Page 1

_

+

4-20

INPUT

ma

+

_

24 VDC

HIGH ALARM

LOW ALARM

4

5

6

7

8

9

10

11

1

2

3

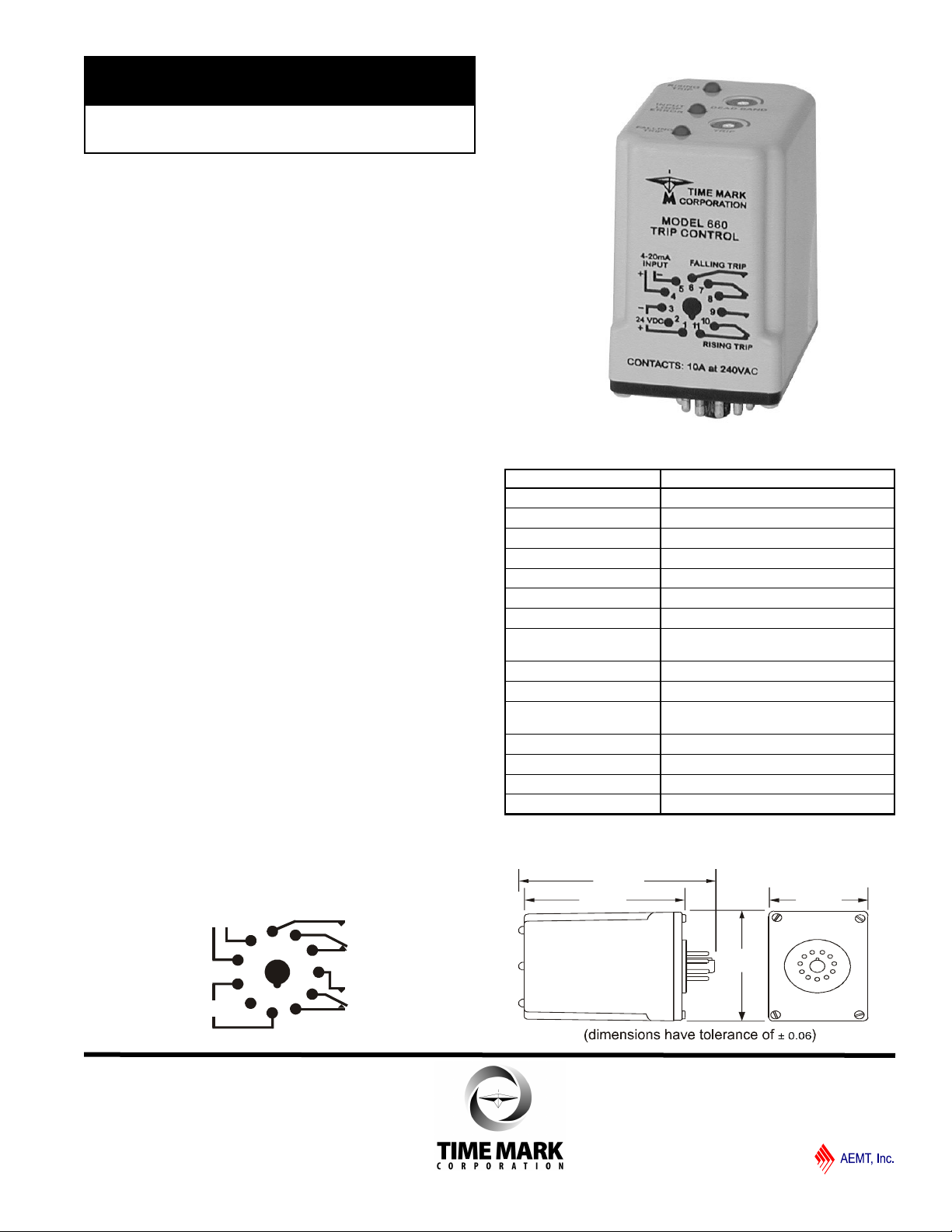

2.88”

2.44”

1.75”

3.52”

MODEL 660

TIME MARK is a division of

Trip Control

Automatic reset

Adjustable trip points

Adjustable dead band

5-Year unconditional warranty

DESCRIPTION

The Model 660 Trip Control, part of the 600 series line of

instrumentation controls, is designed to monitor and maintain

a set level on a measurable variable, such as liquid level,

temperature, pressure, flow, etc. A user-provided 4-20ma

current loop represents the measurable application.

Two trip points, the rising setpoint, and the falling setpoint are

field adjustable. They are set by calibrating the DEAD BAND

and TRIP adjustments. If the input is between the two setpoints, the relays are de-energized. If the input goes above

the rising setpoint, the RISING TRIP relay energizes to

provide a tripped condition. This tripped condition will

automatically reset when the input falls back below the

setpoint. If the input falls below the falling setpoint the

FALLING TRIP relay energizes to provide a tripped condition.

