Tim Sistem NORTH Owner's Manual

NORTH

Owners’s manual

INSTALATION, ADJUSTMENT AND OPERATING INSTRUCTION

EN 12815

Page 2

Dear Customer,

We appreciate your trust wested in us and decision touse "TIM SISTEM" product.

You have invested in energy-efficient and high-quality product - NORTH wood burning cooker.

Your purchase will provide you long-term clean and comfortable heating with minimal maintenance.

Please read these instructions carefully and completely.

It’s purpose is to inform you about the installation, operation and maintenance of your stove. Keep it handy

and refer to it as needed. You will find in it information that will be useful now and in the years to come.

Make sure that when installing the stowe all security standards have been respected and that all gas

pipes, connections between tubes and pipes and walls are connected properly.

Failure to comply with these standards and carelessness during installation can result in damage to

property or put your health and life in danger!

Set your cooker to a safe place, away from the frequent passages and doors, somewhere near chimney

and chimney connection.

We wish you manypleasant moments with NORTH.

TIM SISTEM d.o.o.

Safety: UL1482 ; ULC-S627

U.S. Environmental Protection Agency

This unit is not a certified wood heater. The primary use for this unit is for cooking and baking.

Tested by: GUARDIAN Fire Testing Laboratories, Inc

gftli@earthlink.net

www.firetesting.com

Imported by: Sopka Inc

www.sopkainc.com

contact@sopkainc.com

Page 3

WARNING BEFORE USE

To keep your cooker working properly, it is important to read this manual and strictly stick to the instructions

for use and handling.

For use with solid fuel only, such as wood and wood briquettes. It is forbidden putting explosive devices

and materials combustion chamber or the limited thermal furnace. It is forbidden to keep flammable

materials near the stove.

For proper combustion, in normal operating mode, draft in the chimney should be 10-12 Pa. If the draft is

greater than 15Pa, the valve should be installed in the chimney.

Room where the cooker is positioned must be vented regularly for the fresh air needed for combustion.

Some parts of cooker heat up during operation and it takes appropriate precaution when handling it. Do not

allow children to handle and play near the cooker.

Only spare partes reccomended and allowed by the manufacturershould be installed on the cooker. You

must not make any changes on the cooker.

With first firing there might show a mild smoke, especially from the plate’s surface. It is a common

appearance that occurs due to combustion deposits on the plate’s surface (corrosion protection, paint, dust

...). The room where the cooker is should be vented during the first firing.

It’s not reccomended connecting the cooker to the common chimney because it can adversely affect the

required draft.

Device that uses gas as fuel must notbe connected to same chimney.

During firing, use protection gloves because the door handles get heated.

National and local regulations for the installation of the furnace must be respected.

In a case of non-copliance with instructions given in this manual, manufacturer does not take any

kind of responsability for caused damage.

