TIP TIG TECHNICAL MANUAL

V4.5

www.tiptigusa.com 155 E 9th Ave Suite A, Runnemede, NJ 08078

Preface

We are very pleased that you have chosen to place your trust in our product. We

place great value in ensuring that you draw great pleasure, benefit and work

enhancement from your use of the TIPTIG Hot Wire Unit.

For that reason, we would like you to read through the Technical Manual thoroughly

before installing and starting to use the TIPTIG Hot Wire Unit.

It will help you to familiarize yourself with your new product as rapidly as possible and

to use it more efficiently.

This Technical Manual details the TIPTIG Hot Wire Unit, providing you with assistance

and support in installing it and getting started, as well as demonstrating how to use it

safely and effectively

The Manual is structured as follows:

TABLE OF CONTENTS

SECTION I − SAFETY PRECAUTIONS - READ BEFORE USING Pg

I-I Symbol Usage 1

I-II Arc Welding Hazards 1

I-III Additional Symbols For Installation, Operation and Maintenance 2

I-IV California Safety Standards 3

I-V Principal Safety Standards 3

I-VI EMF Information 3

SECTION II − Labels+symbols,Safety instruction especially TIPTIG

II-I Labelling+Symbols 4

II-II Safety instructions (CE) 5

II-III Safety instructions (CE) 6

II-IV Safety instructions (CE) 7

SECTION III − Installation-Getting Started

III-I Installation/Getting Started 8

III-II Getting Started 9

III-III Getting Started 10

III-IV What is the TIP TIG Process, How is it operated and Benefits 11

III-V Wire Selection 12

III-VI Tungsten Selection and Angles 13-14

III-VII Teflon Guide inside the feeder 15

III-VIII Loading wire for the first time 16-19

SECTION IV − Introduction-Tips-Warnings

IV-I Introduction 20

IV-II Tips II Function of TIP TIG Torch 18 SC 21-22

IV-III Tips III Function of TIP TIG Interconnect Cable 23

IV-IV Tips IV Function of Interface board 24

SECTION V − Pictures/Spare parts numbers

V-I Front View TIP TIG 25

V-II Left + Right Side TIP TIG 26

V-III Parts list TIPTIG Hot Wire Unit 27

V-IV Parts list 4-rolls Wire Feeder 28

V-V Picture Inside Connection Hot Wire Module 29

V-VI Spare list inside connection Hot Wire Module 30

V-VII Wire Feeder Diagram and Parts Breakdown 31-32

SECTION VI – Warranty 33

SECTION VII WP18 SC JUMBO / MEDIUM CONFIGURATION 34-35

SECTION VIII WP20 SC JUMBO / MEDIUM CONFIGURATION 36-37

SECTION IX WP 18 / 20 Torch Instruction Guide 38-42

SECTION X TIPTIG Hotwire Spare box TW18 SC-JUMBO 43-44

TABLE OF CONTENTS

SECTION XI WP 410 Straight (Handheld Addition) 45

SECTION XII Straight Handheld / Fixed Instruction Guide 46

SECTION XIII WP 410 Straight (Fixed Addition) 47

SECTION XIV TIP TIG FEEDER PC BOARD DIAGRAM 48

SECTION XV TIP TIG HOTWIRE CASE DIAGRAM 49 -51

SECTION XVI Miller Maxstar / TIP TIG Setup 52

SECTION XVII Miller Dynasty / TIP TIG Setup 53

SECTION XVIII MILLER MAXSTAR 350 / DYNASTY 350 54-55

BASIC SETTINGS

SECTION XIX TIP TIG Data Sheet 56

SECTION XX Troubleshooting 57-58-59

Protect yourself and others from injury-read and follow these precautions

I - I Symbol Usage

Instead of the examination mark, the danger sign often shows

the source of the danger in question. The yellow highlighted text

contains details of how to prevent personal injury or substantial

damage to property

Failure to comply with the instructions given may pose risk This group of symbols means Warning! Watch Out!

of injury '-or even danger of life! ELECTRIC SHOCK,MOVING PARTS, and HOT PARTS hazards.

Consult symbols and related instructions below for necessary

NOTICE- Indicates statements not related to personal injury

actions to avoid the hazards

I - II Arc Welding Hazards

The symbols shown below are used throughout this manual to Properly install and ground this equipment according to the

call attention to and identify possible hazards. When you see the Owner's Manual and national,state,and local codes.

symbol, watch out, and follow the related instructions to avoid the Always verify the supply ground-check and be sure that input

hazard. The safety information given below is only a summary of power cord ground wire is properly connected to ground terminal

he more complete safety information found in the Safety in disconnected box or that cord plug is connected to a properly

Standards listed in Section 1-V.Read and follow all Safety grounded receptacle outlet.

Standards When making input connections, attach proper grounding conductor-

tor first-double-check connections.

Only qualified persons should install,operate,maintain,and Keep cords dry, free of oil and grease, and protected from hot

repair this unit metal and sparks.

Frequently inspect input power cord for damage or bare wiring-

During operation, keep everybody, especially children, away. replace cord immediately if damaged-bare wiring can kill.

Turn off all equipment when not in use.

ELECTRIC SHOCK can kill.

Do not use worn,damaged,undersized,or poorly spliced cables.

Touching live electrical parts can cause fatal shocks or severe Do not drape cables over your body.

burns. The electrode and work circuit is electrically live whenever If earth grounding of the work piece is required, ground it directly

the output is on. The input power circuit and machine internal with a separate cable.

circuits are also live when power is on. In semiautomatic or Use only well-maintained equipment. Repair or replace damaged

automatic wire welding, the wire, wire reel, drive roll housing parts at once. Maintain according to manual.

and all metal parts touching the welding wire are electrically live. Wear a safety harness if working above floor level.

Incorrectly installed or improperly grounded equipment is a Keep all panels and covers securely in place.

hazard. Clamp work cable with good metal-to-metal contact to work piece

Don't touch live electrical parts. or worktable as near the weld as practical.

Wear dry, hole-free insulating gloves, and body protection Insulate work clamp when not connected to workspace to prevent

Insulate yourself from work and ground using dry insulating mats or contact with any metal object.

covers big enough to prevent any physical contact with the of ground.

Do not use AC output in damp areas, if move, movement is confined, or

SIGNIFICANT DC VOLTAGE exists in Inverter welding

if there is a danger of falling.

power sources AFTER removal of input power!

Use AC output ONLY if required for the welding process. Turn OFF inverter,diconnect input power, and discharge input

If AC output is required, remote output control is present on unit. capacitors according to instructions in Maintenance Section

Additional safety precautions are required when any of the following before touching any parts.

electrically hazardous conditions are present: in damp locations or while

wearing wet clothing: on metal structures such as floors,gratings,or

HOT PARTS can burn.

scaffolds; when in cramped positions such as sitting,kneeling,or lying, Do not touch hot parts bare handle.

or when there is a high risk of unavoidable or accidental contact with Allow cooling period before working on equip-

the work piece or ground. ment.

Disconnected input power or stop engine before installing or servicing To handle hot parts, use proper tools and/or

this equipment. Lockout/tag out input power according to wear heavy, insulated welding gloves and

OSHA 29 CFR 1910.147 (see Safety Standards). clothing to prevent burns.

SAFETY PRECAUTIONS -READ BEFORE USING

1

SECTION I

I - III Additional Symbols For Installation,Operation,And Maintenance

FIRE OR EXPLOSION hazard. MOVING PARTS can injure.

Do not install or place unit on,over,or near combustible Kee p away from moving parts such as fan

surfaces Kee p all doors,pa nels,covers and guards clos ed

Do not install unit near flammables . and securely in pla ce

Have only qualified persons remove doors,pa nels,covers , or

Do not overload building wring,-be sure power supply system is guards for maintenance and troubleshooting as necessary.

properly sized,rated,and protected to handle this unit Reinsta ll doors,panels ,covers or guards when maintenance is

finis hed and before reconnecting input power.

FALLING EQUIPMENT can injure.

