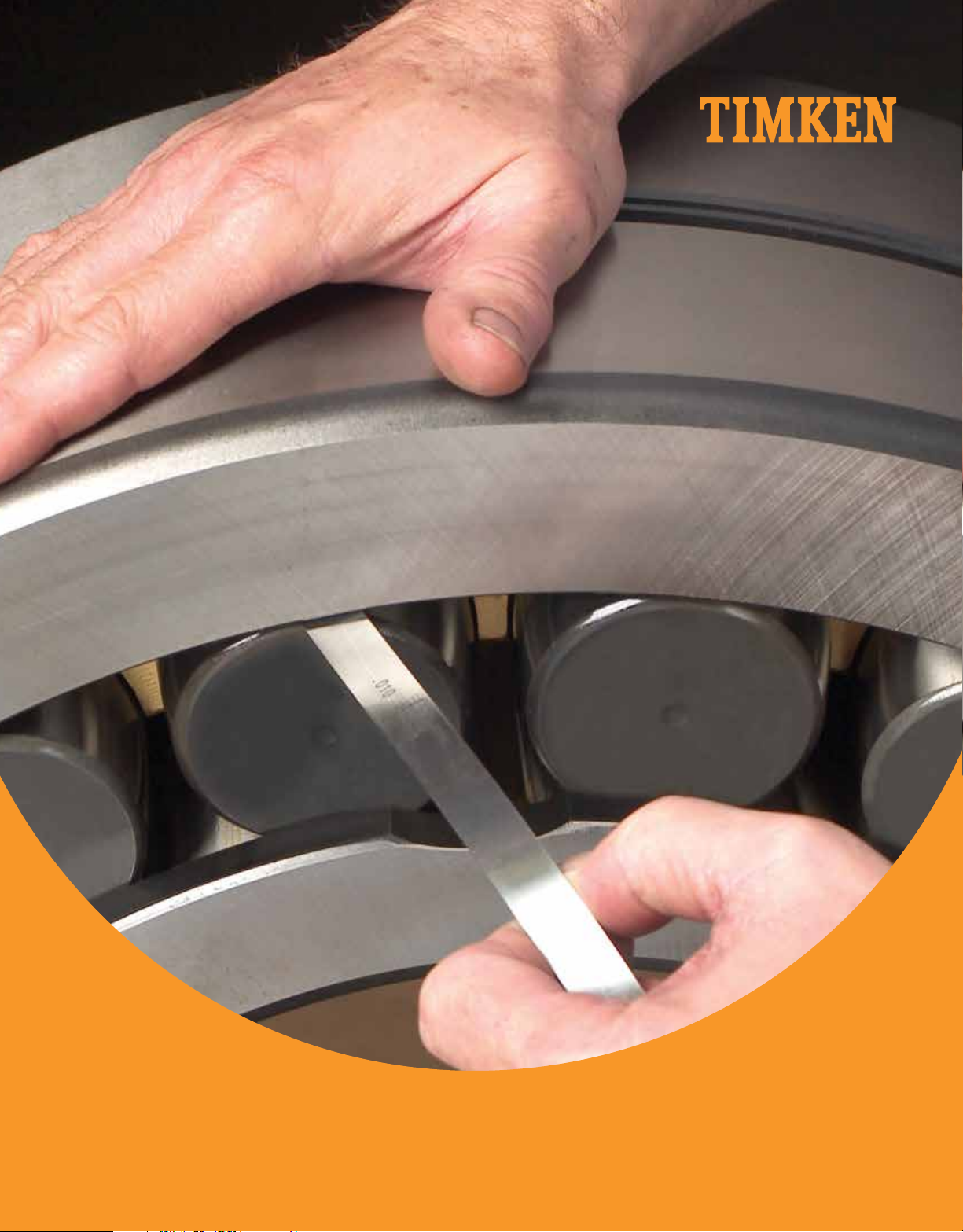

Timken Industrial Bearing Maintenance Manual

Industrial Bearing Maintenance Manual

WARNING

Failure to observe the following warnings could

create a risk of serious injury.

Proper maintenance and handling practices are critical.

Always follow installation instructions and

maintain proper lubrication.

Never spin a bearing with compressed air.

The rolling elements may be forcefully expelled.

CAUTION

Failure to observe the following cautions could

create a risk of serious injury.

Do not attempt to disassemble unitized bearings.

Remove oil or rust inhibitor from parts before heating

If a hammer and bar are used for installation or removal

of a part, use a mild steel bar (e.g. 1010 or 1020 grade).

Mild steel bars are less likely to cause release of high speed

fragments from the hammer, bar or the bering.

to avoid fire or fumes.

NOTE

This manual is not intended to substitue for the specific

recommendations of your equipment supplier.

Every reasonable effort has been made to ensure the accuracy

of the information contained in this catalog, but no liability is

accepted for errors, omissions or for any other reason.

INDEX

TIMKEN - WHERE YOU TURN..................................5

A

GENERAL BEARING HANDLING AND INSPECTION...............9

B

INTERNAL CLEARANCES ....................................19

C

SHAFT AND HOUSING REQUIREMENTS .......................31

D

SHAFT AND HOUSING TOLERANCES ABMA STANDARD 7.......37

E

TAPERED ROLLER BEARINGS.................................55

F

SPHERICAL ROLLER BEARINGS...............................89

G

CYLINDRICAL ROLLER BEARINGS............................101

H

THRUST BEARINGS ........................................109

I

BALL BEARINGS ...........................................117

J

MAINTENANCE TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

K

LUBRICATION AND SEALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

L

INDUSTRIAL BEARING MAINTENANCE MANUAL

3

INDUSTRIAL BEARING MAINTENANCE MANUAL

4

T

I

M

K

E

N

A

-

W

H

E

R

E

Y

O

U

T

U

R

N

A

A

TIMKEN - WHERE YOU TURN

A

K

E

N

-

W

H

E

R

E

Y

O

U

T

U

R

N

T

M

I

A

TIMKEN - WHERE YOU TURN

TIMKEN - WHERE YOU TURN

A

Maintenance professionals around the world turn to Timken to help

improve the performance and extend the life of their equipment.

The information in this manual will help you follow proper industrial

maintenance practices to get the most out of your Timken

products and the equipment in which they operate. You will find

practical information describing how to install, adjust, lubricate

and maintain all of the primary types of anti-friction bearings. We

have also included additional information on maintenance tools

and proper lubrication.

ENGINEERING EXPERTISE

Timken has more than a century of experience developing bearings

and related products that reduce friction, improve efficiency and

minimize customer maintenance. Our advancements in bearing

design, quality and materials create a customer advantage we

call “power density.” This means we are increasing bearing loadcarrying capability, enabling a smaller bearing to carry the same

load for the same predicted life as a previously larger one. Power

density gives equipment designers greater flexibility and leads to

lower total system cost.

CUSTOMER SERVICE AND SUPPORT

Practices such as bearing mounting, adjustment and proper

lubrication are very specific to an application. While we are not

able to encompass every practice for every application in this

manual, additional Timken publications and resources are available

to assist with specialized tasks for a wide range of applications.

In addition, our Timken sales representatives are available to help

you address unique bearing-related application problems. Backed

by a global team of experts that include metallurgists, lubrication

specialists, scientists, service engineers and customer service

representatives, they comprise an unmatched technical resource

for our customers.

A COMPLETE LINE OF FRICTION MANAGEMENT

PRODUCTS AND SERVICES

Our friction management knowledge is being applied to a broader

array of products and services than ever before. We have a total

system approach to our engineering philosophy and our product

and service offering, which impacts uptime, maintenance costs

and your bottom line. Turn to us today for one of the world’s most

complete friction management offerings, including:

Condition Monitoring

•

Lubrication

•

Maintenance Tools

•

Remanufacture and Repair

•

Seals

•

Training

•

INDUSTRIAL BEARING MAINTENANCE MANUAL

7

A

TIMKEN - WHERE YOU TURN

INDUSTRIAL BEARING MAINTENANCE MANUAL

8

G

E

N

B

E

R

A

L

B

E

A

R

I

N

G

H

A

N

D

L

I

N

G

B

GENERAL BEARING

HANDLING AND INSPECTION

General Bearing Handling And Inspection ................11

Bearing Storage ........................................11

Removing Bearings From Equipment .....................12

Damaged Bearings .....................................14

Installation .............................................14

Lubrication .............................................17

A

N

B

N

I

O

T

C

E

P

S

I

N

D

B

E

R

A

N

I

G

H

A

N

D

L

I

N

G

A

N

D

N

O

I

T

C

E

P

S

N

I

E

N

E

G

A

R

L

B

B

GENERAL BEARING HANDLING AND INSPECTION

GENERAL BEARING

HANDLING AND INSPECTION

Bearings are a vital component in major industrial equipment.

Bearing problems can result in costly downtime, equipment

damage and breakdowns. In addition, large industrial bearings

represent a significant capital investment.

To attain reliable operation with high equipment performance and

the lowest possible maintenance costs, it is essential to follow

proper handling practices. This includes bearing storage, removal,

cleaning, inspection and installation.

BEARING STORAGE

Bearings with special anti-corrosion coatings are available, but

most bearings are not manufactured from corrosion resistant

materials. When handling and storing bearings, care must be

taken to ensure that they will not rust or corrode. Even a small

amount of moisture or chemical left on an unprotected bearing

by a glove or hand can result in a small etched area, which may

initiate bearing fatigue.

B

The useful life of any bearing depends to a great extent on the care

and maintenance it receives. This is especially true in industrial

applications, where operating conditions tend to be harsh, loads

are heavy, and contamination from dirt and scale are common.

Details about specific handling and inspection processes for

different types of bearings are included in those sections of this

manual. This section addresses general processes and practices

that apply to all anti-friction bearing designs.

New and remanufactured Timken bearings are shipped with a

protective coating, are typically covered in a protective paper

or other wrapping, and are shipped in a carton or crate. When

receiving a new or remanufactured bearing, do not remove it from

its packaging until ready to install in the application.

Do not store bearings directly on concrete floors, where water

can condense and collect on the bearing. Store the bearings on a

pallet or shelf, in an area where the bearings will not be subjected

to high humidity or sudden and severe temperature changes that

may result in condensation forming.

Always put oiled paper or, if not available, plastic sheets between

rollers and cup races of tapered roller bearings.

INDUSTRIAL BEARING MAINTENANCE MANUAL

11

GENERAL BEARING HANDLING AND INSPECTION

REMOVING BEARINGS FROM EQUIPMENT

B

Each type of bearing design has a unique removal process.

Regardless of the bearing type, the bearing must be removed with

extreme care. If done incorrectly, you can damage the bearings,

shafts or housings, requiring expensive repairs.

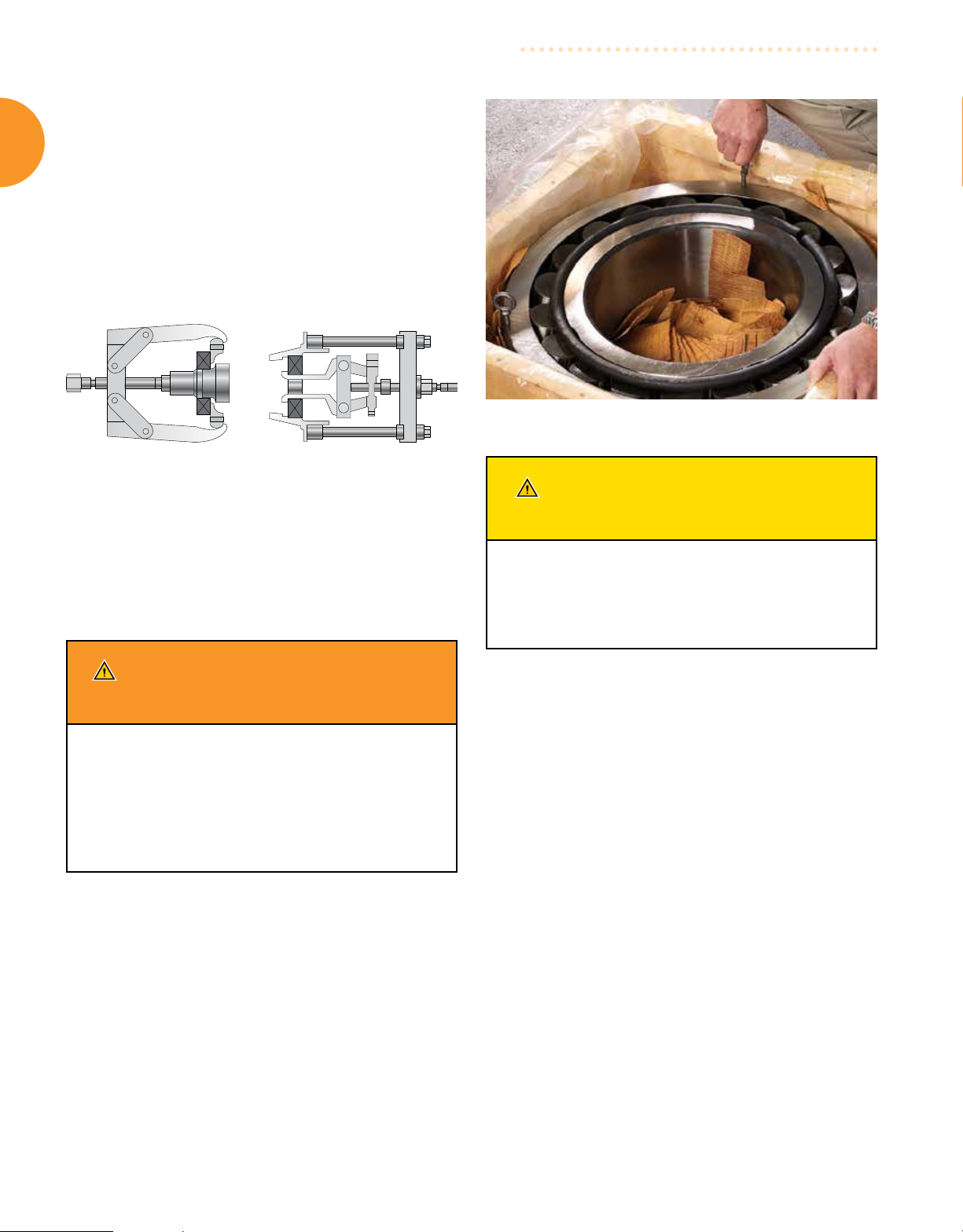

For smaller bearings, there are a variety of pullers available to

assist with bearing removal (Fig. 1). Information concerning special

pullers or other removal devices can be obtained by contacting

your Timken representative.

