Page 1

TIMKEN ENGINEERING MANUAL

Page 2

Page 3

ENGINEERING MANUAL INDEX

TIMKEN OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SHELF LIFE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

WARNINGS/DISCLAIMERS ..................................8

BEARING SELECTION PROCESS ..............................9

Bearing Types ..........................................10

Cages .................................................28

Determination of Applied Loads and Bearing Analysis .......32

Bearing Reactions ......................................39

Bearing Ratings ........................................47

System Life and Weighted Average Load and Life ..........55

BEARING TOLERANCES, INCH AND METRIC SYSTEMS .........56

Metric System .........................................57

Inch System ...........................................68

MOUNTING DESIGNS, FITTING PRACTICE,

SETTING AND INSTALLATION ..............................74

Tapered Roller Bearings .................................77

Spherical and Cylindrical Roller Bearings ..................82

Angular Contact Ball Bearings ...........................95

Radial Ball Bearings ....................................99

Precision Bearings ....................................109

FITTING PRACTICE TABLES ...............................126

Spherical Roller Bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Cylindrical Roller Bearings ..............................128

Radial Ball, Spherical and Cylindrical Roller Bearings ......132

Angular Contact Ball Bearings ..........................146

Radial Ball Bearings ...................................147

Tapered Roller Bearings ................................154

Precision Tapered Roller Bearings .......................168

Thrust Bearings .......................................180

OPERATING TEMPERATURES ..............................184

Heat Generation and Dissipation ........................187

TORQUE .................................................188

SPEED RATINGS ..........................................193

CONVERSION TABLES ....................................196

LUBRICATION AND SEALS .................................199

Lubrication ...........................................200

Seals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

TIMKEN ENGINEERING MANUAL

1

Page 4

OVERVIEW

TIMKEN

GROW STRONGER WITH TIMKEN

Every day, people around the world count on the strength

of Timken. Our expertise in metallurgy, friction management

and mechanical power transmission helps them accelerate

improvements in productivity and uptime.

We supply products and services that can help keep your

operations moving forward, whether you need drive train

kits for commercial vehicles, durable housings for bearings

in dirty environments, couplings that avoid metal-to-metal

contact between motors and gearboxes, repair services for

bearings and gearboxes, roller chain for dry, abrasive and

high-moisture applications or other products and services for

your applications.

When you choose Timken, you receive more than high-quality

products and services: You gain a worldwide team of highly

trained and experienced Timken people committed to working

collaboratively with you to improve your business.

Globally, our 17,000 people provide reliable answers for a

wide range of operations in manufacturing, mining, medical

equipment, aerospace, transportation, oil and gas – and other

diverse industries.

2 TIMKEN ENGINEERING MANUAL

Page 5

OVERVIEW

INCREASE YOUR EQUIPMENT UPTIME

In addition to high-quality bearings and mechanical power

transmission components, we provide valuable integrated

products and services. For example, we offer repair services

and equipment monitoring equipment that can alert you to

problems before they impact your uptime.

Additionally, we offer a broad selection of seals, premium

TIMKEN

lubricants, lubricators, couplings and chain to keep your

operations moving smoothly.

Our 12 technology and engineering centers in the United

States, Europe and Asia help pioneer tomorrow’s innovations

with extensive basic and applied scientific research programs.

Through internal development and strategic acquisition of

innovative companies, we continue to expand our portfolio

of highly engineered bearings, power transmission products

and advanced services.

TIMKEN ENGINEERING MANUAL

3

Page 6

TIMKEN

INTRODUCTION

INTRODUCTION

Timken is a leader in the advancement of bearing

technology. Expert craftsmanship, well-equipped

production facilities, and a continuing investment in

technology programs ensure that our products are

synonymous with quality and reliability. Today, our

plants manufacture several bearing types over a

broad range of sizes.

Anti-friction bearings inherently manage broad ranges

of speed and many combinations of radial and thrust

loads. Other important environmental conditions, such

as low and high temperature, dust and dirt, moisture,

and unusual mounting conditions, affect bearing

operation.

This engineering section is not intended to be

comprehensive, but does serve as a useful guide in

bearing selection.

Where more complex bearing applications are involved,

your Timken engineer should be consulted. The following

topics are covered within this manual:

Bearing design types.

•

Cage design types.

•

Life analysis procedure.

•

Bearing tolerances.

•

Fitting practice and mounting recommendations.

•

Operating temperatures.

•

Speed ratings.

•

Lubrication recommendations.

•

Seal design options.

•

4 TIMKEN ENGINEERING MANUAL

Page 7

HOW TO USE THIS CATALOG

HOW TO USE THIS CATALOG

We designed this catalog to help you find the Timken®

spherical roller bearing solid-block housed units best suited to

your specifications.

Timken offers an extensive range of bearings and accessories

in both imperial and metric sizes. For your convenience, size

ranges are indicated in millimeters and inches. Contact your

Timken engineer to learn more about our complete line for the

special needs of your application.

This publication contains dimensions, tolerances and load

ratings, as well as engineering sections describing fitting

practices for shafts and housings, internal clearances,

materials and other bearing features. It provides valuable

assistance in the initial consideration of the type and

characteristics of the bearings that may best suit your

particular needs.

TIMKEN

ISO and ANSI/ABMA, as used in this publication, refer to

the International Organization for Standardization and the

American National Standards Institute/American Bearing

Manufacturers Association.

TIMKEN ENGINEERING MANUAL

5

Page 8

TIMKEN

SHELF LIFE AND STORAGE OF GREASE-LUBRICATED BEARINGS AND COMPONENTS

SHELF LIFE AND STORAGE OF

GREASE-LUBRICATED BEARINGS

AND COMPONENTS

To help you get the most value from our products, Timken

provides guidelines for the shelf life of grease-lubricated

ball and roller bearings, components and assemblies. Shelf

life information is based on Timken and industry test data

and experience.

SHELF LIFE

Shelf life should be distinguished from lubricated bearing/

component design life as follows:

Shelf life of the grease-lubricated bearing/component

•

represents the period of time prior to use or installation.

The shelf life is a portion of the anticipated aggregate design

•

life. It is impossible to accurately predict design life due to

variations in lubricant bleed rates, oil migration, operating

conditions, installation conditions, temperature, humidity and

extended storage.

Shelf life values, available from Timken, represent a

•

maximum limit and assume adherence to the storage and

handling guidelines suggested in this catalog or by a Timken

associate. Deviations from the Timken storage and handling

guidelines may reduce shelf life. Any specification or

operating practice that defines a shorter shelf life should be

used.

European REACH Compliance

Timken lubricants, greases and similar products sold in

standalone containers or delivery systems are subject to the

European REACH (Registration, Evaluation, Authorization

and Restriction of CHemicals) directive. For import into the

European Union, Timken can sell and provide only those

lubricants and greases that are registered with ECHA

(European CHemical Agency). For further information, please

contact your Timken engineer.

Timken cannot anticipate the performance of the grease

lubricant after the bearing or component is installed or placed

in service.

TIMKEN IS NOT RESPONSIBLE FOR THE SHELF LIFE

OF ANY BEARING/COMPONENT LUBRICATED BY

ANOTHER PARTY.

6 TIMKEN ENGINEERING MANUAL

TIMKEN ENGINEERING MANUAL

6

Page 9

SHELF LIFE AND STORAGE OF GREASE-LUBRICATED BEARINGS AND COMPONENTS

STORAGE

Timken suggests the following storage guidelines for our

finished products (bearings, components and assemblies,

referred to as “products”):

Unless directed otherwise by Timken, products should be

•

kept in their original packaging until they are ready to be

placed into service.

Do not remove or alter any labels or stencil markings on the

•

packaging.

Products should be stored in such a way that the packaging

•

is not pierced, crushed or otherwise damaged.

After a product is removed from its packaging, it should be

•

placed into service as soon as possible.

When removing a product that is not individually packaged

•

from a bulk pack container, the container should be resealed

immediately after the product is removed.

Do not use product that has exceeded its shelf life.

•

Contact your local Timken engineer for further information

on shelf life limits.

The storage area temperature should be maintained

•

between 0° C (32° F) and 40° C (104° F); temperature

fluctuations should be minimized.

The relative humidity should be maintained below 60 percent

•

and the surfaces should be dry.

The storage area should be kept free from airborne

•

contaminants such as, but not limited to, dust, dirt, harmful

vapors, etc.

The storage area should be isolated from undue vibration.

•

Extreme conditions of any kind should be avoided.

•

Due to the fact that Timken is not familiar with your particular

storage conditions, we strongly suggest following these

guidelines. However, you may be required by circumstances

or applicable government requirements to adhere to stricter

storage requirements.

TIMKEN

A

Most bearing components typically ship protected with a

corrosion-preventive compound that is not a lubricant. These

components may be used in oil-lubricated applications without

removal of the corrosion-preventive compound. When using

some specialized grease lubrications, we advise you to remove

the corrosion-preventive compound before packing the

bearing components with suitable grease.

We pre-pack most housed unit types in this catalog with

general-purpose grease suitable for their normal applications.

It may be necessary for you to frequently replenish the grease

for optimum performance.

Be careful in selecting lubrication, however, since different

lubricants are often incompatible. You may order housed units

pre-lubricated with a specified lubrication.

When you receive a bearing or housed unit shipment, do not

remove products from their packaging until they are ready for

mounting so they do not become corroded or contaminated.

Store bearings and housed units in an appropriate atmosphere

so they remain protected for the intended period.

TIMKEN ENGINEERING MANUAL

7

Page 10

TIMKEN

WARNINGS/DISCLAIMERS

WARNING

Failure to observe the following warnings could

create a risk of death or serious injury.

Proper maintenance and handling practices are critical.

Always follow installation instructions and

maintain proper lubrication.

Never spin a bearing with compressed air.

The rollers may be forcefully expelled.

DISCLAIMER

This catalog is provided solely to give you analysis tools and data

to assist you in your product selection. Product performance is

affected by many factors beyond the control of Timken.

Therefore, the suitability and feasibility of all product selection

must be validated by you.

Timken products are sold subject to Timken's terms and conditions

of sale, which include its limited warranty and remedy, which terms

may be found at www.timken.com/ termsandconditionsofsale.

Please consult with your Timken sales engineer for more

information and assistance.

Warnings for this product line are found in this catalog

and posted on www.timken.com/warnings

CAUTION

Failure to observe the following warnings could

create a risk of death or serious injury.

Remove oil or rust inhibitor from parts before heating,

to avoid fire and fumes.

NOTE

Mixing greases can result in improper bearing lubrication.

Always follow the specific lubrication instructions of your

equipment supplier.

NOTE

Product performance is affected by many factors beyond the control

of Timken. Therefore, the suitability and feasibility of all designs and

product selection should be validated by you. This catalog is provided

solely to give you, a customer of Timken or its parent or affiliates,

analysis tools and data to assist you in your design. No warranty,

expressed or implied, including any warranty of fitness for a particular

purpose, is made by Timken. Timken products and services are sold

subject to a Limited Warranty.

You can see your Timken engineer for more information.

Every reasonable effort has been made to ensure the accuracy

of the information in this writing, but no liability is accepted for

errors, omissions or for any other reason.

COMPLIANCE

To view the complete engineering catalog, please visit

www.timken.com. To order the catalog, please contact your Timken

sales engineer and request a copy of the Timken Engineering Manual

(order number 10424).

European REACH compliance Timken-branded lubricants, greases

and similar products sold in stand-alone containers or delivery

systems are subject to the European REACH (Registration, Evaluation,

Authorization and Restriction of CHemicals) directive. For import

into the European Union, Timken can sell and provide only those

lubricants and greases that are registered with ECHA (European

CHemical Agency). For further information, please contact your

Timken sales engineer.

The Timken Company products shown in this catalog may

be directly, or indirectly subject to a number of regulatory

standards and directives originating from authorities in the USA,

European Union, and around the world, including:

REACH (EC 1907/2006, RoHS (2011/65/EU), ATEX (94/9/EC),

'CE' MARKING (93/68/EEC), CONFLICT MINERALS

(Section 1502 of the Dodd-Frank Wall Street Reform and

Consumer Protection Act).

For any questions or concerns regarding the compliancy or

applicability of Timken products to these, or other unspecified

standards, please contact your Timken sales engineer or

customer services representative.

NOTE

Never attempt a press fit on a shaft by applying pressure

to the outer ring or a press fit in a housing by applying

pressure to the inner ring.

8 TIMKEN ENGINEERING MANUAL

Updates are made periodically to this catalog.

Visit www.timken.com for the most recent version of the

Timken Spherical Roller Bearing Solid-Block Housed Units Catalog.

Page 11

BEARING SELECTION PROCESS

The first step in bearing selection is to identify the best bearing

type for the application. Each bearing type has advantages and

disadvantages based on its internal design. Table 1, on page

10, ranks the different bearing types on various performance

characteristics.

The next step is to assess the bearing size constraints

including the bore, outside diameter (O.D.) and width. This

is done by defining the minimum shaft diameter, maximum

housing diameter and available width for the bearing in the

application. At this point, bearings may be selected from the

manual that fit within the defined size constraints. Several

bearings with different load-carrying capacities may be

available that fit within the envelope.

The third step is to evaluate the known environmental

conditions and application requirements. Environmental

conditions include factors such as ambient temperature,

applied load, bearing speed and cleanliness of the environment

immediately surrounding the bearing. Application requirements

such as bearing fits, bearing setting, lubricant type, cage type

and flange arrangements are determined based on the speed,

temperature, mounting conditions and loading conditions

within the application.

BEARING SELECTION PROCESS

Lastly, bearing life calculations are performed that take into

account all of the environmental and application conditions.

If more than one bearing has been evaluated up to this point,

selection is based on the bearing that provides the best overall

performance for the application. A detailed explanation of this

analysis procedure is included in the following sections. For

assistance, contact your Timken engineer for a comprehensive

computer analysis of your bearing application.

To view more Timken catalogs, go

to www.timken.com/catalogs

for interactive versions, or to

download a catalog app for your

smart phone or mobile device

scan the QR code or go to

timkencatalogs.com.