Page 4

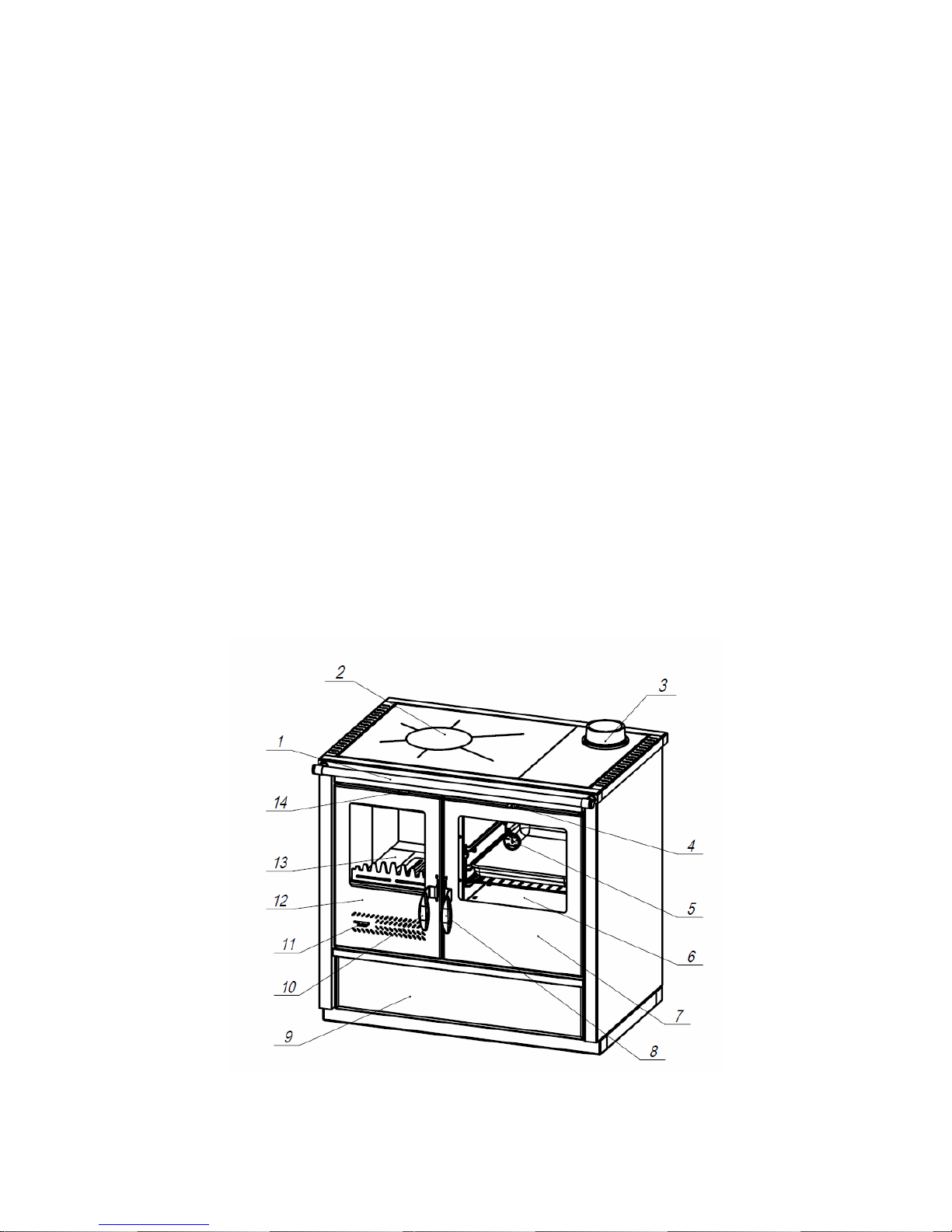

DESCRIPTION OF THE COOKER

North Wood burning cooker is intended to be used for cooking and baking food and it's manufactured and tested

according European EN 12815 and UL1482, ULC-S627, American and Canadian standards.

The upper plate of the fireplace is made of steal.

Firebox doors are made of steal with fireproof glass.

Connection for smoke drainis being put on the plate and connected with screws.

All the materials that NORTH cooker is made can be recycled.

Sealing elements are made of materials that NOT contain asbestos.

Parts of the COOKER:

