Tim Sistem NORTH HYDRO User Manual

TABLE OF CONTENS

Warning before use 4

Description of the cooker 5

Technical data 6

Installing the cooker 7

Disadvantages of the chimney 8

Ignition and lighting 9

Handling the cooker operation 11

Authomatic regulation of stove’s operation 12

Installing the cooker into the sistem for water heating 13

Installation on closed central heating system 13

Installation on opened central heating system 15

Cleaning and maintenance 17

General recommandation 18

Advices for environment protection 19

2

Dear Customer,

We appreciate your trust wested in us and decision to use TIM SISTEM product.

You have invested in energy-efficient and high-quality product - NORTH HYDRO wood

burning cooker.

Your purchase will provide you long-term clean and comfortable heating with minimal

maintenance.

Please read these instructions carefully and completely.

It’s purpose is to inform you about the installation, operation and maintenance of your stove.

Keep it handy and refer to it as needed. You will find in it information that will be useful now

and in the years to come.

Make sure that when installing the stowe all security standards have been respected and

that all gas pipes, connections between tubes and pipes and walls are connected properly.

Disregarding these standards and negligence during installation can damage your property

or put your health and life in danger!

Set your cooker to a safe place, away from the frequent passages and doors, somewhere

near chimney and chimney connection.

We wish you manypleasant moments with NORTH HYDRO.

TIM SISTEM d.o.o.

3

WARNING BEFORE USE

To keep your cooker working properly, it is important to read this manual and strictly stick to

the instructions for use and handling.

For combustion use solid fuels such as wood and wood briquettes. It is forbidden putting

explosive devices and materials combustion chamber or the limited thermal furnace. It is

forbidden to keep flammable materials near the stove.

For proper combustion and regular operation of the stove, draft in the chimney should be 1217PA. If the draft is greater than 17Pa, the regulatory valve should be installed in the chimney.

Room where the cooker is positioned must be vented regularly because of the fresh air

needed for combustion.

Some parts of cooker heat up during operation and it takes appropriate precaution when

handling it. Do not allow children to handle and play near the cooker.

Only spare partes reccomended and allowed by the manufacturer should be installed on the

cooker. You must not make any changes on the cooker.

During the first firing there might show a lighter smoke, especially from the plate’s surface. It

is a common appearance that occurs due to combustion deposits on the plate’s

surface(corrosion protection, paint, dust, ....). The room where the cooker is should be vented

during the first firing.

It’s not reccomended connecting the cooker to the common chimney because it can

adversely affect the required draft.

Device that uses gas as fuel must not be connected to same chimney.

During firing, use protection gloves because the door handles get heated.

National and local regulations for the installation of the furnace must be respected.

In a case of non-copliance with instructions given in this manual, manufacturer does

not take any kind of responsability for caused damage.