TIMKEN ENGINEERING MANUAL

9

Page 12

BEARING SELECTION PROCESS

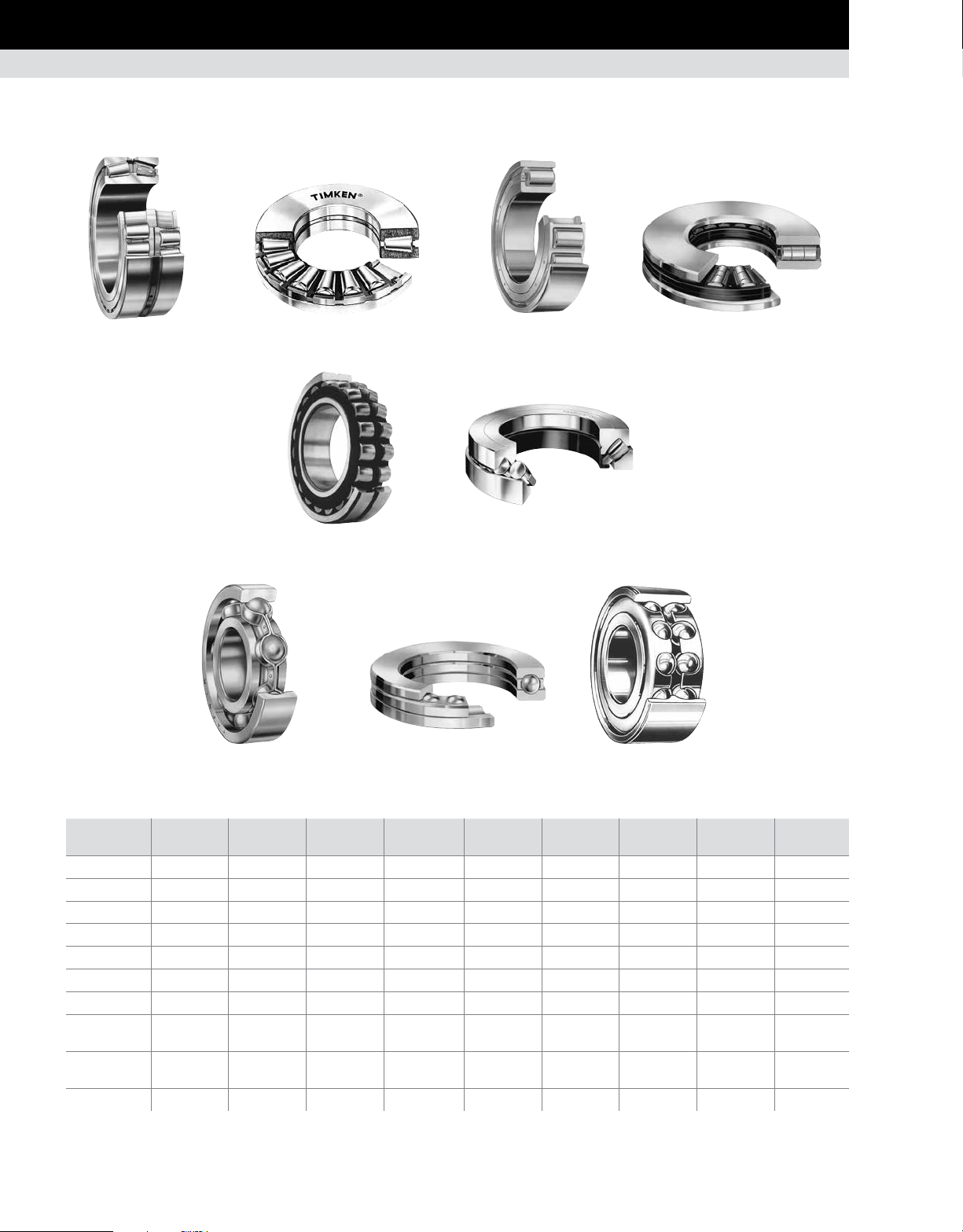

BEARING TYPES

BEARING TYPES

Cylindrical roller bearingTapered roller bearing Thrust tapered roller bearing Thrust cylindrical roller bearing

Spherical roller bearing

Thrust spherical roller bearing

Radial ball bearing Thrust ball bearing Angular contact ball bearing

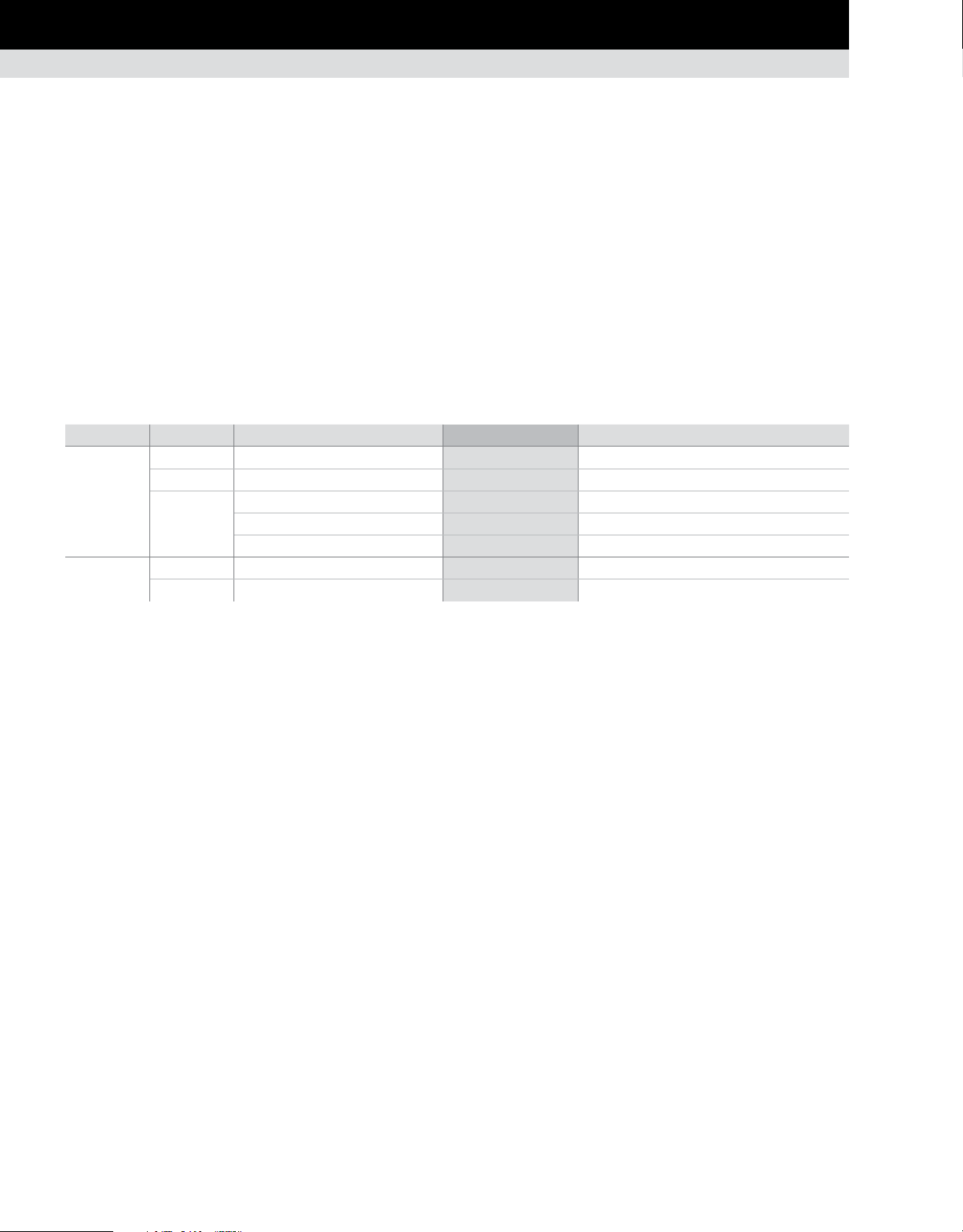

TABLE 1. RELATIVE OPERATING CHARACTERISTICS OF VARIOUS BEARING TYPES

Characteristic

Pure radial load Good Unsuitable Excellent Unsuitable Good Unsuitable Good Poor Fair

Pure axial load Good Excellent Unsuitable Good Fair Excellent Fair Excellent Good

Combined load Excellent Poor Fair Unsuitable Good Fair Good Poor Excellent

Moment load Excellent Poor Unsuitable Unsuitable Unsuitable Unsuitable Fair Poor Good

High stiffness Excellent Excellent Good Excellent Good Good Fair Good Good

Low friction Good Good Excellent Poor Fair Fair Excellent Good Good

Misalignment Poor Poor Poor Unsuitable Excellent Excellent Good Poor Poor

Locating position

(fixed)

Non-locating

position (floating)

Speed Good Good Excellent Poor Fair Fair Excellent Excellent Excellent

Tapered Roller

Bearing

Excellent Good Fair Fair Good Good Good Excellent Good

Good Unsuitable Excellent Unsuitable Good Unsuitable Good Unsuitable Good

Thrust Tapered

Roller Bearing

Cylindrical Roller

Bearing

Thrust Cylindrical

Roller Bearing

Spherical Roller

Bearing

Thrust Spherical

Roller Bearing

Radial

Ball Bearing

Thrust Ball

Bearing

Angular Contact

Ball Bearing

10 TIMKEN ENGINEERING MANUAL

Page 13

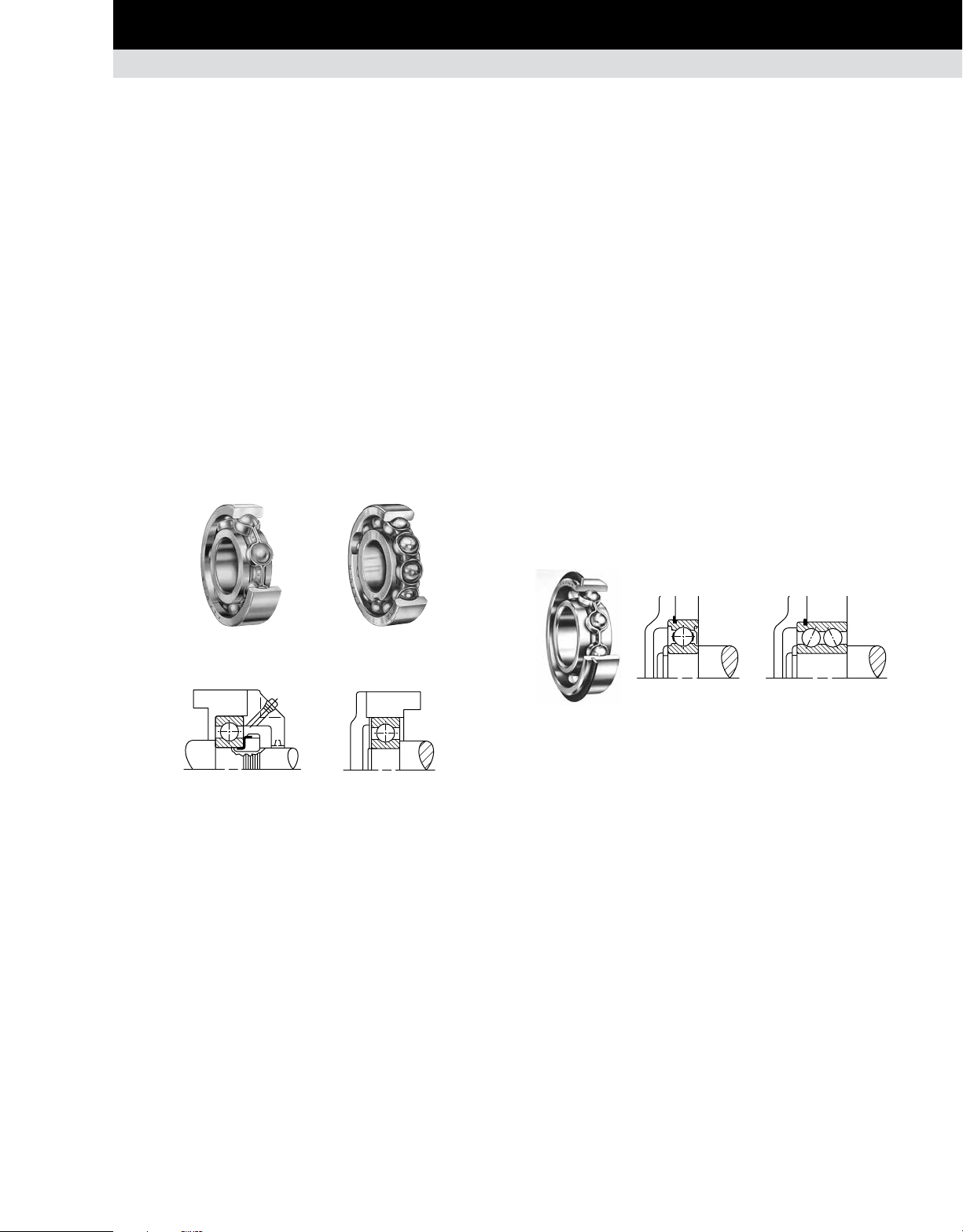

RADIAL BALL BEARINGS

Although radial ball bearings are designed primarily to support a

radial load, they perform relatively well under thrust or combined

radial and thrust load conditions.

Deep-groove ball bearings, commonly called Conrad or nonfilling-slot bearings, are assembled by displacing the inner

ring relative to the outer ring and inserting balls into the space

between the rings. By this method, only slightly more than half

the annular space between the inner and outer rings can be filled

with balls. Thus, capacity is limited.

To increase capacity, a filling slot or notch can be cut into the

inner ring, permitting the insertion of balls. Once the balls have

been inserted, the slot is filled by an insert. The increased number

of balls increases radial load capacity, but thrust load capacity

is sacrificed because of the filling slot.