1. Protection rail 9. Wood drawer

2. Hotplate 10. Firebox door handle

3. Smoke exhaust 11. Primary air regulator

4. Flue gases register 12. Firebox door

5. Thermometer 13. Firebox

6. Oven 14. Secondary air regulator

7. Oven door

8. Oven door handle

Page 5

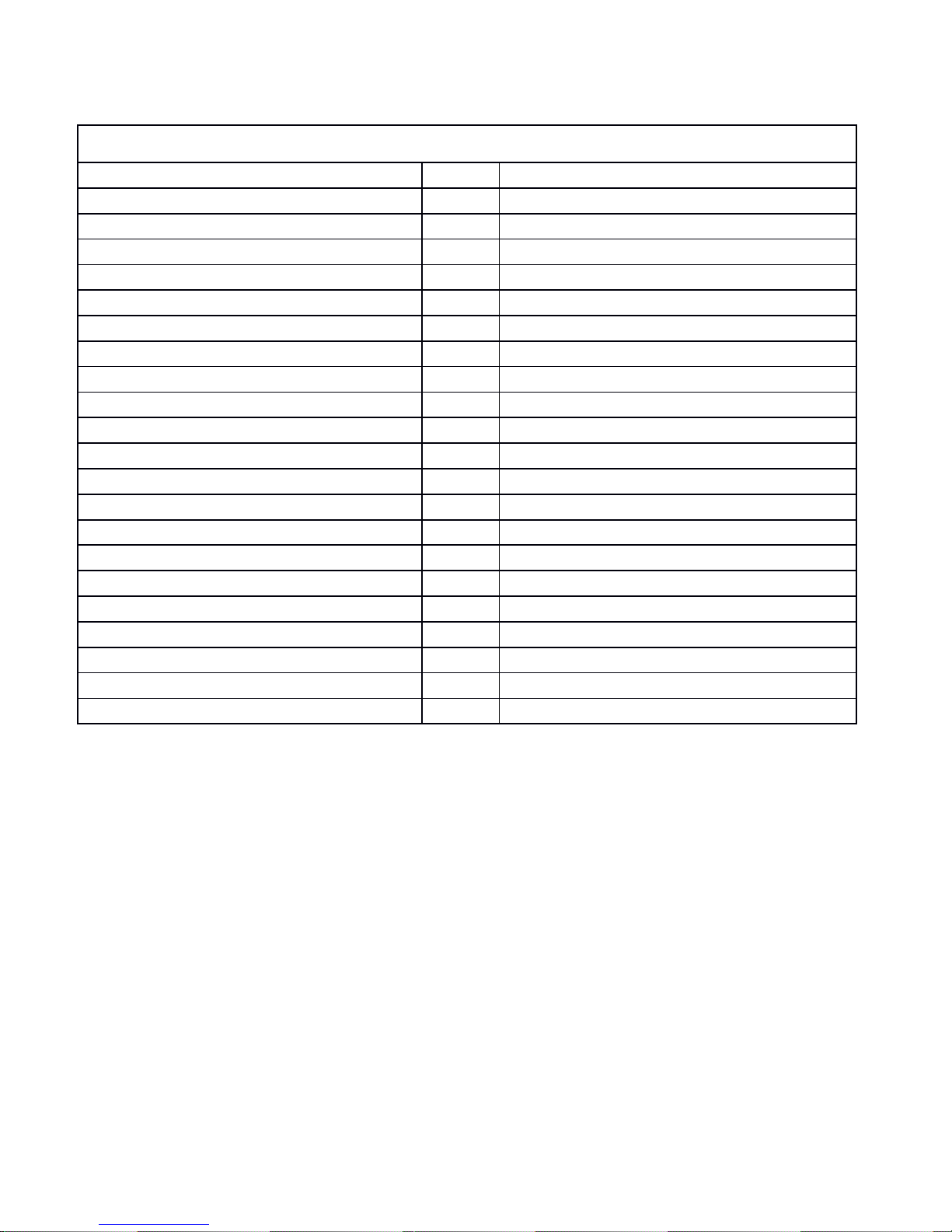

TECHNICAL DATA

Name NORTH

Use

Solid fuel cooker

Nominal power Btu

31,500

efficiency %

84

Fuel

Wood, wood briquets

Dimensions of the cooker W x L x H in

35.5x23.7x33.5

Dimensions of the fire place W x L x H in

11.5x17.7x11

Dimensions of the oven W x L x H in

13.8x18.7x11.6

Weight lbs

265

Minimum distance from flammable materials

Back in

6

Side in

6

Front in

36

Content CO (reduced on 13% O2) [%] %

0,091

Chimney connection in

6

Chimney connection position

Left/right upper plate

Consuption by nominal power kg/h

1,5

Emission temperature °C

239

Air regulation

Primary

Secondary

Required draft Pa/wc

12±2/ 0.040 – 0.057

Page 6

INSTALLING THE COOKER

Cooker must not be set up near the wooden parts, refrigeration parts, plastic furniture and other flammable

materials because during operation (during fuel combustion) it achieves high operating temperature that is

distributed on the outside of the furnace. Minimum distance between the stove and the

surrounding elements is 6”.

If the ground on which you set the cooker is made of easily flammable material (wood, warm floor, laminate

...) you need to set under the cooker a protetion sheet metal or any non flammable floor protector.

Because of its weight, the cooker must be installed on the appropriate base. If it does not satisfie necessary

standard, you must take appropriate measures to make it possible (eg, weight distribution).

Connect the cooker to a chimney and flue pipes through the connector on top of the furnace, so as to

ensure adequate tightness and flow of smoke from the stove to the chimney. Flue pipe must not be drawn

too deeply into the chimney that would reduce the cross sectional area and thus undermined draft in the

chimney. Do not use reducers which reduce the cross section of pipe smoke.

The cooker requires insertion of fresh air in the room where it is installed, with surface openings for

insertion of fresh air should not be less than 0.4 dm ². The unit for fresh air set outside the common room

for ventilation, which must be insured by door and gride.

Fans that work in the same room where the cooker is installed may make interference wit the the cooker.

