Page 1

Installation Guide

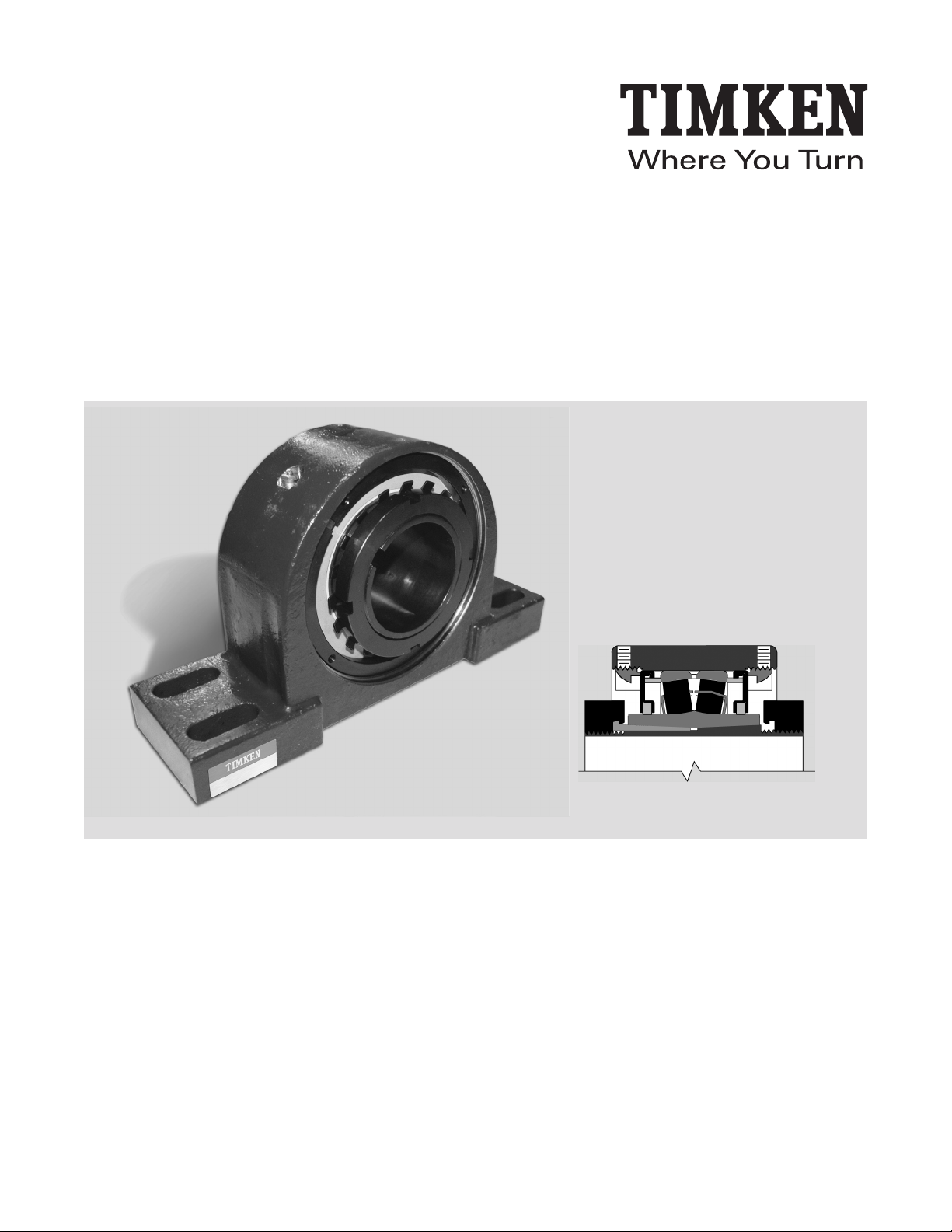

Timken® Spherical Roller Bearing Solid-Block Housed Unit

V-Lock Series

Page 2

Wedge Nut

Wedge

Housing

Insert

Sleeve

Sleeve Nut

*Only supplied with

double-nut units

Setscrews

Double-nut “QVV” Single-nut “QV”

Setscrews

Wedge Nut

Wedge

Housing

Insert

Sleeve

Setscrews

INSTALLATION GUIDE

V-LOCK SERIES, SPHERICAL ROLLER BEARING SOLID-BLOCK HOUSED UNIT

Timken solid-block housed unit V-Lock bearings are easy to install and remove

because of their unique adapters.

