achieve optimum wire electrode feed, the feed rollers must be suitable for the diameter

and alloy of the wire being welded.

NOTE! Only use feed rollers that match the wire electrode.

Inserting/replacing feed rollers

- Slide new drive rollers into place so that the diameter of the wire used is visible on the drive

roller.

- Fix the drive rollers in place with the built-in lock system (no tools needed).

6.3.2 Inserting the wire spool

Safety

Inserting the wire spool

Standard D300 wire spool holder can be used. Adapters are required when using standardized

basket coils (DIN 8559).

- Loosen knurled nut from spool holder.

- Fix welding wire reel onto the spool holder so that the carrier pin locks into the spool bore.

- Fasten wire spool using knurled nut.

Page 30 of 58

6.3.3 Inching the wire electrode

CAUTION

Risk of injury and material damage from the welding current and accidental ignition of an arc.

Before starting work, disconnect the ground earth connection between the welding system and

the workpiece.

CAUTION

Risk of damage to the welding torch from sharp end of wire electrode. Deburr the end of the

wire electrode well before feeding in.

CAUTION

Risk of injury from springiness of spooled wire electrode. When inserting the wire electrode into

the 4-roller drive, hold the end of the wire electrode firmly to avoid injuries caused by the wire

springing back.

CAUTION

Risk of injury and damage from wire electrode emerging. While working:

• hold the welding torch with the point directed away from the face and body

• wear suitable protective goggles

• do not point the welding torch at people

• make sure that the wire electrode does not touch any conductive or earthedparts, such as

the housing, etc.

Safety

General Information

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Incorrect contact pressure will cause extensive wear of the wire feed rollers!

- With the adjusting nuts of the pressure units set the contact pressure so that the wire

electrode is conveyed but will still slip through if the wire spool jams.

- Set the contact pressure of the front rollers (in wire feed direction) to a higher value!