The non-filling-slot or Conrad bearing is designated by the suffix

K and the filling slot bearing is designated by the suffix W.

BEARING SELECTION PROCESS

BEARING TYPES • RADIAL BALL BEARINGS

BALL BEARINGS WITH SNAP RINGS (WIRELOC)

Single-row radial ball bearings, including those with seals or

shields and open and shielded double-row types, are available

with snap rings. The snap ring protrudes from a groove in the

outer ring and acts as a shoulder to maintain bearing position. It

is designed for mounting in through-bored housings. This feature

is designated by adding the suffix G to the standard bearing

number. Single-shielded or sealed bearings with snap rings can

be supplied with the snap ring on the same side or opposite the

shield or seal position.

These bearings are advantageous in automobile transmission

design and in all applications where compactness is essential,

or where it is difficult and costly to machine housing shoulders.

The snap ring provides an adequate shoulder for the bearings

without a sacrifice in bearing capacity. The thrust capacity of the

snap ring in shear exceeds the thrust capacity of the bearing.

Typical designs illustrating how mounting simplification can be

accomplished through the use of snap ring bearings are shown

below.

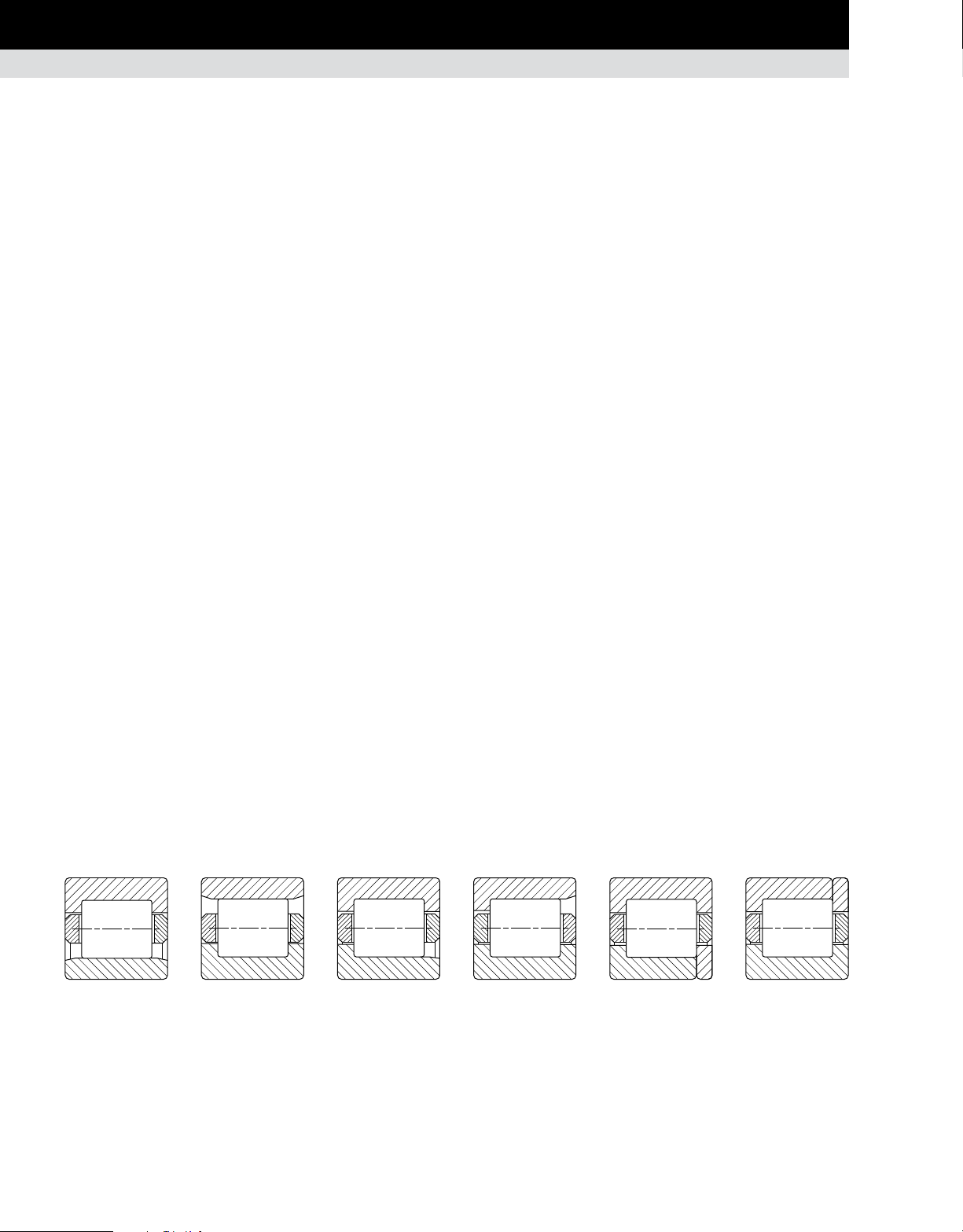

Suffix K Suffix W

Conrad Filling Slot

Fixed mounting Floating mounting

Fig. 1. Typical mountings for radial ball bearings.

Fig. 2. Typical mountings for snap ring bearings.

TIMKEN ENGINEERING MANUAL

11

Page 14

BEARING SELECTION PROCESS

BEARING TYPES • ANGULAR CONTACT BALL BEARINGS

ANGULAR CONTACT BALL BEARINGS

SINGLE-ROW

Single-row, angular contact ball bearings are designed for

combination loading with high thrust capacity in one direction,

and are suggested for applications where the magnitude of the

thrust component is high enough to preclude the use of radialtype ball bearings. They are dimensionally interchangeable with

single-row radial bearings of corresponding sizes.

The angular contact ball bearing has a relatively large contact

angle, high ring depths, and a maximum complement of balls

assembled through a counterbore in the outer ring. These

features provide bearings with significantly more thrust capacity

than radial bearings of the same size.

Angular contact bearings are used in such applications as gear

reducers, pumps, worm drives, vertical shafts and machine tool

spindles, where they are frequently mounted in various singlerow arrangements.

DOUBLE-ROW

Double-row, angular contact ball bearings are used effectively

where heavy radial, thrust or combined loads demand axial

rigidity of the shaft. This type is similar to a duplex pair of singlerow bearings by virtue of its two rows of balls and angular-contact

construction, which provide greater axial and radial rigidity than

can be obtained by using a single-row radial bearing.

With the exception of small sizes, double-row ball bearings are

made in the filling slot construction, and therefore, do not have

as much thrust capacity as equivalent size single-row, angular

contact bearings mounted in duplex pairs. Fixed and floating

mountings of double-row bearings are shown. Smaller sizes are

supplied with polymer retainers.

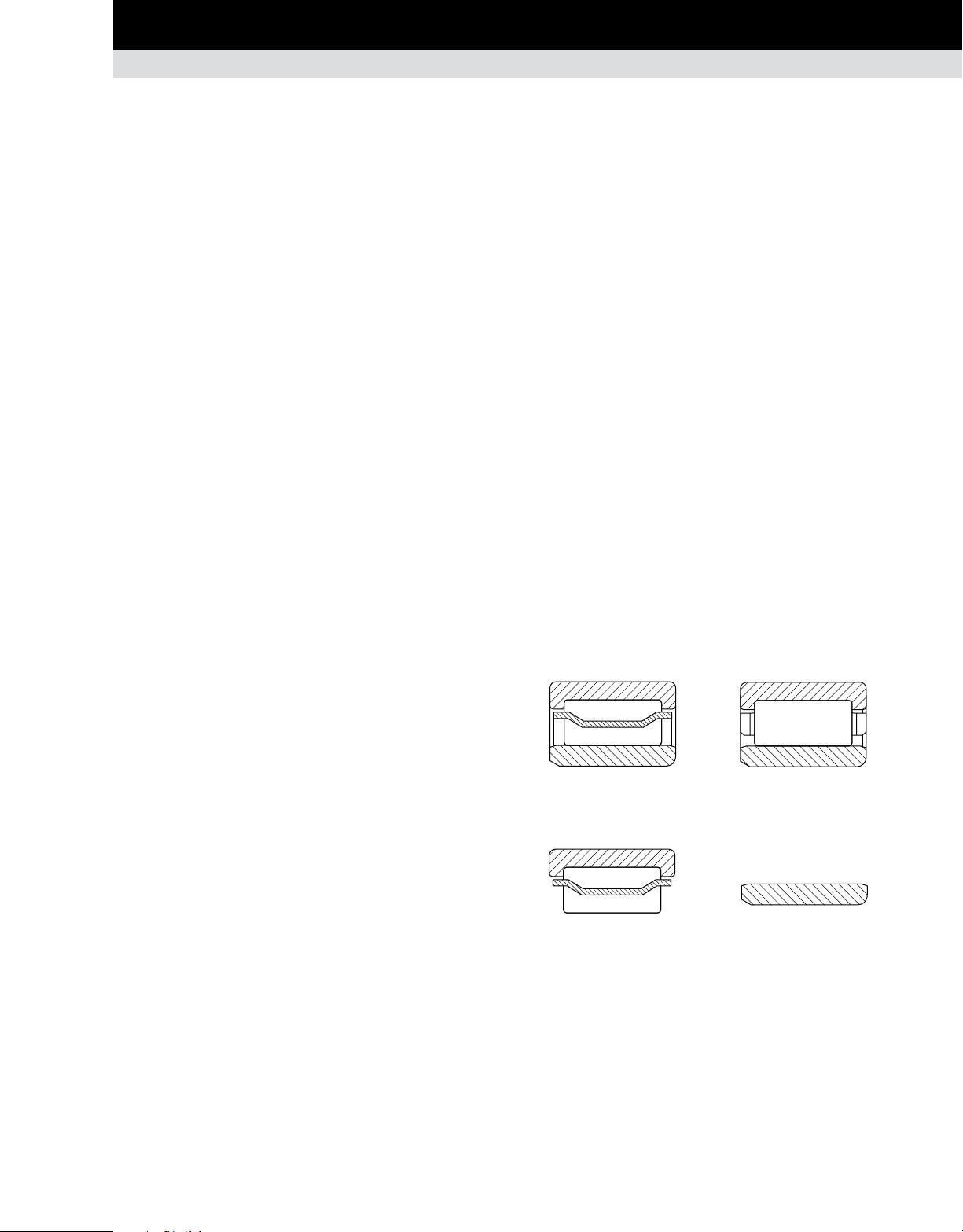

Fixed mounting Floating mounting

Fig. 4. Typical mountings for double-row,

angular contact ball bearings.

Fig. 3. Typical mounting for single-row, angular

contact ball bearings.

12 TIMKEN ENGINEERING MANUAL

Page 15

BEARING SELECTION PROCESS

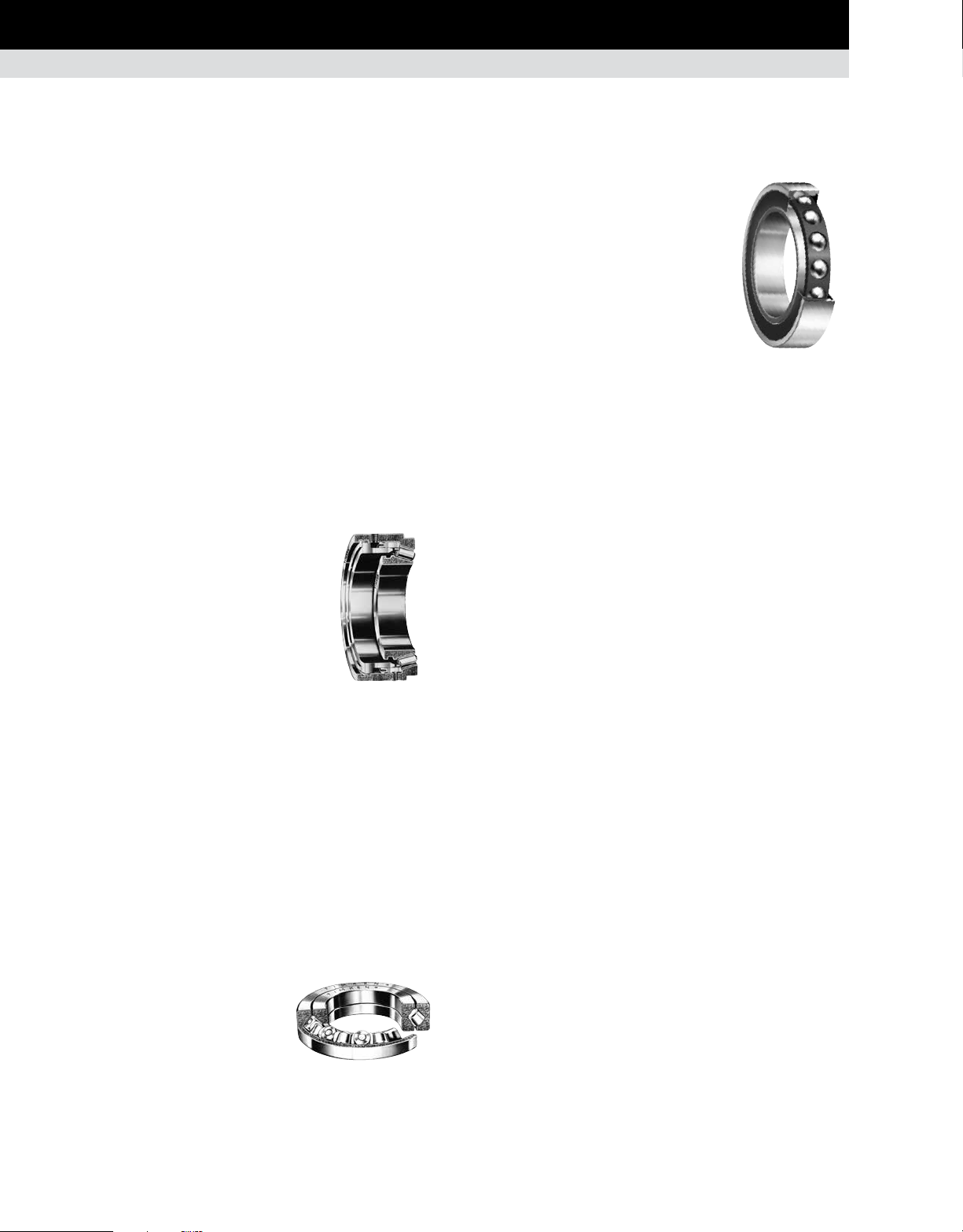

BEARING TYPES • PRECISION BEARINGS

PRECISION BEARINGS

(1)

MINIATURE AND THIN-SECTION

BALL BEARINGS

Timken produces precision ball bearings and assemblies

in miniature, instrument and thin-section series. All are

manufactured with quality steel, tolerances and features that

meet demanding application challenges. These precision

bearings and assemblies are found in surgical and diagnostic

imaging devices, precision pumps, measurement and material

handling equipment, as well as guidance, weapons and space

applications. Standard sizes range from 1 mm to 279.40 mm bore

(0.0250 in. to 11.000 in. bore).

