USER MANUAL

Welcome.

Congratulations on becoming the owner

of a brand new Ditto

This user manual will assist you with the

unboxing and initial setup of the printer,

and provide guidance on general

maintenance and troubleshooting

procedures. So welcome to the

Tinkerine

using the Ditto

family, we hope you will enjoy

™

Pro 3D printer.

™

Pro as much as we do.

Table of Contents

SAFETY WARNINGS

2

WARRANTY

3

SPECIFICATIONS

4

PRINTER OVERVIEW

5

UNBOXING

6

FILAMENT INSTALLATION

8

PRINT BED INSTALLATION

9

10

11

12

13

14

15

16

18

20

23

PRINT BED CALIBRATION AND STARTING A PRINT

BED LEVELING GUIDE

TINKERINE SUITE SOFTWARE INSTALLATION

IMPORTING AND PRINTING A MODEL

SLICING SETTINGS

EXPORTING A FILE

MODEL ROTATION

MODEL SCALING

SLICING SETTINGS EXPLAINED

MEASURING FILAMENT DIAMETER

24

26

29

33

42

UPDATING PRINTER FIRMWARE

TROUBLESHOOTING

PRINTER CARE MAINTENANCE

HOTEND REPLACEMENT

GLOSSARY

1

Safety Warnings

FRAGILE

The Ditto™Pro contains delicate electronic components and sensors. Handle with care.

The Ditto™Pro 3D printer is not user serviceable.

HOT SURFACE

The Ditto™Pro 3D printer hotend heats up to high temperatures during operation.

Allow the hotend to properly cool down before reaching in your hand.

MOVING PARTS

The Ditto™Pro 3D printer contains multiple moving parts that can cause injuries.

Do not reach inside the Ditto™Pro 3D printer during operation.

Hot Surface.

Allow to cool before servicing.

Pinch Point.

Keep hands and fingers clear.

Electric Shock Hazard.

This equipment is to be serviced

by trained personnel only.

SHOCK

There is a risk of shock. Contact a certied technician to service your Ditto™Pro 3D printer.

In case of emergency disconnect the power cable from the socket.

VENTILATION

The Ditto™Pro 3D printer prints with molten plastic which emits a slight odor

during operation. Setup the Ditto™Pro 3D printer in a well-ventilated environment.

BRIGHT LIGHTS

Do not look directly at any operating LED’s.

2

Warranty

STANDARD WARRANTY

Tinkerine Studios, LTD warrants the equipment and accessories comprising the Ditto™Pro 3D Printer will be free from

defects in material and workmanship for one (1) year from the date of customer purchase. Original serial number must

appear on product. Removal of serial numbers will void this warranty and any equipment and accessories that have been

altered or modied in any way and are not as originally purchased will void this warranty.

Tinkerine will at its option repair, replace or refund the purchase price of any accessories, supplies or equipment found to be

defective under this warranty. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, INCLUDING BUT

NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE.

In the event of breach of this expressed warranty, or any other warranty, whether expressed or implied, Tinkerine liability

shall be limited to the remedy provided by the preceding paragraph. IN NO EVENT WILL TINKERINE BE LIABLE FOR ANY

DIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, NOR WILL TINKERINE EVER BE LIABLE FOR BREACH OF

WARRANTY, WHETHER EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF THE

MERCHANTABILITY OR FITNESS, IN AN AMOUNT GREATER THAN THE PURCHASE PRICE OF THE PRODUCTS

DESCRIBED BY THIS EXPRESSED WARRANTY. No agent, distributor, salesperson, wholesaler or retail dealer has authority

to bind Tinkerine to any other afrmation, representation or warranty concerning these goods.

TECHNICAL SUPPORT

For technical assistance, please contact the Tinkerine Technical Support team:

• Email: contact@tinkerine.com

• Phone: 1-604-288-8778

DISCLAIMER

While every precaution has been taken in preparation of this document, Tinkerine assumes no liability to any party for any

loss or damage caused by errors or omissions or by statements resulting from negligence, accident, or any other cause.

Tinkerine further assumes no liability arising out of the application or use of any product or system described, herein; nor

any liability for incidental or consequential damages arising from the use of this document. Tinkerine disclaims all warranties

of merchantability or tness for a particular purpose. Tinkerine reserves the right to make changes without further notice to

any product or system herein to improve reliability, function, or design.

3

Safety Warnings

Ditto™Pro 3D Printer

Physical

Dimensions 37 x 39 x 43.6 cm (14.6 x 15.4 x 17.2 in)

Weight 10 kg (22.0 lb)

Printing

Build Volume 22 x 16.5 x 22 cm (8.7 x 6.5 x 8.7 in)

Filament Diameter 1.75 mm

Layer Resolution 50-300 microns (0.05-0.3 mm)

Material PLA

Nozzle Diameter 0.35mm

Technology Fused Filament Fabrication (FFF)

Software

File Type STL, OBJ

Os Compatibility Windows, Mac

Software Tinkerine Suite

Electrical

Connectivity USB (rmware), SD Card (printing)

Consumption ~15W (idle), ~70W (operational)

Electronics RAMPS 1.4, AT mega 2560,

A4988 Stepper Drivers,

Power Input AC 100-240VAC, 50-60 Hz, 1.0A

Power Output DC 12V, 15A

Operational Temp 5 C ~ 35 C

Mechanical

Body Aluminum composite

Build Platform Glass (adhesive material required)

