ASSEMBLY

MANUAL

TINKERINE STUDIO

3D Printer + Creative Solution

CONTENTS

TINKERINE

STUDIO

STUDIO

Safety Instructions

Litto at a Glance

Bill of Materials

Before You Start

Z-Platform

Litto Frame pt.1

Litto Frame pt.2

Gantry pt.1

Gantry pt.2

Gantry pt.3

Carriage

Electronics / Spool Holder

Print Bed

3

4

6

7

8

13

21

27

38

46

50

59

67

Wiring

Preliminary Run Through

71

75

support@tinkerines.com | 1-604-288-87782

TINKERINE

STUDIO

STUDIO

IMPORTANT SAFETY INSTRUCTIONS

WARNING

!

SHARP EDGES

printer to ensure no sharp edges will cut you.

Inspect the printer for any damage prior to use.

! WARNING

HOT SURFACE

Motor surfaces become hot during operation.

Hotend and heater cartridge become hot during

operation.

DO NOT touch hot surfaces, because they can cause

severe burns.

Allow the hotend to cool before touching it without

proper tools.

! WARNING

WARNING

!

FIRE

Use caution to minimize risk of re.Use caution during assembly and operation of the 3D

Always operate the printer a safe distance away from

ammable items. Use in well-ventilated areas.

DO NOT place a storage cover on the unit during

operation. Only place a cover on the printer after it has

thoroughly cooled down.

!

WARNING

SHOCK

There is a danger of electric shock.

Use only undamaged electrical chords.

DO NOT touch bare wires or receptacles.

DO NOT touch the 3D printer or chords if hands

are wet.

Ensure that all cords are free of damage before

connecting to the power supply.

Ensure that you have a sufcient electrical supply for

supporting the requirements of the motor.

RISK TO BREATHING

Always use your 3D printer in a well-ventilated and

clean area.

Gas emitted by melting of Polylactide (PLA) or

Acrylonitrile butadiene styrene (ABS) can contain

contaminants that are harmful to breathe.

Never breathe the air that comes directly out of the

hotend. This air is not suitable for breathing.

If you feel ill from breathing while operating your 3D

printer, stop and seek medical attention immediately.

!

WARNING

Fragile

Electrical pins and sensors are delicate. Handle with

care.

Unless instructed, DO NOT force components together.

Read the instructions carefully to prevent damaing parts

during assembly or operation.

support@tinkerines.com | 1-604-288-87783

TINKERINE

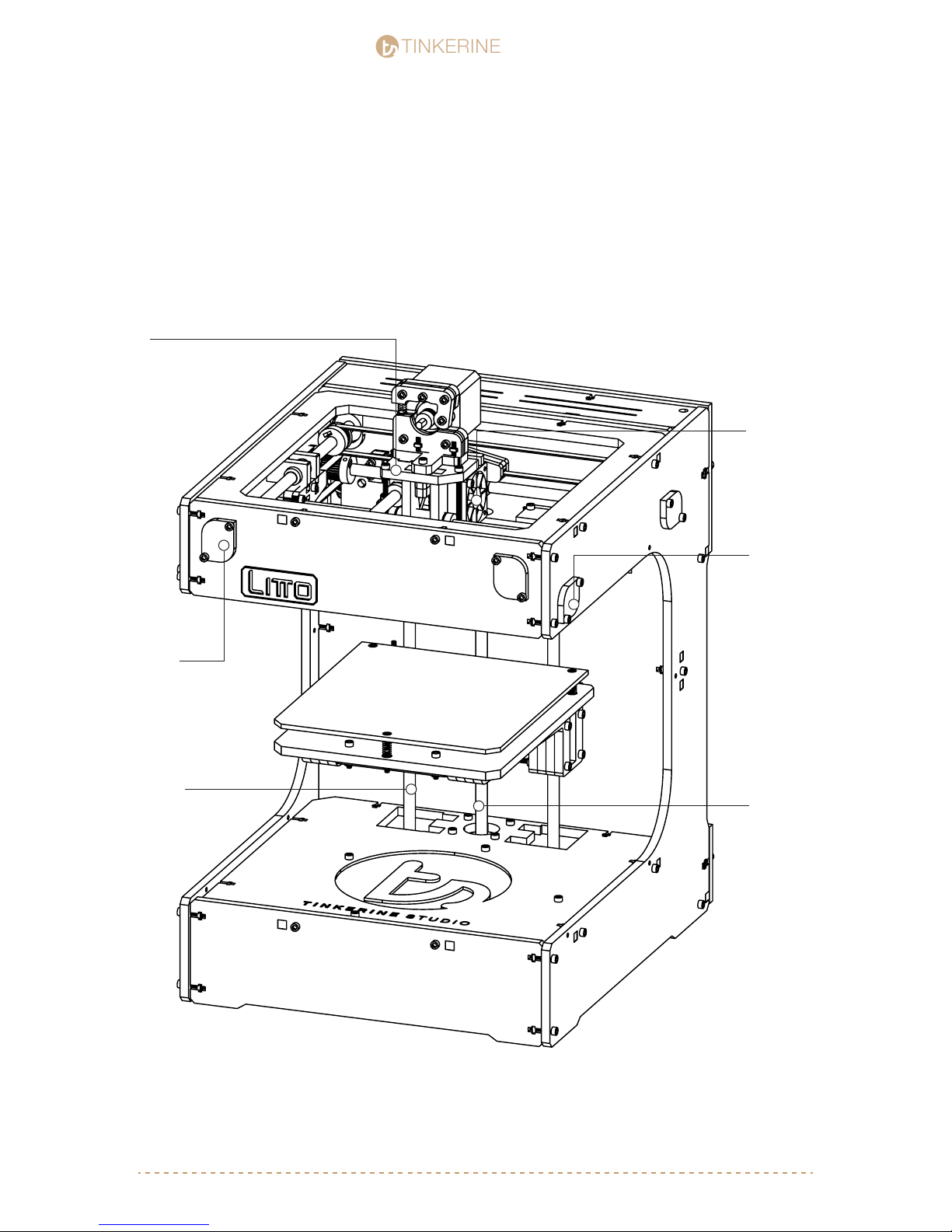

LITTO AT A GLANCE

CARRIAGE

STUDIO

STUDIO

HOTEND

COOLING FAN

Y-AXIS

BEARING CAP

Z-AXIS

SMOOTH ROD

X-AXIS

BEARING CAP

Z-AXIS

THREADED ROD

support@tinkerines.com | 1-604-288-87784

TINKERINE

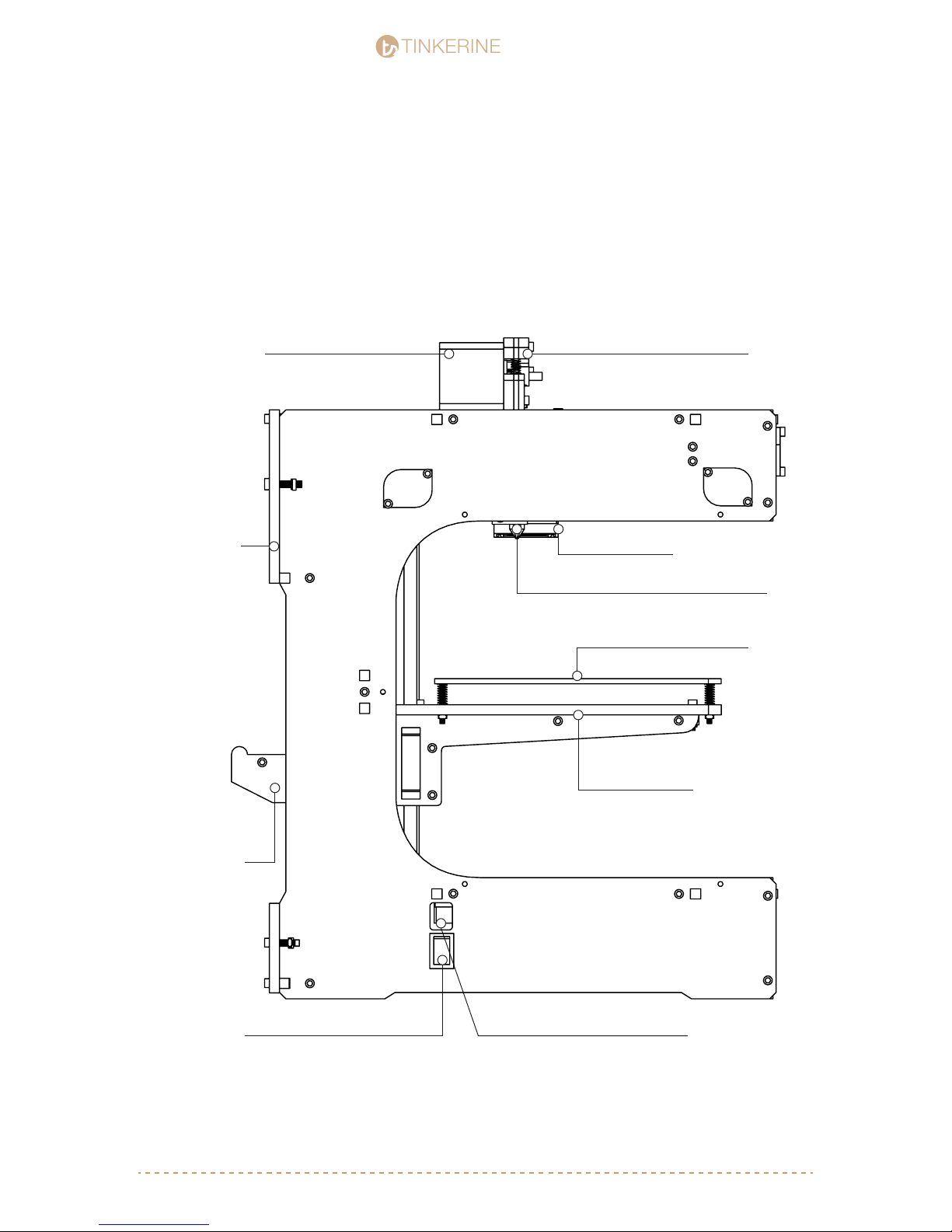

LITTO AT A GLANCE

STUDIO

STUDIO

EXTRUDER MOTOR

MOTOR

COMPARTMENT

EXTRUDER

PRINT COOLING FAN

HOTEND

PRINT BED

Z-AXIS PLATFORM

SPOOL HOLDER

POWER SWITCH

USB CONNECTION

support@tinkerines.com | 1-604-288-87785

TINKERINE

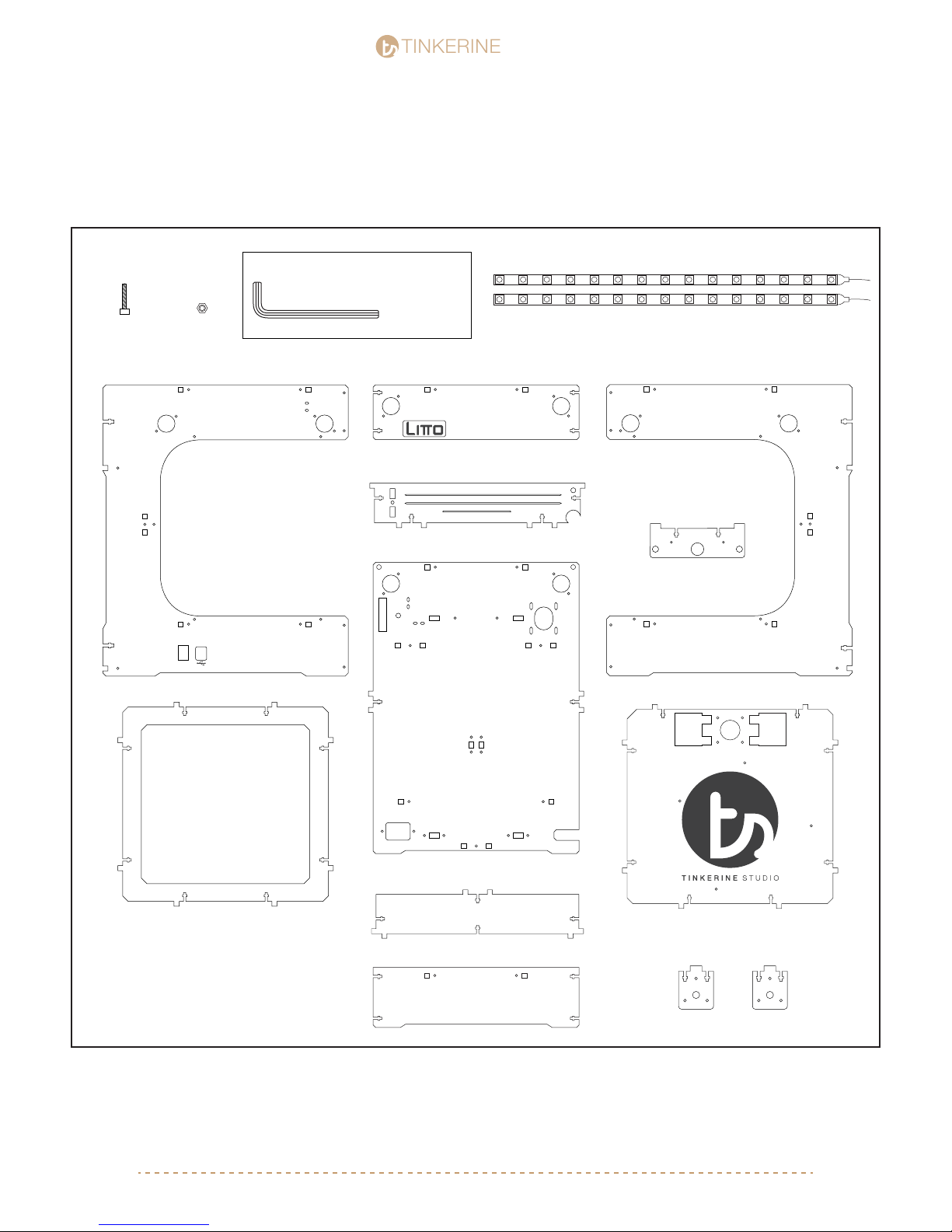

Litto Bill of Material

STUDIO

STUDIO

Litto Laser Panels

(1) Hotend

(1) Cartridge heater

(1) Thermistor

(1) Extruder motor

(1) Extruder bearing

(1) Cooling fan ducts

(1) Filament guiding tube

(1) 164mm GT2 belt

(1) 188mm GT2 belt

(2) 423mm GT2 belts

(2) 454mm GT2 belts

(8) Brass slider bushing

(8) 608ZZ ball bearings

(4) LM8 linear bearings

(8) Pulleys + (8) 3x5mm set screws

(2) 36-tooth pulleys

(8) Aluminum rods

(1) Bed plate

(3) Calibration springs

(3) Mechanical endstops

(3) Brass Thumb Screw

(2) LED strips

(2) 40mm cooling fans

(1) 50mm cooling fans

(3) NEMA17 stepper motors

(1) NEMA17 stepper motor with threaded rod

(1) Arduino MEGA 2560

(1) RAMPS 1.4

(4) A4988 stepper drivers

(1) Power supply

(1) Power switch

(1) Female power plug

(1) Power cord

(1) USB cable

(30) M3 x 10 screws

(85) M3 x 16 screws

(12) M3 x 20 screws

(8) M3 x 25 screws

(15) M3 x 35 screws

(3) M3 x 25 athead

(1) M4 x 16 screws

(3) M4 x 20 screws

(10) M3 washers

(100) M3 nuts

(1) M4 washers

(10) M4 nuts

(2) Wires (Arduino to Power)

Tool List

Included In Kit

(1) M4 Allen Key

(1) M3 Allen Key

(1) 1.5mm Hex Key

(2) Zip Ties

support@tinkerines.com | 1-604-288-87786

TINKERINE

STUDIO

STUDIO

Before you Start

Before you attempt to assemble any of part the Ditto / Litto 3D Printer, it is imperative that you

read the build instructions fully and ensure you understand every part of the instruction.