Also, all devices or ventilation that creates negative pressure in the room where the cooker is installed,

must be set in the way that does not make decompression that prevents normal operation of the furnace.

Before installing the cooker, check the chimney drafts because it is a key factor in the proper functioning of

the cooker. Draft depends on the proper opration of the chimney and meteorological conditions. One of the

easiest ways to check the draft in the chimney is with a candle flame, as shown in Figure 2 . Put a candle

near the chimney connection drain. If the flame bends towards drain, the draft is satisfying (Figure 2b). If

the flame doesn’t bend or bends a little, that indicates poor draft (Figure 2a).

If there is poor draft in the chimney (Figure 2a), check the chimney operation. The chimney should be

located inside the building, and if it’s located on the external walls of the building, it’s recommended

insulation chimney.

Fi

gure 2a. Figure 2b.

Page 7

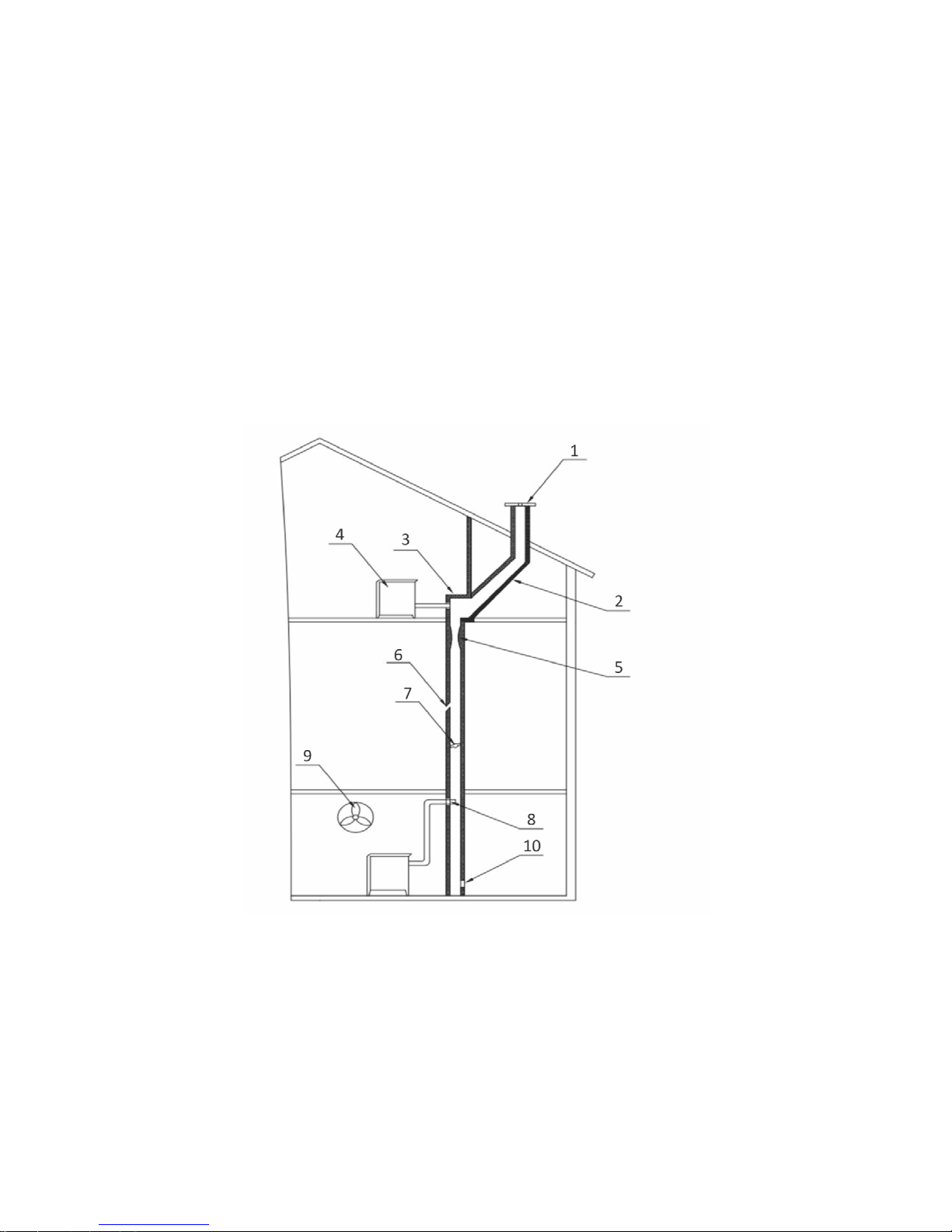

Disadvantages of the chimney (Figure 3): `

1. The chimney is higher than the top of the roof, a small cross section of the output,

2. Excessive slope

3. A sudden change of direction of the flue channel

4. Stove or some other device connected to the same flue channel,

5. Bulges in the flue channel

6. Cracks

7. Alien body or accumulated grime,

8. Tube inserted too deeply,

9. Fan or other device that creates a vacuum in the room

10. Unsealed or opened cleaning hole

Figure 3.

Page 8

IGNITION AND LIGHTING

Before the first firing, wipe all painted surfaces withclean and dry cloth, in order to avoid burning impurity on

the oven and creation of unpleasant smells.

Start the fire in the stoveby following order:

• open the fire door,

• place the fluel into the fire place (chopped wood to non greasy wrinkled paper)

• light a fire

• leave open primary air regulator until the flame gets stable and after

having stabilized the flame,control burning intensity with draftsregulator (Fig. 1, pos. 11)

• secondary air regulator leave opened until the flame gets stable and after

having stabilized the flame, control burning intensity with regulator (Fig. 1, poz.14)

• close the firebox door,

• after creating a basic flame insert larger pieces of wood or briquettesin the firebox, and

close the firebox door. If you use briquettes as a fuel, you must wait that all biquettes are lit and

then reduce the draft in half.

• when adding fuel, (Fig. 1, pos. 12) open the fire door step by step

wait for 4-5 seconds, and then slowly open it wide.

Do not open the doorsuddenly, when there’s a strong flame in the combustion chamber, it may come to it’s

spreaading into the room.

Regulating the draft in the cooker, you can regulate temperature, power and the combustion of fuel, and

this is done by running draft regulator on the firebox door (Fig. 1, pos. 11). Combining primary air through

