Page 1

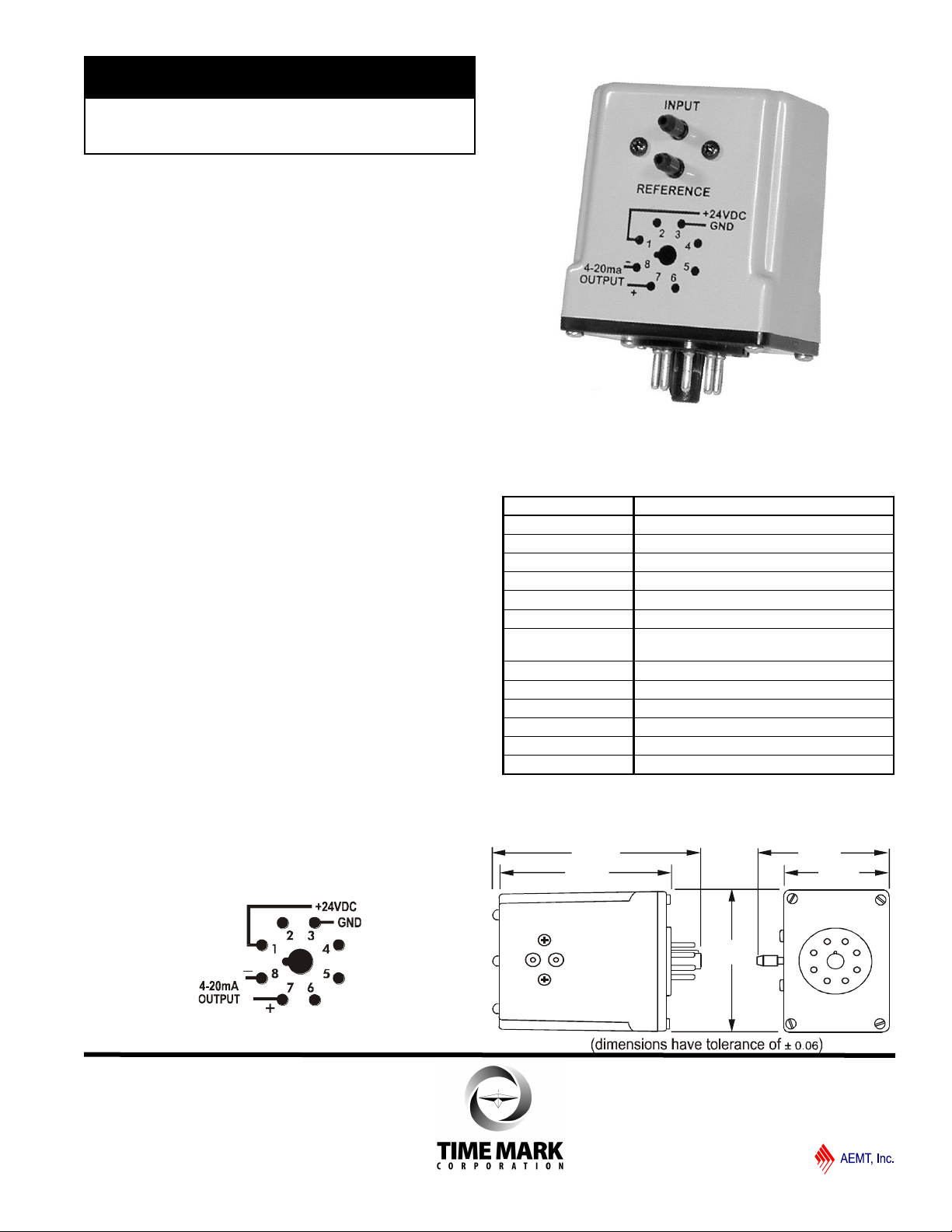

MODEL 672

3.42"

2.88"

2.25"

1.75"

2.44”

TIME MARK is a division of

Pressure Transducer

0-15 psi Air Pressure Input

4-20 mA Output

5-Year Unconditional Warranty

DESCRIPTION

The Model 672 Pressure Transducer, part of the 600

series line of instrumentation controls, is a differential

pressure transducer. The 0-15 psi input allows the

Model 672 to output a proportional 4-20mA signal. It

can be DIN rail-mounted or mounted in a standard 8-pin

socket.

