Page 1

Timken C-Power

Multi-Point Lubricator

Operating System

Manual

Page 2

QUICK REFERENCE TIMKEN C-POWER MULTI-POINT LUBRICATOR GUIDE

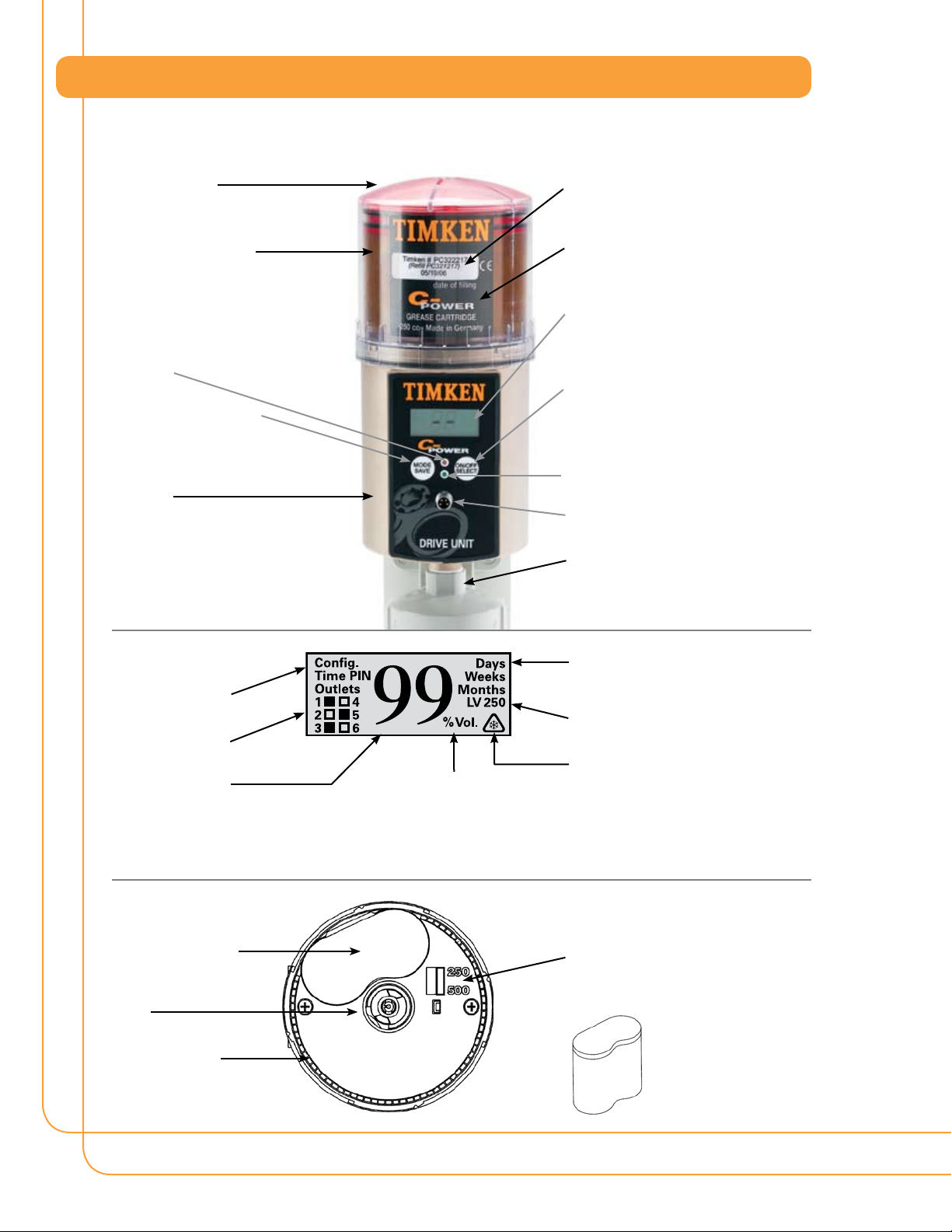

Protection Cover

With bayonet catch for quick

opening and closing.

Timken C-Power LV-Unit

(Lubrication Canister)

Cartridge, piston, spindle

filled with lubricant.

Red LED

Additional malfunction

indication.

Push Button: MODE/SAVE

Leads to the Configuration

Menu and saves the selected settings.

Drive Unit

Contains electronics, motor

and pump system.

Content

Description of the contained lubricant and

the filling date.

Type

Product type and size of Timken C-Power

LV-Unit.

Display

Information about operating conditions,

malfunctions, settings and the lubricant

volume left in the Timken C-Power LV-Unit.

Push Button: ON/OFF/SELECT

To turn system ON or OFF and to

change settings.

Green LED

Additional indication of the current

operating condition.

Timken C-Power Distributor Block

Connection Thread

G 3/8 outside and G 1/8 inside for

application into a lubrication point or for

connecting a grease tube.

Display

Configuration menu

For entering the settings.

Outlets 1-6

Shows activated outlets.

Number

Shows remaining volume,

discharge period, outlet no., PIN

and malfunction codes.

Drive Unit

Battery Compartment

For insertion of

battery set.

Catch

For driving the spindle.

Interlocking teeth

To position the

Timken C-Power LV-Unit.

Remaining volume of the

Timken C-Power LV-Unit

Shows the lubricant remaining

in the Timken C-Power LV-Unit

in percent volume.

Setting Mode

Displays the current setting in days,

weeks or months.

Size of Timken C-Power LV-Unit

Displays volume of LV-Unit (250 or 500 cc)

Ice Icon

Indicates either that the temperature

fell below 0° C/ 32° F (icon blinking) or

that the low temperature shutoff (below

-20° C/-4° F) has turned the system off

(icon permanent).

No Function

Setting of C-Power LV-Unit size

is done via menu on the display.

Battery – Set

(Timken C-Power B)

2

Page 3

On this page, you will find some important information for quick and easy operation and setting of the

Timken C-Power. Before the first installation of the Timken C-Power, and whenever you need detailed

instructions, you should read the complete Operating Manual, which contains information that must

be observed. Make sure to follow the instructions given in the chapter “Safety Notes.”

1. Assembly of the Timken C-Power/Exchange of Timken C-Power

LV-Unit (refer to Chapters 4 and 7)

Mount the drive unit on the mounting plate and secure it at

•

the three pre-drilled holes (see attached template).

Insert a new battery set into the battery compartment (follow

•

directions of the arrows).

Place the LV-Unit inside the cover and remove the plug of the

•

LV-Unit.

Push the LV-Unit into the cover until lubricant comes out of

•

the opening.

Place the LV-Unit with its cover on the drive unit. Make sure

•

that the catch locks and that the teeth of LV-Unit and drive

unit interlock.

Turn the cover clockwise until the bayonet catch locks.

•

2. Determine the Discharge Period (refer to Chapter 6.7)

Refer to the manufacturer’s guidelines about the lubrication point that you want to lubricate

•

to determine the required lubricant amount in cc per one hundred operating hours.

Refer to Chart 3 (Chapter 6.7, Chart 4) and find your required lubrication amount. Based on that, the

•

chart will show you the required C-Power LV-Unit size, the setting of the discharge period, and

the setting mode.

You also may refer to our Timken Select program, which can be downloaded from our web page

•

free of charge. It helps you in selecting the correct settings.

3. Setting of LV-Unit Size, Discharge Period, Outlets and PIN (refer to Chapter 6.8)

Hold down the MODE/SAVE button until the set time is displayed.

•

Hold down the MODE/SAVE button again until you reach the current PIN (PIN cannot be changed

•

here/PIN setting at delivery is “00”).

Hold down the MODE/SAVE button again until you reach the other setting menus:

•

LV-Unit, discharge period, outlets and PIN change. Change settings with a short push of

MODE/SAVE or ON/OFF/SELECT.

4. Save Settings (refer to Chapter 6.8)

Keep the MODE/SAVE button pressed until display shows “– –”.

•

5. Starting Timken C-Power (refer to Chapter 6.5)

Hold down the ON/OFF/SELECT button until the “Remaining Volume” appears in the

•

display and the green LED starts blinking.

6. Stopping Timken C-Power (refer to Chapter 6.6)

Keep the ON/OFF/SELECT button pressed until the display shows (“––”).