Inching the wire electrode

Page 31 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

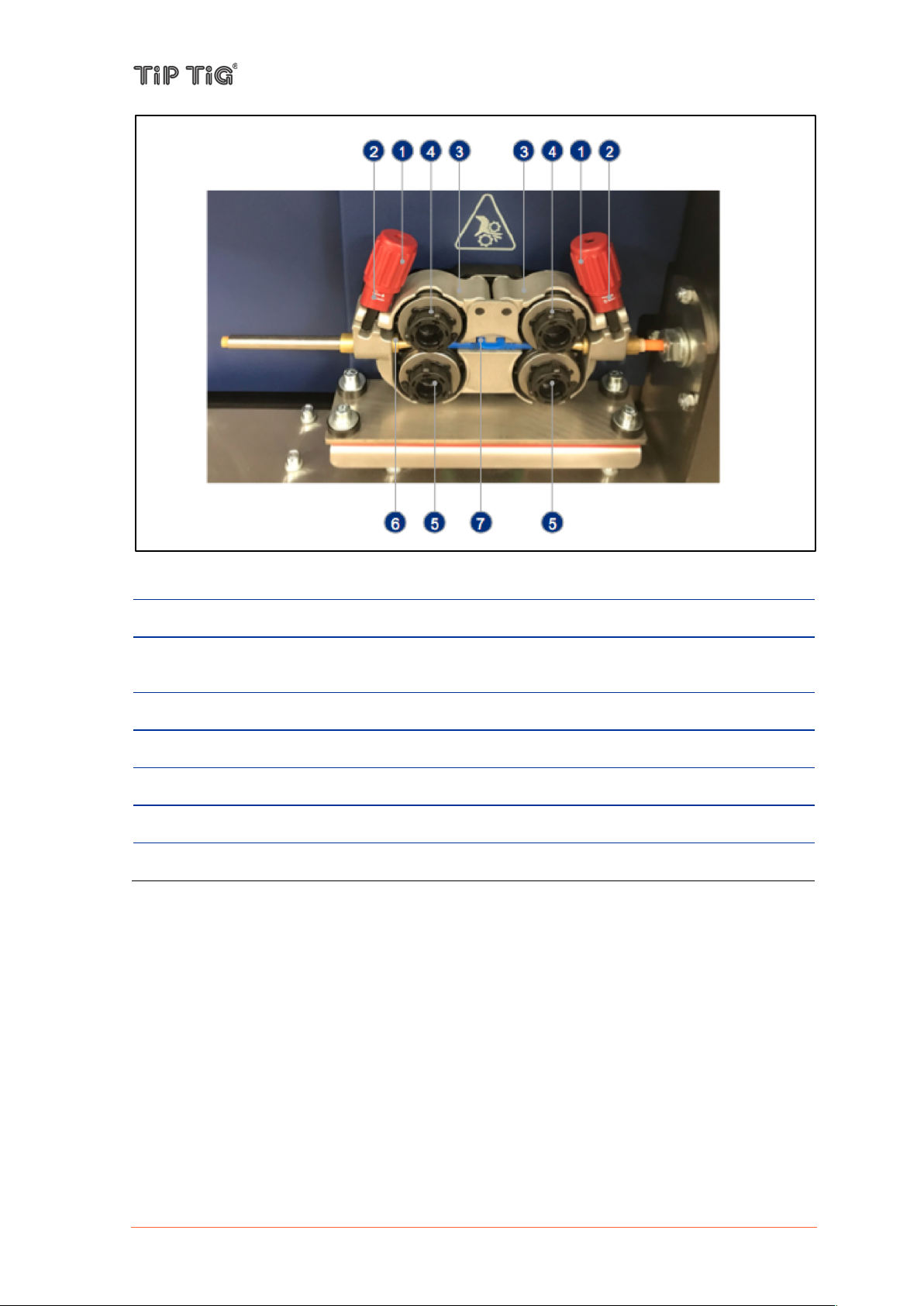

No.

Description

(1)

Adjusting nut

(2)

Feed roll tensioner

for fixing the clamping unit and setting the pressure.

(3)

Clamping unit

(4)

Pressure roller

(5)

Drive roller

(6)

Wire feed nipple

(7)

Guide tube

- Extend and lay out the torch hose package.

- Unfasten pressure units and fold out (clamping units and pressure rollers will automatically flip

upwards).

- Unwind welding wire carefully from the wire spool and insert through the wire inlet nipple over

the drive roller grooves and the guide pipe into the capillary tube and Teflon core using guide

pipe.

- Press the clamping element with the pressure roller back downwards and fold the wire units

back up again (wire electrode should be in the groove on the drive roller).

- Set the contact pressure with the adjusting nuts of the pressure unit.

- Press the wire inching button until the wire electrode projects out of the welding torch.

Page 32 of 58

6.3.4 Spool brake setting

CAUTION

Risk of injury and material damage from the welding current and accidental ignition of an arc.

Before starting work, disconnect the ground earth connection between the welding system and

the workpiece.

CAUTION

Risk of injury and damage from wire electrode emerging. While working:

• hold the welding torch with the point directed away from the face and body

• wear suitable protective goggles

• do not point the welding torch at people

• make sure that the wire electrode does not touch any conductive or earthedparts, such as

the housing, etc.

Safety

General Information

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

After releasing the torch trigger the wire spool must stop unreeling. If it continues unreeling,

readjust the brake.

Setting the brake

- Tighten the Allen screw (8 mm) in the clockwise direction to increase the braking effect.

Page 33 of 58

7. WELDING

According to DIN EN 60974-1, a welding unit with a hazard reduction

device (in this unit a changeover device from AC to DC according to

DIN EN 60974-1, clause 13.2.2) must offer the possibility to test the

device without tools.

When the rotary knob is turned to the Test position, the unit will cycle

for max 0.3s at idle. This fault must be detected, the system switches

off, the green LED no longer lights up, 3 horizontal bars are flashing

in the display, the LED inverter fault lights up. Turn the rotary knob

back to the required welding mode, open the main switch and wait

until the display on the front does not light up. Then the switch can be

closed again, the device is ready for operation.

If, after pressing the torch key in 2-stroke and 4-stroke welding

operation, it does not ignite within 5 seconds, then the forced

shutdown takes place.

If the sequence is stopped by the torch button before the current

flows, it will be stopped directly without gas post flow.

WARNING

Perform this test daily before starting welding. If the green LED

does not go out and the welding unit does not switch off, the

device should be shut down immediately.

WARNING

Operating the equipment incorrectly can cause serious injury and damage. Do not use the

functions described until you have thoroughly read and understood the following

documents:

• these operating instructions !