Use lifting eye to lift unit only, NOT running gear, gas READ INSTRUCTIONS

cylinders , or any other accessorie s. Read and follow all la bels and the Owner's

Use equipment of adequa te capa city to lift and support unit. Manual carefully before installing, opera ting or

servicing unit. Read the safety information at

the beginning of the manua l and in each section

If using lift forks to move unit, be sure forks are long enough to extend Use only genuine repla cement parts from the manufacturer.

beyond opposite side of unit. Perform maintenance and service according to the Owner's

Kee p equipment (cables and cords)away from moving vehicles when Manuals, indus try sta ndards , and national,state,a nd loca l codes

working from an aerial location

Follow the guideline in the Applications Manual for the Revised NIOSH H.F.RADIATION can cause interference.

Lifting Equation (publica tion No.94-110) when manually heavy parts High-frequency (H.F) can interference with radio

or equipment. navigation, safety service s,computers,and

communications equipment.

OVERUSE can ca use OVERHEATIING Have only qualified persons familiar with

Allow cooling peri od, follow rated duty cycle electronic equipment perform this insta lla tion

Reduce current or reduce duty cycle before sta rting to The user is respons ible for having a qualified electrician promptly

weld again correct any interference problem res ulting from the ins tallation

Do not block or filte r airflow to unit. If notified by the FCC about interference , stop using the equipment

at once.

FLYING SPARKS can i njure. Have the insta lla tion regularly checked and maintained.

Wea r a face shield to protect eyes and face Kee p high-frequency source doors and panels tightly shut, keep

Shape tungsten electrode only on grinder with proper spa rks gaps at correct setting, and use grounding and shielding

guards in a sa fe loca tion wearing proper fa ce,hand,a nd to minimize the possibility of interference.

body protection.

Sparks can cause fires -keep flamma bles away.

STATIC (ESD) can damage PC boards

Put on grounded wrist strap BEFORE handling boards or

parts .

Use proper static-proof bags and boxes to store,move,or

ship PC boa rds.

MOVING PARTS can injure.

Kee p away from moving parts

Kee p away from pinch points such as drive rolls.

WELDING WIRE can inj ure.

Do not press gun trigger(button) until instructed to do so.

Do not point gun towa rd any part of body, other people,

or any metal threa ding welding wire

2

SECTION I

CALIFORNIA PROPOSITION 65 WARNINGS

Welding or cutting equipment produces fumes or gases which

contain chemicals known to the State of California to cause birth

defects and ,in some cases, cancer,

(California Health & Safety Section 25249.5 et.s eq.)

I - V Principal Safety Standards

Safety in Welding,Cutting,and Allied Processes

ANSI Standa rdZ49.1 from Gl oba l Engine e ring Documents

(www.gl o ba l .i hs .com)

Safety in Welding,Cutting,and Allied Processes

CSA Standa rd W 117.2 from Cana di a n Standa rds As s ocia tion

(www.cs a -i nterna ti ona l .com)

OSHA,Occupational Safety and Health Standards for

General Industry

Title 29,Code of federal Regulations (CFR) Part 1910,Subpart Q

and Part 1926,SubpartI from Government Printing Office

(www.osha.gov)

Electric current flowing through any conductor causes localized 4 Keep head an trunk as far away from the equipment in the

electric and magnetic fields(EMF).Welding current crea tes an EMF field welding circuit as possible.

around the welding circuit and welding equipment.EMF fields may 5. Connect work clamp to work piece as close to the weld as

interfe re with s ome me di ca l i mpl a nts, e.g. pea ce ma ke rs. possible.

Protective measures for persons wea ring medical impla nts have to

6. Do not work next to, sit or lean on the welding power source.

be taken. For example, access restrictions for passers -by or individual

7. Do not weld whilst carrying the welding power source or wire

risk as s essment for welders . All welders should use the following feeder.

procedures in order to minimize expos ure to EMF fields from the

welding circuit:

1. Keep cables close together by twisting or taping them, or using

a cable cover.

2. Do not pla ce your body between welding cables. Arrange cables

to one side and away from the operator

3. Do not coil or drape cables around your body

3

SECTION I

Symbols used in the Manual

This Technical manual uses a range of symbol and pictograms. You will need to

familiarize yourself closely with their meanings.

The symbols will help you to understand the information presented more rapidly and

point out of potentially important information, hints and tips.

Pay attention to the instructions and information presented adjacent to these

symbols with particular care

Danger sign Instead of the examination mark, the danger sign often shows the source of

the danger in question. The yellow highlighted text contains details of how

to prevent personal injury or substantial damage to property.

Failure to comply with the instructions given may pose risk of injury

-or even danger of life!

Prohibition sign The prohibition sign often shows the action or object which is prohibited.

The text accompanying this symbol details things to be avoided in order

to prevent personal injury or damage to property.

Essential action sign The action required (such as wearing protective equipment) is detailed in

in place of exclamation mark. Identifies essential action to be taken in order

to prevent injury.

Caution sign The text accompanying this symbol details action to be taken in order to

prevent damage.

Information sign Note, information or tip as a help in enhancing use of the equipment

Hand book sign Read the instructions-For your own safety and to avoid risk, be sure to

read and follow the instructions set out in this Technical Manual

SECTION 2 SAFETY INSTRUCTIONS

4

SECTION II-I

General safety instructions

The recognized technical rules and applicable standards and regulations

were followed and applied in the development and manufacture of the

TIPTIG High Speed Hot Wire Unit.

The TIPTIG High Speed Hot Wire Unit is designed and manufactured such that,

if used in accordance with it's designed purpose, any potential danger is

largely avoided.

Ing.Siegfried Plasch nonetheless feels obliged to detail the following safety

precautions which you should undertake in order to avoid any residual risk

Follow the operating Caution! When using TIPTIG Hot Wire Unit, the following fundamental

instructions! safety precautions must be taken in order to protect against electric

shock, potential injury and fire risk. Read and follow the instructions

for use,cleaning,care and maintenance given in this Technical Manual

before beginning work. Keep the Technical Manual within easy reach of

the machine operator and pass it on to new operators as and

when appropriate

The TIPTIG High Speed Hot Wire Unit is only for commercial and

industrial use. Any other use of this machine must be authorized in writing

by the manufacturer-Ing.Siegfried Plasch. Only personnel that have trained

for use and servicing of welding equipment may operate this machine

The operator for this equipment must carefully read and fully understand

all the information contained within before the unit can be put into

operation!

The information contained in this manual has been given the

manufacturer's best knowledge. However, the manufacturer can't be held

liable for the use of this information

Ing.Siegfried Plasch reserves the right to make any changes to this

machine and/or operations manual without prior notice.

Check function! Before beginning work, check that the guards and the TIPTIG Hot Wire Unit

itself are in good working order. Check the torch and machine for damage

and make sure that all parts in good working order!

Look out for damage! All parts must be correctly fitted and all conditions to met ensure trouble-free

operation of the machine. If the machine is damaged in any way, it must

no longer be used. In such cases, ensure that the machine is professionally

repaired. Identify the defect and mark the machine clearly so that it is not

used until such time as the repair has been carried out.

Maintain good order! Maintain good order in your work area! Disorder in a work area can cause

accidents. Secure your workplace when leaving it.

SAFETY INSTRUCTIONS

5

SECTION II-II

Installation and servicing of the TIPTIG Hot Wire unit welding machines

and components may only be performed in accordance with the national

rules and regulations of the respective organization operators safety.

Never come into contact with any metal parts that are under stress or

use with bare hands or wet clothing. During welding operation always wear

safety gloves, welding helmet with correct filter!

Be especially careful that anything, such as clothing that comes in

contact with the work area including the welding torch, welding ground

clamp and welding machine are always dry.

Never work in wet clothing!

When working with metal in the work area or in areas with high voltage

always be sure that all metal parts are isolated. Always use dry gloves

and wear rubber soled shoes!

Also, make sure that you are standing on a dry, isolated underlay!

Do not use any worn or damages welding cable!

Make sure that any welding cables are not overloaded!

Turn off the TIPTIG Hot Wire Unit and the welding machines if it is not

in use for long periods of time!