Fig. 1. Pullers for bearing removal.

For bearings installed with a tight or press fit, or that have

become locked in place on a shaft and cannot be removed with a

mechanical puller, the inner ring of the bearing can be heated to

ease removal. Heat lamps or other heating devices can be used.

If a torch is used, it will change the properties of the bearing steel

and the bearing must be discarded.

Fig. 2. Eyebolts can be inserted into lifting holes.

CAUTION Failure to observe the following

cautions could create a risk of injury.

If the bearing is to be reused or returned for repair,

do not use heat from a torch.

Extreme heat from a torch can alter the bearing hardness and

metallurgical structure, resulting in irreparable damage.

WARNING Failure to observe the following

warnings could create a risk of serious bodily harm.

Tensile stresses can be very high in tightly fitted bearing

components. Attempting to remove such components by cutting

the cone (inner race) may result in a sudden shattering of the

component causing fragments of metal to be forcefully expelled.

Always use properly guarded presses or bearing pullers to

remove bearings from shafts, and always use suitable personal

protective equipment, including safety glasses.

Lifting large bearings

Large bearings can be lifted and moved using a variety of slings,

hooks, chains and mechanical devices. Some large bearings are

manufactured with tapped holes in the face of inner rings or outer

rings. Eyebolts or other points of attachment can be inserted in

these lifting holes (Fig. 2).

Many large bearings have threaded lifting holes in the cage ring

that can be used to lift the inner ring assembly.

A clean, heavy duty nylon sling provides one of the best means

of handling large bearing components because it eliminates the

possibility of burring or scratching.

Regardless of what method is used to lift the bearings, use care

to avoid damaging any of the bearing surfaces. Be especially

cautious when lifting or moving bearings that are equipped with a

cage. The cage is typically the most deformable component of the

bearing and is more susceptible to damage.

Cleaning

After removing a bearing from a piece of equipment, thoroughly

clean it to remove all scale, water, lubricant, debris and any other

contaminants. Bearings must be cleaned thoroughly to allow for

proper bearing inspection.

Smaller bearings can be cleaned in a wash tank that circulates a

cleaning solution such as kerosene, mineral spirits or a commercial

solvent through the bearing (Fig. 3). Use the cleaning solution

to remove all lubricant and contamination, making sure that the

internal rolling elements are completely clean.

INDUSTRIAL BEARING MAINTENANCE MANUAL

12

GENERAL BEARING HANDLING AND INSPECTION

B

Fig. 3. Smaller bearings can be cleaned in a wash tank.

WARNING Failure to observe the following

warnings could create a risk of serious bodily harm.

Proper maintenance and handling practices are critical.

Failure to follow installation instructions and to maintain

proper lubrication can result in equipment failure.

Never spin a bearing with compressed air.

The rolling elements may be forcefully expelled.

Alkali cleaners, such as trisodium phosphate (TSP) mixed two

or three ounces per gallon of hot water, may also be used. Hot

cleaning solutions are often used as a final cleaning or rinse after

the initial cleaning.

For large bearings, or to clean large numbers of bearings, special

cleaning equipment such as a large tank containing appropriate

cleaning solution is required. Tanks are typically heated with

electrical coils, and a pump is used to agitate the cleaning solution

(Fig. 4). Final cleaning is done by suspending the bearing and using

a hose to flush away any contamination.

To reduce bearing contamination from other sources, all parts of the

housing, shaft and gears should also be thoroughly cleaned. After

the bearing has been cleaned, it can be dried with compressed air,

taking care not to let the bearing spin.

Fig. 4. Tanks are heated with electric coils and a pump is used to

agitate the cleaning solution.

Inspection

When a piece of equipment is taken out of service for routine

inspection or maintenance, take the opportunity to also inspect

and measure the bearings to ensure that they are still within

tolerance specifications for the application. In some applications,

the expected bearing life may be the limiting factor in the equipment

maintenance schedule.

The schedule for equipment tear downs for bearing inspection will

vary depending on operating conditions. Consult your equipment

maker for the appropriate inspection schedule.

Between equipment tear downs where full bearing inspections are

conducted, you should conduct routine inspections to ensure that

bearings are operating normally and have proper lubrication. To

reduce the need for these inspections, and to more closely monitor

bearing and equipment health, Timken condition monitoring

systems are available that sense the vibration and temperature

in bearings.

The inspection area must be clean and free from dirt and debris to

avoid contaminating the bearing. Even a small piece of debris that

enters a bearing can create a point of high stress that could lead

to spalling and early fatigue.

After cleaning, the bearing should be carefully inspected for

damage and wear. If the bearing is not going to be returned to

service immediately, it should be covered with a coating of light oil

to protect against rust and corrosion.

INDUSTRIAL BEARING MAINTENANCE MANUAL

13

GENERAL BEARING HANDLING AND INSPECTION

B

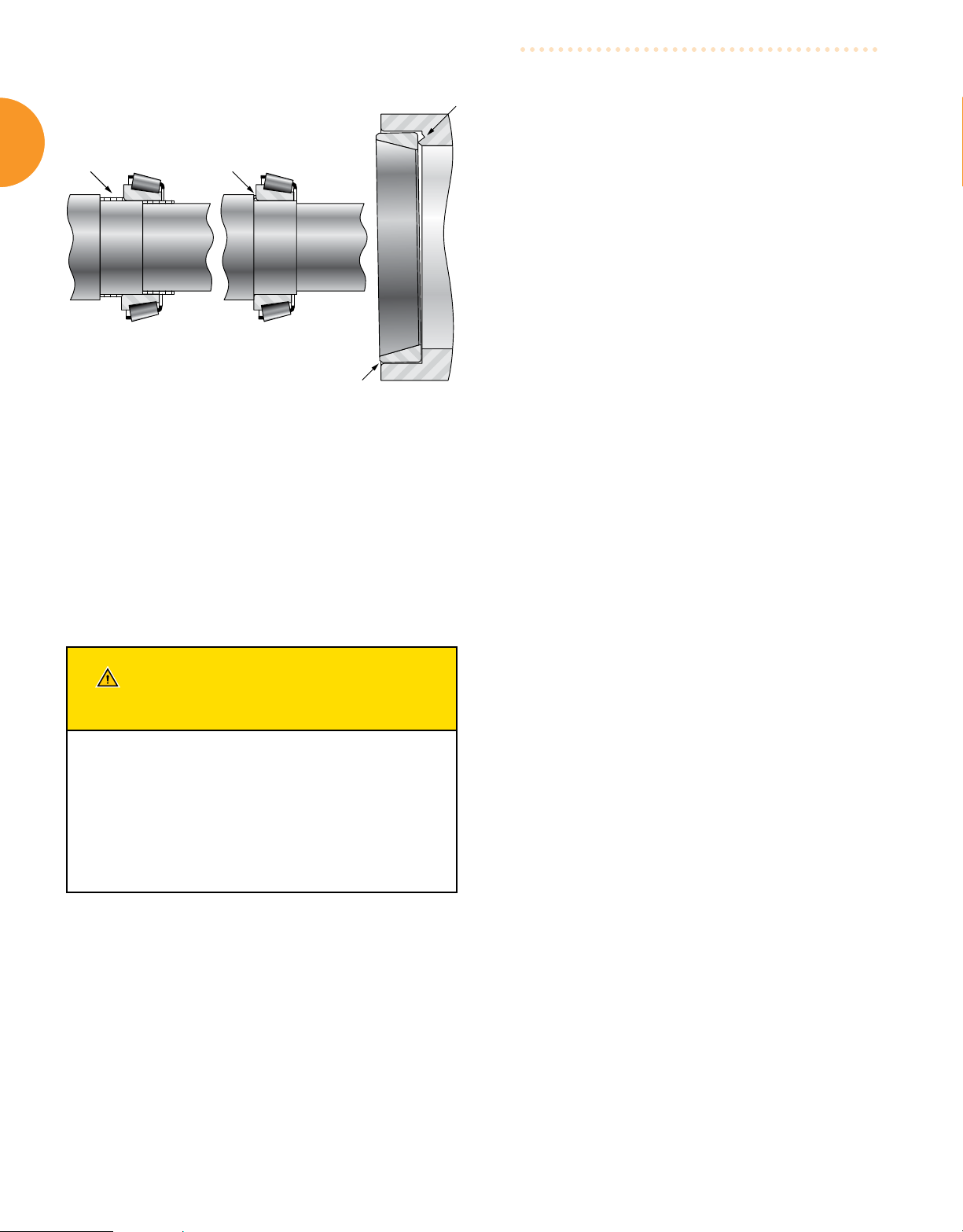

Chips on the bearing

seat are trapped

between face of bearing

and shoulder

Fig. 5. It is important to check for burrs on the

inner and outer ring seats and backing surfaces.

In addition to examining the bearing, a full inspection should

include the housing and shaft. Check for burrs or metal chips

on the inner and outer ring seats and backing surfaces (Fig. 5).

Burrs or chips can be removed by scraping or filing the damaged

surfaces.

Inspect the shaft for proper size, roundness, burrs or other damage.

A 12-point check of the shaft with a micrometer is suggested

(see page 33). If there is evidence of shaft or housing wear, it

should be checked against original equipment manufacturer’s

specifications.

Burrs on shoulder or

bearing seat

valuable clues that can help analyze and identify possible causes,

leading to corrective actions that will help ensure longer bearing

life in the replacement bearing.

There are several Timken resources available to assist you in

analyzing bearing damage, including online resources at timken.

com and publications with photos representing common types

of bearing damage. Contact your Timken representative for more

information.

Bearing repair

Small areas of damage on bearing races, and on the contact

surface of the rolling elements, can sometimes be repaired by

grinding out the loose metal. Any raised or rough areas should be

smoothed flat with grinding and polishing tools.

Light rust or corrosion should be removed with emery paper

(240 – 320 # grit). As much of the damage should be removed as

possible to prevent it from contaminating the bearing when it is

returned to service.

For more complex bearing repairs, Timken offers remanufacture

and repair services.

INSTALLATION

Do not remove the bearing from its packaging until you are ready to

mount it. The packaging provides protection from contamination.

CAUTION Failure to observe the following

cautions could create a risk of injury.

Do not attempt to disassemble unitized bearings.

Remove oil or rust inhibitor from parts before heating

to avoid fire or fumes.

If a hammer and bar are used for installation or removal of a

part, use a mild steel bar (e.g. 1010 or 1020 grade). Mild steel

bars are less likely to cause release of high speed fragments

from the hammer, bar or the bearing.

DAMAGED BEARINGS

Despite taking proper precautions, bearings may become damaged

either through improper storage and handling or through normal

wear in use. Bearings that have been damaged or are no longer

within specifications may still be returned to service after repair or

refurbishment. Some bearings can be refurbished more than once.

Eventually all bearings will sustain sufficient wear or damage and

will have to be replaced.

If a bearing is damaged or worn beyond repair sooner than

expected, do not discard it. The nature of the damage can provide

When installing a new bearing, do not remove the lubricant or

preservative applied by the manufacturer. The preservatives

used on almost all bearings are fully compatible with commonly

used oils and other lubricants. Leaving it in place will protect the

bearing from fingerprints and corrosion.

Bearings should be installed in a clean environment, free from

dust, debris, moisture and other contaminants. When installing a

bearing in the field, make an effort to ensure a clean work area.

Use protective screens around the work area, and provide a clean

resting surface for the bearing and other components until they

can be installed.

Before beginning the installation, plan your work. Be certain that

you have the correct replacement bearing and necessary additional

components. Also determine what tools will be required, including

adjustment tools if appropriate, and have them on hand. Finally,

if the bearing needs to be lubricated as part of the installation

process, have the appropriate lubricants and tools available.

Planning your work will enable you to perform the installation

more quickly with few delays, shortening the amount of time the

bearing is out of the equipment and exposed to contamination and

possible handling damage.