Radial ball bearings

These Conrad bearings are available

in ISO P5/ABEC 5 to ISO P4/ABEC 7

precision levels as a standard catalog

offering. The deep-groove construction

allows for handling of radial, thrust or

combination loads. These are offered

primarily with 440C stainless-steel rings

and balls with one-piece fully machined

snap-in phenolic cages. In addition to

52100, other material and cage options

are available, as well as shields and

seals, and ceramic or titanium carbidecoated balls. Flanges are offered on miniature product. Typical

applications include guidance systems, medical (surgical

instruments and devices) and robotic joints.

Fig. 5. Radial ball

bearing.

Angular contact ball bearings

Angular contact ball bearings offer

maximum ball complement with a onepiece precision-machined retainer. The

increased ball complement, combined

with a relatively high contact angle,

maximizes axial stiffness. Angular

contact ball bearings are manufactured

to the same tolerances and standards

as the radial ball bearings. Rings and

balls are normally 440C stainless steel,

but other material options are offered.

Steel and ceramic balls are available

as standard. Typical applications use

preloaded pairs for maximum stiffness,

high speeds and precise positioning. These include surgical

handpieces, control moment gyros and other high-speed or highstiffness applications.

Fig. 6. Angular

contact ball bearing.

Fractured ring ball bearings

These bearings have outer rings

that are radially fractured in one

location. This permits the ring to be

opened for complete flexibility in the

choice of ball complement and cage

in a deep-groove radial bearing.

High-strength stainless-steel holding

bands are pressed on the ground

shoulders to retain tight abutment

and alignment of the fractured

surface during handling and normal

operation. Full complement and

retainer configurations are available.

Typical applications have a limited radial cross section and a

limited axial width. These applications require a bearing with

maximum radial capacity, as well as axial capacity in both

directions.

Fig. 7. Fractured ring

ball bearing.

Pivot ball bearings

Designed for space

constrained environments

where low torque is required,

pivot bearings use the mating

shaft for the inner raceway.

These bearings achieve

maximum power density with a

full complement of larger balls,

no cage or inner ring. Shields are available for the standard line.

Typical applications are in guidance systems, such as commercial

gyroscopes.

Fig. 8. Pivot ball bearing.

Thrust ball bearings

These bearings are designed for

applications where high axial

load, low speed and relatively high

torque are allowable. The standard

offering has all stainless steel

components for use where inert

materials are required. Stainless

steel allows operation as a fuel

control governor.

Fig. 9. Thrust ball bearing.

(1)

For additional information, refer to the Timken Super Precision Bearings for

Machine Tool Applications Catalog (order no. 5918) on www.timken.com.

TIMKEN ENGINEERING MANUAL

13

Page 16

BEARING SELECTION PROCESS

BEARING TYPES • PRECISION BEARINGS

PRECISION BEARINGS – continued

TAPERED ROLLER BEARINGS

Timken’s high-precision tapered roller bearings consist of

carefully matched components that offer an added degree of

fine-tuning in the bearing setting and adjustment procedure to

maximize customer machine productivity. Timken manufactures

high-speed designs with a variable preload capability for optimum

performance. Timken also manufacturers Precision Plus bearings –

having an overall radial runout less than a single micron.

TS and TSF single-row bearings

These bearings are similar in design to the types described on

page 16. They are only produced in high-precision quality, to be

used in machine tool spindles, printing press cylinders and other

applications where accuracy of rotation is required.

TSHR - Hydra-Rib™ bearing with

preload adjustment device

For many applications, notably in

the machine tool industry, bearings

are required to run at high speeds

with a controlled preload setting. The

Hydra-Rib™ bearing has a floating

outer ring rib controlled by hydraulic

or pneumatic pressure, which ensures

that the required bearing preload is

maintained irrespective of the differential

expansions or changes in loading taking

place within the system.

Fig. 10. Hydra-Rib™

bearing.

TXR - crossed roller bearing

A crossed roller bearing is two sets of bearing rings and rollers

brought together at right angles with alternate rollers facing

opposite directions. TXR bearings have a section height not

much greater than that of a TS bearing. The steep angle, tapered

geometry of the bearing causes the load-carrying center of each

of the rings to be projected along the axis, resulting in a total

effective bearing spread many times greater than the width of

the bearing itself. This type of bearing offers a high resistance to

overturning moments.

The normal design of the bearing

is type TXRDO, which has a double

outer ring and two inner rings,

with rollers spaced by polymer

cages. Crossed roller bearings are

manufactured in precision classes.

Fig. 11. TXR crossed roller

bearing.

TXR

SUPER PRECISION BALL BEARINGS

The Timken line of super precision

machine tool ball bearings is designed

to meet ISO and ABEC tolerance levels.

However, Timken manufactures all

super precision ball bearings to surpass

ISO/ABMA criteria to ensure that the

end users receive only the highest

quality product to maximize machine

performance. Spindle bearings are the

most popular type of super precision

ball bearing used within the machine

tool industry. These angular contact

bearings are used primarily in precision, high-speed machine

tool spindles. Timken manufactures super precision machine

tool bearings in four metric ISO dimensional series. In addition,

because of specialized variations of bearing design and geometry,

Timken offers a total of seven angular contact bearing types within

these four basic series:

ISO 19 (9300WI, 9300HX series).

•

ISO 10 (9100WI, 9100HX, 99100WN series).

•

ISO 02 (200WI series).

•

ISO 03 (300WI series).

•

Multiple internal geometries are available to optimize either loadcarrying capacity or speed capability with part number suffixes

designated as: WI, WN, HX or K. WI-type bearings are designed to

maximize capacity of the various bearing cross sections and are

used in low to moderate speeds. The HX is Timken’s proven highspeed design. It has a significant advantage at higher speeds,

generating less heat and less centrifugal loading forces. The

WN-type is generally a compromise between the WI and HX as

it offers higher speed capability than the WI, but lower capacity,

higher stiffness and lower speed capability than the HX design.

Most of the bearing types are available in either 15 degree

(2MM) or 25 degree (3MM) contact angles. In addition, Timken

now stocks more ceramic ball sizes than ever for the highest

speed requirements. The K-type deep-groove (Conrad) super

precision radial ball bearing is generally used in applications

where capacity and stiffness do not require sets containing

multiple bearings. By virtue of the single-row, radial deep-groove

construction, and super precision level tolerances, these are

capable of carrying thrust loads in either direction. Also, they

Fig. 12. Super precision

ball bearing.

14 TIMKEN ENGINEERING MANUAL

Page 17

BEARING SELECTION PROCESS

BEARING TYPES • PRECISION BEARINGS • BALL BEARINGS WITH LOCKING DEVICES

have a relatively high-speed capability – especially if a light axial

preload is applied. Timken offers deep-groove super precision ball

bearings in the following ISO dimensional series:

ISO 10 (9100K series).

•

ISO 02 (200K series).

•

ISO 03 (300K series).

•

For additional information, refer to the Timken Super Precision

Bearings for Machine Tool Applications Catalog (order number

5918) on www.timken.com. Or, contact your Timken engineer.

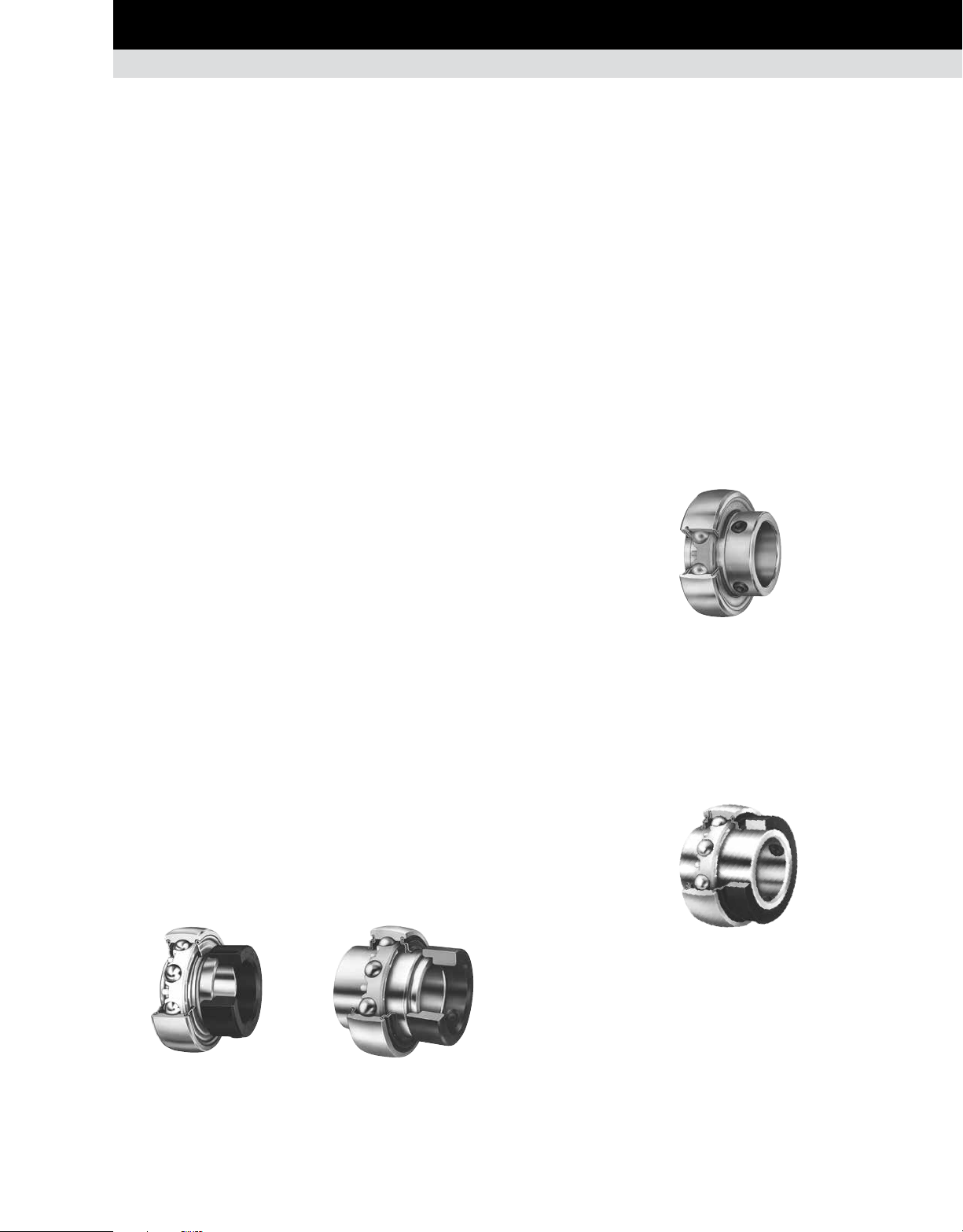

BALL BEARINGS WITH

LOCKING DEVICES

By virtue of their independent locking devices, these bearings

are suitable for mounting on straight shafting (no shoulders,

etc.). They are often supplied with spherical outer rings for selfalignment at mounting. Mounted alignment is usually required

because these bearings are generally assembled into pillow

blocks or flanged cartridges, or other housings bolted to pedestals

or frames independent of each other.

Easiest of all to install, wide inner ring ball bearings with selflocking collars are available in various sizes. These bearings,

shown with various seal and inner ring width variations, serve

many purposes in farm and industrial applications.

SETSCREW SERIES BEARINGS

The GYA-RRB and the GY-KRRB series are extended inner ring and

wide inner ring type bearings with specially designed setscrews

to lock on the shaft. These bearings can be purchased so that

they can be relubricated. Positive contact land-riding R-Seals

provide protection against harmful contaminants and retain

lubricant. Extended inner ring bearings are used when space is

at a premium and overturning loads are not a problem. The wide

inner ring setscrew series is available when additional surface

contact on the shaft is a requirement for added stability.

Fig. 14. YA-RR series.

SELF-LOCKING (ECCENTRIC) COLLAR

Timken invented the eccentric self-locking collar to facilitate

mounting of wide inner ring bearings. The self-locking collar

eliminates the need for locknuts, lock washers, shoulders, sleeves

and adapters.

The locking collar has a counterbored recess eccentric with

the collar bore. This eccentric recess engages or mates with an

eccentric cam end of the bearing inner ring when the bearing is

assembled on the shaft.

The collar is engaged on the inner ring cam of the bearing. This

assembly grips the shaft tightly with a positive binding action that

increases with use. No adjustments are necessary. The collar

setscrew provides supplementary locking.

RA-RR series Shroud-seal KRRB series

extended inner ring wide inner ring

with locking collar with locking collar

CONCENTRIC COLLAR

Using the concentric collar, the bearing is locked to the shaft by

two setscrews, 120 degrees apart, tightened in the collar and

passing through drilled holes in the inner ring. These units are

suited for applications where space is limited and reversing shaft

rotation is encountered.

Fig. 15. GC-KRRB series.

Fig. 13. Self-locking (eccentric) collar.