4

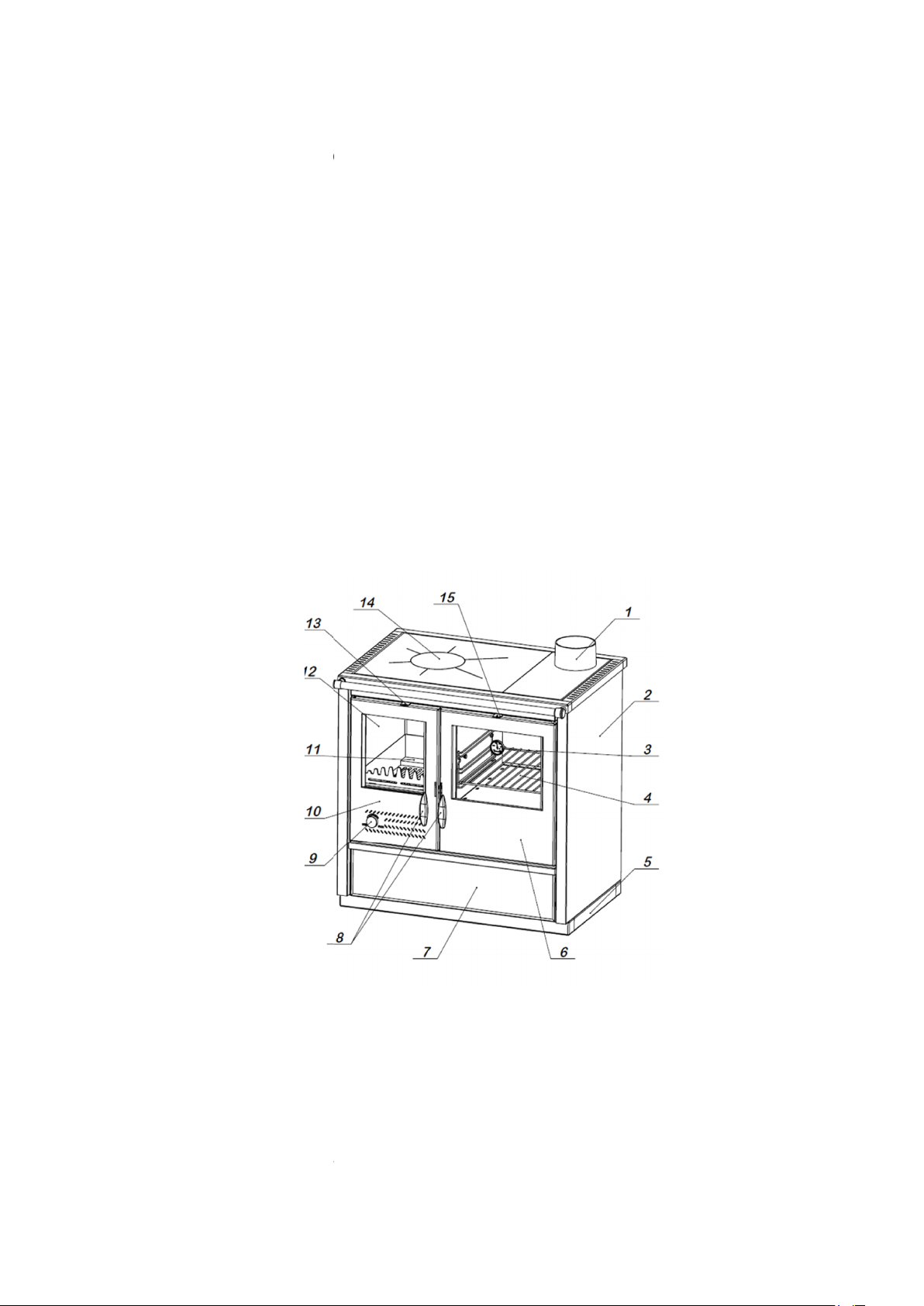

DESCRIPTION OF THE COOKER

HYDRO

EN 12815. On the figure 1 is shown the appearance of the stove with all it's components

HYDRO

plates, tickness prescribed by standards. This kind of a manufacture prolongs life of the

boiler. Water connections are 1.

Working surface of the cooker is made of a tin hotplate (figure 1, position 14) with a cast

smoke drain connection (Figure 1, pos

two screws. Firebox door (Figure 1, position 10) are made of tin, with interior thermosetting

The sealing elements are made of materials that do not contain asbestos.

8. Handles

9. Regulation of primary air (Rathgeber)

10. Firebox

11. Firebox door

12.Boiler

13. Secondary air lever

14. Hot plate

15. Draft regulation

manufactured and tested according to European standard

has a boiler (figure 1, position 12), 16l volume made of boiler

ition 1) which is installed on the cooking surface with

Figure 1

Storey stove NORTH

important for handling.

Storey stove NORTH

tin-

transparent glass.

Components:

