Page 1

METALS INDUSTRY EDITION

TIMKEN ENGINEERING MANUAL

Page 2

TIMKEN ENGINEERING MANUAL

Page 3

TIMKEN ENGINEERING MANUAL -

METALS INDUSTRY EDITION

INDEX

TIMKEN OVERVIEW.................................................................................2

Shelf Life Policy ................................................................................... 8

Storage .................................................................................................9

LUBRICATION AND SEALING ..............................................................95

Lubrication ..............................................................................................96

Lubrication Fundamentals ............................................................... 96

Main Lubricant Characteristics ...................................................... 99

Lubrication Selection .....................................................................100

Sealing ................................................................................................... 110

Sealing Types ...................................................................................110

Sealing Systems .............................................................................. 112

POPULAR BEARING TYPES IN THE METAL INDUSTRY .................. 11

Steelmaking ............................................................................................12

Continuous Casting ................................................................................ 13

Rolling Mill Stands ................................................................................. 14

Radial Bearings ................................................................................. 14

Thrust Bearings ................................................................................. 16

Auxiliary Equipment ............................................................................... 18

APPLICATION CONSIDERATIONS AND BEARING SELECTION ..... 21

Steelmaking ............................................................................................22

Continuous Casting ................................................................................ 27

Rolling Mill...............................................................................................33

Flat Product Rolling...........................................................................33

Long Product Rolling ........................................................................35

Bearing Solutions: Radial Positions .................................................... 36

Work and Intermediate Rolls: Flat Product Mills .........................36

Work Rolls: Long Product Mills ......................................................43

Backup Rolls ...................................................................................... 46

Bearing Solutions: Axial Positions ...................................................... 53

Auxiliary Equipment ............................................................................... 58

Main Mill Drive and Pinion Stand Gearboxes .............................. 58

Pay-off and Rewind Reels ............................................................... 60

Shears and Shear Drives ................................................................. 62

Table Rolls .......................................................................................... 64

BEARING LIFE CALCULATIONS AND RELATED ANALYSIS ............ 67

Summary of Symbols ............................................................................. 68

Fatigue Life .............................................................................................. 69

Bearing Ratings ...................................................................................... 69

Applied Loads ......................................................................................... 72

Bearing Life Equations .......................................................................... 81

Bearing Internal Clearance .................................................................. 86

Advanced Analysis ................................................................................ 92

APPLICATION CHALLENGES AND ENHANCED

BEARING SOLUTIONS.........................................................................115

High-Performance Bearings .............................................................. 116

Contact Fatigue ....................................................................................117

Debris ..................................................................................................... 120

Lubrication ............................................................................................122

Corrosion ............................................................................................... 124

Precision Rolling ..................................................................................126

High Acceleration ................................................................................ 127

RELATED PRODUCTS...........................................................................129

Seals and Lubricant ............................................................................. 130

Maintenance Tools .............................................................................. 131

Condition Monitoring Equipment ....................................................... 133

®

Timken

Timken Quick-Flex

Precision Chain Products ................................................................... 140

BEARING STORAGE, HANDLING AND INSTALLATION ................143

Bearing Packaging and Storage ....................................................... 144

Bearing Marking ..................................................................................144

Roll Neck Maintenance Guidelines .................................................. 147

Chock and Roll Neck Maintenance Guidelines .............................. 151

Mounting and Dismounting Roll Neck Bearings ............................157

Bearing Setting Techniques ............................................................... 168

SERVICES ..............................................................................................175

Gearbox Repair.....................................................................................176

Bearing Reconditioning and Reclamation ....................................... 177

Chock and Roll Upgrades ................................................................... 180

MILLTEC™ Rolling Mill Program ........................................................182

Service Engineering ............................................................................182

Training .................................................................................................. 182

Housed Units ........................................................................ 134

®

Couplings .......................................................... 138

TIMKEN ENGINEERING MANUAL

1

Page 4

TIMKEN

GROW STRONGER WITH TIMKEN

GROW STRONGER WITH TIMKEN

Every day, people around the world count on the strength

of Timken. Our expertise in metallurgy, friction management

and mechanical power transmission helps them accelerate

improvements in productivity and uptime.

We supply products and services that can help keep your

operations moving forward, whether you need drive train kits

for commercial vehicles, durable housings for bearings in dirty

environments, couplings that avoid metal-to-metal contact

between motors and gearboxes, repair services for bearings

and gearboxes, roller chain for dry, abrasive and high-moisture

applications, steel for an aircraft engine shaft, or other

products or services for your applications.

When you choose Timken, you receive more than high-quality

products and services: you gain a worldwide team of highly

trained and experienced Timken people committed to working

collaboratively with you to improve your business.

Globally, our 20,000 people provide reliable answers for a

wide range of operations in manufacturing, mining, medical

equipment, aerospace, transportation, oil and gas – and other

diverse industries.

TIMKEN ENGINEERING MANUAL

2

Page 5

INCREASE YOUR EQUIPMENT

UPTIME

In addition to high-quality bearings and mechanical power

transmission components, we provide valuable integrated

products and services. For example, we offer repair services

and equipment monitoring equipment that can alert you to

problems before they impact your uptime.

Additionally, we offer a broad selection of seals, premium

lubricants, lubricators, couplings and chain to keep your

TIMKEN

INCREASE YOUR EQUIPMENT UPTIME

operations moving smoothly.

Our technology centers in the United States, Europe and

Asia help pioneer tomorrow’s innovations with extensive

basic and applied scientific research programs. Through

internal development and strategic acquisition of innovative

companies, we continue to expand our portfolio of highly

engineered bearings and components.

TIMKEN ENGINEERING MANUAL

3

Page 6

TIMKEN

METALS INNOVATOR

METALS INNOVATOR

Today, metal processing equipment handles heavier loads,

faster speeds and greater output than ever before. Finished

product quality requirements increase, while across the

industry manufacturers continue to place a very high premium

on equipment uptime and performance.

As the leader in friction-management and power-transmission

solutions for the metals industry, Timken helps metals operators

improve their equipment’s performance and uptime. We

accomplish this by providing custom solutions – from bearings

that can stand up to harsh environments to condition monitoring

that helps minimize maintenance costs and improve

plant productivity.

We have more than a century of experience developing

bearings and related solutions that help equipment run

more efficiently in a wide range of applications, including

steelmaking, continuous casting and rolling both flat and long

products.

INNOVATION AND

CUSTOMER SUPPORT

Timken operates technology centers around the world

dedicated to developing innovative concepts and products that

help you operate more efficiently. Our technical leadership and

customer support reaches far beyond our products. Timken

customers have access to sales and service engineering

support at their plants and options for additional support from

application engineers, who specialize in the metals industry.

CORE CAPABILITIES

Timken has evolved from its early roots as a bearing and

steel producer to a supplier offering much more, including

friction-management and power-transmission solutions that

add value throughout the complete life cycle of a system. Our

material enhancements improve bearing life and can protect

against debris and corrosion – two common challenges in

processing metals. Our precision manufacturing capabilities

and commitment to quality ensure global consistency in

design and manufacturing at every Timken facility. A global

distribution network provides our customers with easy access

to Timken products and services throughout the world.

We leverage these core capabilities as we work with

original equipment manufacturers (OEM) and designers

to integrate our technologies into equipment so that end

users can enjoy the performance benefits of Timken

products from the first day of operation. OEMs depend

on Timken for our engineering expertise, manufacturing

capabilities and emphasis on reliable performance.

TIMKEN ENGINEERING MANUAL

4

Page 7

PRODUCTS AND SERVICES

We offer equipment builders and operators one of the most

extensive friction-management product and service portfolios

in the industry.

BEARINGS

We provide a broad range of bearing designs and

configurations for use in steelmaking vessels, caster segments,

work rolls, backup rolls, screwdown systems, mill drives,

pinion stands, coilers, table rolls, and auxiliary equipment.

Bearing types include:

Tapered roller bearings – Tapered roller bearings are

•

uniquely designed to manage both thrust and radial loads

and are available in single- and multi-row designs with a

wide range of assembly options. Our extensive offering

of tapered roller bearing combinations offers equipment

builders and operators simple, reliable and less costly

design solutions.

Cylindrical roller bearings –This design generally offers

•

the highest possible radial load capacity for a given size

compared to other roller bearing types. One row and two

row cylindrical roller bearings are ideal for many mill stand,

gear drive and other auxiliary equipment applications,

while four row cylindrical roller bearings are used in roll

neck applications. Timken offers both single and multi-row

cylindrical roller bearing. Custom designs are available

upon request for specific applications.

TIMKEN

PRODUCTS AND SERVICES

Thrust roller bearings – Thrust roller bearings for rolling

•

mill applications are available in cylindrical, spherical and

tapered designs. Thrust bearings are ideal for applications

experiencing heavy axial loads, such as mill stands,

screwdown systems and piercing mills.

Ball bearings – Ball bearings are used extensively in

•

auxiliary applications that have light loads and/or high

speed conditions. Timken offers a range of radial, thrust

and angular-contact ball bearings in both metric and inch

sizes. Please contact your Timken engineer for detailed

information on these product ranges.

Housed units – Timken® spherical roller bearing solid-

•

block housed units possess a unique cast-steel design

that handles demanding conditions in metal industry

applications. These solid-block housed units come in

several styles and five advanced locking configurations.

Timken spherical roller bearing solid-block housed units

are designed for challenging circumstances. A full line of

primary seals, covers and housings is available to find the

right roller housed unit to fit your application. In case of

high thrust loads, in excess of the spherical roller bearing

carrying capabilities, the Timken

Timken also provides a broad range of split-block housings

in both metric and inch sizes.

®

Type E is your solution.

Spherical roller bearings – Spherical roller bearings offer

•

high radial and moderate thrust capacity together with

maximum static and dynamic misalignment capability.

Timken spherical roller bearings provide high-static load

capacity and advanced geometry that reduces friction and

heat generation. These bearings are available in a range

of dimensionally stabilized configurations to suit elevated

operating temperatures.

TIMKEN ENGINEERING MANUAL

5

Page 8

TIMKEN

PRODUCTS AND SERVICES

HIGH-PERFORMANCE BEARING

SOLUTIONS

Timken provides the metals industry with a variety of

high-performance bearing solutions, including Timken

AquaSpexx

corrosion protection. Our debris-resistant bearings are ideal

for contaminated and/or marginal lubrication conditions.

We also provide customized bearing solutions such as special

race profiles to meet special application requirements.

In addition to component geometry and metallurgy, we find

many ways to enhance bearing performance by applying

unique surface finishes and special coatings on rollers,

raceways and other functional surfaces. Engineered surfaces

and topographical modification reduce surface roughness

to lower levels than can be achieved through conventional

grinding and honing methods. We also offer proprietary

coatings that can create a surface up to four times harder than

steel with twice the elasticity. For more information on Timken

high-performance bearings and engineered surfaces, see

the Application Challenges and Enhanced Bearing Solutions

section of this manual (pages 115-127).

®

, DuraSpexx® and thin dense chrome bearings for

®

Timken manufactures precision roller

chain that are designed to meet

demanding steel industry applications.

We build chains to precise specifications

for strength and maximum wear life. The

offering includes a complete line of roller

chain, attachment chain and engineered

conveyor chain.

POWER TRANSMISSION

COMPONENTS AND SYSTEMS

Timken offers an expanding range of power transmission

components including seals, couplings and engineered chain.

Extreme temperatures and high contamination levels can

disable your equipment and significantly lower productivity.

Timken develops seals using advanced material and process

solutions that help protect machinery and minimize plant

downtime. We offer a comprehensive line of large-bore oil and

grease seals and metallic and non-metallic bearing isolators.

®

Timken

minimal maintenance. They are easy to install and require no

lubrication. These couplings are designed to connect motors

and gearboxes with other moving equipment with capacity to

transmit the same or more torque than a gear coupling with

the same dimensions. The Quick-Flex coupling's innovative

design utilizes an advanced elastomeric element to transmit

the torque and therefore eliminates any interference between

coupling hubs that can damage equipment.

Quick-Flex® couplings are highly durable, yet need

LUBRICATION

Timken lubricants reduce friction, reduce wear and protect

bearing surfaces from corrosion. We offer a wide selection of

lubricants, including Timken Mill Grease, which we formulated

to perform in the difficult roll neck bearing environment. Timken

single- and multi-point lubricators and lubrication delivery

devices help mill maintenance professionals simplify their

lubrication practices, saving time and money.

TIMKEN ENGINEERING MANUAL

6

Page 9

CONDITION MONITORING DEVICES

Powerful diagnostic tools from Timken are designed to detect

potential bearing failure before it occurs. A variety of handheld

devices and online options – including our ultra-accurate

Online Intelligence System – let you monitor bearing condition,

lubrication quality and machine vibration (either periodically

or continuously) for increased productivity, safety and peace

of mind.

MAINTENANCE TOOLS

Timken maintenance tools may extend bearing life by

facilitating proper installation, removal and service.

They also help simplify maintenance practices.

We provide induction heaters, impact fitting tools

and hydraulic and mechanical pullers.

TIMKEN

PRODUCTS AND SERVICES

SERVICES

Used bearings and related components often can be returned

to their original specifications with less time and costs than

purchasing new. We offer complete remanufacture and

reconditioning services for many components, including

bearings, chocks, housings, rolls and more.

Our gearbox repair services are globally recognized as experts

in power transmission solutions for heavy industrial markets,

repairing virtually any large gearbox make or model, with

onsite emergency breakdown service available if needed.

Timken offers a full range of maintenance and reconditioning

services through our remanufacturing and repair operations.

Using these services can lead to improved plant efficiency and

reduced overall production costs.

Beyond bearing repair and depending on the location, we offer

chock maintenance and roll rebuilding to help mill operators

get the most out of their chock/bearing assembly.

In addition, our MILLTEC

around-the-clock management of the roll shop with the goal of

minimizing operational costs and downtime.