INDUSTRIAL BEARING MAINTENANCE MANUAL

14

GENERAL BEARING HANDLING AND INSPECTION

B

Fig. 6. Bearings can be heated in a pan or metal container filled

with oil.

Thoroughly clean all machine components near where the bearing

will be installed, giving special attention to the mounting surfaces

and housings. Housings should be cleaned, including blowing

out the oil holes. If the equipment has blind holes where air is

ineffective, use a magnetic rod to remove metal chips that might

have become lodged there during machining or maintenance.

Shaft surfaces that will support and contact the bearing must be

clean and free from nicks or burrs. Shaft shoulders and spacer

rings contacting the bearing should be square with the shaft axis.

The shaft fillet must be small enough to clear the radius of the

bearing.

Do not install bearings in a damaged or worn housing, or on a

damaged or worn shaft. Inner and outer ring seat damage should

be repaired by using properly fitted sleeves. Shafts can be built

up by metal spray and machined to the correct size. If there is not

a press fit on the shaft, a weld overlay and re-grind process is

recommended to bring the shaft back to specification.

Heating bearings

Fig. 7. Induction heater.

A heat lamp can also be used to heat rings, and the temperature

regulated by adjusting the distance from the light to the ring.

The fastest method of safely heating bearings is an induction

heater (Fig. 7). Induction heaters work very quickly. Take care

to avoid heating the bearing to temperatures higher than 120ºC

(250ºF).

For larger bearings, you may need to use an oil bath to heat the

bearing (Fig. 8). Maximum temperature of the oil bath should

not exceed 120ºC (250ºF). The bearing should be positioned in

the center of the tank, and allowed to heat long enough to fully

expand. Do not allow the bearing to come in direct contact with

the heat source.

Bearing

Oil

Bearing support

block

In applications that require a tight fit of the inner ring on the shaft,

it can be easier to install the bearing if it is first heated to expand

slightly. For applications that require a tight fit of the outer ring in

a housing, it may also be possible to heat the housing to expand it,

allowing the bearing to install more easily.

Small bearings can be heated using several methods. They can be

heated in a pan or metal container filled with oil (Fig. 6). A screen

or platform should be used to keep the bearing from resting on the

bottom of the pan where heat is applied.

Flame burner

Fig. 8. Oil bath.

Bearing held from bottom by

screen/platform

INDUSTRIAL BEARING MAINTENANCE MANUAL

15

B

GENERAL BEARING HANDLING AND INSPECTION

TEMPERATURE GUIDELINES FOR HEATING OR COOLING

CAUTION Failure to observe the following

cautions could create a risk of injury.

If the bearing is to be reused or returned for repair,

do not use heat from a torch.

Extreme heat from a torch can alter the bearing hardness and

metallurgical structure, resulting in irreparable damage.

Keep the bearings away from any localized high-heat source

that may raise the bearing temperature too high, resulting in race

hardness reduction.

When heating bearings, be sure that they have enough time to

fully heat. Bearings typically require 20 to 30 minutes of soak time

per inch of inner-ring cross section to fully heat in an oil tank.

While the bearing is still warm, remove it from the heater or tank

and place it on the shaft. Slide the bearing up the shaft until it

squarely contacts the shaft shoulder. Then install the locknut/

washer or clamping plate to prevent the bearing from backing off

the shoulder while cooling. As the bearing cools, the locknut or

clamping plate should be tightened.

ROLLING ELEMENT BEARINGS FOR INSTALLATION

These maximum and minimum temperatures, as well as maximum

time-at-temperature limits, have been established to prevent

metallurgical transformation of steel components, and potential,

detrimental physical changes in seals or non-metallic components.

During the manufacturing process, bearing rings and rolling

elements are heat treated to define the strength, hardness and

dimensional stability for proper operation. Heating or cooling

bearings or bearing components beyond these limits may affect

performance.

These suggestions are merely guidelines and, as new data is

developed, the values as shown may change. These guidelines do

not cover all Timken

NOTE: Always use protective safety equipment and clothing when

handling parts that have been heated or cooled.

Never heat a bearing with a torch, as localized heating will irreparably

damage bearing components.

Never rapidly heat or freeze a bearing or bearing component.

Only use approved equipment, methods and controls to achieve

desired temperature.

Always follow OEM instructions to ensure bearings and rings are

properly positioned after heating or cooling.

®

products.

Thermal growth of components can be calculated using the

formula:

d x ΔT x α = Thermal Growth

Where:

d = bearing bore diameter

ΔT = maximum bearing temperature after heating minus

ambient temperature

α = coefficient of linear expansion: 11 x 10

for ferrous metal shaft and housing materials

-6

/ ºC (6.1 x 10-6/ ºF)

Sample calculation

Example:

For a bearing with a 3-1/2 in. bore heated from an ambient

temperature of 70° F to 200° F, the thermal growth of the bearing

bore diameter can be calculated as follows:

Thermal Growth = 3.500” x (200° - 70°) x 6.1x10

For a bearing with a 90 mm bore heated from an ambient

temperature of 21° C to 93° C:

Thermal Growth = 90 mm x (93° - 21°) x 11x10

-6

= 0.0028 in.

-6

= 0.071 mm

Heating

Standard class bearings or rings (with metallic cages and without seals):

Include Class 2, 4, 7, K, N, ABEC-1 and ABEC-3

•

93°C (200°F) - 24 Hours

•

121°C (250°F) - 8 Hours

•

Precision bearings or rings (with non-metallic cages and polymer or elastomer seals):

Special considerations may apply for phenolic cages or spe-

•

cial fluorocarbon lip seals.

Include Class 3, 0, 00, 000, C, B, A, AA, ABEC 5 and 7

•

Precision and superprecision class bearings and rings (any)

66°C (150°F) - 24 Hours

•

INDUSTRIAL BEARING MAINTENANCE MANUAL

16

Cooling (Freezing)

GENERAL BEARING HANDLING AND INSPECTION

Freezing standard class bearings and rings

54°C (-65°F) - 1 Hour

•

Freezing precision class outer rings or cups

-29°C (-20°F) - 2 Hours

•

Note: This temperature can be obtained by commercial freezer/

refrigeration equipment.

Cone bore temperature reading in degrees

Thermometer Temperature Reading in Degrees

Cone Bore

mm

in.

25.4 0.012 0.020 0.027 482.6 0.231 0.375 0.520

1 0.0005 0.0008 0.0011 19 0.0091 0.0148 0.0205

50.8 0.025 0.040 0.055 508 0.243 0.396 0.548

2 0.0010 0.0016 0.0022 20 0.0096 0.0156 0.0216

76.2 0.036 0.058 0.081 533.4 0.256 0.416 0.576

3 0.0014 0.0023 0.0032 21 0.0101 0.0164 0.0227

101.6 0.048 0.078 0.109 558.8 0.269 0.436 0.604

4 0.0019 0.0031 0.0043 22 0.0106 0.0172 0.0238

127 0.061 0.099 0.137 584.2 0.279 0.454 0.629

5 0.0024 0.0039 0.0054 23 0.011 0.0179 0.0248

152.4 0.073 0.119 0.165 609.6 0.292 0.475 0.657

6 0.0029 0.0047 0.0065 24 0.0115 0.0187 0.0259

177.8 0.086 0.139 0.193 635 0.304 0.495 0.685

7 0.0034 0.0055 0.0076 25 0.012 0.0195 0.027

203.2 0.096 0.157 0.218 660.4 0.317 0.515 0.713

8 0.0038 0.0062 0.0086 26 0.0125 0.0203 0.0281

228.6 0.109 0.177 0.246 685.8 0.330 0.535 0.741

9 0.0043 0.0070 0.0097 27 0.013 0.0211 0.0292

254 0.121 0.198 0.274 711.2 0.340 0.553 0.767

10 0.0048 0.0078 0.0108 28 0.0134 0.0218 0.0302

279.4 0.134 0.218 0.302 736.6 0.353 0.574 0.795

11 0.0053 0.0086 0.0119 29 0.0139 0.0226 0.0313

304.8 0.147 0.238 0.330 762 0.365 0.594 0.823

12 0.0058 0.0094 0.013 30 0.0144 0.0234 0.0324

330 0.157 0.256 0.355 787.4 0.378 0.614 0.85

13 0.0062 0.0101 0.014 31 0.0149 0.0242 0.0335

355.6 0.170 0.276 0.383 812.8 0.391 0.635 0.878

14 0.0067 0.0109 0.0151 32 0.0154 0.025 0.0346

381 0.182 0.297 0.411 838.2 0.401 0.652 0.904

15 0.0072 0.0117 0.0162 33 0.0158 0.0257 0.0356

406.4 0.195 0.317 0.439 863.6 0.414 0.673 0.932

16 0.0077 0.0125 0.0173 34 0.0163 0.0265 0.0367

431.8 0.208 0.337 0.467 889 0.426 0.693 0.960

17 0.0082 0.0133 0.0184 35 0.0168 0.0273 0.0378

457.2 0.218 0.355 0.492 914.4 0.439 0.713 0.988

18 0.0086 0.014 0.0194 36 0.0173 0.0281 0.0389

65º C

150º F

mm

in.

90º C

200º F

mm

in.

120º C

250º F

mm

in.

Cone Bore

mm

in.

Thermometer Temperature Reading in Degrees

65º C

150º F

mm

in.

90º C

200º F

mm

in.

120º C

250º F

mm

in.

B

INDUSTRIAL BEARING MAINTENANCE MANUAL

17

GENERAL BEARING HANDLING AND INSPECTION

B

Pressing on bearings

Smaller bearings may be pressed onto the shaft or into a housing

with an arbor press and mounting tube. Between the press ram

and the bearing, use a tube of soft steel with an inside diameter

slightly larger than the shaft. The outside diameter of the tube

should not exceed the maximum shoulder height for the bearings.

The tube should be square at both ends, thoroughly clean inside

and out, and long enough to clear the end of the shaft after the

bearing is mounted.

Inspect the shaft and housing for proper size, roundness,

•

burrs or other damage. A 12-point check of the shaft with a

micrometer is suggested (see page 33).

Coat the shaft with light machine oil or assembly paste to

•

reduce the force needed to press the bearing on the shaft.

Use a tube or pipe with an inner diameter (I.D.) that is slightly

•

larger than the outer diameter (O.D.) of the shaft. The O.D.

of the tube or pipe should be small enough that it does not

contact the rolling elements or cage of the bearing.

Position the tube on the inner ring and apply steady pressure

•

with sufficient force to smoothly press the ring into place, and

firmly against the shoulder or backing surface (Fig. 9).

Adjusting bearing clearance

The space between the rolling elements and the races of an antifriction bearing is known as the bearing clearance, referred to in

tapered roller bearings as the lateral, lateral clearance or end play.

In other types of anti-friction bearings such as spherical, cylindrical,

or ball bearings, the radial internal clearance or RIC, is specified.

Clearance is desirable in applications where allowance must be

provided for thermal growth of components, to accommodate for

slight misalignment or other application requirements.

Bearings may also have zero clearance, with the contact surfaces

of the rolling elements brought into contact with the races in lineto-line contact.

Finally, bearings may have the rolling elements and races brought

into contact with a defined initial force, a condition known as

preload. This enables precise control over the internal geometry

of the mating parts, and is desirable where runout must be held

within critical limits, such as high precision applications.

Bearings with separable races, such as tapered roller bearings,

allow the clearance (preload) to be “adjusted” to meet application

requirements. Other types of bearings are manufactured with a

known clearance or preload, but the clearance can be slightly

reduced through an interference fit on the inner or outer race.

Fig. 9. Positioning the tube on the inner ring.

Never attempt to make a press fit on a shaft by applying pressure

to the outer ring of an assembled bearing. However, because

they have a separable outer ring, the outer ring of tapered roller

bearings can be pressed into a housing. See page 61.

For specific information regarding bearing installation in your

equipment, contact the equipment manufacturer.

For information about adjusting various types of bearings, see the

section of this manual for each bearing design.

LUBRICATION

See the Lubrication Section of this manual beginning on page 155.

INDUSTRIAL BEARING MAINTENANCE MANUAL

18

I

N

T

E

R

N

A

L

C

C

L

E

A

R

A

N

C

E

S

C

C

INTERNAL CLEARANCES

Tapered Roller Bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Radial Ball Bearings ....................................22

Spherical Roller Bearings ...............................25

Cylindrical Roller Bearings ..............................27

C

N

I

T

E

R

N

A

L

C

L

E

A

R

A

N

C

E

S

C

INTERNAL CLEARANCES

TAPERED ROLLER BEARINGS

INTERNAL CLEARANCES

In tapered roller bearings, internal clearance is usually defined

as a specific amount of either end play or preload. Establishing

this clearance, or setting, at the time of assembly is an inherent

advantage of tapered roller bearings. They can be set to provide

optimum performance in almost any application. Fig. 10 gives

an example of the relationship between fatigue life and bearing

setting. Unlike some types of anti-friction bearings, tapered roller

bearings do not rely strictly on housing or shaft fits to obtain a

certain bearing setting. One race can be moved axially relative to

the other to obtain the desired bearing setting.

L10 life

Light preload

Heavy preload

Zero Clearance

Large end play

Bearing setting obtained during initial assembly and adjustment is

the cold or ambient bearing setting and is established before the

equipment is subjected to service.