•

3

Page 4

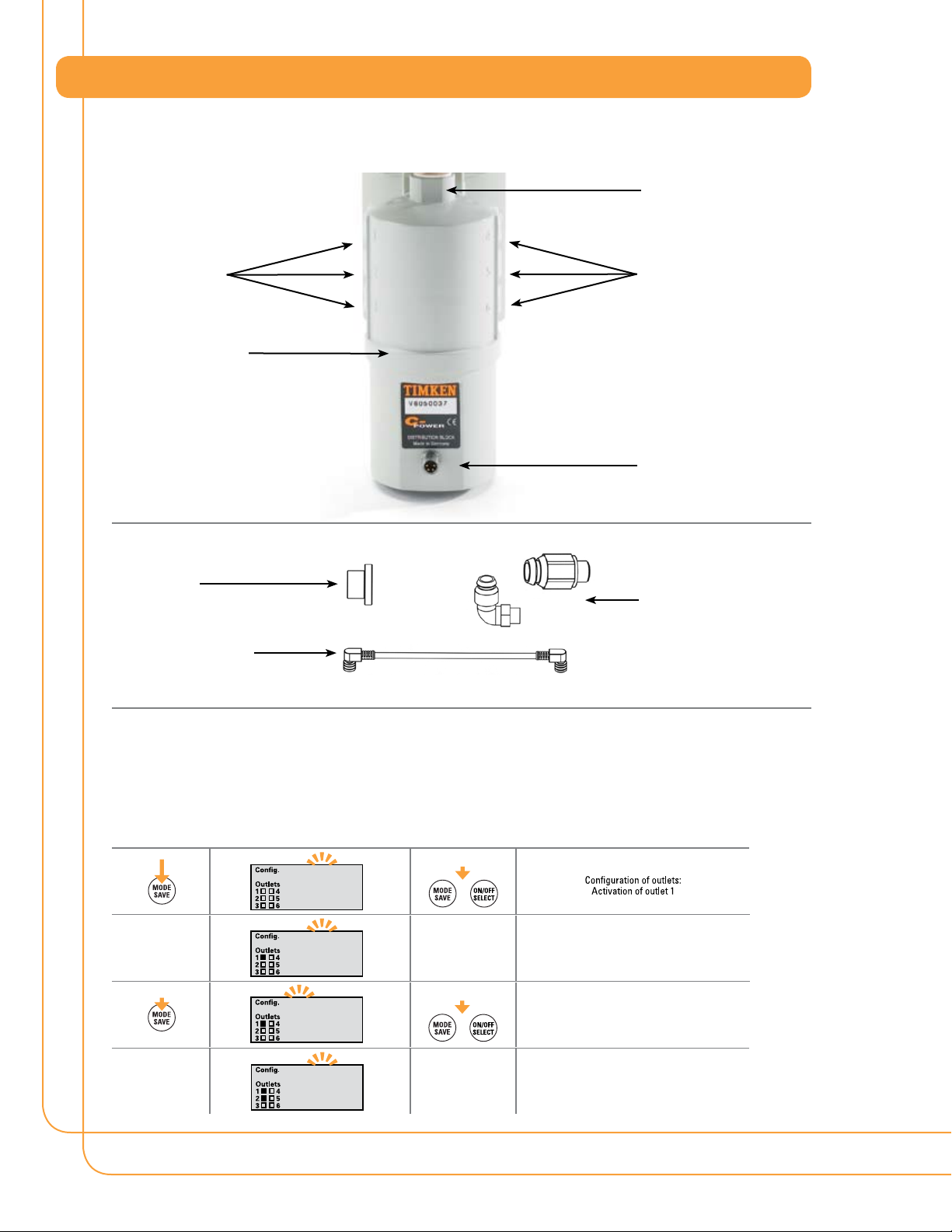

QUICK REFERENCE DISTRIBUTION GUIDE

Outlets 1 to 3

With connections

for grease lines.

Housing

Contains drive unit and

distribution system.

Connection Thread

For attaching a lubricator of

the Timken C-Power Line.

Outlets 4 to 6

With connections

for grease lines.

Connector

Used for plugging in

the connecting cable.

Accessories

Plugs (4 pcs.)

For sealing the outlets

that are not used.

Connecting Cable (1 pc.)

Used for power supply and

for communication.

Activation of Outlets on Timken C-Power Multi-Point Lubricator/Timken C-Power Control

Multi-Point Lubricator

Activation/selection of outlets is done on the connected Timken C-Power/Timken C-Power Control. Please

observe operating instructions (refer to Chapter 6.8) of the attached lubrication system since

the following chart does not go into detail. Outlets must be activated by the user before operation (factory

setting = all outlets inactive).

On/Off Outlet 1

or

6 Connections

Straight or angle. For

grease lines.

1

Outlet 1 active

1

2

2

4

On/Off Outlet 2

or

Outlet 2 active

(if desired, remaining outlets can

be turned On/Off the same way)

Page 5

On this page, you will find some important information for quick and easy operation and setting of your Timken

C-Power Distributor Block. Before the Timken C-Power Distributor Block is used, prior to the assembly of the

distributor with a lubricator of the Timken C-Power range and whenever you need detailed information, you

should read the complete Operating Instructions, which contain information that must be observed. Make sure

to follow the instructions given in the chapter “Safety Instructions.“

Additionally, you have to observe the Operating Instructions of the connected lubricator.

1. Assembly of Timken C-Power (refer to Chapters 4.1 and 4.2)

Screw connections into the outlets that you want to activate and seal the other outlets with plugs.

•

2. Connect Timken C-Power to the Lubricator (refer to Chapter 4.2)

Connect the lubricant tubes (Ø 8 x 1.5, inner-Ø 5mm, admissible total length per pipe up to 5 m) to the

•

connecting pieces of the distributor and lay them between the distributor and the lubrication point.

Connect the lubricator with the distributor using the enclosed connecting cable. For this, the

•

lubrication system must be switched off.

3. Determine Discharge Period (refer to Chapter 6.7)

Determine the required lubricant volume (cc) per one hundred operating hours while taking into

•

account the number of open outlets. For this, you have to multiply the lubricant volume with the

number of open outlets.

You have to take into account that this distributor is able to supply an equal amount of lubricant to up

•

to six lubrication points.

Determine the required discharge volume using the Operating Instructions of the lubricator. Depending

•

on the size of the Timken C-Power LV-Unit, you can then determine the setting of the discharge period

and the setting mode.

You also may refer to our Timken Select program. It helps you in selecting the correct settings.

•

4. Setting and Starting the Complete Lubrication System (refer to Chapter 6.5)

Set discharge period or Impulse mode, size of Timken C-Power LV-Unit, outlets, PIN (refer to

•

Timken C-Power Multi-Point Lubricator/Timken C-Power Control Multi-Point Lubricator operating

instructions, Chapter 6.8, of each lubricator).

Keep the ON/OFF/SELECT button of the Timken C-Power Multi-Point Lubricator pressed until the

•

display no longer shows “––” (for Off).

An automatic initialization is carried out by the lubrication system and the display shows the counting

•

of the outlets.

After the initialization is complete, the display of the lubricator shows the remaining volume and the

•

lubrication system starts to operate.

5

Page 6

TABLE OF CONTENTS

The Timken C-Power mulTi-PoinT lubriCaTor SySTem

QuiCk referenCe Guide

1. Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Delivery/Content

1.2 Storage

1.3 Markings

1.4 Intended Usage

1.5 Legal Requirements

2. Safety Instructions

2.1 Persons Responsible for Safety

2.2 General Safety Instructions

2.3 Safety Information for Timken C-Power

Multi-Point Lubricator

3. Technical Data

3.1 Design of the Timken C-Power Multi-Point Lubricator

4. Mounting and Assembly of the Lubrication System

4.1 Mounting the Drive Unit on to a Fixing Device

for Wall-Mounting

4.2 Distributor Housing

4.3 Assembly of the Lubricator

5. Display and Control Elements of the

Lubrication System

5.1 Display Elements

5.2 Function Indication on the Display

5.3 Function Indication via the LEDs

5.4 Control Buttons

6. Operation and Control

6.1 Preparations

6.2 Prior to Operation

6.3 Setting into Operation

6.4 During Operation

6.5 Switching the Lubrication System On

6.6 Switching the Lubrication System Off

6.7 Determining the Discharge Period

6.8 Setting the Discharge Period

6.9 Settings and Display

6.10 Initialization of Distributor

6.11 Determining the Discharge Period Without Impulse Mode

6.12 Calculation of the Remaining Discharge Period

7. Replacement of the Timken C-Power LV-Unit

7.1 Setting the Volume of the Timken C-Power LV-Unit

7.2 How to Replace the Timken C-Power LV-Unit

8. Troubleshooting

8.1 Error Messages on the Display

8.2 Troubleshooting Guide

9. Disposal

10. Service

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . .14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6

Page 7

1. MISCELLANEOUS

About this Operating Manual

This operating manual is intended for the safe operation of the Timken C-Power Multi-Point Lubricator.