Do not leave the welding cable coiled up and do not wrap it around any

parts of the equipment casing!

When leaving the TIPTIG Hot Wire Unit and the welding unit, make sure

that it has been turned off and never leave it running unattended!

Make sure that the welding ground is connected close by the welding area

to the work piece!

Poor Welding ground connections, or poor grounding taken from parts of

the building or remote points decrease efficiency.

Furthermore the risk of electrical damage to equipment will increase!

Make sure that welding voltage can not come into contact with any chains

or steel ropes from equipment such as powered lifts and cranes!

Wear suitable work wear Damaging effect of the rays generated by the electrical arc and from any

and personal safety gear! hot metals can lead to severe burns to unprotected skin and eyes.

To protect your eyes and body from damaging sparks and rays always use

welding helmets with the proper certified filter lens. Also, wear the proper

protective clothing etc., even if you are only observing the welding process

Any person in the vicinity of the work area must be advised not to look

directly into the arc and that metal sparks could be sent through the air.

Protect your skin and hair with leather gloves and a welding helmet/mask

from the rays and metal sparks emitted.

Protect the personnel in the surrounding work area from the welding rays

and hot sparks with approved anti-flame retardant gear.

Gas tanks under pressure are a potential danger. Follow all safety

measures as suggested by gas suppliers and the safety procedures

imposed by safety inspectors!

Make sure that gas tanks are in a safe place and cannot fall over!

SAFETY INSTRUCTIONS

6

SECTION II-III

7

SECTION II-IV

Do not use the welding equipment close to flammable liquids or gases!

Danger from electrical energy! There is electrical equipment inside the TIPTIG Hot Wire Unit. Check the

machine for external damage before beginning work. Check especially

if wires and cables are damaged.

Do not continue working with the equipment if it is damaged.

Pull the plug! In the event of repairs and maintenance work, or when the

equipment is not in use, always disconnect the mains power supply plug

from wall socket

WARNING! Work on the electrical equipment may only be carried out by a

qualified electrician. Only original spares may be used. Failure to comply

with this requirement may result in users suffering accidents

Use only original parts! WARNING! Use only spares as specified in this Manual. The use of non-

approved parts may pose a risk of injury to you.

SAFETY INSTRUCTIONS

Make sure the correct power The TIPTIG Hot Wire Unit must be connected to a socket outlet fitted

supply is connected! with a properly installed ground contact.

Before connecting the TIPTIG Hot Wire Unit, make sure the main

power cable and the plug are undamaged. Make sure the main voltage

matches the specifications on the rating plate.

The TIPTIG Hot Wire Unit may only be connected to a voltage

of 115/120VAC /50/60Hz.

The power circuit must be fuse-protected to a maximum of 16A.

Recommendation: To protect you against electric shock, the circuit should

be protected by an GFI circuit-breaker(ground fault circuit-breaker)

The TIPTIG Hot Wire Unit can now be operated as detailed in the "Operator control"

section

Using in tanks and Don't take the TIPTIG Hot Wire Unit into a tank or container

container structures! structure!

It's possible to take only the TIPTIG Feeder into any tank and container

structure!

You have only to separate the TIPTIG Feeder from the TIPTIG

Trolley!

In this case the operating supply voltage is only 32 VAC!

Installation/Getting started

8

SECTION III-I

Getting start step 1 Connect the TIPTIG Hot Wire Unit interconnecting cable to

welding machine.

Connection step 2 Plug the TIPTIG Hot Wire Unit main cable plug to the socket

Only 115/120 VAC socket

Connection step 3 Put the wire spool in the spool holder and secure the spool with

the plastic nut an secure the plastic nut with the plastic screw!

Feed the wire by hand through the 4 feeder rollers and through

out the central torch connector about 2 inches

Connect the TIPTIG torch to the TIPTIG feeder

Check that all connections are tight!

Getting Started

9

SECTION III-II

The Hotwire Power Switch is located in the front on the unit.

Press the I/O rocket switch to POWER ON the Hotwire Process.

If AC Welding. DO NOT USE HOTWIRE….Power Off Hotwire

When first Powered On, The LED Indicator light

will flash several times then become solid.

The Hot Wire Unit is activated.

The Hot Wire Amp Range is from 60 to 100.

Recommended Setting is 80 Amps for All Alloys and Steels

SECTION III-III

Getting Started

10

What is the TIP TIG process?

The TIP TIG process is a dynamic GTAW process that combines our

patented vibratory effect of the wire in part with a hotwire current

applied to the wire prior to entering the weld puddle.

• The vibratory effect is created by a linear forward/backward

mechanical motion created by the custom wire feeder system

• The Hotwire current is created by a secondary power source within

the Tip Tig unit.

How is the TIP TIG Process Operated?

• The TIP TIG process is operated by using a standard solid core MIG spool, a

conventional TIG power supply with a minimum of 350 amps with HF start

and trigger hold function because the TIP TIG process doesn’t use a foot

petal.

• The TIP TIG process can be operated in all welding positions both manually

or combined with our automated equipment such as the TIP TIG Tractor,

TIP TIG Orbital and TIP TIG Oscillator.

Weld Process Benefits from TIP TIG?

The wire entering the weld pool is mechanically and electrically superimposed

from the TIP TIG process which creates a high speed vibration and preheating of

the weld wire while entering the weld puddle.

The vibratory effect and the preheating of the wire create a more fluid weld

puddle allowing for improved sidewall wetting and significant deposition rate

increases as well as porosity off gassing.

SECTION III-IV

11

Wire Selection for TIP TIG

• Always Use a Good Quality Weld Wire.

• The preferred wire diameter is .035 a secondary choice will

be .045 based on wire type and availability.

• Plastic Reels are preferred over the Wire Steel Reels.

• Wire Steel Reels may Bend or Break Causing Wire Feed

Problems.

• With TIP TIG the Wire Cast and Helix are Important for good

Feedability.

• Use standard 30LB to 40LB Wire Spools.

Please visit Oxford Alloys at www.oxfordalloys.com for your wire selections.

Mild Steel, Stainless Steel, Duplex, Super Duplex, Nickel Alloy

Titanium, Bronze & Copper Wire

12

SECTION III-V

1.5% Lanthanated “Gold” Recommended

Most commonly is used non-radioactive tungsten. Offers long electrode life

under heavy or pulsing amperage loads. It has the ability to resist thermal

shock which provides the user with excellent ignition with a lower burn off

rate.