C

Bearing setting during operation is known as the operating bearing

setting and is a result of changes in the ambient bearing setting

due to thermal expansion and deflections encountered during

service.

The ambient bearing setting necessary to produce the optimum

operating bearing setting varies with the application. Application

experience, or testing, generally permits the determination of

optimum settings. Frequently, however, the exact relationship

of ambient to operating bearing setting is an unknown and an

educated estimate has to be made. To determine a suggested

ambient bearing setting for a specific application, consult with

your Timken representative.

Generally, the ideal operating bearing setting is near zero to

maximize bearing life. Most bearings are set with end play at

assembly to reach the desired near zero setting at operating

temperature when mounted.

Axial end play

Preload End play

0

Bearing operating setting

Fig. 10. Relationship between fatigue life and bearing setting.

At assembly, the conditions of bearing setting are defined as:

End play – An axial clearance between rollers and races pro-

•

ducing a measurable axial shaft movement when a small axial

force is applied - first in one direction, then in the other, while

oscillating or rotating the shaft (Fig. 11).

Preload – An axial interference between rollers and races

•

such that there is no measurable axial shaft movement when

a small axial force is applied - in both directions, while oscillating or rotating the shaft.

Line-to-line – A zero setting condition; the transitional point

•

between end play and preload.

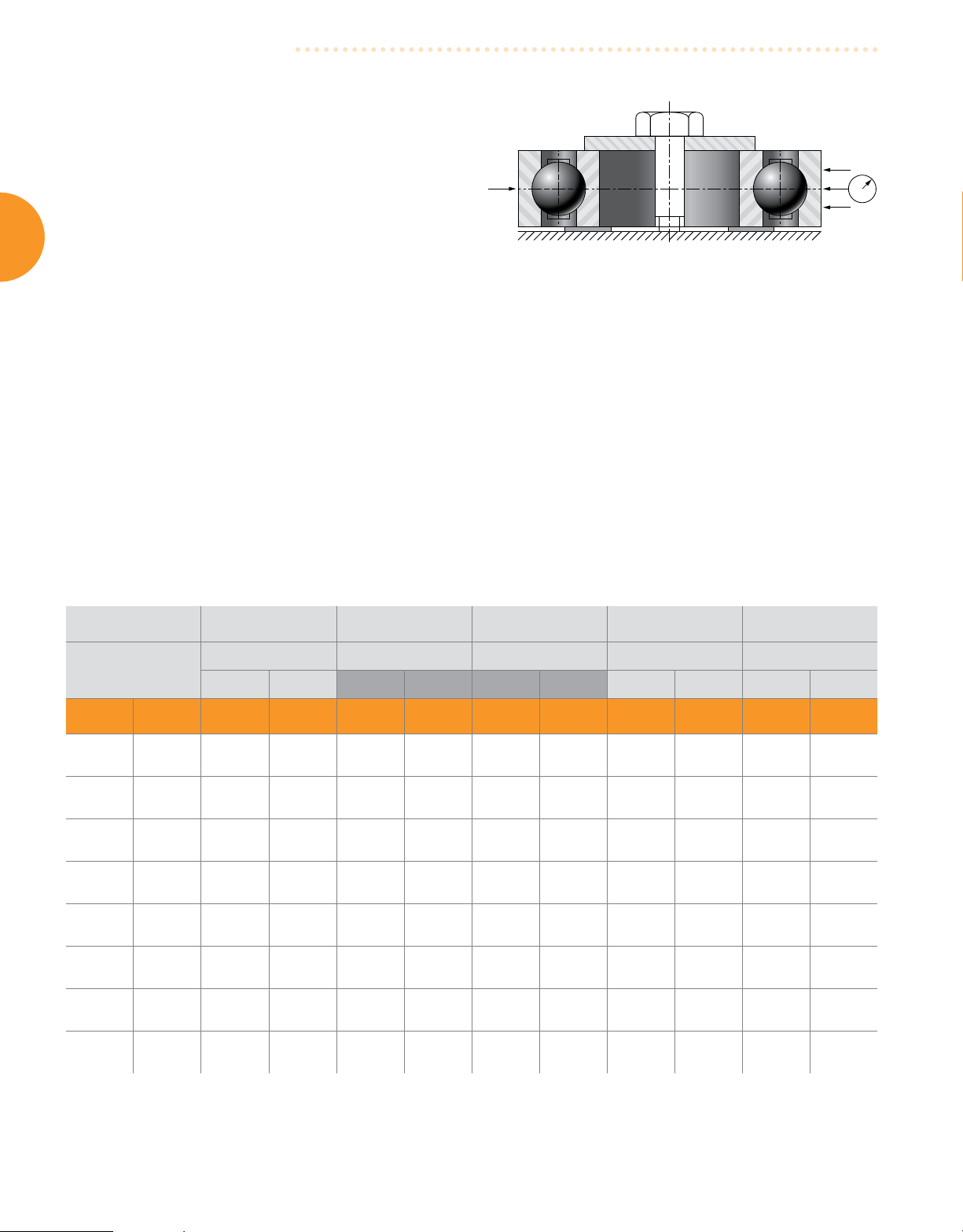

Fig. 11. Axial force is applied in both directions while rotating

the shaft.

INDUSTRIAL BEARING MAINTENANCE MANUAL

21

INTERNAL CLEARANCES

RADIAL BALL BEARINGS

In the manufacture of ball bearings, it is standard practice to

assemble rings and balls with a specified internal clearance. This

characteristic is necessary to absorb the effect of press fitting the

bearing rings at mounting.

C

Internal clearances sometimes are used to compensate for

thermal expansion of bearings, shafts and housings or to provide

a contact angle in the bearing after mounting. Internal clearance

Fig. 12. RIC can be measured mechanically by moving the outer ring

horizontally.

can be measured either by gaging radially or axially.

Radial measurement is accepted as the more significant

characteristic because it is more directly related to shaft and

housing fits. It also is the method prescribed by the American

Bearing Manufacturers Association (ABMA).

the average inner ring raceway diameter minus twice the ball

diameter.

RIC can be measured mechanically by moving the outer ring

horizontally as pictured in Fig. 12. The total movement of the

outer ring when the balls are properly seated in the raceways

Radial internal clearance

The radial internal clearance (RIC) of a radial contact ball bearing

can be defined as the average outer ring raceway diameter minus

determines the radial internal clearance. Several readings should

be taken using different circumferential orientations of the rings in

order to get a comprehensive average reading.

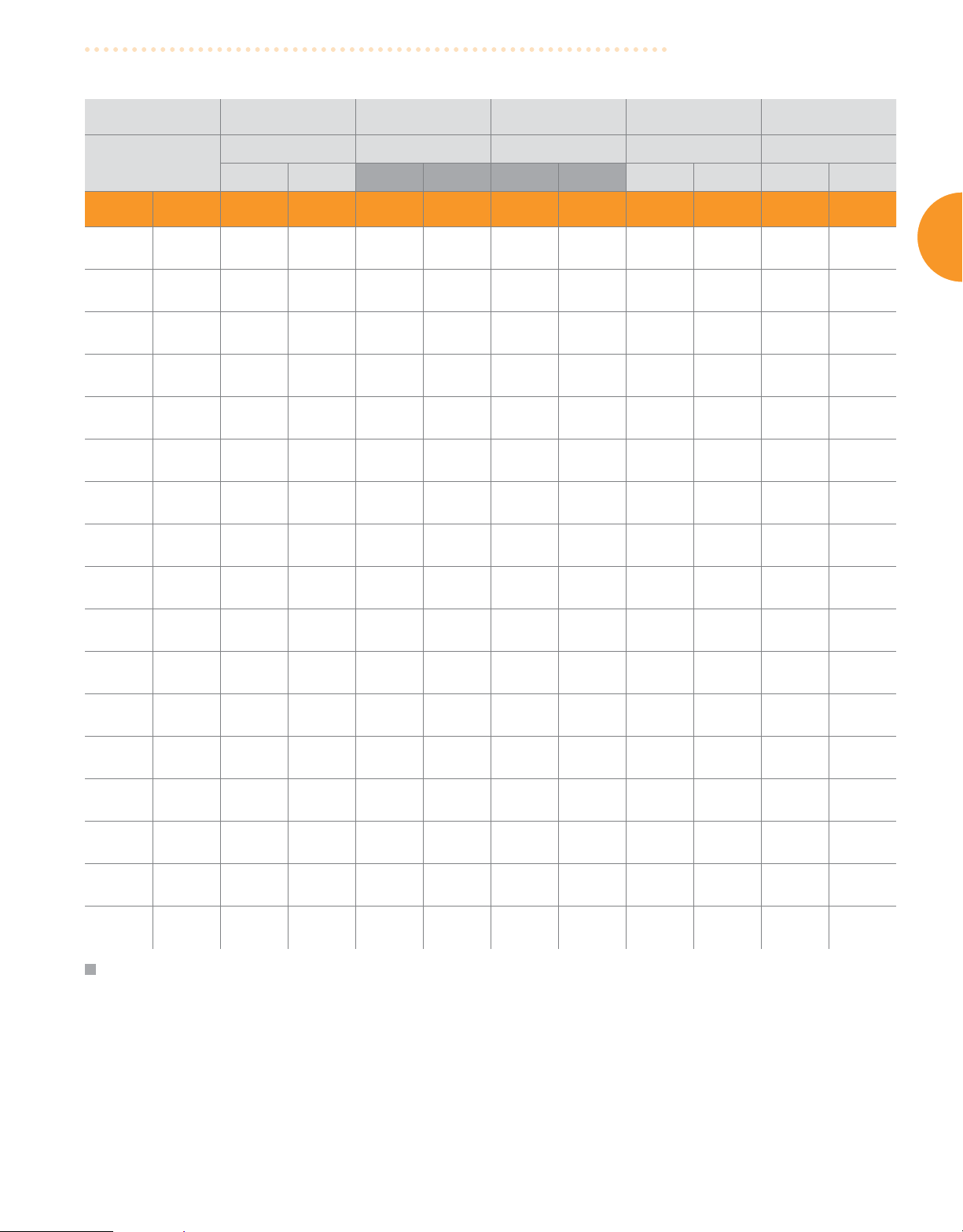

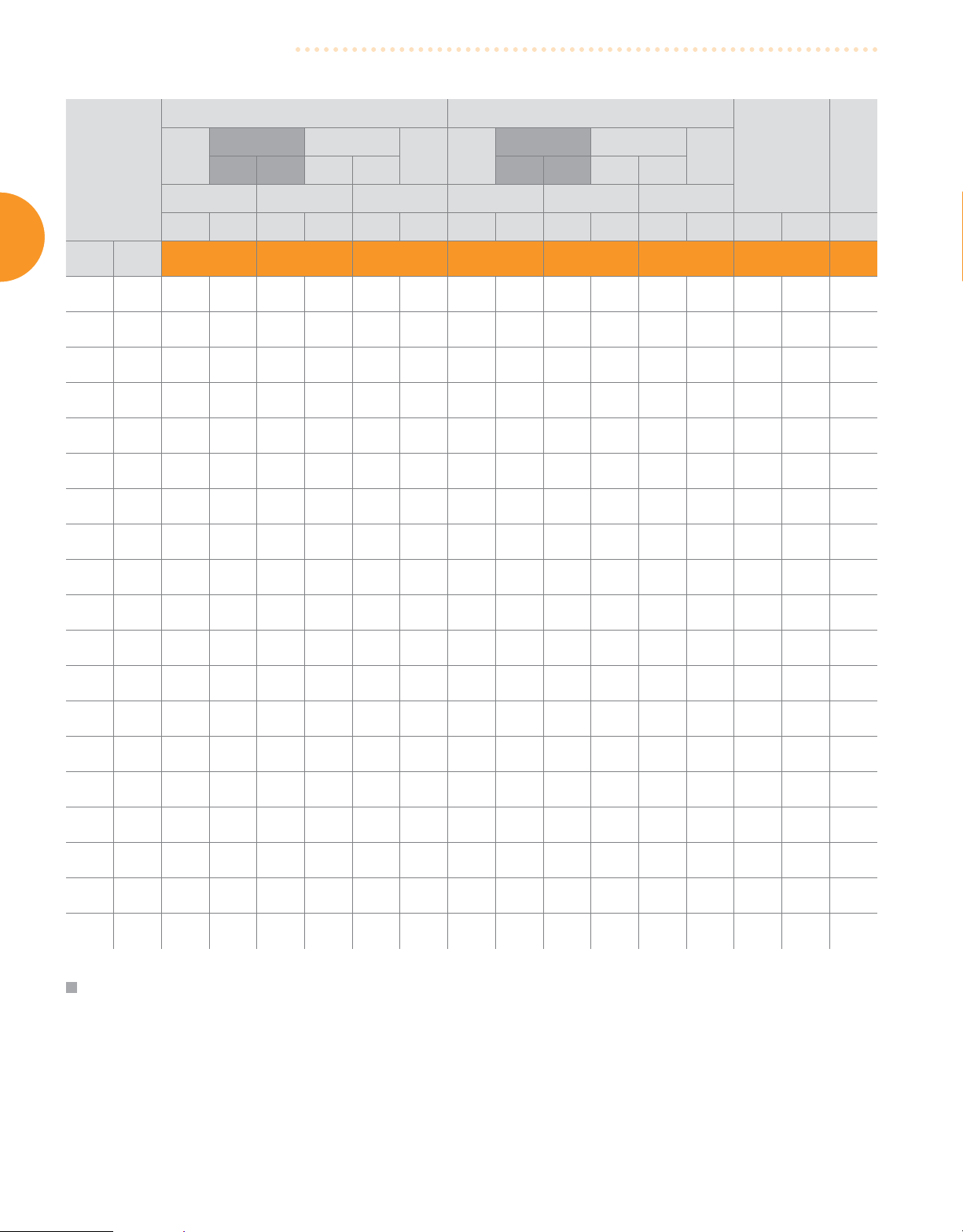

Limits for radial internal clearance of single-row, radial contact ball bearings under no load

(Applies to bearings of ABEC-1, ABEC-3, ABEC-5, ABEC-7, and ABEC-9 Tolerances)

Timken® Prefix

(ABMA designation)

Basic Bore Diameter

mm

over incl.