Linear Motion Linear bearings, bronze bushings

Motor 1.8° step angle, 1/16 micro-stepping

4

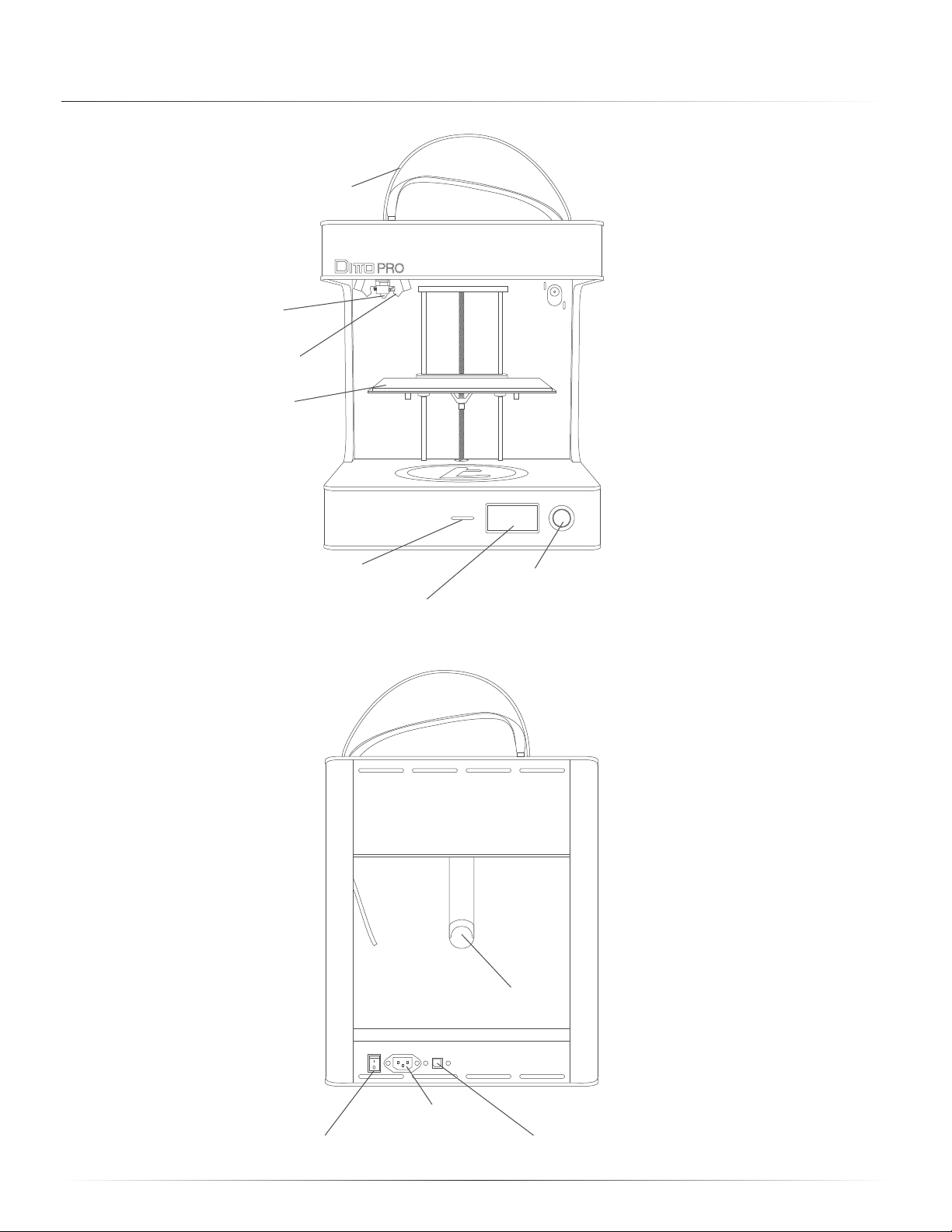

Printer Overview

Filament Guide Tube

Hotend

Print Cooling Fan

Print Bed

FRONT

SD Card Reader Control Dial

Control Menu

Power Switch

BACK

Spool Holder

Power Socket

USB Port

5

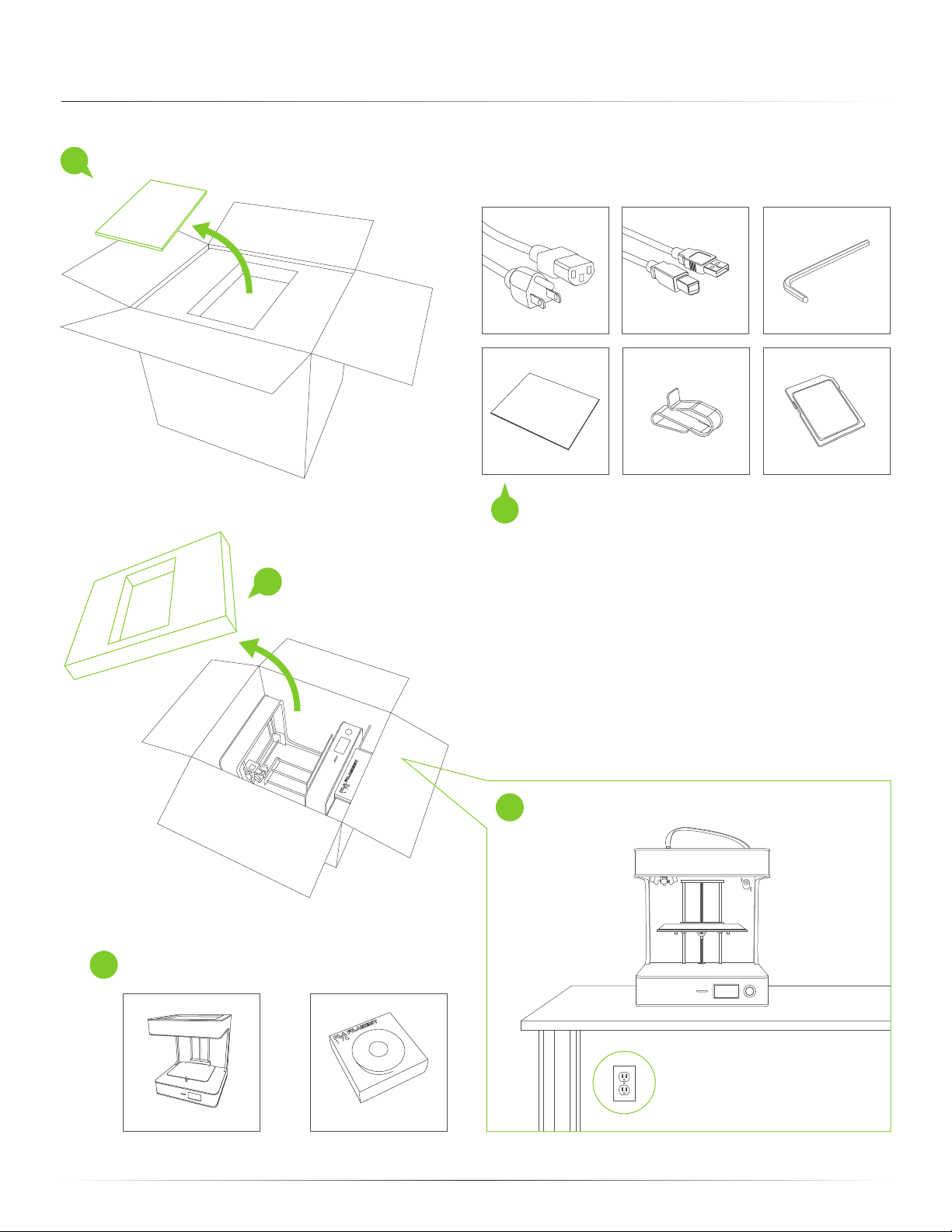

Unboxing

Peel back aps and remove compartment lid.1

Power Cable

Glass Print Bed

2

Remove printer accessories from compartment.

Remove foam bracket and remove the printer and lament.

3

Print Bed Clips x4

USB Cable

Hex Wrench

SD Card

Remove the printer and lament from the box.