The Model 672 may be used to provide the input signal

for other instrumentation controls, including the

following Time Mark controls in the 600 series

instrumentation line:

Model 660 Trip Control

Model 661 Alarm Control

Model 662 Pump Up Control

Model 663 Pump Down Control

Model 670 Buffer/Scalar

Model 681 Digital Meter

PIN DIAGRAM

SPECIFICATIONS

Model 672

Input Voltage 24VDC ± 5%

Power Consumption 1W maximum

Air Pressure Input 0 to 15 psi

Max. Air Pressure 30 psi

Input Air Supply Fitting 3/16” I.D. tubing

Repeat Accuracy ± 1%

Signal Output 4-20mA proportional to 0-15 psi

(in water: 0-15 psi = 0 to 34.6 feet at 77º F)

Max. Load Resistance 500 ohms

Compensated Temp +32º to +158º F

Operating Temp -13º to +185º F

Enclosure Material ABS plastic

Mounting 8-pin socket (*order separately)

Weight 3 oz.

* Order 8-pin socket number 51X120

DIMENSIONS

01/2012

© 2012 TIME MARK CORPORATION

Page 2

MODEL 672

TIME MARK is a division of

Pressure Transducer

READ ALL INSTRUCTIONS BEFORE INSTALLING, OPERATING OR SERVICING THIS DEVICE.

KEEP THIS DATA SHEET FOR FUTURE REFERENCE.

GENERAL SAFETY

THE MODEL 672 PRESSURE TRANSDUCER IS NOT TO BE USED WITH INPUT VOLTAGES OTHER THAN

24VDC. ALL ELECTRICAL POWER SHOULD BE REMOVED WHEN CONNECTING OR DISCONNECTING

WIRING. THIS DEVICE AND WIRING SHOULD BE INSTALLED AND SERVICED BY QUALIFIED PERSONNEL.

