Timken Ball Bearing Housed Installation Manual

U SERIES

TIMKEN® BALL BEARING HOUSED

UNIT INSTALLATION GUIDE

INSTALLATION

UC 200 AND UC 300 SERIES

UK SERIES

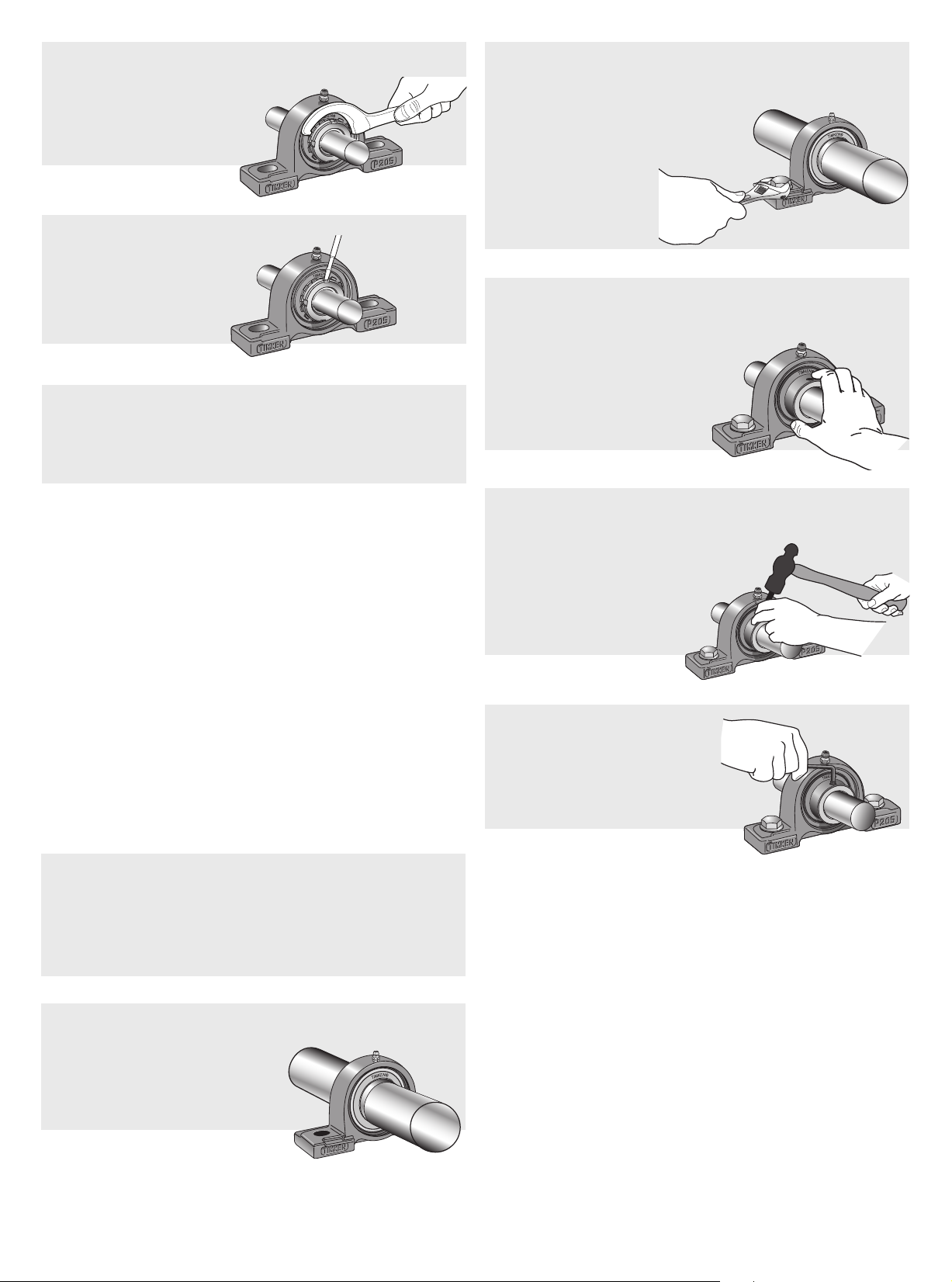

SET SCREW STYLE UNITS

Set screw style units are mounted on the shaft with the help of two set

screws in the inner ring located at 120 degrees to each other. The set

screw locking mechanism provides ease in mounting and is suitable for

applications where the shaft rotation is bidirectional.