•

It contains safety instructions that must be adhered to.

Everyone who works on or with the lubricator must have access to this operating manual during their

•

shift. They also must pay attention to all relevant instructions and notices.

The operating manual must always be kept complete and in easy to read condition.

•

Terms Used

Timken C-Power Multi-Point Lubricator

•

In the following text, the Timken C-Power Multi-Point Lubricator will either be called lubricator or

by its name, Timken C-Power Multi-Point Lubricator.

Lubrication Canister

•

In the following text, the “Canister” will be called Timken C-Power LV-Unit. The user can order the

Timken C-Power LV-Unit with different lubricants and in size 250 cc and 500 cc.

Usage of Safety Instructions

All safety instructions in this operating manual are standardized.

Danger Signs

This sign warns you of any danger to people’s health or to subjects.

Tips

This sign alerts you to application tips that will help you in doing certain tasks quicker and safer.

1.1 Delivery/Content

Timken C-Power Multi-Point Lubricator will be delivered according to customer specifications in

•

regard to type of grease and size of Timken C-Power LV-Unit. The user must only assemble it and

adjust the desired settings.

Mounting device and screws included.

•

Operating instructions and EC Conformity Declaration included. Upon delivery, make sure to check if

•

the delivered goods correspond to your order. Timken will not accept liability for subsequent claims of

any shortcomings.

Please immediately forward any claims:

•

• of noticeable transport damage: directly to the forwarder.

• of noticeable faults, shortcomings or defects: directly to your Timken distributor.

1.2 Storage

When the lubricators are not immediately installed, you must ensure appropriate storage

conditions in dry, dust-free places with a temperature of +20° C ±5° C (+68° F ±9° F).

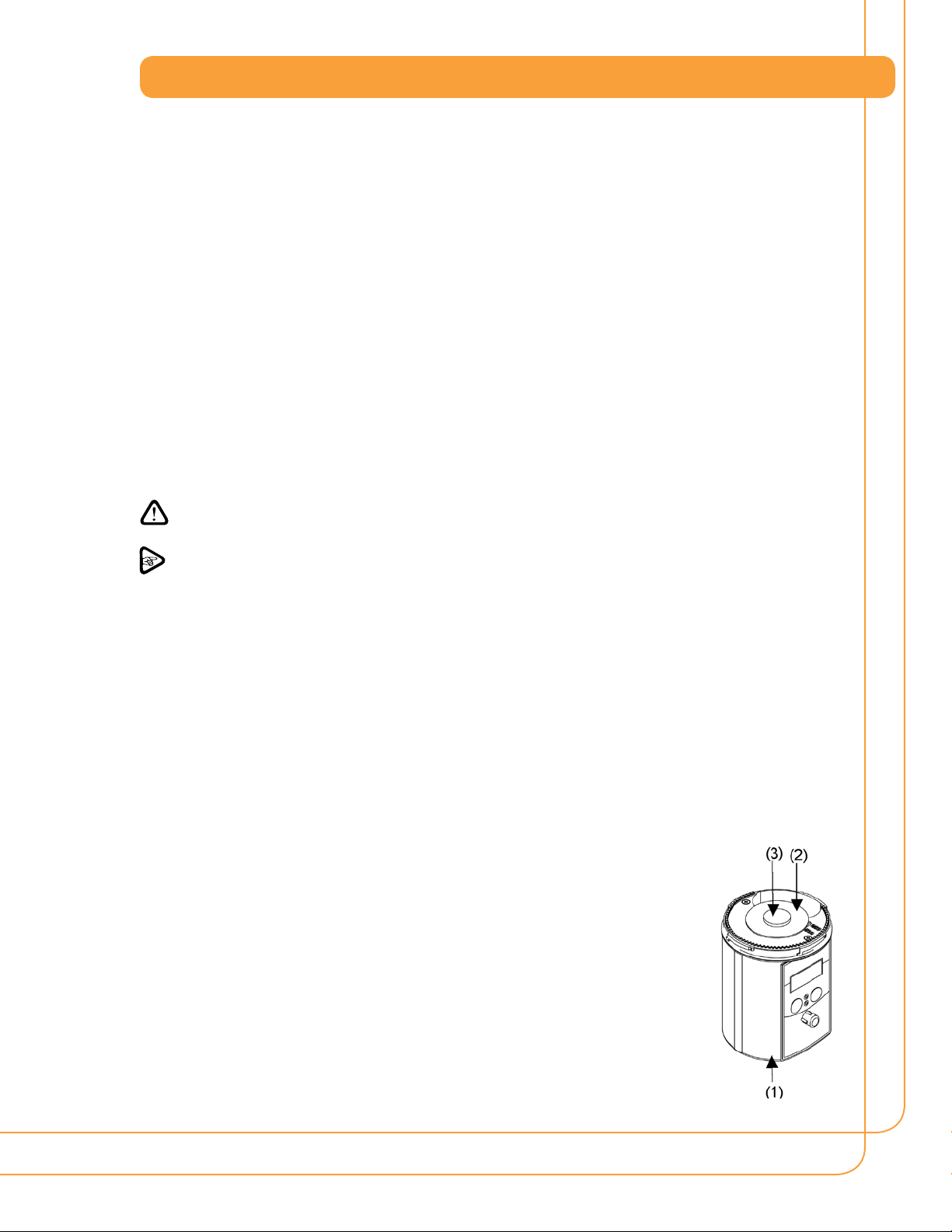

Please make sure that the cover disc (2) with plug (3) on Timken C-Power/ Timken

C-Power Control Multi-Point Lubricator drive units (1) is never removed for a longer

period since this will cause the internal support battery to empty prematurely.

Remove the cover disc only right before you intend to use the lubricator.

Extended storage periods without cover disc/plug or without a Timken

C-Power LV-Unit should be avoided.

Make sure that Timken C-Power LV-Units and battery sets are not stored

longer than one year.

Fig. 1.

7

Page 8

1.3 Markings

The lubricator is clearly marked with a label (serial number) on the drive system and a label

•

on the Timken C-Power LV-Unit.

CE mark on the drive unit and the Timken C-Power LV-Unit.

•

Manufacturer:

•

Timken

Hammelburger Straße 21

97717 Euerdorf, Germany

This equipment is suitable for use in Class I, Division 2, Groups A, B, C and D or non-hazardous

locations only.

WARNING–EXPLOSIVE HAZARD–substitution of components may impair suitability for Class I, Division 2.

1.4 Intended Usage

• Immediately supplies all lubrication points with lubricant, at a pressure build-up of maximum 25 bar

(360 psi.), permanently, precisely and independent of temperature.

• Can be used for all lubrication points of sliding and roller bearings, drive and transport chains,

sliding guideways, open gears and seals.

• Should only be connected to/used with original lubrication tubes from Timken.

• Is intended for use on machinery and equipment.

• Is only to be used for the ordered purpose and purposes confirmed by Timken.

• Is only to be used for operating conditions recommended in this operating manual.

• Is only to be used with settings and variations recommended in this operating manual.

The Timken C-Power Multi-Point Lubricator

•

Any other usage, setting, addition and/or variation is considered inappropriate.

1.5 Legal Requirements

Liability

•

• The information, data and tips stated in this operating manual were up-to-data as of the printing date.

No claims for already delivered Timken C-Power Multi-Point Lubricators can be made based on the

information, pictures and descriptions

• Timken cannot be held liable for damages and malfunctions caused by:

- inappropriate usage;

- unauthorized alterations to the drive system or the Timken C-Power LV-Unit;

- inappropriate operations on or with the lubricator;

- incorrect operation and settings of the lubricator;

- incorrect settings of time and size of the lubricator;

- ignoring the operating manual.