While Tinkerine Studio provides warranty for all parts of the 3D printer, this does not cover damage

caused by not following the instruction manual or other end-user error.

Go down the BoM (Bill of Material) and tools checklist and ensure that you have all the

required parts to assemble the Ditto 3D Printer. Extra screws have been included into the kit.

If you nd anything missing, please contact us via e-mail at support@tinkerines.com

Give yourself plenty of room and clean space during the assembly process. This prevents

delicate components like the electronics or bearings from being damage by dust or blunt force.

To ensure proper alignment of the panel and overall rigidity of the printer, it is highly

recommended that the assembly is done on a at surface.

Wipe off any excess grease you nd on the screws with a napkin or an old towel. Screws

are generally greased in order to prevent rusting during production. Cleaning off excess

grease will keep your hands and printer clean during assembly.

Ditto is a rigid and robust 3D printer once assembled, however during the assembly process,

extra care needs to be taken to make sure delicate parts require more precision than force to

come together. If during the assembly process, you are unsure of the instructions, please

contact us for support. Remember, unless instructed, no part in the assembly process should

you need to exert a high amount of force to t pieces together.

Before starting calibration, ensure that all screws and pulley setscrews are properly tightened.

Common calibration issues such as skipping and backlash are usually caused by loose pulleys

and unsecured components.