The tripped condition resets when the input rises back above

the setpoint.

The Model 660 has top-mounted LEDs for status indication.

Individual RISING TRIP or FALLING TRIP LEDs turn ON in a

tripped condition. The INPUT LOOP ERROR LED turns ON if

the input is outside the 4-20ma range.

A Time Mark Model 650 Loop Power Supply (or equivalent)

is required to provide DC operating voltage. A Time Mark

Model 672-15 Pressure Transducer (or equivalent) is

required to provide the input signal.

SPECIFICATIONS

Model 660

Operating voltage 24VDC ±5%

Supply current 30mA maximum

Input signal 4-20mA

Input resistance 50W

Input loop error High: 23 - 25mA

Trip adjustment 4 - 20mA

Dead band adjustment 1 - 10%

Hysteresis

Contact 10 amps at 240VAC resistive

Operating temperature -13º to +122º F

Expected relay life Mechanical: 10 million operations

Humidity tolerance 0-97% w/o condensation

Enclosure material ABS plastic

Weight 6 oz.

Mounting 11-pin socket (*order separately)

*order 11-pin socket number 51X016

Rising trip point: 0.9% at midrange

Falling trip point: 0.4% at midrange

Electrical: 100,000 at rated load

PIN DRAWING

DIMENSIONS

01/2012

© 2012 TIME MARK CORPORATION

Page 2

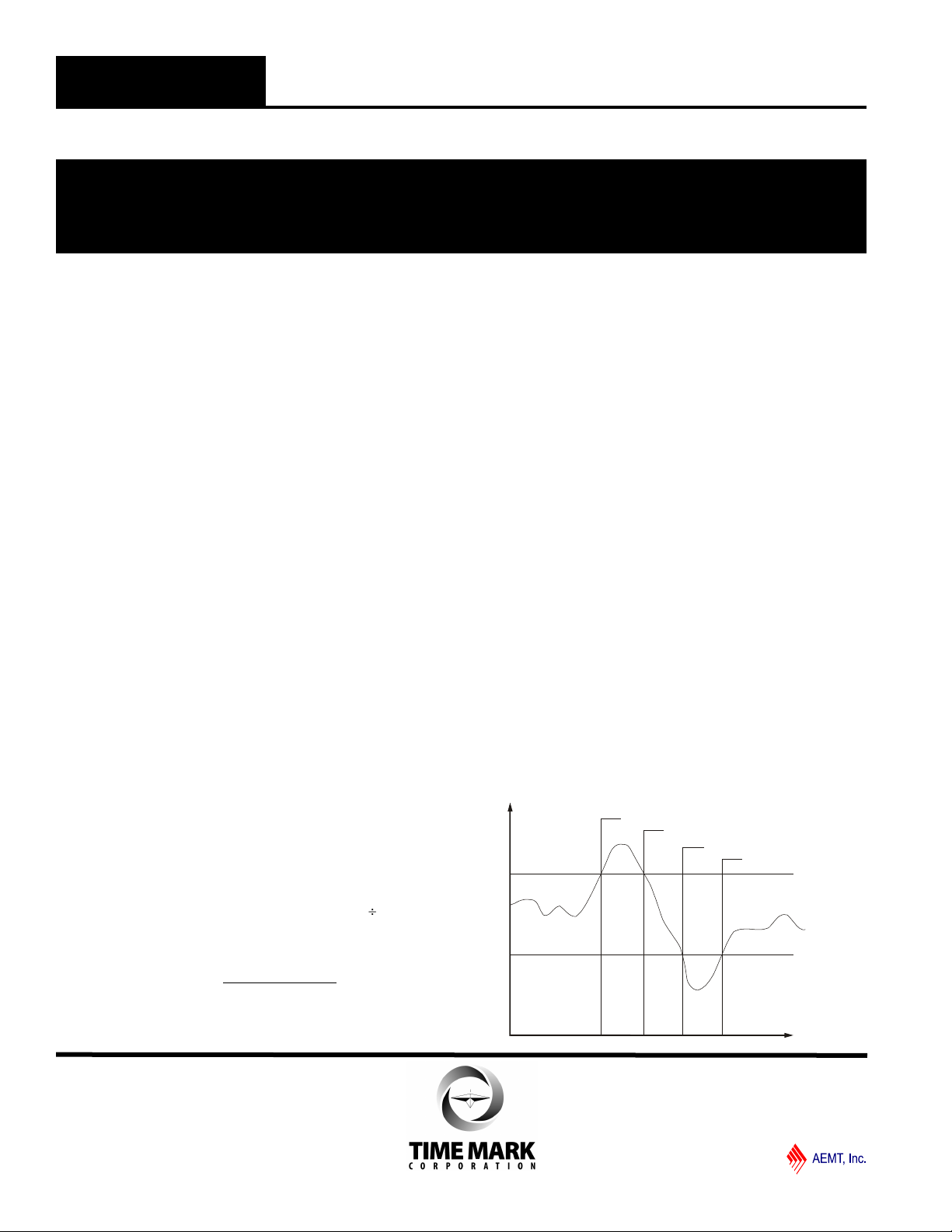

0

2

4

6

8

10

14

16

18

20

12

LOW TRIP POINT

HIGH TRIP POINT

TIME (MINUTES)