Warranty

•

• Warranty terms and conditions: see terms and conditions of sale and delivery pertaining to Timken.

• Lodge any warranty claims with your local supplier immediately after the defect or error has

been identified.

• The warranty expires in all instances where no liability claims can be enforced.

8

Page 9

2. SAFETY INSTRUCTIONS

2.1 Persons Responsible for Safety

The operator or his safety officer must warrant:

•

• that all the relevant regulations, instructions and laws are adhered to;

• that only qualified personnel will work with and on the lubricator;

• that unauthorized personnel are not allowed to work with and on the lubricator;

• that the safety regulations are adhered to when mounting the lubricator or during maintenance.

2.2 General Safety Instructions

We are not laying claim to completeness in regards to these safety instructions. Please contact

•

Timken Customer Service if you have any questions or problems.

At the time of delivery the lubricator is in line with state-of-the-art technology and in principle is

•

considered to be safe to operate.

Dangers emanate from the lubricator for persons, the lubricator itself and for other material assets of

•

the operator if:

• unqualified personnel operate the lubricator;

• the lubricator is used inappropriately and for operations for which it was not intended;

• the lubricator setting/variation is incorrect;

• the lubricator is opened by force while in operation;

• the lubricator is not mounted with the Timken mounting device;

• the tube connection to the lubrication point was not carried out and attached correctly;

Operate the lubricator only when it is in perfect condition.

•

Retrofitting, changing or reconstructing the lubricator is prohibited. Timken must be consulted first.

•

Only original tube connections and connectors from Timken can be used on or with the lubrication

•

system since these will withstand high pressures of up to 25 bar (360psi).

Ambient media, especially chemically aggressive substances, can attack seals and plastic.

•

2.3 Safety Information for Timken C-Power Multi-Point Lubricator

Safety During Installation and Maintenance

•

• Ensure that all workstations and traffic routes are clean and safe.

• Ensure that the relevant regulations and guidelines are adhered to when the installation or

maintenance work is carried out in places where danger of falling exists.

• Ensure that the relevant safety and operating instructions are observed when the lubricators are

installed or serviced on machines or in factories (i.e. to stop the machine).

• Avoid contact of lubricant with eyes, skin and clothing.

• Avoid swallowing lubricant.

• Prevent lubricant from getting into soil or sewer system.

• Observe lubricant safety data sheets.

• Lubricant on traffic ways will increase the danger of slipping. Therefore, immediately clean lubricant

from floors with special cleaner.

• Only use original Timken C-Power LV-Units from Timken.

• Avoid contact of battery substances with eyes, skin and clothing.

• Avoid swallowing any leaking battery substances.

• Observe safety data sheets for batteries.

• Do not expose batteries to extreme heat and do not throw into open fire.

• Do not recharge batteries.

• Ensure that regulations for waste disposal of batteries are observed.

• Only use original battery sets from Timken.

Safety When Handling the Timken C-Power LV-Unit

•

Safety when Handling Batteries.

•

9

Page 10

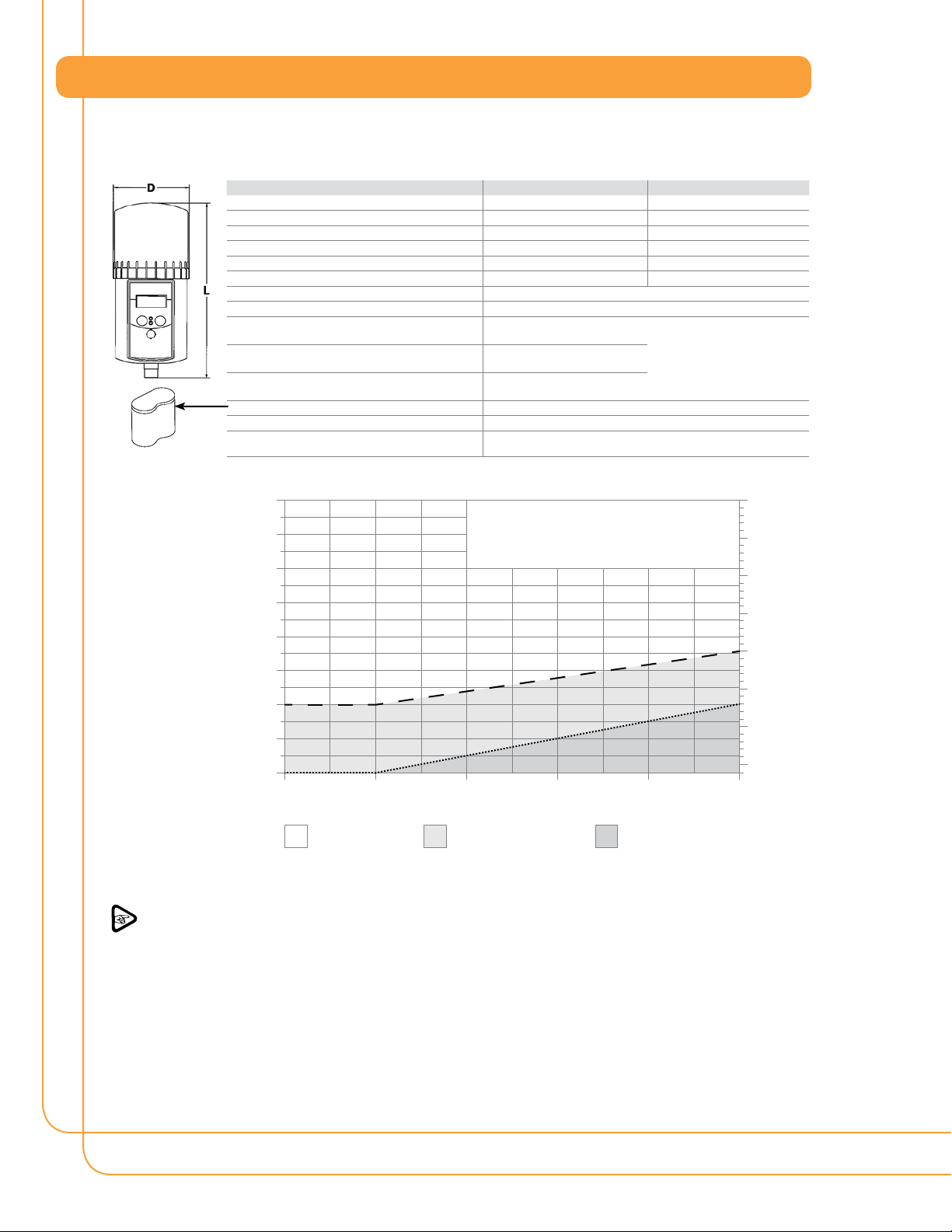

3. TECHNICAL DATA FOR DRIVE UNIT

Table 1.

Table 2.

Volume of t he C-Pow er LV-Uni t 25 0 cc 50 0 cc

Leng th (L) 210 mm 26 0 mm

Diame ter (D) 92 mm 92 mm

Weigh t, empt y 1.3 0 kg 1.3 7 mm

Weigh t, fill ed with SF0 4 1.5 3 kg 1.82 mm

Discharged volume per lubricatio n impulse 0. 5 cc

60˚

50˚

40˚

30˚

20˚

10˚

0˚

Temperature Degrees Celsius

-10˚

-20˚

The dashed standard grease and dotted low temperature lines show the maximum values allowed.

Discharge period 1 day to 24 mont hs 1 day t o 12 months

Applicat ion temperature -20° C t o +60 ° C/-4° F to +14 0° F

Maximum p ressure b uildup 25 bar/3 60 psi

Maximum t ube length (inner-Ø 5 mm) 5m

Lubrican ts

Power supply Bat tery set C- Power B (3 V alka line mangan ese, not r echargeabl e)

Connecti on thread G 3/ 8 outside – G 1 /8 inside

Protect ion class

Diagram showing dependency of application

temperature and tube length (inner-ø 5 mm) for Timken

standard grease and low-temperature grease

0 1 2 3 4 5

Tube Length in Meters

Application area

for standard grease

Application area

for low temperature grease

C-Power 2 50 C-Power 5 00

Comb ination of these

maximum-values can o nly be

reali zed by tem peratures of

≥2 0° C/68° F. At lower

temperat ures, th e applicat ion

Greas es up to ra ted

consi stency N LGI 2

Protect ion class I P 54 D L

UL Ce rtification and listing informat ion

Out of specification range

No warranty!

is limite d according

to the diagram below.