Tungsten Electrodes Sizes to Amperage Ranges

3/32” (.093”) 2.4 mm = 60 - 250

1/8” (.125”) 3.2 mm = 100 - 400

5/32” (.156”) 4.0 mm = 160 - 500

SECTION III-VI

13

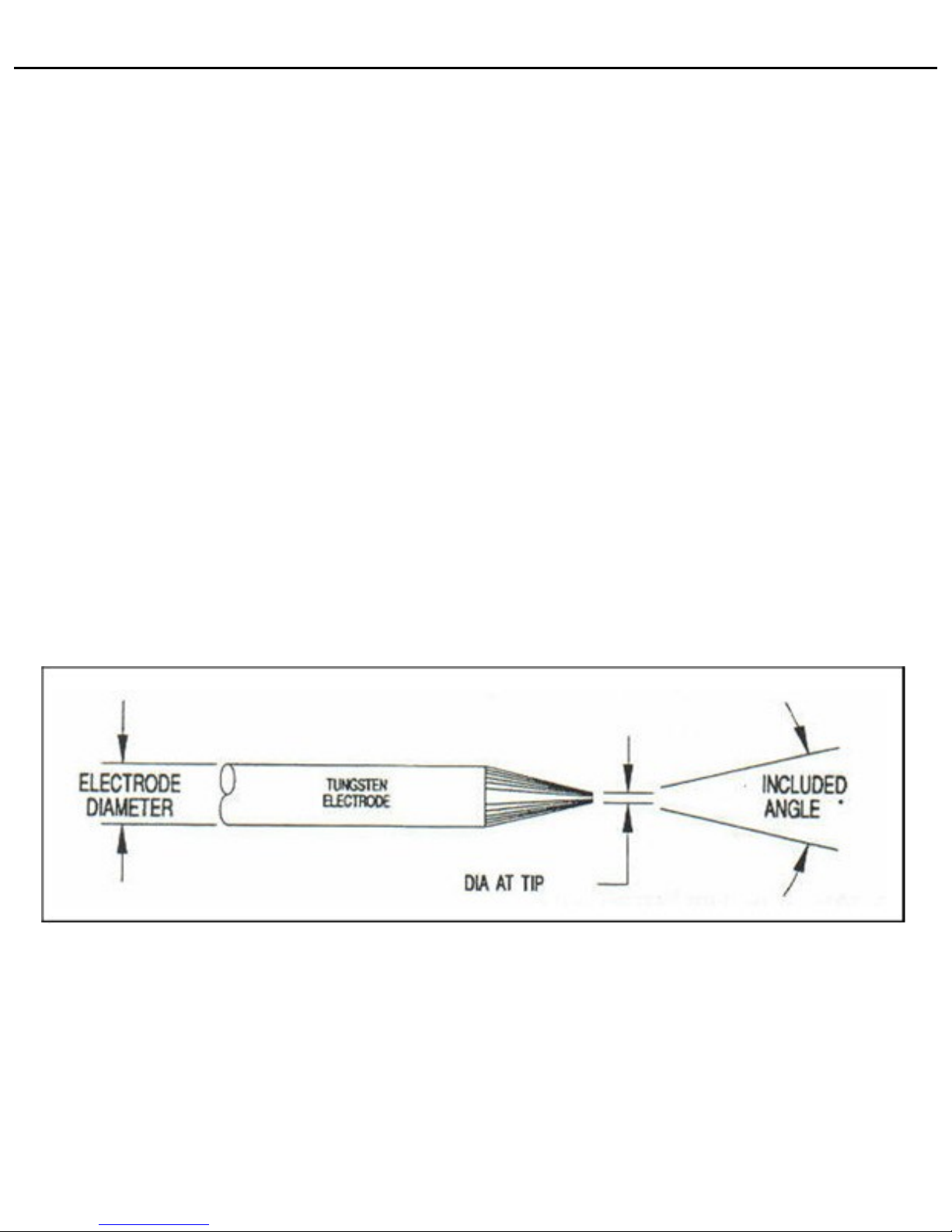

Selecting Tungsten for the TIP TIG Process

With the TIP TIG Process, you will be welding with more wire so your weld

current will be higher than normal. 150 – 350 amps is typical. You will have

much longer arc on times. How the tungsten is sharpened will have dramatic

effect on the weld duty cycle attained.

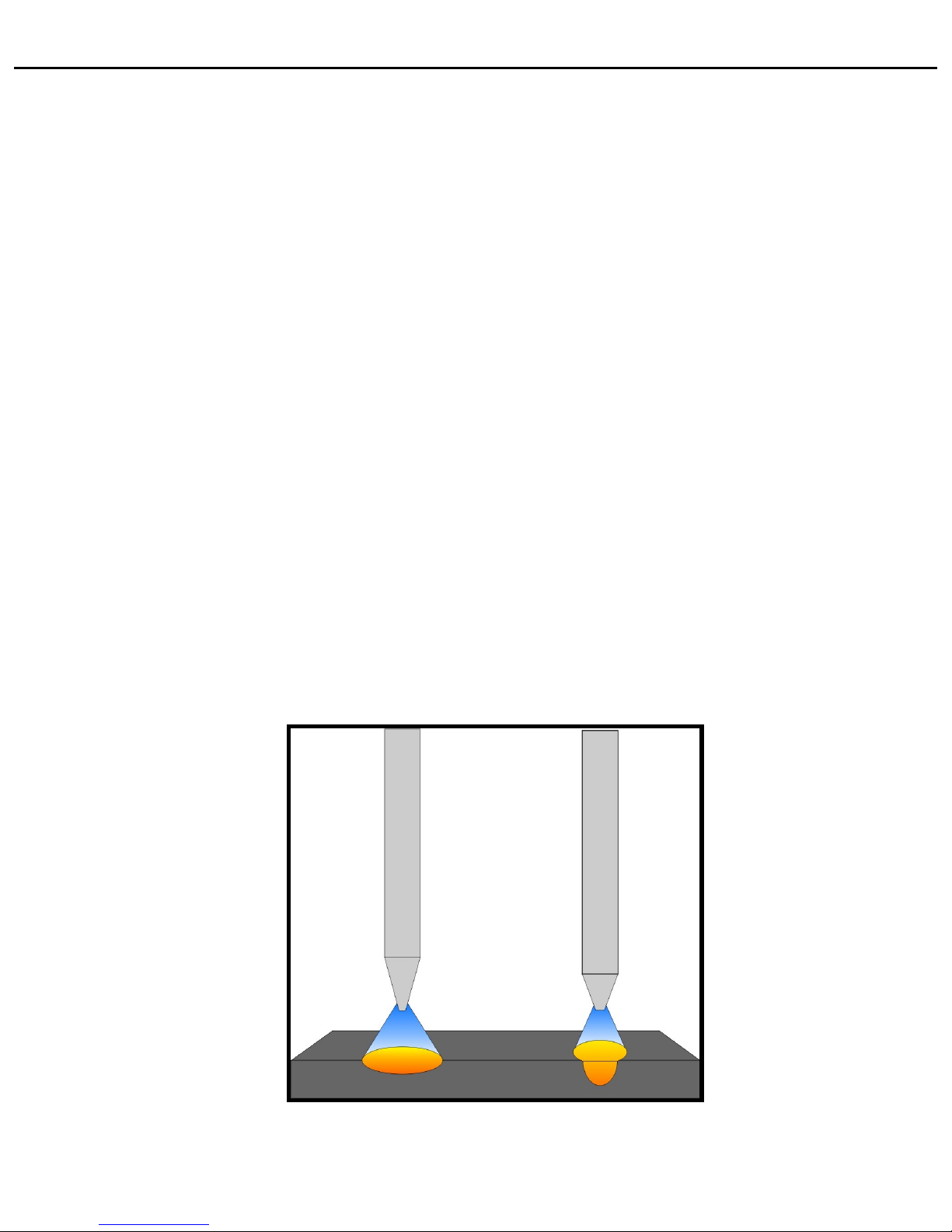

For manual TIP TIG welds you want an included

angle of “25 degree” with a flat on the tungsten

tip. This provides a wider arc plasma suited for

most TIG welds.

For better penetration at high travel rates, you

will need a included angle of “35 degree”. This

angle provides a narrow, more concentrated arc

plasma better suited for automation.