®

rolling mill program provides

TRAINING

We offer industry-specific training programs designed for plant

professionals, as well as on-site customized training to meet

your specific needs. Our metals industry training programs

are available at select locations around the world and cover

every phase of bearing performance in the metal-making

environment. Class time is balanced with extensive hands-on

training and tours of Timken facilities.

TIMKEN ENGINEERING MANUAL

7

Page 10

TIMKEN

HOW TO USE THIS CATALOG • SHELF LIFE AND STORAGE OF GREASE-LUBRICATED BEARINGS AND COMPONENTS

HOW TO USE THIS CATALOG

We designed this catalog to help you find the bearings best

suited to your specifications.

Timken offers an extensive range of bearings and accessories

in both imperial and metric sizes. For your convenience, size

ranges are indicated in millimeters and inches. Contact your

Timken sales engineer to learn more about our complete line

for the special needs of your application.

This publication contains dimensions, tolerances and load

ratings, as well as engineering sections describing fitting

practices for shafts and housings, internal clearances,

materials and other bearing features. It provides valuable

assistance in the initial consideration of the type and

characteristics of the bearings that may best suit your

particular needs.

ISO and ANSI/ABMA, as used in this publication, refer to

the International Organization for Standardization and the

American National Standards Institute/American Bearing

Manufacturers Association.

Updates are made periodically to this catalog. Visit www.

timken.com for the most recent version of the Timken Metals

Engineering Catalog.

DISCLAIMER

This catalog is provided solely to give you analysis tools

and data to assist you in your product selection. Product

performance is affected by many factors beyond the control

of Timken. Therefore, you must validate the suitability and

feasibility of all product selections.

SHELF LIFE AND STORAGE OF

GREASE-LUBRICATED BEARINGS

AND COMPONENTS

To help you get the most value from our products, Timken

provides guidelines for the shelf life of grease-lubricated

ball and roller bearings, components and assemblies. Shelf

life information is based on Timken and industry test data

and experience.

SHELF LIFE POLICY

Shelf life should be distinguished from lubricated bearing/

component design life as follows:

Shelf life of the grease-lubricated bearing/component

represents the period of time prior to use or installation.

The shelf life is a portion of the anticipated aggregate design

life. It is impossible to accurately predict design life due to

variations in lubricant bleed rates, oil migration, operating

conditions, installation conditions, temperature, humidity and

extended storage.

Shelf life values, available from Timken, represent a maximum

limit and assume adherence to the storage and handling

guidelines suggested in this catalog or by a Timken associate.

Deviations from the Timken storage and handling guidelines

may reduce shelf life. Any specification or operating practice

that defines a shorter shelf life should be used.

Timken cannot anticipate the performance of the grease

lubricant after the bearing or component is installed or placed

in service.

Timken products are sold subject to Timken terms and

conditions of sale, which include our limited warranty and

remedy. You can find these at http://www.timken.com/en-us/

purchase/Pages/TermsandConditionsofSale.aspx

Please consult with your Timken engineer for more information

and assistance.

Every reasonable effort has been made to ensure the accuracy

of the information in this writing, but no liability is accepted for

errors, omissions or for any other reason.

TIMKEN ENGINEERING MANUAL

8

TIMKEN IS NOT RESPONSIBLE FOR THE

SHELF LIFE OF ANY BEARING/COMPONENT

LUBRICATED BY ANOTHER PARTY.

European REACH Compliance

Timken lubricants, greases and similar products sold in

standalone containers or delivery systems are subject to the

European REACH (Registration, Evaluation, Authorization

and Restriction of CHemicals) directive. For import into the

Page 11

SHELF LIFE AND STORAGE OF GREASE-LUBRICATED BEARINGS AND COMPONENTS

European Union, Timken can sell and provide only those

lubricants and greases that are registered with ECHA

(European CHemical Agency). For further information, please

contact your Timken engineer.

STORAGE

Timken suggests the following storage guidelines for our

finished products (bearings, components and assemblies,

referred to as “products”):

Unless directed otherwise by Timken, products should be

•

kept in their original packaging until they are ready to be

placed into service.

Do not remove or alter any labels or stencil markings on the

•

packaging.

TIMKEN

Products should be stored in such a way that the packaging

•

is not pierced, crushed or otherwise damaged.

After a product is removed from its packaging, it should be

•

placed into service as soon as possible.

When removing a product that is not individually packaged

•

from a bulk pack container, the container should be

resealed immediately after the product is removed.

Do not use product that has exceeded its shelf life as

•

defined in the Timken shelf life guidelines statement.

The storage area temperature should be maintained

•

between 0º C (32º F) and 40º C (104º F); temperature

fluctuations should be minimized.

The relative humidity should be maintained below 60

•

percent and the surfaces should be dry.

The storage area should be kept free from airborne

•

contaminants such as, but not limited to, dust, dirt, harmful

vapors, etc.

The storage area should be isolated from undue vibration.

•

Extreme conditions of any kind should be avoided.

•

Due to the fact that Timken is not familiar with your particular

storage conditions, we strongly suggest following these

guidelines. However, you may be required by circumstances

or applicable government requirements to adhere to stricter

storage requirements.

Most bearing components typically ship protected with a

corrosion-preventive compound that is not a lubricant. These

components may be used in oil-lubricated applications without

removal of the corrosion-preventive compound. When using

some specialized grease lubrications, we advise you to remove

the corrosion-preventive compound before packing the

bearings components with suitable grease.

We pre-pack most housed unit types in this catalog with

general-purpose grease suitable for their normal applications.

It may be necessary for you to frequently replenish the grease

for optimum performance.

Be careful in selecting lubrication, however, since different

lubricants are often incompatible. You may order housed units

pre-lubricated with a specified lubrication.

When you receive a bearing or housed unit shipment, do not

remove products from their packaging until they are ready for

mounting so they do not become corroded or contaminated.

Store bearings and housed units in an appropriate atmosphere

so they remain protected for the intended period.

TIMKEN ENGINEERING MANUAL

9

Page 12

TIMKEN

SHELF LIFE AND STORAGE OF GREASE-LUBRICATED BEARINGS AND COMPONENTS

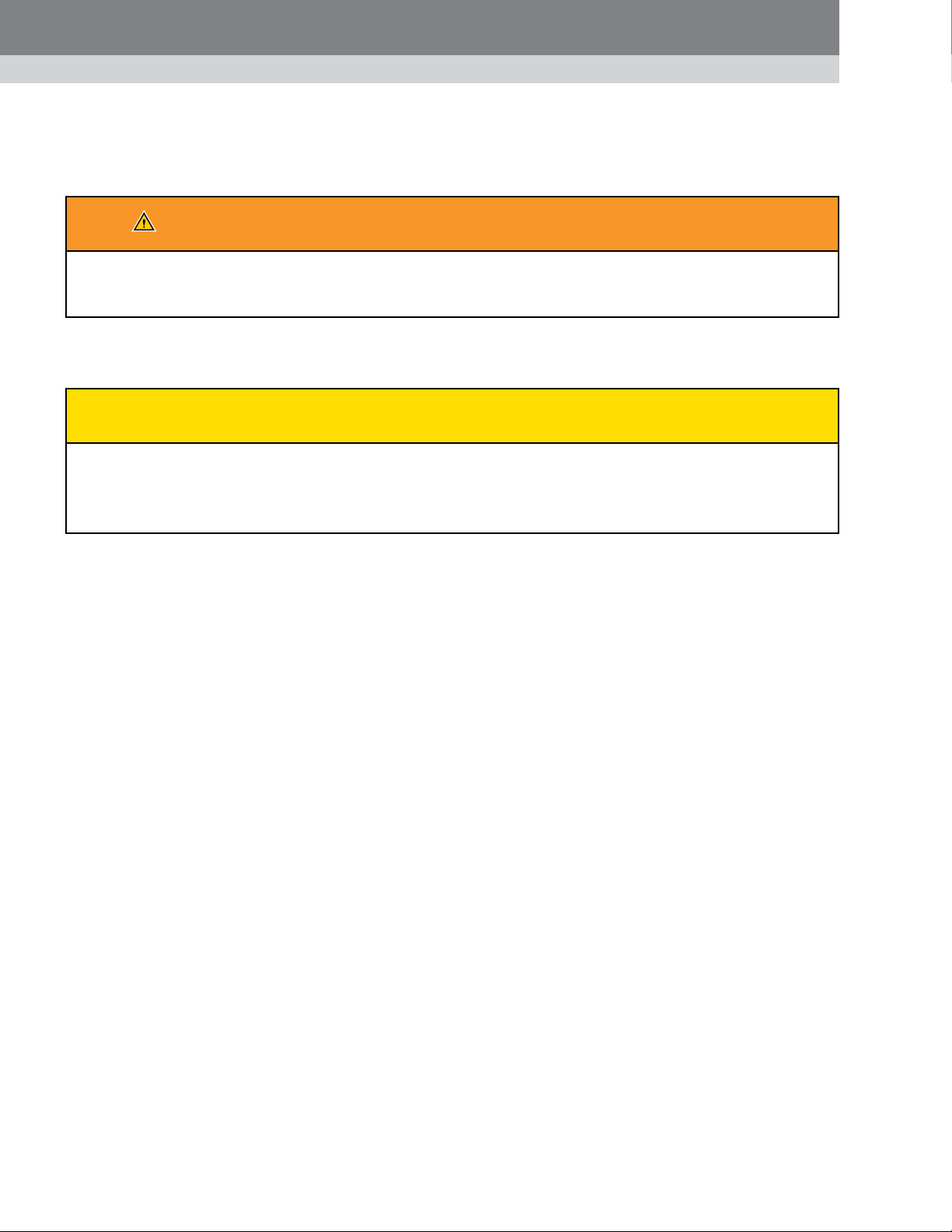

WARNING Failure to observe the following warnings could create a risk of serious injury.

Proper maintenance and handling practices are critical.

Always follow installation instructions and maintain proper lubrication.

Warnings for this product line are in this catalog and posted on

www.timken.com/en-us/products/warnings/Pages/default.aspx.

CAUTION Failure to follow these cautions may result in property damage.

If hammer and bar are used for installation or removal of a part, use a mild steel bar (e.g., 1010 or 1020 grade). Mild steel bars are

Timken products are sold subject to Timken’s terms and conditions of sale, which include its limited warranty and remedy,

European REACH compliance Timken-branded lubricants, greases and similar products sold in stand-alone containers or

delivery systems are subject to the European REACH (Registration, Evaluation, Authorization and Restriction of CHemicals)

directive. For import into the European Union, Timken can sell and provide only those lubricants and greases that are registered

less likely to cause release of high-speed fragments from the hammer, bar or the part being removed.

Do not use damaged housed units. The use of a damaged housed unit can result in equipment damage and/or injury.

NOTE

Components may become damaged and affect the performance and service life of the bearing.

Do not mix components of matched assemblies. Mixing components can reduce the service life of the bearing.

This catalog is provided solely to give you analysis tools and data to assist you in your product selection.

Product performance is affected by many factors beyond the Control of Timken.

Therefore, the suitability and feasibility of all product selection must be validated by you.

which terms may be found at http://www.timken.com/en-us/purchase/Pages/TermsandConditionsofSale.aspx.

Please consult with your Timken engineer for more information and assistance.

Every reasonable effort has been made to ensure the accuracy of the information in this writing,

but no liability is accepted for errors, omissions or for any other reason.

To view the complete engineering catalog, please visit www.timken.com. To order the catalog, please contact your

Timken engineer and request a copy of the Timken Engineering Manual, order number 10424.

with ECHA (European CHemical Agency). For further information, please contact your Timken engineer.

Visit www.timken.com for the most recent version of the Timken

Do not attempt to disassemble unitized bearings.

DISCLAIMER

Updates are made periodically to this catalog.

®

Engineering Manual - Metals Industry Edition.

TIMKEN ENGINEERING MANUAL

10

Page 13

POPULAR BEARING TYPES IN THE METALS INDUSTRY

POPULAR BEARING TYPES

IN THE METALS INDUSTRY

The following applications are covered in this

section:

Steelmaking.

•

Continuous casting.

•

Rolling mill stands.

•

Radial bearings.

•

Thrust bearings.

•

Auxiliary equipment.

•

TIMKEN ENGINEERING MANUAL

11

Page 14

POPULAR BEARING TYPES IN THE METALS INDUSTRY

STEELMAKING

STEELMAKING

The main support positions for the ladle furnace present a challenging application for bearings. They experience very high loads

and misalignment at very low speeds. In addition, cyclic and reversing rotation occurs. The Timken solution uses solid or split

high-performance spherical roller bearings mounted in custom-designed housings. The float position housing incorporates cylindrical

roller ladder bearings to accommodate the significant thermal axial growth of the furnace assembly.

SPHERICAL ROLLER BEARINGS

YMB TYPE

Composition: One double inner ring, one

double outer ring, two rows of spherical rollers

with land riding one-piece brass cage.

Application: Basic oxygen furnace (BOF) or

argon oxygen decarburization (AOD) furnace

pivots (trunnions).

Remarks: YMB type is designed for large size

bearings to manage high radial loads when

shaft deflection is important.

Fig. 1. YMB type.

SPLIT TYPE

Composition: One split

double inner ring with

clamp rings, one split

double outer ring, two rows

of spherical rollers with

steel pin-type split cages.

LADDER BEARINGS

CYLINDRICAL ROLLER TYPE

Composition: One top plate, one bottom plate, cylindrical rollers

with spring-centered retainer and one bottom seat.

Application: Linear bearing for float side BOF or AOD furnace

pivot bearing assembly.

Remarks: Used in pairs. Provide ± 65 mm (2.5 in.) axial float.

Fig. 3. Cylindrical roller type.

Fig. 2. Split type.

12

TIMKEN ENGINEERING MANUAL

Application: BOF or AOD

furnace pivots (trunnions).

Remarks: Often used to

replace conventional

spherical roller bearings on

drive-side pivot (trunnion).