support@tinkerines.com | 1-604-288-87787

TINKERINE

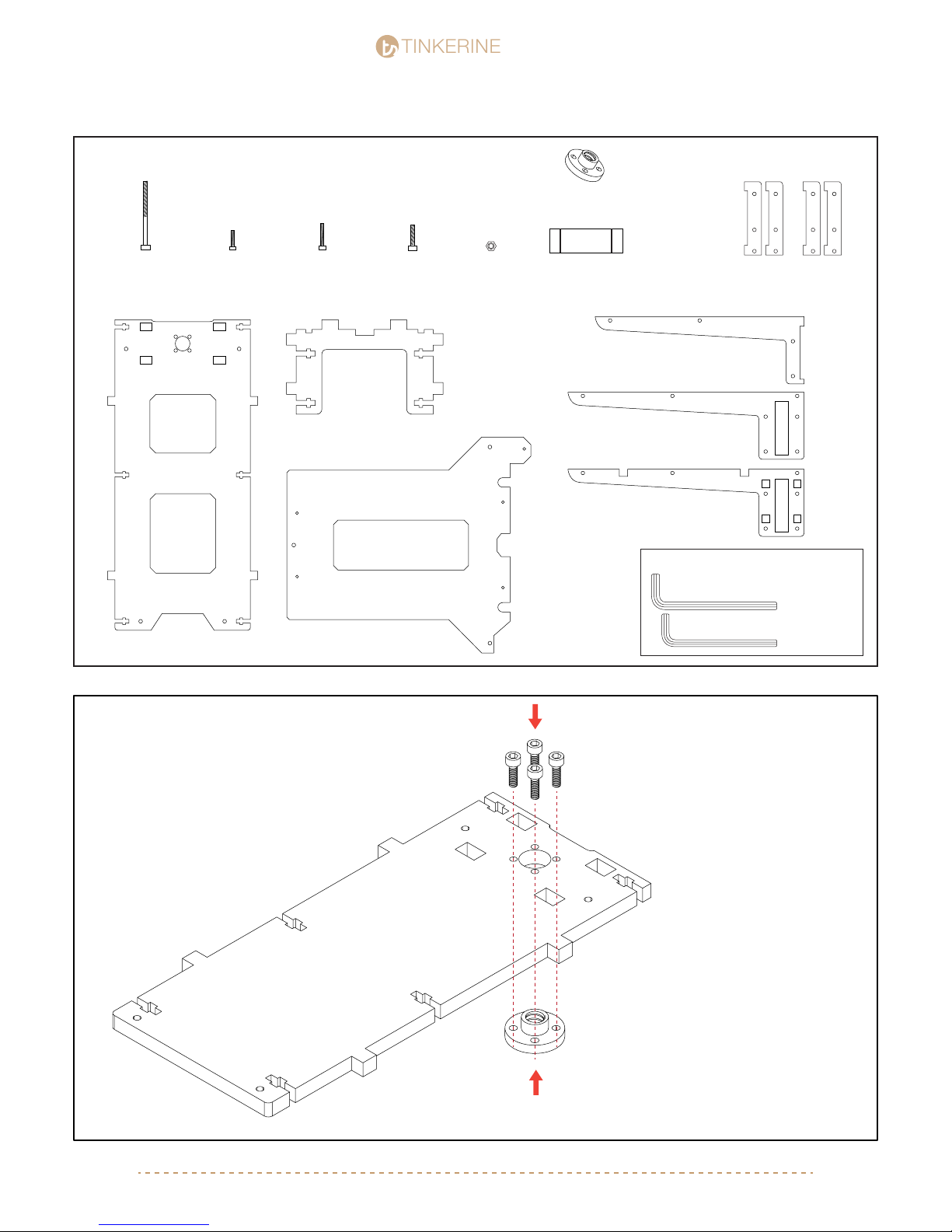

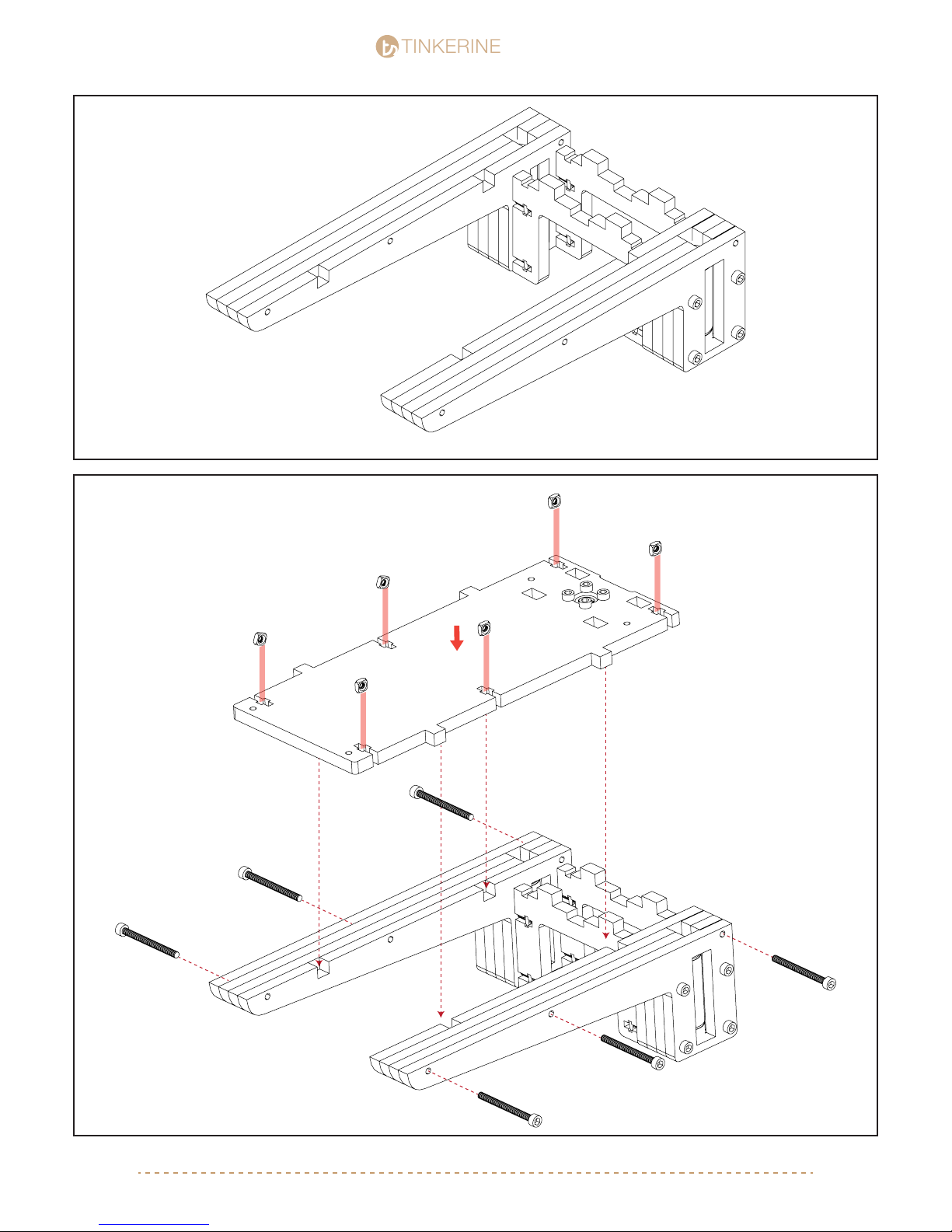

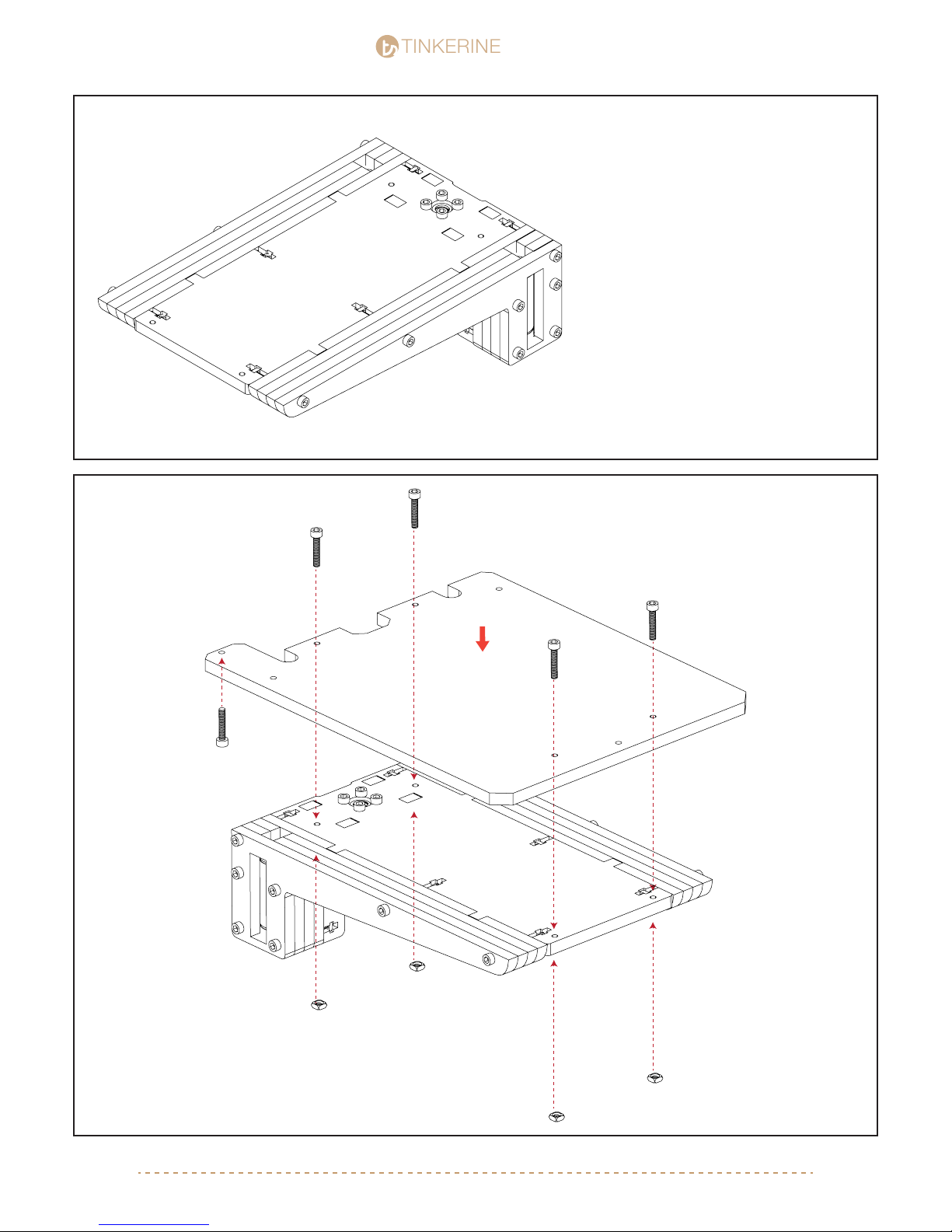

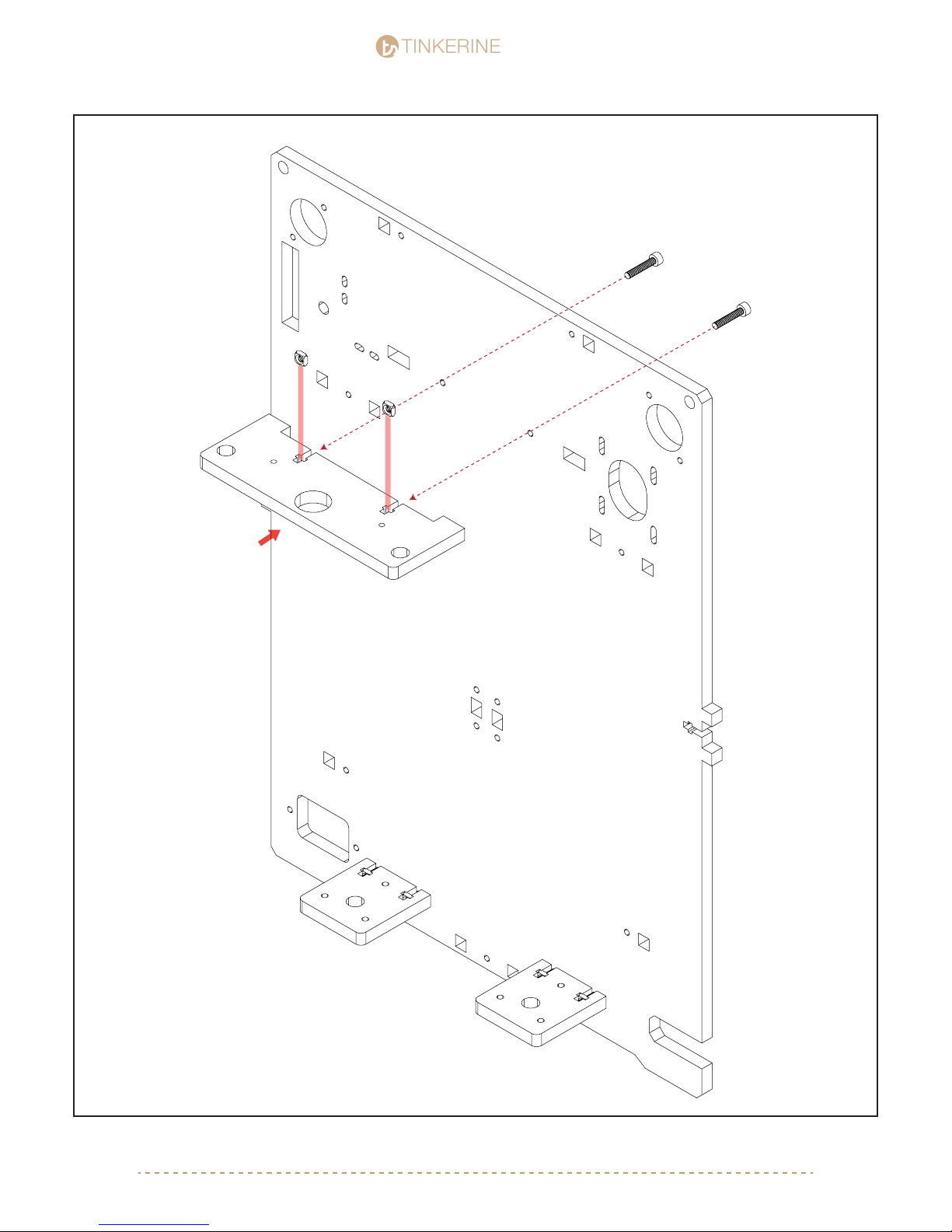

Z - Platform Assembly

Parts Required

STUDIO

STUDIO

Lead Screw Nut

x1

M3x35 Screw

x14

Z-Base

M3x10 Screwx4M3x16 Screwx4M4x20 Screw

x1

Z-Bridge

x2

Bed Plate

M3 Nuts

x18

45mm Bearing

x2

Bearing Holder

Z-Arm

x4

Z-Arm

x2

Z-Arm

x2

Tools Required

M4 Allen Key

M3 Allen Key

1.

M3x10 (x4)

Screw nut comes attached to the

lead screw motor. Remove from

screw and wipe off excess grease

before installation to bed.

support@tinkerines.com | 1-604-288-87788

TINKERINE

STUDIO

STUDIO

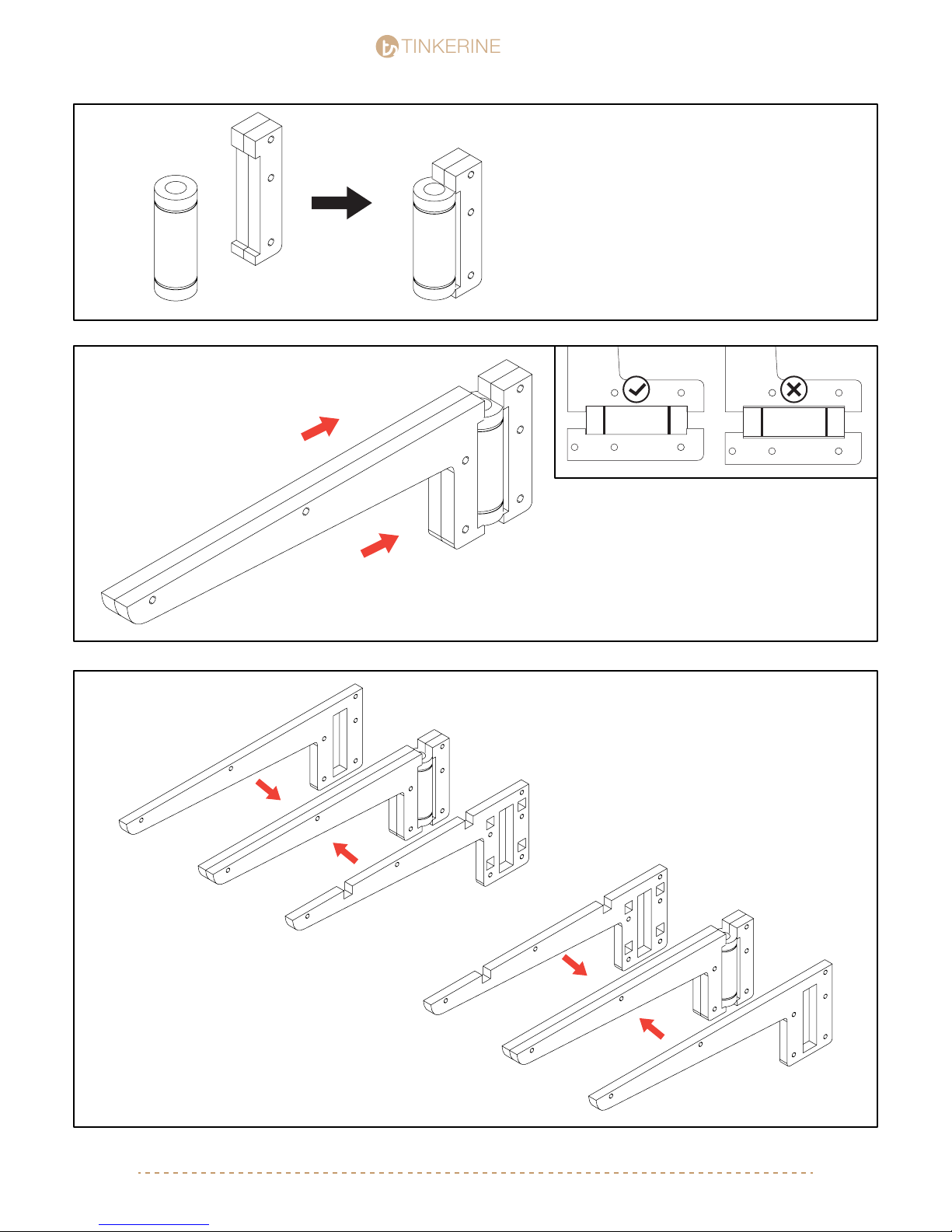

2.

45mm Linear Bearing

3.

Insert a 45mm linear bearing into two bearing

clips. Note the rounded edge on the clips

should be facing the same direction. Check

to make sure the bearing is fully seated into

the clip and aligned in the middle. You will

need two sets.

x2

Similar to Step 2, take two z-axis arms and

wedge it into the other side of the linear

bearing. At this point, check to see that there

is no gaps and both sides are evenly press

tted into the linear bearing. Do this for both

sets.

4.

x2

Add the side arm panels to the existing

assembly, note the different panels + orientation of the arms shown in the picture.

Arm B

Arm A

support@tinkerines.com | 1-604-288-87789

TINKERINE

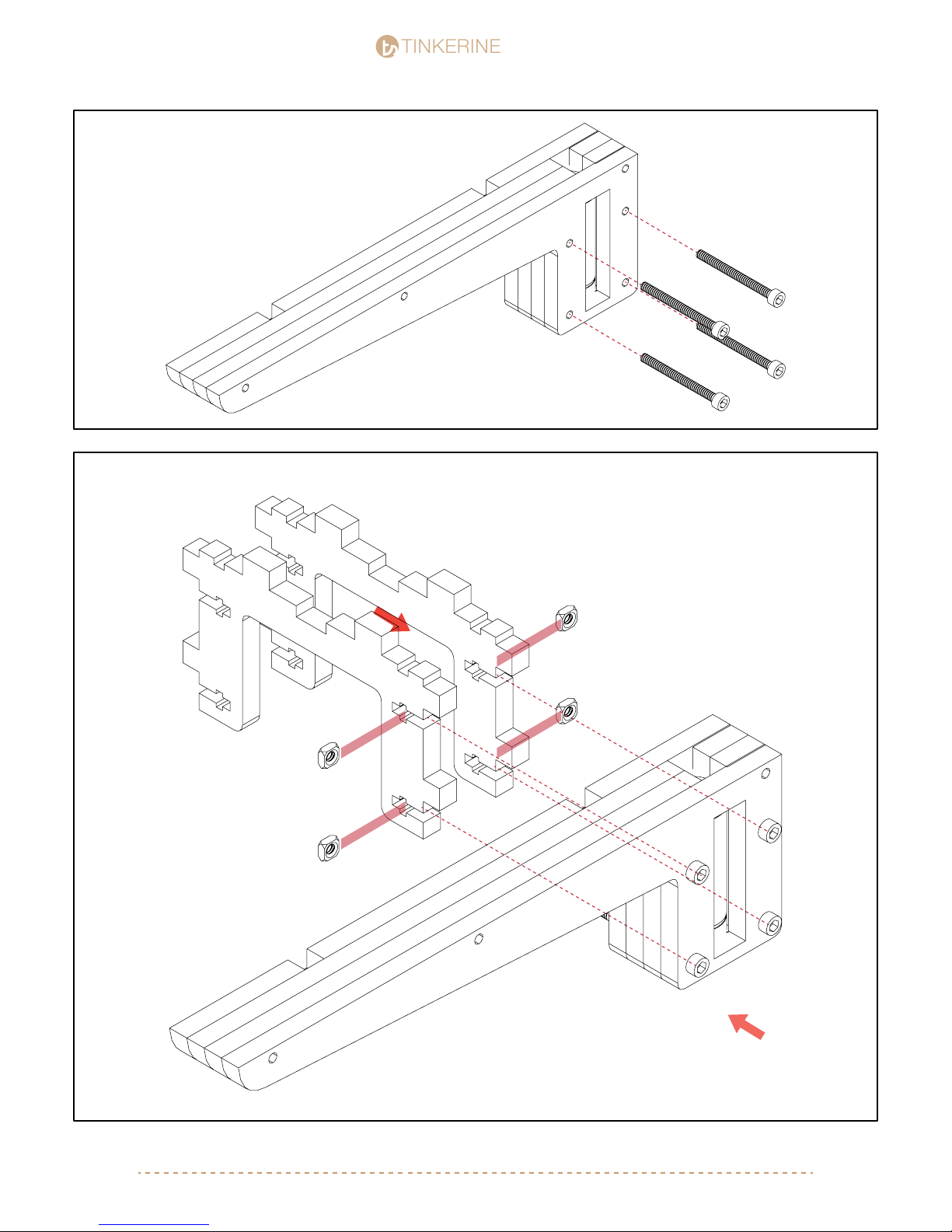

5.

STUDIO

STUDIO

6.

Arm A

M3 Nut (x4)

M3x35 (x4)

One by one, insert the M3 Nut into the

T-slots shown in the picture. Screw the four

M3x35 screws in but do not tighten them all

the way.

x2

Arm A

x2

support@tinkerines.com | 1-604-288-877810

TINKERINE

STUDIO

STUDIO

support@tinkerines.com | 1-604-288-877811

7.

8.

Arm A

Arm B

M3x35 (x6)

M3 Nut (x6)

Repeat step 6 and attach the second arm to

the assembly.

Place the mid section into the

respective slots on the assembly.

One by one, insert the M3 nuts into

the T-slots and secure with the

M3x35 screw.

TINKERINE

9.

STUDIO

STUDIO

During this point, double check to make sure

all panels are properly aligned and the top

side of the bed is leveled with the arms.

Tighten all screws.

10.