• all the operating instructions for the system components, especially the safe- ty rules

7.1 Preparation

Safety

7.1.1 S-Test (AC only)

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

7.1.2 Forced switch-off

Page 34 of 58

7.2 Operating modes

There is no activation of ignition device, gas valve or water pump.

The output voltage is applied to the socket of the welding machine,

regardless of the status of the torch trigger.

Hot-Start Function

During the hot start, a current increase of 30% occurs with the set

welding current I1.

After detecting "I <0", the hotstart time of 600ms expires, after which it

switches back to the set welding current.

Advantages

- Improvement of the ignition properties, even with electrodes with

poor ignition properties

- Better melting of the basic material in the starting phase, thus fewer

cold spots

- Extensive avoidance of slag inclusions

Arc-Force Function

If the arc voltage drops below a certain minimum value during welding,

the welding current is increased by 50%. However, the value is limited

to the electrode maximum.

When the minimum voltage is reached again, the system switches

back to the set current setpoint.

Anti-Stick Function

If the INVCB_45 detects a short circuit in the welding process, it

switches to the minimum current after 0.5 seconds to prevent the

electrode from glowing.

After elimination of the short circuit, the commanded setpoint is output

again

WARNING

Operating the equipment incorrectly can cause serious injury and damage. Do not use the

functions described until you have thoroughly read and understood the following

documents:

• these operating instructions !

• all the operating instructions for the system components, especially the safe- ty rules

Safety

7.2.1 MMA

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Page 35 of 58

7.2.2 TIG 4-Stroke with HF

1. Stroke

Press and hold the torch button. When the gas pre-flow time has

elapsed, the arc ignites at 20% of I1 (search arc).

2. Stroke

Open torch button. The welding current rises to the set value of I1.

3. Stroke

Press and hold the torch button. The welding current decreases to the

minimum current during the set time.

4. Stroke

Open torch button. The arc goes out.

The shielding gas flows during the set gas post-flow time.

1. Stroke

Press and hold the torch button. After expiration of the gas pre-flow

time the arc ignites. The welding current increases to the value I1 with

the time set on the soft start rotary knob. The welding current I1 can be

adjusted continuously on the knob I1.

2. Stroke

Open torch button. The welding current drops to minimum with the

time set on the soft-down rotary knob. The arc goes out. The shielding

gas flows during the set gas post-flow time.

In this mode, the ignitor is switched off. This operating mode cannot be

used with AC welding (TIG 500AC only) as the ignitor is also required

for welding.

1. Stroke

The TIG electrode must touch the workpiece.

Press and hold the torch button. After the gas pre-flow time has

elapsed and the TIG electrode has been lifted off, the arc ignites at

20% of I1 (search arc).

2. Stroke

Open torch button. The welding current rises to the set value of I1.

3. Stroke

Press and hold the torch button. The welding current decreases to the

minimum current during the set time.

4. Stroke

Open torch button. The arc goes out.

The shielding gas flows during the set gas post-flow time.

7.2.3 TIG 2-Stroke with HF

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

7.2.4 TIG 4-Stroke Liftarc

Page 36 of 58

7.2.5 TIG 2-Stroke Liftarc

In this mode, the ignitor is switched off. This operating mode can not

be used with AC welding (TIG 500AC only), as with AC, the ignitor is

also required for welding.

1. Stroke

The tungsten electrode must touch the workpiece.

Press and hold the torch button. After expiration of the gas pre-flow

time and lifting of the TIG electrode, the arc ignites. The welding

current increases to the value I1 with the time set on the soft start

rotary knob. The welding current I1 can be adjusted continuously on

the rotary knob I1.

2. Stroke

Open torch button. The welding current drops to minimum with the

time set on the soft-down rotary knob. The arc goes out. The shielding

gas flows during the set gas post-flow time.

1. Stroke

Press and hold the torch button. When the gas pre-flow time has

elapsed, the arc ignites at 20% of I1 (search arc).

2. Stroke

Open torch button. The welding current rises to the set value of I1. The

arc is pulsing. The welding current 1 can be adjusted continuously on

the rotary knob I1. The welding current 2 can be adjusted continuously

on the rotary knob I2, as a percentage of I1. The rotary knob t1 is used

to select the pulse time for I1 and the rotary knob t2 for the pulse time

for I2.