4

Ditto™Pro Printer

Filament Spool

Place the printer on a rm at surface.

5

Requires accessible power outlet.

6

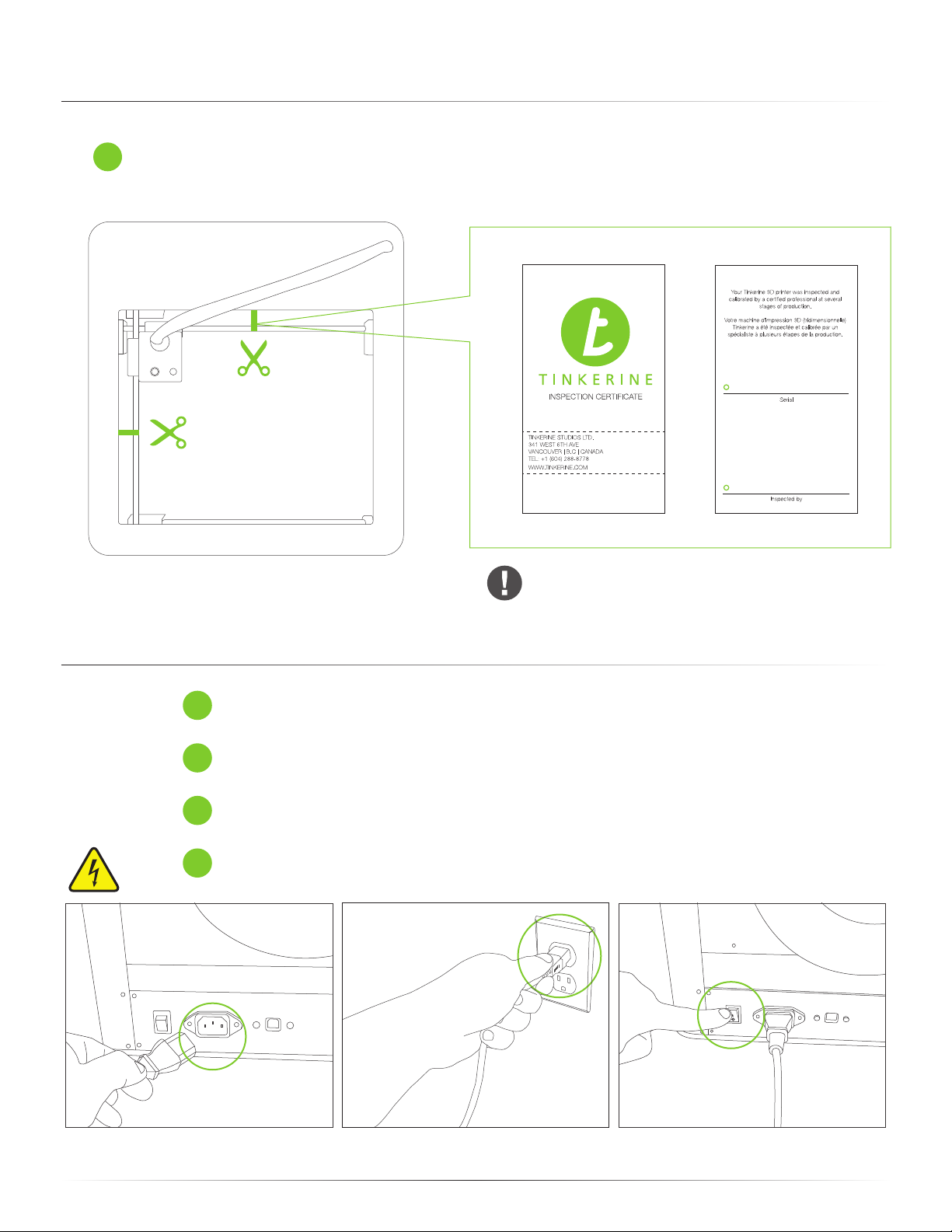

Unboxing

Using a pair of scissors, cut away the two zip ties that are securing the extruder in place, and remove

6

the printer certication card.

DPR1234567

John Doe

Powering On

1

Make sure the power switch on the printer is in the Off position ( O ).

Insert the female end into the power socket located on the back of the printer.2

Insert the male end of the power cord into an electrical socket.

3

4

Turn on the printer by ipping the power switch to the On position ( I ).

Use extra caution when cutting off the zip ties to

prevent damage to the motion belts or wires.

7

Filament Installation

Extend the lament guide tube from the retracted position.

1

Remove the lament spool from

2

the packaging and place it on

the spool holder.

Take the end of the lament from the spool and

3

insert it into the guide tube.

If you are having trouble feeding the lament into

the lament guide tube, pull the lament out and

trim the tip of the lament with a pair of scissors.

54

Thread the lament through the guide tube and insert

it into the extruder. You’ll need to push down on the

tensioner button to open up a gap.

Once the lament is inserted all the way down into the

hotend, insert the guide tube into the top of the

extruder cap.