25 DEG 35 DEG

SECTION III-VI

14

Tungsten Included Angles and their Benefits

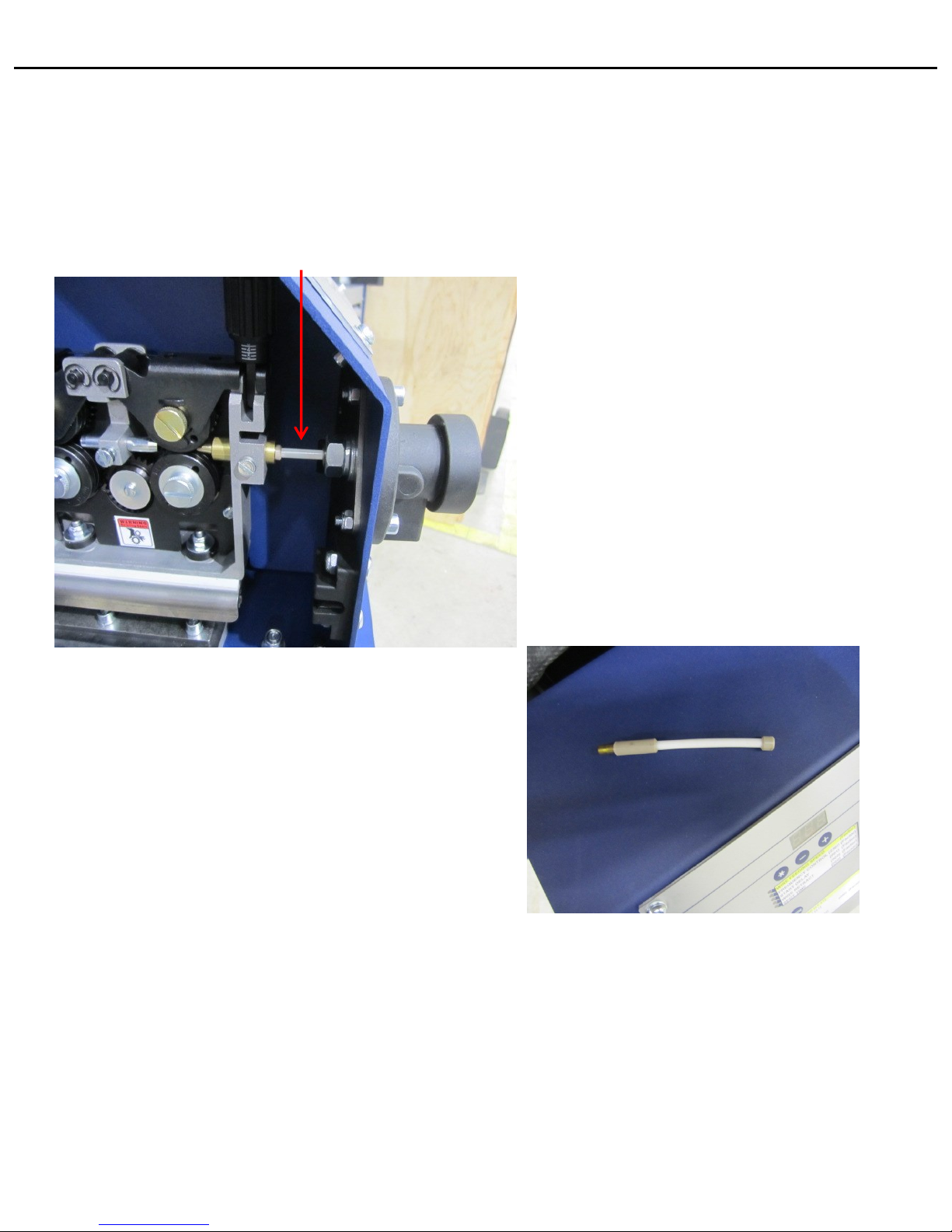

When removing or installing the torch,

make sure the Teflon Inlet Guide is installed

inside the main connection terminal as shown below.

Teflon Inlet Guide Tube is 4” Long.

The purpose of the Teflon Inlet Guide Tube is to keep the wire

centered from the action of the wire feeder's

forward and backwards motion and

acts as the outlet guide for the wire.

Teflon Wire Guide

SECTION III-VII

15

When installing a wire spool, make sure the drive wheels

are set to the correct wire diameter.

Each drive wheel is reversible.

The number shown on the front side of the drive wheel

indicates the correct wire size used.

Available Drive Roll Sizes (.8-1.0) (1.0-1.2) (1.2-1.6)

Drive Rolls labeled both

Metric / Standard Wire

Hand Tighten all screws on the drive rolls

and make sure drive rolls are able to spin

freely.

16

SECTION III-VIII

Loading the Wire

When installing the upper drive wheels,

make sure the metal tension spring

is against the bracket before installing the drive wheel.

Set the Drive wheel Tension to 3 for most wire types

17

Loading the Wire

Make sure the Inlet Guide and the Outlet Guide are as close

to the drive rolls as possible.

This will greatly reduce any wire feed issues.

INCORRECT

CORRECT

Loading the Wire

18

Tungsten Stick Out – 5/8” – 3/4”

Tungsten to Wire = 3/32”

Tungsten to Wire = 3/32”

Tungsten Stick Out = 5/8”- 3/4”

1. Remove all liner consumables so the torch is bare.

2. Make sure the correct drive rolls are installed.

3. Set the wire feed speed to 100.

4. Use a file to round off wire before inserting in into the TIP TIG.

5. Run the wire until it is about 12 inches past the handle.

6. Install liner and guide blocks…Make all settings as shown below.

7. Orientate the guide block to the desired position.

8. Run 15 inches of wire to ensure the wire cast has been straightened.

9. Set tensioners to around 3 and you are ready to weld.

Load Welding Wire on the TIP TIG

Loading the Wire

19

TIPTIG TIPTIG Hot Wire Unit can be use for TIG/PLASMA/LASER techniques

TIPTIG Hot Wire Unit is suitable for Hot and Cold Wire Welding

All filler diameters can be used (0.030in-0.063in)

For Aluminum it's recommended 0.045in (0.063in)

Use the welding machines with the water cooler running.

If not you will damage the torch.

Display value The display value:- multiplied by 2.5 is the result in inches!

feeding speed Example: Factor 100 = 250inches/min (6.4m/min)!

Display value The value is as shown as factor!

frequency For all applications use 230!!

Display value The value is shown as factor!

start delay Useful for tack weld !

Display value The value is shown as a factor!

wire retract delay Is an option -normally not used!

Display value The value is shown as factor!

spot time Only for spot weld!

To use spot time it's needed to adjust the mode spot function

Mode 4 -step Generally select 4- stroke mode for hand welding > see page 8

Mode 2 -step 2- stroke mode mostly used for tack welding

UP/DOWN Function If a remote control or an UP/DOWN torch is used, it's possible to

Wire Feed Speed

adjust wire speed+- 33% from the setup of wire feed value

Option

UP/DOWN Function If a remote control or an UP/DOWN torch is used, it's possible to

AMPS

adjust amps + -!

This option belongs to the feature of the welding machine!

Introduction

20

SECTION IV-I

NEW!!

TIPTIG EXTREME

Hotwire 18 Water Cooled Torch

Standard Length 14ft (4.25m)

Duty cycle 400A/100%

Part Number # 10002460

TIPTIG Hotwire 18 Water Cooled Torch

Up Function = Arc On and Off

Down Function = Wire On and Off

To Start the Weld process

Step 1 – Press Up Button to Start Arc

Step 2 – Press Down Button to Start Wire

To Stop the Weld Process

Step 3 – Press Down Button to Stop Wire

Step 4 – Press Up Button to Stop Arc

21

SECTION IV-III

TIPS II

TIP TIG FEEDER

1 - Main Torch Connection Terminal

2 - 5 Pin Female Bajonet Connector

3 - Current / Water Connection G3/8 RH

4 - Gas Connection G1/4 RH

5 - Water Inlet Connection G3/8 LH

6 - Hotwire Terminal 25

Connecting the Torch to the Feeder can only go ONE WAY!

See Pictures Below

1

2

3

4

5 6

TIP TIG TORCH

1 - Torch Connection

2 - 5 Pin Male Bajonet Connector

3 - Current / Water Connection G3/8 RH

4 - Gas Connection G1/4 RH

5 - Water Inlet Connection G3/8 LH

6 - Hotwire Terminal SK25

1

2

3

4

5

6

22

Working Ground Connection

TIP TIG Interconnect Cable

2 Way Adapter

Hotwire Lead

TIG Lead

NOTE: Cable Ends will be labeled with RED and indicators to

match the location on the Power Supply.

Coolant

Miller Plug

Gas Line

TIPS III

SECTION IV-IV

23

Operating microprocessor Function of the microprocessor control

control How to adjust parameter

To choose parameter Wire feed speed

F

press

Oscillation frequency

F

press

Start delay

F

press

Wire retract time

F

press

Spot time

F

press

To change values 4-Stroke – Regular Welding

F

press

2- Stroke – Tack Welding

F

press

Lead Voltage 0-10v (AUTO)

F

press

Spot Function

F

press

Program Load

F

press

TIPS III Function of Interface Board

*

-

MO

?

MO

DE

?

?

