Page 1

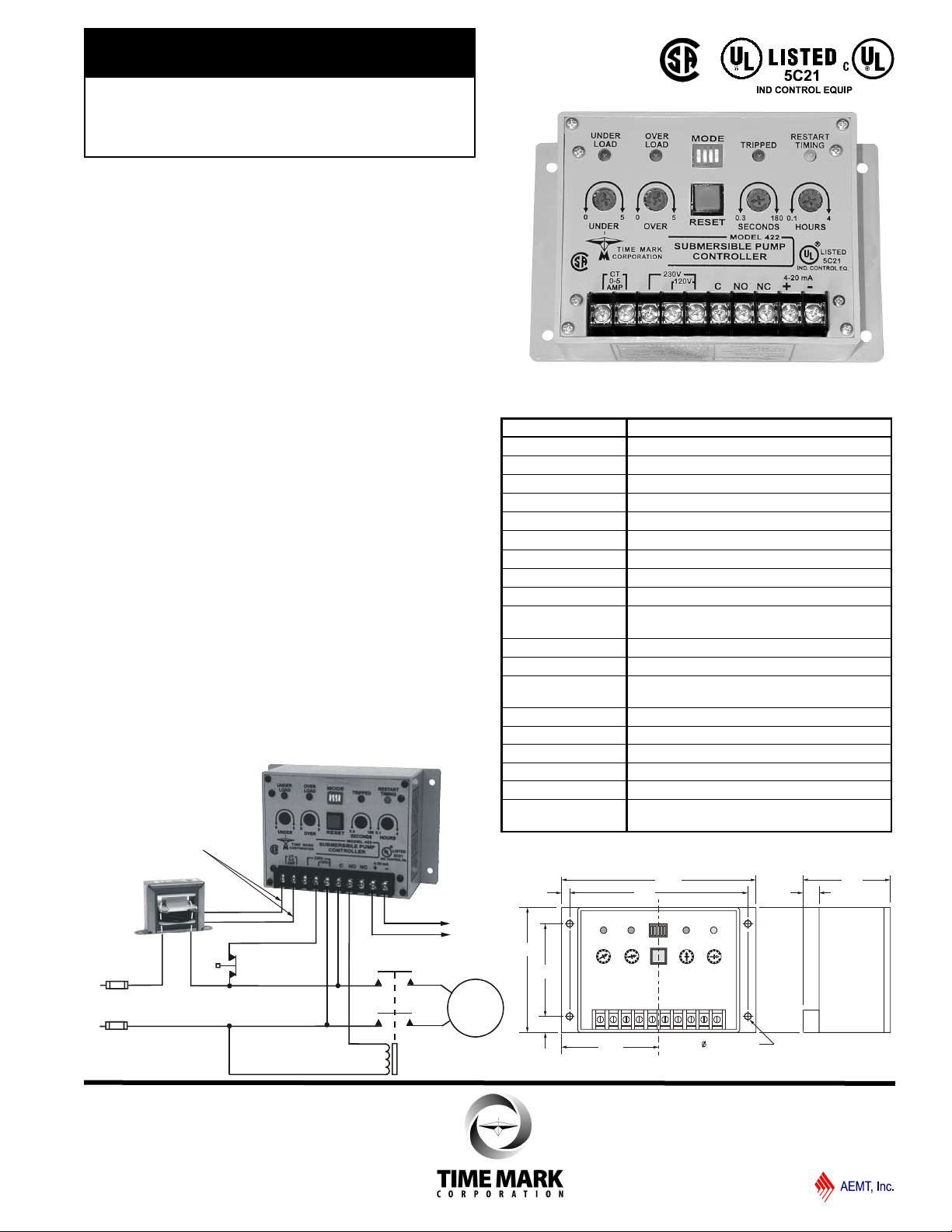

C

L

3.88"

3.0"

0.44"

3.03"

Holes are symetrical

about center line.

0.203" 4 PL.