140˚

120˚

100˚

80˚

60˚

40˚

20˚

0˚

Temperature Degrees Fahrenheit

10

If your application is out of the specification range shown in this diagram, please contact your local

distributor. Timken cannot be held liable for these applications.

Example:

1. The application temperature is +5° C/+41° F. What is the maximum tube length allowed for

standard grease?

Correct Answer: 3 m maximum tube length for standard grease, 5 m maximum tube length for low

temperature grease (arrow 1 meets the dashed line of the standard grease range at 3 m)

2. You want to use a 4 m tube. Up to what temperature can the system be used?

Correct Answer: +10° C/50° F with standard grease -5° C/23° F with low-temperature grease (arrow 3

meets the dotted line of low-temperature grease at the -5° C mark; and the dashed line of the standard

grease at the +10° C mark)

Page 11

Table 4.

Leng th 148 mm

Diame ter 64 mm

Weigh t ca. 0 .960 kg

Number of outlets

Maximum w orking pressure 25 bar (3 60 psi)

Lubrican ts Greas es up to ra ted consistency NL GI2

Ambient t emperat ure -20 ° C to +4 0° C/ -4° F to +104° F

Power supply fro m the lubr icator via connecting cab le

Connecti on thread for lu bricators of the

Timken C-Power line

Connecti on thread for gr ease line G 1/8 insi de

Diame ter of grease line 8 x 1.5 (inner-Ø 5mm)

Leng th of the grease line

Sto rage condi tions Dry, dust-free at temperatur es of +20 ° C ± 5° C /68° F ± 9° F

Protect ion class IP 5 4

Admi ssible total length per pipe up to 5 m. For details , please refer to the oper ating man ual

Timken C-Power/ Timken C -Power C ontrol , Chapter 3, page 7.

Timken C-Power Dis tribut or Block

2 minimum

6 max imum

G 3/8 inside

Fig. 2.

148

38

11

Page 12

3.1 Design of the Timken C-Power Lubricator

Lubricators are available as 250 cc and 500 cc versions and they can be supplied with the lubricant

requested by the customer. They consist of (refer to Fig. 3):

Protection cover for the drive unit, reusable.

Timken C-Power LV-Unit can be supplied as

250 cc and 500 cc versions with the lubricant

requested by the customer. Usage of Timken

C-Power LV-Units only.

12

Battery set, consisting of two batteries. The

batteries are not rechargeable and must be

changed every time the Timken C-Power LV-Unit is

replaced. Batteries can only be used once. Usage

of Timken battery sets only.

Drive unit, consisting of a gear motor, a pump

system and an electronic unit for the control

system, reusable.

Table 3.

Page 13

Each distributor (refer to Fig. 4) is supplied with all necessary accessories (refer to Fig. 5).

The user must install the required connections or plugs and must connect the distributor to a

lubricator of the Timken C-Power line. The Timken C-Power Distributor Block consists of:

Housing containing the drive unit and the

distribution system (maximum 6 outlets).

Accessories

Fig. 5.

Fig. 4.

Connections (6 pcs.) for grease lines.

Plugs (4 pcs.) for sealing the outlets

that are not used.

Connecting cable (short) for power supply

of the distributor and for communication

between distributor and lubricator.

13

Page 14

4. ASSEMBLY AND MOUNTING OF THE DISTRIBUTOR

4.1 Mounting the Connections

Chose the number (6 maximum) and the position of the outlets that you intend to use.

•

Screw the connections tightly (maximum torque of 2Nm) into the outlets to be opened

•

(refer to Fig. 6).

Seal all the remaining outlets using the enclosed plugs.

•

1 4

2 5

3 6

4.2 Distributor Housing

Fig. 6.

Never loosen these screws at the bottom of the

distributor and never open the housing.

Fig. 7.

14

Page 15

15

Page 16

4.3 Assembly of the Lubricator

Insert the battery set into the drive unit (according to the direction of the arrow on the label).

•

No Function

Battery set

Catch Interlocking teeth

Fig. 8.

Setting of C-Power LV-Unit size

is done via menu on the display.

Place the Timken C-Power LV-Unit inside the protection cover and remove the plug (refer to Fig. 9).

•

16

Protection cover

C-Power LV-Unit

Plug

Fig. 9.

Page 17

Push the C-Power LV-Unit into the protection cover until lubricant comes out of the opening

•

(refer to Fig. 10).

Fig. 10.

Place the Timken C-Power LV-Unit with its protection cover on the drive-unit. Make sure that the

•

catch locks in place and that the teeth of the Timken C-Power LV-Unit and the drive unit interlock

(refer to Fig. 8 and Fig. 11).

Turn the cover clockwise until the bayonet catch locks.

•

Fig. 11.

17

Page 18

5. DISPLAY AND CONTROL ELEMENTS OF THE LUBRICATION SYSTEM

5.1 Display Elements

The operating status of the lubricator can be determined via the green or the red LED and via the

display at the control unit (refer to Fig. 12) of the Timken C-Power Multi-Point Lubricator.

The Timken C-Power offers menu-guided setting. Changes of the settings are shown on the display.

Error messages (for example, if the pressure in the lubricant tube gets too high) also are indicated on

the display.

LCD

ON/OFF SELECT Push-button

Red LED

MODE SAVE Push-button

Fig. 12.

5.2 Function Indication on the Display

The display is located on the control unit of the Timken C-Power (refer to Fig. 8, Chapter 5.1).

The display shows settings, operating conditions and error messages of the lubricator.

In error-free operation of the lubrication system, the display shows the remaining volume of the

mounted Timken C-Power LV-Unit in percent volume (% Vol.). Fig. 13 shows an example of the

displayed information if the Timken C-Power LV-500 Unit is new and full.

Green LED

Connector for

C-Power distributor

18

Fig. 13.

The display cannot be switched off by the operator. If the lubrication system is switched off, the

display will always show two lines (see Fig. 14 below).

Fig. 14.

5.3 Function Indication via the LEDs

LED Signa l Signa l Length Explanation

Green Flas h Ever y 10 seconds Operation (OK)

Red Flas h Ever y 3 second s Error/malfunction

Green and Red Flas h Ever y 3 second s C-Power LV-uni t empty

Green L ight Per manentl y Lubricat or is disch arging

Green and Red None None Lubr icator s witched off or batt ery low

Table 5.

Page 19

5.4 Control Buttons

There are two push-buttons on the control unit (refer to Fig. 8), which can be used for a menu-guided

change of the settings.

With the MODE/SAVE button (refer to Fig. 15), you can reach the configuration menu, change the

•

mode and save the modified settings for further operation.

With the SELECT button (refer to Fig. 16), you can do the following: increase discharge period

•

(Days, Weeks, Months – each press of the button increases the discharge period by one calendar

unit), change Timken C-Power LV-Unit size, activate C-Power distributor outlets and set PIN.

Pres s Shor t Shor t

But ton

Fig. 15. F ig. 16. F ig. 17. F ig. 18.

Func tion

Selection in curren t

display

Chang ing of values

Table 6.

Long > 4 seconds until the displa yed

cont ent change s complet ely

Moves to ne w menu and

saves selec ted value s

Long > 4 seconds until the displa yed

cont ent change s complet ely

Returns to original menu w ithout

savi ng changes

19

Page 20

6. OPERATION AND CONTROL

Please note that the Timken C-Power Distributor Block may only be connected to a lubricator of the

Timken C-Power line. If you combine the distributor with a Timken C-Power Multi-Point Lubricator, you

also have to observe the Operating Instructions of the lubricator.

6.1 Preparations

Prior to installing the lubrication system (lubricator and distributor), all lubrication points must be

•

pre-lubricated and all grease lines must be sufficiently pre-filled with the same lubricant that is

contained in the LV-Unit of the Timken C-Power Multi-Point Lubricator. For this, Timken offers a 400 g

lubrication cartridge for grease presses with the corresponding lubricant (refer to Chart 3, Chapter 7).