8

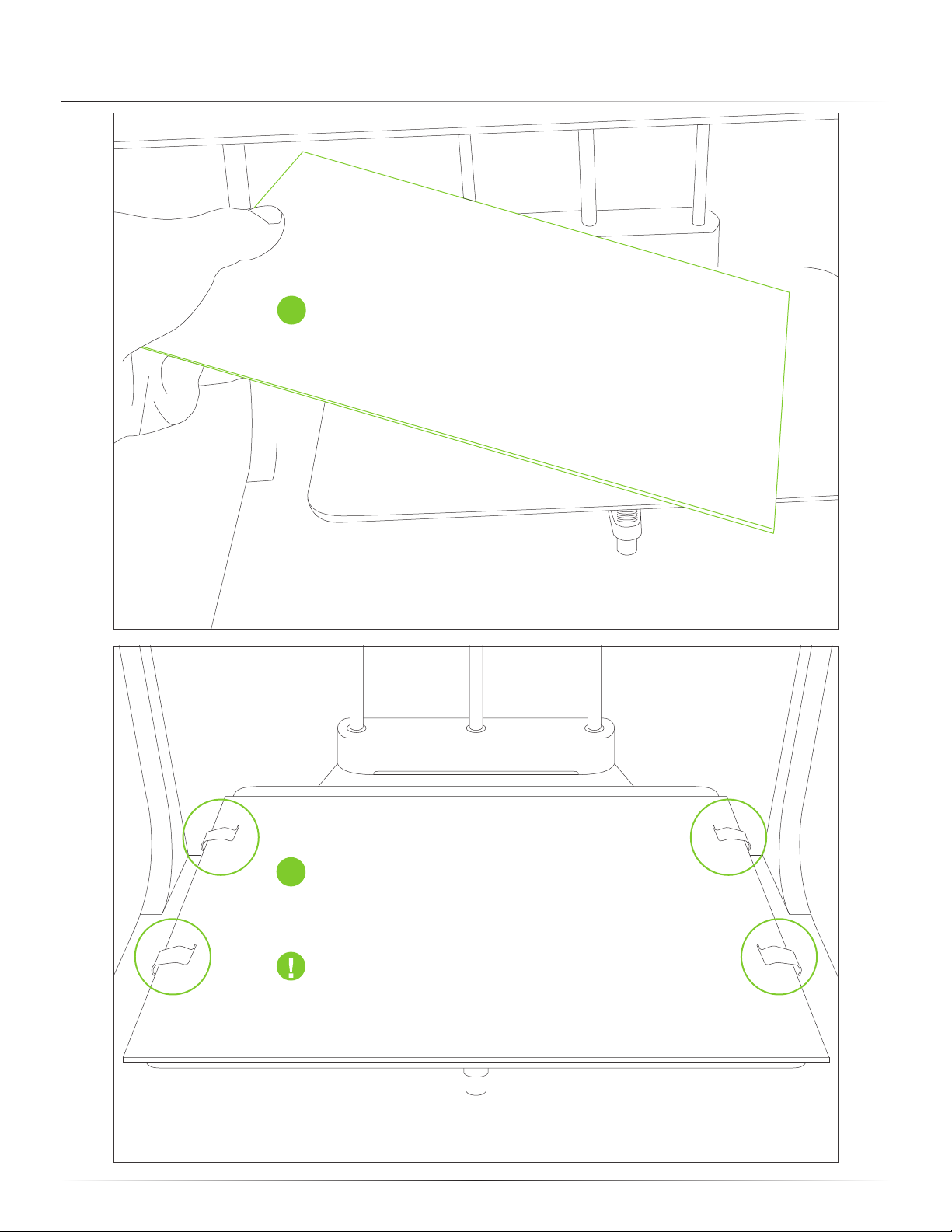

Print Bed Installation

Place the glass print surface onto the bed with the

1

blue painter’s tape side facing upward. The tape

will act as an adhesion material for the plastic.

With the clips provided in the accessory kit, slide

each clip on to pinch the bed platform and glass

2

print surface together. Repeat until all four clips are

secured onto the bed as shown.

Replace any worn or damaged blue painter’s tape

as needed to ensure that your prints stick properly

during the printing process.

9

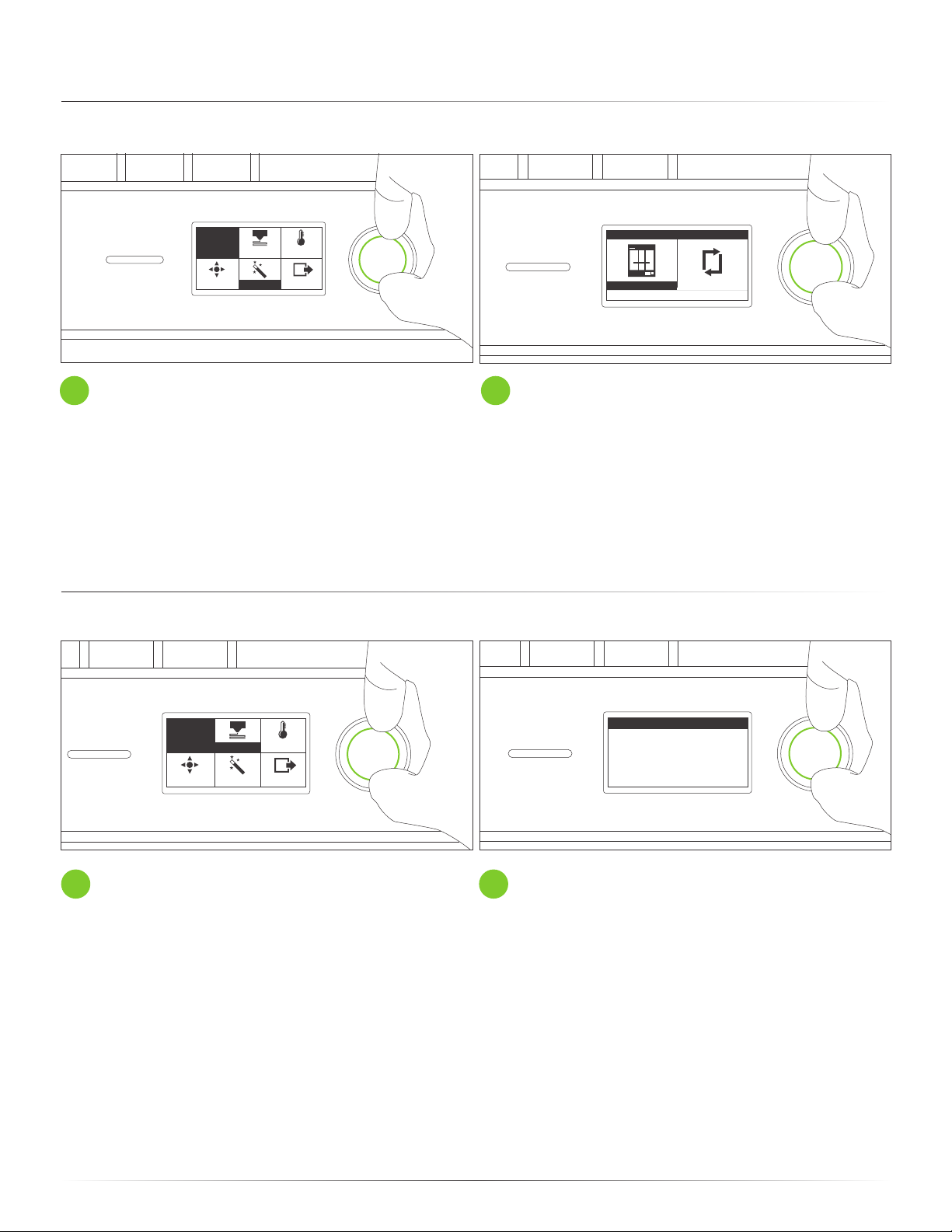

Print Bed Calibration

MAIN

MENU

Control

From the main menu, turn the dial to scroll to Wizard.

1

Push down on the dial to select.

Wizard

TempPrint

Status

Starting a Print

WIZARD

Bed Level New Filament

Exit

Select the Bed Level option and follow the on-screen

2

instructions to level the print bed.

MAIN

MENU

Control

From the main menu, turn the dial to scroll to Print.

1

Push down on the dial to select.

Wizard

TempPrint

Status

MAIN

TEST_PRINT.G

VASE.G

BRACELET.G

YOUR_PRINT.G

Scroll down to the le you want to print and push

2

down again to start the print.