MO

+

Program Save

24

SECTION IV-V

FRONT VIEW

1

3

13

4

5

7

8

9

10

11

12

14

15

16

17

18

19

20

21

22

2

6

25

SECTION V

LEFT+RIGHT SIDE

23

24

25

26

27

28

29

30

31

32

33

34

35

36

38

39

41

42

37

40

45

44

43

26

SECTION V-II

27

Pos Description Article no

1 1 pc TIP TIG Micro processor control hand version 77700103

2 1 pc TIP TIG Front plate new design 88800410

3 1 pc TIP TIG Case housing 88800690

4 1 pc TIP TIG Female socket 5-pin,bajonet connector 88800457

5 1 pc TIP TIG Male x Male connector with inner cone for gas G1/4" RH 88800429

6 1 pc TIP TIG Plastic blind nipple 77700190

7 1 pc TIP TIG Built in plug BEM 25 88800426

8 1 pc TIP TIG Male x Male connector with inner cone G3/8" LH 88800431

9 1 pc TIP TIG Water/current connection G3/8" right hand complete 77700162

10 1 pc TIP TIG Rocker switch without flash-IP 65 88800501

11 1 pc TIP TIG Pot knob for hot wire unit 88800510

12 1 pc TIP TIG Front plate hot wire module 88800862

13 1 pc TIP TIG Plastic mask 77700046

14 1 pc TIP TIG Torch central brass connector 77700048

15 1 pc TIP TIG Door knob 77700049

16 1 pc TIP TIG Basic plate 88800601

17 1 pc TIP TIG Label sticker Hot Wire Module 88800480

18 1 pc TIP TIG LED yellow 88800504

19 1 pc TIP TIG LED green 88800503

20 1 pc TIP TIG Plate for wheels 88800552

21 1 pc TIP TIG Steering roller with brake 88800555

22 1 pc TIP TIG Steering roller without brake 88800556

23 1 pc TIP TIG Plastic wire cover black 77700044

24 1 pc TIP TIG Plastic handle 77700690

25 1 pc TIP TIG Wire spool holder 88800620

26 1 pc TIP TIG Male x Male connector with inner cone for water G3/8" LH 88800431

27 1 pc TIP TIG Built in plug BEM 25 88800426

28 1 pc TIP TIG Built-in socket SE 50/70 88800428

29 1 pc TIP TIG Male x Male connector with inner cone for water G3/8" RH 88800430

30 1 pc TIP TIG Rocker switch with red flash-IP 65 88800500

31 1 pc TIP TIG Fuse holder IP 67 88800506

32 1 pc TIP TIG Plastic blind nipple ` 88800508

33 1 pc TIP TIG Male x Male connector with inner cone for gas G1/4" RH 88800429

34 1 pc TIP TIG Male socket 6+PE, screw termination (Series 693) 88800452

35 1 pc TIP TIG Case plate back hot wire module 88800860

36 2 pc TIP TIG Trestle roller 88800558

37 2 pc TIP TIG Sticker 88800560

38 1 pc TIP TIG Case plate right 88800635

39 4 pc TIP TIG Rubber feet 88800760

40 2 pc TIP TIG Grounding clip Hot Wire Module 88800866

41 1 pc TIP TIG Case housing Hot Wire Module 88800868

42 1 pc TIP TIG Right side cover plate Hot Wire Module 88800870

43 1 pc TIP TIG Screw wire cover 77700045

44 1 pc TIP TIG Door 88800632

45 2 Stk TIP TIG Plastic hinge 88800755

PARTS LIST TIPTIG HIGH SPEED HOT WIRE MODULE

SECTION V-III

CONNECTION

TIPTIG TO TIPTIG HOT WIRE MODUL

CONNECTION

TIPTIG HOT WIRE MODUL TO WELDING UNIT

VIEW CONNECTION INSIDE HOT WIRE MODULE

1

2

3

4

5

6

7

8

9

10

11

12

13

28

SECTION V-V

Pos Description Article no

1 1 pc TIP TIG Male socket 6+PE, screw termination (Series 693) 88800452

2 1 pc TIP TIG Male x Male connector with inner cone for water G3/8" LH 88800431

3 1

pc

TIP TIG Male x Male connector with inner cone for water G3/8" RH 88800430

4 1 pc TIP TIG Male x Male connector with inner cone for gas G1/4" RH 88800429

5 1 pc TIP TIG Built in plug SEM 25 88800454

6 1 pc TIP TIG Built in plug BE 50/70 77700050

7 1 pc TIP TIG Female socket 6+PE, screw termination (Series 693) 88800453

8 1 pc TIP TIG Male x Male connector with inner cone for water G3/8" LH 88800431

9 1 pc TIP TIG Male x Male connector with inner cone for water G3/8" RH 88800430

10 1 pc TIP TIG Male x Male connector with inner cone for gas G1/4" RH 88800429

11 1 pc TIP TIG Built in plug BEM 25 88800426

12 1 pc TIP TIG Built-in socket SE 50/70 88800428

13 1 pc TIP TIG Male socket 3+PE, screw termination (Series 693) 88800458

PART LIST VIEW CONNECTION INSIDE

29

SECTION V-VI

Wire Feed Diagram

30

SECTION V-VII

1

2

3

4

5

6

7

8

9

10

11

12

13

14

31

15

10

16

17

25

1

18 24

19

20

21

22

23

Wire Feed Diagram

SECTION V-VII

Pos. Description Part no.

1 TIPTIG Pressure device complete 88874002

2 TIPTIG Feed plate 88807002

3 TIPTIG Inlet guide with liner 88807024

4 TIPTIG Screw 5 88874021

5 TIPTIG Axle shaft gear adaptor -feed roll 88874015

6 TIPTIG Intermediate guide standard 88874013

7 TIPTIG Screw 6 88874022

8 TIPTIG Brass outgoing guide 77700569

9 TIPTIG Screw 5 88874021

10 TIPTIG Gear adaptor feed 88874029

11 TIPTIG Washer 2 88874036

12 TIPTIG Knurled screw rolls 88874018

13 TIPTIG Screw 7 88874034

14 TIPTIG Guard safety kit 88874004

15 TIPTIG Axle pressure roll 88874014

16 TIPTIG Pin gear adaptor feed 88874027

17 TIPTIG U-Drive roll Ø 0.8-1.0mm 88807058

17 TIPTIG U-Drive roll Ø 1.0-1.2mm 88807060

17 TIPTIG U-Drive roll Ø 1.2-1.6mm 88807062

17 TIPTIG U-Drive roll Ø 0.9-0.9mm 88807064

18 TIPTIG Pressure arm left 88807011

24 TIPTIG Pressure arm right 88807012

19 TIPTIG Pressure device axis 88807007

20 TIPTIG Axle pressure roll 88807014

21 TIPTIG Circlip 88807016

22 TIPTIG Knurled screw pressure arm 88807017

23 TIPTIG Spring pressure arm auto lift 88807012

25 TIPTIG Pin 88807025

32

Wire Feed Diagram

SECTION V-VII

33

SECTION VI

Warranty

WARRANTY INFORMATION

TIP TIG FEEDERS, TIPTIG HOTWIRE MODULES, TIP TIG POWERSUPPLYS

Within the warranty period of 12 Months from the date of purchase, TIP TIG USA will

replace any warranted parts or components that fail due to such defects in material or

workmanship. TIP TIG USA must be notified in writing within thirty (30) days of such

defect or failure, at which time TIP TIG USA will provide information on the warranty claim

procedures to be followed.

TIP TIG USA shall honor warranty claims on warranted equipment listed below in the

event of such a failure within the warranty time periods. All warranty time periods start

on the delivery date of the equipment to the original end-user purchaser, and not to

exceed one year after the equipment is shipped to a North American location.

TIP TIG USA shall not bear the costs of transportation.

12 Month Parts and Labor

• Transformer

• Hotwire Unit

• PC Board

• Feed and Oscillator Motor

• Water Fitting and Bulkhead Connection

• Linear Motion Slide and Extenders

• Torches (Upon Initial Delivery Only)

What is Not Covered Under the Warranty

Consumable components; such as contact tips, nozzles, insulators, rings, collets

gas lenses, back caps, liners, tungsten, universal tip guides or any torch accessory

Is not covered under the manufactures warranty.