The pulse times are adjustable from 20 ms to 1.3 s.

3. Stroke

Press and hold the torch button. The welding current decreases to the

minimum current during the set time.

4. Stroke

Open torch button. The arc goes out.

The shielding gas flows during the set gas post-flow time.

1. Stroke

Press and hold the torch button. After expiration of the gas pre-flow

time the arc ignites. The welding current increases to the value I1 with

the time set on the soft-start rotary knob. The welding current I1 can

be adjusted continuously on the rotary knob I1. The welding current 2

can be adjusted continuously on the rotary knob I2, as a percentage of

I1. The rotary knob t1 is used to select the pulse time for I1 and the

rotary knob t2 for the pulse time for I2.

7.2.6 TIG 4-Stroke Pulse with HF

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

7.2.7 TIG 2-Stroke Pulse with HF

Page 37 of 58

2. Stroke

Open torch button. The welding current drops to minimum with the

time set on the soft-down rotary knob. The arc goes out. The shielding

gas flows during the set gas post-flow time.

7.3 Welding current types (TIG 500AC only)

With this type of current, the arc is ignited with plus at the burner.

Immediately after the ignition of the arc it is switched to minus. This

makes it easier to ignite even under difficult conditions (mixed gases).

This mode corresponds to the known DC welding.

The arc shape is a bit softer, the arc noise a bit quieter. The frequency

is adjustable from 20 to 250 Hz, the balance from 80:20 to 20:80. The

ignitor is permanently active for AC welding.

The arc shape is a bit harder and more stable. The frequency is

adjustable from 20 to 250 Hz, the balance from 80:20 to 20:80. The

ignitor is permanently active for AC welding.

WARNING

Operating the equipment incorrectly can cause serious injury and damage. Do not use the

functions described until you have thoroughly read and understood the following

documents:

• these operating instructions !

• all the operating instructions for the system components, especially the safe- ty rules

Safety

7.3.1 DC welding with pulse start

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

7.3.2 DC welding

7.3.3 AC welding sinus (soft)

7.3.4 AC welding rectangle (hard)

Page 38 of 58

7.4 MMA welding

WARNING

Operating the equipment incorrectly can cause serious injury and damage. Do not use the

functions described until you have thoroughly read and understood the following

documents:

• these operating instructions !

• all the operating instructions for the system components, especially the safe- ty rules !

WARNING

An electric shock can be fatal. If the power source is connected to the mains electricity

supply during installation, there is a high risk of very serious in- jury and damage. Before

carrying out any work on the device make sure that:

• the power source mains switch is in the "O" position !

• the power source is unplugged from the mains !

CAUTION

Risk of injury and damage from electric shock. As soon as the mains switch is in the "I" position,

the rod electrode in the electrode holder is live. Make sure that the rod electrode does not touch

any persons or electrically conducting or earthed parts (e.g. the housing etc.).

Safety

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Preparation

1. Switch off cooling units

2. Move the mains switch to the O position

3. Disconnect the mains plug

4. Disconnect the TIG welding torch

5. Plug the grounding (earthing) cable in and latch it into place

6. Use the other end of the grounding (earthing) cable to establish a connection to the workpiece

7. Plug in the electrode cable and twist it clockwise to latch it into place

8. Plug in the mains plug

9. Move the mains switch to the I position

Manual metal arc welding

1. Select operating mode with the rotary knob:

- Operating mode MMA

2. Set the desired welding current I1 using the rotary knob

- The value for the welding current is displayed in the welding data display.

3. Start welding

Page 39 of 58

7.5 TIG welding

WARNING

Operating the equipment incorrectly can cause serious injury and damage. Do not use the

functions described until you have thoroughly read and understood the following

documents:

• these operating instructions !

• all the operating instructions for the system components, especially the safe- ty rules !

WARNING

An electric shock can be fatal. If the power source is connected to the mains electricity

supply during installation, there is a high risk of very serious in- jury and damage. Before

carrying out any work on the device make sure that:

• the power source mains switch is in the "O" position !

• the power source is unplugged from the mains !

CAUTION

Risk of injury and damage from electric shock. As soon as the mains switch is in the "I" position,

the tungsten electrode of the welding torch is live. Make sure that the tungsten electrode does

not touch any persons or electrically conducting or earthed parts (e.g. the housing etc.).