H (C2) R (C0) P (C3) J (C4) JJ (C5)

Acceptance Limits Acceptance Limits Acceptance Limits Acceptance Limits Acceptance Limits

Max. Min. Max. Min. Max. Min. Max. Min. Max. Min.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

2.5 10

10 18

18 24

24 30

30 40

40 50

50 65

65 80

INDUSTRIAL BEARING MAINTENANCE MANUAL

22

0.007

0.0003

0.009

0.00035

0.010

0.0004

0.011

0.00045

0.011

0.00045

0.011

0.00045

0.015

0.0006

0.015

0.0006

0.000

0.0000

0.000

0.0000

0.000

0.0000

0.001

0.0001

0.001

0.0001

0.001

0.0001

0.001

0.0001

0.001

0.0001

0.013

0.0005

0.018

0.0007

0.020

0.0008

0.020

0.0008

0.020

0.0008

0.023

0.0009

0.028

0.0011

0.030

0.0012

0.002

0.0001

0.003

0.0001

0.005

0.0002

0.005

0.0002

0.006

0.0002

0.006

0.00025

0.008

0.00035

0.010

0.0004

0.023

0.0009

0.025

0.001

0.028

0.0011

0.028

0.0011

0.033

0.0013

0.036

0.0014

0.043

0.0017

0.051

0.0020

0.008

0.0003

0.011

0.0004

0.013

0.0005

0.013

0.0005

0.015

0.0006

0.018

0.0007

0.023

0.0009

0.025

0.0010

0.029

0.0011

0.033

0.0013

0.036

0.0014

0.041

0.0016

0.046

0.0018

0.051

0.0020

0.061

0.0024

0.071

0.0028

0.014

0.0006

0.018

0.0007

0.020

0.0008

0.023

0.0009

0.028

0.0011

0.030

0.0012

0.038

0.0015

0.046

0.0018

0.037

0.0015

0.045

0.0018

0.048

0.0019

0.053

0.0021

0.064

0.0025

0.073

0.0029

0.090

0.0035

0.105

0.0041

Continued on next page.

0.020

0.0008

0.025

0.0010

0.028

0.0011

0.030

0.0012

0.040

0.0016

0.045

0.0018

0.055

0.0022

0.065

0.0026

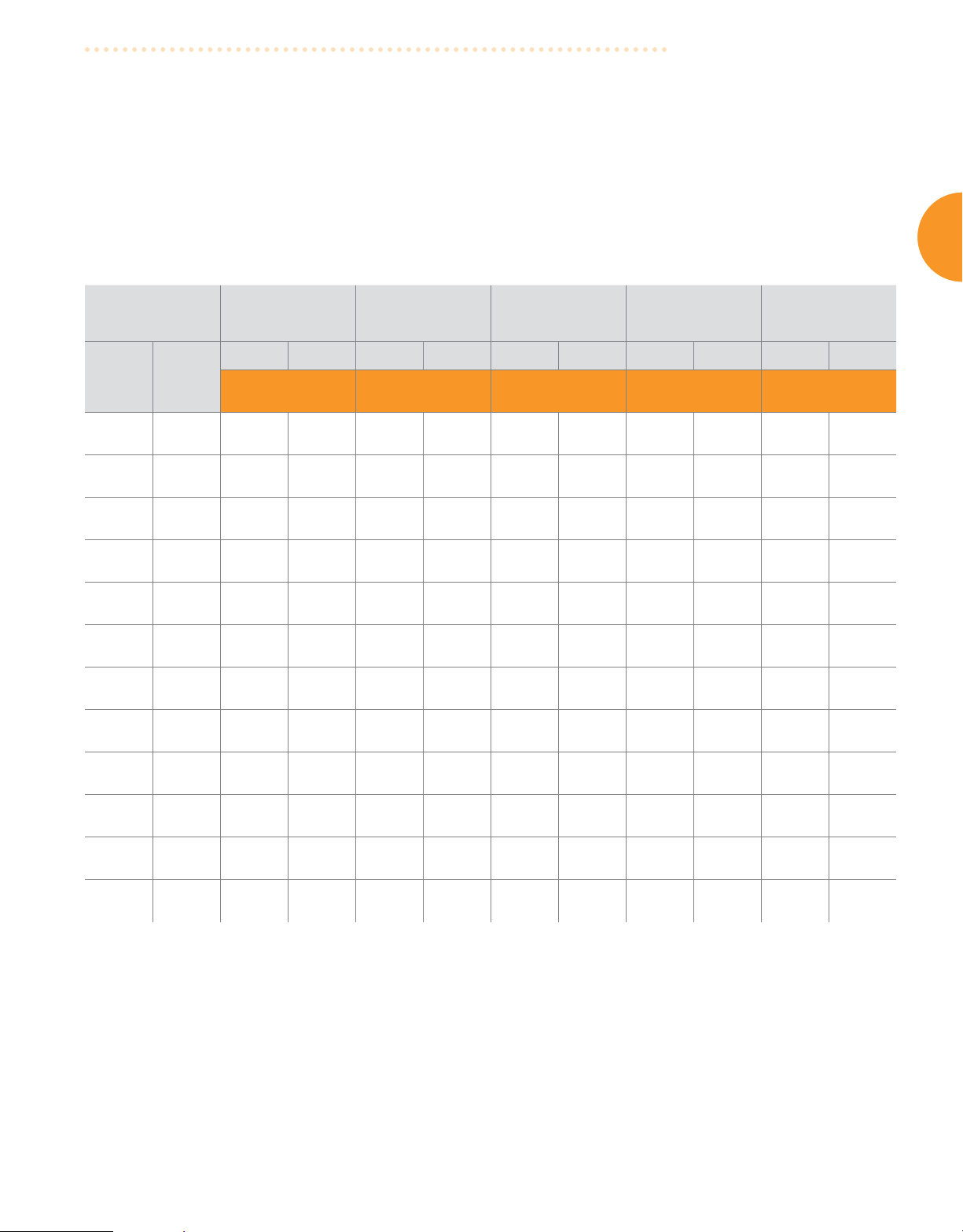

INTERNAL CLEARANCES

Timken® Prefix

(ABMA designation)

Basic Bore Diameter

mm

over incl.

80 100

100 120

120 140

140 160

160 180

180 200

200 240

240 280

H (C2) R (C0) P (C3) J (C4) JJ (C5)

Acceptance Limits Acceptance Limits Acceptance Limits Acceptance Limits Acceptance Limits

Max. Min. Max. Min. Max. Min. Max. Min. Max. Min.

mm

in.

0.018

0.0007

0.020

0.0008

0.023

0.0009

0.023

0.0009

0.025

0.0010

0.030

0.0012

0.036

0.0014

0.041

0.0016

mm

in.

0.001

0.0001

0.002

0.0001

0.002

0.0001

0.002

0.0001

0.002

0.0001

0.002

0.0001

0.003

0.0001

0.003

0.0001

mm

in.

0.036

0.0014

0.041

0.0016

0.048

0.0019

0.053

0.0021

0.061

0.0024

0.071

0.0028

0.081

0.0032

0.097

0.0038

mm

in.

0.012

0.00045

0.015

0.0006

0.018

0.0007

0.018

0.0007

0.020

0.0008

0.025

0.0010

0.030

0.0012

0.033

0.0013

mm

in.

0.058

0.0023

0.066

0.0026

0.081

0.0032

0.091

0.0036

0.102

0.0040

0.117

0.0046

0.137

0.0054

0.157

0.0062

mm

in.

0.030

0.0012

0.036

0.0014

0.041

0.0016

0.046

0.0018

0.053

0.0021

0.063

0.0025

0.074

0.0029

0.086

0.0034

mm

in.

0.084

0.0033

0.097

0.0038

0.114

0.0045

0.130

0.0051

0.147

0.0058

0.163

0.0064

0.193

0.0076

0.224

0.0088

mm

in.

0.053

0.0021

0.061

0.0024

0.071

0.0028

0.081

0.0032

0.091

0.0036

0.107

0.0042

0.127

0.0050

0.147

0.0058

mm

in.

0.120

0.0047

0.140

0.0055

0.160

0.0063

0.180

0.0071

0.200

0.0079

0.230

0.0091

0.267

0.0105

0.310

0.0122

0.075

0.0030

0.090

0.0035

0.105

0.0041

0.120

0.0047

0.135

0.0053

0.150

0.0059

0.183

0.0072

0.213

0.0084

mm

in.

C

280 320

320 370

370 430

430 500

500 570

570 640

640 710

710 800

800 1060

0.048

0.0019

0.053

0.0021

0.064

0.0025

0.074

0.0029

0.081

0.0032

0.091

0.0036

0.114

0.0045

0.140

0.0055

0.211

0.0083

0.005

0.0002

0.005

0.0002

0.008

0.0003

0.010

0.0004

0.010

0.0004

0.013

0.0005

0.020

0.0008

0.020

0.0008

0.028

0.0011

0.114

0.0045

0.127

0.0050

0.147

0.0058

0.170

0.0067

0.193

0.0076

0.216

0.0085

0.239

0.0094

0.269

0.0106

0.353

0.0139

0.041

0.0016

0.046

0.0018

0.056

0.0022

0.066

0.0026

0.074

0.0029

0.085

0.0033

0.107

0.0042

0.130

0.0051

0.201

0.0079

: Standard fits for Timken radial ball bearings. P(C3) for bearing O.D. greater than 52 mm.

