Tinytag Ultra 2 TGU-4550 User Manual

…………………………………………………………………………….

inytag Ultra 2

Tinytag Ultra 2

T

Tinytag Ultra 2 Tinytag Ultra 2

Thermocouple Manual

Thermocouple Manual

Thermocouple ManualThermocouple Manual

TGU

TGU----4550

TGUTGU

4550

45504550

Warnings

Warnings

WarningsWarnings

• This logger must be used in accordance with the information provided in this

manual.

• This equipment contains a lithium battery. Do not cut open, incinerate,

recharge or expose to temperatures in excess of 100°C (212°F). Danger of

explosion if the battery is incorrectly fitted.

• The battery should only be replaced with the battery type specified in this

document, observing the correct polarity.

• This equipment should only be connected to a computer using a CAB-0007-

USB interface cable.

• This equipment should be used within the temperature range and other

environmental conditions specified in this manual.

Getting Started

Getting Started

Getting StartedGetting Started

To use a Tinytag Ultra 2 thermocouple data logger you will require the following

items:

• A copy of the Tinytag Explorer software

• A CAB-0007-USB download cable

Install Tinytag Explorer and the USB download cable, as described in the

software’s quick start guide and plug the USB cable into the socket on the front of

the logger.

For further information on how to start the data logger recording and how to view

the results from the unit, please see the Tinytag Explorer quick start guide.

Thermocouple Specific Configuration Options

Thermocouple Specific Configuration Options

Thermocouple Specific Configuration Options Thermocouple Specific Configuration Options

in Tinytag Explorer

in Tinytag Explorer

in Tinytag Explorerin Tinytag Explorer

When starting a thermocouple data logger in Tinytag Explorer you will see two

options specific to this type of logger that are not mentioned in the software’s

quick start guide.