When installing the lubrication system, the supplied Timken mounting device should be used. The

•

lubricator and the distributor should be fixed to this mounting device (refer to Chapter 4.3).

The grease lines must be installed and mounted correctly. Grease lines must be from Timken and

•

cannot exceed a length of 5 m per outlet.

For the initial setting into operation of a Timken C-Power Multi-Point Lubricator, the pump system in the

drive unit is pre-filled with SF 04 from Timken’s standard range of lubricants. An exception is made

with regard to lubricants for the food industry. A complete discharge of this pump filling is guaranteed

after approximately 10 discharges (carry out additional discharges, if necessary).

6.2 Prior to Operation

Check all parts of the distributor and the complete lubrication system for obvious damages.

•

Did you correctly assemble, mount and tighten all of the connections and the plugs of the distributor?

•

Are the grease lines coming from the distributor mounted correctly on the connections?

•

Did the lubricator recognize the distributor with all open outlets during initialization?

•

Was the drive unit of the lubricator set to the discharge period requested by the operator while

•

taking into account the required discharge volume and the number of open outlets?

Did you correctly assemble, mount and tighten all of the parts?

•

6.3 Setting into Operation

Open the required number of outlets by mounting the connections and seal the unused outlets with

•

plugs (refer to Chapter 4.1).

Screw together the distributor and the lubricator (refer to Chapter 4.2).

•

If required, mount the distributor together with the lubricator onto the mounting device and onto a

•

fixing device for wall mounting (refer to Chapter 4.2).

Connect the distributor to the lubricator with the connecting cable to enable signal exchange

•

(refer to Chapter 4.2).

If necessary, carry out a manual initialization (refer to Chapter 6.10).

•

Determine the discharge period for the open outlets (refer to Chapter 6.7).

•

Set the discharge period with the push buttons on the lubricator (refer to Chapter 6.8).

•

Activate the desired outlets with the push buttons on the lubricator (refer to Chapter 6.9).

•

If necessary, do a manual initialization after a distributor exchange (refer to Chapter 6.10).

•

Did the lubricator correctly recognize the distributor during initialization?

•

Carry out an additional discharge (refer to Chapter 5.8). If the drive motor has started and the green

•

LED is lit, the lubricator has started to discharge. The display of the lubricator indicates the remaining

volume (% Vol.) of the Timken C-Power LV-Unit.

The operator must always check the customer-specific settings and, if necessary, change them

before the lubricator is set into operation. In addition, the Operating Instructions of the lubricator must

be observed.

20

Page 21

6.4 During Operation

Carry out regular inspections during operation. You should pay special attention to leakage, to the

•

condition of the distributor, and the complete lubrication system.

Regularly check the condition of the grease lines and the connections.

•

Regularly check the filling level of the transparent Timken C-Power LV-Unit of the lubricator.

•

After one or several additional discharges, calculate the remaining discharge period and mark it in

•

your lubrication and maintenance schedule.

If a malfunction is indicated on the display, you can determine the cause using the troubleshooting

•

guide (refer to Chart 3, Chapter 6.2). If the fault cannot be fixed, please contact your supplier for

technical support.

Additional discharges and long machine standstills must always be taken into account with regard to

the remaining discharge period of the lubrication system.

6.5 Switching the Complete Lubrication System On

To switch on the Timken C-Power Multi-Point Lubricator (refer to Fig. 19), keep the ON/OFF/SELECT

button of the lubricator pressed until the display no longer shows “––”.

To start the Timken C-Power Control Multi-Point Lubricator you have to switch on the power supply.

After switch-on, the lubricator automatically does an initialization (system recognizes the activated

outlets). During initialization, the outlets (represented by squares) in the display are blinking. Activated

outlets (squares) will be blackened, inactive outlets (squares) are blank.

system is switched off.

When the lubrication system is switched on for the first time, the initialization is carried out automatically

by the lubricator. After the initialization is complete, the remaining volume is shown.

Only with

Timken C-Power.

Initialization finished.Fig. 19. The lubrication

The lubrication

system is on.

6.6 Switching the Complete Lubrication System Off

To switch off the Timken C-Power Multi-Point Lubricator (refer to Fig. 20), keep the ON/OFF/SELECT

button of the lubricator pressed until the display no longer indicates the remaining volume but indicates

“––” instead.

When the lubrication system is switched off, all of the settings are saved. This means that if you start the

lubricator again, it will start the operation at the point where it had been switched off.

6.7 Determining the Discharge Period

The required discharge period must be determined using the Operating Instructions of the connected

lubricator. You have to take into account that the Timken C-Power Distributor Block is able to

supply an equal amount of lubricant to up six lubrication points.

When determining the discharge volume, multiply the number of open outlets with the required discharge

volume per outlet. With the result of this calculation, you can determine the setting point of the discharge

period using the Operating Instructions of the connected lubricator.

Fig. 20. Only with Timken C-Power.

21

Page 22

6.8 Setting the Discharge Period

The discharge period can be set any time via the lubricator, and without having to interrupt

the operation. It does not matter if the lubrication system is switched on or off, since the system switches

back to its original operating status after the changes have been made.

For a precise setting of the discharge period, please refer to the Operating Instructions of the

connected Timken C-Power Multi-Point Lubricator.

Additional Discharge

With an additional discharge, all open lubrication points can be supplied with an additional amount of the

lubricant. Each open outlet provides 1.0 cc of the lubricant.

For an additional discharge, the lubrication system must be switched on and you have to press and hold

down both buttons of the lubricator simultaneously (refer to Fig. 21).

An additional discharge is carried out at each activated outlet (it takes approximately 30 seconds

between outlets). This means that if all outlets are open, the process of an additional discharge takes a

maximum of 14 minutes.

Timken C-Power.

An additional discharge is only possible at temperatures above 0° C (32° F).

Fig. 21. For an additional discharge, press both buttons

of the lubricator and hold them down.

Timken C-Power Control.

Every additional discharge reduces the remaining discharge period since an increased amount of

the lubricant has been supplied. This must be taken into account in your lubrication and maintenance

schedule.

The time between two additional discharges is at least 30 seconds. Each additional long push of both

buttons (Fig. 22) will be recorded by the system and leads to further additional discharges on all

outlets. The system records up to 5 additional discharges.

Calculation of the Remaining Discharge Period

Please note, that in case of one or several additional discharges, the remaining discharge period of the

lubrication system must be recalculated. This also applies in case of a shut-off of the lubrication system

due to an extended machine standstill (i.e. weekends or annual holidays) or in case of a low-temperature

shut-off carried out by the system if temperatures reach -20° C (-4° F).

For information on the calculation of the remaining discharge period, please refer to the Operating

Instructions of the connected Timken C-Power Multi-Point Lubricator.

You also should note the result of your calculation of the remaining discharge period in your lubrication

and maintenance schedule.

22

Page 23

6.9 Settings and Display

Display Meaning/ Descrip tion

Display at delivery with

attached Tim ken LV-Uni t

Chang e first digit

Chang e second

digi t

Chang e from

LV5 00 to LV 250

Chang e months

Chang e days

or wee ks

Out let 1 On/ Off

Show s discharge peri od

PIN -reset

Ent er first digi t of curre nt PIN

PIN “ 00”at deliver y

Ent er second digit of current PIN

Set LV-Unit size

Set d ischarge period :

Eit her Mont hs, Weeks or Day s

Set d ischarge period :

Go to “Day s” or “Weeks”

Activat e outle ts: Act ivate ou tlet 1

Info

PIN-Entry

LV

Time

Configur ation Me nu Intro

Table 7.

Out let 2 On/ Off

Chang e first digit

Chang e second

digi t

Out let 1 activat ed

Out let 2 activat ed

(if desired, other o utlets may be turned

On/ Off the same way)

PIN ( first digit ) enter f or initial

conf igurati on or after a P IN-rese t –

otherw ise, set ting is complete

PIN (second digit) en ter for initial

conf igurati on or after a P IN-rese t

Configur ation finished

Out lets

PIN

23

Page 24

Caption for Chart on Left Side

Instructions should be followed from top to bottom and from left to right (also refer to Chart 3).