Page 15

POPULAR BEARING TYPES IN THE METALS INDUSTRY

CONTINUOUS CASTING

CONTINUOUS CASTING

The continuous caster presents one of the most challenging environments for bearings. Caster-roll support bearings are subjected to

high loads and low rotational speeds, often at elevated temperatures. Below the bender segments, the Timken ideal solution combines

our high-performance spherical roller bearing for the fixed position and our latest design innovation, the Timken

for the floating position.

®

ADAPT™ bearing,

NEEDLE ROLLER BEARINGS

NA TYPE

Composition: One single inner ring, one

single outer ring, one or two rows of caged

needle rollers.

Application: Bender section support rolls.

Remarks: Low radial cross section with

high radial dynamic and static load rating.

Available with special clearance and higher

stabilizing heat treatment to accommodate

Fig. 4. NA type.

continuous caster operating conditions.

CYLINDRICAL ROLLER BEARINGS

NNCF TYPE

Composition: One double inner ring,

one double outer ring, two rows of

full-complement cylindrical rollers.

SPHERICAL ROLLER BEARINGS

EJ TYPE

Composition: One double inner ring, one double

outer ring and two rows of spherical rollers with

stamped steel cages.

Application: Caster rolls; fixed and float positions.

Remarks: EJ-type spherical roller bearings feature

a hardened stamped steel window-type cage with

face slots for improved lubrication. Designed to

accept misalignment during operation and with

high radial load capacity for maximum reliability.

Fig. 6. EJ type.

ADAPT

Composition: One single cylindrical inner ring,

one single profiled outer ring, full-complement

design with a roller/retainer assembly.

Application: Caster rolls; float position.

™

Application: Continuous caster bender

section support rolls.

Remarks: Available with special clearance

and higher stabilizing heat treatment

to accommodate continuous caster

operating conditions. This type includes

Fig. 5. NNCF type.

direction and permit small axial displacement.

integral flanges on inner and outer rings

and can manage light axial loads in one

Remarks: The ADAPT full-complement roller

bearing is designed specifically for continuous

casters, combining traditional cylindrical and

spherical roller bearing configurations into a new

Fig. 7. ADAPT™.

and high axial displacement capabilities). This bearing also offers

high-static radial load capacity for optional reliability.

design so operators benefit from the key attributes

of both types (simultaneous full misalignment

WARNING

Failure to observe the following warnings could

create a risk of serious injury.

ADAPT™ bearings feature a separable inner ring. Care

must be taken when handling or installing a fully assembled

bearing to prevent the inner ring from accidentally sliding

out of the assembly. When using this bearing to replace a

unitized bearing it is important to check the design of the

installation for positive retention on the shaft.

Proper maintenance and handling practices are critical.

Always follow installation instructions and maintain

proper lubrication.

TIMKEN ENGINEERING MANUAL

13

Page 16

POPULAR BEARING TYPES IN THE METALS INDUSTRY

ROLLING MILL STANDS

ROLLING MILL STANDS

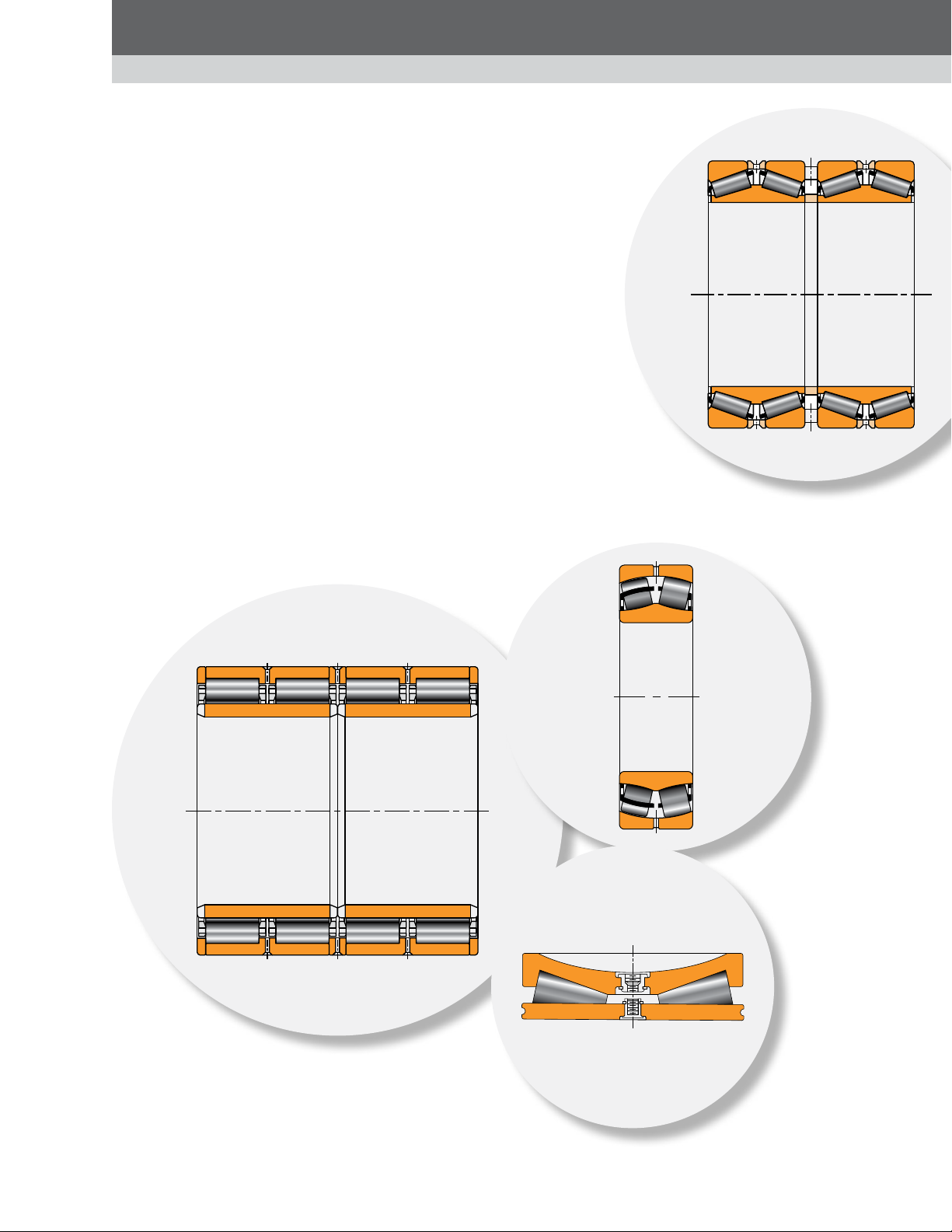

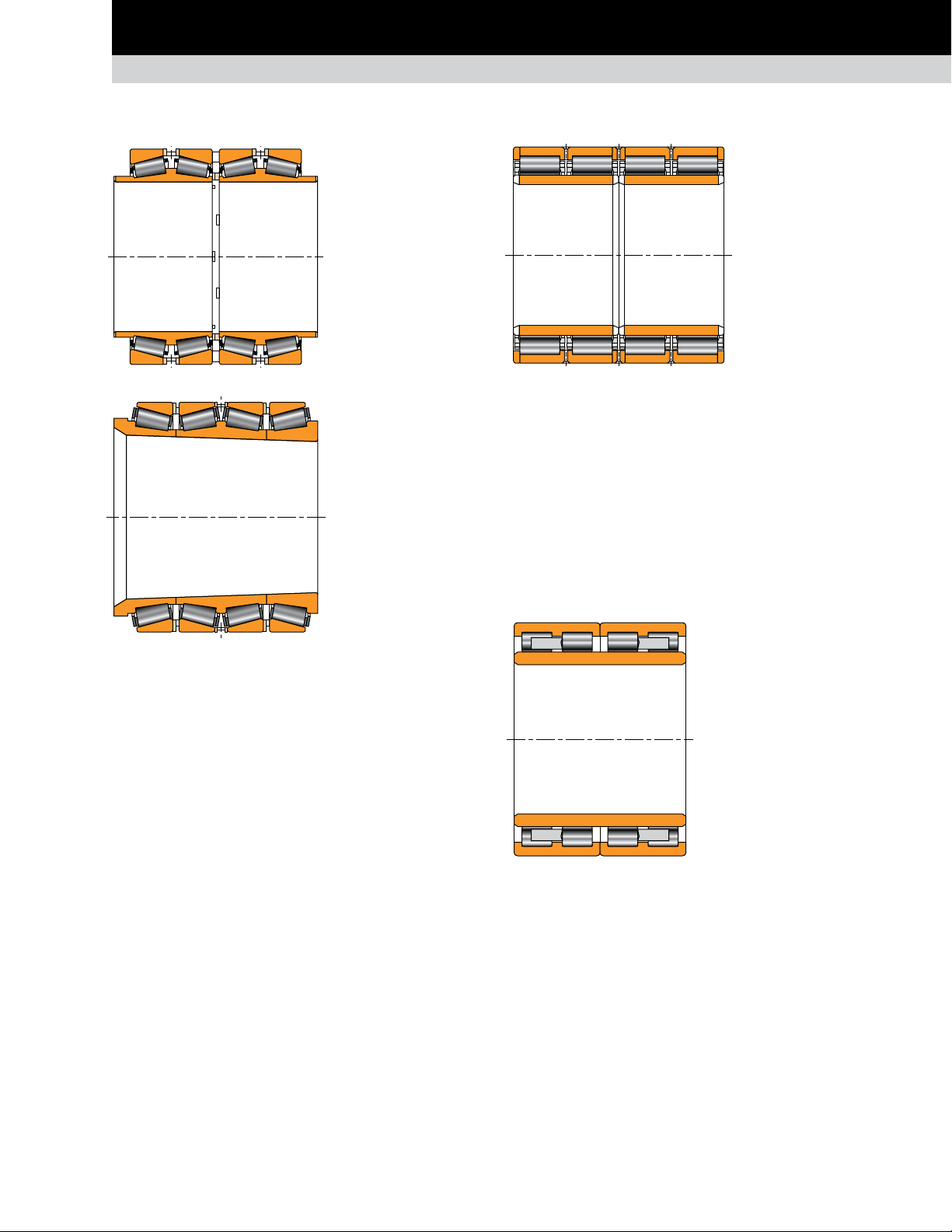

Rolling mill applications typically encounter very high radial loads and varying degrees of axial load while running at slow to highspeed. To accommodate these operating conditions, roll neck bearings must have enhanced contact surfaces, material strength

properties, and internal geometry and cage characteristics. Available designs include two-, four- or six-row tapered roller bearings,

and multi-row cylindrical bearings.

RADIAL BEARINGS

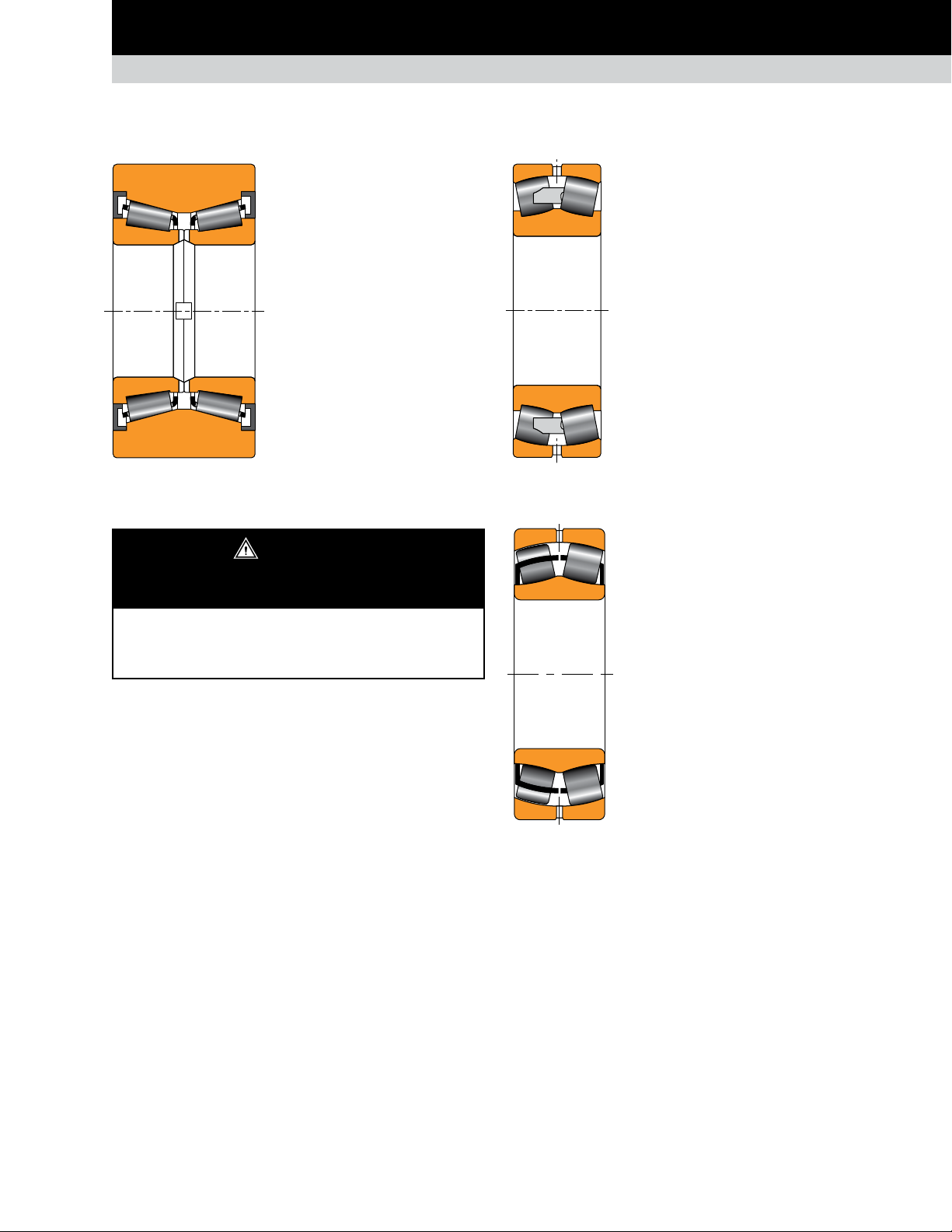

TAPERED ROLLER BEARINGS

TQOW

Composition: Two double cones

with tapered rollers, one cone

spacer, two single cups, two cup

spacers, one double cup.