TIMKEN ENGINEERING MANUAL

15

Page 18

BEARING SELECTION PROCESS

BEARING TYPES • TAPERED ROLLER BEARINGS

TAPERED ROLLER BEARINGS

SINGLE-ROW BEARINGS

TS - Single-row

This is the basic and the most widely

used type of tapered roller bearing. It

consists of the inner ring assembly and

the outer ring. It is usually fitted as one

of an opposing pair. During equipment

assembly, single-row bearings can

be “set” to the required clearance

(endplay) or preload condition to optimize

performance.

TSF - Single-row,

with flanged outer ring

The TSF type is a variation on the basic

single-row bearing. TSF bearings have

a flanged outer ring to facilitate axial

location and accurately aligned seats in

a through-bored housing.

Fig. 16. Single-row

TS bearing.

Fig. 17. Single-row

TSF bearing with

flanged outer ring.

DOUBLE-ROW BEARINGS

TDO - Double outer ring

This has a one-piece (double) outer ring

and two single inner-rings. It is usually

supplied complete with a inner-ring

spacer as a pre-set assembly. This

configuration gives a wide effective

bearing spread and is frequently chosen

for applications where overturning

moments are a significant load

component. TDO bearings can be used

in fixed (locating) positions or allowed to

float in the housing bore, for example, to

compensate for shaft expansion. TDOCD

outer rings also are available in most

sizes. These outer rings have holes in the

O.D. that permit the use of pins to prevent

outer ring rotation in the housing.

Fig. 18. Double-row

TDO bearing.

TDI - Double inner ring

TDIT - Double inner ring with tapered bore

Both comprise a one-piece (double) inner ring and two single

outer rings. They are usually supplied complete with an outerring spacer as a pre-set assembly. TDI and TDIT bearings can be

used at fixed (locating) positions on rotating shaft applications.

For rotating housing applications, the double inner ring of type

TDI can be used to float on the stationary shaft. Type TDIT has

a tapered bore to facilitate removal when an interference fit is

essential, yet regular removal is required.

16 TIMKEN ENGINEERING MANUAL

TDI

Fig. 19. Double-row, double-inner-ring bearings.

TDIT

Page 19

BEARING SELECTION PROCESS

BEARING TYPES • TAPERED ROLLER BEARINGS

TNA - Non-adjustable

TNASW - Non-adjustable with lubricant slots

TNASWE - Non-adjustable with lubricant

slots and extended back face rib

These three bearing types are similar to the TDO with a one-piece

(double) outer ring and two single inner rings. The inner ring

front faces are extended so they abut, eliminating the need for a

separate inner-ring spacer. Supplied with a built-in clearance to

give a standard setting range, these bearings provide a solution

for many fixed or floating bearing applications where optimum

simplicity of assembly is required.

Types TNASW and TNASWE are variations having chamfers

and slots on the front face of the inner ring to provide lubrication

through the shaft. Type TNASWE have extended back face ribs

on the inner rings which are ground on the O.D. to allow for the

use of a seal or stamped closure. These designs are typically

used on stationary shaft applications.

SPACER ASSEMBLIES

Any two single-row bearings (type TS) can be supplied as a

double-row, pre-set, ready-to-fit assembly by the addition of

spacers, machined to pre-determined dimensions and tolerances.

Spacer assemblies are provided in two types: "2S" and "SR". This

concept can be applied to produce custom-made double-row

bearings to suit specific applications. In addition to providing

a bearing that automatically gives a pre-determined setting at

assembly without the need for a manual setting, it is possible

to modify the assembly width to suit an application, simply by

varying the spacer widths.

2S

Fig. 21. Spacer assemblies.

SR

TNA TNASW TNASWE

Fig. 20. Double-row, non-adjustable bearings.

2S - Two single-row assembly

Often referred to as snap-ring assemblies, type 2S consist of

two basic single-row bearings (type TS). They are supplied

complete with inner-ring and outer-ring spacers to give a predetermined bearing setting when assembled. Type 2S have a

specified setting range to suit the duty of the application. They

have an inner-ring spacer and a snap-ring, which also serves as

the outer-ring spacer, to give axial location in a through-bored

housing.

SR - SET-RIGHT™ assembly

Type SR are made to a standard setting range, based on Timken’s

SET-RIGHT™ automated setting technique suitable for most

industrial applications. They have two spacers and an optional

snap-ring that may be used for axial location. Because both types

are made up of popular sizes of single-row bearings, they provide

a low-cost option for many applications.

TIMKEN ENGINEERING MANUAL

17

Page 20

BEARING SELECTION PROCESS

BEARING TYPES • TAPERED ROLLER BEARINGS

TAPERED ROLLER BEARINGS – continued

There are three basic mounting arrangements for spacer

assemblies.

Type 2TS-IM (indirect mounting)

•

These consist of two single-row bearings with an inner-ring

and outer-ring spacer. In some applications, the outer-ring

spacer is replaced by a shoulder in the bearing housing.

Type 2TS-DM (direct mounting)

•

These consist of two single-row bearings, with inner rings

abutting and an outer-ring spacer. They are generally used

at fixed (locating) positions on rotating shaft applications.

Type 2TS-TM (tandem mounting)

•

Where combined radial and thrust load capacity is

required, but the thrust component is beyond the capacity

of a single bearing (within a given maximum O.D.), two

single-row bearings can be mounted in tandem.

Appropriate inner-ring and outer-ring spacers are supplied.

Consult your Timken engineer for the most effective

and economical solution.

2TS-IM

2TS-DM

Fig. 22. Basic spacer assemblies.

2TS-™

18 TIMKEN ENGINEERING MANUAL

Page 21

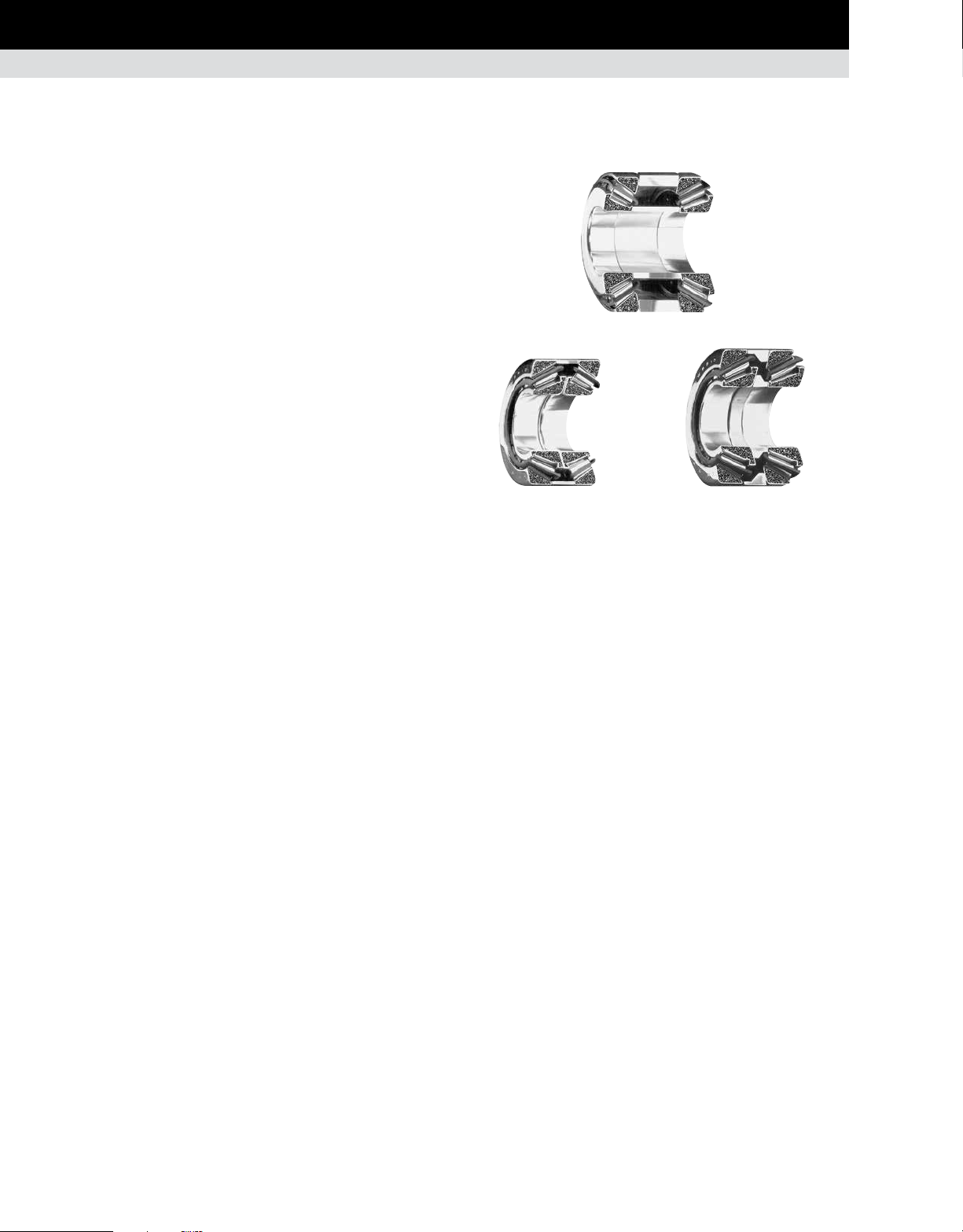

PACKAGED BEARINGS

BEARING SELECTION PROCESS

BEARING TYPES • TAPERED ROLLER BEARINGS

PINION PAC

Fig. 23. Packaged bearings.

Pinion Pac

™

™

bearing

UNIPAC

™

UNIPAC-PLUS

™

The Pinion Pac™ bearing is a ready-to-install, pre-set and sealed

package consisting of two rows of tapered roller bearings

mounted in a carrier. It is custom designed for the final drive

pinions of heavy commercial vehicles. The package gives the

differential pinion builder considerable improvements in reliability,

ease of assembly and supply logistics.

™

UNIPAC

bearing

The UNIPAC-PLUS™ bearing is a ready-to-install, pre-set,

pre-lubricated and sealed double-row assembly with a flanged

outer ring. Originally designed for the high-volume needs of

passenger car wheels, the UNIPAC bearing now has wider

application in wheel hubs of heavy vehicles as well as in industrial

equipment.

The UNIPAC bearing provides improvements in reliability, ease

of assembly and supply logistics.

AP

™

bearing

AP

™

SP

™

The AP™ bearing is a self-contained assembly, made in a wide

range of sizes. It consists of two single inner rings, a counterbored

double outer ring, a backing ring, two radial seals, an end cap

and cap screws. The AP bearing is supplied as a pre-set, prelubricated and sealed package. It was originally designed for

railroad journals, but also is used in many industrial applications.

™

SP

bearing

Similar in concept to AP bearings, the SP™ bearing is designed

for rail journal bearing applications. The SP bearing type differs

from the AP bearing in that SP bearings are more compact in size

and are manufactured to metric boundary dimensions.

™

UNIPAC-PLUS

bearing

The UNIPAC-PLUS™ bearing is a ready-to-install, pre-set,

sealed double-row assembly with a flanged outer ring. It also is

lubricated for the reasonable life of the bearing. It is designed

for wheel applications subjected to moderate to heavy loading.

The UNIPAC-PLUS bearing provides advantages of improved

reliability, reduced weight and easier assembly.

TIMKEN ENGINEERING MANUAL

19

Page 22

BEARING SELECTION PROCESS

BEARING TYPES • TAPERED ROLLER BEARINGS

HIGH-SPEED BEARINGS

TSMA - Single-row with axial oil

TSMR - Single-row with radial oil

Some applications require extreme high-speed capability where

special lubrication methods must be provided.

The TSMA and TSMR are single-row

bearings with provisions for lubrication of

critical roller-rib contact area to ensure

adequate lubrication at high speeds.

The TSMA concept works by capturing

oil in a manifold (attached to the inner

ring), which is then directed to the

rib-roller contact through holes drilled

axially through the large inner ring rib.

The TSMR functions in a similar manner

with the difference being that holes are

drilled radially from the inner ring bore

to the large rib face. Oil is captured in

a circumferential groove in the inner

ring bore. It is directed to the rib-roller

contact area through radial holes.

Fig. 24. TSMA bearing.

OTHER DOUBLE-ROW BEARINGS

Type TDIE - Extended double inner ring

Type TDIA - Extended single inner ring

These double-row bearings are designed for applications where

it is required to lock the loose-fitted inner ring to a shaft, with

provision also for effective closure or sealing. Typical applications

include pillow blocks, disc-harrow and similar agricultural

machinery shafts and line shafts.

Type TDIE is available in two forms – cylindrical bore with the

inner ring extended at both ends and provisions for setscrews

and locking collars at each end, or with an inherently self-locking

square bore – ideal for farm machinery applications.

Type TDIA is similar to type TDIE with a cylindrical bore. There

is a provision for a locking collar at one end only. The compact

configuration is suited to pillow blocks and similar applications.

On all types, the hardened and ground O.D. of the inner ring

extension provides an excellent surface for effective closure

or sealing.

Type TNASWH - Non-adjustable, heavy-duty,

double outer ring

Type TNASWHF - Non-adjustable, heavy-duty,

with flanged double outer ring

These are double-row bearing assemblies with two inner rings

and a one-piece outer ring, similar to type TNASWE listed in this

manual on page 17.

The outer rings have a heavy wall section (type TNASWH),

allowing the bearings to be used directly as steady rest rollers,

in sheet and strip levellers or, with a flange (type TNASWHF), as

a complete wheel assembly for use on rails.

The outer ring is extended at both ends and counterbored to

accept stamped closures. Contacting seals are available for

certain sizes. These bearings are typically supplied as a unit

assembly and are pre-lubricated.

TDIE TDIE (square bore)

Fig. 25. Other double-row bearings.