Installation Instructions

INSTALLATION

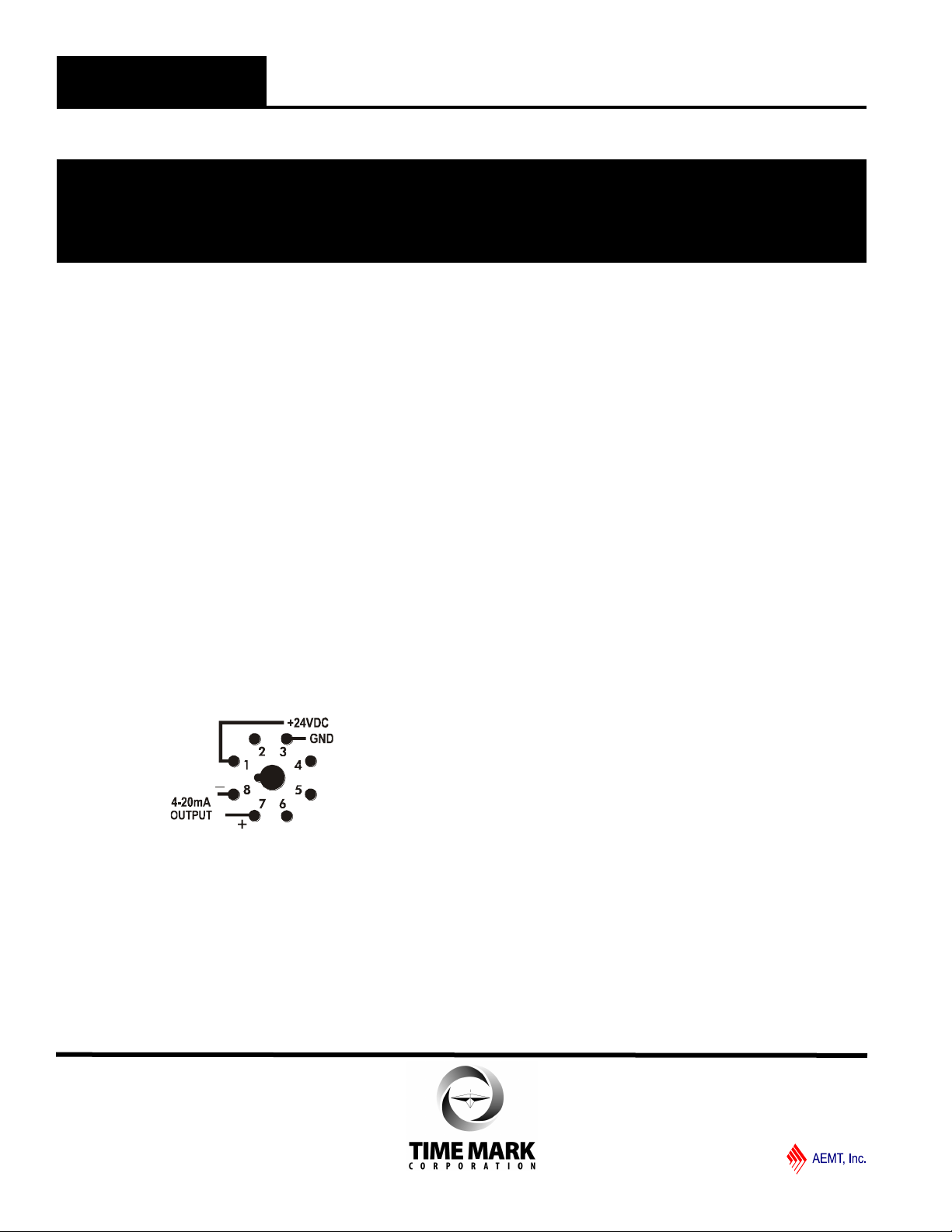

Observing the pin diagram shown below and on the

unit, connect the Model 650 Power Supply, or other

regulated 24 VDC power source to pins 1 and 3 on the

8-pin socket.

Connect the output leads for the 4-20mA current loop to

pins 7 and 8. Pay careful attention to polarity.

NOTE: When installing the Model 672 Transducer in areas

of high humidity or contamination, it is recommended that the

base area and all exposed metal parts of the socket be coated

liberally with a good quality silicone grease, such as Dow

Corning DC-4 or DC-4X. Insert the unit into the socket and

wipe off excess grease around the base. This will prevent the

entrance of moisture and other contaminates into the base

and socket areas.

PIN DIAGRAM

Connect a 3/16” I.D. air hose to the Model 672 INPUT

hose connection. Connect the other end of the input

hose to the measurement device air pressure output.

Connect a 3/16” I.D. air hose to the Model 672

REFERENCE hose connection. Connect the other end

of the input hose to the reference pressure source. If

the reference source is atmospheric pressure, do

not connect a hose to the REFERENCE hose

connector.

TROUBLESHOOTING

Should the Model 672 Pressure Transducer fail to

operate, check the power supply connections, making

sure that the polarity and voltage levels are correct.

Verify that all electrical connections are firmly attached

to the terminals.

Check the full length of the air hose and hose

connections, to insure there are no pressure leaks.

Connect a known pressure source to the INPUT

connection, while measuring the output current from

pins 7 and 8.

The output current must have a complete circuit,

through the controller, returning to the pressure

transducer. Should problems persist, contact the

factory for assistance.

WARRANTY

This product is warranted to be free from defects in

materials and workmanship, and is covered by our exclusive 5-year Unconditional Warranty. Should this

device fail to operate for any reason, we will repair it for

five years from the date of manufacture. For complete

warranty details, see the Terms and Conditions of

Sales page in the front section of the Time Mark catalog or contact Time Mark at 1-800-862-2875.

01/2012

© 2012 TIME MARK CORPORATION

Loading...

Loading...