M3x16 (x4)

M4x20 (x1)

M3 Nut (x4)

support@tinkerines.com | 1-604-288-877812

TINKERINE

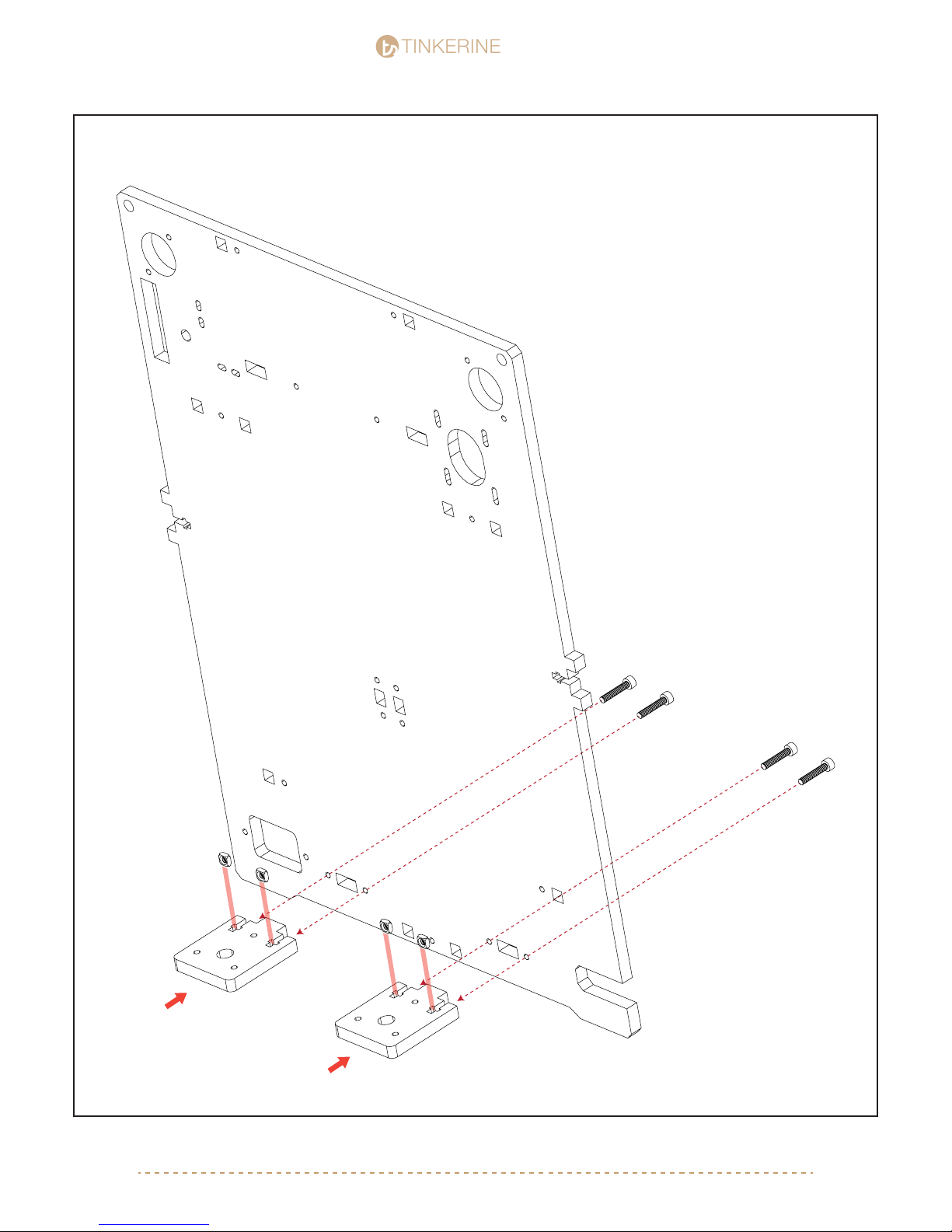

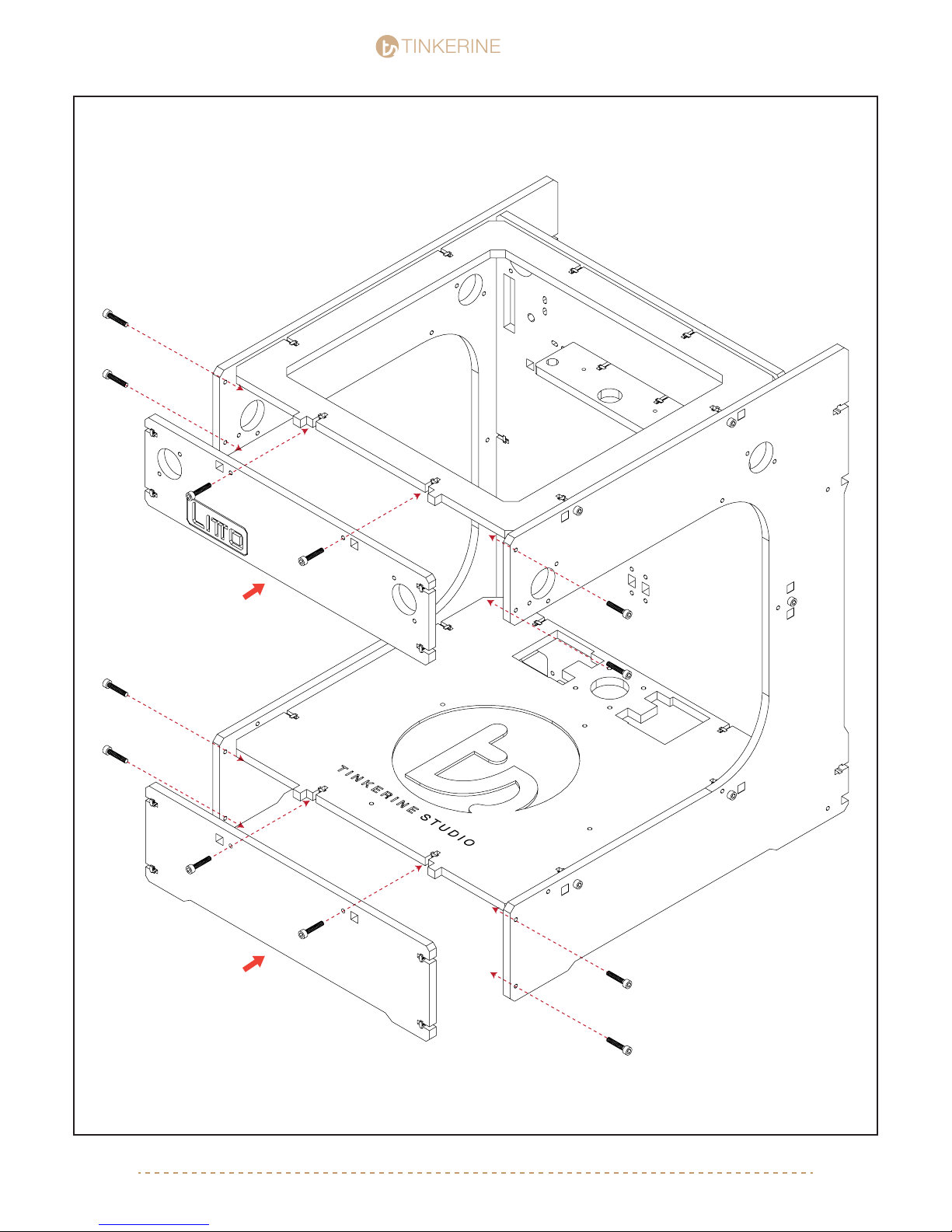

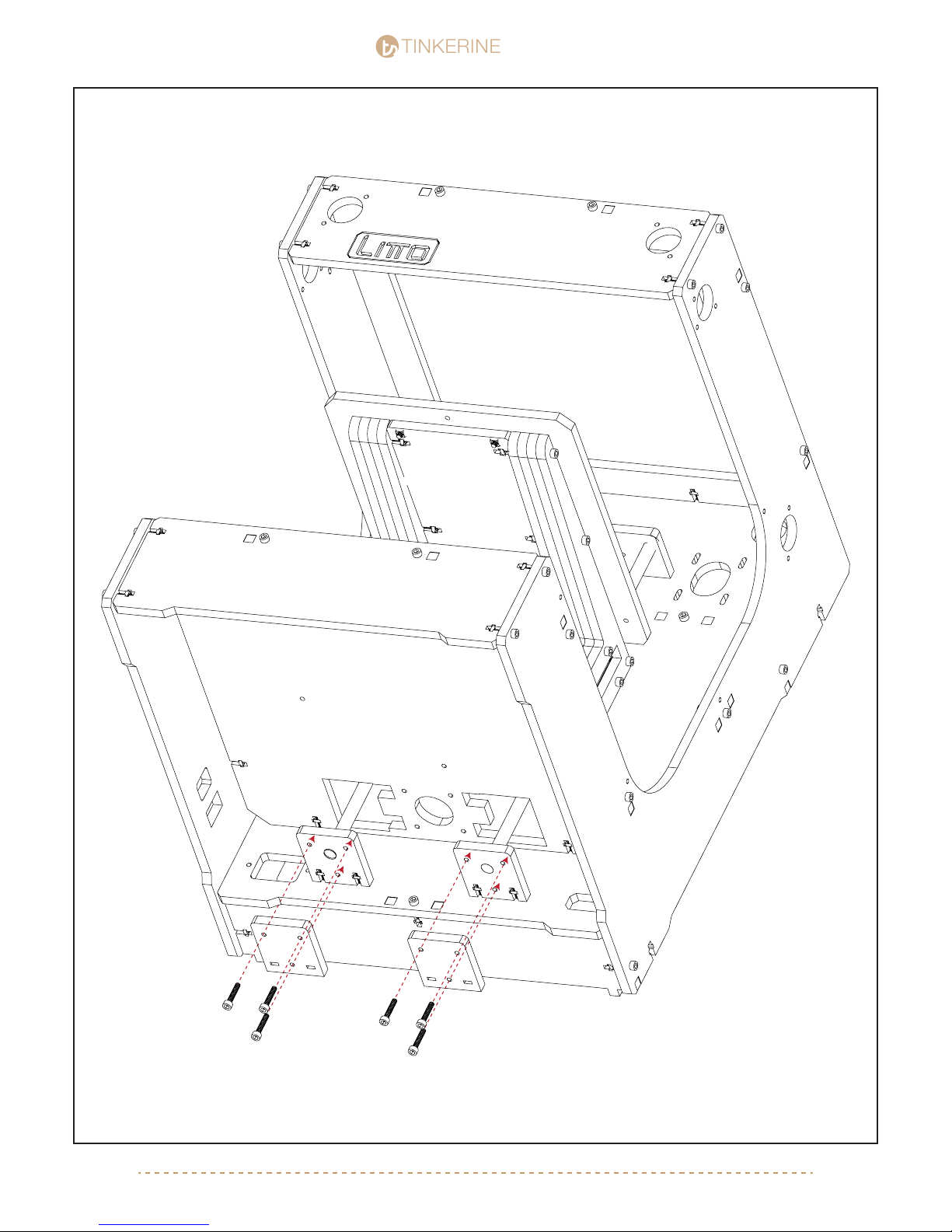

Litto Frame Assembly pt.1

STUDIO

STUDIO

Parts Required

M3x16 Screw

x39

M3 Nuts

x39

Right Side Panel

Top Ring Panel

Tools Required

M3 Allen Key

Top Front Panel

Motor Bracket

Central Back Panel

Adhesive LED Strips

Left Side Panel

Z-Constraint A

Z-Constraint A

Base Panel

Bottom Bracket

Bottom Front Panel

support@tinkerines.com | 1-604-288-877813

Z-Constraint C

TINKERINE

STUDIO

STUDIO

1.

Install the two Z-Constraints B as shown in

the picture. Make sure to face the back panel

the correct. Insert the constraint into the

corrent tabs, place the M3 nuts in position

and screw in the M3x16 screws from the

other side.

Z-Constraint C

M3x16 (x4)

support@tinkerines.com | 1-604-288-877814

TINKERINE

2.

M3 Nut (x2)

STUDIO

STUDIO

M3x16 (x2)

Install the top Z-Constraint A. Similar to the

bottom Z-Constraint, insert the piece into the

slots and secure with nut + screw.

support@tinkerines.com | 1-604-288-877815

TINKERINE

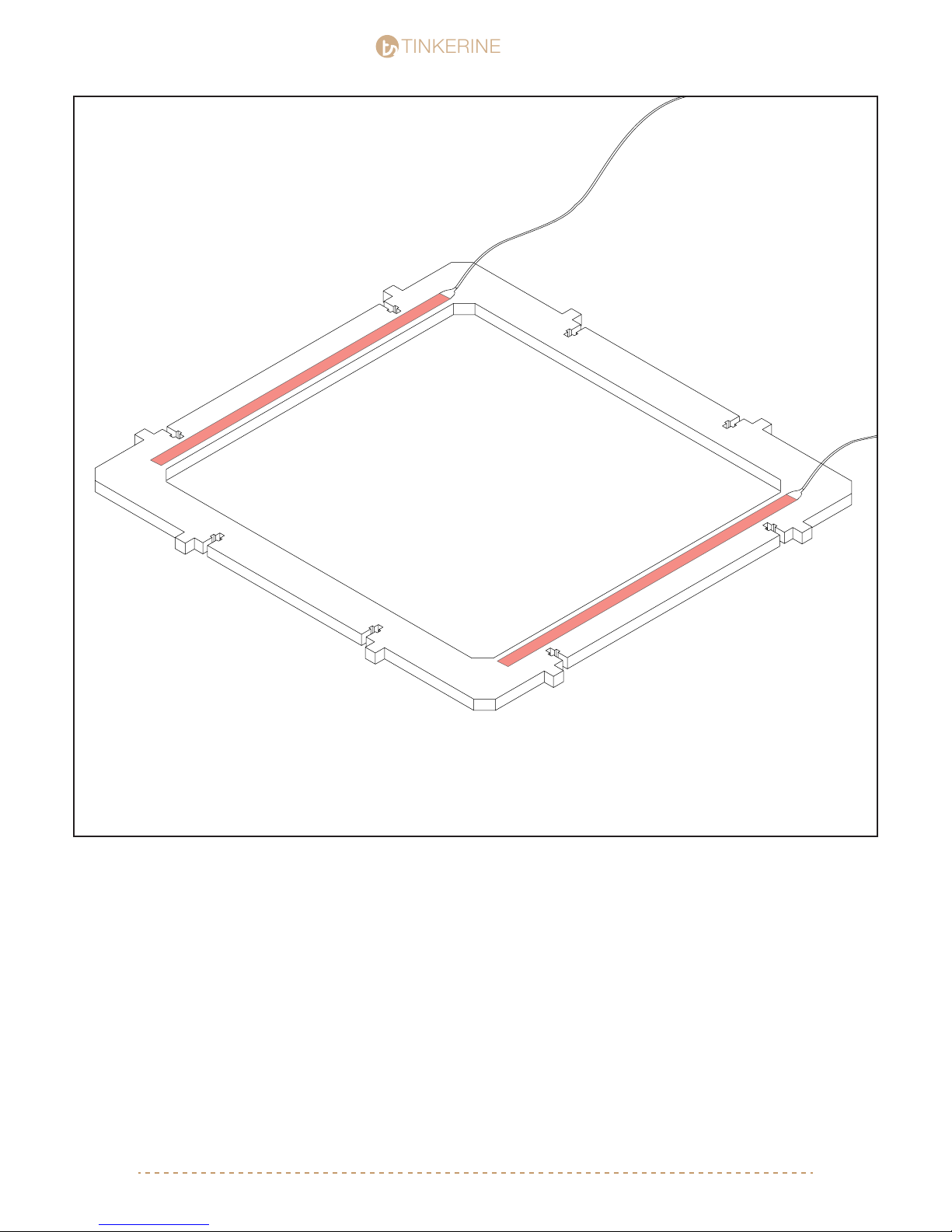

Top Ring Panel

STUDIO

STUDIO

LED Strip (x2)