it’s

1. Smoke drain

2. Lateral side

3. Thermometar

4. Oven

5. Stand

6. Oven door

7. Drawer

lever

5 6

3

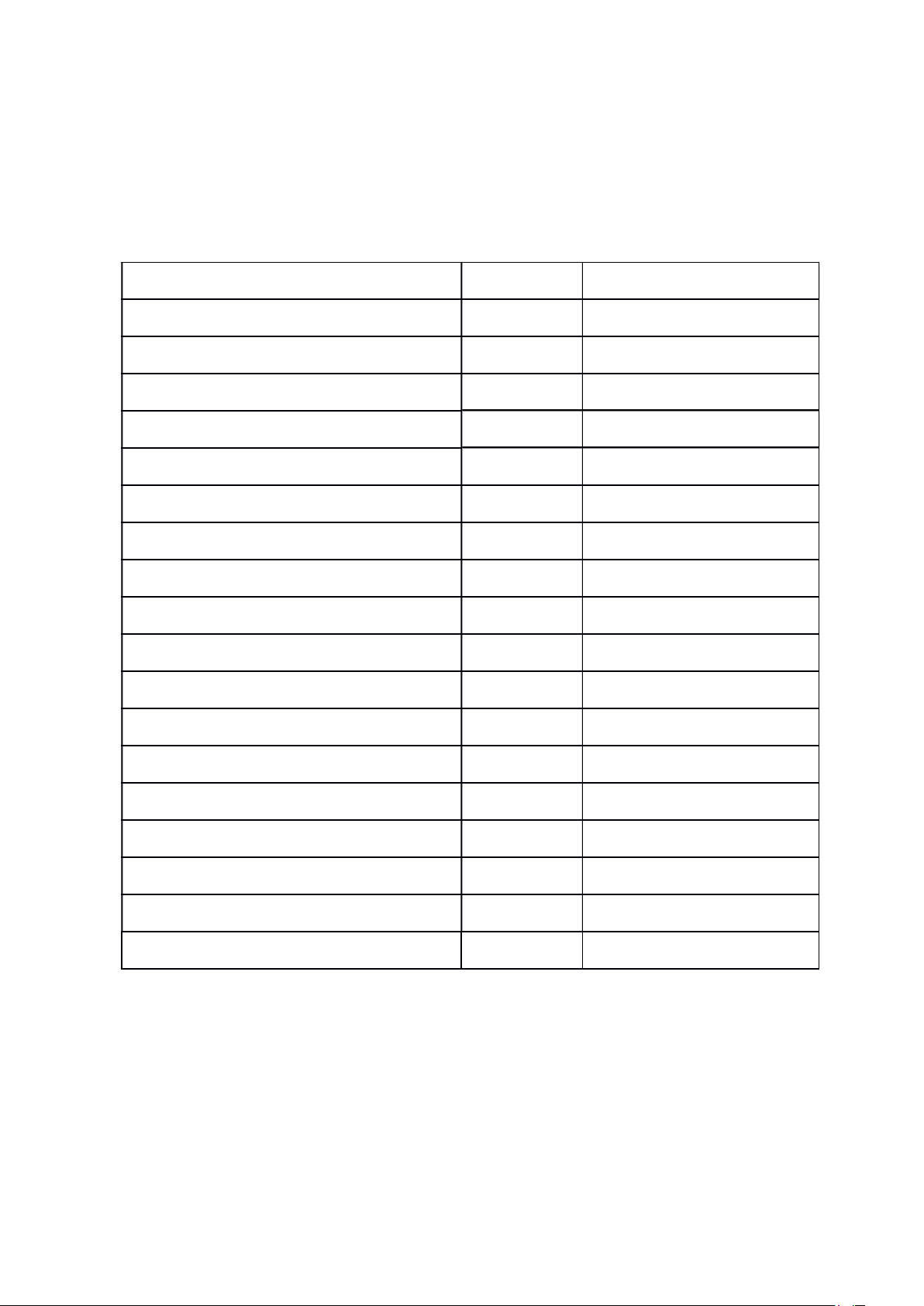

TECHNICAL DATA

Fuel Wood, wood briquet

Nominal power kW 16

Efficiency % 85

Thermal power delivered to water kW 7,2

Thermal power delivered to room kW 8,3

Dimensions of the cooker WxLxH mm 900 x 600 x 850

Dimensions of the fire place WxLxH mm 290 x 450 x 270

Dimensions of the oven WxLxH mm 350 x 740 x 295

Weight kg 153

Minimum distance from flammable materials

Back mm 500

Side mm 350

Front mm 600

Content CO (reduced on 13% O2) mg/Nm

Chimney connection mm 150

Chimney connection position Top right-left, Rear right-left

Consuption by nominal power kg/h 3,8

Emission temperature °C 162

Required draft Pa 10-14

4271

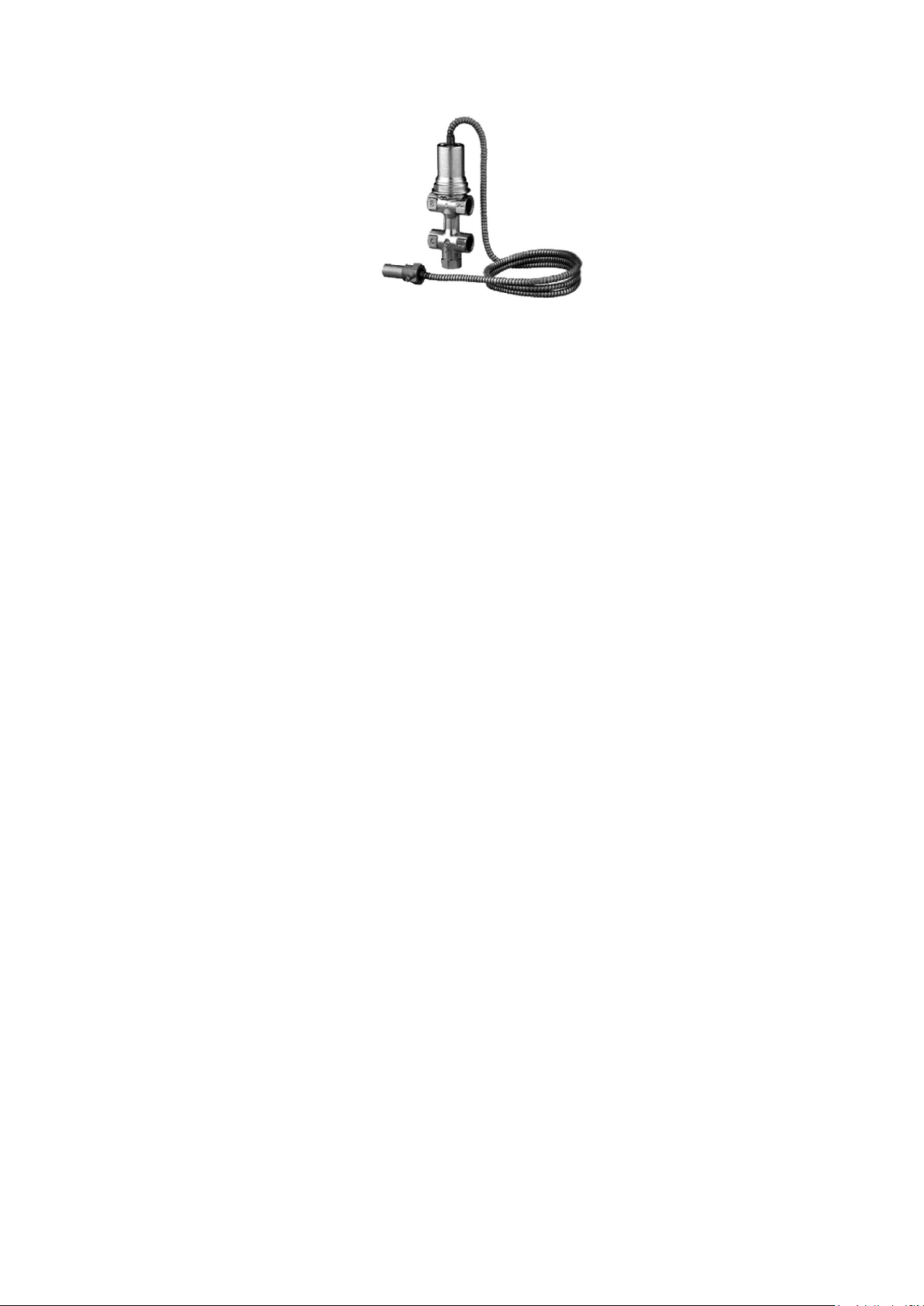

Storey stove is made for heating residential premises, cooking and baking. An integral part of

the installation is thermal drain valve that serves as a thermal fuse of a possible overheating.

The recommended thermal fuse is Caleffi 1/2 544, shown in Figure 2.

Note: The thermal fuse is not part of the product and it's not supplied with the product. The

guarantee is valid only if the termar fuse gets installed into the boiler.

Figure 2: Termal fuse Caleffi

INSTALLING THE COOKER

Cooker must not be set up near the wooden parts, refrigeration parts, plastic furniture and

other flammable materials because during operation (during fuel combustion) it achieves

high operating temperature that is distributed on the outside of the furnace. Minimum

distance between the stove and the surrounding elements is 50 cm, and the from flamable

materials 80 cm.