10

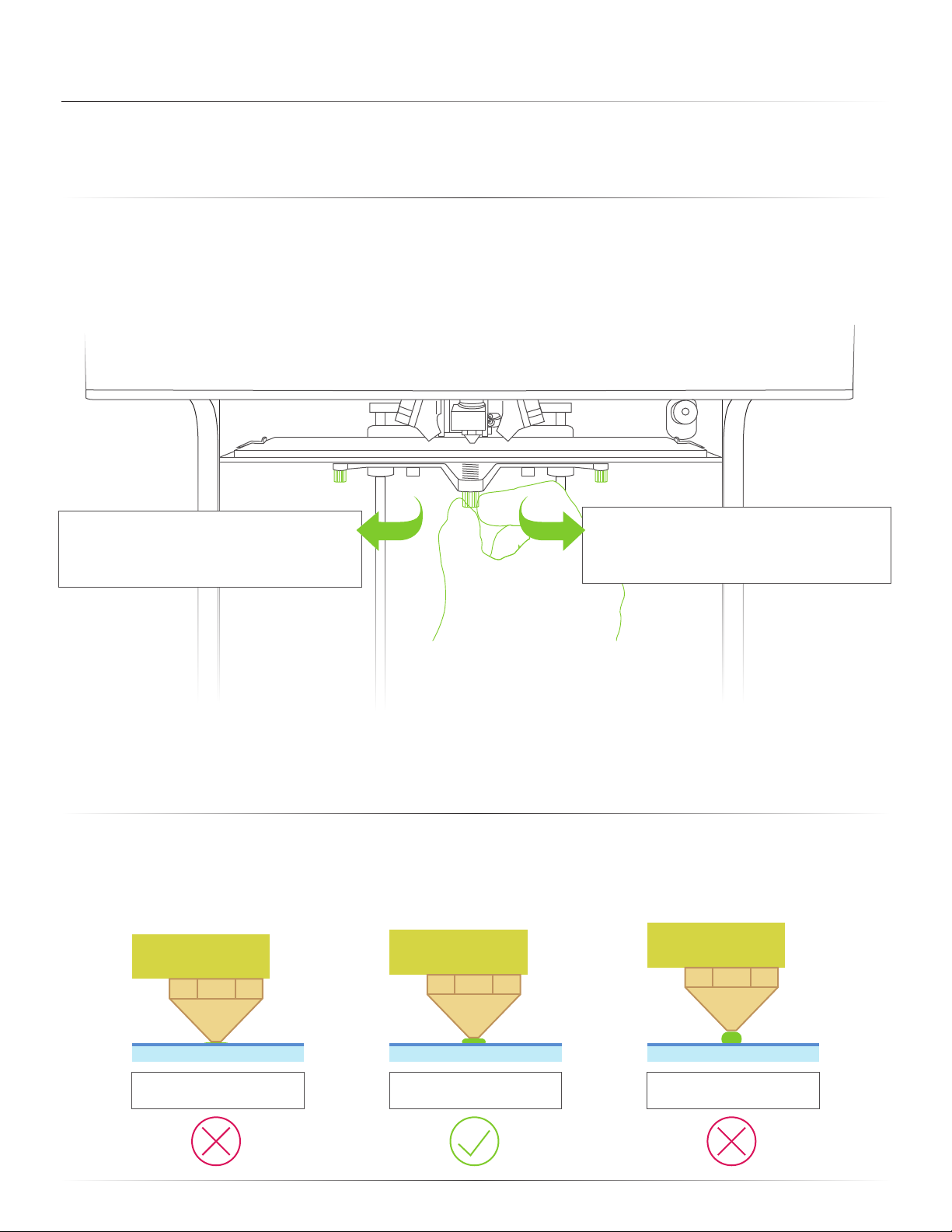

Bed Leveling Guide

To ensure that your prints always stick to the glass build plate, the build surface must be properly leveled so that the

nozzle is at an equal set distance across the print surface. Use the Bed Leveling Wizard and follow the on-screen

instructions to assist you in leveling the print bed.

Initialize the Bed Leveling Wizard from the LCD menu on your Ditto™Pro 3D Printer and follow the

on-screen instructions to begin bed leveling. To level your bed, the wizard will move the extruder to

three points on the print bed and ask you to adjust the thumb screws to make the distance between

the nozzle tip and print bed equal across the print surface.

Turning Clockwise

This loosens the spring tension and brings

the print surface closer to the nozzle.

With each of the three thumbscrews, adjust until the gap between the nozzle tip and print surface is roughly the

thickness of a piece of paper. If there is a large gap, you will need to turn the screw clockwise to bring the bed

closer to the nozzle. If there is no gap and the nozzle is scraping the print tape, you will need to turn the thumbscrew

counter-clockwise until you see a small gap.

Whenever you begin a print, always check that the rst layer of the print is properly stuck onto the blue

painter’s tape. A properly leveled bed should have the extruded lament a bit squished and shouldn’t pop

off the bed easily. While the printer is performing the skirt nozzle purge, observe the deposited lament and

make micro-adjustments with the thumbscrew if necessary.

Turning Counter-Clockwise

This tightens the spring tension and brings

the print surface further away from the nozzle.

TOO CLOSE LEVELED TOO FAR

11

Tinkerine Suite Software Installation

Out with the old and in with the new. The new Tinkerine Suite interface will

streamline all its function on one convenient screen while de-cluttering the

main screen by removing buttons that are not commonly used. From

importing your 3D le to exporting it for your 3D printer, Tinkerine Suite allow

you to have complete control of each le, allowing for multiple item printing,

rotation, and scaling of each individual component.

Supported OS: Windows XP+, Mac OS X 10.6.8 or higher

A.

B.

C.

A.

D. E. F. G.

Import model

H.

E.

Model view

B.

C.

D.

12

F.

G.

H.

Rotate model

Scale model

Slicing settings

Begin slice

Camera view Traying Area

Importing a Model

Importing a model within Tinkerine Suite Software

1

2

3

To import a 3D model, click on the Import icon. In the dialogue box that appears, navigate

to the directory where the model is saved, select the model and Open.

Accepted mesh le formats:

.STL , .OBJ

Pre-sliced:

.GCODE

Multiple les can be imported in at the same time to tray up multiple models on one print tray.

13

Slice Settings

Once you imported a 3D model, select the Settings button from the side bar to open up

the slicing setting.

PROFILE

RESOLUTION

INFILL

WALL

TEMP

SPEED

A - Change resolution settings. Choose from 300, 200, 100, and 50 micron. Default set to Medium - 200.

B - Change Inll percentage. Adjust object density, default set to

C - Filament Diameter. Input the diameter of your lament. Use of a digital caliper is recommended.

D - Change Wall amount. Adjust the wall amount or thickness on your model. Default is set at

E - Toggles Brim support. Activating Brim will add a ring to the base edge of your print.