BACK

FRONT

Using the two LED light strip supplied in your kit, one-by-one peel off the backing to reveal the adhesive strip

and stick the LED strip in the area shown in the picture. Make sure the LED is applied inbetween the T-Slot

and edge of the inner ring.

support@tinkerines.com | 1-604-288-877816

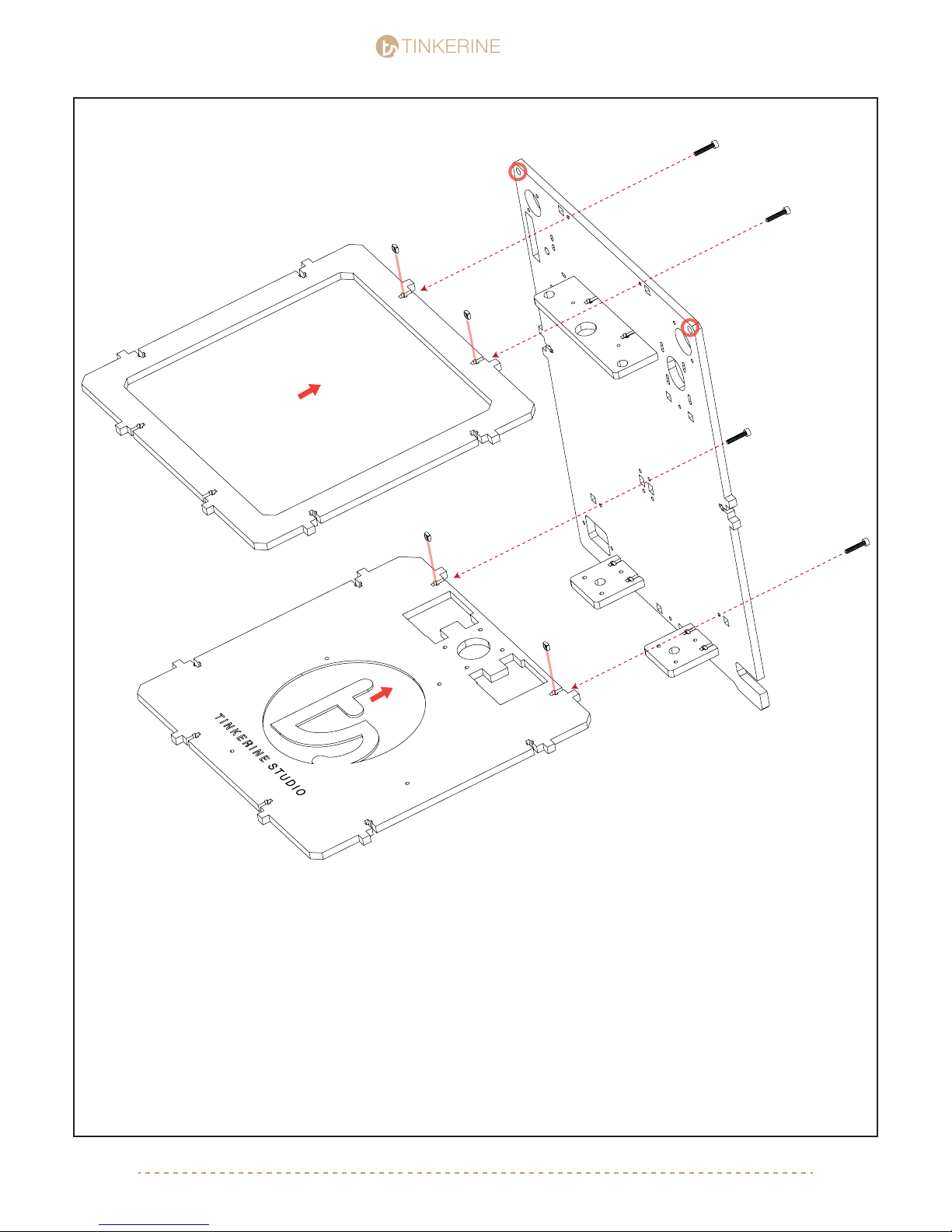

TINKERINE

3.

LED Side Facing Down

STUDIO

STUDIO

M3x16 (x4)

M3 Nut (x4)

Insert the top ring and and bottom plate into the back plate, then secure with T-Slots. For the top ring, the

side with the led should be facing downward. Thread the LED wires into the hole shown in the picture.

support@tinkerines.com | 1-604-288-877817

TINKERINE

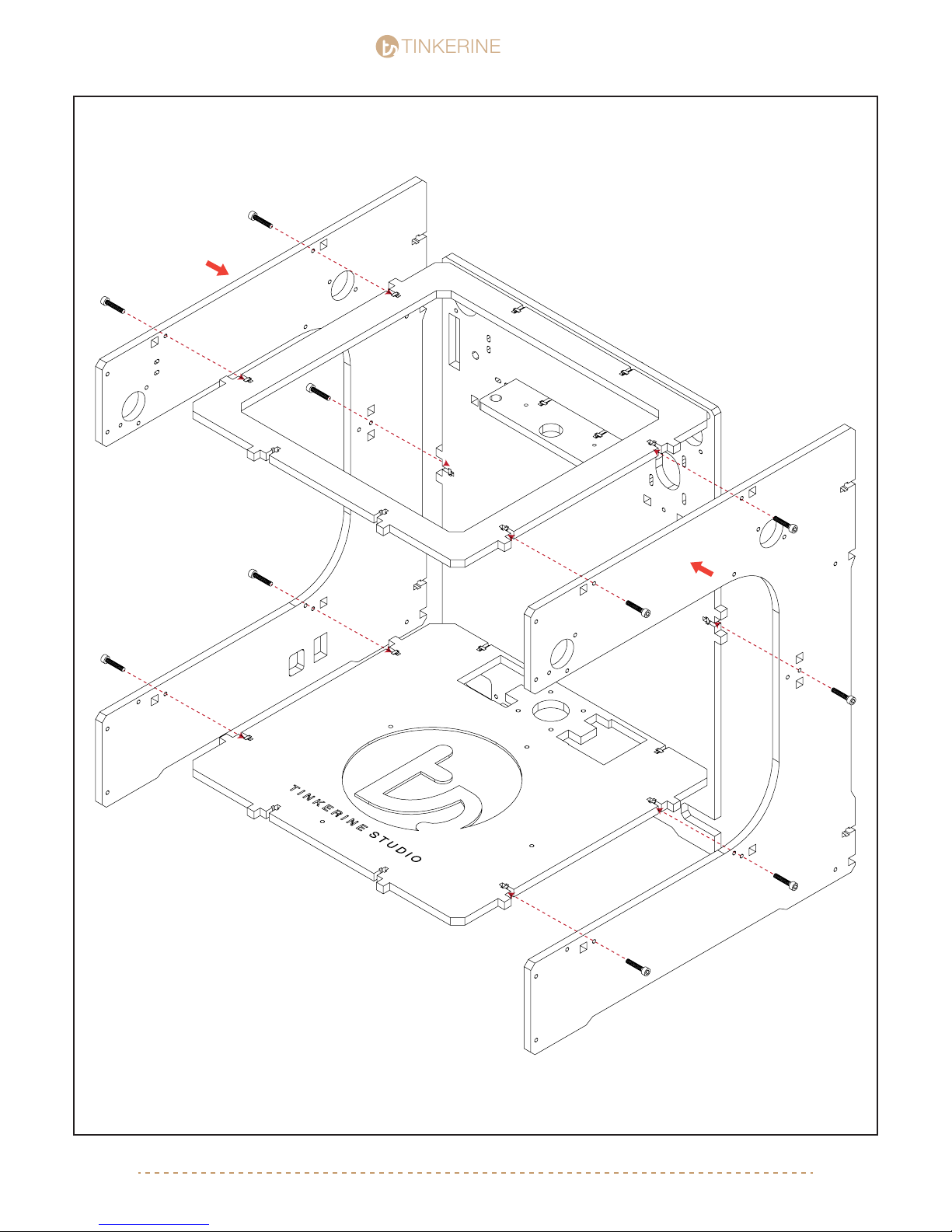

4.

STUDIO

STUDIO

M3x16 (x10)

M3 Nut (x10)

Install the two side panels into the main body. Secure each side with ve M3x16 screws and nut. Make sure

the panel with the power switch cutout is on the left side.

support@tinkerines.com | 1-604-288-877818

TINKERINE

5.

STUDIO

STUDIO

M3x16 (x12)

M3 Nut (x12)

Install the top front and top bottom panels. At this point, you will want to make sure all the panels are properly

aligned and leveled to a at surface. Due to the natural property of wood you wooden frame may not be perfectly

tapered to the surface, however we can correct this later on once the other components are installed.

support@tinkerines.com | 1-604-288-877819

TINKERINE

6.

STUDIO

STUDIO

Install the top and bottom brackets into the main body. You will need to insert some screws from the front of the

machine.

M3x16 (x7)

M3 Nut (x7)