Application: Work rolls,

intermediate rolls and backup

rolls. Typically used in mills with

speeds up to 800 m/min. (2600 ft./

Fig. 8. TQOW.

Remarks: The TQOW is a preset four-row assembly with

hardened cone spacers to minimize face wear. The bearing

clearance in the TQOW design can be reset after extended use

by regrinding the spacers.

The bearing is mounted loose on the roll neck and in the chock.

Slots on the cone faces provide lubrication access to cone and

fillet ring faces for reduced wear. Available with spiral bore

groove for additional lubrication access to the roll neck.

min.) when used on backup rolls.

2TDIW

Composition: Two double cones

with tapered rollers, four single

cups, and two or three cup

spacers.

Application: Work rolls,

intermediate rolls and backup

rolls. Typically used in mills with

speeds up to 800 m/min. (2600 ft./

Fig. 9. 2TDIW.

Remarks: The 2TDIW type interchanges with the TQOW type on

external boundary dimensions and achieves the same load rating.

Under combined axial and radial loads, the two central single

cups of the 2TDIW bearing offer better load distribution than the

double cups used in the TQOW type.

min.) when used on backup rolls.

Sealed roll neck

bearing

Composition: Same

construction as the 2TDIW, plus

two main seals, one bore seal,

and O-ring to seal statically in

the chock bore.

Application: Primarily used in

work rolls and intermediate rolls

and some backup rolls.

Fig. 10. Sealed roll neck bearing.

Remarks: The sealed roll neck

bearing is supplied as a unitized, preset assembly with or

without grease.

TQITS

Composition: One double

cone and two single cones all

with matched tapered bores,

four single cups, three cup

spacers.

Application: Backup rolls,

typically used in high-speed

mills where strip speeds

exceed 800 m/min. (2600 ft./

min.).

Fig. 11. TQITS.

Remarks: The TQITS type

mounts tight using a 1:12 taper on the roll neck and the bearing

bore for accurate control of the interference fit. Typically used

on high-speed mills to minimize neck wear.

14

TIMKEN ENGINEERING MANUAL

Page 17

POPULAR BEARING TYPES IN THE METALS INDUSTRY

ROLLING MILL STANDS

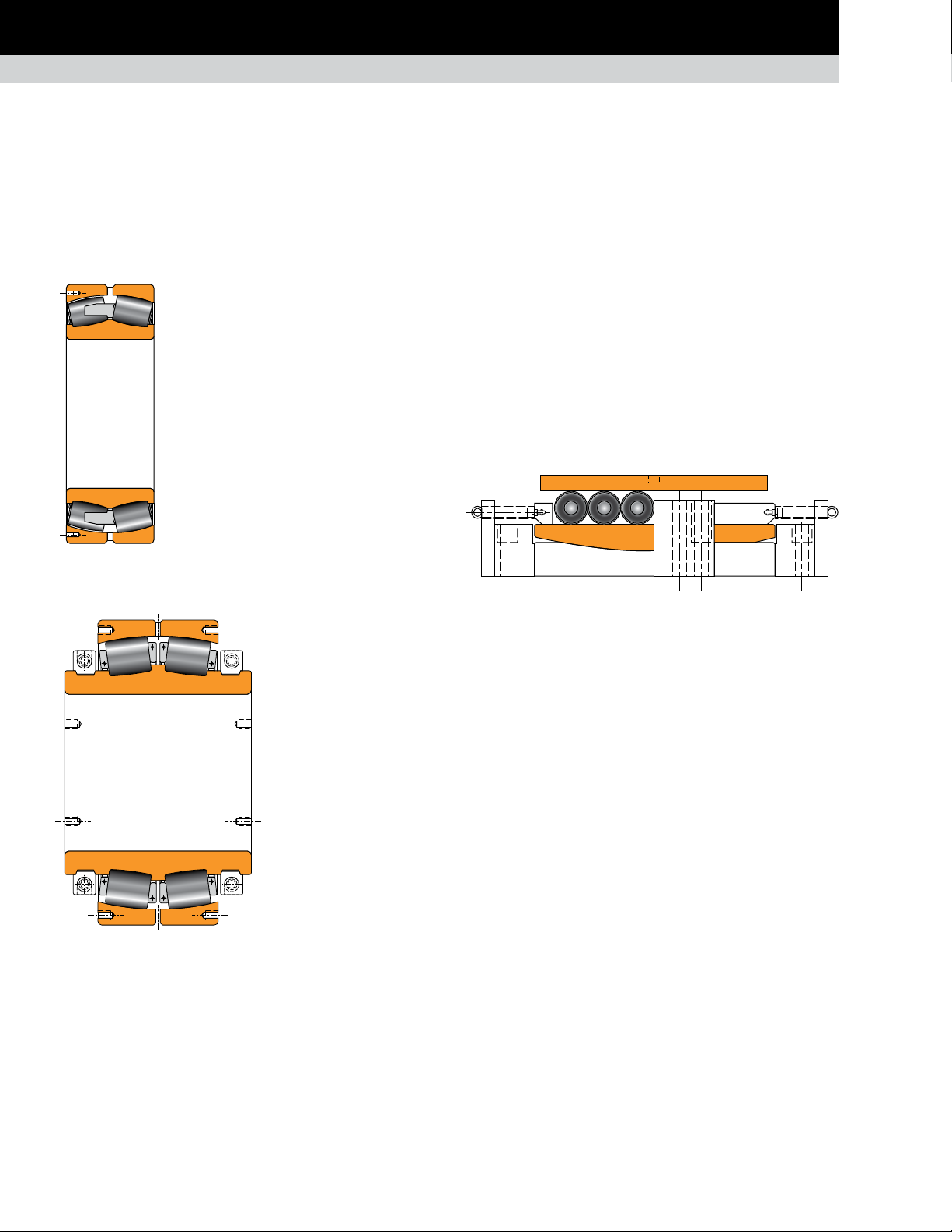

CYLINDRICAL ROLLER BEARINGS

Fig. 12. TQOWE.

Fig. 13. TQITSE.

TQOWE and TQITSE

Composition: Same

construction as the TQOW

and TQITS respectively

with cone extension on

one or both sides of the

bearing.

Application: Work rolls,

intermediate rolls and

backup rolls.

Remarks: The TQOWE

and TQITSE versions

include cone extensions

to accommodate chock

seals. This bearing design

allows an optimal chock

seal running surface.

The seal integration

permits the bearing to be

positioned closer to the

roll face, which improves

the neck stiffness.

RX

Composition: Tw o

cylindrical inner rings,

two flanged outer rings

and separated rib rings

for roller spacing.

Typically includes a pintype cage(s).

Application: Backup roll

Fig. 14. RX.

Remarks: The bearing is mounted tight on the roll neck and loose

in the chock when used on backup rolls. Generally provided with

semi-finished (CF) inner ring races to be finished ground by the

customer once mounted on the roll neck. Separated rib rings

allow for complete disassembly for inspection. The RX style

is usually preferred in bearings above 400 mm (15.75 in.) bore.

Long product mill applications are generally supplied as preset

assembly and mounted tight on the roll neck.

radial position for flat

product mills. Roll neck for

long product mills.

RY and RYL

Composition: Typically one

single-piece inner ring, two

outer rings with triple flanges

(solid ribs). Fully machined

brass (RY) or steel (RYL) cages.

Application: Roll neck for long

product mills.

Remarks: The most recent RYL

design is specifically designed

Fig. 15. RY and RYL.

features a machined-steel cage and enhanced design features

to maximize bearing life and optimize bearing handling. For

specific applications, four-row cylindrical roller bearings also

can be supplied with spiral grooves on inner ring bore, extended

inner rings or tapered bore.

for long-product mills and

TIMKEN ENGINEERING MANUAL

15

Page 18

POPULAR BEARING TYPES IN THE METALS INDUSTRY

ROLLING MILL STANDS

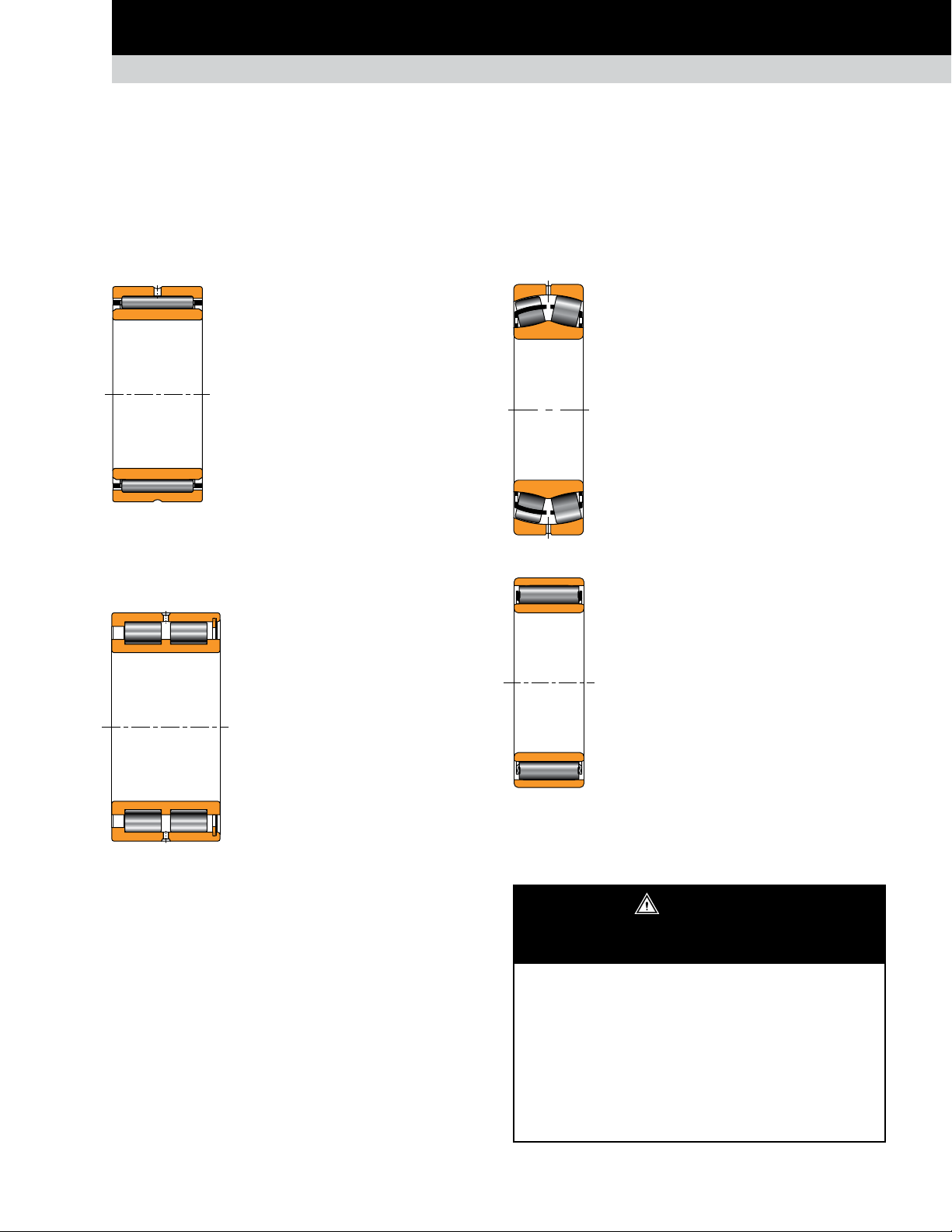

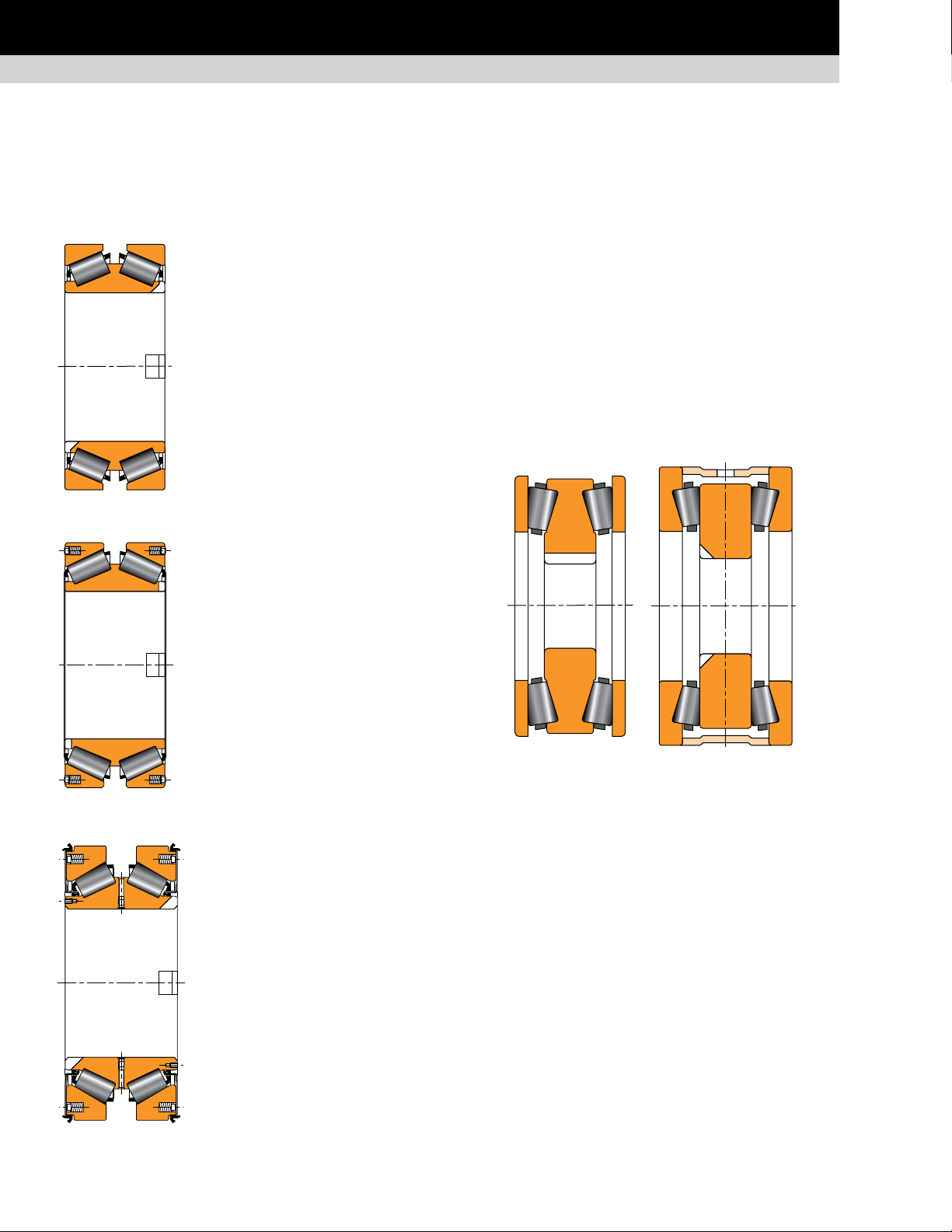

THRUST BEARINGS

Applications mounted with cylindrical roller bearings, oil-film bearings or systems with axial shift or roll crossing, generally need an

additional thrust bearing.