D L DP

10% 1.75

1

220 HotendC

70mm/s

FILAMENT

BRIM

SUPPORT

ANGLE

Ditto™Pro 3D Printer

Medium: 200 micron

Off

ExtOnAll

Off

50

10%

2.

F - Temperature settings for the Hotend. Recommended hotend temp -

G - Change the speed of the printer. Recommended amount: 60-70 mm/s

H - Toggle switches for activating Support and Support Angle setting.

14

220-225C°

Exporting a File

To export the model, press the Slice button on the side bar. This will begin the

export process which generally takes a couple of minutes depending on the size of

the model.

Once slicing is completed, use the dialogue box to save the .GCODE le onto a

SD card or le directory on your computer.

15

Model Rotation

Sometimes when you import a model it may not be facing the right way, with the

rotate tool, you can adjust the rotational angle on each individual axis. In the rst

image, you can see that the vase is lying on its side. Since we want to print it with

the at base as the bottom, we'll use the Rotate Tool to correct this.

16

Model Rotation

Once the Rotate tool is activated, three rotational rings will envelope the 3D model, each

individual ring will allow you to control one of the three rotational axis (X,Y,Z). In this example, we

rotated the Y-axis ring to bring the model upright. To rotate, click on the axis you wish to wish to

rotate on, hold down your left mouse button and drag until you are satised with the angle. You

can also hold down your Shift key to rotate in 90 degree increments.

Click on the Reset button to reset the orientation back to the model’s imported state.

17

Model Scaling

When importing in an oversized model that exceeds the printer’s print volume, the model will be

shaded in gray. We can utilize the Scale Tool to adjust model sizes bigger or smaller.

To scale uniformly, click on the scaling node (grey) and drag your mouse left or right until the

model is at your desired size.

18

Model Scaling

UNIFORM

SCALING

RESET

C

D

A

B

100% 100% 100%

WIDTH DEPTH HEIGHT

74.5 64.2 54.8

mm mm mm

A Percentage Control

Scale the model using % scaling. Regardless of the original measurement, the model is

set to 100% scale when you rst import it. Double the original size by typing in 200% or

shrink the original size by half when you change the number to 50%. With the Uniform

Scaling Lock in place, changing one axis will affect all other axes and prevent the model

from being distorted.

B Measurement Control

Scale the model using precise measurement input (in mm). Select either the Width, Depth,

or Height measurement control and change the numbers by typing your new measurements in. Changing the measurement while the Uniform Scaling Lock is in place will scale

the two measurements in relation to the rst.

C Uniform Scaling Lock

On by default, the Uniform Scaling Lock will prevent scaling of object on a single axis. So if

the Width was increased by 50%, the Length and Height will also increase by 50%. You

can toggle this function On or Off by clicking on the lock button.

D Reset Scaling

Made a mistake? No worries. Clicking on the Reset button will reset any transformation

applied to the model and resize it to its original scale.

19

Slicing Settings Explained

Resolution

Change resolution settings. Choose from 300, 200, 100, and 50 micron. Default set to

Medium - 200 (0.2mm per layer). Printing at a lower resolution (300 micron) will allow for a

faster print, while printing at higher resolutions (50 micron) will take the longest, but allow for the

best nish.

Inll

The inll setting adjusts the model’s density, default is set to 10%.

From left to right: 0% Inll, 10% Inll, 20% Inll

Filament

Input the diameter of your lament. Use of a digital caliper is recommended. If you are using

Tinkerine PLA lament and do not have a caliper on hand, set to 1.75 mm.

Wall

Changes the thickness of the wall that make up the outer surface of the model. Default is set

at 2.

From left to right: 1 Wall, 2 Wall, 3 Wall.

20

Slicing Settings Explained

Support

Activate support when you have steep angles or overhanging structures on your model; there

are two modes of support:

Ext Mode (Builds support on the exterior of the object): This mode is useful when you don’t

want support structures in every nook and cranny of your model, and only on the exterior

where it’s easier to remove.

All Mode (Builds support everywhere it needs): This mode of support will print structures

everywhere it is needed, which is useful when you have several overhanging points at different

areas of the print.

Support: ALL

Angle: 30 Degree

In this example, support setting is set to ALL. Thus, support structure is printed for both tiers of

the overhanging roof. Since the angle threshold is set to 30 degrees, supports were also

generated for the angled piece on the right side of the image (not required).

Support: ALL

Angle: 85 Degree

In this example, support setting is still set to ALL, but the angle is set to 85 degrees now. This

means that support will only be generated for the overhanging roofs but not the angled portion

of the model. Since the angle is well within the printer’s capabilities, it will print out just ne

without the need for support pillars.

Support: EXT

Angle: 85 Degree

In the nal example, the support setting is turned to EXT mode. This means that although

support structure is required for both levels of the overhanging roof, only the bottom one will

have supports printed for it. In this mode, the base of the support structures will never be in

contact with the printed model.

21

Model Rotation

Speed

This sets the printing speed of the printer. Recommended speed range is 50-70 mm/s for best

printing quality.

Temperature

This sets the temperature to which the hotend heats up to. For Tinkerine 1.75 PLA lament, set

the hotend temperature to 215-220 degrees Celsius.

Brim

Turning on the Brim printing feature in the settings menu will add a one layer brim to the edges

of your printed model . This is useful for countering the lifting effect on the corner of your prints

and will also provide better adhesion to the print surface. Brim can also be added to support

structures for more stability.

22

Measuring the Filament Diameter

Measuring the lament diameter with a digital caliper and inputting that information into Tinkerine

Suite will allow you to achieve the best quality from your prints. Follow the steps below to measure your lament.

1. Make sure to zero your caliper in its closed

position before you start. Take your caliper to a

section of the lament and lightly pinch the

lament and take a reading. In this case, the

lament diameter is 1.73 mm.

2. Move down on the lament to take a second

reading. Here we have 1.74 mm.

3. Finally, move to a new section on the lament

and take a third reading. Here we have 1.72 mm.

4. With the readings you have gathered, nd

the average by adding the three numbers and

dividing by three.

(1.73 + 1.74 + 1.72) / 3 = 1.73mm

The nal number that you end up with will be

the number you want to set in Tinkerine Suite.

23

Updating Printer Firmware

From time to time, you will want to download the rmware updates for your Ditto™Pro 3D Printer.

These updates will aim to address overall printer performance and specic software usability

issues. Follow the steps below to update your printer rmware.

1. Take the USB wire included with your

printer and connect the USB B end to the

back of the printer. Your printer does not need

to be turned on to perform a rmware update.

2. Connect the other end into a USB slot on

your computer.