20 TIMKEN ENGINEERING MANUAL

TDIA

TNASWH

TNASWHF

Page 23

BEARING SELECTION PROCESS

BEARING TYPES • TAPERED ROLLER BEARINGS

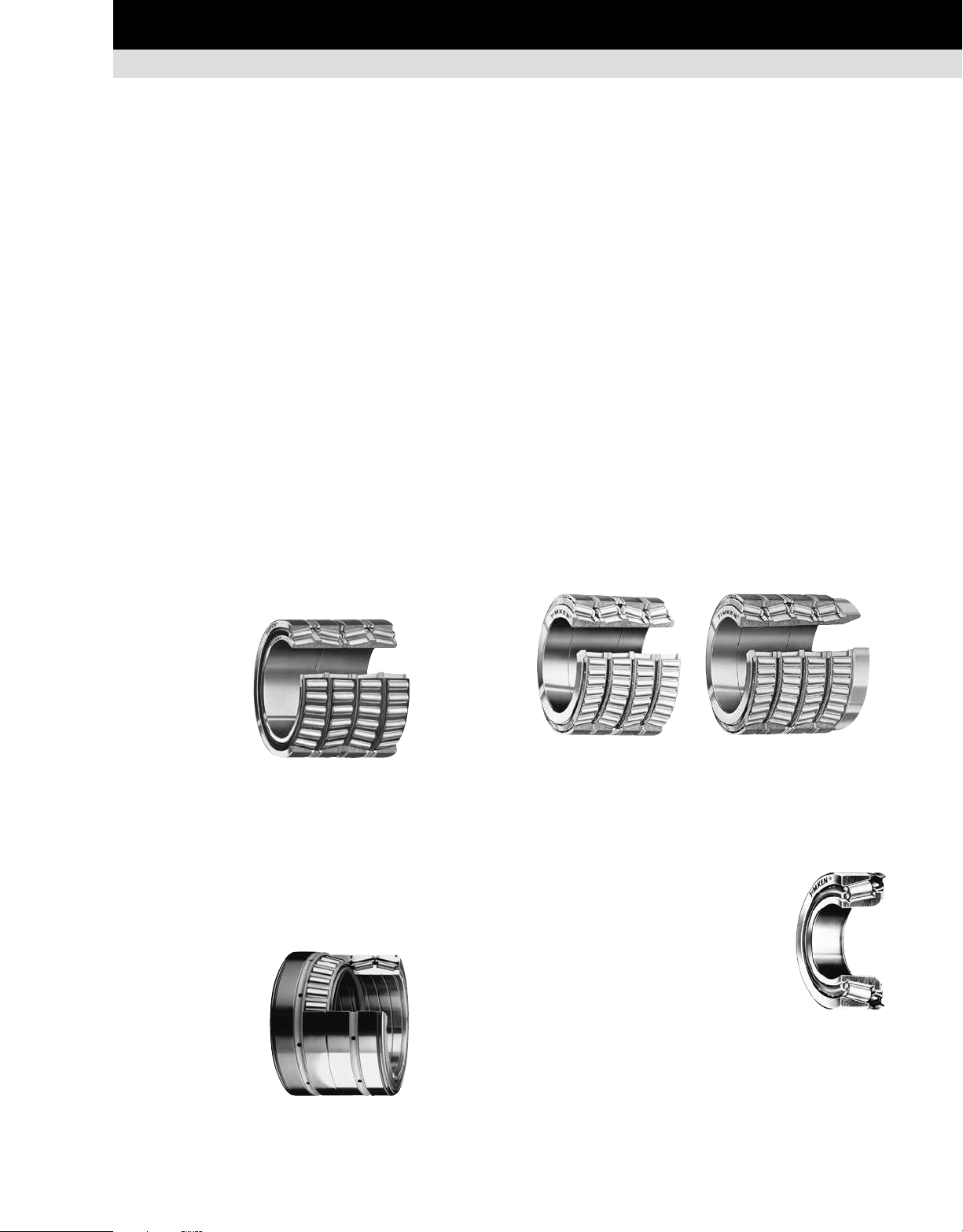

FOUR-ROW BEARINGS

Four-row bearings combine the inherent high-load, radial/thrust

capacity and direct/indirect mounting variations of tapered roller

bearings into assemblies of maximum load rating in a minimum

space. Their main application is on the roll necks of rolling mill

equipment.

All four-row bearings are supplied as pre-set matched assemblies,

with all components numbered to ensure correct installation

sequence.

Type TQO - Quad taper

Type TQOW - Quad taper with lubrication slots

These pairs of directly mounted bearings consist of two double

inner rings, two single and one double outer ring, with an innerring spacer and two outer-ring spacers. These types are used

on roll necks of low- and medium-speed rolling mills, applied to

the necks with a loose fit. When the fillet and/or filler rings do

not have lubrication slots, they are provided in the faces of the

bearing inner rings (type TQOW). Slots in the inner-ring spacer

permit lubricant to flow from the bearing chamber to the roll neck.

The inner-ring spacers also are hardened to minimize face wear.

Type TQITS

Type TQITSE

The main feature of these bearings is a tapered bore – the taper

being matched and continuous through the inner rings. This

permits an interference fit on the backup rolls of high-speed mills,

where a loose inner ring fit of a straight bore type TQO bearing

could result in excessive neck wear.

These four-row bearings consist of two pairs of indirectly

mounted bearings: two single and one double inner ring, four

single outer rings and three outer-ring spacers. The adjacent

faces of the inner-rings are extended so that they abut,

eliminating the need for inner-ring spacers. The indirect mounting

of the bearing pairs increase the overall effective spread of the

bearing, to give optimum stability and roll rigidity.

Type TQITSE is the same as TQITS, but has an extension to the

large bore inner ring adjacent to the roll body. This not only

provides a hardened, concentric and smooth surface for radial

lip seals, but also improves roll neck rigidity by eliminating a fillet

ring. This allows the centerline of the bearing to move closer to

the roll body. It also permits shorter and less costly rolls.

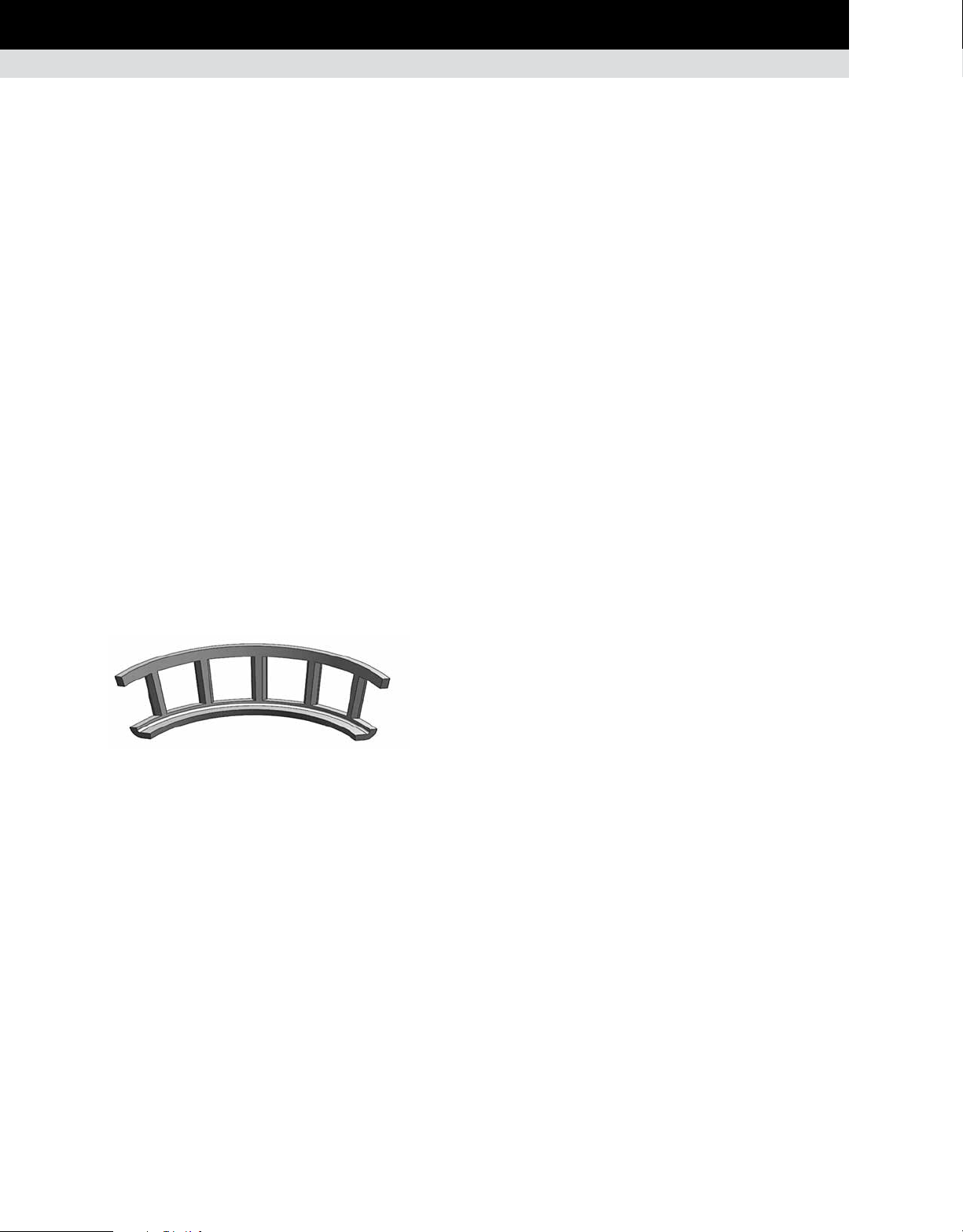

Fig. 26. Four-row

bearing assemblies.

TQO/ TQOW

Sealed roll neck

The sealed roll neck bearing is similar to the TQO. A specially

designed sealing arrangement is incorporated in the bearing

to endure highly contaminated environments. The special seal

design is built into the bearing to prevent ingress of contamination

from outside the bearing envelope and extend the useful

bearing life.

Fig. 27. Sealed roll neck

bearing.

TQITS TQITSE

Fig. 28. Four-row bearings with tapered bore.

SEALED BEARINGS

TSL

Timken offers a wide range of sealed

bearings such as the DUO-FACE

shown in fig 29. The TSL incorporates a DUOFACE PLUS seal, making it an economical

choice for grease-lubricated applications

at moderate speeds. See the SEALS section

in the back of this manual for additional seal

designs.

®

PLUS seal

Fig. 29. TSL sealed

bearing.

TIMKEN ENGINEERING MANUAL

21

Page 24

BEARING SELECTION PROCESS

BEARING TYPES • THRUST BEARINGS

THRUST BEARINGS

Standard types of thrust bearings manufactured by Timken are

included in this section. Each type is designed to take thrust

loads, but four types (TVL, DTVL, TTHD and TSR) accommodate

radial loads as well. All types reflect advanced design concepts,

with large rolling elements for maximum capacity. In roller thrust

bearings, controlled-contour rollers are used to ensure uniform,

full-length contact between rollers and raceways with resultant

high capacity. Thrust bearings should operate under continuous

load for satisfactory performance.

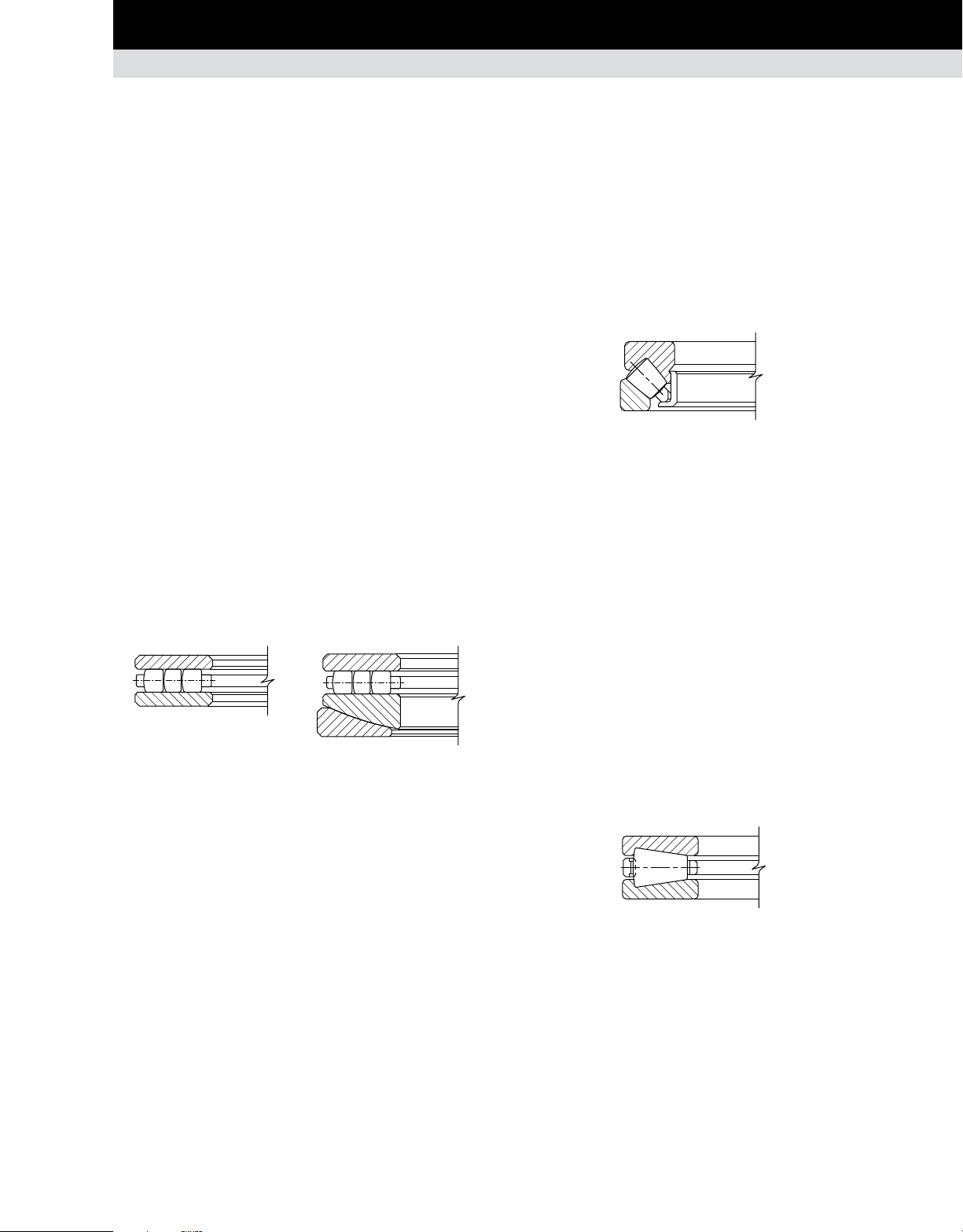

Type TVB – Grooved-ring thrust ball bearing

Type TVL – Angular contact thrust ball bearing

Type DTVL – Two direction angular contact thrust ball bearing

Type TP – Thrust cylindrical roller bearing

Type TPS – Self-aligning thrust cylindrical roller bearing

Type TTHD – Thrust tapered roller bearing

Type TSR – Thrust spherical roller bearing

Type TTHDFL – V-flat thrust tapered roller bearing

Type TTVS – Self-aligning V-flat thrust tapered roller bearing

Type TTSP – Steering pivot thrust cylindrical roller bearing

ring is shaft-mounted. The stationary ring should be housed with

sufficient O.D. clearance to allow the bearing to assume its proper

operating position. In most sizes, both rings have the same bore

and O.D. The housing must be designed to clear the O.D. of the

rotating ring, and it is necessary to step the shaft to clear the

bore of the stationary ring.