5.5"

6.06"

0.55"

2.63"

0.28"

MOTOR

4-20mA

OUTPUT

REVERSE WIRES TO CT

IF MOTOR FAILS TO RUN

FOR MORE THAN THE INITIAL

2 SECOND PERIOD.

MODEL 276A-xx

L1

L2

MANUAL

RESTART

120VAC

COIL

TIME MARK is a division of

MODEL 422

Submersible

Pump Controller

Monitors True Motor Power

(volts x current x power factor)

Detects Motor Overload or Underload

Operates on 120 or 240VAC,

Single-phase or 3-phase

Built-in Trip and Restart Delay Options

SPECIFICATIONS

DESCRIPTION

The Model 422 Submersible Pump Controller detects

an overload or underload condition on all types of

running pump motors: suction pumps, submersible

pumps, etc.

This Monitor detects the actual power used (voltage x

current x power factor) and is more sensitive than

simple current monitors. The 422 can be used with

single phase pumps or, using the Model 276C current

transducer, with 3-phase pumps. Matching CT’s allow

the Model 422 to be used with most pump motor sizes.

Optional trip and restart delays are provided.

TYPICAL APPLICATION -single-phase monitoring

Model 422

Input Voltage Range 100-130VAC or 200-250VAC

Frequency 50/60Hz

Power Consumption

Nominal Current

Minimum Current

Current Adjustment 0 - 5 amps x PF

Current Output 4-20mA for chart recorders

Repeat Accuracy 1% (fixed conditions)

Output SPDT 10A at 240VAC resistive

Expected Relay Life Mech: 10 million operations

Trip Delay

Restart Delay

Indicators Red LED: Overload or Underload; tripped

Transient Protection 2500V for 10ms

Operating Temp - 20º to 131º F

Humidity Tolerance 97% w/o condensation

Enclosure Material ABS plastic

Weight 1 lb.

Agency Approvals UL Listed to US and Canadian safety

0.5 VA max.

2.5 amps

0.25 amps

Elec: 100,000 operations at rated load

OFF or 0.3 to 180 seconds

OFF or 0.1 to 4 hours

Yellow LED: Restart timing

standards CSA Certified

DIMENSIONS

Page 1 of 8 11/2011

© 2011 TIME MARK CORPORATION

Page 2

TIME MARK is a division of

MODEL 422

READ ALL INSTRUCTIONS BEFORE INSTALLING, OPERATING OR SERVICING THIS DEVICE.

Submersible Pump Controller

KEEP THIS DATA SHEET FOR FUTURE REFERENCE.

APPLICATION GUIDE

GENERAL

This application guide is written for equipment designers,

maintenance personnel, electrical contractors, etc.

It is intended to aid in the installation of the Model 422

Submersible Pump Controller into pump protection systems.

The notes and diagrams deal with methods of protecting motors in

the event of an underload condition or an overload condition.