support@tinkerines.com | 1-604-288-877820

TINKERINE

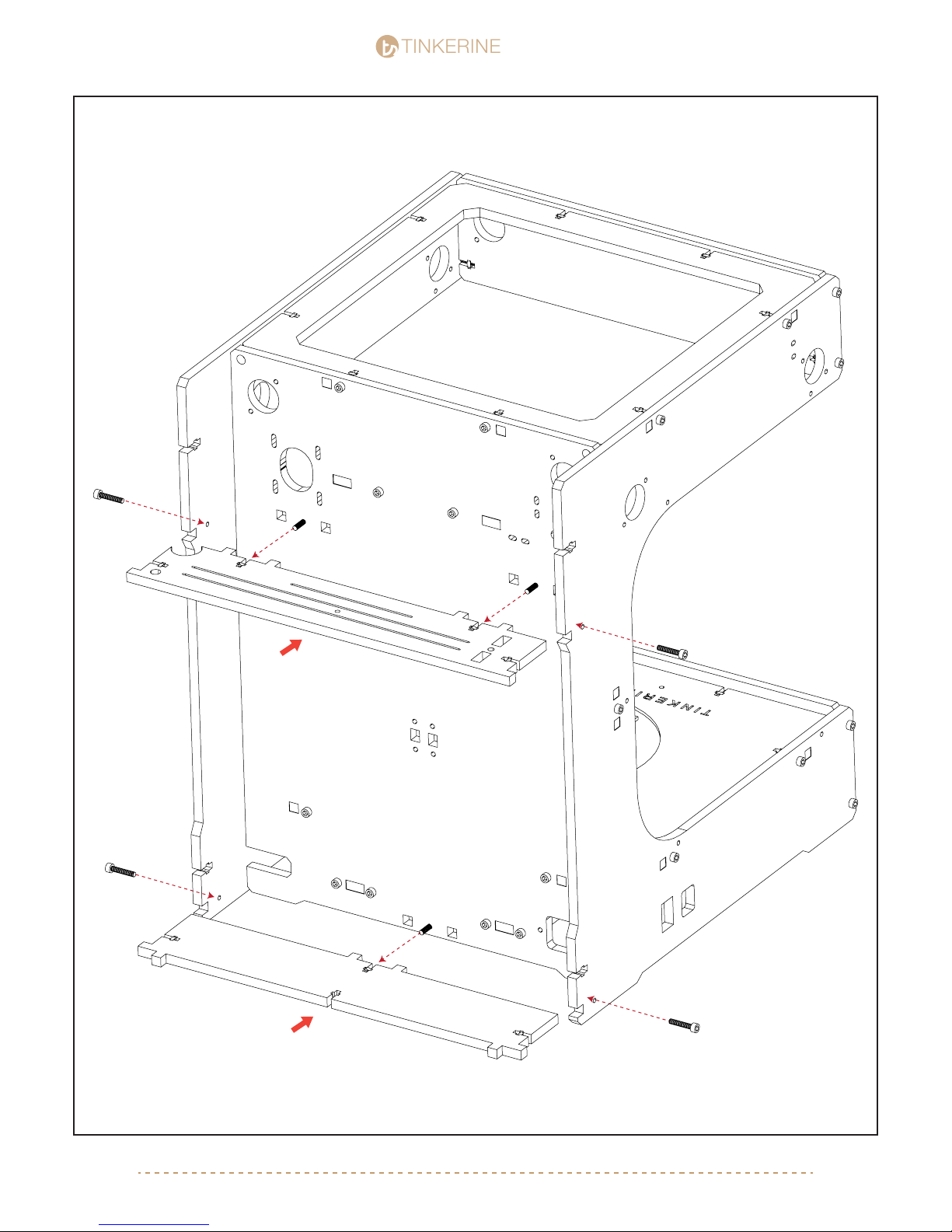

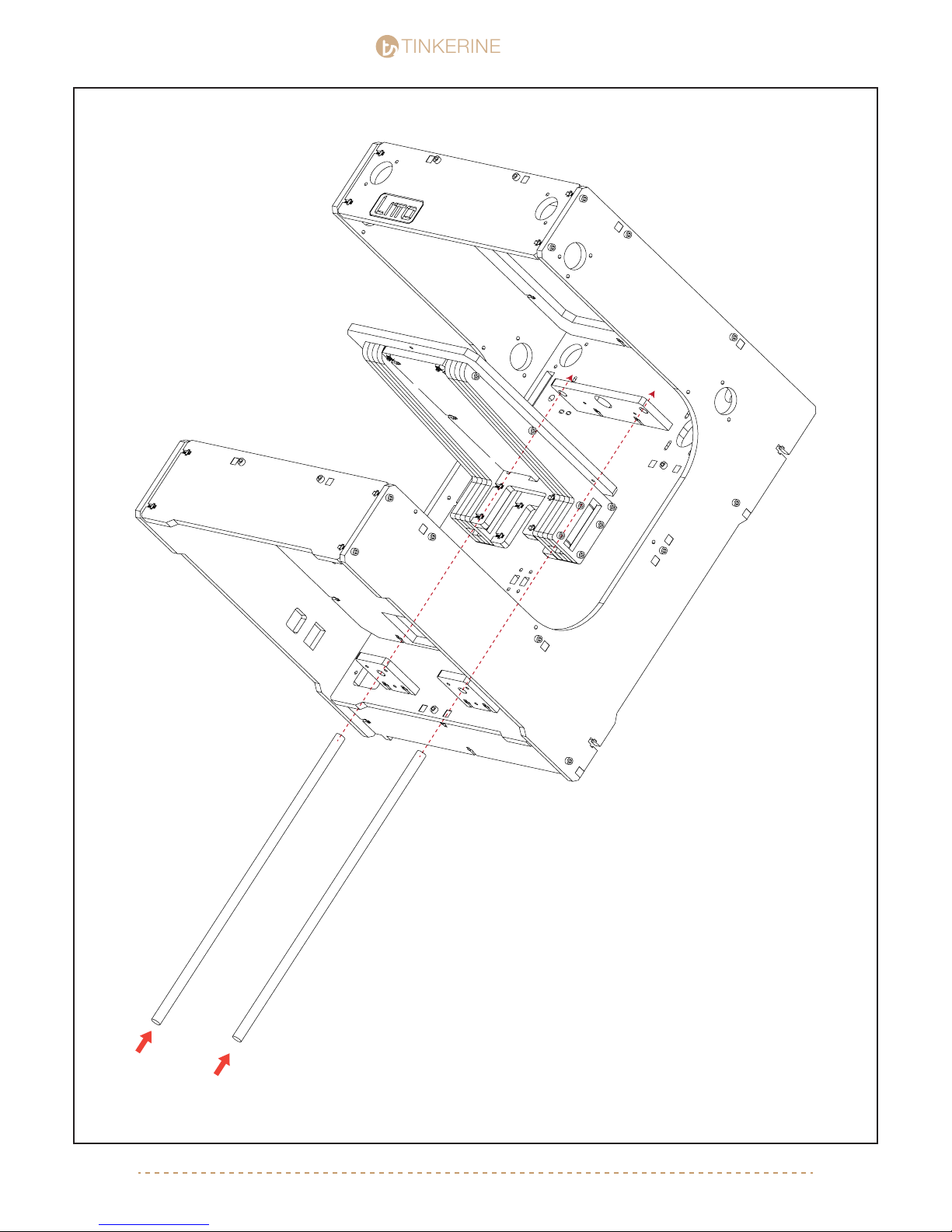

Litto Frame Assembly pt.2

Parts Required

STUDIO

STUDIO

M3x10 Screw

x6

Z-Constraint D

Z-Constraint B

M3x16 Screwx6M3x20 Screwx4M3x25 Screw

x2

Endstop Switch

x3

Endstop Spacer

x7

Z-Axis Smooth Rod (270mm)

x2

M3 Nuts

x12

Assembled Z-Platform

Lead Screw NEMA17 Stepper Motor

Tools Required

M3 Allen Key

support@tinkerines.com | 1-604-288-877821

1.

TINKERINE

STUDIO

STUDIO

Z-Axis Rods (270mm)

Gently insert the Z-Axis smooth rods through the bottom Z-Constraint, linear

bearing of the Z-Axis bed and nally the top Z-Constraint. If you feel there is any

amount of resistance once you reach the linear bearings within the z-axis arms, do

not force it in. Pull the rod backwards gently and retry. Rotating the rod gently

while inserting may help it slide in more easily. Take your time with the bearing,

forcing the rod in will cause the bearing balls to dislodge.

support@tinkerines.com | 1-604-288-877822

TINKERINE

2.

STUDIO

STUDIO

M3x16 (x6)

M3 Nut (x6)

The Z-Axis rods should now sit ush within the bottom and top

Z-Constraint. Attach Z-Constraint D to C, secure the two

pieces together with three M3x16 screws each.

support@tinkerines.com | 1-604-288-877823

TINKERINE

STUDIO

STUDIO

support@tinkerines.com | 1-604-288-877824

3.

M3x10 (x2)

The Z-Axis rods should now sit ush within the bottom

and top Z-Constraint. Attach Z-Constraint D to C, secure

the two pieces together with three M3x16 screws each.

TINKERINE

4.

STUDIO

STUDIO

M3x10 (x4)

Insert the Z-Axis Motor and lead screw from the

bottom and into the Z-Axis platform. To connect the

the lead screw into the nut within the platform you will

need to manually turn the lead screw rod until it

threads into the nut. Secure the motor to the frame

with four M4x10 screws. Face the pin connectors of

the motor toward the front.

support@tinkerines.com | 1-604-288-877825

1.

TINKERINE

STUDIO

STUDIO

M3x20 (x2)

Install each endstop triggers as shown. Note the orientation of

the trigger and the direction its pointing. Depending on the

trigger, you will need to different amounts of spacers with the

endstop.

After the endstop trigger is installed. Thread the

wires through the holes shown in the picture. Use

one of the smaller adhesive wooden clips provided

in your kit to prevent the wire from slacking/getting

caught once the printer is in motion. Insert the wire

into the clip and tape it to the bottom side of the top

ring beside the LED strip.

M3x20 (x2)

M3x25 (x2)

support@tinkerines.com | 1-604-288-877826

TINKERINE

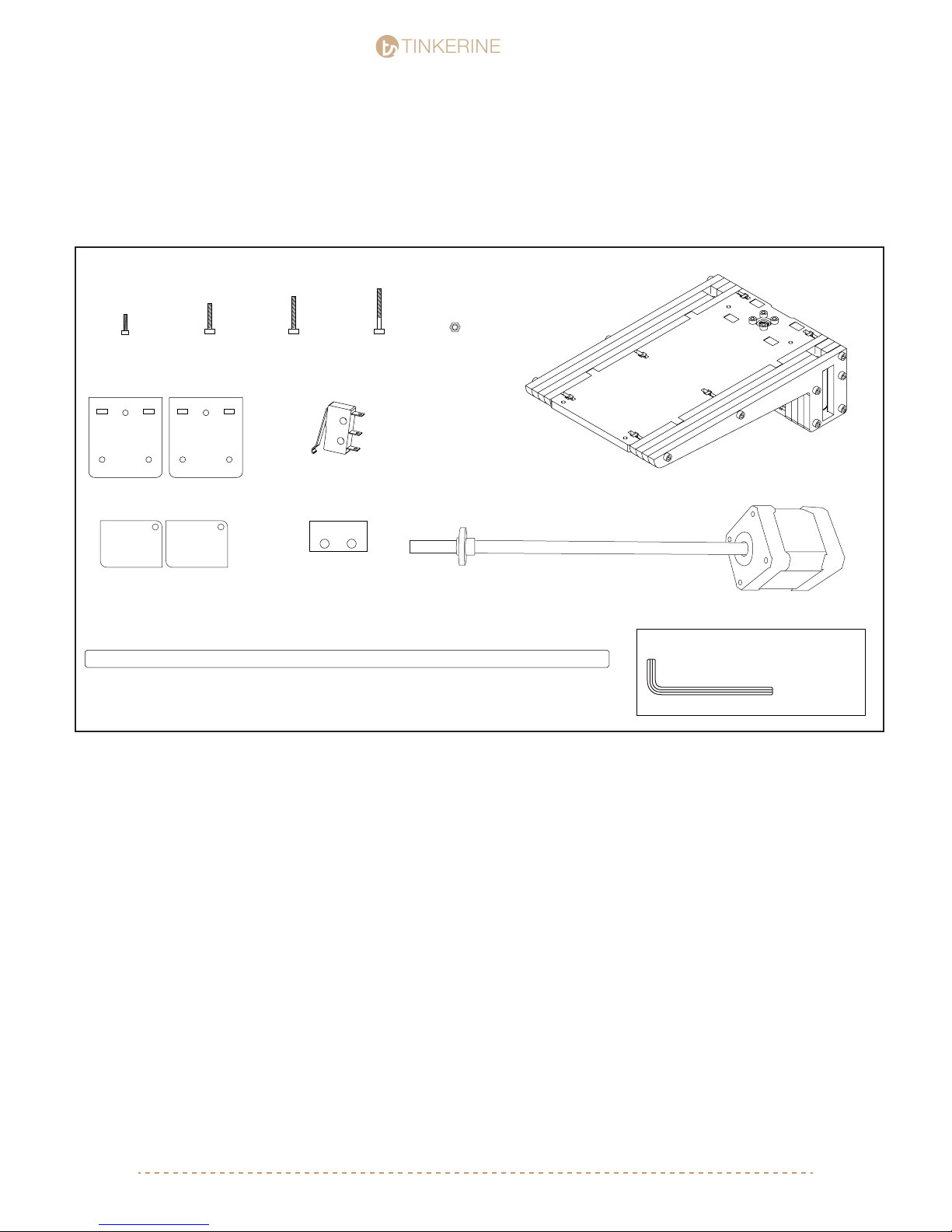

Gantry Assembly pt.1

STUDIO

STUDIO

Parts Required

M3x16 Screw

x20

Tools Required

Slider Core

Slider Side Panels

M3 Allen Key

Pulley (Large)

x2

Bearing

x8

GT2 Loop Belt (166mm)

x2

Pulley (Small)

x6

GT2 Belt (417mm) x2

GT2 Belt (415mm) x2

Inner Bearing Cap

8 Pieces

Outer Bearing Cap

Bushing Holder w/ Brass Bushing

8 Pieces

8 Pieces

X-Axis Smooth Rod (270mm) x2

Y-Axis Smooth Rod (255mm) x2

1.

B

Insert both ends of the belt onto the Slider B piece. Make sure to line up the belt with the teeth so that there is no

spaces left at the end of the slots. Make sure to note the two different sets of belt length during the assembly. The

two longer sets will be for the Front and Back slider, and the short sets are for the Left and Right sliders.

support@tinkerines.com | 1-604-288-877827

TINKERINE

2. Front Slider

X Axis Belt - 417 mm

STUDIO

STUDIO

M3x16

support@tinkerines.com | 1-604-288-877828

TINKERINE

3. Back Slider

!

STUDIO

STUDIO

X Axis Belt - 417 mm

M3x16

support@tinkerines.com | 1-604-288-877829

TINKERINE

!

STUDIO

STUDIO

Left Slider4.

Y Axis Belt - 415 mm

M3x16

support@tinkerines.com | 1-604-288-877830

TINKERINE

Right Slider5.

M3x16

Y Axis Belt - 415 mm

STUDIO

STUDIO

support@tinkerines.com | 1-604-288-877831

TINKERINE

6.

STUDIO

STUDIO

x8

Insert eight bearing into the respective slots within the frame. The cutouts are meant to be a snug t with the

bearings, however if you have trouble putting the bearings in there, give the wooden inner ring a very light sand

with some sand paper.

support@tinkerines.com | 1-604-288-877832

TINKERINE

Bearing

Inner Bearing Cap

Small Pulley

Front Slider

With the previously assembly slider unit, you will now need

to add the rod, pulleys, inner bearing cap, and depending

on the slider you may need to include a looped belt.

Assemble the slider units as shown on the picture and

note the orientation of the pulley and panel direction of the

inner bearing cap.

Assembled each and set aside until you have all four slider

units ready for the next step.

X-Axis Rod (270mm)

STUDIO

STUDIO

Small Pulley

7.

Front Rod

Bearing

Inner Bearing Cap

Large Pulley

Back Slider

GT2 Looped Belt (166mm)

Inner Bearing Cap

Bearing

Bearing

8.

Back Rod

X-Axis Rod (270mm)

Small Pulley

Inner Bearing Cap

support@tinkerines.com | 1-604-288-877833

TINKERINE

Left Rod

9.

Small Pulley

Y-Axis Rod (255mm)

STUDIO

STUDIO

Small Pulley

Bearing

Inner Bearing Cap

Left Slider

Bearing

10.

Right Rod

Small Pulley

Inner Bearing Cap

Large Pulley

Y-Axis Rod (255mm)

Bearing

Inner Bearing Cap

GT2 Looped Belt (166mm)

Bearing

Inner Bearing Cap

Right Slider

support@tinkerines.com | 1-604-288-877834

TINKERINE

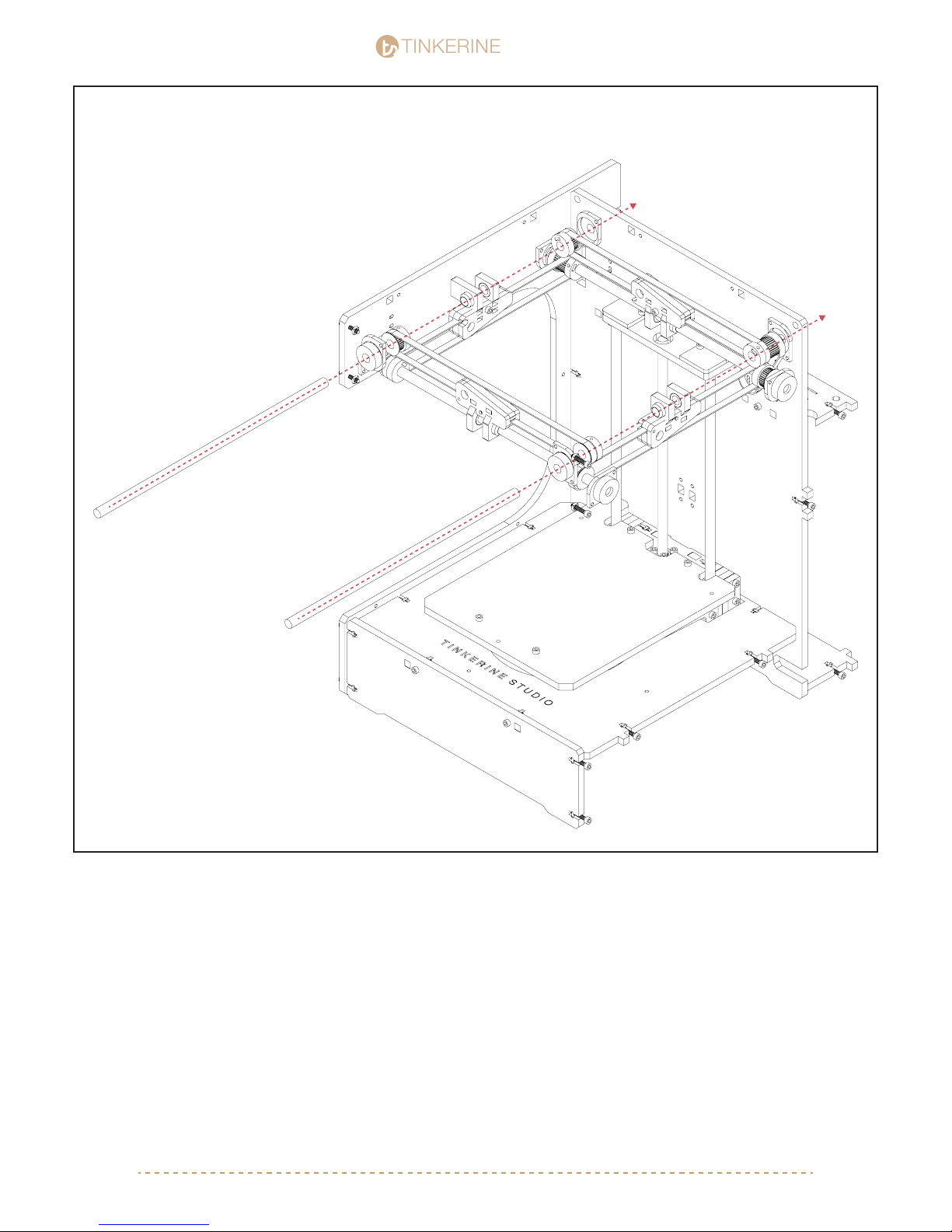

11. Font + Back Slider

STUDIO

STUDIO

X-Axis Rod (270mm)

* Front panel has been hidden to show gantry*

Using the previous slider assembly pictures as a reference. Insert the Front and Back slider assembly into the frame.