TAPERED ROLLER THRUST BEARINGS

Fig. 16. TDIK.

Fig. 17. TDIK with

spring system.

TDIK

Composition: One double cone with tapered

rollers, two single cups, spacer or spacerless.

Application: Backup and work roll thrust

positions for flat product mills.

Remarks: These bearings come designed

with steep angles to accommodate thrust

in both directions. Cups and cones are

mounted with a loose fit. The cone is keyed

onto the shaft to prevent cone rotation and

bore fretting.

TDIK with spring system

Timken developed a version with

a spring system in the cups without a spacer

to ensure that the unloaded cup always

remains seated and to help prevent any

roller skewing.

Application: Work rolls, intermediate rolls

with axial shift, and backup roll equipped

with cylindrical roller bearing.

TDIK sealed with spring system

Timken developed the sealed version of the

TDIK with a spring system.

TTDWK and TTDFLK

Composition: One double central ring with tapered rollers, two

outer rings.

Application: Heavy-duty flat product mills with axial shift and

long product mills.

Remarks: Double-acting thrust bearings come available in two

versions with tapered central ring or flat central ring. Mounted

loose on the neck and in the housing.

Fig. 19. TTDWK. Fig. 20. TTDFLK.

The tapered central ring version enables a smaller overall width

of the bearing. These TTDFLK assemblies can be provided with

or without an outer spacer. However, we generally prefer to use

the design without outer spacers and include a spring mounting in

the chock shoulders to ensure that the rollers of both rows remain

properly seated (see configuration on page 55).

Application: Work rolls, intermediate rolls

with axial shift, and backup roll equipped

with cylindrical roller bearing.

Fig. 18. TDIK with sealed spring system.

16

TIMKEN ENGINEERING MANUAL

Page 19

POPULAR BEARING TYPES IN THE METALS INDUSTRY

ROLLING MILL STANDS

SPHERICAL ROLLER THRUST BEARING

TTHD

Composition: Two tapered thrust rings, cage or cageless.

Application: Thrust positions for piercing mills, sendzimir mills

and auxiliary equipment.

Remarks: This design offers up to 40 percent more capacity

than cylindrical and spherical bearings with the same envelope

dimensions. Used only when axial loads are unidirectional. Medium

speed capability when provided with a cage. A cageless design is

available for high loads and low speeds.

Fig. 21. TTHD.

TTHDFLSX and TTHDFLSV

Composition: Identical to the TTHD construction with a top ring

generally made with convex outer face (TTHDFLSX). A concave

(TTHDFLSV) top ring also can be supplied if needed.

Application: Screwdown thrust bearing.

Remarks: Full-complement design for maximum capacity. Lifting

holes exist in each ring for handling purposes.

Both designs are also available with a tapered bottom race design

(TTHDSX and TTHDSV).

TSR

Composition: One single inner ring with spherical

rollers with cage retainer and one single outer ring.

Application: Thrust position for gearboxes and

auxiliary equipment.

Remarks: Type TSR spherical roller thrust bearings

maintain a high-thrust capacity and accommodate

misalignment.

Fig. 24. TSR.

2TSR assembly

Composition: Two single

inner rings with spherical

rollers and cage retainer

installed in a sleeve and

two single outer rings, all

mounted in a carrier.

Application: Thrust

position for gearboxes

and auxiliary equipment.

Fig. 22. TTHDFLSX.

Fig. 23. TTHDFLSV.

Remarks: To maintain

loading in the row

unloaded by the axial

Fig. 25. TSR assembly.

TIMKEN ENGINEERING MANUAL

load, the whole assembly

is preloaded using springs

mounted in the carrier.

17

Page 20

POPULAR BEARING TYPES IN THE METALS INDUSTRY

AUXILIARY EQUIPMENT

AUXILIARY EQUIPMENT

Timken offers a wide range of bearings for auxiliary equipment applications such as gear drives, table rolls, coilers, end coilers,

levelers, pinion stands, handling equipment and more.

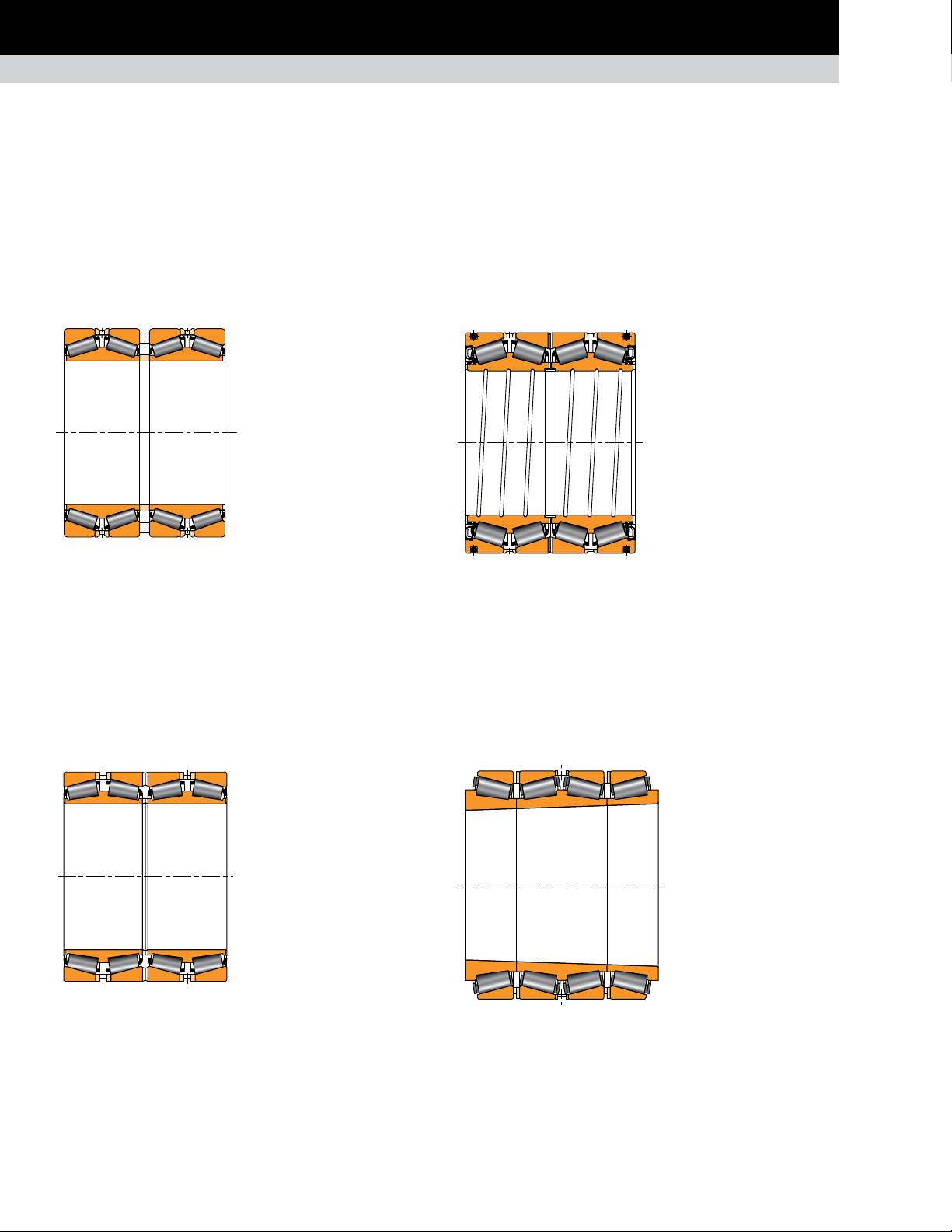

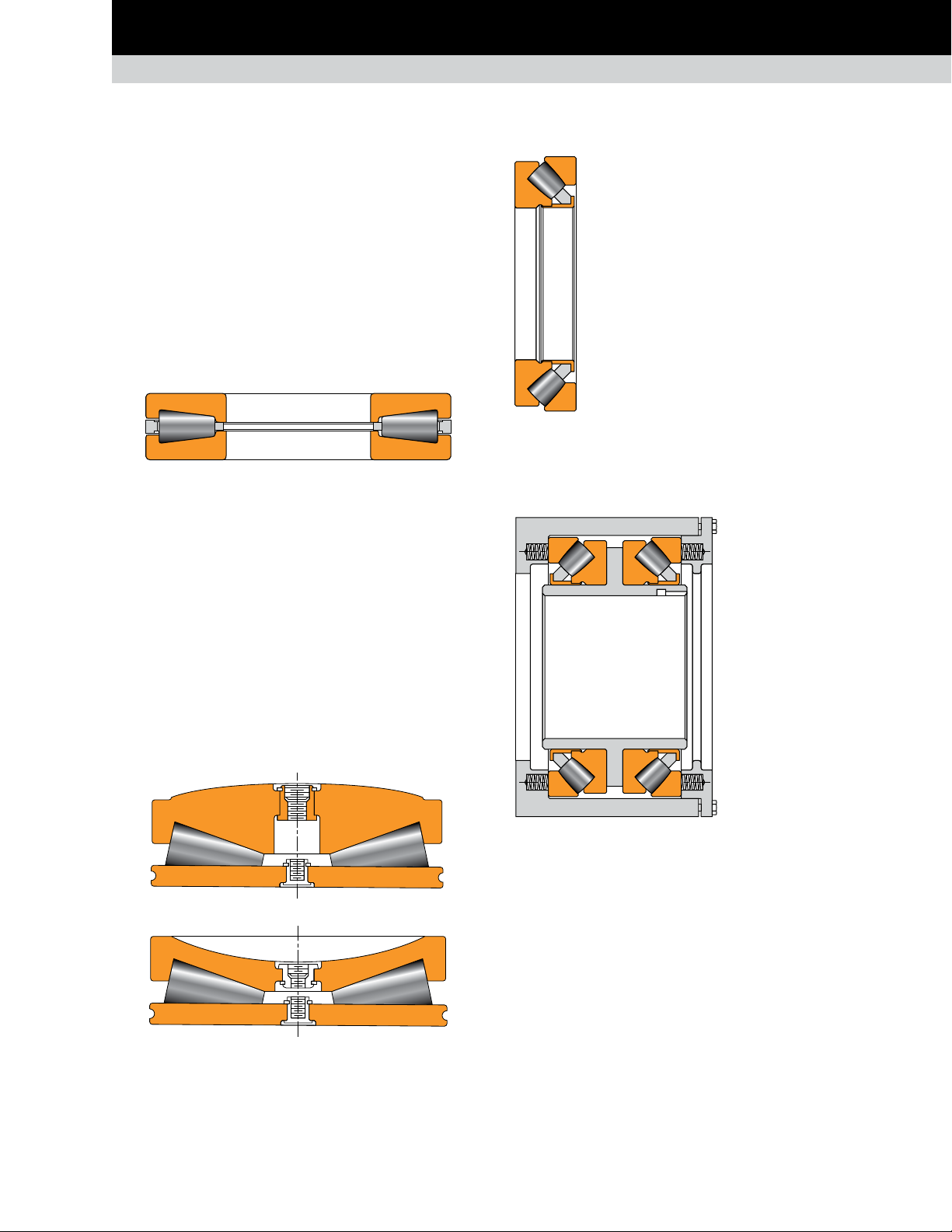

TAPERED ROLLER BEARINGS

Fig. 26. TS.

TS

Composition: One single cone with tapered

roller and one single cup.

Application: Saws, guiding rolls, scrap choppers

and small drives.

Remarks: The TS is the most common tapered

roller bearing that allows the designer a

large choice of mountings. TS bearings

always are fitted in pairs, whether mounted

directly like a TDI or indirectly like a TDO.

TDI AND TDIT

Composition: One double cone, two

single cups, spacer or spacerless.

TDI version with straight

bore (illustrated).

TDIT version with a tapered bore.

TDO

Composition: Two single cones,

one double cup and one cone

spacer.

Application: Mill drives, pinion

stands, coilers, uncoilers, side

trimers and scrap choppers.

Remarks: The TDO is a preset

assembly and works at fixed and

floating positions on rotary shaft

applications. Holes and circular

grooves are normally provided

Fig. 28. TDO.

purposes, one counterbored hole is usually included. This permits

the provision of a locking pin to keep the loose-mounted cup from

rotating at the floating position. This is then referred to as a CD cup.

on the double cup for lubrication

TNA AND TNAT

Composition: Similar to the TDO

version. Cone small faces are

extended to abut and eliminate the

need for a spacer.