3. Launch Tinkerine Suite. From the top menu

bar, select Expert > Install custom rmware

4. Select the rmware le you have downloaded for your printer.

24

Updating Printer Firmware

5. Allow the rmware to upload to the printer.

Do not disconnect the cable at this time.

6. All done! Click Ok to close the window and

you can now disconnect the USB cable from

the printer and computer.

25

Troubleshooting

Printing Issues

ISSUE SOLUTION

Cannot insert lament into the Ditto™Pro 3D

Printer extruder.

Cannot remove lament from the Ditto™Pro 3D

Printer extruder.

No molten lament is coming out from the

extruder nozzle.

There are skip lines / missing gaps along the

layer of the print.

Remove the lament, trim off the tip off the lament with a pair of

scissors and try loading the lament again.

With one hand, grab the end of the lament and insert it into the

extruder. Using a pinching motion with your other hand, grab the

extruder and press down on the lament tensioning button to allow

the lament to feed through the drive gear. The lament should

thread through and feed into the hotend.

Use the change lament wizard found on the LCD control. Allow the

printer to heat up, extrude some lament and retract the lament

out of the extruder.

Alternatively, manually toggle the hotend preheat through the LCD

menu. Once the hotend has heated up, manually push the lament

down to extrude the lament and then pull the lament out.

Retract and insert the lament again. Make sure the lament is fully

inserted into the hotend. Also make sure the lament spool is free of

tangles and knots that may prevent the extruder from feeding.

The drive gear teeth may be dirty from use over time. Remove drive

gear and clean with a brush. Re-position the drive gear on the

extruder motor so it aligns correctly with the lament channel and is

tightened.

Print is not sticking onto the print surface; peels

off during printing.

Ensure that the software extrusion temperature is above 215 degree

Celsius. Lower than normal extrusion will cause additional back

pressure to the hotend, leaving the print surface with gaps.

Ensure that printing speed setting in Tinkerine Suite does not

exceed the rate in which the lament can be melted. Printing at

speed between 100-120mm/s is considered high and may affect

the quality of large surface on prints.

Build platform needs to be re-leveled. Make sure that the rst layer

of the print adheres to the print surface slightly at and consistent.

This will prevent the print object from peeling off mid print.

Use isopropyl alcohol to clean off dirt and oil off the blue tape.

Replace section of the tape if it’s damaged. Ensure that the tape is

applied wrinkle free and edge-to-edge to prevent a uneven surface.

Turn on ‘Brim’ in the slicing software to add a printed border on the

base of your models. This is especially helpful for prints that have

multiple small isolated sections on the base layer.

26

Troubleshooting

Printer Issues

ISSUE SOLUTION

Prints do not stick to the bed despite using the

bed-leveling wizard.

Hard to remove the print from the print surface. For large prints, remove the bed clips securing the glass build

X/Y/Z axis homes abruptly during printer or

printing stops before completion.

The bed-leveling wizard will serve as a good reference point to

which to level your bed. Depending on the accuracy of the calibration, you may need to make micro adjustments once the printer

begins a print.

As the printer begins a print and extrudes the outer skirt of the

model, check to see if the skirt is sticking rmly onto the blue tape.

If the lament seems bead-like, adjust the thumbscrew closest to

the affected area cclockwise to bring the distance of the print

surface closer to the nozzle.

surface and place it down on the at surface. Use a thin metal palette

knife and nd a corner edge of the print to wedge the knife under.

Slowly repeat this process around accessible areas on the model.

Once the knife is mostly under the printed object, twist the knife and

use the leverage to pop the print object off the build surface.

The le being printed may be improperly combined or manifolded

within the modeling software. Correct within source software or use

a model repair software. Check for structural defects within the

slicing software by using the layer viewer after slicing.

Corrupted SD card. Reformat the SD card to FAT format and

re-save the GCode le onto the SD card.

27

Troubleshooting

Software Issues

ISSUE SOLUTION

Printer driver not recognized when connected to

the computer.

Imported a model into the Tinkerine Suite slicing

software but cannot slice and export.

Install the Tinkerine Suite slicing software to obtain the required

drivers for the printer connection.

To install the drivers manually, navigate the Tinkerine Suite slicing

software directory:

C:/Program Files(x86)/Tinkerine Suite/drivers/

Run dpinst32 or dpinst64 depending on if the computer is running a

32bit or 64bit OS.

Scale any oversized model within the Tinkerine Suite slicing

software down to not exceed the build volume. Oversized models

will be shaded in grey.

28

Printer Care and Maintenance

Filament Care

INSTALLING THE SPOOL:

Rest the spool on the spool holder on the back of the printer. Make sure

the spool will spin clockwise as the lament feeds into the guide tube.

WHEN NOT IN USE:

Retract the lament and coil back onto the spool. Thread the loose

end through any of the holes to prevent the lament from tangling.

29

Printer Care and Maintenance

Gantry Linear Bearing + Rod Lubrication

BEFORE YOU BEGIN:

Only use machining oil on the X+Y axis smooth rods and linear bearings. Grease based lubricant can seize and damage

linear bearings.

Apply a single drop on each of the smooth rods and manually move the carriage around so the machining oil can seep

into the linear bearings and bushings.

30

Printer Care and Maintenance

Screw Rod Lubrication

APPLYING GREASE:

1. Grasp both sides of the build platform and push it up or downward to expose as much of the threaded rod as

possible.

2. Clean off the rod by wiping off excess grim and dirt with a cloth.

3. Apply PTFE-based grease onto the threaded rod with a lint-free rag or your nger. Even out the application and

make sure to get the grease into the threads. PTFE-based grease can obtained at most hardware stores or online

retailers.

31

Printer Care and Maintenance

Drive Gear Cleaning

Overtime, lament bits may accumulate in the drive gear’s teeth, causing the gear to lose grip on the lament. In this

situation, we will need to remove the drive gear from the extruder and clean off the lament debris.

With a 1.75mm hex key, insert it from the top of the extruder cap and rotate the motor shaft to line up the set screw

with the hex key. Rotate counter-clockwise to loosen the set screw and pull out the drive gear from the motor shaft.

With a razor or a brush, remove any lament debris from the drive gear teeth, taking care not to damage any of the

teeth. Once the gear is cleaned, slide it back onto the motor shaft and line up the groove with the bearing. Make sure to

also tighten the set screws down on the at edge of the motor shaft.

Top Down View

BEARING

DRIVE GEAR

32

Hotend Replacement

Before You Begin

Hotend swaps are performed to replace a hotend that is fully/partially jammed. A partially jammed hotend will affect the

print quality and leave striations on the print surface. Go through the checklist below to see if there may be other issues

before resorting to a hotend swap.

DRIVE GEAR:

Ensure the drive gear’s lament channel is clean and free of lament shavings (1). The drive gear should also be aligned

with the tensioning bearing (2) and properly tightened down on the at edge of the motor shaft.