0.180

0.0071

0.208

0.0082

0.241

0.0095

0.279

0.0110

0.318

0.0125

0.356

0.0140

0.394

0.0155

0.445

0.0175

0.587

0.0231

0.104

0.0041

0.117

0.0046

0.137

0.0054

0.160

0.0063

0.183

0.0072

0.206

0.0081

0.229

0.0090

0.259

0.0102

0.345

0.0136

0.257

0.0101

0.295

0.0116

0.340

0.0134

0.396

0.0156

0.450

0.0177

0.505

0.0199

0.564

0.0222

0.630

0.0248

0.833

0.0328

0.170

0.0067

0.198

0.0078

0.231

0.0091

0.269

0.0106

0.307

0.0121

0.345

0.0136

0.384

0.0151

0.434

0.0171

0.577

0.0227

0.353

0.0139

0.409

0.0161

0.475

0.0187

0.551

0.0217

0.630

0.0248

0.706

0.0278

0.780

0.0307

0.879

0.0346

1.148

0.0452

0.246

0.0097

0.284

0.0112

0.330

0.013

0.386

0.0152

0.439

0.0173

0.495

0.0195

0.554

0.0218

0.620

0.0244

0.823

0.0324

INDUSTRIAL BEARING MAINTENANCE MANUAL

23

INTERNAL CLEARANCES

C

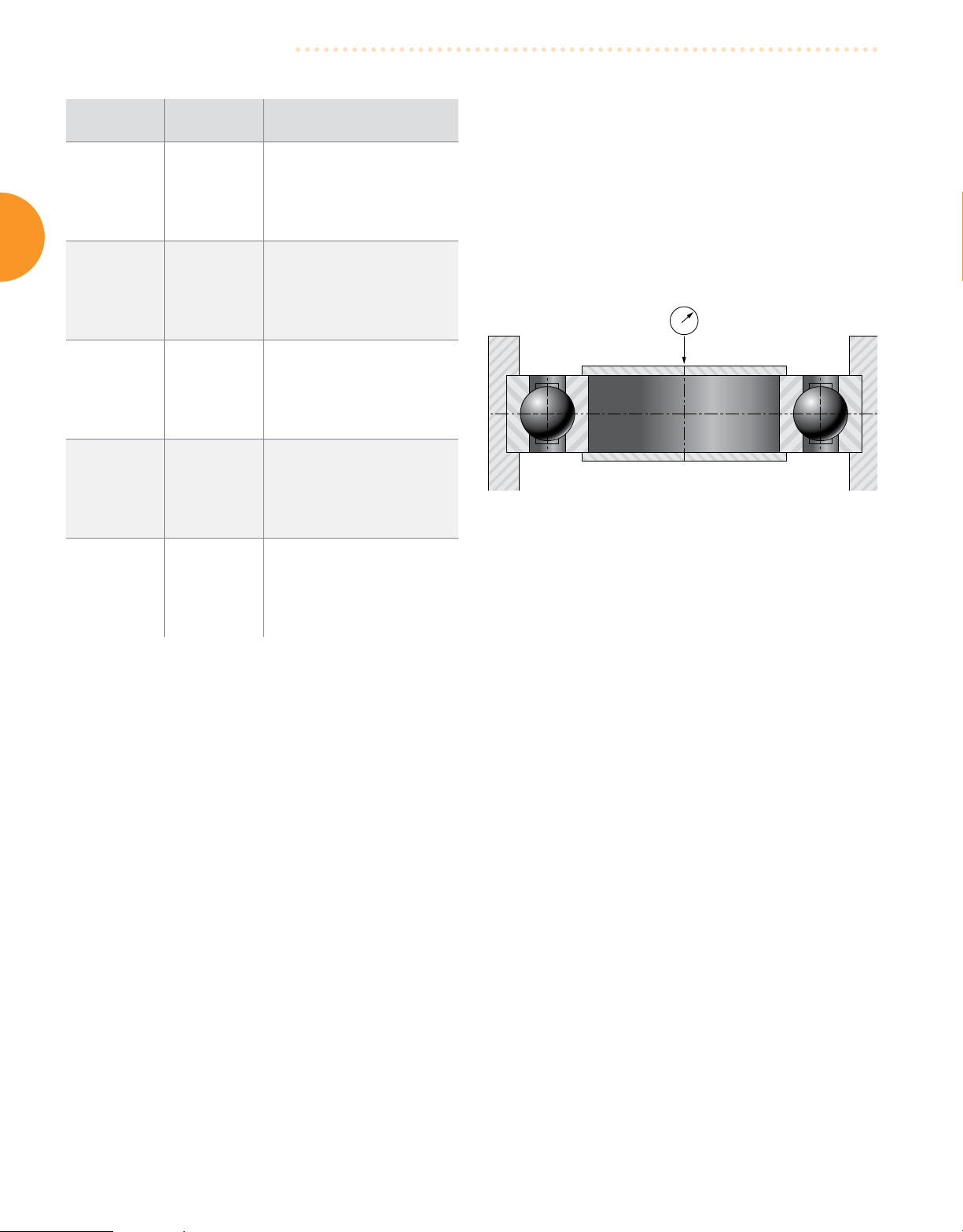

Timken Bearing

Number Prefix

H C2

R C0

P C3

J C4

ISO/ABMA Symbol Description

Snug fit; slight internal clearance;

sometimes used to achieve a minimum

of radial or axial play in an assembly.

Example: H204K

Medium fit; internal clearance generally

satisfactory with recommended shaft

and housing fits. Example: RMM204K.

Loose fit; considerable internal

clearance required for applications

involving press fits on both inner and

outer rings, extra interference fits, or

temperature differentials. Example:

Extra loose fit; large amount of internal

clearance for applications involving

large interference fits or temperature

P204K.

differentials. Example: J204K.

End Play

End play is an alternate method of measuring internal clearance

and is rarely used except for certain special applications. End play

is determined by mounting the bearing, as shown in Fig. 13, with

one of its rings clamped to prevent axial movement. A reversing

measuring load is applied to the unclamped ring so the resulting

movement of that ring is parallel to the bearing axis. End play is

the total movement of the unclamped ring when the load is applied

first in one direction and then in the other.

Fig. 13. End play is determined by mounting the bearing with one of

its rings clamped.

Extra-extra loose fit; extra large amount

JJ C5

of internal clearance for applications

with large temperature differential and

interference fits on both rings.

Table 1. Radial clearance designations correlate with ISO/ABMA

symbols.

INDUSTRIAL BEARING MAINTENANCE MANUAL

24

INTERNAL CLEARANCES

SPHERICAL ROLLER BEARINGS

RIC is the radial internal clearance or radial play within a bearing.

The bearing’s RIC allows a tight fit, with sufficient internal

clearance after installation for normal operating conditions.

Spherical roller bearings with tapered bore (K) require a slightly

greater interference fit on the shaft than a cylindrical bore bearing.

The effect of this greater interference fit is a reduction of RIC. For

tapered bore bearings, it is critical to select the RIC that allows for

this reduction.

Example #1 - Calculating RIC Reduction Using a Spherical Roller

Bearing with Tapered Bore

Given bearing number 22328K C3 (140 mm bore with a C3 clearance)

is to be mounted on a tapered shaft. Using a set of feeler gauges,

RIC is found to be –

RIC = 0.178 mm (0.007 in.)

Suggested Reduction of RIC Due to Installation = 0.064 to 0.089 mm

(0.0025 in. to 0.0035 in.), found in chart on page 26.

Calculate the clearance after mounting –

0.178 mm - 0.077 mm = 0.101 mm or

Therefore, the locking nut should be tightened until RIC reaches

0.101 mm (0.004 in.).

It should also be noted that the value obtained by reading the

Suggested RIC after Installation directly from the table on page 97

is 0.075 mm (0.0030 in.). This differs from the value calculated in the

above example. The value taken directly from the table is provided

as a minimum value. It is not suggested to use a calculated value

that falls below this minimum.

Several factors influence RIC reduction. Inner rings pressed onto

solid steel shafts expand approximately 80 percent of the interference

fit. Outer rings pressed into steel or cast iron housings reduce RIC by

about 60 percent of the interference fit. For RIC reduction on hollow

shafts or non-steel materials, consult a Timken representative.

®

Timken

brand bearings are supplied with normal RIC, unless

specified otherwise. The desired RIC code must be added to the

bearing number, following all other suffixes.

Minimum/maximum values for each RIC are shown in the two

adjacent columns directly beneath the selected RIC. For example,

the minimum values shown for C5 are also the maximum values for

C4; minimum values for C4 are also the maximum values for C3; etc.

C

0.007 in. - 0.003 in. = 0.004 in.

NOTE: For this example, the value of 0.077 mm (0.003 in.) was

obtained by taking the mid-range value of the upper and lower

limits found in the table on page 26.

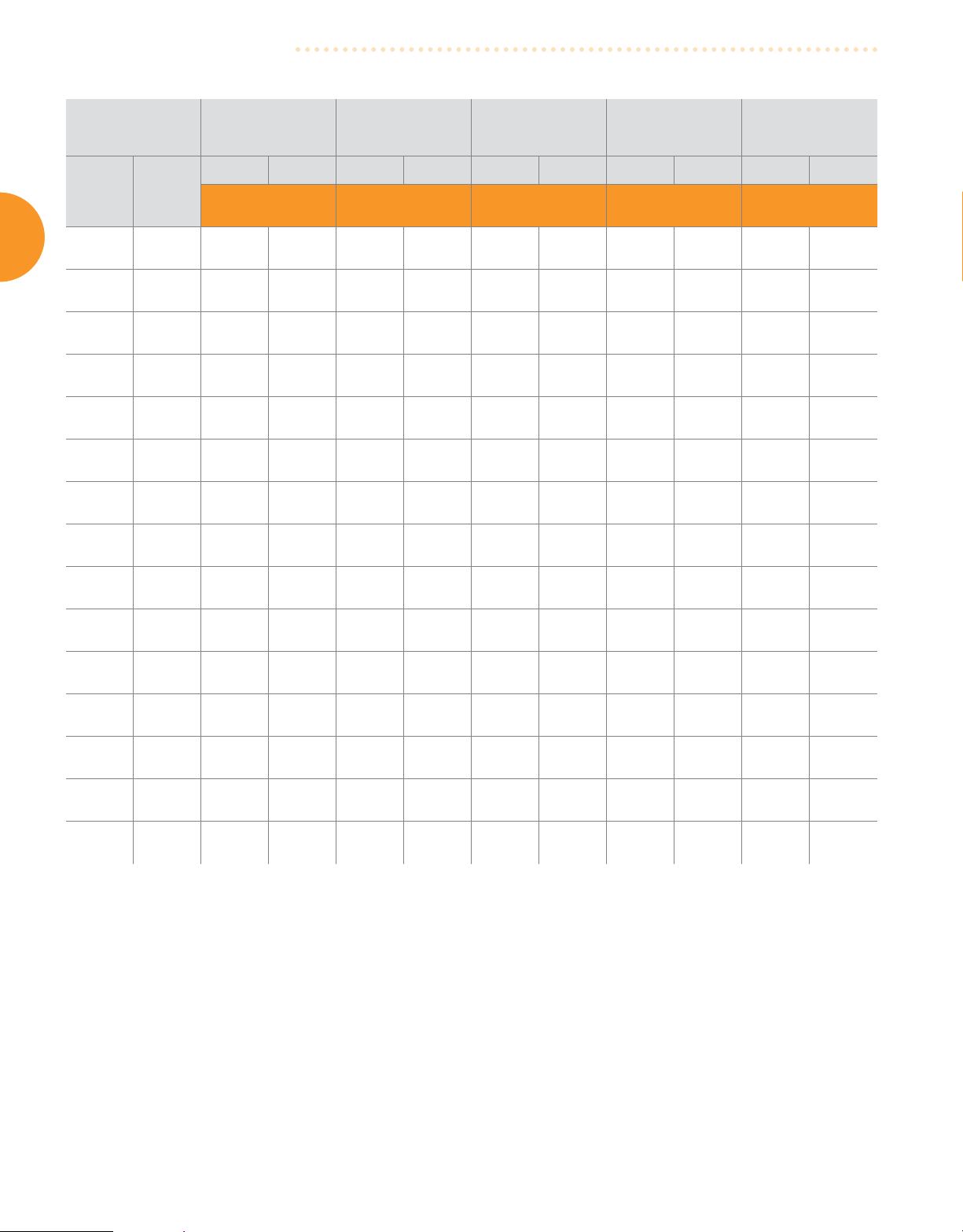

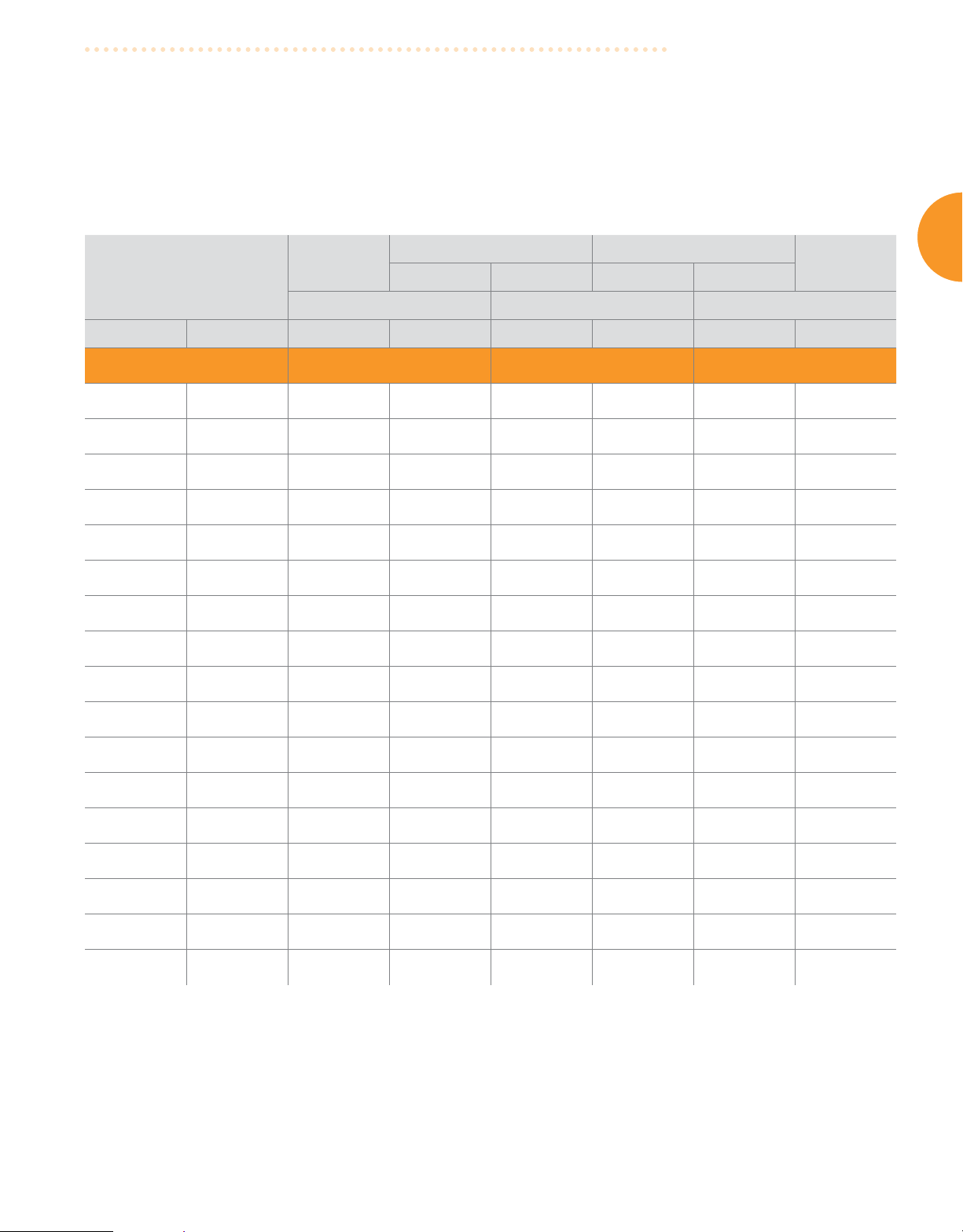

Radial internal clearance limits - radial spherical roller bearings

Cylindrical Bore Tapered Bore

Normal CO C4 Normal CO C4

Bore

(Nominal)

mm

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min.