THEORY

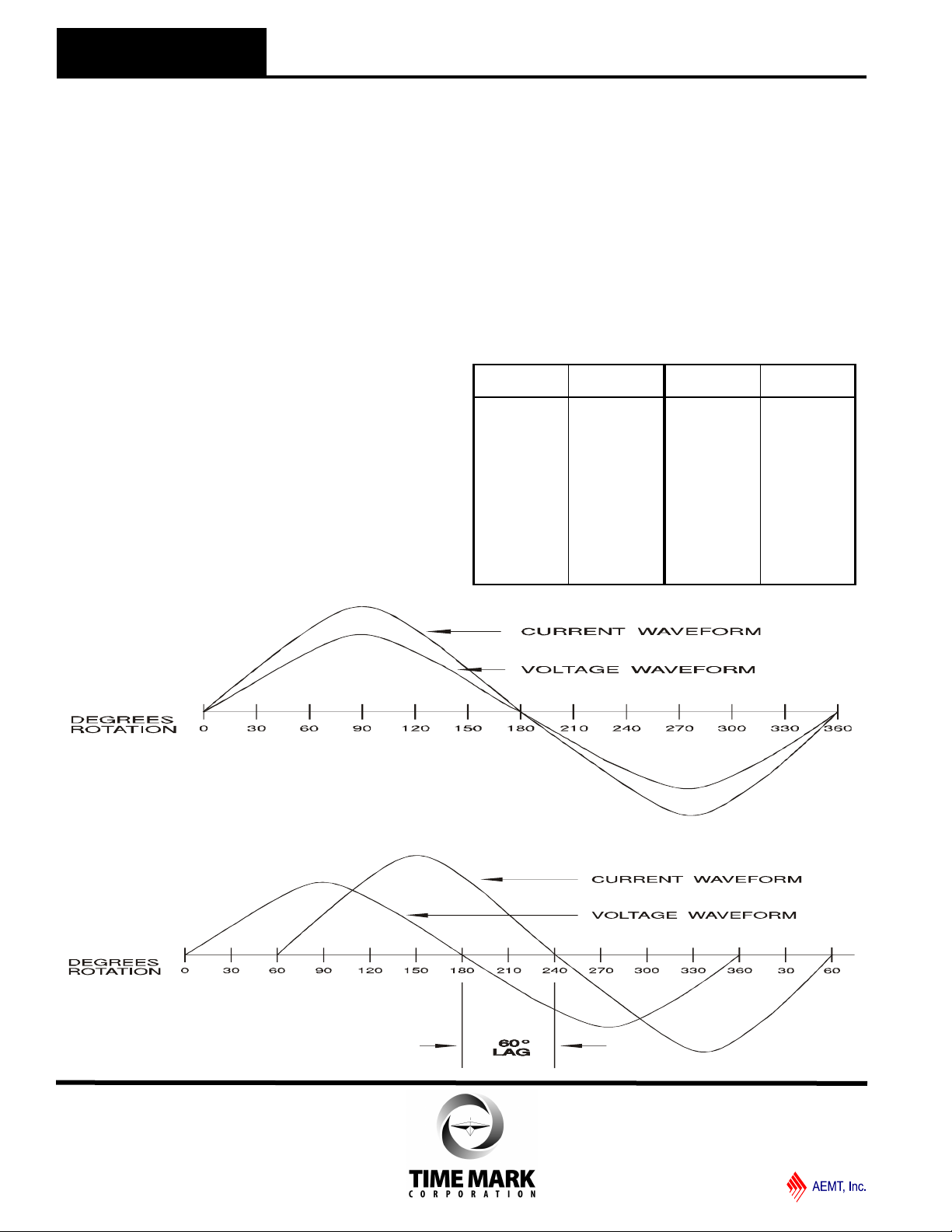

The need for a system to detect an underload condition other than

by the simple monitoring of current becomes clear when

examining the following waveforms.

In a purely resistive circuit, as in Figure 1, the current (amps) is

directly proportional to the power (watts) being consumed. To find

the power, multiply the voltage across the load times the current

through the load. The result is in watts (V x A = W).

In Figure 2, When the load is not resistive, but inductive as it is

with a motor, the formula is no longer correct. The inaccuracy

occurs because the current and the voltage waveforms are not in

phase.

The current waveform lags the voltage waveform by as much as

90 degrees in a completely unloaded condition, or as little as 5 or

10 degrees in a fully loaded condition.

The current, as measured with an ammeter, may only vary a slight

amount as the motor changes from a fully loaded condition to a

completely unloaded condition. This makes it difficult to detect an

unloaded condition by simply monitoring current alone.

To obtain an accurate picture of real power consumption of any

inductive device, such as a motor, the formula V x A x Cosø = W

is used.

The Cosø is a multiplication factor derived from the number of

degrees of lag between the current and voltage waveforms.

This is called the “power factor” (or “PF”). The power factor is the

natural cosine of the degrees of lag:

Degrees

of lag

0 1.000 50 0.643

5 0.996 55 0.574

10 0.985 60 0.500

15 0.966 65 0.423

20 0.940 70 0.342

25 0.906 75 0.259

30 0.866 80 0.174

35 0.819 85 0.087

40 0.766 90 0.000

45 0.707

Power

Factor

Degrees

of lag

Power

Factor

Figure 1. RESISTIVE

LOAD

With a purely resistive load, the current and voltage

waveforms are occurring simultaneously.

Figure 2. INDUCTIVE

LOAD

With an inload, the current waveform lags

the voltage waveform by 60°.