One way to do this would be to skewer the items on one by one as you insert the rods from one end.

For example, to insert the back rod from the right side of the frame, the order would be:

Right Inner Bearing Cap > Small Pulley > Back Slider > Large Pulley > Looped Belt > Left Inner Bearing Cap

To insert the front rod from the right side of the frame, the order would be:

Right Inner Bearing Cap > Small Pulley > Back Slider > Small Pulley > Left Inner Bearing Cap

Make sure to note the orientations of the inner bearing caps, and directions of the pulleys.

support@tinkerines.com | 1-604-288-877835

TINKERINE

12. Left + Right Slider

STUDIO

STUDIO

Y-Axis Rod (255mm)

* Side panel has been hidden to show gantry*

Similar to the Front and Back rod assembly, installing the Left and Rod right will require you to insert the rod from

one end while inserting the parts in order. Here is the tricky part: While skewering the pulleys onto the left and right

rods, you will also need to skewer the belts from the front and back sliders.

To insert the left rod from the front side of the frame, the order would be:

Front Inner Bearing Cap > Small Pulley > Back Slider > Small Pulley > Back Inner Bearing Cap

To insert the right rod from the front side of the frame, the order would be:

Front Inner Bearing Cap > Small Pulley > Back Slider > Large Pulley > Looped Belt > Back Inner Bearing Cap

Once the Left and Right rods are installed, you will need to pop the Front and Back rods back out slightly to loop

the belts onto the pulleys. Once the belts are seated onto the pulley, you will need to use a bit of force to insert the

rods into the bearing.

After installed the the gantry, all the belts (except for the closed loop belts) should be looping across a pulley on

each end.

support@tinkerines.com | 1-604-288-877836

TINKERINE

12.

STUDIO

STUDIO

M3x16 (x16)

Install the outer bearing caps to cover the exposed bearing and prevent the rods from sliding out. If you have

oriented the inner bearing caps correctly in the previous steps, it will align with the outer bearing caps. If not,

you need need to ip the inner bearing cap.

support@tinkerines.com | 1-604-288-877837

TINKERINE

Gantry Assembly pt.2

STUDIO

STUDIO

Parts Required

M3x10 Screw

x4

Carriage Bottom Carriage Top Linear Bearing Holder

M3x50 Screw

x3

X-Axis Carriage Smooth Rod (225mm)

Y-Axis Carriage Smooth Rod (225mm)

45mm Bearing

x2

Tools Required

M3 Allen Key

B

C

!

If your carriage comes to you partially assembled. Skip ahead to page 40 of

the assembly manual and follow the instructions listed for assembled units.

support@tinkerines.com | 1-604-288-877838

TINKERINE

1. Carriage (X-Axis Bearing)

B

STUDIO

STUDIO

C

B

C

45mm Bearing

Carriage (Y-Axis Bearing)2.

45mm Bearing

A

A

A

support@tinkerines.com | 1-604-288-877839

A

TINKERINE

3.

X-Axis Bearing

STUDIO

STUDIO

Take extra care when inserting the smooth

rod into the linear bearing. Go at it slowly

!

and make sure to not force the rod into

the bearing to prevent the ball bearings

from dislodging.

B

C

4.

X-Axis Cross Rod (225mm)

Y-Axis Cross Rod (225mm)

A

A

Y-Axis Bearing

Take extra care when inserting the smooth

rod into the linear bearing. Go at it slowly

!

and make sure to not force the rod into

the bearing to prevent the ball bearings

from dislodging.

support@tinkerines.com | 1-604-288-877840

X-Axis Cross Rod (225mm)

Y-Axis Cross Rod (225mm)

TINKERINE

STUDIO

STUDIO

support@tinkerines.com | 1-604-288-877841

5.

B

A

A

C

The frame has been hidden to give you a clearer view. To insert the cross rods, one by one take the rods and

insert it into one end of the slider. Push the rod into the rst slider to give you enough room to bring the rod up

into the gantry so it becomes leveled with the second slider. Then retract the rod so it can be inserted into the

second slider.

For Pre-Assembled Carriage:

Position the carriage in the right direction (Arrow on assembly pointing toward back of printer), take any of the

two rods and insert it carefully into the respectively linear bearing. Bring the rod and carriage into the gantry

space, and insert one end of the rod into the slider, twist the rod while supporting the slider will help you move

the rods easier. Once you have enough clearance to insert the other of the rod into the slider, twist the rod again

to insert into the slider on the opposite side. Repeat with second rod.

Take extra care when inserting the smooth

rod into the linear bearing. Go at it slowly

and make sure to not force the rod into

the bearing to prevent the ball bearings

from dislodging.

!

TINKERINE

6.

STUDIO

STUDIO

At this point this is what your gantry should look like from the top. Make sure to aligned the pulleys on both

sides of the belt so the belt is sitting parallel with the middle of the sliders. Tighten the sets screws on the

pulleys once you have aligned them all.

support@tinkerines.com | 1-604-288-877842

TINKERINE

7.

STUDIO

STUDIO

M3x50 (x3)

support@tinkerines.com | 1-604-288-877843

TINKERINE

8.

STUDIO

STUDIO

You’re almost done with the gantry assembly. For the most part you should now have a gantry system that you

can move manually by hand. Move on to part three of the gantry assembly to complete the gantry system.

support@tinkerines.com | 1-604-288-877845

TINKERINE

Gantry Assembly pt.3

STUDIO

STUDIO

Parts Required

M3x10 Screw

x8

NEMA17 Stepper Motor

M3 Washer

x2

x8

M4x16 Screw

x1

Motor Bracket

M4 Washer

x1

M4 Nuts

x1

Motor Wedge

Tools Required

M4 Allen Key

M3 Allen Key

x2v.1 v.2 x2

36 Tooth Timing Pulley 18 Tooth Timing Pulley

You may have v.2 timing pulley included in

the kit. Follow the instruction as per the v.1

pulley.

support@tinkerines.com | 1-604-288-877846

TINKERINE

1.

STUDIO

STUDIO

M3x10 (x4)

M3 Washer (x4)

2.

As shown in Step 1, fasten the motor

bracket to the motor and slide the pulley

onto the motor shaft. Lightly tighten the

motor bracket screws as you will need to

make minor adjustments in the second

step.

1. Before inserting the motor bracket into

the slot on the frame, insert a M4 nut into

the T-slot.

2. Look the belt around the pulley and seat

the motor into the slot. You may need to

shift the motor foward or backward within

the bracket to make sure the belt is

tensioned and does not have extra slack.

Tighten the screws once the motor is in the

correct position.

4. Position the pulley so the belt is perpendicular and not angled in a way that the

belt is rubbing against hte pulley or the

wooden frame. Tighten the set screw on

the at edge of the shaft once you have

positioned the pulley.

M4x20

M4 Nut + Washer

support@tinkerines.com | 1-604-288-877847

5. Insert the M4 screw from the button and

secure the motor bracket to the frame.

Insert the motor wedge to tuck it under the

other side of the motor.

6. Connect the 4-pin motor wire to the port

located on the bottom edge of the motor.

TINKERINE

3.

M3x10 (x4)

M3 Washer (x4)

STUDIO

STUDIO

4.

1. As shown in Step 3, insert the motor

from the back with the pulley already sitting

in the looped belt from the front. The

tapered end of the pulley should be

pointing away from the motor.

2. Insert the M3 screws to secure the

motor to the frame. Make sure to position

the motor on the frame at a point where the

belt is properly tensioned to avoid giving

the belt any slack.

3. Tighten the setscrew within the pulley on

the at edge of the motor shaft to secure

the pulley.

4. As shown in Step 4, take a minute to

ensure that all belt are properly aligned.

Belt should always sit perpendicular to the

pulley and should not be angled in any

way. Also make sure the the belt teeth is

fully seated into the grooves of the pulley

and not chewing into the walls of the

pulley. You may need to loosen the sets

screws on the pulley to re-adjust the

positions.

5. Connect the 4-pin motor wire to the port

located on the bottom edge of the motor.

support@tinkerines.com | 1-604-288-877848

TINKERINE

5.

STUDIO

STUDIO

Your printer’s gantry system should be fully assembled now. You should be able to manually move the carriage

around on the X+Y axis. Double check to make sure all belts are properly secures + tensioned, and that all

setscrews are properly tightened.

support@tinkerines.com | 1-604-288-877849

TINKERINE

Carriage Assembly

STUDIO

STUDIO

Parts Required

M3x16 Screw

x36

Extruder Assembly Hotend Assembly

M3x25 Screw

x2

Tools Required

M3 Allen Key

Electric Fan

x2

Ceramic Heater CartridgeThermistor

Fan Shield

x1

Fan Duct

x2

support@tinkerines.com | 1-604-288-877850

TINKERINE

STUDIO

STUDIO

1.

M3x25 (x2)

Place the bottom portion of the extruder onto

the carriage and insert the hotend + hotend

mount into the center of the carriage through

the slot located on the back on the carriage.

With the two M3x20 screws, secure the

extruder and hotend to the top plate of the

carriage. The screws should thread into the

hotend mount, securing all the components

together.

Ensure that the acrylic spacer is attached to

the top of the hotend and leave the ceramic

insulation wrapping attached to the hotend.

Acrylic Spacer

2.

Hotend + Hotend mount

From the front, your carriage should now look

like this. Make sure the larger portion of the

extruder is on the left side. The extended

portion of the hotend should also be pointing

toward the left.

support@tinkerines.com | 1-604-288-877851

TINKERINE

3.

STUDIO

STUDIO

M3x16 (x2)

Now that the hotend and the bottom portion of the extruder is secured to the carriage, we’ll

now re-assemble the extruder. Place the spring back into the holder pin and pinch it with the

top portion of the extruder. Line up the mounting hole and screw in the two M3 screws that

we have removed earlier.

support@tinkerines.com | 1-604-288-877852

TINKERINE

4.

STUDIO

STUDIO

From the top of the extruder, look down and check that there is a clear path from the extruder to the nozzle.

The groove of the hobbed bolt should be positioned that it feeds into the hotend. If the aligment of the hob is

off, use a allen key to loosen the setscrew on the hob and reposition. Make sure to set the screw on the at

face of the extruder motor shaft.

support@tinkerines.com | 1-604-288-877853

TINKERINE

5.

STUDIO

STUDIO

Take extra care when tightening the

setscrew for the thermistor. Turn the

!

setscew very slowly as the glass on the

thermistor will crack if there is too much

pressure applied. There just needs to be

enough force applied so the thermistor

does not slide out of its slot.

On the back face of the hotend, there will be two slots. The large of the two slot will be for the heater cartridge,

and the smaller one is designated for the thermistor. Insert the heater cartridge and therminstor into their respective slots and secure them in place using the setscrews located on the sides of the hotend. Once the thermistor

and heater cartridge are in place, route the wire into the wire guide shown in the picture.

Themistor

Heater Cartridge

support@tinkerines.com | 1-604-288-877854

TINKERINE

6.

STUDIO

STUDIO

To install the print bed fan, grab a fan and

point the sticker side downward. Orientate

the fan so the wire is pointing toward the

back of the printer, doing so will give you

cleaner look when you are perforing wire

management. Similar to the wires for the

hotend, route the fan wire up the wire guide.

With the M3 screws, thread it through the fan

duct and fan into the screw holes located on

the the bottom plate of the carriage. The

mouth of the fan duct should be point toward

the hotend.

M3x20 (x2)

support@tinkerines.com | 1-604-288-877855

TINKERINE

7.

STUDIO

STUDIO

M3x16 (x2)

1

2

To install the hotend cooling fan, grab the fan and point the sticker side toward the hotend. The fan should sit

between the two carriage plates so if it does not t, you will need to loosen the carriage screws. Route the fan

wires so that it comes out of the top right corner and sits infront of the fan and wire guide. Secure the fan to the

carriage with screw 1 and attach the fan guard to the with screw 2 + M3 Nut.

support@tinkerines.com | 1-604-288-877856

TINKERINE

8.

STUDIO

STUDIO

You have complete the extruder and fan assembly. Double check to make sure all the fans are facing the right

way and that all the wires are properly routed to go up the wire guide. All components on the carraige (hotend,

motor, fan) should be properly secured and tightened. Connect the 4-pin motor wire to the extruder motor.

support@tinkerines.com | 1-604-288-877857

TINKERINE

9.