Safety

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Preparation

1. Plug in the mains plug

2. Move the mains switch to the I position

TIG welding

1. Select operating mode with the rotary knob:

- TIG 4-Stroke

- TIG 2-Stroke

- TIG Liftarc 4-Stroke

- TIG Liftarc 2-Stroke

- TIG Pulse 4-Stroke

- TIG Pulse 2-Stroke

2. Select the welding current type using the rotary knob:

- DC welding with pulse start

- DC welding

- AC welding sinus (soft)

- AC welding rectangle (hard)

3. Use the rotary knobs to set the parameters to the desired values:

- Pulse time t1

- Pulse time t2

- Soft Start (Upslope)

- Welding current I1

- Welding current I2

- Soft Down (Downslope)

- Gas post-flow time

Page 40 of 58

- Frequency

- Balance

4. Open the gas cylinder valve

5. Set the shielding gas flow rate

6. Start welding (ignite the arc)

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Page 41 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

WARNING

Work that is carried out incorrectly can cause serious injury or damage. All the work

described below must only be carried out by trained and qualified personnel. Do not carry

out any of the work described below until you have fully read and understood the following

documents:

• this document

• all the operating instructions for the system components, especially the safety rules

WARNING

An electric shock can be fatal. Before starting the work described below:

• turn the power source mains switch to the "0" position

• disconnect the power source from the mains !

• ensure that the power source remains disconnected from the mains until all work has

been completed

After opening the device, use a suitable measuring instrument to check that electrically

charged components (e.g. capacitors) have been discharged.

WARNING

An inadequate ground conductor connection can cause serious inju- ry or damage. The

housing screws provide a suitable ground conductor connec- tion for earthing the housing

and must NOT be replaced by any other screws that do not provide a reliable ground

conductor connection.

CAUTION

Risk of scalding by hot system components. Before starting work, allow all hot system

components to cool down to room temperature (+25 °C, +77 °F). For example:

• coolant

• water-cooled system components

• wire-feed unit drive motor

8. TROUBLESHOOTING, MAINTENANCE AND DISPOSAL

8.1 Troubleshooting

Safety

General

All products are subject to rigorous production checks and final checks. If, despite this, something

fails to work at any time, please check the product using the following checklist. If none of the fault

rectification procedures described leads to the correct functioning of the product, please inform

your authorized dealer.

Page 42 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Mains fuse defective

- Change mains fuse

Power supply interrupted

- Check mains supply

- Litz terminated, terminals loose

- Exchange mains supply

Malfunction in the cooling circuit

- Check coolant level

- Check pump

- Check fuses F1, F2 and F3 (F3 on the control

transformer)

- Remove kinks in the hose system

The test device of the hazard

reduction device has triggered.

Rotary knob is in position S-test

- Turn the rotary knob to the desired welding current

mode, switch off the device, wait until the display

completely extinguishes, then switch on the device again.

The danger reduction device has

failed

- Switch off the device, wait until the display turns off

completely, then switch on the device again.

- If the display flashes again and the green S-Test LED is

off, stop the unit immediately and notify the service

Device was overloaded

- Leave the appliance switched on and wait until it has

cooled down

Power module defective

- Notify service

Wrong mode of operation

- Select operating mode TIG with HF

Ignitor defective

- Replace ignitor

Power supply for ignitor interrupted

- Check power supply 230V

- Check fuses F1, F2 and F3 (F3 on the control

transformer)

Trigger voltage is missing

- Check trigger inputs

Troubleshooting-Checklist

Main power switch on, no function

10s after starting welding under TIG the welding process is stopped, the message H20

flashes

Display flashes, green LED for S-test does not light up

Display flashes, green LED for S-test does not light up

Display flashes, yellow LED lights up

When switched on, the mains fuse triggers

It can be welded under TIG DC, but HF does not fire

Page 43 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Plug from the torch trigger is not

inserted (correctly)

- Check, plug in

Burner button line has interruption

- Check control line

Burner button is defective

- Replace the button or replace the burner

Fan is blocked

- Remove blockage

Supply voltage 24V missing

- Check wiring

Power supply 24V is defective

- Notify service

Defect in the inverter

- Check ribbon cables

- Notify service

Too little power set

- Turn the trimmer on the back to the right

Start does not take place

- Check wiring

Power supply for hot wire power

source is missing

- Check 230V, check fuses F1, F2 and F3 (F3 on the

control transformer)

Hot-wire power source defective

- Notify service

Hot wire power source overloaded

- Allow the hot wire power source to cool down

Loose welding current connections

N! Tighten power connections on the torch and/or on the

workpiece

- Tighten contact tip correctly

Overload

N!Check and correct welding current setting

- Use a more powerful welding torch!