Please complete the following steps to install and/or remove Timken steel housed

unit V-Lock bearings. (Refer to fig. 1.)

INSTALLATION

1. Ensure that the shaft is clean, free from nicks and burrs, straight and

of proper diameter. See table 1 for recommended shaft tolerances.

The housed unit should not be mounted on a worn section of the shaft.

Use of shafts with hardness greater than Rc 45 will reduce the

effectiveness of locking devices.

2. If using an open-end cover, slide the open-end cover/seal combination

into position on shaft.

3. Remove the wedge assembly from the sleeve by unscrewing the wedge

nut. See fig. 1.

4. Clean oil off of the sleeve and wedge.

5. Apply a thin oil film to the shaft only.

For QV housed units:

- Slide the sleeve, non-threaded end first, into position on shaft.

For QVV housed units:

- Make sure the sleeve nut is flush with the end of the sleeve.

- Slide the sleeve/nut assembly, nut end first, into position on the shaft.

6. Slide the housed unit into place over the sleeve.

7. Loosely install the housed unit mounting bolts. Check the housed unit

alignment (fig. 2). Verify mounting surfaces are in the same flat plane to

help make sure good alignment is achieved. If shimming is required to

minimize misalignment, use full shims across entire housing base where

possible (fig. 2). Washers should be properly sized to bold diameter and

should not be an SAE grade, which is smaller.

- Seat the sleeve as best as possible into mounted unit.

8. Slide the wedge and wedge nut into the housed unit over the sleeve.

9. Tighten the wedge assembly by turning the wedge nut clockwise until tight.

Please note that it is designed to eliminate over-tightening.

10. If installing double-nut housed unit, tighten the sleeve assembly by turning

the sleeve nut clockwise until snug.

11. Tighten both the wedge nut and sleeve nut set screws alternately

according to table 2.

12. Install the housed unit mounting bolts. Check the housed unit alignment.

Verify mounting surfaces are in the same flat plane to help make sure good

alignment is achieved. If shimming is required to minimize misalignment,

use full shims across entire housing base

where possible (fig. 2). The bolts then need

to be alternately torqued securely to their

mounting supports.

13. Tighten the housed unit mounting bolts.

14. If using covers:

- Make sure the mating surface of cover and

retaining nut are clean and dry.

- If using a urethane cover, slightly roughen the

mating surface of the cover.

- Place a 1⁄8 in. - 1⁄4 in. bead of polyurethane

adhesive sealant on the mating surface of the

cover.

- Align cover mounting holes with the mounting

holes on the retaining housing nut (make

sure that the grease fitting on the cover is

accessible when doing so).

- Apply and tighten cover mounting hardware.

REMOVAL

1. Remove covers, if applicable, by removing

cover hardware and disengaging cover from

housed unit retaining nut.

2. Loosen the setscrews on the wedge nut.

3. Turn the wedge nut counterclockwise to

remove the wedge from the locked position.

4. Completely remove the wedge/wedge nut

assembly.

For QV housed units:

- Remove the bearing and sleeve from the shaft.

For QVV housed units:

- Loosen the setscrews on the sleeve nut.

- Turn the sleeve nut clockwise to un-seat the

sleeve.

- Remove the bearing and sleeve/sleeve nut

from the shaft.

Fig. 1. V-Lock insert components.