The instructions correspond to the operating sequence on the turned off Timken C-Power Multi-Point

Lubricator. Configuration also is possible if Timken C-Power is On.

Table 8.

Func tion Short Push Long Push Blinking Display G o To

Sym bol

Configuration sections (see Table 7).

INTRO. INTRO informs (INFO) and asks for the current PIN (PIN-entry). Settings can be changed in the

configuration menu with its different sections (LV, Time, Outlets, PIN).

CONFIGURATION MENU. LV. You can change the C-Power LV-Unit size from LV250 to LV500 and back by

pushing the ON/OFF/SELECT button (refer to Chapter 7.1 and 7.2).

Time. The discharge period can only be set in one type of calendar unit (i.e. either Months, Weeks, or

Days). When the highest unit is reached, counting starts again with number 01.

Outlets. Outlets 1-6 can be set individually. The activated outlets 1-6 are displayed with a filled-in square

in the display).

PIN. We strongly suggest entering a personal PIN to protect your settings from unauthorized

access. The PIN can only be changed during initial configuration or after a PIN reset. A PIN reset

(short push of buttons: left-left-right-right-left in the INTRO-Info-menu) changes your personal PIN back

to “00.” The PIN reset was successful when the displayed time disappears for a second and then comes

back on. All other settings remain unchanged.

Save or Reject Changed Settings. The display settings can be saved with a long push of the MODE/SAVE

button. If you do not want to save your changes to settings that are currently displayed in the

configuration menu (LV, Time, Outlets, PIN), press the ON/OFF/SELECT button until the display shows

either (“– –”) for Off or the remaining volume of the Timken C-Power LV-Unit in % Vol. All other settings

and already saved changes remain valid.

Automatic Termination of the Configuration Mode. If you do not press a button in the configuration menu

for 180 seconds, the control system automatically switches back to the previously set mode (“On” or

“Off”) without saving the changes. All other settings and already saved changes remain valid.

Additional Discharge. With an additional discharge, a lubrication point can be supplied with an additional

amount of the lubricant. For an additional discharge, the lubrication system must be switched on (display

shows remaining volume) and you have to press both buttons simultaneously and hold them down (refer

to Fig. 15).

24

Fig. 22. Lubricator On. For an additional discharge, press both

buttons at the same time and hold them down.

An additional discharge is only possible at temperatures above 0° C/32° F (Fig. 25, ice crystal is not

visible) and when the lubrication system is not currently conducting a regular discharge. Every additional

discharge reduces the remaining discharge period since an increased amount of the lubricant has been

supplied. This must be taken into account in your lubrication and maintenance schedule. A calculation is

possible with the formula from Chapter 6.9 and with the remaining volume which is displayed.

The time between two additional discharges is 30 seconds. Each additional long push of both buttons

(simultaneously, Fig. 22) during this time is being registered and will lead to even more additional

discharges. The system remembers a maximum of 5 additional discharges.

Page 25

6.10 Initialization of Distributor

Automatic Initialization of the Distributor

To supply lubricant to all open outlets and ensure a correct operation of the Timken C-Power distributor,

an automatic initialization of the lubrication system is carried out when the system is switched on for the

first time.

During initialization the system recognizes the activated outlets. Outlets (represented by squares) in the

display are blinking. Activated outlets (squares) will be blackened, inactive outlets (squares) are blank.

When initialization is finished, the display shows the remaining volume and activated outlets. The green

LED starts to blink and the lubrication system operates.

Manual Initialization of the Distributor

If you connect a new distributor to the lubricator (exchange old distributor with new one), you must do

a manual initialization of the Timken C-Power Distributor Block. The system recognizes the activated

outlets. Outlets (represented by squares) in the display are blinking. Activated outlets (squares) will be

blackened, inactive outlets (squares) are blank.

A manual initialization (long push of both buttons on the lubricator – refer to Fig. 23) can only be done

when the lubrication system is turned OFF (display of lubricator shows “––” for OFF).

Timken C-Power will immediately start initialization (refer to Fig. 12).

Timken C-Power.

Fig. 23. For a manual initialization, press and hold down

both buttons of the lubricator simultaneously.

Timken C-Power Control.

Timken C-Power Multi-Point Lubricator

When the manual initialization is completed, the display of the lubricator Timken C-Power shows “––”

for OFF and the lubrication system is switched off.

Fig. 24.

Initialization Sequence

Initialization finished.

25

Page 26

6.11 Determining the Discharge Period

The discharge period is automatically factory set to six months according to the supplied Timken C-Power

LV-Unit. The size of the Timken C-Power LV-Unit is taken into account.

If you want to determine the discharge period, you need to know the required amount of the lubricant in

cubic centimeters for 100 operating hours (cc/100 h). This information can be taken from the technical

documents of the manufacturer of the lubrication point. With this information, you can determine the

discharge period using the following chart (Table 9).

Average discharge volum e in cc per 10 0 operating hours

C-Power LV-Unit 25 0 cc 50 0 cc

Set ting mode

Set ting point

Discharge period Days Weeks Mont hs Days Weeks Months

1 1041.7 14 8.8 34 .3 20 83.3 2 97.6 68 .5

2 5 20.8 74 .4 17.1 1041.7 14 8.8 34 .3

3 347.2 49.6 11.4 6 94.4 99.2 2 2.8

4 2 60.4 3 7.2 8.6 520.8 74 .4 17.1

5 2 08.3 29.8 6 .9 416.7 5 9.5 13.7

6 173.6 24 .8 5.7 347.2 49 .6 11.4

7 148.8 21. 3 4 .9 297.6 42.5 9.8

8 130.2 18.6 4 .3 26 0.4 37.2 8.6

9 115.7 16 .5 3.8 231.5 3 3.1 7.6

10 104 .2 14.9 3.4 2 08.3 29.8 6 .9

11 9 4.7 13.5 3.1 189 .4 27.1 6.2

12 86.8 12.4 2 .9 173. 6 2 4.8 5.7

13 80.1 11.4 2 .6 160.3 22 .9 --

14 74. 4 10 .6 2.4 148 .8 21.3 --

15 69.4 9.9 2 .3 13 8.9 19. 8 - -

16 65 .1 9 .3 2.1 130 .2 18.6 --

17 61. 3 8 .8 2.0 122.5 17. 5 --

18 57. 9 8 .3 1.9 115.7 16.5 --

19 5 4.8 7. 8 1.8 109 .6 15.7 --

20 52.1 7.4 1.7 104.2 14.9 - -

21 49 .6 7.1 1.6 9 9.2 14.2 - -

22 47.3 6 .8 1.6 94 .7 13 .5 --

23 45 .3 6.5 1.5 9 0.6 12.9 --

24 43 .4 6 .2 1.4 86 .8 12 .4 --

25 41.7 -- - - 8 3.3 -- --

26 4 0.1 -- -- 80 .1 - - --

27 38 .6 -- -- 77. 2 - - --

28 3 7.2 -- -- 7 4.4 -- - -

29 35 .9 -- -- 71.8 -- --

30 34.7 -- - - 6 9.4 -- --

26

Table 9.

In case of one or several additional discharges, the remaining discharge period of the lubrication system

must be recalculated (refer to Chapter 6.9). This also applies in case of a cut-off of the lubrication system

due to a long machine standstill (i.e. weekends or annual holidays). You also should note the result of your

calculation of the remaining discharge period in your lubrication and maintenance schedule.

Page 27

Low-Temperature Cut-Off of the Lubrication System

The temperature range from 0° C to -19° C (32° F to -2.2° F) is indicated by a blinking ice crystal symbol

(refer to Fig. 16). In this temperature range, the lubrication system Timken C-Power continues to

operate without interruption.

Please note that in this temperature range an additional discharge is not possible.

To protect the system from damage, the low-temperature cut-off of the lubrication system is automatically

carried out by the control system and the built-in temperature sensor.

If the temperature reaches or falls below -20° C (-4° F), the lubricator is switched off by the low-

temperature cut-off and the ice crystal symbol is permanently indicated on the display. The remaining

volume is still displayed in % Vol.

From this time onward, the lubricant is no longer discharged. To prevent damages take this fact into

account if your system continues to operate.

As soon as the temperature rises and reaches -19° C (-2.2° F) or higher, the control system switches the

lubrication system on. The display shows the remaining volume and the blinking ice icon. All discharges

(except additional discharges) accumulated during the shut-off will be caught up when the system

continues operation (at a maximum of two additional discharges with every regular discharge).