Installation procedures for set screw style units are shown below.

1.

2.

3.

Ensure that the shaft is clean, free from burrs, straight and

of proper diameter. The bearing should not be mounted on a

worn section of the shaft. Using shafts with hardness greater

than HRC 45 will reduce effectiveness of locking devices.

See table 2 for suggested shaft tolerances.

Install the supplied grease fitting

into the threaded lubrication hole

on the housing. Align the bearing

in its housing and slide the unit

into position on the shaft.

Bolt the housing tightly to its

mounting supports using an

appropriately sized fastener and

suggested bolt torque (table 4).

Flat washers should be used

when installing any kind of

housed unit. Washers should be

properly sized to bolt diameter.

Grease fitting in

lubrication hole

ADAPTER STYLE UNITS

Adapter style units have a tapered bore bearing mounted to the shaft with

adapter sleeve assembly, comprised of an adapter sleeve, locknut and

lockwasher. This design offers the best shaft concentricity and highest

capacity while having the ability to accommodate undersized shafting.

These units are most suitable where they are exposed to excessive

vibration and impact.

Installation procedures for adapter style units are shown below.

1.

2.

3.

4.

Ensure that the shaft is clean, free from burrs, straight and

of proper diameter. The bearing should not be mounted on

a worn section of the shaft. See table 5 for suggested shaft

tolerances.

Slide the adapter sleeve into position on the shaft. If the

sleeve is too tight, expand the slot by using a screwdriver

as required.

Slide the bearing unit over the adapter sleeve and loosely

install the housed unit to its mounting supports using an

appropriately sized fastener. Flat washers should be used

when installing any kind of housed unit. Washers should be

properly sized to bolt diameter.

Assemble the lockwasher on the sleeve and thread the

locknut onto the adapter sleeve leaving approximately 6.35

mm (¼ in.) between the lockwasher and the inner ring of

the bearing.

4.

Lock the bearing to the shaft

by tightening each inner ring

set screw incrementally to

suggested torque levels (see

table 3).

5.

Use a large screwdriver or pry bar to lever the sleeve into

position until there is no relative movement between the

shaft, adapter sleeve and the bearing’s inner ring.

6.

7.

8.

Rotate the locknut until hand-tight. Use a spanner wrench

to tighten the locknut to

the suggested torque

(see table 6).

Bend a tang on the

lockwasher into a

slot on the locknut to

prevent the locknut

from loosening.

Rotate the shaft by hand while tightening the mounting bolts

to make sure the shaft rotates freely. Tighten the housed unit

mounting bolts to the recommended bolt tightening torque

given in table 4.

3.

4.

Bolt the housing tightly to its mounting supports using an

appropriately sized fastener and suggested bolt torque

(see table 4). Flat

washers should be

used when installing

any kind of housed

unit. Washers should

be properly sized to

bolt diameter.

Place the eccentric locking collar on the shaft with its

cam adjacent to the cam on the end of the bearing inner

ring. The eccentric collar’s

recessed cam will engage

the corresponding cam on

the bearing inner ring. Turn

the collar in the direction of

shaft rotation.

UEL SERIES

ECCENTRIC LOCKING COLLAR UNITS

The self-locking collar eliminates the need for locknuts, lockwashers,

shoulders, sleeves and adapters. For many agricultural and industrial

applications, self-locking collars are the easiest housed units to install.

The locking collar has a recessed cam made eccentric to the collar bore.

When assembled on the shaft, the locking collar engages or mates with

the eccentric cam end of a bearing’s inner ring. This assembly grips the

shaft tightly with a positive binding action that increases with use. No

adjustments of any kind are necessary. The collar set screw provides

supplementary locking.

Installation procedures for eccentric locking collar style units are

shown below.

1.

Ensure that the shaft is clean, free from burrs, straight and

of proper diameter. The bearing should not be mounted on a

worn section of the shaft. Using shafts with hardness greater

than HRC 45 will reduce effectiveness of locking devices.

See table 2 for suggested shaft tolerances.

5.

6.

Using a light weight hammer and a drift pin inserted in the

blind hole, tap lightly

in the direction of shaft

rotation to positively

engage the collar. The

insert is now locked to

the shaft.

Tighten the set screw to

suggested torque level (see

table 3).

2.

Install the supplied grease fitting into the threaded

lubrication hole on the housing.

Align the bearing in its housing

and slide the unit into position

on the shaft.

Loading...

Loading...