Over Incl.

24 30

30 40

40 50

50 65

65 80

80 100

(1)

For bearings with normal initial clearance.

0.015

0.0006

0.015

0.0006

0.020

0.0008

0.020

0.0008

0.030

0.0012

0.035

0.0014

Min. Max. Min. Max. Min. Max. Min. Max.

C2 C3 C5 C2 C3 C5

mm

in.

0.025

0.0010

0.030

0.0012

0.035

0.0014

0.040

0.0016

0.050

0.0020

0.060

0.0024

0.040

0.0016

0.045

0.0018

0.055

0.0022

0.065

0.0026

0.080

0.0031

0.100

0.0039

mm

0.075

0.0030

0.080

0.0031

0.100

0.0039

0.120

0.0047

0.145

0.0057

0.180

0.0071

mm

in.

0.095

0.0037

0.100

0.0039

0.125

0.0049

0.150

0.0059

0.180

0.0071

0.225

0.0089

in.

0.055

0.0022

0.060

0.0024

0.075

0.0030

0.090

0.0035

0.110

0.0043

0.135

0.0053

0.020

0.0008

0.025

0.0010

0.030

0.0012

0.040

0.0016

0.050

0.0020

0.055

0.0022

mm

in.

0.0012

0.0014

0.0018

0.0022

0.0028

0.0030

0.030

0.035

0.045

0.055

0.070

0.080

0.040

0.0016

0.050

0.0020

0.060

0.0024

0.075

0.0030

0.095

0.0037

0.110

0.0043

mm

(1)

Suggested

Reduction of RIC

Due to Installation

0.075

0.0030

0.085

0.0033

0.100

0.0039

0.120

0.0047

0.150

0.0059

0.180

0.0071

mm

in.

0.095

0.0037

0.105

0.0041

0.130

0.0051

0.160

0.0063

0.200

0.0079

0.230

0.0091

in.

0.055

0.0022

0.065

0.0026

0.080

0.0031

0.095

0.0037

0.120

0.0047

0.140

0.0055

mm

in.

0.015

0.0006

0.020

0.0008

0.025

0.0010

0.030

0.0012

0.038

0.0015

0.046

0.0018

0.020

0.0008

0.025

0.0010

0.030

0.0012

0.038

0.0015

0.051

0.0020

0.064

0.0025

Continued on next page.

Suggested RIC

after Installation

mm

in.

0.015

0.0006

0.015

0.0006

0.020

0.0008

0.025

0.0010

0.025

0.0010

0.036

0.0014

INDUSTRIAL BEARING MAINTENANCE MANUAL

25

INTERNAL CLEARANCES

C

Bore

(Nominal)

mm

Over Incl.

100 120

120 140

140 160

160 180

180 200

200 225

225 250

250 280

280 315

315 355

355 400

400 450

450 500

500 560

560 630

630 710

710 800

800 900

900 1000

Cylindrical Bore Tapered Bore

Normal CO C4 Normal CO C4

Min. Max. Min. Max. Min. Max. Min. Max.

C2 C3 C5 C2 C3 C5

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min.

0.040

0.0016

0.050

0.0020

0.060

0.0024

0.065

0.0026

0.070

0.0028

0.080

0.0031

0.090

0.0035

0.100

0.0039

0.110

0.0043

0.120

0.0047

0.130

0.0051

0.140

0.0055

0.140

0.0055

0.150

0.0059

0.170

0.0067

0.190

0.0075

0.210

0.0083

0.230

0.0091

0.260

0.0102

mm

in.

0.075

0.0030

0.095

0.0037

0.110

0.0043

0.120

0.0047

0.130

0.0051

0.140

0.0055

0.150

0.0059

0.170

0.0067

0.190

0.0075

0.200

0.0079

0.220

0.0087

0.240

0.0094

0.260

0.0102

0.280

0.0110

0.310

0.0122

0.350

0.0138

0.390

0.0154

0.430

0.0169

0.480

0.0189

0.120

0.0047

0.145

0.0057

0.170

0.0067

0.180

0.0071

0.200

0.0079

0.220

0.0087

0.240

0.0094

0.260

0.0102

0.280

0.0110

0.310

0.0122

0.340

0.0134

0.370

0.0146

0.410

0.0161

0.440

0.0173

0.480

0.0189

0.530

0.0209

0.580

0.0228

0.650

0.0256

0.710

0.0280

mm

0.210

0.0083

0.240

0.0094

0.280

0.0110

0.310

0.0122

0.340

0.0134

0.380

0.0150

0.420

0.0165

0.460

0.0181

0.500

0.0197

0.550

0.0217

0.600

0.0236

0.660

0.0260

0.720

0.0283

0.780

0.0307

0.850

0.0335

0.920

0.0362

1.010

0.0398

1.120

0.0441

1.220

0.0480

mm

in.

0.260

0.0102

0.300

0.0118

0.350

0.0138

0.390

0.0154

0.430

0.0169

0.470

0.0185

0.520

0.0205

0.570

0.0224

0.630

0.0248

0.690

0.0272

0.750

0.0295

0.820

0.0323

0.900

0.0354

1.000

0.0394

1.100

0.0433

1.190

0.0469

1.300

0.0512

1.440

0.0567

1.57

0.0618

in.

0.160

0.0063

0.190

0.0075

0.220

0.0087

0.240

0.0094

0.260

0.0102

0.290

0.0114

0.320

0.0126

0.350

0.0138

0.370

0.0146

0.410

0.0161

0.450

0.0177

0.500

0.0197

0.550

0.0217

0.600

0.0236

0.650

0.0256

0.700

0.0276

0.770

0.0303

0.860

0.0339

0.930

0.0366

0.065

0.0026

0.080

0.0031

0.090

0.0035

0.100

0.0039

0.110

0.0043

0.120

0.0047

0.140

0.0055

0.150

0.0059

0.170

0.0067

0.190

0.0075

0.210

0.0083

0.230

0.0091

0.260

0.0102

0.290

0.0114

0.320

0.0126

0.350

0.0138

0.390

0.0154

0.440

0.0173

0.490

0.0193

mm

0.135

0.0053

0.160

0.0063

0.180

0.0071

0.200

0.0079

0.220

0.0087

0.250

0.0098

0.270

0.0106

0.300

0.0118

0.330

0.0130

0.360

0.0142

0.400

0.0157

0.440

0.0173

0.490

0.0193

0.540

0.0213

0.600

0.0236

0.670

0.0264

0.750

0.0295

0.840

0.0331

0.930

0.0366

mm

in.

0.170

0.0067

0.200

0.0079

0.230

0.0091

0.260

0.0102

0.290

0.0114

0.320

0.0126

0.350

0.0138

0.390

0.0154

0.430

0.0169

0.470

0.0185

0.520

0.0205

0.570

0.0224

0.630

0.0248

0.680

0.0268

0.760

0.0299

0.850

0.0335

0.960

0.0378

1.070

0.0421

1.190

0.0469

in.

0.100

0.0039

0.120

0.0047

0.130

0.0051

0.140

0.0055

0.160

0.0063

0.180

0.0071

0.200

0.0079

0.220

0.0087

0.240

0.0094

0.270

0.0106

0.300

0.0118

0.330

0.0130

0.370

0.0146

0.410

0.0161

0.460

0.0181

0.510

0.0201

0.570

0.0224

0.640

0.0252

0.710

0.0280

0.220

0.0087

0.260

0.0102

0.300

0.0118

0.340

0.0134

0.370

0.0146

0.410

0.0161

0.450

0.0177

0.490

0.0193

0.540

0.0213

0.590

0.0232

0.650

0.0256

0.720

0.0283

0.790

0.0311

0.870

0.0343

0.980

0.0386

1.090

0.0429

1.220

0.0480

1.370

0.0539

1.520

0.0598

mm

in.

0.280

0.0110

0.330

0.0130

0.380

0.0150

0.430

0.0169

0.470

0.0185

0.520

0.0205

0.570

0.0224

0.620

0.0244

0.680

0.0268

0.740

0.0291

0.820

0.0323

0.910

0.0358

1.000

0.0394

1.100

0.0433

1.230

0.0484

1.360

0.0535

1.500

0.0591

1.690

0.0665

1.860

0.0732

Suggested

Reduction of RIC

Due to Installation

mm

in.

0.051

0.0020

0.064

0.0025

0.076

0.0030

0.076

0.0030

0.089

0.0035

0.102

0.0040

0.114

0.0045

0.114

0.0045

0.127

0.0050

0.140

0.055

0.152

0.0060

0.165

0.0065

0.178

0.0070

0.203

0.0080

0.229

0.0090

0.254

0.0100

0.279

0.0110

0.305

0.0120

0.356

0.0140

0.071

0.0028

0.089

0.0035

0.102

0.0040

0.114

0.0045

0.127

0.0050

0.140

0.0055

0.152

0.0060

0.165

0.0065

0.178

0.0070

0.190

0.0075

0.203

0.0080

0.216

0.0085

0.229

0.0090

0.254

0.0100

0.279

0.0110

0.305

0.0120

0.356

0.0140

0.381

0.0150

0.432

0.0170

0.051

0.0020

0.056

0.0022

0.056

0.0022

0.061

0.0024

0.071

0.0028

0.076

0.0030

0.089

0.0035

0.102

0.0040

0.102

0.0040

0.114

0.0045

0.127

0.0050

0.152

0.0060

0.165

0.0065

0.178

0.0070

0.203

0.0080

0.203

0.0080

0.229

0.0090

0.252

0.0100

0.279

0.0110

(1)

Suggested RIC

after Installation

mm

in.

(1)

For bearings with normal initial clearance.

: For bearings with normal initial clearance.

Min./Max. values for each RIC are shown in the two adjacent columns directly beneath the selected RIC. Each

single column represents a boundary between adjacent RIC’s. For example, the minimum values shown for C5

are also the maximum values for C4; minimum values for C4 are also the maximum values for C3; etc.

* Special clearances can be provided (C6, C7, etc.)

INDUSTRIAL BEARING MAINTENANCE MANUAL

26

INTERNAL CLEARANCES

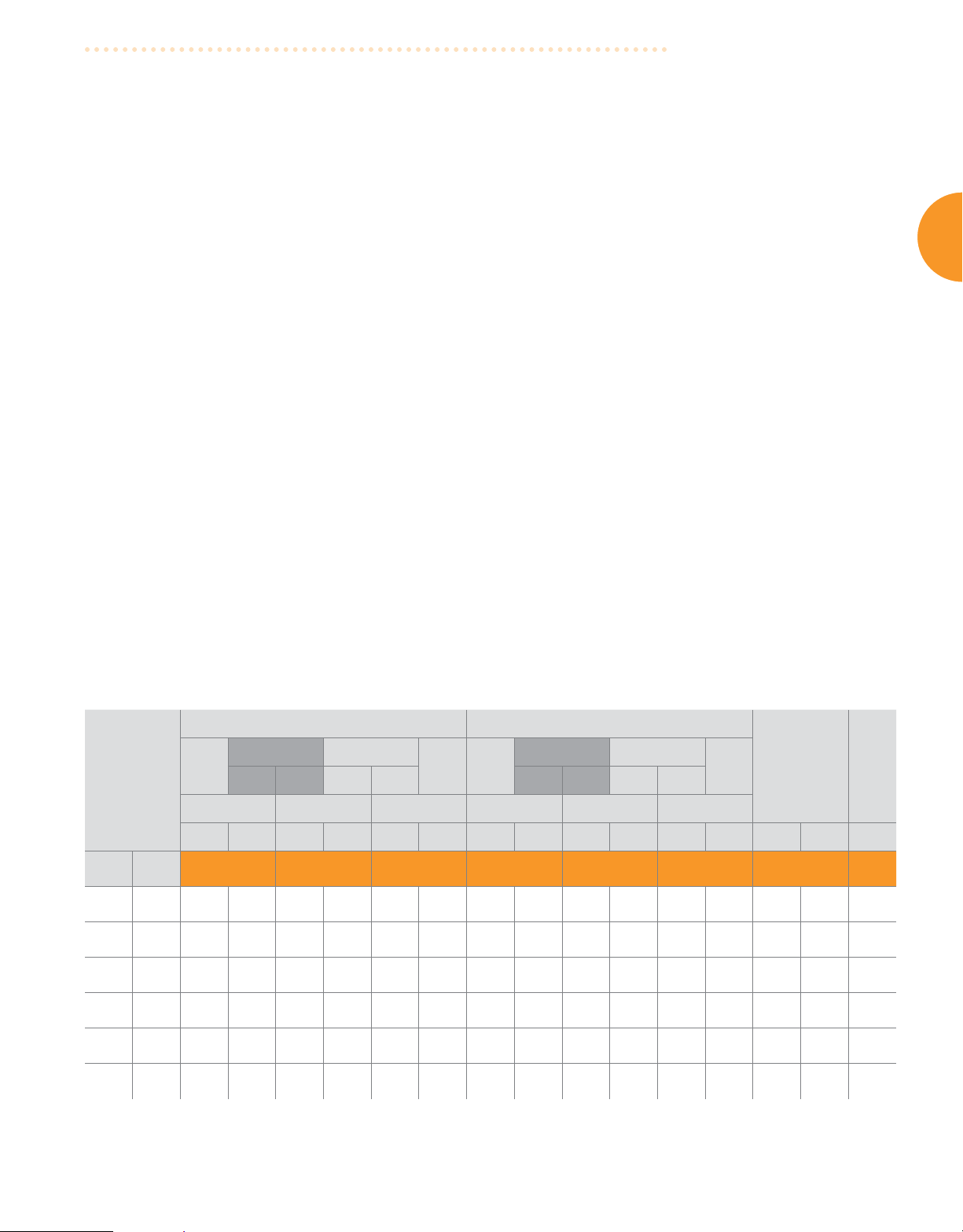

CYLINDRICAL ROLLER BEARINGS

Cylindrical roller bearings are available with RIC designations

per either of the following tables: “Timken ‘R’ Clearance” or “ISO/

ABMA ‘C’ Clearance.” Non-standard values are also available by

special request. Standard radial internal clearance values are

listed in the following tables based on bore size. The clearance

ISO/ABMA radial internal clearance limits

Bore

mm

in.