TNA version with straight

bore (illustrated).

Application: Edgers, bar mills and rod

mills. We suggest the tight-fitted TDIT

assembly when mill speeds exceed 600

Fig. 27. TDI and TDIT.

Remarks: TDI/TDIT bearings can be delivered as a preset

assembly. The cups and cones are normally mounted loose on

the top version. The bearing works at fixed positions on rotating

shaft applications. For a rotating housing application, it can float

on the stationary shaft.

18

TIMKEN ENGINEERING MANUAL

m/min. (2000 ft./min.).

TNAT version with tapered

cone bores.

Application: Mill drives, pinion

Fig. 29. TNA and TNAT.

Remarks: Preset assembly. These bearings provide a solution

for many fixed or floating bearing applications where simplicity

of assembly is required.

stands, coilers and uncoilers.

Page 21

POPULAR BEARING TYPES IN THE METALS INDUSTRY

AUXILIARY EQUIPMENT

SPHERICAL ROLLER BEARINGS

TNASWH

Composition: Same as the TNA

bearing with one heavy section

double cup and two closures.

Application: Levelers, chock wheels,

conveyor car wheels, various railcars

and crane sheaves.

Remarks: Preset assembly with

profile cup. Cones mounted loose on

the stationary shaft. Assembly also

could function as a wheel.

Fig. 30. TNASWH.

WARNING

Failure to observe the following warnings could

create a risk of death or serious injury.

EM TYPE

Composition: One double inner ring, one double

outer ring, two rows of spherical rollers with

roller-riding brass cage(s).

Application: Mill drives, pinion stands, coilers

and uncoilers.

Remarks: EM-type bearings manage high

radial loads when shaft deflection is important.

Fig. 31. EM type.

EJ TYPE

Composition: One double inner ring, one

double outer ring and two rows of spherical

rollers with stamped-steel cages.

Never spin a bearing with compressed air.

The components may be forcefully expelled.

Application: Gear drives, table rolls and

auxiliary equipment.

Remarks: EJ-type spherical roller bearings

feature a hardened stamped steel windowtype cage with face slots for improved

lubrication flow. It offers high load ratings for

longer life.

Fig. 32. EJ type.

TIMKEN ENGINEERING MANUAL

19

Page 22

POPULAR BEARING TYPES IN THE METALS INDUSTRY

AUXILIARY EQUIPMENT

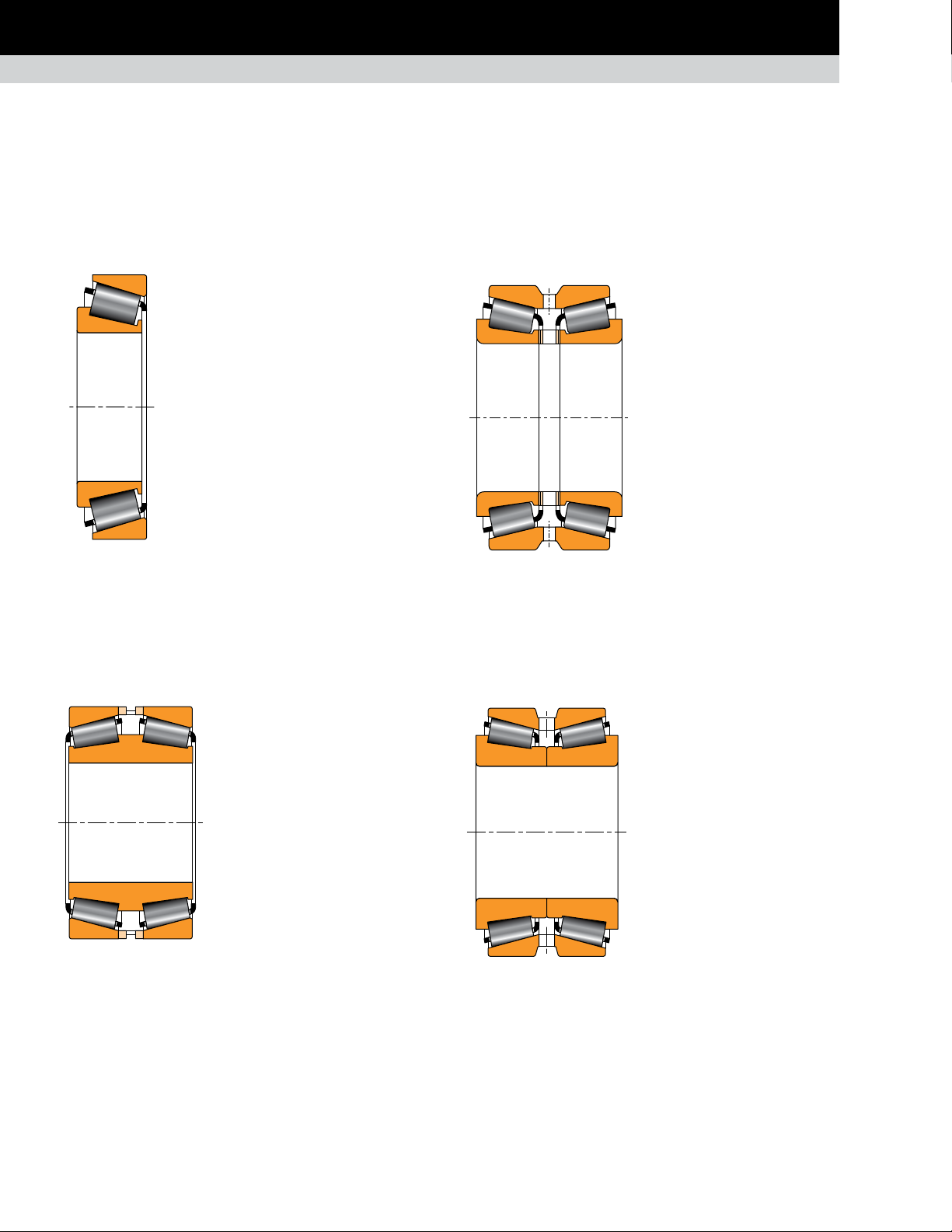

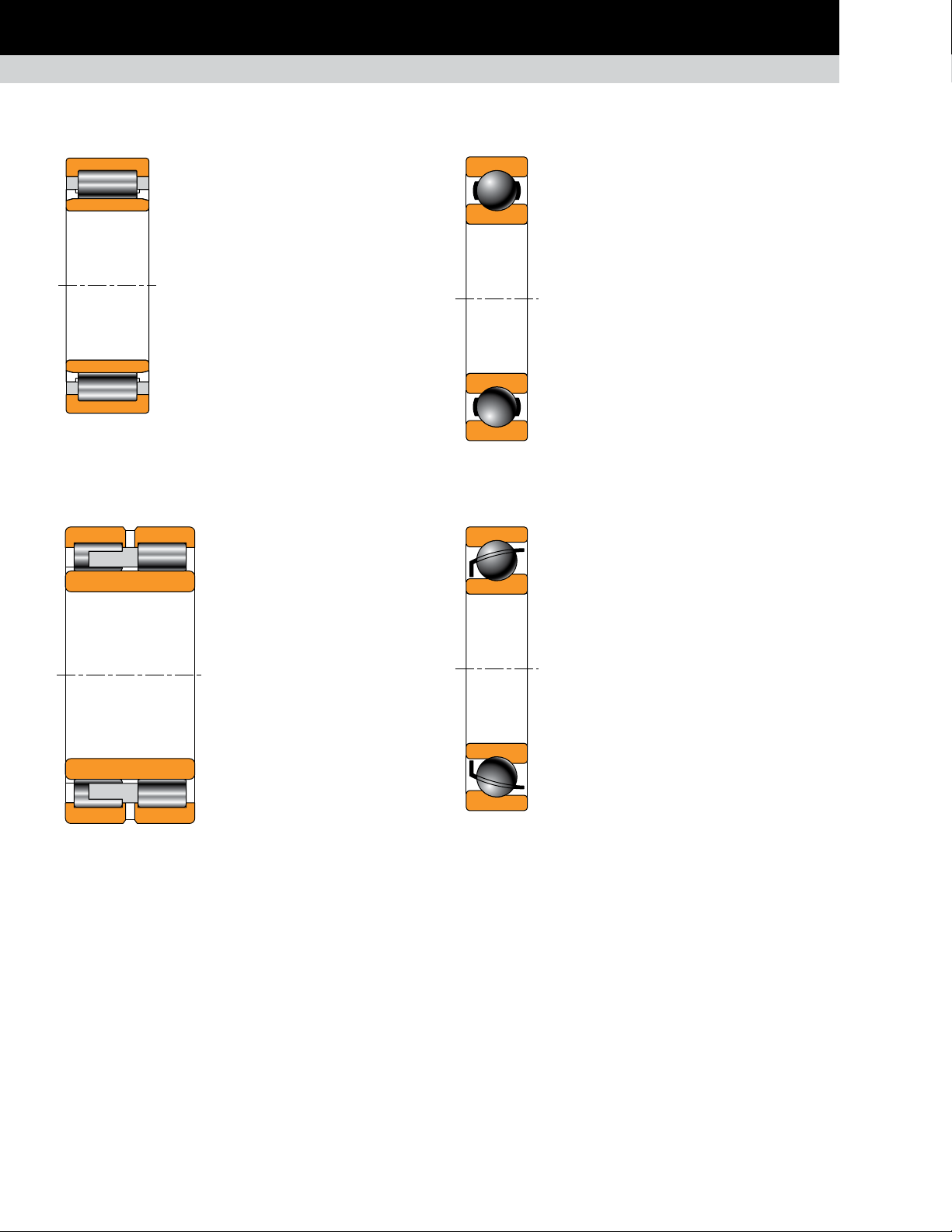

CYLINDRICAL ROLLER BEARINGS

ONE-ROW EMA TYPE

Composition: One single inner ring, one

single outer ring, one row of cylindrical

rollers with a one piece, land-riding

window-type brass cage.

Application: Gear drives, electric motors.

Remarks: Available in multiple configurations:

NU, N, NJ, NF and more.

Fig. 33. One-row

EMA type.

TWO-ROW CYLINDRICAL

ROLLER BEARINGS

Composition: One single inner ring,

one single outer ring, two rows of

cylindrical rollers with a one piece,

land-riding, finger-type brass cage.

Application: Gear drives, crop shear.

Remarks: Standard cage design

includes a drilled pocket, finger-style

brass retainer.

BALL BEARINGS

DEEP-GROOVE RADIAL

BALL BEARING

Composition: Inner and outer ring with a cage

containing a complement of balls.

Application: Gear drives, electric motors, fly

wheels and auxiliary equipment.

Remarks: The standard deep-groove

construction handles radial and light axial

loads for moderate- to high-speed applications.

Available in multiple configurations.

Fig. 35. Deepgroove radial ball

bearing.

ANGULAR-CONTACT

BALL BEARING

Composition: Inner and outer ring with a cage

containing a complement of balls.

Application: Work roll thrust position for long

product mill. Auxiliary equipment.

Remarks: Designed for combination radial and

axial loading. Single-row bearings have thrust

capacity in one direction. Typically used in pairs

to accommodate thrust in both directions.

Fig. 34. Two-row

cylindrical roller bearings.

20

TIMKEN ENGINEERING MANUAL

Fig. 36. Angularcontact ball bearing.

Page 23

APPLICATION CONSIDERATIONS AND BEARING SELECTION

APPLICATION

CONSIDERATIONS

AND BEARING SELECTION

The following processes are covered in this

section:

Steelmaking.

•

Continuous casting.

•

Rolling mill.

•

Flat product rolling.

•

Long product rolling.

•

Bearing solutions: radial positions.

•

Work and intermediate rolls: flat product mills.

•

Work rolls: long product mills.

•

Backup rolls.

•

Bearing solutions: axial positions.

•

Auxiliary equipment.

•

Main mill drive and pinion stand gearboxes.

•

Pay-off and rewind reels.

•

Shears and shear drives.

•

Table rolls.

•

TIMKEN ENGINEERING MANUAL

21

Page 24

APPLICATION CONSIDERATIONS AND BEARING SELECTION

STEELMAKING

The basic processes for the production of semi-finished and

finished products includes the following stages: mining the ore,

smelting, alloying, casting, rolling and finishing. Depending on the

metal type and production method, the processes used during

the smelting stage, where the metal is extracted from the ore,

can vary dramatically. After the smelting stage, the processes

for metals production have much more in common.

This section outlines the critical bearing applications used in the

metals production process after the smelting stage. Specifically,

it covers applications in basic oxygen furnaces (BOF) and

continuous casters used in steel production, as well as hot-rolling

and cold-rolling mills that can be used in the production of flat

and long metal products.