If the ground on which you set the cooker is made of easily flammable material (wood, warm

floor, laminate ...) you need to set under the cooker a protetion sheet metal - lateral width of

10 cm and 50 cm in the front.

Because of it’s weight, the cooker must be installed on the appropriate base. If it does not

satisfie necessary standard, you must take appropriate measures to make it possible (eg,

weight distribution).

Connect the cooker to a chimney and flue pipes through the connector on top of the furnace,

so as to ensure adequate tightness and flow of smoke from the stove to the chimney. Flue

pipe must not be drawn too deeply into the chimney that would reduce the cross sectional

area and thus undermined draft in the chimney. Do not use reducers which reduce the cross

section of pipe smoke.

NORTH cooker requires insertion of fresh air in the room where it is installed, with surface

openings for insertion of fresh air should not be less than 0.4 dm ². The unit for fresh air set

outside the common room for ventilation, which must be insured by door and gride.

Fans that work in the same room where the cooker is installed may make interference wit the

the cooker. Also, all devices or ventilation that creates negative pressure in the room where

the cooker is installed, must be set in the way that does not make decompression that

prevents normal operation of the furnace.

Before installing the cooker, check the chimney drafts because it is a key factor in the proper

functioning of the cooker. Draft depends on the proper opration of the chimney and

meteorological conditions. One of the easiest ways to check the draft in the chimney is with a

7

Loading...

Loading...