Page 3

TABLE 1. RECOMMENDED SHAFT TOLERANCES

TABLE 2. SETSCREW TORQUE VALUES

Shaft Size

in. mm

1 15⁄16

2

2 3⁄16

2 1⁄4

2 7⁄16

2 1⁄2

2 11⁄16

2 3⁄4

2 15⁄16

3

3 3⁄16

3 1⁄4

3 7⁄16

3 1⁄2

3 11⁄16

3 15⁄16

4

4 7⁄16

4 1⁄2

4 15⁄16

5

Bearing

Number

50 22211

55

60

65

70

75

80

85

90

22212

22213

22214

22215

22216

22217

22219

22220

100 22222

110

115

125

130

22226

22228

Tolerance

in.

mm

+0.000/-0.0015

+0.000/0.0381

+0.000/-0.002

+0.000/-0.0508

+0.000/-0.003

+0.000/-0.0762

+0.000/-0.005

+0.000/-0.127

Bearing Size Setscrew Size Torque

in. in.-lbs.

SLV11 TO SLV20

SLV22

SLV26 TO SLV28

washer

shim

3

⁄8 - 24TPI 290

7

⁄16 - 20TPI 420

1

⁄2 - 20TPI 620

Use washers and full shims.

Fig. 2.

washer

shim

TABLE 3. RE-LUBRICATION INTERVALS

Shaft Size

Bearing

Number

Weight

Initial

Relubri-

cation

Weight

100 RPM 250 RPM 500 RPM 1000 RPM 2000 RPM 3000 RPM

in. mm oz. oz. <160° F >160° F <160° F >160° F <160° F >160° F <160° F >160° F <160° F >160° F <160° F >160° F

1 15⁄16

2

2 3⁄16

2 1⁄4

2 7⁄16

2 1⁄2

2 11⁄16

2 3⁄4

2 15⁄16

3

3 3⁄16

3 1⁄4

3 7⁄16

3 1⁄2

50 22211 1 0.3 1200 600 800 400 440 220 160 80 100 50 60 30

22212 1.2 0.3 1150 580 750 380 400 200 140 70 90 50 50 20

55

22213 1.3 0.4 1130 570 740 370 380 190 130 65 85 45 45 20

22214 1.4 0.4 1120 560 720 360 360 180 120 60 80 40 40 20

60

65

22215 2 0.5 1080 540 700 350 350 175 110 55 70 35

22216 2.7 0.7 1040 520 680 340 340 170 100 50 60 30

70

75

22217 3.4 0.9 1000 500 640 320 320 160 100 50 60 30

22219 3.7 0.9 960 480 600 300 300 150 80 40 40 20

80

85

22220 6.5 1.6 840 420 520 260 240 120 70 35 30 18

90

3 11⁄16

3 3⁄4

3 15⁄16

100 22222 7.4 1.9 680 340 440 220 200 100 60 30 20 16

4

4 7⁄16

4 1⁄2

4 15⁄16

5

110

22226 10.6 2.7 560 280 360 180 160 80

115

125

22228 14 3.5 520 260 340 170 140 75

130

Relubrication Interval (Hours of Service Based On RPM and Temperature)

Page 4

LUBRICATION

This information is to aid in the proper lubrication of Timken spherical roller

bearing solid-block housed units for the majority of the applications.

Housed units have been factory prelubricated with an NLGI No. 2 lithium-complex

extreme-pressure synthetic grease that combines the benefits of wide operating

temperatures and broad compatibility with varied materials. This grease offers

excellent thermal stability through temperatures ranging from -40° to 177° C

(-40° to 350° F). Housed units should be relubricated with this grease or one that

is compatible and made for roller bearings. It is vital that the greases used are

compatible. Please consult with your Timken engineer for the grease specifications

if the use of a grease other than the grease mentioned above is needed.

Normal service is considered as operation in a clean, dry environment at

temperatures between -34° C to +82° C (-30° F and +180° F). If service is beyond

normal conditions due to speed, temperature or exposure to moisture, dirt or

corrosive chemicals, periodic relubrication may be advisable. For extreme conditions

or conditions in which special chemicals are used, your Timken engineer should

be consulted.