For TIPTIG Service please call:

856-312-8166

Gas Lens

3/32” 99900524

1/8” 99900526

5/32” 99900528

Collets

3/32” 99901031

1/8” 99901032

5/32” 99901033

Ring

77700630

Ring Insulator

77700214

Nozzle Insulator

77700605

Nozzles

#6 3/8” 77700530 #6XL 3/8” 77700575

#8 1/2” 77700532 #8XL 1/2” 77700576

#10 5/8” 77700533 #10XL 5/8” 77700577

#12 3/4” 77700534 #12XL 3/4” 77700578

#6L 3/8” 77700571 #6XXL 3/8” 77700585

#8L 1/2” 77700572 #8XXL 1/2” 77700586

#10L 5/8” 77700573 #10XXL 5/8” 77700587

#12L 3/4” 77700574 #12XXL 3/4” 77700588

Back Caps

Small 77700240

Med 77700241

Large 77700242

Tip Holder

39 Deg Fillet 77700686

42 Deg Butt 77700685

Liner

Bronze Liner 77700566

Insulator

Fiberglass Sleeve 77700548

Tips Regular

Cooper .035” 77700536

Cooper .045” 77700537

Cooper .068” 77700538

Narrow Groove Tips

.035” 77700536B

.045” 77700537B

WP18 SC JUMBO CONFIGURATION

SECTION VII

34

Gas Lens

3/32” 99900024

1/8” 99900026

5/32” 99900028

Collets

3/32” 99901031

1/8” 99901032

5/32” 99901033

Ring

77700630

Ring Insulator

77700214

Nozzle Insulator

77700252

Nozzles

#7 7/16” 54N15

#8 1/2” 54N14

#5L 5/16” 54N17L

#6L 3/8” 54N16L

#7 7/16” 54N15L

#8 1/2” 54N14L

Back Caps

Small 77700240

Med 77700241

Large 77700242

Tip Holder

39 Deg Fillet 77700686

42 Deg Butt 77700685

Liner

Bronze Liner 77700566

Insulator

Fiberglass Sleeve 77700548

Tips Regular

Cooper .035” 77700536

Cooper .045” 77700537

Cooper .068” 77700538

Narrow Groove Tips

.035” 77700536B

.045” 77700537B

WP18 SC MEDIUM CONFIGURATION

SECTION VII

35

WP20 SC JUMBO CONFIGURATION

Gas Lens

1/16” 99900110

3/32” 99900112

1/8” 99900114

Collets

1/16” 77700445

3/32” 77700456

1/8’ 77700457

Ring

77700630

Ring Insulator

77700230

Nozzle Insulator

77700605

Nozzles

#6 3/8” 77700530

#8 1/2” 77700532

#10 5/8” 77700533

#12 3/4” 77700534

Back Caps

Small 99903008

Med 99903009

Large 99903010

Tip Holder

39 Deg Fillet 77700686

42 Deg Butt 77700685

Liner

Bronze Liner 77700566

Insulator

Fiberglass Sleeve 77700548

Tips Regular

Cooper .035” 77700536

Cooper .045” 77700537

Cooper .068” 77700538

Narrow Groove Tips

.035” 77700536B

.045” 77700537B

SECTION VIII

36

WP20 SC MEDIUM CONFIGURATION

Gas Lens

1/16” 99900100

3/32” 99900102

1/8” 99900104

Collets

1/16” 77700445

3/32” 77700456

1/8’ 77700457

Ring

77700630

Ring Insulator

77700230

Nozzle Insulator

77700252

Nozzles

#7 7/16” 54N15

#8 1/2” 54N14

#5L 5/16” 54N17L

#6L 3/8” 54N16L

#7 7/16” 54N15L

#8 1/2” 54N14L

Back Caps

Small 99903008

Med 99903009

Large 99903010

Tip Holder

39 Deg Fillet 77700686

42 Deg Butt 77700685

Liner

Bronze Liner 77700566

Insulator

Fiberglass Sleeve 77700548

Tips Regular

Cooper .035” 77700536

Cooper .045” 77700537

Cooper .068” 77700538

Narrow Groove Tips

.035” 77700536B

.045” 77700537B

SECTION VIII

37

Step 1- Install the Ring Insulator

Step 2- Install the Ring for Universal Tip Holder

Step 3- Install the Nozzle Insulator

1

2

3

Step 4- Install the Gas Lens by hand, then tighten slightly with pliers as shown.

4

WP18 SC and WP20 SC Torch Instruction Guides

SECTION IX

38

Step 5- Install the Gas Nozzle

Step 6- Install the Collet

Step 7- Install the Tungsten

7

6

5

Step 8- Install the Back Cap and tighten to secure the tungsten in place.

39

SECTION IX

Universal Tip Holder Assembly

Tip / Liner Assembly

Includes:

Contact Tip

.035, .045

Liner

Fiberglass Sleeve

Assembly Holder Block

42 (RED) Deg Tip Holder for PIPE Applications

Adjustment Shaft

Also Available in 39 (BLUE) Deg Tip Holder for PLATE Applications

7.5” Liner Assembly will work on Regular and Large Nozzle Sizes

40

SECTION IX

Installing the Tip Assembly to the Universal Tip Holder

Loosen the Set Screw inside the Tip Holder

Install the Tip Assembly into the Tip Holder and tighten.

41

SECTION IX

Install the weld

repellant tape as

shown.

Install the Tip Assembly Shaft.

Step 9- Install the Assembly Holder Block to the Ring and secure with screw.

Step 10- Attach Hotwire Cable to Assembly Holder Block with screw..

9

10

Step 11- Push in Liner Assembly to Hull Adapter on torch

Step 12- Connect Adjustment Shaft to Assembly Holder Block and tighten screws

11

12

Adjustment Screws

Radius of Tip Assembly needs to have a uniformed radius

as shown for best wire feeding results

42

SECTION IX

Push in liner and twist counter

clockwise to seat in place.

Part Number # 77701000-A

TIPTIG Hotwire Spare box TW18 SC-JUMBO

For Reordering Parts, see Individual Parts Breakdown on next slide

SECTION X

43

PN # 77700685

One 42 Deg Tip Holder for PIPE

Part Number # 77700686

One 39 Deg Tip Holder for PLATE

PN # 77700632

Two Tip Tig Ring Holder

PN # 77700214

Two Ring Insulators

PN # 77700605

Two Nozzle Insulators

PN # 99900526

Three 1/8 Gas Lens

PN # 99900528

Three 5/32 Gas Lens

PN # 99901032

Three 1/8 Collets

PN # 99901033

Three 5/32 Collets

PN # 77700240

Two Small Back Caps

PN # 77700241

Two Medium Back Caps

PN # 77700242

Two Large Back Caps

PN # 77700569

One Inlet Guide Tube w/

Guide Bearing

PN # 77700603

Three .035” Liner Complete

PN # 77700604

Three .045” Liner Complete

PN # 88807060

Four 1.0 1.2mm Drive Rolls

PN #77700538 .068 Tip

(20) PN # 069-67-123

One Heavy Duty Side Cutters

(21) PN # J4974CG

One Fold Hex Key

1.5mm – 6.0mm Allen

Two 1.5% Lanthanum 1/8" DIA 7" Long PC 25 Deg Taper

Two 1.5% Lanthanum 5/32" DIA 7" Long PC 25 Deg Taper

(25) x1 #6 77700530 x1 #8 77700532

x1 #10 77700533 x1 #12 77700534

(26) x4 #6L 77700570 x4 #8L 77700571

x4 #10L 77700572 x4 #12L 77700574

PN # 99900524 3/32 Gas Lens

PN # 99901031 3/32 Collets

SECTION X

44

WP410 AUTO JUMBO CONFIGURATION HANDHELD

Gas Lens

3/32” 99900726

1/8” 99900728

5/32” 99900730

Collets

1/16” 77700441

3/32” 77700442

1/8’ 77700443

Ring Insulator

77700845

Nozzles

#6 3/8” 77700530

#8 1/2” 77700532

#10 5/8” 77700533

#12 3/4” 77700534

Back Caps

TIP TIG AUT Torch Cap "A"

77700415

TIP TIG AUTO Electrode Case

77700420

Tip Holder

39 Deg 77700686

42 Deg 77700685

Liner

Bronze Liner 77700566

Insulator

Fiberglass Sleeve 77700548

Tips Regular

Cooper .035” 77700536

Cooper .045” 77700537

Cooper .068” 77700538

Narrow Groove Tips

.035” 77700536B

.045” 77700537B

45

SECTION XI

Handheld / Fixed Torch Instruction Guide

Insert the two parts together

2

Identify the Tungsten Collet (left) and

the Electrode Case (Right).