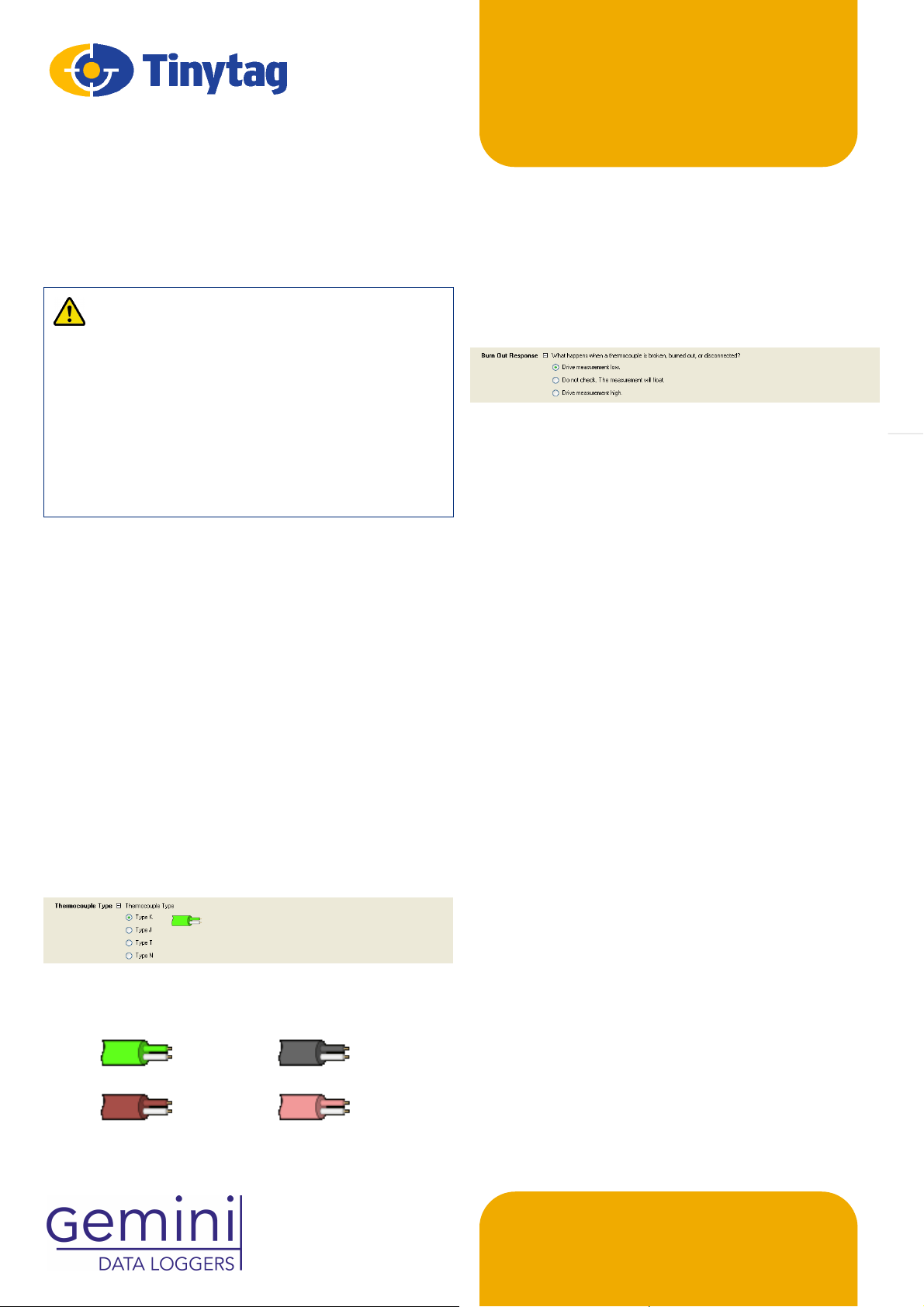

Thermocouple Type

Thermocouple Type

Thermocouple TypeThermocouple Type

Select the thermocouple type you are using from the options listed.

If you are unsure what type of thermocouple you have, the plug or cable on it may

be coloured coded and you can match this to the diagram next to each option.

Colours for the different types of thermocouple are as follows:

ThermocoupleLogger

Burnout Response

Burnout Response

Burnout ResponseBurnout Response

The burnout response option allows you to tell the data logger what to do in the

event of a problem with the thermocouple being used.

If a faulty thermocouple is attached to the data logger it is possible for the logger

to show readings that may appear to be correct. The burnout response can

deliberately drive readings low or high in the event of a problem, to make it clear

to the user that there is a problem.

Choose what you want the data logger to do from the options listed.

Using the Thermocouple Data Logger

Using the Thermocouple Data Logger

Using the Thermocouple Data LoggerUsing the Thermocouple Data Logger

To get the best results, ensure that the data logger and the thermocouple plug

have sufficient time to reach the same temperature before recording begins. If the

thermocouple has been stored at a significantly different temperature from the

logger, allow 30 minutes for stabilisation.

It is advisable to keep the logger at a constant temperature whilst recording, and

to avoid large temperature gradients across the unit (for example, avoid placing

the logger on a very hot or very cold surface).

Large fluctuations in logger temperature can cause temporary errors in the probe

measurement, although these are unlikely to exceed 1°C.

Measurement Specification

Measurement Specification

Measurement SpecificationMeasurement Specification

Thermocouple

Thermocouple

Thermocouple Thermocouple

Sensor Type Type K, J, T or N Thermocouple

Sensor Type

ensor Type Sensor Type

S

Range

Range

RangeRange

Type K

Type K -270 to +1370°C (-454 to 2498°F)

Type KType K

Type J

Type J -210 to +1200°C (-346 to 2192°F)

Type JType J

Type T

Type T -270 to +400°C (-454 to 752°F)

Type TType T

Type N

Type N -270 to +1300°C (-454 to 2372°F)

Type NType N

Reading Resolution

Reading Resolution 0.01°C

Reading Resolution Reading Resolution

Cold Junction Compensation

Cold Junction Compensation -10 to +70°C

Cold Junction CompensationCold Junction Compensation

Accuracy

Accuracy Better than ±1.0°C across all thermocouple

AccuracyAccuracy

Note: The above accuracy figures do not include the thermocouple probe.

Logger Temperature

Logger Temperature

Logger TemperatureLogger Temperature

Range

Range -40 to +85°C (-40 to +185°F)

RangeRange

Sensor Type

Sensor Type 10K NTC Thermistor

Sensor Type Sensor Type

Response Time

Response Time 20 mins to 90% FSD in moving air

Response TimeResponse Time

Reading Resolution

Reading Resolution 0.02°C or better

Reading Resolution Reading Resolution

Accuracy

Accuracy Better than ±0.5°C

AccuracyAccuracy

ranges when the logger is between

-10 & +70°C.

Type K

Type K Type J

Type KType K

Type T

Type T Type N

Type TType T

…………………………………………………………………………….