MANUAL EXTRUSION:

Detach the lament guide tube to reveal a portion of the lament. Heat up the hotend and manually feed the lament

into the extruder. If the molten lament emerges from the tip of the nozzle and quickly curls upward (3), the hotend may

be partially jammed.

1

2

3

SLICING SETTINGS:

High speed or resolution settings may over-work the extruder motor and heater cartridge causing the printed surface to

have missing gaps and other imperfections.

A. Resolution - Lower resolution (300 micron) requires a higher lament ow rate. Keep printing temperature above 220

degrees Celsius and print speed under 80mm/s.

B. Speed - Under default resolution, the recommended printing speed is between 60mm/s - 80mm/s.

C. Temperature - Temperature defaults at 220 degrees Celsius, and should not exceed 230 degrees Celsius.

33

Hotend Replacement

MAKE SURE TO REMOVE ANY FILAMENT IN THE

HOTEND AND ALLOW THE HOTEND TO COOL

DOWN BEFORE PERFORMING THE SWAP.

Hot Surface.

Allow to cool before servicing.

Pinch Point.

Keep hands and fingers clear.

Electric Shock Hazard.

This equipment is to be serviced

by trained personnel only.

1

Unscrew the two screws from the top of the carriage

that secures the hotend mount.

34

2

Loosen the three screws from the left side of the

carriage that secures the hotend blower fan. The

screws can remain attached to the blower fan, we

just need access to remove the outer fan cap.

Hotend Replacement

3

Move the right print bed cooling fan to give enough

clearance to the hotend. Pull down on the hotend and

retract the unit out of the seating.

35

4

With the hotend still attached to the thermistor and

heater cartridge wire, swing the hotend around the

backside of the cooling fan panel to expose the wires.

Hotend Replacement

5

Using the 1.75mm hex key, loosen the heater

cartridge set screw located on the back of the hotend

heater block.

36

6

With the setscrew loosened, remove the heater

cartridge from the hotend.

Hotend Replacement

7

Remove the thermistor from the heater block by

unscrewing the bronze setscrew by hand.

37

8

Take the new hotend unit and screw the thermistor

back into the heater block by hand. Avoid screwing in

the thermistor setscrew with tools to prevent causing

damage to the thermistor bulb.

Hotend Replacement

9

Insert the heater cartridge back into the right side of

the heater block. Orientate the heater cartridge wires

so they point toward the back of the extruder.

38

10

Use the 1.75mm hex key to tighten the setscrew that

secure the heater cartridge in place.

Hotend Replacement

11

Carefully thread the cooling fan panel in between the

heater cartridge and thermistor wire.

39

12

Once the components are in place, the thermistor

wires should go around the back of the hotend heater

block, and both wires from the cartridge and thermistor will come under and out from the cooling fan

mount.

Hotend Replacement

13

Insert the hotend mount back into the carriage.

40

14

Insert both hotend mount screws in. You will need to

push from the bottom of the hotend mount to align

the mounting holes.

Hotend Replacement

15

Tighten both mounting screws.

41

16

Screw all three blower fan mounting screws back into

the panel. Ensure the wiring is routed as shown in the

picture and obstruction free during printing.

Glossary

BLUE TAPE:

Blue painter’s tape that acts as an adhesion layer for models

to be printed on. Find blue tape at your local hardware store.

Recommended: ScotchBlue™ Painter's Tape Original Multi-Use 2090

BRIM:

A printed plate attached to the base layer of the model often

used to stabilize small parts or isolated sections of a model.

BUILD PLATE:

The at sheet of glass that the blue tape is applied to. This is

the surface where the printer prints on.

BUILD PLATFORM:

Support platform for the build plate. The plate includes

thumb screws for adjusting the bed level.

CONTROL DIAL:

Rotary + push dial located to the right of the LCD screen.

Rotate the dial to scroll through options and push down on

the dial to make a selection.

FILAMENT GUIDE TUBE:

A plastic tube that acts as a channel for the PLA lament to

go from the spool into the top of the extruder.

FILAMENT SPOOL HOLDER:

Hinge located on the back of the printer to load a spool of

PLA lament.

FIRMWARE:

Control software for the printer. New rmware version can be

upload via the USB connection cable.

GANTRY:

Gantry assembly (X and Y axis) is responsible for the carriage

movement.

.GCODE / .G:

The format of print les for your Ditto™Pro 3D Printer.

Print le contains gantry movement and extruder instructions .

CONTROL MENU:

Main selection menu from the LCD screen. Options include:

print, temperature settings, printer control, operation wizard,

and printer status.

DRIVE GEAR:

A teethed gear attached to the extruder motor shaft responsible for feeding the lament into the hotend.

ENDSTOP:

Mechanical switch for the home position of the carriage on

three axis.

EXTRUDER CARRIAGE:

The extruder carriage houses the extruder assembly component and is attached to the X and Y axis for movement.

EXTRUDER NOZZLE:

Top of the hotend with a 0.34mm orice to extruder molten

lament onto the print bed.

HEATER BLOCK:

Metal block that gets heated by the heater cartridge to heat

the hotend nozzle. The block is insulated by ceramic tape for

temperature stability.

HEATER CARTRIDGE:

A industrial heating element used to heat up the heater block

in order to melt lament passing through the melt zone.

HOTEND:

Active part of the printer that melts the lament. Allows a

strand of molten plastic to exit from the nozzle tip (0.34mm).

PLA FILAMENT:

Biodegradable polymer that can be produced from lactic

acid. PLA is harder than ABS, but melts at a lower temperature (around 180°C to 220°C).

RESOLUTION:

Resolution settings within the slicing software that determine

the layer height for each print. Ranges from 50-300 Micron.

42

Glossary

SD CARD READER:

Located on the front panel of the printer. Load your sliced

model les onto the supplied SD card and insert it into the

reader slot. Select a le from the LCD menu to start a print.

SLICING:

The process of exporting your 3D models into a 3D print

ready le for your printer. Print ready les will be denoted

with the extension .G / .GCODE.

.STL:

A widely used le format for rapid prototyping, 3D printing,

and computer-aided manufacturing (CAD). STL is support

by many 3D model creation softwares.

SUPPORT MATERIAL:

Software generated printed support structures that hold up

any sections of a print that will not stand alone.

THERMISTOR:

Temperature dependent resistor used to monitor temperature readings of the hotend.

USB CABLE:

The printer comes with a USB A to B cable that connects

the printer to the computer for rmware updates.

X-AXIS:

Axis responsible for the left to right movement in the gantry.

Y-AXIS:

Axis responsible for the front to back movement in the

gantry.

Z-AXIS:

Axis responsible for the up and down movement of the

build plate.

43

Loading...

Loading...