Electrode works but TIG has no function

Device overheats but fans do not start

At the input of the AC switch (DC link), the open circuit voltage can be measured, not at the

output of the AC switch. (Attention, the ignition voltage may destroy the meter! Only check

in position MMA)

Hot wire power source does not bring power

Green LED on the front does not light up

Yellow LED on the front lights up

Welding torch overheated

Page 44 of 58

Unstable arc

Unsuitable or worn welding torch

equipment

N! PHcID0! 7,<0170! 05>! 0,! -563! H51;3036! 1<H! N;103651/! 1<H!

63>/173!5E!<373DD16@!

N! PHcID0! -563! 2I5H3! 0,! ;103651/! 5<! ID3V! ?/,-! 0[6,I2[! 1<H!

63>/173!5E!<373DD16@!

Material inclusions in the tungsten

electrode due to contact with filler

material or workpiece

N!Regrind or replace the tungsten electrode!

Incompatible parameter settings

- Check settings and correct if necessary!

Unsuitable or worn welding torch

equipment

- Adjust contact tip (cold wire/hot wire) to wire diameter,

blow through and replace if necessary

- Adjust wire guide to material in use, blow through and

replace if necessary

Contact tip blocked

- Clean, spray with anti-spatter spray and replace if

necessary

Setting the spool brake > see

chapter 6.3.4 Spool brake setting

- Check settings and correct if necessary

Setting pressure units > see

chapter 6.3.3 Inching the wire

electrode

- Check settings and correct if necessary

Worn wire rolls

- Check and replace if necessary

Wire feed motor without supply

voltage

- Check and replace fuse if necessary

Kinked hose packages

- Extend and lay out the torch hose package

Incompatible parameter settings

- Check settings and correct if necessary

Arc between gas nozzle and

workpiece (metal vapor on the gas

nozzle)

- Replace gas nozzle

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Page 45 of 58

Pore formation

Inadequate or missing gas

shielding

N! Check shielding gas setting and replace shielding gas

cylinder if necessary!

N! Shield welding site with protective screens (draughts

affect the welding result)

- Use gas lens for aluminum applications and high-alloy

steels!

Unsuitable or worn welding torch

equipment

N!Check size of gas nozzle and replace if necessary!

Condensation (hydrogen) in the gas

tube

- Replace hose package!

Workpieces dirty

- Clean workpieces

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Page 46 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

WARNING

Work that is carried out incorrectly can cause serious injury or damage. All the work

described below must only be carried out by trained and qualified personnel. Do not carry

out any of the work described below until you have fully read and understood the following

documents:

• this document

• all the operating instructions for the system components, especially the safety rules

WARNING

An electric shock can be fatal. Before starting the work described below:

• turn the power source mains switch to the "0" position

• disconnect the power source from the mains

• ensure that the power source remains disconnected from the mains until all work has

been completed

After opening the device, use a suitable measuring instrument to check that electrically

charged components (e.g. capacitors) have been discharged.

CAUTION

Risk of scalding by hot system components. Before starting work, allow all hot system

components to cool down to room temperature (+25 °C, +77 °F). For example:

• 7,,/1<0!!

• -1036N7,,/3H!D@D03;!7,;>,<3<0D!!

• -563!E33H!I<50!H6583!;,0,6!!

8.2 Care, maintenance and disposal

General

Under normal operating conditions, the device requires only a minimum of care and maintenance.

However, it is vital to observe some important points to ensure the welding system remains in a

usable condition for many years.

Safety

Every start-up

- Check all hose package and the ground earth connection for damage. Replace any damaged

components.

- Check feed rollers and inner liners for signs of damage. Replace any damaged components.

- Check contact pressure of feed rollers and adjust if necessary.

Every 6 months

NOTE! Risk of damage to electronic components. Do not bring the air nozzle too close to

electronic components.