STEELMAKING

THE BASIC OXYGEN FURNACE

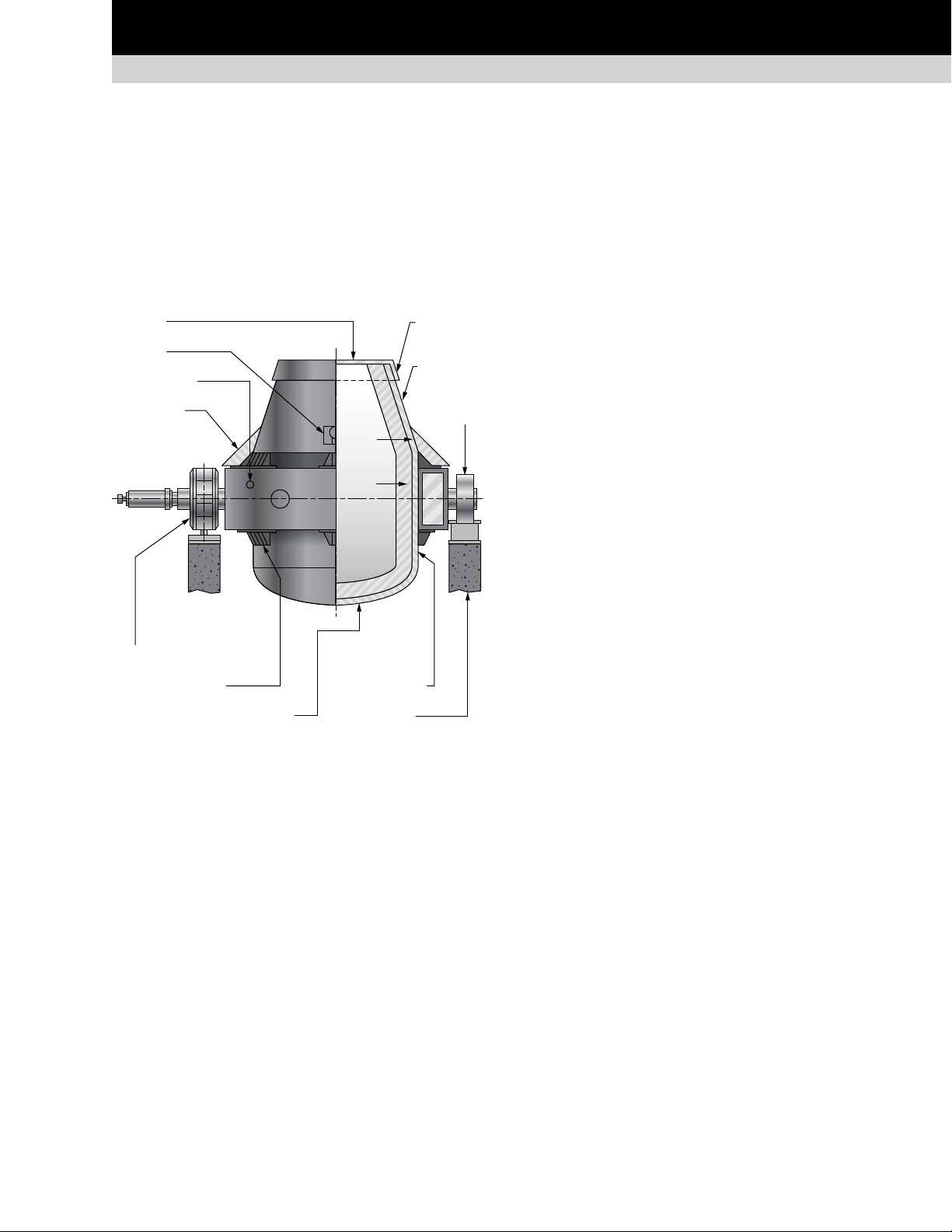

In the BOF (fig. 37) and the mechanically similar bottom-blown

oxygen process (BBOP) and argon-oxygen decarburization (AOD)

furnace, steel is melted for final alloy adjustment and purification.

The three furnaces are all types of converters. Each type has its

own configuration but they all are generally comprised of the

following equipment:

Furnace vessel. The furnace vessel usually resembles a

•

barrel-shape with a dished bottom and a conical top. The

inside includes a refractory material lining and a retractable

hood that closes off the top of the conical section.

Trunnion ring. A trunnion ring wraps around and supports

•

the vessel. The trunnion ring allows the vessel to tip

back and forth, pivoting on two stub shafts about 180

degrees apart.

Main support bearing and

housing assemblies

Drive assembly

Fig. 37. Basic oxygen furnace.

22

TIMKEN ENGINEERING MANUAL

Furnace vessel

Trunnion ring

Page 25

APPLICATION CONSIDERATIONS AND BEARING SELECTION

Top ring

Taphole

Trunnion ring

Slag shield

Nose (lip)

STEELMAKING

Main support bearings and housing assemblies. These

•

bearings come mounted to the stub shafts on the trunnion

ring and support the entire weight of the loaded furnace

and its drive.

Drive assembly. The drive assembly rotates the vessel

•

forward and backward from the vertical position through

approximately 135 degrees in each direction. In modern

vessels, a trunnion stub shaft supports the drive and a

torque arm anchors it to the foundations.

ring

Top cone

Float

bearing

Fixed bearing (drive side)

Support brackets

Torispherical bottom section

Fig. 38. Bearing support on basic oxygen furnace.

Barrel section

Support pier

Safety

lining

Working

lining

The second key bearing locations exist within the drive for the

BOF rotation. The drive is generally comprised of several smaller

enclosed gear reducers and motors mounted to a common

gear case that also enclose the bull gear. Each of the smaller

drive units has its own pinion that meshes with the bull gear.

Bearing selection for this application follows traditional power

transmission guidelines.

MAIN SUPPORT POSITIONS

The preferred bearing type for main support trunnion positions is

the spherical roller bearing due to its high-radial capacity, ability

to function as a fixed position bearing and high-misalignment

capability. Bearing selection is based primarily on static load

capacity because of the slow rotational speed. The target static

capacity-to-load ratio is 3:1 or greater. Typical sizes fall in the

range of 600 mm (23.62 in.) bore to 900 mm (35.43 in.) bore but go

as high as 1250 mm (49.21 in.).

We also must consider when establishing the bearing

requirements unique application conditions. These conditions

may include:

Structural deflections that may exceed ±1.5 degrees.

•

Very high loads at very low speeds and elevated

•

temperatures. This is particularly important in relation to

lubrication.

Oscillating motion through a maximum of 270 degrees of

•

rotation.

Significant axial growth of the trunnion ring due to

•

temperature changes over a large bearing spread up to

12 m (40 ft.).

There are two key positions for roller bearings in BOF applications.

The first and most challenging include the two main support

positions for the vessel and its trunnion ring (fig. 38). The second

lies within the drive.

The main support position bearings allow the vessel to tip forward

for raw material loading and for pouring out the refined steel.

The vessel tips backwards after the refined steel is poured off

(teemed) for slag removal. The melting completes with the vessel

in the vertical position. The combined weight of the vessel,

trunnion ring and the melt max exceed 1000 metric tons. In modern

designs, where the drive mounts directly to the trunnion support

shaft rather than to the foundation, the loads can approach 1500

metric tons.

Significant vibration from the agitation of the steel during

•

melting and from blowing oxygen through the liquid steel.

Vibration is particularly extreme in AOD furnaces.

Highly contaminated operating environments and the

•

resulting demanding sealing requirements.

Practical accessibility for inspection and future bearing

•

replacement.

For these applications and operating conditions, Timken suggests

using a complete bearing and housing system that is tailored

to the specific installation. This system generally includes two

housed assemblies – one for the float position and one for the

fixed position.

TIMKEN ENGINEERING MANUAL

23

Page 26

APPLICATION CONSIDERATIONS AND BEARING SELECTION

Ladder Bearing Arrangement

STEELMAKING

BOF trunnion float position

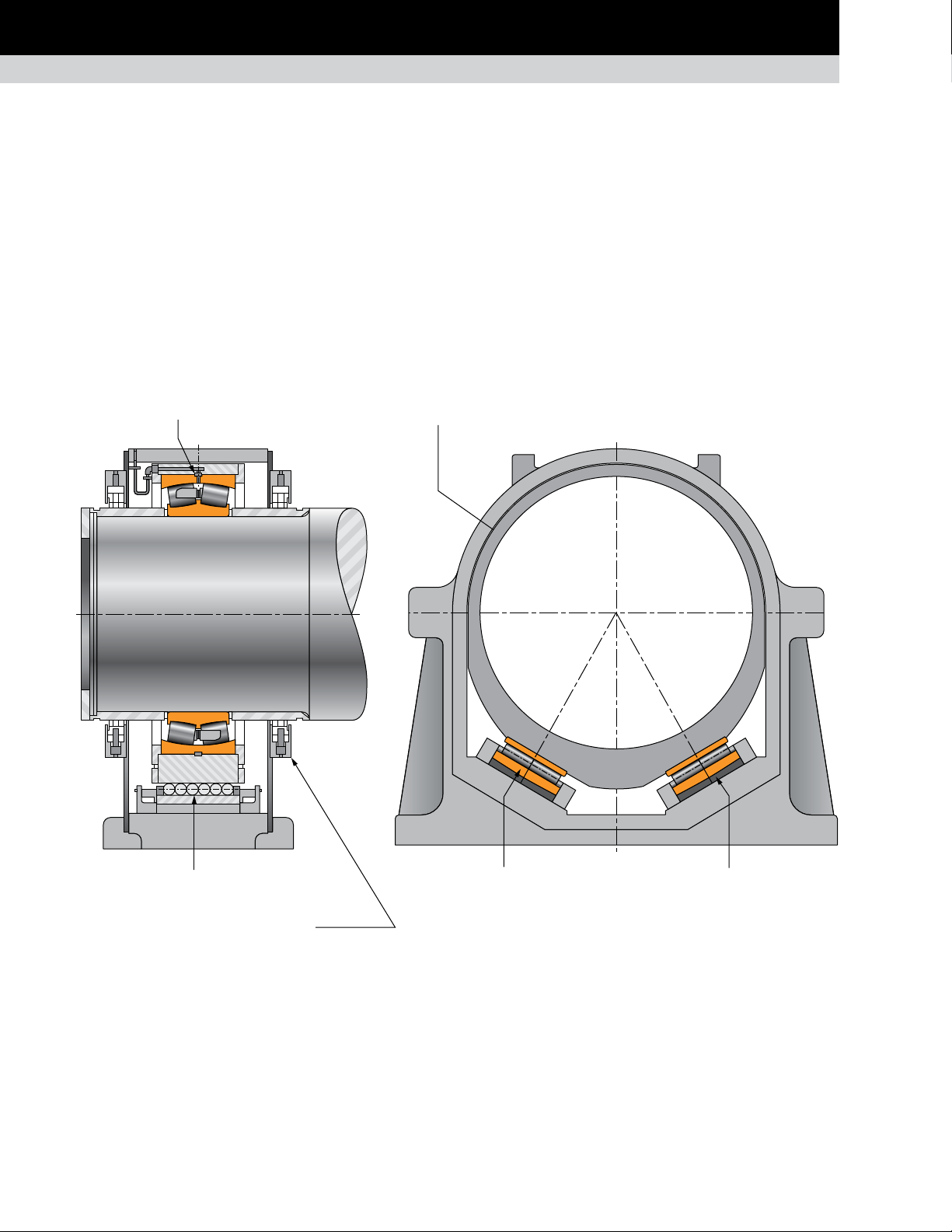

The float position assembly (fig. 39) generally mounts on the

non-driven side of the vessel and must accommodate several

centimeters (inches) of axial movement. The typical bearing

solution mounts the support bearing in a cartridge supported

on a pair of inclined linear bearings, often referred to as ladder

bearings (fig. 40).

The ladder bearings typically offer a float capability of ± 60 to

100 mm (2.5 to 4.0 in.) from its centered position. The static load

capacity of each ladder bearing approximately equals that of the

main support bearing.

FLOAT SIDE OF BOF HOUSING ASSEMBLY:

Full ring to contain radial bearing.

This design does not require the float bearing to move axially in

its housing. This eliminates the risk of galling and wear that can

occur on the bore or outer diameter surfaces when high radial

load forces the bearing to move. Ladder bearings are inclined

towards each other in a shallow V configuration to stabilize and

locate the cartridge in a crosswise direction.

The main support bearing generally has a loose fit on the trunnion

shaft and in the cartridge to facilitate installation and removal. The

floating cartridge assembly and ladder bearings mount in a fully

enclosed steel housing that also includes the main seals.

Bearing cartridge floats on ladder bearing to

accommodate thermal expansion.

Complete assembly installed as a unit;

all bearing areas completely sealed.

Fig. 39. Float side of BOF housing assembly.

Plain seatSpherical seat

Fig. 40. Ladder bearing arrangement.

24

TIMKEN ENGINEERING MANUAL

Page 27

APPLICATION CONSIDERATIONS AND BEARING SELECTION

Bearing with tapered bore and adapter sleeve.

STEELMAKING

BOF trunnion fixed position assembly

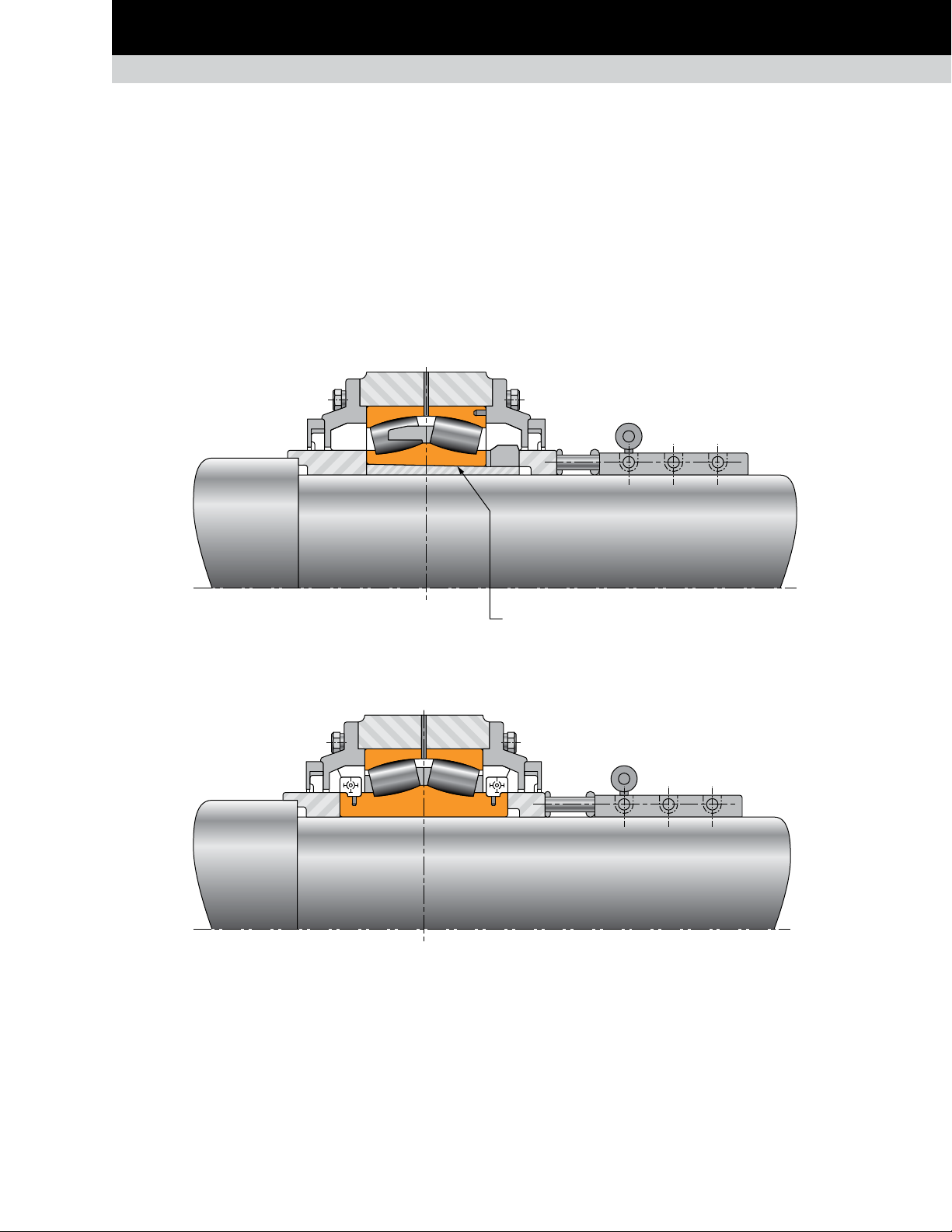

The fixed position assembly is simpler and smaller because it

does not require the floating internal cartridge or ladder bearings.