Over Incl.

0

0

10

0.3937

24

0.9449

30

1.1811

0.3937

0.9449

1.1811

1.5748

10

24

30

40

C2 C0 C3 C4 C5

Max. Min. Max. Min. Max. Min. Max. Min. Max. Min.

0.025

0.0010

0.025

0.0010

0.025

0.0010

0.030

0.0012

mm

in.

0.000

0.0000

0.000

0.0000

0.000

0.0000

0.005

0.0002

0.045

0.0018

0.045

0.0018

0.045

0.0018

0.050

0.0020

mm

in.

0.020

0.0008

0.020

0.0008

0.020

0.0008

0.025

0.0010

required for a given application depends on the desired operating

precision, rotational speed of the bearing, and the fitting practice

used. Most applications use a normal, or C0, clearance. Typically,

a larger clearance reduces the operating zone of the bearing,

increases the maximum roller load, and reduces the bearing’s

expected life.

0.060

0.0024

0.060

0.0024

0.060

0.0024

0.070

0.0028

mm

in.

0.035

0.0014

0.035

0.0014

0.035

0.0014

0.045

0.0018

0.075

0.0030

0.075

0.0030

0.075

0.0030

0.085

0.0033

mm

in.

0.050

0.0020

0.050

0.0020

0.050

0.0020

0.060

0.0024

-

-

0.090

0.0035

0.095

0.0037

0.105

0.0041

mm

in.

-

-

0.065

0.0026

0.070

0.0028

0.080

0.0031

C

40

1.5748

50

1.9685

65

2.5591

80

3.1496

100

3.9370

120

4.7244

140

5.5118

160

6.2992

50

1.9685

65

2.5591

80

3.1496

100

3.9370

120

4.7244

140

5.5118

160

6.2992

180

7.0866

0.035

0.0014

0.040

0.0016

0.045

0.0018

0.050

0.0020

0.055

0.0022

0.060

0.0024

0.070

0.0028

0.075

0.0030

0.005

0.0002

0.010

0.0004

0.010

0.0004

0.015

0.0006

0.015

0.0006

0.015

0.0006

0.020

0.0008

0.025

0.0010

0.060

0.0024

0.070

0.0028

0.075

0.0030

0.085

0.0033

0.090

0.0035

0.105

0.0041

0.120

0.0047

0.125

0.0049

0.030

0.0012

0.040

0.0016

0.040

0.0016

0.050

0.0020

0.050

0.0020

0.060

0.0024

0.070

0.0028

0.075

0.0030

These values indicate the expected range of mounted RIC following suggested push up values.

Timken suggests that customers consult with our engineers to evaluate unique applications or

requirements for special operating conditions.

0.080

0.0031

0.090

0.0035

0.100

0.0039

0.110

0.0043

0.125

0.0049

0.145

0.0057

0.165

0.0065

0.170

0.0067

0.050

0.0020

0.060

0.0024

0.065

0.0026

0.075

0.0030

0.085

0.0033

0.100

0.0039

0.115

0.0045

0.120

0.0047

0.100

0.0039

0.110

0.0043

0.125

0.0049

0.140

0.0055

0.165

0.0065

0.190

0.0075

0.215

0.0085

0.220

0.0087

0.070

0.0028

0.080

0.0031

0.090

0.0035

0.105

0.0041

0.125

0.0049

0.145

0.0057

0.165

0.0065

0.170

0.0067

0.125

0.0049

0.140

0.0055

0.165

0.0065

0.190

0.0075

0.220

0.0087

0.245

0.0096

0.275

0.0108

0.300

0.0118

Continued on next page.

0.095

0.0037

0.110

0.0043

0.130

0.0051

0.155

0.0061

0.180

0.0071

0.200

0.0079

0.225

0.0089

0.250

0.0098

INDUSTRIAL BEARING MAINTENANCE MANUAL

27

INTERNAL CLEARANCES

Bore

mm

in.

Over Incl.

C2 C0 C3 C4 C5

Max. Min. Max. Min. Max. Min. Max. Min. Max. Min.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

C

180

7.0866

200

7.8740

225

8.8583

250

9.8425

280

11.0236

315

12.4016

355

13.9764

400

15.7480

450

17.7165

500

19.6850

560

22.0472

200

7.8740

225

8.8583

250

9.8425

280

11.0236

315

12.4016

355

13.9764

400

15.7480

450

17.7165

500

19.6850

560

22.0472

630

24.8031

0.090

0.0035

0.105

0.0041

0.110

0.0043

0.125

0.0049

0.130

0.0051

0.145

0.0057

0.190

0.0075

0.210

0.0083

0.220

0.0087

0.240

0.00945

0.260

0.01024

0.035

0.0014

0.045

0.0018

0.045

0.0018

0.055

0.0022

0.055

0.0022

0.065

0.0026

0.100

0.0039

0.110

0.0043

0.110

0.0043

0.120

0.00472

0.140

0.00551

0.145

0.0057

0.165

0.0065

0.175

0.0069

0.195

0.0077

0.205

0.0081

0.225

0.0089

0.280

0.0110

0.310

0.0122

0.330

0.0130

0.360

0.01417

0.380

0.01496

0.090

0.0035

0.105

0.0041

0.110

0.0043

0.125

0.0049

0.130

0.0051

0.145

0.0057

0.190

0.0075

0.210

0.0083

0.220

0.0087

0.240

0.00945

0.260

0.01024

0.195

0.0077

0.220

0.0087

0.235

0.0093

0.260

0.0102

0.275

0.0108

0.305

0.0120

0.370

0.0146

0.410

0.0161

0.440

0.0173

0.480

0.0189

0.500

0.01969

0.140

0.0055

0.160

0.0063

0.170

0.0067

0.190

0.0075

0.200

0.0079

0.225

0.0089

0.280

0.0110

0.310

0.0122

0.330

0.0130

0.360

0.01417

0.380

0.01496

0.250

0.0098

0.280

0.0110

0.300

0.0118

0.330

0.0130

0.350

0.0138

0.385

0.0152

0.460

0.0181

0.510

0.0201

0.550

0.0217

0.600

0.02362

0.620

0.02441

0.195

0.0077

0.220

0.0087

0.235

0.0093

0.260

0.0102

0.275

0.0108

0.305

0.0120

0.370

0.0146

0.410

0.0161

0.440

0.0173

0.480

0.0189

0.500

0.01969

0.330

0.0130

0.365

0.0144

0.395

0.0156

0.440

0.0173

0.485

0.0191

0.535

0.0211

0.600

0.0236

0.665

0.0262

0.735

0.0289

0.810

0.03189

0.900

0.03543

0.275

0.0108

0.305

0.0120

0.330

0.0130

0.370

0.0146

0.410

0.0161

0.455

0.0179

0.510

0.0201

0.565

0.0222

0.625

0.0246

0.690

0.02717

0.780

0.03071

630

24.8031

710

27.9528

800

31.4961

900

35.4331

710

27.9528

800

31.4961

900

35.4331

1000

39.3701

0.285

0.01122

0.310

0.0122

0.350

0.01378

0.390

0.01535

0.145

0.00571

0.150

0.00591

0.180

0.00709

0.200

0.00787

0.425

0.01673

0.470

0.0185

0.520

0.02047

0.580

0.02283

0.285

0.01122

0.310

0.0122

0.350

0.01378

0.390

0.01535

These values indicate the expected range of mounted RIC following suggested push up values.

Timken suggests that customers consult with our engineers to evaluate unique applications or

requirements for special operating conditions.

0.565

0.02224

0.630

0.0248

0.690

0.02717

0.770

0.03031

0.425

0.01673

0.470

0.0185

0.520

0.02047

0.580

0.02283

0.705

0.02776

0.790

0.0311

0.860

0.03386

0.960

0.0378

0.565

0.02224

0.630

0.0248

0.690

0.02717

0.770

0.03031

1.005

0.03957

1.135

0.04469

1.265

0.0498

1.405

0.05531

0.865

0.03406

0.975

0.03839

1.095

0.04311

1.215

0.04783

INDUSTRIAL BEARING MAINTENANCE MANUAL

28

INTERNAL CLEARANCES

Min./Max. values for each RIC are shown in the two adjacent

columns directly beneath the selected RIC. Each single column

represents a boundary between adjacent RIC’s. For example, the

minimum values for R4 are also the maximum values for R3; etc.

The desired RIC code (R1, R2, etc.) must be added to the bearing

number, following all other suffixes.

minimum values shown for R5 are also the maximum values for R4;

Timken radial internal clearance limits

R2 R4

Bore

(Nominal)

Over Incl. Min. Max. Min. Max. Min. Max.

80

3.1496

100

3.9370

120

4.7244

140

5.5118

160

6.2992

180

7.0866

200

7.8740

220

8.6614

260

10.2362

300

11.8110

350

13.7795

400

15.7480

450

17.7165

500

19.6850

560

22.0472

630

24.8031

710

27.9528

mm

in.

100

3.9370

120

4.7244

140

5.5118

160

6.2992

180

7.0866

200

7.8740

220

8.6614

260

10.2362

300

11.8110

350

13.7795

400

15.7480

450

17.7165

500

19.6850

560

22.0472

630

24.8031

710

27.9528

800

31.4961

0.013

0.0005

0.013

0.0005

0.023

0.0009

0.025

0.0010

0.028

0.0011

0.036

0.0014

0.041

0.0016

0.056

0.0022

0.061

0.0024

0.081

0.0032

0.107

0.0042

0.14

0.0055

0.152

0.0060

0.165

0.0065

0.178

0.0070

0.190

0.0075

0.216

0.0085

mm

Min. Max. Min. Max.

R1 R3 R5

in.

0.041

0.0016

0.046

0.0018

0.056

0.0022

0.066

0.0026

0.069

0.0027

0.081

0.0032

0.086

0.0034

0.102

0.0040

0.107

0.0042

0.127

0.0050

0.165

0.0065

0.203

0.0080

0.216

0.0085

0.229

0.0090

0.254

0.0100

0.279

0.0110

0.330

0.0130

0.081

0.0032

0.091

0.0036

0.104

0.0041

0.124

0.0049

0.132

0.0052

0.152

0.0060

0.157

0.0062

0.173

0.0068

0.178

0.0070

0.198

0.0078

0.236

0.0093

0.279

0.0110

0.292

0.0115

0.305

0.0120

0.356

0.0140

0.381

0.0150

0.457

0.0180

mm

in.

0.130

0.0051

0.152

0.0060

0.170

0.0067

0.196

0.0077

0.208

0.0082

0.234

0.0092

0.239

0.0094

0.254

0.0100

0.259

0.0102

0.279

0.0110

0.318

0.0125

0.361

0.0142

0.381

0.0150

0.406

0.0160

0.483

0.0190

0.508

0.0200

0.584

0.0230

0.196

0.0077

0.226

0.0089

0.256

0.0101

0.284

0.0112

0.300

0.0118

0.330

0.0130

0.335

0.0132

0.351

0.0138

0.356

0.0140

0.376

0.0148

0.414

0.0163

0.457

0.0180

0.508

0.0200

0.533

0.0210

0.610

0.0240

0.635

0.0250

0.711

0.0280

mm

C

in.

0.272

0.0107

0.310

0.0122

0.353

0.0139

0.384

0.0151

0.401

0.0158

0.437

0.0172

0.4420

0.0174

0.455

0.018

0.462

0.0182

0.483

0.0190

0.521

0.0205

0.564

0.0222

0.645

0.0254

0.671

0.0264

0.747

0.0294

0.772

0.0304

0.848

0.0334

INDUSTRIAL BEARING MAINTENANCE MANUAL

29

C

INTERNAL CLEARANCES

INDUSTRIAL BEARING MAINTENANCE MANUAL

30

Loading...

Loading...