Type J

Type JType J

Type N

Type NType N

ThermocoupleL

ogger

………………………………………………………………………

Physical Specification

Physical Specification

Ph

ysical SpecificationPhysical Specification

Logger

Logger

LoggerLogger

IP Rating

IP Rating IP51

IP RatingIP Rating

Working Temperature Range

Working Temperature Range -40 to +85°C (-40 to +185°F)

Working Temperature RangeWorking Temperature Range

Case Dimensions

Case Dimensions

Case DimensionsCase Dimensions

Height

Height 42mm / 2.83”

HeightHeight

Width

Width 60mm / 2.36”

WidthWidth

Depth

Depth 33mm / 1.30”

DepthDepth

Weight

Weight 65g / 2.29oz

WeightWeight

Supplied Type K Thermocouple

Supplied Type K Thermocouple

Supplied Type K ThermocoupleSupplied Type K Thermocouple

Temperature Range

Temperature Range -100 to +250°C (-148 to 482°F)

Temperature RangeTemperature Range

Lead length

Lead length 1m / 39.37”

Lead length Lead length

Battery Information

Battery Information

B

attery InformationBattery Information

Battery Type

Battery Type Tekcell SBAA02P;

Battery TypeBattery Type

The logger will operate with other ½AA 3.6V Lithium (Li-SOCl2) batteries but

performance cannot be guaranteed.

Replacement Interval

Replacement Interval Annually

Replacement Interval Replacement Interval

Before replacing the battery the data logger must be stopped.

Data stored on the logger will be retained after a battery is replaced.

LED Flash Patterns

LED Flash Patterns

LE

D Flash PatternsLED Flash Patterns

When logging, status LEDs on the front of the logger will flash as follows:

Flash Pattern

Flash Pattern Indication

Flash PatternFlash Pattern

A green flash every 4 seconds Logging

A green flash every 8 seconds Waiting to log (set for a delayed start)

A red flash every 4 seconds Alarm limit breached

For more information on the alarms and how they work, please see the Tinytag

Explorer quick start guide and help file.

Notes

Notes

N

otesNotes

If used at low temperatures the data logger should be allowed to warm to room

temperature before it is opened to avoid condensation forming inside it.

The IP51 rating is valid only when the logger’s connector cover is fitted and the

unit is orientated with it’s hanging tab uppermost.

Trigger Start

Trigger Start

Trigger Start Trigger Start

The trigger start option allows a logger to be set up as required and then started

at a later time with a magnet. The position of the trigger start switch is indicated

by the • • • marking on the back of the logger. When the "Wait until trigger

event" option is selected in the Tinytag Explorer software the green LED on the

logger will flash once every eight seconds to indicate that it is waiting to start.

When a magnet is swiped past the • • • marking, the green LED will light to

indicate the switch is closed. After the magnet has been removed, the green LED

will flash every four seconds to indicate that the logger is recording.

SAFT LS14250 or LST14250

Indication

IndicationIndication

…….

Calibration

Calibration

C

alibrationCalibration

This logger is configured to meet Gemini’s quoted specification during its

manufacture.

We recommend that the calibration of the logger should be checked annually

against a calibrated reference meter.

A certificate of calibration, traceable to national standards, can be supplied for an

additional charge either at the point of purchase, or if the logger is returned for a

service calibration.

Approvals

Approvals

A

pprovalsApprovals

Gemini Data Loggers (UK) Ltd. operates a Business Management System which

conforms to ISO 9001 and ISO 14001.

Warranty

Warranty

W

arrantyWarranty

This product carries a manufacturing defects warranty of 12 months from the date

of purchase. Units returned under warranty will be repaired or replaced at the

manufacturer’s discretion. This warranty does not cover mishandling, modification

or battery replacement and is subject to the standard Terms and Conditions of

Sale, a copy of which is available on request.

The equipment/goods are sold “as is” and with “all faults” (applies in USA).

The equipment/goods are sold “as is” and with “all faults” (applies in USA).

The equipment/goods are sold “as is” and with “all faults” (applies in USA). The equipment/goods are sold “as is” and with “all faults” (applies in USA).

Claims under warranty should be referred to the point of sale.

Claims under warranty should be referred to the point of sale.

Claims under warranty should be referred to the point of sale.Claims under warranty should be referred to the point of sale.

Disposal

Disposal

D

isposalDisposal

Data loggers, accessories and batteries should be disposed of at

organised facilities, where available, in compliance with local

regulations.

In accordance with the WEEE directive Gemini Data Loggers (UK) Ltd.

will take back and dispose of any equipment purchased directly.

Equipment not purchased directly should be returned to the point of

sale for disposal.

Further Information

Further Information

rther InformationFurther Information

Fu

Further information on Tinytag data loggers, software and accessories can be

found on our web site at:

www.micronmeters.com

If you should have any further questions, please contact your distributor or:

Gemini Technical Support

Gemini Technical Support

Gemini Technical SupportGemini Technical Support

metersinfo@micronmeters.com

………………………………………………………………….

…………

9800-0116: Issue 3 (17th October 2014)

Loading...

Loading...