the regulator onthe firebox door and secondary air over the leverage above the firebox door (Fig. 1, pos.

14) you get desired combustion.

Cooker contains auxiliary tools in order to facilitate its maintenance.

Recommended fuel: cord wood max length 16".

You must not use gasoline and similar fuels, because by using liquid fuels you crate conditions for

damaging the stove and to provoce an explosion.

Page 9

Attention!

• Do not use organic wasteas fuel, food residue, plastic, combustible or explosive materials, which

combustion disturbs the proper functioning of the cooker and may cause damage and environmental

pollution.

• Increased ambient temperature can cause poor air circulation (drafts) in the chimney, and in that case is

recommended more frequent firing in smaller quantities.

• Avoid using the cooker when there are bad weather conditions for the cooker andin the case of strong

wind, because it reflects the required vacuum in the chimney. In these cases there may occure potential

return of smoke in the room where the cooker is placed. Ignition is difficult then.

We recommend firing every hour with the amount of fuel in the combustion chamber up to 15cm with cross

stacking wood for better airflow.

After each refilling, it’s reccomender to leave the oven running in full speed for 30 minutes,in order to

destroy all volatile elements that may cause condesation in the cooker.

Correct cooker operation demands:

- Regular cleaning of the cooker and chimney

- Regular room ventilation for better combustion

- Regular ash tray cleaning

- Accumulated slag and unburned material regularly remove from the grid

WORKING REGIMES

There are four working regimes, which could be selected by adjusting the draught in the cooker.

Combined working regime - working regime in which it could be cooked in the oven, cooked on the top of

the hotplate and heat the room at the same time. It is necessary to push the flue gas register handle

towards the inside of the cooker, move primary air regulator to create medium inlet of the air.

Quick cooking - during this process it is the hotplate heats up intensively and to be able to do that with

small quantity of fuel, draw flue gas register handle completely outside, oven door should be shut and

move primary air regulator to create medium inlet of the air.

Heating for this regime it would be recommended to use wood or coal. If the coal is been used it would

require more frequent firing in order to create the ember which would intensively heat the hotplate of the

cooker. Push the flue gas register handle towards the inside of the cooker, move primary air regulator to

create medium inlet of the air and the oven’s door closed.

Baking for this regime push the flue gas register handle towards the inside of the cooker, move primary air

regulator to create medium inlet of the air and the oven’s door closed after putting the baking pan inside.

Loading...

Loading...