Type TVL is a separable angular contact ball bearing primarily

designed for unidirectional thrust loads. The angular contact

design, however, will accommodate combined radial and thrust

loads since the loads are transmitted angularly through the balls.

The bearing has two hardened and ground steel rings with

ball grooves and a one-piece brass cage that spaces the ball

complement. Although not strictly an angular ball bearing, the

larger ring is still called the outer ring, and the smaller the inner

ring. Timken standard tolerances for type TVL bearings are

equivalent to ABEC 1 where applicable, but higher grades of

precision are available.

Usually the inner ring is the rotating member and is shaft mounted.

The outer ring is normally stationary and should be mounted with

O.D. clearance to allow the bearing to assume its proper operating

position. If combined loads exist, the outer ring must be radially

located in the housing.

THRUST BALL BEARINGS

Thrust ball bearings are used for lighter loads and higher speeds

than thrust roller bearings. Types TVB, TVL and DTVL are shown

in fig. 30.

Type TVB thrust ball bearing is separable and consists of two

hardened and ground steel rings with grooved raceways, and

a cage that separates and retains precision-ground and lapped

balls. The standard cage material is brass, but this may be varied

according to the requirements of the application. Timken

tolerances for type TVB bearings are equivalent to ABEC 1 where

applicable, but higher grades of precision are available.

Type TVB bearings provide axial rigidity in one direction and their

use to support radial loads is not suggested. Usually the rotating

Fig. 30. Thrust ball bearing types.

standard

Type TVL bearings should always be operated under thrust load.

Normally, this presents no problem as the bearing is usually

applied on vertical shafts in oil field rotary tables and machine

tool indexing tables. If constant thrust load is not present, it should

be imposed by springs or other built-in devices.

Low friction, cool running and quiet operation are advantages of

TVL bearings, which may be operated at relatively high speeds.

TVL bearings also are less sensitive to misalignment than other

types of rigid thrust bearings.

DTVL is similar in design to TVL except the DTVL has an additional

ring and ball complement permitting it to carry moderate thrust

in one direction and light thrust in the other direction.

DTVLTVLTVB

22 TIMKEN ENGINEERING MANUAL

Page 25

BEARING SELECTION PROCESS

BEARING TYPES • THRUST BEARINGS

THRUST CYLINDRICAL ROLLER BEARINGS

Thrust cylindrical roller bearings withstand heavy loads at

relatively moderate speeds. Standard thrust bearings can be

operated at bearing O.D. peripheral speeds of 3000 fpm (15 m/s).

Special design features can be incorporated into the bearing and

mounting to attain higher operating speeds.

Because loads are usually high, extreme-pressure (EP) lubricants

should be used with cylindrical roller thrust bearings. Preferably,

the lubricant should be introduced at the bearing bore and

distributed by centrifugal force.

All types of thrust roller bearings are made to Timken Standard

Tolerances. Higher precision may be obtained when required.

Type TP thrust cylindrical roller bearings have two hardened

and ground steel rings, with a cage retaining one or more

controlled-contour rollers in each pocket. When two or more

rollers are used in a pocket, they are of different lengths and are

placed in staggered position in adjacent cage pockets to create

overlapping roller paths. This prevents wearing grooves in the

raceways and helps prolong bearing life.

Because of the simplicity of their design, type TP bearings are

economical. Shaft and housing seats must be square to the axis

of rotation to prevent initial misalignment problems.

THRUST SPHERICAL ROLLER BEARINGS

Type TSR

The TSR thrust spherical roller bearing design achieves a high

thrust capacity with low friction and continuous roller alignment.

The bearings can accommodate pure thrust loads as well as

combined radial and thrust loads. Typical applications are air

regenerators, centrifugal pumps and deep well pumps. Maximum

axial misalignment between inner and outer ring is ±2.5 degrees.

Fig. 32. Thrust spherical roller bearing, type TSR.

THRUST TAPERED ROLLER BEARINGS

Type TTHD

Type TTHD thrust tapered roller bearings have an identical pair

of hardened and ground steel rings with conical raceways and a

complement of controlled-contour tapered rollers equally spaced

by a cage. The raceways of both rings and the tapered rollers

have a common vertex at the bearing center. This assures true

rolling motion.

TP

TPS

Fig. 31. Thrust cylindrical roller bearings.

Type TPS bearings are the same as type TP bearings except one

ring is spherically ground to seat against an aligning ring, thus

making the bearing adaptable to initial misalignment. Its use

is not suggested for operating conditions where alignment is

continuously changing (dynamic misalignment).

TTHD bearings are well-suited for applications such as crane

hooks, where extremely high thrust loads and heavy shock must

be resisted and some measure of radial location obtained.

For very low-speed, heavily loaded applications, these bearings

are supplied with a full complement of rollers for maximum

capacity. For application review of the full complement type TTHD

bearing, consult your Timken engineer.

Fig. 33. Thrust tapered roller bearing, type TTHD.

TIMKEN ENGINEERING MANUAL

23

Page 26

BEARING SELECTION PROCESS

BEARING TYPES • THRUST BEARINGS

THRUST BEARINGS – continued

TTC cageless

TTSP steering pivot

There are two basic types of Timken® tapered roller thrust

bearings designed for applications where the only load

component is thrust, TTC and TTSP. The TTC bearing uses a full

complement of tapered rollers without a cage and is used when

the speeds are slow. The TTSP bearing uses a cage and is wellsuited for the oscillating motion of steering pivot positions.

Type TTHDFL Type TTVS

Type TTHDSX Type TTHDSV

V-flat tapered roller bearings (TTHDFL and TTVS) combine the

best features of thrust tapered and cylindrical roller bearings,

offering the highest possible capacity of any thrust bearing of its

size. V-flat design includes one flat ring and the second with a

tapered raceway matching the rollers. The design was originally

developed to be screwed down in metal rolling mill applications

where the thrust loads commonly exceed one million pounds.

These bearings have exceptional dynamic capacity within a given

envelope and provide superior static capacity. They are used

inheavily loaded extruders, cone crushers and other applications

where a wide range of operating conditions are found.

TTSPTTC

TTVSTTHDFL

TTHDFL

Most sizes utilize cages with hardened pins through the center

of the rollers, allowing closer spacing of the rollers to maximize

capacity. Smaller sizes have cast-brass cages, carefully

machined to permit full flow of lubricant.

Self-aligning V-flat bearings (TTVS) employ the same basic roller

and raceway design, except the lower ring is in two pieces, with

the contacting faces spherically ground permitting self-alignment

under conditions of initial misalignment. TTVS bearings should

not be used if dynamic misalignment (changing under load) is

expected.

TTHDSV

Fig. 34. Thrust tapered roller bearings.

TTHDSX

24 TIMKEN ENGINEERING MANUAL

Page 27

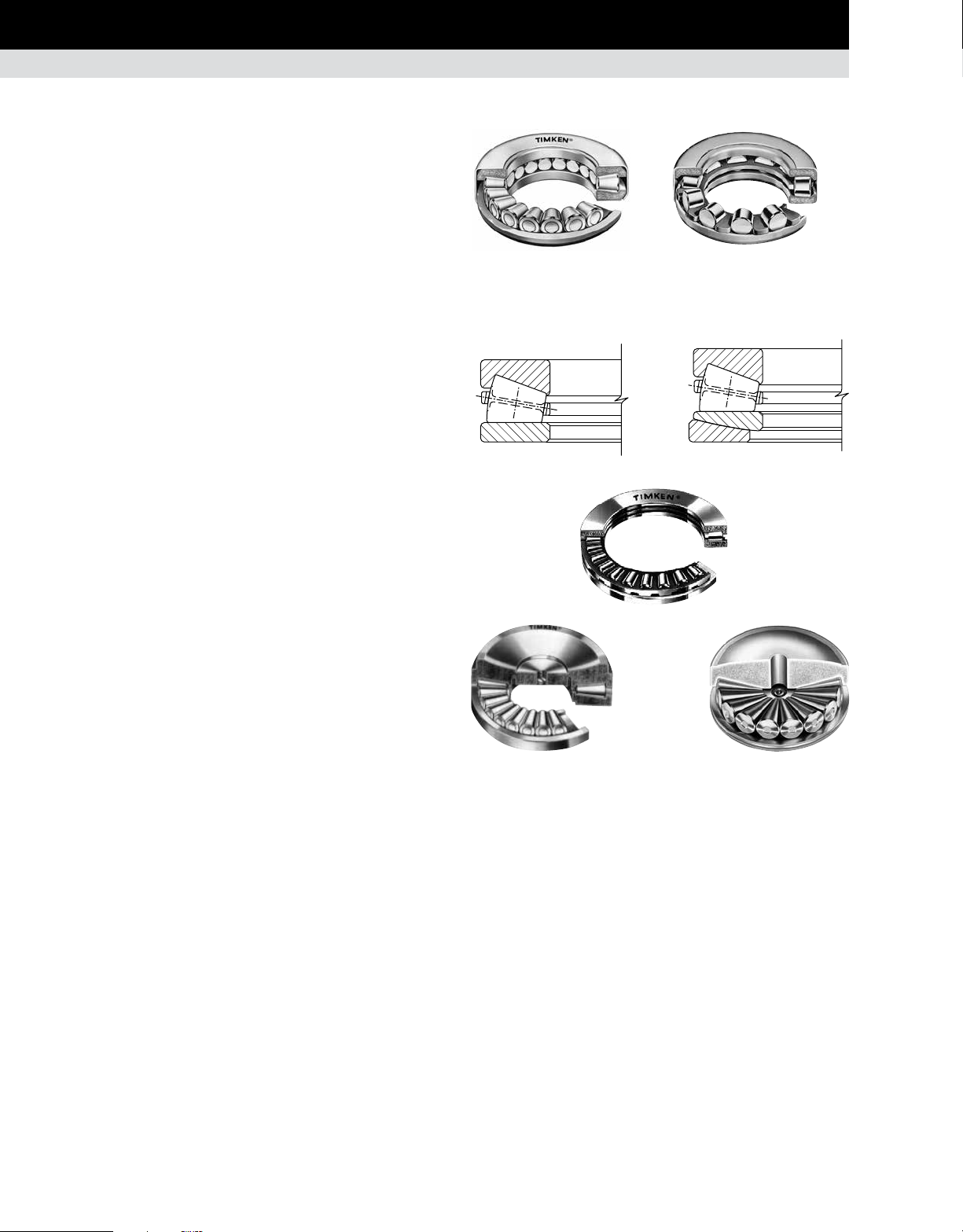

RADIAL SPHERICAL ROLLER BEARINGS

BEARING SELECTION PROCESS

BEARING TYPES • RADIAL SPHERICAL ROLLER BEARINGS

The principle styles of radial spherical roller bearings that Timken

offers are:

≤400 mm outer diameter: EJ, EM and EMB.

•

>400 mm outer diameter: YM, YMB, YMD and YP.

•

The newly redesigned Timken

higher load ratings, increased thermal speed ratings and reduced

operating temperatures compared to the previous offering.

In addition to these improvements, cage designs vary between

the different styles as noted below. See the cage section for

more details.

Style Cage Design

EJ Land-riding steel cage; one per row

EM / YM Roller-riding one-piece brass cage

EMB/YMB Land-riding one-piece brass cage

YMD Land-riding two-piece brass cage

YP Steel pin-type cage

EM/YM and

EMB/YMB

Fig. 35. Radial spherical roller bearings.

Most Timken spherical roller bearings are available with a

cylindrical bore as well as a tapered bore. Tapered bore bearing

part numbers are designated with a K suffix.

®

EJ, EM and EMB bearings offer

YMDEJ

YP

OPTIONAL FEATURES AVAILABLE WITH

TIMKEN SPHERICAL ROLLER BEARINGS

W33 lubrication groove and oil holes

A lubrication groove and three oil holes are provided in the

bearing outer ring as standard. This is designated by the W33

suffix. It eliminates the expense of machining a channel in the

housing bore for introducing lubricant to the bearing. This design

feature allows the lubricant to flow between the roller paths,

through a single lubrication fitting. The lubricant moves laterally

outward from the center of the bearing, reaching all contact

surfaces and flushing the bearing. To order, add the suffix W33

to the bearing number (e.g. 22216EMW33).

Bearings for vibratory applications

Timken offers specific spherical roller bearing designs for

vibratory applications. They are designated by the W800

modification code and made to a C4 clearance. Specify W800

when ordering. This design provides:

A lubrication groove on the outer ring with three lubrication

•

holes to facilitate bearing lubrication.