1

Insert the Inner Collet as per Tungsten Size

into the electrode case.

3

NOTE: Inner Collets NOT USED on Handheld torch

Insert the Tungsten into the

Electrode Case, adjust stick out

and tighten Electrode Case.

4

Install the ring insulator and the ring onto

the torch shaft.

(you need to remove the steel stud on ring)

5

Install the Nozzle Insulator and the

Gas Lens on the torch.

Screw in tight.

6

46

SECTION XII

Gas Lens

3/32” 99900726

1/8” 99900728

5/32” 99900730

Collets

1/16” 77700441

3/32” 77700442

1/8’ 77700443

Ring Insulator

77700845

Nozzles

#6 3/8” 77700530

#8 1/2” 77700532

#10 5/8” 77700533

#12 3/4” 77700534

Back Caps

TIP TIG AUT Torch Cap "A"

77700415

TIP TIG AUTO Electrode Case

77700420

TIP TIG AUT 410 S Collet 2.4mm 77700432

TIP TIG AUT 410 S Collet 3.2mm 77700433

TIP TIG AUT 410 S Collet 4.0mm 77700434

Tip Holder

39 Deg 77700686

42 Deg 77700685

Liner

Bronze Liner 77700566

Insulator

Fiberglass Sleeve 77700548

Tips Regular

Cooper .035” 77700536

Cooper .045” 77700537

Cooper .068” 77700538

Narrow Groove Tips

.035” 77700536B

.045” 77700537B

WP410 AUTO JUMBO CONFIGURATION FIXED

47

SECTION XIII

48

SECTION XIV

TIP TIG FEEDER PC BOARD DIAGRAM

49

SECTION XV

TIP TIG HOTWIRE DIAGRAM

50

SECTION XV

51

SECTION XV

52

SECTION XVI

53

SECTION XVII

MILLER MAXSTAR 350 / DYNASTY 350

BASIC SETTINGS

POLARITY (DC) - Steel Alloys, Stainless Steel, Nickel, Copper, Titanium

(AC) - Aluminum, Magnesium

PROCESS - TIG HF IMPULSE is the standard selection for High Frequency Starts

OUTPUT - RMT 2T HOLD – is used in replace of a foot pedal to engage and hold

the arc while welding.

AMP - Main Amperage Set

INERT GAS USED - 100% Argon used with a regular at 30-40 CF for most

welding.

ADVANCED SETTINGS

PULSER – Not Recommended.

SEQUENCER - The TIP TIG Process does not require a foot pedal. The Sequencer

settings is where you can control your start and stop settings in replace of the

foot pedal.

INITIAL AMPERAGE (AMP VALUE)

INITIAL SLOPE TIME (TIME VALUE)

FINAL SLOPE TIME (TIME VALUE)

FINAL AMPERAGE (AMP VALUE)

GAS/DIG - PreFlow and PostFlow provide shielding before and after the starts

and stops and are set in seconds.

54

Setting Power Source for the TIP TIG Process

SECTION XVIII

DO NOT PLUG THE TIP TIG INTO THE BACK OF YOUR POWERSUPPLY

AS THE HF INTERFERS WITH THE TIP TIG EQUIPMENT.

USE A SEPARATE 115V OUTLET.

55

56

TIPTIG Hand Hotwire Welding Wire Ø 0.035 and Ø0.045in!

Baseline Start Up Parameters!

Please test all parameters before start of any work!

TIP TIG WELD DATA CHART

Tungsten Selection

125-150

150-175

175-200

200-225

225-250

250-275

275-300

300-325

325-350

350-375

375-420

Amps (A)

Wire speed

(Factor)

Wire Ø 0.035

Materials: All (except Aluminium)

Hotwire current: 80A

Ø 3/32"

Ø 1/8"

Ø 5/32"

25-40

30-45

35-50

40-55

45-60

50-65

55-70

60-75

65-80

70-85

75-90

Wire speed

inch/min

75-120

90-135

105-150

120-165

135-180

150-195

165-210

180-225

195-240

210-255

225-270

Daily

Check for excess ive wear and wire alignment insi de the groove.

Re-align upper dri ve rolls or replace drive rol ls to the approate wi re si ze.

Check for excess ive wear and wire alignment insi de the groove.

Outlet guide shoul d move freely between the brass block and the torch connection.

Replace as needed.

Drive rol ls should move freely. Tension should be set around 3 for adequate

Should be free to latch and unl atch.

Adjust setting as needed or repla ce parts as needed.

Make sure power suppl y is ful l with cool a nt before use.

Add coolant as needed.

Check for any cracked or worn fi ttings on the front and back of feeder.

Replace as needed.

Wire Spool Hub - Check wire spool hub tensi on. Too much tension wil l cause wire to slip causi ng

feed i ssues.

Adjust the tension so the spool stops the instant the wire is turned off.

Preventative Maintenance Schedule

Drive Roll Alignment -

Inlet and Outlet Guides -

Wire Pressure Device -

Coolant Levels -

Water,Gas Connections -

Every 3 Monthly

Check the connecting rod attached to the Oscil lator motor for wear and exessive noise.

Remove 4 screws on the face o fthe PC board. Visually i nspect and phyi call y check rod for excessive

wear and vi sual damage Repl ace part as needed

Remove the left si de panel on Hotwire module. Check to make sure al l Dinse connections are

tightly secured to the pa nel mounts.

Tightly secured to the pa nel mounts.

Preventative Maintenance Schedule

Bulkhead Dinse Connections

Oscillator Connecting Rod -

57

Trouble Remedy 1 of 2

Check 115V input power supply.

Check fuse on rear panel.

Check vol tage at PC board (Plug 14 - BRN + BLU wire = 32V)

Checl 115V input at trans former

Check 32V output at transformer

Check 115V input to TIP TIG. Do not use GFI protected circui t.

Do not use receptacle in back of power supply. TIP TIG will not operate from this.

Replace PC Board due to damage.

Worn drive rol ls or pressure device not set properly. Replace or adj ust as needed.

Drive rolls not matched properly to wire size. Correct drive toll wire size.

Wire not ridi ng true inside drive roll s . Adjust.

Incorrect radius for bronze liner. Liner shoul d be 7.5" and the liner from the torch, with the hull

device on should be just below the WP18 torch body.

Wire to tip si ze not matched properl y. Try then next larger size tip.

Worn or defective bronze liner. Repla ce

Liner i n torch defective. Repl ace

Tension on pressure device to set properly. Adjust pressure to avoid s l ippage or dragging of wire.

Wire spool too tight. Adjust pressure at wire hub to correct dragging of wire.

No Hi Frequency Power suppl y not set to TIG HF. Set to TIG HF on power supply.

Bad torch ground. Check power cable inside handl e for proper ins ulation. Correct as needed.

Bad ground insi de TIP TIG feeder. Check that ground l ugs do not have interference with chassic.

Correct as needed

Tungsten burnback. Wrong pol arity set. Correct polarity.

Positive to ground and hotwire / Neg to TIG cabl e.

Trouble Shooting Guide

Erratic Meter Display

Wire Feeding Issues

Feeder will not power up

/ LED Display blank

58

Trouble Remedy 2 of 2

Check LED on Front panel and make sure switch on front panel i s on.

Check high temp / over heat light. If on, check to see if power suppl y is on.

Check 115V input on trans former.

Check to make sure ground cable is pl ugged into power suppl y.

Trouble Shooting Guide

No Hotwire Output

59

Loading...

Loading...