I

L

o

o

p

(

m

a

)

HIGH ALARM RELAY DE-ENERGIZES

HIGH ALARM RELAY ENERGIZES

LOW ALARM RELAY DE-ENERGIZES

LOW ALARM RELAY ENERGIZES

TIME MARK is a division of

MODEL 660

Trip Control

READ ALL INSTRUCTIONS BEFORE INSTALLING, OPERATING OR SERVICING THIS DEVICE.

KEEP THIS DATA SHEET FOR FUTURE REFERENCE.

INSTALLATION

Connect 24 VDC power to pins 1 and 3 on the 11-pin socket.

Connect the 4-20ma input signal to pins 4 and 5.

Connect the other pins to the appropriate units in your loop

system, following the base diagram shown on the Model 660

device (and on this data sheet).

NOTE: When installing the Model 660 Trip Control in areas of

high humidity or contamination, it is recommended that the base

area and all exposed metal parts of the socket be coated liberally

with a good quality silicon grease, such as Dow Corning DC-4 or

DC-4X. Insert the unit into the socket and wipe off excess grease

around the base. This will prevent the entrance of moisture and

other contaminates into the base and socket areas.

ADJUSTMENT PROCEDURE

The Model 660 Trip Control relays are normally de-energized

when the input is between the trip points. If the input rises

above the RISING TRIP point, or falls below the FALLING

TRIP trip point, the high or low relay will energize. Either way,

the relay returns to the de-energized state when the input

signal is again between the two setpoints (see the

OPERATION DIAGRAM).

The RISING TRIP and FALLING TRIP LEDs may be used to

indicate the tripped condition in the following adjustments.

BEFORE ADJUSTMENT: It is necessary to determine the

TRIP setpoint before adjustment of the Model 660. In order to

determine this setpoint, you must know the RISING TRIP, and

the FALLING TRIP setpoints in milliamps, for your application,

in order to calculate the TRIP setpoint. It is determined by

averaging these two setpoints.

The DEADBAND is also required. This value is expressed as

a percent, determined as shown:

TRIP

NOTE: The DEADBAND value must be in the range of 1-

10%. If it is not, contact the factory for special instructions.

GENERAL SAFETY

THE MODEL 660 TRIP CONTROL IS NOT TO BE USED WITH INPUT VOLTAGES OTHER THAN 24VDC.

ALL ELECTRICAL POWER SHOULD BE REMOVED WHEN CONNECTING OR DISCONNECTING WIRING.

THIS DEVICE SHOULD BE INSTALLED AND SERVICED BY QUALIFIED PERSONNEL.

Installation Instructions

TRIP POINT: Turn the DEADBAND adjustment fully counter-

clockwise, to it’s lowest setting. With the Model 680 4-20ma

Simulator (or other adjustable, known signal source), apply

the current level for the TRIP (as calculated in the previous

step). Adjust the TRIP pot until both the RISING TRIP and the

FALLING TRIP LEDs are off.

DEADBAND: With the DEADBAND still at it’s lowest setting,

Pay careful attention to polarity.

TRIP = (RISING TRIP + FALLING TRIP) 2

DEADBAND = RISING TRIP - TRIP x 100

apply the current level for the RISING TRIP. Turn the

DEADBAND slowly clockwise, until the RISING TRIP LED

goes off. Then turn it slowly counter-clockwise, until the

RISING TRIP LED comes on. You can check the RISING

TRIP and FALLING TRIP setpoints by varying the input

current, and noting where the relays trip.

INPUT LOOP ERROR: Check the INPUT LOOP ERROR

function by applying current levels above and below the 420ma range. The INPUT LOOP ERROR LED should

illuminate when the current is above 20ma or below 4 ma.

WARRANTY

This product is warranted to be free from defects in materials

and workmanship, and is covered by our exclusive 5-year

Unconditional Warranty. Should this device fail to operate

for any reason, we will repair it for five years from the date of

manufacture. For complete warranty details, see the Terms

and Conditions of Sales page in the front section of the Time

Mark catalog or contact Time Mark at 1-800-862-2875.

OPERATION DIAGRAM

© 2012 TIME MARK CORPORATION

01/2012

Loading...

Loading...