Page 1

Manual Wheel Bearing Adjustment Procedures

The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to .127 mm). This procedure

applies to steer, drive and trailer axle assemblies using conventional double nut or single nut systems on Class 6, 7 and 8 trucks. This refers only

to torque specifications and bearing adjustment. Please refer to the original equipment manufacturer’s recommended procedures for complete

installation details.

NOTE: For single nut self-locking systems, consult manufacturers’ instructions. If you have a system that differs from what is indicated in this

procedure, consult the vehicle manufacturer’s recommended procedure.

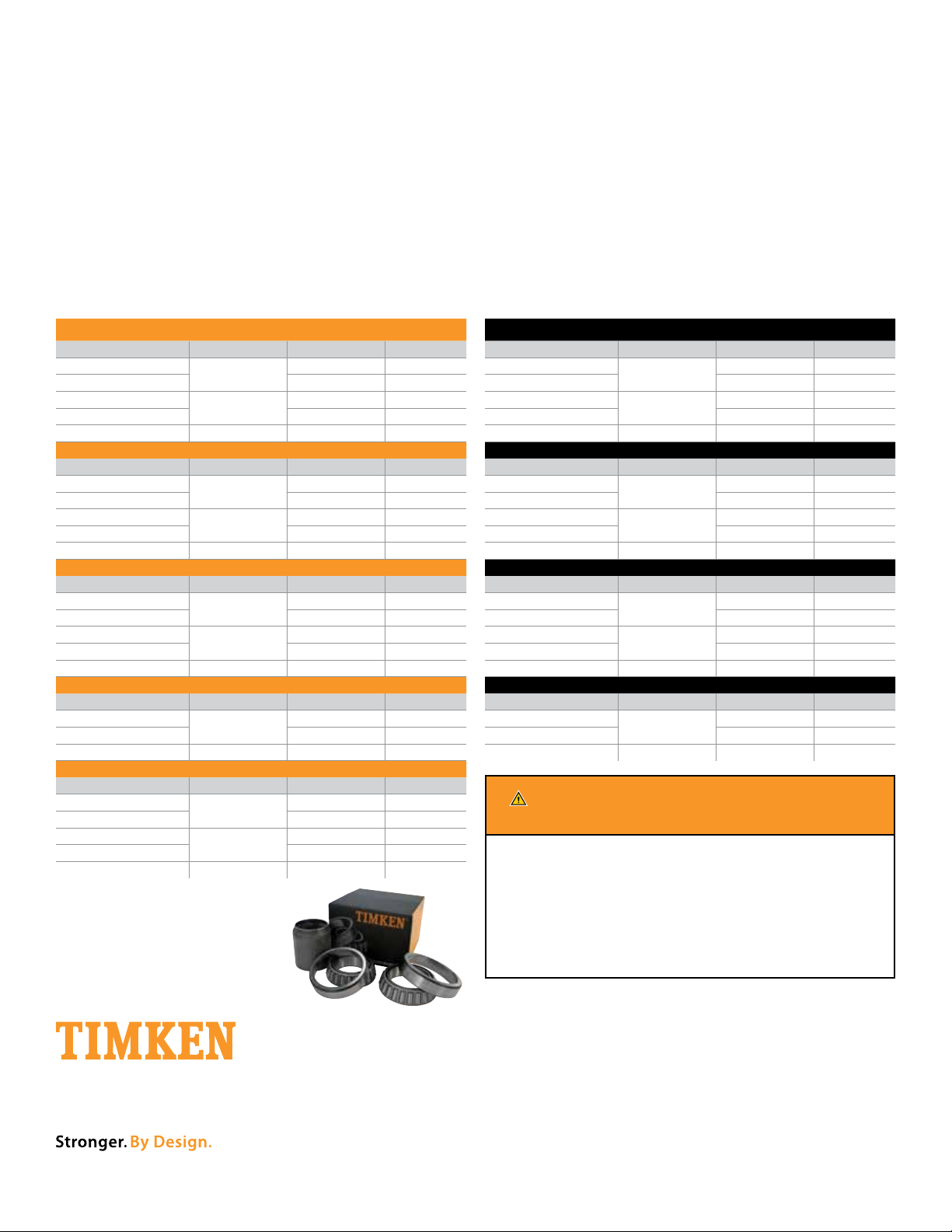

Tapered Roller Bearing Adjustment Procedure RP 618A

Step 1: Lubricate the tapered roller bearing with clean axle lubricant of the same type used in the axle sump or hub assembly.