STUDIO

STUDIO

You are almost done assembling your printer. Move on to the next step to install the power supply and electronics to printer.

support@tinkerines.com | 1-604-288-877858

TINKERINE

STUDIO

STUDIO

Electronics / Spool Holder Assembly

Parts Required

M3x10 Screw

x3

M3x16 Screw

x15

M3x20 Screwx3M3x25 Screw

Motor Compartment 1 of 2

Motor Compartment 2 of 2

x2

M3 Nuts

x18

Spool Holder

Tools Required

M3 Allen Key

ARDUINO

Arduino Mega 2560

Fan Mount

Back Bracket

Electric Socket

Power Supply

Power Switch

50mm Electric Fan

x1

support@tinkerines.com | 1-604-288-877859

TINKERINE

1.

STUDIO

STUDIO

M3x16 (x2)

Insert the power socket and power switch as shown. The power switch is pressure tted and the power socket

will need to be secured by two M3x16 screw + M3 nut.

N

L

G

G

N

L

Connect the L line (White) from the power socket to the middle prong on the power switch. Leave the other

wires along for now as they will be connected to the power supply later.

Above the power switch slot you will see another slot

designated for the USB connection. Using two M3x10,

secure the USB head to the frame and plug in the other end

into the Arduino board once it has been installed.

support@tinkerines.com | 1-604-288-877860

TINKERINE

2.

STUDIO

STUDIO

M3x10

50mm Fan

Secure the fan mount to the power supply with a M3x10 screw and mount the fan onto the fan mount using the

two M3x16 screws. The sticker side of the fan should be point away from the power supply.

M3x16 (x2)

support@tinkerines.com | 1-604-288-877861

TINKERINE

3.

STUDIO

STUDIO

M3x25 (x2)

M3x10 (x2)

110v <> 220v

Secure the power supply and Arduino board to the bottom of the face plate. You will need to use M3 nuts to

secure the Arduino board. Orientate the board and power supply so the ports are facing the left side of the

machine.

The power supply is set to 110v by default for use in North America. To use 220v (Europe), follow the instruc-

!

tion on the power supply to ick the switch to 220v.

support@tinkerines.com | 1-604-288-877862

TINKERINE

4.

STUDIO

STUDIO

M3 Nut (x3)

M3x16 (x3)

After the power socket is in place, install the outer bracket by securing it with the T-Slots shown in the picture.

You may also choose to install this bracket as the last step after you have nished all the wire management,

doing so will give you a bit more room to work with as you guide the wires into the eletronic compartment.

support@tinkerines.com | 1-604-288-877863

TINKERINE

6.

M3 Nut (x4)

STUDIO

STUDIO

M3x16 (x4)

The back motor cover is composed of two pieces, assemble and secure with the two T-Slots on the top edge.

The motor cover is then secured with two T-Slots on the sides. The nuts on the side will require more effort to

push in as they were intended to be pressure tted.

support@tinkerines.com | 1-604-288-877864

TINKERINE

STUDIO

STUDIO

7.

M3x20 (x3)

M3 Nut (x3)

To assemble the spool holder, sandwich the smaller of the three spool holder pieces with the other two and

secure it with the M3 screw and M3 nut. Do not tighten this yet as it will make it hard to insert the assembly into

the main body.

support@tinkerines.com | 1-604-288-877865

8.

TINKERINE

STUDIO

STUDIO

M3x16 (x4)

M3 Nut (x4)

Insert the spool holder assembly to the frame and secure the spool holder with four M3 screws inserted from the

front side of the printer. Tighten all screws.

support@tinkerines.com | 1-604-288-877866

TINKERINE

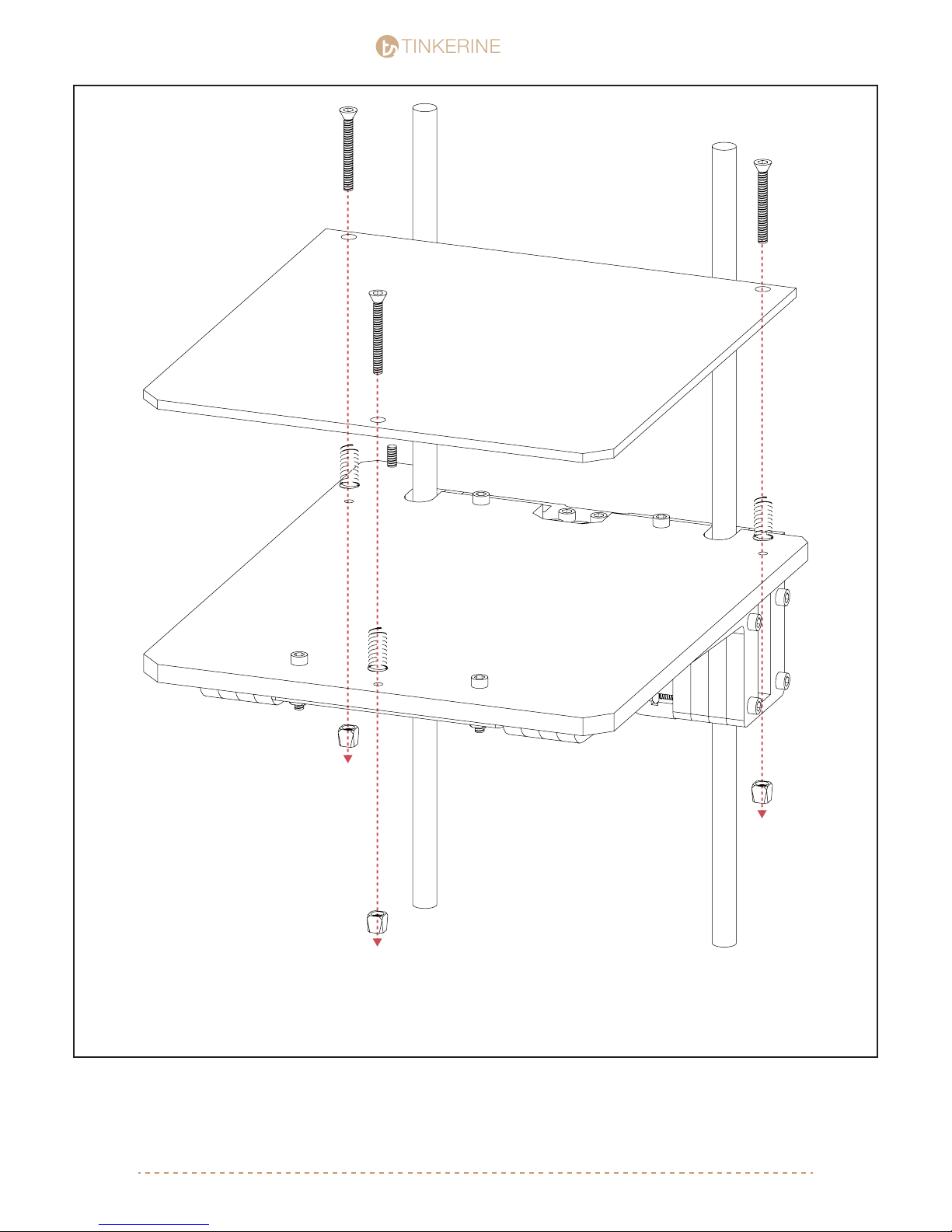

Print Bed Assembly

STUDIO

STUDIO

Parts Required

M3x25 Inset Screw

x3

Calibration Springs

x3

Filament Guide Tube

Tools Required

M3 Allen Key

Thumb Screws

x3

Print Bed

support@tinkerines.com | 1-604-288-877867

1.

TINKERINE

STUDIO

STUDIO

M3x25 Inset Screw (x3)

Calibration Sping (x3)

M3 Thumb Nut (x3)

One by one, place a spring between the print bed and the wooden platform. Insert the inset M3x25 screw from

the top and secure it with a thumb screw. Repeat until you have all three points secured. Turn the thumb screw

to tension the spring, idealy you will want the spring to be fairely compressed so the bed is rmly planted onto

the platform.

support@tinkerines.com | 1-604-288-877868

TINKERINE

2.

STUDIO

STUDIO

Take the lament guide tube and thread it through the cut out located on the corner of the motor cover and

motor bracket. Insert the other end into the top of the extruder. If you are having trouble threading the tube into

the top of the motor compartment, lightly sand the inner ring.

support@tinkerines.com | 1-604-288-877869

3.

TINKERINE

STUDIO

STUDIO

You’ve nished assembly your very own 3D printer (well almost!). With all of the components in the printer, move

on to the next step to begging the wiring portion of the assembly.

support@tinkerines.com | 1-604-288-877870

TINKERINE

Fan, Thermistor, Heater Cartridge, Motor Wire

STUDIO

STUDIO

Remove the motor cover and lament

guide.

1. Route the wires from the Left Side LED,

X+Y+Z-Axis Endstop, X+Y Motor wire

through the wire holes from the front side

of the machine to the back. Route the wire

so it runs behind the Y-Axis motor and

underneath the X-Axis motor. Run all wires

through the hole located on the back

corner of the motor bracket.

X-Axis Motor Wire

Y-Axis Motor Wire

Large Wire Sleeve

Y-Axis Endstop Wire

Left Side LED WireRight Side LED Wire

X-Axis Endstop Wire

Z-Axis Endstop Wire

2. Gather all the wires from the carriage

fan, heater cartrige, thermister, Right Side

LED, and extruder and route the wires

through the hole located on the motor

bracket.

3. You may choose to label the wires with

masking tape before you route them

through the hole located on the bottom left

corner of the printer. This will help you

indentify the wires later on.

NOTE 1: For the wires coming from the

extruder units, make sure to leave enough

slack so the wires still have some slack

once the extruder moves to it’s homing

location (Front left corner).

NOTE 2:

Once the wires are all routed and connected to the electronics, use the supplied wire

sleeve to clean up the exposed wires on

the back and top of the machine. Use the

larger sleeve for the back portion of the

machine and the smaller wire sleeve to

wrap the wires coming from the extruder.

NOTE 3:

After the machine is fully wired, apply xx

support@tinkerines.com | 1-604-288-877871

TINKERINE

STUDIO

STUDIO

Extruder Motor

X Motor

Y Motor Z Motor

!

IMPORTANT

There is a small triangle on the rightmost side.

Make sure it aligns as shown in the diagram.

support@tinkerines.com | 1-604-288-877872

TINKERINE

STUDIO

STUDIO

X Endstop

Y Endstop

Z Endstop

Thermistor

LED Strips

X Motor Y Motor Z Motor

*After you have thread the endstop

wires through the black plate, attach

the pins into the connector housing

before you plug them in.

Extruder Motor

(Print Bed)

Cooling Fans

Heater Cartridge

RAMPS 1.4

-

-

+

+

Heated Bed

Gnd

Cooling Fans

(Hotend + Electronics)

L

N

NG

L

Power Socket + Switch

*Negative ends of the wire that do not have

connector pins are marked with a black ink

on the ends*

Power Supply

support@tinkerines.com | 1-604-288-877873

TINKERINE

STUDIO

STUDIO

That’s it! You have just nished assembling your very own Litto 3D printer. However there are just a few things to

check before you power-up the printer for the very rst time:

1. Make sure all screws and components are properly screwed down and secured.

2. While manually moving the the gantry system (extruder, belts, pulley, smooth rods, bearings), all components

should operate smoothly and not interferre with one another. Check that all sets screws on the pulley are

tightened, and all belts are aligned so they are seating fully in the teeths of the pulley.

3. All electronics are properly plugged in and seated into their correct ports. Make sure there are no exposed

wires in contact with electronic components, and the electronic cooling fan is properly mounted and directing

airow to the Pololu driver.

4. Make sure there is no foreign objects along the path of moving components. Avoid using lubricant on the

linear bearing (Z Axis + Carriage). Most lubricants (especially ones that contain propellants) might absorb dirt

and become more viscous over time, which can cause more friction and cause damage to the bearings.

support@tinkerines.com | 1-604-288-877874

TINKERINE

STUDIO

STUDIO

Preliminary Run-Through

Stage 1

1. Plug in the printer. Do not turn on the printer yet.

2. Connect the USB from the printer to the USB port on your computer. If you have an LCD/SD card unit,

connect it to your printer.

3. Test the X-Axis endstop. Manually move the carriage by hand and push it to the left side of the printer and

check to see if the slider will trigger the endstop. You will hear a click when enstop is trigger. Repeat the test

with the Y-Axis Endstop. If the endstop does not trigger, you will need to re-adjust the position of the endstop

so it makes contact with the trigger pieces on the slider.

4. Tighten the thumb screws underneath the print bed springs. This will tension the springs and prevent the

bed from moving around during printing.

5. Test the Z-axis endstop. Manually turn the lead screw to bring the bed upward. As the bed approaches the

nozzel, adjust the Z-axis trigger screw located on the back corner of the printer bed so that it makes contact

with the endstop leaver before the nozzle touches the surface of the bed. The ideal distance between the

nozzle and print surface should roughly be the thickness of a piece of paper.

6. Calibrate the print bed. Using the 3-point leveling system, manually move the hotend to the each of the four

corners on the print bed. At each of the four point, adjust the thumb screws so the bed is evely leveled on all

sides.

Stage 2

1. Turn on the printer.

2. Check that both LED light strip are lit.

3. Check that the hot-end cooling fans are on and directing airow to the hot-end within the carriage unit.

4. Check that the electronics cooling fans are on and directing airow to the Arudino board + Pololu drivers.

5. Check that the print bed cooling fan isn’t on. The fan for the print bed should only activate during printing.

6. If the LED or fan do not turn on, turn off the printer and disconnect the power source. Check your wiring to

see if all wire are properly seated and secured in their sockets.

Stage 3

1. Using Coordia (Control Software) or the T.I.M Controller, connnect to the printer and test move each axis.

2. Home all axis. If the printer triggers the any of the endstop but doesn’t stop, shut off the printer immediately.

Check the enstop pin connector to see if the pins are fully seated into the housing, then make sure the housing

are properly connected to the pins on the electronics board. Since the X and Z axis endstop are grouped

together, there might be a chance that you have them plugged in reversed.

3. Using Coordia or T.I.M, set the preheat temperature for PLA (180c). Monitor the temperature level and check

that the heater cartriged and thermistor is working properly. If the hotend does not heat up, check that the

heater cartrige and thermistor is plugged in correctly. Do not touch hotend with your nger to check the

temperature as the cartridge can be functioniing correctly while the thermistor is providing a false reading.

4. Your printer is ready to start printing. Follow the calibration guide to start printing your rst object!

support@tinkerines.com | 1-604-288-877875

Loading...

Loading...