The fixed position is usually on the drive side of the furnace. One

important design feature of the fixed position assembly involves

the ability to replace the original standard bearing (fig. 41) with

a split version (fig. 42). This proves necessary because the

replacement of a standard bearing would require the removal

of the complete drive assembly. This is a difficult and very timeconsuming task.

FIXED SIDE OF BOF HOUSING ASSEMBLY:

Initial mounting of standard bearing is done in one of two ways.

Either mount a straight bore bearing directly to the shaft using a

tight fit; or mount a tapered bore bearing using a tapered adapter.

The use of the adapter allows final control of the bearing

position on the shaft and some adjustment of the bearing

internal clearance. The adapter also facilitates bearing removal

through the use of hydraulic pressure that frees the bearing from

the adapter.

Fig. 41. Standard bearing.

Fig. 42. Split bearing.

Bearing with tapered bore and adapter sleeve.

TIMKEN ENGINEERING MANUAL

25

Page 28

APPLICATION CONSIDERATIONS AND BEARING SELECTION

STEELMAKING

The use of a split replacement bearing facilitates removal of the

standard bearing. First remove the housing cap, slightly raise the

trunnion shaft, then remove the standard bearing by cutting or

fracturing it into halves. If a tapered adapter was used, remove

it in the same manner. An axial slot in the adapter-bore facilitates

burn off without trunnion shaft damage. The new split bearing

builds up around the shaft before lowering back down into

the housing.

The tight-fitted adapter helps reduce the risk of impact damage

to the bearing components due to potentially violent vibration of

the vessel during operation.

Spherical roller bearings used in BOF housings have a standard

misalignment capability of 1.5 degrees. When higher misalignment

is required, the bearing may be supplied with a wide outer ring

that increases the misalignment capability to 3 degrees. Timken

identifies bearings with this feature using W57 in the part number.

Timken usually supplies assemblies with sleeves located on the

trunnion shaft on both sides of the bearing. The backing sleeves

facilitate axial clamping of the complete assembly onto the shaft

and function as seal riding surfaces. When installing a split

bearing, replace these sleeves with narrower versions to make

room for the wider inner ring.

Because BOF bearing assemblies must function in the dustcontaminated and often hot environment of a steel mill, effective

sealing is critical. Bearings subjected to contamination by

abrasive converter dust may suffer premature wear. To help

prevent this, robust sealing accommodates the displacement

of the shaft that results from trunnion ring thermal growth

and deflection.

Additional considerations for trunnion

bearing selection

Furnaces must tolerate the significant and sometimes violent

vibration that occurs during furnace charging, melting and

purification. Consider these factors during the design and

selection of bearings and housings. For optimal bearing

performance, we prefer light-to-tight bearing fits on the shaft

and in the housing. However, it also is important to consider the

ease of installation and removal.

Minimized bearing radial clearance limits risks of fretting

corrosion (false brinelling) of the rollers and raceways. Minimizing

operating clearances and applying light-to-tight fits also improves

the seating of the bearing’s inner and outer rings and maximizes

the load zone within the bearing. These bearings are traditionally

through-hardened but Timken also offers the bearings with casecarburized components for applications where shock loading is

a particular concern.

In this application, the lubricant primarily functions to help prevent

corrosion and to help keep contaminants out. To achieve this,

we suggest 100 percent grease fill of the bearing and housing

cavity. These furnaces use an extremely slow rotational speed.

Rollers and raceways cannot generate a normal lubricant film.

A heavy consistency, extreme-pressure (EP) grease with a very

high base-oil viscosity can improve lubrication conditions. We

suggest synthetic base oil, lithium complex types.

Timken also manufactures split and special bearing designs and

can review your specific application needs. For more details,

contact your Timken engineer.

26

TIMKEN ENGINEERING MANUAL

Page 29

APPLICATION CONSIDERATIONS AND BEARING SELECTION

CONTINUOUS CASTING

The continuous caster for producing steel slabs (fig. 43), blooms

and billets represents the most significant development in steel

production since the Bessemer converter. Compared to the

traditional, individually poured cast ingot route, the continuous

caster offers significant improvements in yield, consistency

and energy efficiency as well as reduced emissions and

waste products. In addition, the ability to cast thinner slabs

(alloy dependent) may significantly reduce the subsequent hot

rolling requirements.

Generally, the conventional slab caster produces slabs between

180 mm (7 in.) and 300 mm (12 in.) thick at speeds of 0.8 to

2.0 m/min. (2.6 to 6.5 ft./min.). The medium slab caster produces

slabs between 100 mm and 180 mm (4 and 7 in.) thick at speeds of

1.0 to 3.0 m/min. (3.3 to 10 ft./min.). The thin slab caster produces

slabs less than 100 mm thick at speeds of 3.0 up to 6.0 m/min. (10

to 20 ft./min.).

CONTINUOUS CASTING

Fig. 43. Typical continuous slab caster layout.

TIMKEN ENGINEERING MANUAL

27

Page 30

APPLICATION CONSIDERATIONS AND BEARING SELECTION

CONTINUOUS CASTING

CASTER DESIGN

Fig. 44 shows the main components of the continuous caster. Nearly all installations possess this overall configuration, although minor

variations will exist depending on the original equipment manufacture's technology, steel grade being cast, and end-user preferences.

The following description refers to slab casting but bloom and billet casters can receive similar considerations.

Foot rolls

Bender section

Fig. 44. Continuous slab caster schematic.

Horizontal withdrawing section

SEQUENCE OF OPERATIONS

First, molten steel transfers from the steelmaking furnace to the

casting platform in a ladle.

Then the ladle pours the molten steel into the tundish through

a shroud.

Another shroud takes the molten steel into the water-cooled mold.

The mold lining, typically comprised of a copper alloy, oscillates

to minimize the chance of the steel sticking to the mold. The steel

solidifies at the surface to form its shape (slab, billet or bloom)

before it emerges from the mold, attached to the dummy bar. The

dummy bar detaches at the exit end of the caster.

Once the slab leaves the mold, it proceeds through the top

zone (foot rolls) via the bender to the curved (bow) section

through a straightener section and finally to the horizontal

withdrawal section.

A straight-mold equipped caster includes a bender section that

forms the slab to match the curvature of the bow section. Casters

with a curved mold do not require the bender.

Bow section

Straightener section

Below the mold, caster sections break down into eight to 12

discrete segments, each with five to seven roll pairs with one roll

of each pair above and one below the slab. One of the roll pairs

is a driven pair that controls the speed of the slab. The other,

idler rolls, support the slab and maintain its thickness and shape.

Many casters will make a small reduction in the slab thickness as

it descends through the bow section. This is referred to as soft

core reduction and is done for metallurgical reasons rather than

for slab thickness control.

The top and bottom rolls are mounted on two separate frames and

adjustment is provided to allow setting the position of the top rolls

relative to the bottom rolls. Each of the individual roll segments

can be removed from the caster as a complete assembly.

External, high-volume water sprays cool the slab. The

support rolls also are water cooled via rotary couplings and

internal passages. Cooling the rolls and bearing housings

controls component temperature and the integrity of their

mechanical properties.

After the slab exits the straightener segment(s) it passes through

the horizontal withdrawal segments and is cut to length with a

traversing gas torch. Finally, the slab is brought to a cooling yard

where it is marked before being transferred to the hot rolling mill.

28

TIMKEN ENGINEERING MANUAL

Page 31

APPLICATION CONSIDERATIONS AND BEARING SELECTION

CONTINUOUS CASTING

CASTER BEARING POSITIONS

LADLE TURRET

The rotating portion of the turret, supports the main bearing

application in the ladle turret.

Mould and

Ladles

Fig. 45. Typical ladle turret layout.

Tundish

Ladle turret bearings

The bearings must resist very high overturning moments resulting

from the cantilevered loads. The highest overturning moments

occur when one side supports a full ladle while the other side

is empty. They also must tolerate shock loads that occur when

a full ladle is loaded onto the support arms. The total weight of

the ladle turret, ladles and molten steel can exceed 1000 metric

tons, while the rotational speed reaches no more than 1 rev./min.

Two turret design styles exist. The first (fig. 45) uses a single

turntable attached to both support arms. The turntable is mounted

onto a large-diameter slewing ring bearing that can measure

several meters in diameter. This is the most common design.

The second design utilizes a central column, or mast, around

which sleeve-attached support arms rotate around the center

column on radial and thrust bearings. This style can be configured

to accommodate independent rotation of each ladle support arm.

oscillator

assembly

Rotating

turret

MOLD OSCILLATOR

Oscillating the mold is critical to help minimize the sticking of the

steel to the mold liner. Early caster styles achieved this oscillation

through mechanical mechanisms using cams or eccentrics and

an electric motor drive. Hydraulic resonant oscillators replaced

most of these designs because they provide a more compact

design and control flexibility. The hydraulic design also eliminates

mechanical drive components that can wear quickly and require

frequent maintenance.

Mold oscillator bearings

Casters that use mechanical oscillators require bearings

specifically designed to handle the oscillating loads and

vibrations. Cylindrical, spherical and tapered roller bearings

commonly meet this need. They are generally specified with

high-strength cages and are manufactured with tight control of

internal clearances and run-out.

FOOT ROLL (TOP ZONE) AND

BENDER SECTIONS

This is the first section of slab support rollers directly beneath

the mold. The skin on the slab is thin and fragile so the support

rollers are close together and small in diameter. These rolls are

usually in the range of 120 to 160 mm (4.7 to 6.3 in.) in diameter

and are idler (non-driven) rolls.

Roll construction utilizes a single, full-width arbor/axle built up

with roll section sleeves and intermediate support bearings. More

commonly, roll construction consists of individual roll sections,

each with a support bearing at both ends. These rolls utilize

external cooling with water sprays.

Caster bearings endure tough conditions in this environment,

including heavy loads, high temperatures, low rotational speed as

well as water, scale and steam contamination. The slab surface,

which passes just a few millimeters (a fraction of an inch) from

the bearing housing, reaches approximately 1000° C (2000° F).

Bearing types used in the mast-style ladle turret will vary

according to the original equipment manufacturer. Generally,

cylindrical roller bearings provide radial support and a dedicated

thrust bearing provides the axial support. This thrust bearing can

utilize a tapered-, spherical- or cylindrical-roller type.

TIMKEN ENGINEERING MANUAL

29

Page 32

APPLICATION CONSIDERATIONS AND BEARING SELECTION

CONTINUOUS CASTING

Foot roll section and bender bearings

Due to these extreme conditions, bearings located at foot roll (fig.

46) and bender roll positions are usually removed from operation

on a fixed schedule rather than on the basis of their condition at

inspection. Replacement typically occurs every four to six months.

Sealing is usually achieved with the use of steel spiral rings or

piston rings since the temperatures are too high for elastomeric

seals. A continuous grease lubrication is typically used to keep

contaminants from entering into the bearing.

Bearing types used here include single- and double-row needle

roller bearings in the NA49, NA59 and NA69 series, as well

as spherical roller bearings and cylindrical roller bearings of

the toroidal or self-aligning type. Our specially heat-treated

bearings offer dimensional stability during operation at elevated

temperatures. These bearings are usually identified with a S2 or

S3 as the suffix to the part number. This identifies the bearings

as being dimensionally stable at temperatures up to 250° C and

300° C (482° F and 572° F) respectively.

Bearing loads in these applications vary by the number of rolls,

the number of bearings per roll, roll position and the ferro-static

pressure within the slab. Speeds often fall in the range of 2 to

15 RPM, depending on the thickness of slab being cast. The low

rotational speed means that loading is considered static because

a hydrodynamic lubricant film generates outside the rollers and

the raceways of the bearing. The bearing’s static capacity is,

therefore, more important than the dynamic capacity. Generally,

bearing selection revolves around a static capacity-to-load ratio

of 3:1. However, the frequent replacement of the bearings means

that many installations operate with a ratio of 2:1. This need for

frequent maintenance, combined with low speeds prompt loose

fits for both the inner and outer rings.

SLAB SUPPORT SEGMENTS (BOW,

STRAIGHTENER AND HORIZONTAL SECTIONS)

The slab support segments in the bow, straightener and horizontal