Extra-close running accuracy (P5) with high and low points

•

marked on the bearing.

Reduced bore and outside diameter tolerances.

•

Radial internal clearance is made in upper two-thirds of

•

C4 clearance range.

These bearings are available with either a cylindrical or tapered

bore.

A taper of 1:12 is standard except for 240, 241 and 242 series,

which have a taper of 1:30.

SERIES

239 230 240 231 241 222 232 213 223 233

Fig. 36. Radial spherical roller bearing series.

TIMKEN ENGINEERING MANUAL

25

Page 28

BEARING SELECTION PROCESS

BEARING TYPES • RADIAL CYLINDRICAL ROLLER BEARINGS

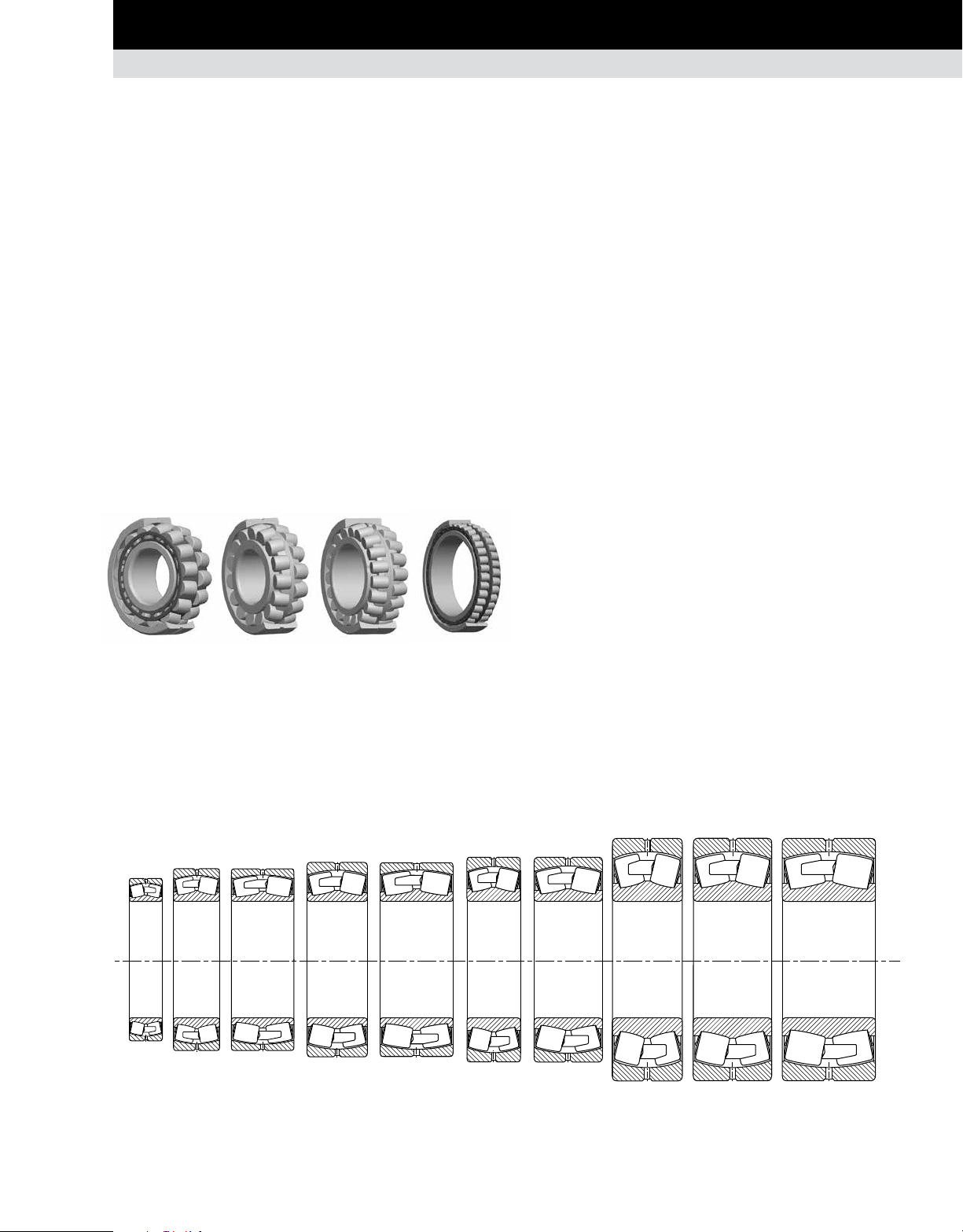

RADIAL CYLINDRICAL ROLLER BEARINGS

STANDARD STYLES

Timken® cylindrical roller bearings consist of an inner and outer

ring, a roller-retaining cage, and a complement of controlledcontour cylindrical rollers. Depending on the type of bearing,

either the inner or the outer ring has two roller-guiding ribs. The

other ring is separable from the assembly and has one rib or

none. The ring with two ribs axially locates the position of the

roller assembly. The ground diameters of these ribs may be used

to support the roller cage. One of the ribs may be used to carry

light thrust loads when an opposing rib is provided.

The decision as to which ring should be double ribbed is normally

determined by considering assembly and mounting procedures

in the application.

Type NU has double-ribbed outer and straight inner rings. Type

N has double-ribbed inner and straight outer rings. The use of

either type at one position on a shaft is ideal for accommodating

shaft expansion or contraction. The relative axial displacement

of one ring to the other occurs with minimum friction while the

bearing is rotating. These bearings may be used in two positions

for shaft support if other means of axial location are provided.

Type NJ has double-ribbed outer and single-ribbed inner

rings. Type NF has double-ribbed inner and single-ribbed outer

rings. Both types can support heavy radial loads, as well as

light unidirectional thrust loads. The thrust load is transmitted

between the diagonally opposed rib faces in a sliding action.

When limiting thrust conditions are approached, lubrication can

become critical. Your Timken engineer should be consulted for

assistance in such applications. When thrust loads are very light,

these bearings may be used in an opposed mounting to locate

the shaft. In such cases, shaft endplay should be adjusted at

time of assembly.

Type NUP has double-ribbed outer and single-ribbed inner ring

with a loose rib that allows the bearing to provide axial location

in both directions. Type NP has a double-ribbed inner ring and

a single-ribbed outer ring with a loose rib. Both types can carry

heavy radial loads and light thrust loads in both directions. Factors

governing the thrust capacity are the same as for types NJ and

NF bearings.

A type NUP or NP bearing may be used in conjunction with type

N or NU bearings for applications where axial shaft expansion is

anticipated. In such cases, the N or NU bearing accommodates

the shaft expansion. The NUP or NP bearing is considered the

fixed bearing because the ribs restrict the axial movement of

the rolling element. The fixed bearing is usually placed nearest

the drive end of the shaft to minimize alignment variations in the

drive. Shaft endplay, or float, is determined by the axial clearance

in the fixed bearing.

Types NU, N, NJ, NF, NUP and NP conform to ISO and DIN

standards for loose rib rings (thrust collars) and typical industry

diameters over or under roller.

The cylindrical roller bearing part numbers are in accordance

with ISO 15. They are composed of four digits, the first two digits

identify the dimensional series and the last two digits of the part

number are the bore size divided by 5. In the dimensional series,

the first digit is the width series and the second is the diameter

(outer) series. The width series increase width in the sequence

8 0 1 2 3 4 5 6 7. The diameter series increase radial section in

the sequence 7 8 9 0 1 2 3 4.

Types having an R prefix are similar in construction to their N

counterparts. However, they were designed to conform to ABMA

standards.

Inch-size bearings are identified by the letter I in the part number.

RIU, for example, indicates an inch bearing while RU indicates

the equivalent style in metric dimensions.

NU, RIU, RU N, RIN, RN NJ, RIJ, RJ NF, RIF, RF NUP, RIT, RT NP, RIP, RP

Fig. 37. Radial cylindrical roller bearings.

26 TIMKEN ENGINEERING MANUAL

Page 29

BEARING SELECTION PROCESS

BEARING TYPES • RADIAL CYLINDRICAL ROLLER BEARINGS

EMA SERIES

The Timken® single-row EMA series cylindrical roller bearings

incorporate a unique cage design, proprietary internal geometry

and special surface textures. These features help to improve

bearing performance and can help to improve uptime and reduce

maintenance costs.

The cage is a one-piece brass design with full-milled pockets.

It is a land-riding cage which, unlike traditional roller-riding

cages, minimizes drag on the roller elements. This reduces heat

generation and improves bearing life. The high cage rigidity

allows for more rollers than possible with other brass cage

configurations.

Proprietary profiles on the rings and/or rollers increase the ability

to handle heavier loads than competing designs.

Engineered processes for rings and rollers provide enhanced

surface textures, resulting in lower friction, lower operating

temperatures and longer bearing life.

EMA series bearings are available in types N, NU, NJ and NUP.

FULL-COMPLEMENT (NCF)

The full-complement (NCF) single-row bearings include integral

flanges on the inner and outer rings. These bearings also can

manage axial loads in one direction and permit small axial

displacements.

5200 METRIC SERIES

This series features enhanced radial load ratings due to its

internal design proportions. In this series, the outer ring is

double-ribbed and the inner ring is full-width with a cylindrical

O.D. The bearing also can be furnished without an inner ring

for applications where radial space is limited. When so used,

the shaft journal must be hardened to HRC 58 minimum, and the

surface finished to 15 RMS maximum. The W designation in the

suffix indicates the outer ring is provided. The inner ring also can

be furnished separately. The A prefix indicates that the inner ring

is furnished either separately or as part of the assembly.

The bearing is usually provided with a rugged stamped-steel cage

(S designation) and is land-riding on the outer ring ribs. The cage

features depressed bars, which not only space rollers evenly, but

retain them as a complete assembly with the outer ring. Cages

of machined brass (M designation) are available for applications

where reversing loads or high speeds might indicate their need.

Outer rings are made from bearing quality alloy steel. The inner

rings are deep-case hardened to accommodate the hoop stresses

resulting from heavy press fits.

The standard bearing is produced with radial internal clearances

designated as R6. Other internal clearances can be supplied upon

request. Proper roller guidance is assured by integral ribs and

roller end clearance control.

A-52xx-WS A-52xx-WM

52xx-WS A-52xx

Fig. 38. 5200 metric series bearings.

TIMKEN ENGINEERING MANUAL

27

Page 30

BEARING SELECTION PROCESS

CAGES • TAPERED ROLLER BEARING CAGES

CAGES

Cages (also referred to as rolling element retainers) serve several

purposes in the proper operation of a rolling element bearing.

Cages separate the rolling elements and prevent rolling element

on rolling element contact and wear. Cages align the rolling

elements on the inner ring to prevent rolling element sliding,

skidding, and skewing to facilitate true rolling motion. For handling

purposes, cages retain the rolling elements on the inner ring

assembly to allow for bearing installation. In some instances,

cages also improve flow of the lubricant to the bearing raceway

or rib contacting surfaces.

The following sections discuss the common types of cages

used for each major bearing design type (tapered, cylindrical,

spherical, and ball bearing). The basic design geometry, material,

and manufacture are discussed for each cage type.

TAPERED ROLLER BEARING CAGES

STAMPED-STEEL CAGES

The most common type of cage used for tapered roller bearings

is the stamped-steel cage. These cages are mass produced

from low-carbon sheet steel using a series of cutting, forming

and punching operations. These cages can be used in high

temperature and harsh lubricant environments.

POLYMER CAGES

Cages for tapered roller bearings made of polymer material are

used primarily for pre-greased and sealed package designs. The

most common polymer materials used are Nylon thermoplastics

with glass reinforcement. Polymer cages can be mass produced

in large quantities and offer more design flexibility than stampedsteel types. Polymer cages are lightweight and easy to assemble.

In some instances, increased bearing rating can be achieved

by allowing one or two extra rollers in the bearing complement.

Care should be exercised when using aggressive lubricants with

EP (extreme-pressure) additives in combination with elevated

temperatures greater than 107° C (225° F).

MACHINED CAGES

Machined cages for tapered roller bearings are robust in design

and are suited for high-speed and high-load applications.

Machined cages use alloy steels and are produced through

milling and broaching operations. Assembly does not require

a close-in operation and rollers can be retained using nibs or

staking. Oil holes also can be easily added for extra lubrication

for demanding applications. Some designs are silver plated for

special applications.

Fig. 39. Stamped-steel cage.

PIN-TYPE CAGES

Tapered roller bearing pin-type cages retain the rolling elements

by the use of a pin located through an axial hole in the center of

the roller. Pin-type cages for tapered roller bearings consist of

two rings with roller pins attached by screw threads at one end

and welding at the other end. These types of cages are primarily

used for larger tapered roller bearing designs (greater than

400 mm [15.7480 in.] O.D.). Pin-type cages are machined out

of steel and typically allow for an increased number of rolling

elements. Pin-type cages are restricted to low-speed applications

(less than 20 m/sec [4000 ft/min] rib speed).

TIMKEN ENGINEERING MANUAL

28

Page 31

SPHERICAL ROLLER BEARING CAGES

BEARING SELECTION PROCESS

CAGES • SPHERICAL ROLLER BEARING CAGES

STAMPED-STEEL CAGES

The redesigned Timken® EJ bearings incorporate a unique

stamped-steel cage design.

The EJ design includes two independent cages, one for each

row of rollers, which are assembled into an individual bearing.

This feature serves to prevent cage bending when the operating

environment is favorable for this to occur.

This cage is guided on the inner ring and runs above pitch. Each

cage is surface hardened (nitrided) to provide improved wear

resistance as well as additional strength to allow the bearing to

operate in even the most severe environment. Face slots have

been designed for improved lubrication flow. This can result in a

lower operating temperature and longer bearing life.

EJ

Fig. 40. EJ bearing.

EJ

Fig. 41. EJ cage.

PIN-TYPE CAGES

Large diameter spherical roller bearings can be supplied with

these cages. Pin-type cages, one for each row of rollers, consist