After extended storage or periods when the housed unit is not in operation, fresh

grease should be added.

It’s important to have the right amount of lubrication because it affects the housed

unit bearing operating temperature as well. An inadequate amount of grease

could lead to higher temperature operation due to inadequate lubrication film

thickness. Excessive grease will lead to higher operating temperatures, due to

grease churning which can cause bearing overheating. It is best to observe the

bearing and its temperature and adjust the lubrication as needed. If necessary,

use the purge valve or seals that purge to reduce the amount of grease.

RELUBRICATION

Adequate lubrication is an essential element to the housed unit bearing life.

Table 3 can be used as a suggested initial point of reference. Relubrication

frequency and quantity intervals are best developed through experience for each

application, based on types of service, which may differ from the suggestions

in the table.

When the housed unit is not in operation for an extended period of time, grease

should be added to prevent corrosion.

Table 3 shows general lubrication suggested starting points only. Please read the

entire installation instructions prior to using these tables. Applications should be

regularly reviewed and lubrication amounts and intervals modified as needed

to assure best results.

Every reasonable effort has been made to ensure the accuracy of the information

contained in this writing, but no liability is accepted for errors, omissions or any

other reason.

NOTE

The average manual grease gun will produce

approximately one (1) ounce of grease per 33

strokes. Please check with the manufacturer

of your grease delivery system for specific

information.

NOTE

Proper maintenance and handling practices are

critical. Failure to follow installation instructions

and to maintain proper lubrication can result in

equipment failure.

Page 5

HOW TO CONVERT A SOLID-BLOCK HOUSED UNIT FROM

FIXED TO EXPANSION (FLOATING)

Flange Cartridge and Flange Block

1. Make a reference mark on the housing and retaining nut.

2. Loosen the Teflon-tipped set screw that locks the retaining nut in place.

3. Loosen the retaining nut by tapping it with a hammer and punch, rotating

the retaining nut counterclockwise one complete revolution.

4. Tighten the Teflon-tipped set screw.

NOTE

When converting a solid-block housed unit bearing from fixed to expansion, it

is imperative that the unit that is going to be converted is correctly oriented.

Since the insert in a housed unit flange housed unit is held against either a

shoulder or snap ring opposite the housing retaining nut, a flange bearing that

has been converted to expansion can only float in the direction of the retaining

nut. Based on this, the retaining nut must be on the side of the housing opposite

the fixed bearing.

Pillow Block

1. Decide the amount and direction of expansion that’s needed. If uni-directional

expansion is required, follow directions outlined in the previous column for

flange housed units on the nut that is on the side you want the expansion.

2. If multi-directional expansion is required, follow the directions outlined in the

previous section for both nuts on flange housed units.

HOW TO CONVERT A SOLID-BLOCK HOUSED UNIT FROM

EXPANSION (FLOATING) TO FIXED

Flange Cartridge and Flange Block

1. Loosen the Teflon-tipped set screw that locks the retaining nut in place.

2. Tighten the retaining nut by tapping it with a hammer and punch, rotating

the retaining nut clockwise until it’s tight. It is not possible to over-tighten

the retaining nut.

3. Tighten the Teflon-tipped set screw.

Pillow Block

1. Follow the directions above for flange housed units on both nuts on either

side of the housing.

NOTE

When converting a solid-block housed unit from expansion to fixed on a mounted

bearing, the locking collar set screws must be released to allow the insert to

move both in the housing and on the shaft.

Page 6

Bearings • Steel •

Power Transmission Systems •

Precision Components •

Gears • Seals • Lubrication •

Industrial Services •

Remanufacture and Repair

www.timken.com

5M 01-12: Order No. 10504

®

Timken

and Where You Turn® are registered trademarks of The Timken Company. • © 2012 The Timken Company • Printed in U.S.A.

Loading...

Loading...