NOTE: Never use an impact wrench when tightening or loosening lug nuts or bolts during the procedure.

Initial Adjusting

Nut Torque

Step 2 Step 3 Step 4 Step 5 Step 6 Step 7 Step 8

200 lbf•ft

(271N•m)

While

Rotating

Wheel

* If dowel pin and washer (or washer tang and nut flat) are not aligned, remove the washer, turn it over and reinstall. If required, loosen the inner (adjusting) nut just enough for alignment.

** Bendable type washer lock only: Secure nuts by bending one wheel nut washer tang over the inner and outer nut. Bend the tangs over the closest flat perpendicular to the tang.

Initial Back Off

One

Full Turn

Final Adjusting

Nut Torque

50 lbf•ft

(68 N•m)

While

Rotating

Wheels

Axle Type Threads Per Inch Final Back Off Nut Size

1

/6 Turn*

1

/4 Turn*

1

/2 Turn*

1

/4 Turn*

1

/4 Turn*

Install Cotter Pin to Lock

Axle Nut in Position

Less Than

2 5/8”(66.7 mm)

Dowel Type Washer

Less Than

2 5/8”(66.7 mm)

Steer

(Front)

Non-Drive

Drive

Trailer

12

18

12 1/3 Turn*

14

18

12

16 Tang Type Washer**

12

16

Torque

Specifications

200-300 lbf•ft

(271-407 N•m)

300-400 lbf•ft

(407-542 N•m)

200-275 lbf•ft

(271-373 N•m)

300-400 lbf•ft

(407-542 N•m)

Acceptable

End Play

0.001” - 0.005”

(.025 - .127 mm)

As Measured Per

Procedure With Dial

Indicator

Verify end play with a dial indicator. Wheel end play is the free movement of the tire and wheel assembly along the spindle axis.

a) Make sure the brake drum-to-hub fasteners are tightened to the manufacturers’ specifications.

b) Attach the dial indicator with its magnetic base to the hub or brake drum.

c) Adjust the dial indicator so that its plunger or pointer is against the end of the spindle with its line of action approximately parallel to the axis of the spindle.

d) Grasp the wheel assembly at the 3 o’clock and 9 o’clock positions. Push the wheel assembly in and out while oscillating it to seat the bearings. Read the bearing end play

as the total indicator movement.

NOTE: If end play is not within specification, readjustment is required.

Common Wheel End Sets

Timken Set Number Timken Part Number Common Application Description

SET401 580, 572 Industry Standard R Drive Axle: Outer Bearing

SET403 594A, 592A Industry Standard R Drive Axle: Inner Bearing

SET406 3782, 3720 Industry Standard FF Steer Axle: Outer Bearing

SET413 HM212049, HM212011 Industry Standard FF Steer Axle: Inner Bearing / Industry Standard N Trailer Axle Outer Bearing

SET414 HM218248, HM218210 Industry Standard N Trailer Axle: Inner Bearing

SET415 HM518445, HM518410 Industry Standard P Trailer Axle Inner and Outer Bearing

SET423 6461A, 6420 Industry Standard FL Steer Axle: Inner Bearing

SET424 555-S, 552A Industry Standard FL Steer Axle: Outer Bearing

TMC RP 618A, Wheel Bearing Adjustment Procedure, appears in TMC’s 2010-2011 Recommended Practices Manual, and is published by the Technology & Maintenance Council (TMC) of American Trucking Associations;

950 N. Glebe Road, Arlington, VA 22203; (703) 838-1763; http://tmc.truckline.com. Reprinted with permission.

Page 2

Pre-Adjusted Wheel Bearing Adjustment Procedures

NOTE: This refers only to torque specifications and bearing adjustment.

Please refer to the original equipment manufacturer’s recommended

procedures for complete installation details.

1) Mount the hub assembly onto the axle spindle, while holding the outer

cone in place. Make sure the bearing cones, spacer and spindle are aligned to

avoid seal damage.

2) Install the inner spindle nut and torque to 300 ft-lbs. Do not back off the

spindle nut.

3) Engage the locking device that is part of the spindle nut system. If the

locking system cannot be engaged when the nut is at 3 00 ft-lbs, advance the

nut until the locking system can be engaged (reference note above). For a

double nut or jam nut system, bend the lock tab or install the set screw after

the outer nut is torqued to 200 ft-lbs.