- Open covers, remove device side panels and clean inside of device with dry reduced

compressed air. After cleaning, restore device to its original state.

Disposal

Dispose of in accordance with the applicable national and local regulations.

Page 47 of 58

9. TECHNICAL DATA

TIG 500 AC

TIG 500 DC

Mains connection

3/PE AC 400 V

3/PE AC 400 V

I

1-TIG

35,5A

35,5A

S

1-TIG

24,6kVA

24,6kVA

I

1-Electrode

34A

34A

S

1-Electrode

23,5kVA

23,5kVA

Fuse, lazy

32A

32A

U 0

71V

71V

Setting range I2 TIG

4-500A

peak

4-500A

Setting range I2 Electrode

15-400A

peak

15-400A

Max ED TIG

40%

40%

Max ED Electrode

40%

40%

Setting range Balance

20-80%

20-80%

Setting range Frequency

20-250Hz

20-250Hz

Dimensions L/W/H

1100 x 1230 x 545 mm

1100 x 1230 x 545 mm

Weight

147 kg.

139 kg

EMC class

A A Safety identification

EAC/S/CE

EAC/S/CE

Harmonized standards used

see declaration of

conformity (machine

documentation)

see declaration of

conformity (machine

documentation)

Hot wire current setting range

60 A to120 A

Max. hot wire voltage

10,5 V

Power Source

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Wire feeder / Hot wire

Page 48 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Duty cycle at 40 °C ambient temperature

35% DC

120 A

60% DC

100 A

100% DC

80 A

Load cycle

10 min. (60% DC; 6 min. welding, 4 min. pause)

Open circuit voltage

82 V

Reduced open circuit voltage

10,5 V

Frequency

50/60 Hz

Mains fuse

T8 A 120/230 VAC

Feeder fuse

T8 A 32 VAC

Max. connected load

2.6 kVA

Recommended generator rating

3.4 kVA

cosj / efficiency

0.99 (86%)

Insulation class / protection classification

H/IP 23

Ambient temperature

–25 °C to +40 °C

Machine cooling

Fan

Hot wire current welding lead

25 mm2

Welding current welding lead

95 mm2

Wire feed speed

0.15 m/min. to 17 m/min.

5.6 IPM to 670 IPM

Standard WF roller equipment

0.8 + 1.0 mm (for steel wire)

Drive

4 rolls (37 mm)

Torch connector

Decentral

Forward/backward motion frequency

17 – 20 Hz

EMC class

A

Safety identification

EAC/S/CE

Harmonized standards used

see declaration of conformity (machine

documentation)

Page 49 of 58

10. APPENDIX

10.1 Spare part list

10.1.1 Four roll wire drive

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Page 50 of 58

TIP TIG - TIG 500 COMPACT, OPERATING MANUAL

Pos.

Description

Item-No.

(1) Feed plate front

88807200

(2) Feed plate rear

88807202

(3) Feed roll shaft

88807204

(4) Hex-nut M6

88807206

(5) Pressure arm assembly left SFT4

88807208

(6) Pressure arm assembly right SFT4

88807208

(7) Torsion spring

88807210

(8) Motor-New Wire Drive

88807212

(9) Motor fixation screws

88807214

(10)

Drive Gear

88807216

(11)

Flat washer

88807218

(12)

Machine screw

88807220

(13)

Pressure adjustment unit

88807222

(14)

Tapered pin

88807224

(15)

Quick change carrier gear

88807226

(16)

Circlip

88807228

(17)

(18)

Quick change feed roll (0.8 / 1.0)

Quick change feed roll (1.0 / 1.2)

Quick change feed roll (1.2 / 1.6)

Quick change feed roll (0.8 / 0.8)

Quick change feed roll (0.9 / 0.9)

Quick change feed roll (1.0 & 1.0)

88807158

88807160

88807162

88807170

88807172

88807174

(19)

Machine screw

88807232

(20)

Wire guide set blue

88807234

Page 51 of 58

10.2 Wire Feeder

Display value

m/min IPM

5

0,32 12,50

10

0,64 25,00

15

0,95 37,50

20

1,27 50,00

25

1,59 62,50

30

1,91 75,00

35

2,22 87,50

40

2,54 100,00

45

2,86 112,50

50

3,18 125,00

55

3,49 137,50

60

3,81 150,00

65