6.12 Calculation of the Remaining Discharge Period

Please note that in case of one or several additional discharges, the remaining discharge period of the

lubrication system must be recalculated. This also applies in case of a cut-off of the lubrication system

due to a long machine standstill (i.e. weekends or annual holidays) or in case of a low-temperature

cut-off carried out by the system if temperatures reach -20° C (-4° F).

You also should note the result of your calculation of the remaining discharge period in your lubrication

and maintenance schedule.

Formula: RDP =

SDP: Set Discharge Period of the lubricator (days, weeks, months)

RV: Remaining Volume (displayed in % Vol.)

RDP: Remaining discharge period (days, weeks, months depending on SDP)

Fig. 25. Display with a blinking ice crystal (in this example with 89% Vol).

SDP * RV

100

Example of a Calculation of the Remaining Discharge Period

The Timken C-Power with a 250 cc Timken C-Power LV-Unit was originally set to a discharge period

(SDP) of eight months, since the lubrication point needs 4.3 cc lubricant /100 h. After two months, the

Timken C-Power indicates a remaining volume (RV) of 75% Vol. At this point, the lubricator is switched

off for six weeks (i.e. machine standstill). When it is switched on again, you would like to determine

when the Timken C-Power LV-Unit will be empty.

RDP = = = = 6

This results in a remaining discharge period of six months. After these six months, the Timken C-Power

LV-Unit will be empty and must be replaced by a new one.

SDP * RV

100

8 * 75

100

600

100

27

Page 28

7. REPLACEMENT OF THE C-POWER LV-UNIT

The Following Must Always Be Taken into Account

If the replacement of an empty Timken C-Power LV-Unit becomes necessary, it will be indicated by a

simultaneous blinking of the red and the green LED. Additionally, the display indicates that the

Timken C-Power LV-Unit is empty (refer to Fig. 26).

Fig. 26.

If you replace the Timken C-Power LV-Unit, you also have to change the battery set. Otherwise, the

correct operation of the lubricator cannot be guaranteed.

If you replace the Timken C-Power LV-Unit with a Timken C-Power LV-Unit of a different size, a

corresponding protection cover must be used.

After the installation of the new Timken C-Power LV-Unit, the control system continues to operate using

the previously valid setting of the discharge period.

7.1 Setting the Volume of the C-Power LV-Unit

The size of the C-Power LV-Unit must be set in the configuration menu with the two buttons on the drive

unit (refer to Fig. 18). Please also refer to the settings and display chart (Table 7, Chapter 6.9).

ATTENTION.

If the displayed setting does not correspond with the attached C-Power LV-Unit size, it will result in

incorrect discharge amounts and wrong signals in the display (Display, LEDs).

OR

Fig. 27.

ATTENTION.

Whenever a C-Power LV-Unit is removed from the lubricator and is replaced by another LV-Unit, the

control system assumes that a new, completely filled C-Power LV-Unit was attached. Therefore NEVER

attach a C-Power LV-Unit that is not completely full.

28

Page 29

7.2 How to Replace the C-Power LV-Unit

Drive system and circuit board must be protected from moisture. Exchanges should only be done in a dry

place and it must be ensured that no moisture enters the drive unit.

a) Turn the protection cover on the drive unit counterclockwise and remove it.

b) Remove the empty Timken C-Power LV-Unit. The display indicates “LV” and the red LED is blinking.

c) Remove the used battery set from the drive unit.

d) Insert the new battery set into the drive unit. Follow the directions of the arrows.

e) Remove the plug of the Timken C-Power LV-Unit (refer to Fig. 9, Chapter 4.3.)

f) Push the Timken C-Power LV-Unit into the protection cover until lubricant comes out of the opening.

(refer to Fig. 10, Chapter 4.3).

g) Place the new Timken C-Power LV-Unit on the drive unit, turn it until the catch locks and the teeth of

the Timken C-Power LV-Unit and the drive unit interlock. The control system automatically recognizes

the new Timken C-Power LV-Unit. The display indicates “– –” if the Timken C-Power was switched off

prior to the replacement of the Timken C-Power LV-Unit. Or it indicates “99% Vol.” if the Timken

C-Power was switched on before the replacement. You should only use completely full Timken

C-Power LV-Units to guarantee a trouble-free operation.

h) The lubrication system continues to operate with the previous setting of the discharge period.

i) If required, change lubricator settings (see Chapter 6.8).

If the lubricator was ON before changing the LV-Unit, it will automatically resume operation with

existing settings. If the lubricator was OFF, it must be turned ON (refer to Fig. 19, Chapter 6.5)

29

Page 30

8. TROUBLESHOOTING

8.1 Error Messages of the Distributor on the Display of the Lubricator

Possible errors of the distributor and the complete lubrication system are detected by the electronic

control unit and are indicated on the display of the lubricator. For example, if the error message F2 is

shown on the display, the required pressure at the second connected lubrication point exceeds 25 bar

(360psi).

This means that this lubrication point is no longer supplied with lubricant. The distributor still provides

lubricant to all other activated lubrication points. Correct the malfunction of the second lubrication point

(i.e. grease line bent or blocked) and acknowledge it by pushing the ON/OFF/SELECT button on the

lubricator Timken C-Power or the SELECT button on lubricator Timken C-Power Control.

Error messages are acknowledged and reset by pushing the ON/OFF/SELECT or SELECT button.

8.2 Troubleshooting Guide

If there are malfunctions during the operation of the distributor or the lubrication system, please check

for possible causes using the following chart (refer to Table 10). If you have a malfunction that is not listed

in the chart below, please contact your local supplier for technical support.

Every time that an error message is shown on the display of the lubricator, the red LED at the lubricator

also is blinking.

Display shows Malfunc tion Possible cause Corrective Act ion

EO

F I to F6

E2

E3

E4

E5 Outle t configu ration m issing Outle ts were n ot activated

LV

Lo

(Only with

Timken C-Power)

Lubricat ion sys tem

has been sw itched of f

Error at t he displayed

lubrication point

Lubricat ion sys tem

has been sw itched of f

Lubricat ion sys tem

has been sw itched of f

Lubricat ion sys tem

has been sw itched of f

Lubricat ion sys tem

does n ot detec t the Tim ken

C-Power LV-Unit

No power supplied

to the lub rication sys tem

Exce ss motor current of the

Timken C-Power Dis tribut or Block

Exce ss motor current of the

lubricator mot or caused b y a blocking

of the displayed out let

Out lets of d istributor

not correc tly reco gnized.

Timeout while acti vating

distributor

Connecti on cable damaged

Drive mechanism of the

lubricator is de fectiv e

No Timken C-Po wer LV-Unit

installe d

No power supplied

to the lubricat or

Replace Timken

C-Power D istrib utor Block

Clear the blockage and ackno wledge

the f ault by pu shing and h olding down the

ON/ OFF/SEL ECT or S ELEC T button

Replace dis tribut or

Replace dis tribut or

Replace conn ection cable

Replace the drive uni t of

the lubricator

Activat e desired outlets (Turn off power

suppl y on Timken C- Power Co ntrol be fore

you acknow ledge error mes sages)

Install a Timken C-Power

LV-Unit (O bserve t he Operating

Instruc tions of the lu bricator)

Establi sh a power suppl y

(Obse rve the Opera ting Ins tructi ons

of the lubr icator)

30

Table 10.

Page 31

9. DISPOSAL

Help us in protecting the environment and saving resources by recycling valuable raw material.

Please follow the individual waste disposal regulations in your country.

10. SERVICE

If you wish to return a Timken C-Power Distributor Block that is no longer used, please check with

•

your local supplier for possible return to recycle or dispose of the used parts in an environmentally

safe manner.

31

Page 32

Printed in U.S.A.

|

© 2015 The Timken Company

|

is a registered trademark of The Timken Company.

®

Timken

|

30 0 03-15 :2 9 Form No . 999 -108

The Timken team applies their know-how to improve the reliability and performance of machinery in diverse

markets worldwide. The company designs, makes and markets high-performance mechanical components,

including bearings, gears, chain and related mechanical power transmission products and services.

www.timken.com

Loading...

Loading...