4) For one-piece spindle nut systems, torque the nut to a minimum of 300 ftlbs. Do not back off the spindle nut. Engage any locking device that is part of

the spindle nut system. If the locking device cannot be engaged when the nut

is at 300 ft-lbs, advance the nut until engagement takes place and the nut

is locked.

Timken Set-Right® Commercial Vehicle Hub Rebuild Kits and Components

FFTC1 - FF Steer Kit

Kit Contents MileMate

Inner NP cone

Inner NP cup NP026773 1

Outer NP cone

Outer NP cup NP435398 1

Spacer 103592TKR 1

Kit Contents MileMate

Inner NP cone

Inner NP cup NP363298 1

Outer NP cone

Outer NP cup NP053874 1

Spacer 103593TKR 1

Kit Contents MileMate

Inner NP cone

Inner NP cup NP503727 1

Outer NP cone

Outer NP cup NP026773 1

Spacer 104144TKR 1

Kit Contents MileMate

NP cone

NP cup NP593561 2

Spacer 104412TKR 1

Kit Contents MileMate

Inner NP cone

Inner NP cup NP039695 1

Outer NP cone

Outer NP cup NP183330 1

Spacer 103807TKR 1

* Includes proprietary Timken part numbers

®

P/N Component P/N Qty

SET427*

SET428*

RDTC1 - R Drive Kit

®

P/N Component P/N Qty

SET429*

SET430*

TNTC1 - N Trailer Kit

®

P/N Component P/N Qty

SET431*

SET427*

TPTC1 - P Trailer Kit

®

P/N Component P/N Qty

SET432*

FLTC1 - FL Steer Kit

®

P/N Component P/N Qty

SET445*

SET446*

NP899357 1

NP874005 1

NP034946 1

NP840302 1

NP965350 1

NP899357 1

NP174964 2

NP294109 1

NP107091 1

Kit Contents MileMate

Inner NP cone

Inner NP cup NP454773 1

Outer NP cone

Outer NP cup NP454398 1

Spacer 103592TKR 1

Kit Contents MileMate

Inner NP cone

Inner NP cup NP454298 1

Outer NP cone

Outer NP cup NP454874 1

Spacer 103593TKR 1

Kit Contents MileMate

Inner NP cone

Inner NP cup NP454727 1

Outer NP cone

Outer NP cup NP454773 1

Spacer 104144TKR 1

Kit Contents MileMate

NP cone

NP cup NP454561 2

Spacer 104412TKR 1

WARNING Failure to follow these warnings could create a

Proper maintenance and handling practices are critical. Always follow installation

instructions and maintain proper lubrication. Never spin a bearing with compressed air.

Always follow wheel torque recommendations. Excessive or inadequate wheel torque

can lead to failure of the wheel mounting system and loss of a wheel.

Do not remove the outer bearing once it has been installed on the spindle. Removing it

could cause the seal to become misaligned and lead to a seal failure or loss of a wheel.

FFTC2 - 454-Series™ FF Steer Kit

®

P/N Component P/N Qty

SET603*

SET605*

RDTC2 - 454-Series™ R Drive Kit

TNTC2 - 454-Series™ N Trailer Kit

TPTC2 - 454-Series™ P Trailer Kit

®

P/N Component P/N Qty

SET600*

SET601*

®

P/N Component P/N Qty

SET602*

SET603*

®

P/N Component P/N Qty

SET604*

NP454357 1

NP454005 1

NP454946 1

NP454302 1

NP454350 1

NP454357 1

NP454964 2

risk of death or serious bodily injury.

The rolling elements may be forcefully expelled.

Every reasonable effort has been made to ensure the accuracy of the information contained in this

writing, but no liability is accepted for errors, omissions or for any other reason.

The Timken team applies their know-how to improve the reliability and performance of machinery in diverse markets worldwide.

The company designs, makes and markets bearings, gear drives, automated lubrication systems, belts, brakes, clutches, chain,

couplings, linear motion products and related power transmission rebuild and repair services.

5-19 :29 Or der No. 10410 | Ti mken® is a reg istered t rademark o f The Timken Com pany. | © 2019 The T imken Comp any | Print ed in U.S. A.

www.timken.com/aftermarket

Loading...

Loading...