Page 2 of 8 11/2011

© 2011 TIME MARK CORPORATION

Page 3

TIME MARK is a division of

2.38"

1.95"

1.63"

Secondary

Space for Primary turn:

0.25" 0.38"x

1.25"

0.43"

.187" dia.

Secondary terminals

(0 - 5 amps)

Loop one leg of AC

line thru transformer

as shown

MODEL 422

Submersible Pump Controller

APPLICATION GUIDE

Example: TRUE POWER CONSUMED BY AN AC

MOTOR

For this example we will use a 3-horsepower, 230 volt,

single phase motor.

Condition 1 represents the motor being used at near full

load, while Condition 2 represents a drop in motor load.

Comparing the results of this example, the motor

current decreased only 10% with a drop of 61% in the

motor load (input power). A drop in pump motor power

cannot be accurately measured by only monitoring the

current and voltage.

By monitoring the phase relationship and applying the

resultant power factor an accurate and selective

method of sensing changes in true power consumption

can be obtained.

The Model 422 Controller is based on the above

principal of detecting the actual power used, and is

more sensitive than simple current monitors.

ADDITIONAL FEATURES

As described previously, the Model 422 would fulfill the

basic requirements in most pump motor protection

control systems. However, there are situations which

would require the pump to restart automatically after a

preset time.

The Model 422 has an adjustable restart timer for

such applications. This timer has a range of 0.1 to 4

hours. If the restart timer is not needed, turn it off with

DIP switch 2.

If restart timing is needed for an underload condition

only, the overload restart can be turned off with DIP

switch 1.

Resetting the Model 422 is accomplished by cycling the

power off and back on, pressing the RESET button, or

by using the restart timer (DIP switch 2).

Some applications require a trip delay period before

shutting down the pump. The Model 422 has a built-in

trip delay timer. The timing range is from 0.3 to 180

seconds. The trip delay timer can be turned off with

DIP switch 4.

Example: (V x A x Cosø = Watts)

Condition 1

230 volts x 10 amps x 0.985 PF = 2265.5 watts

Condition 2

230 volts x 9 amps x 0.423 PF = 875.6 watts

Refer to the chart under INSTALLATION (pg 4) for all

DIP switch settings.

A 4-20mA output is provided for monitoring power

consumption. A 4mA output is equal to 0 watts and a

20mA output is equal to 600 watts at 120 V or 1200

watts at 240 V.

This signal can be sent to a strip chart recorder, a

process controller, computer, etc.

INPUT CURRENT REQUIREMENTS

The CT input of the Model 422 is the isolated winding of

a small current transformer within the unit. Ideally, the

current range needed should be between 2 and 3.5

amps for a fully loaded motor.

Polarity of the wires connected to the CT terminals is

critical to achieve the correct phase relationship

between the current and voltage waveforms as

described earlier.

This is simple to determine after the installation is

complete (refer to the ADJUSTMENT PROCEDURE, pg

5).

If the full load motor current is 3.5 amps or less, and the

pump motor is a single-phase type, connect one leg of

the motor current directly into the Model 422.

Figure 3 shows the Model 276A and Figure 4 shows

the Model 276B Current Transformers; available from

Time Mark.

Figure 3. MODEL 276A CURRENT TRANSFORMER

Page 3 of 8 11/2011

© 2011 TIME MARK CORPORATION

Page 4

2.6"

3.6"

.187" dia. typical

4.0"

2.3"

4.6"

TIME MARK is a division of

3.90"

2.00"

0.44"

1.25"

4.50"

3.88"

(2) 0.27" x 0.44" slots

B

C

MODEL 422

APPLICATION GUIDE INSTALLATION INSTUCTIONS

Figure 4. MODEL 276B CURRENT TRANSFORMER

Use the chart below to cross reference your motor horsepower

to a Time Mark single-phase or 3-phase current transformer.

Figure 5. CURRENT TRANSFORMER CHART

Motor

1 1/2 276A-30 276A-15 276A-10 *

7 1/2 276B-150 276B-60 276A-35 276A-20

100 276B-400 276B-200

125 276B-250

150 276B-300

200 276B-400

250 276B-500

300 276B-600

350 276B-700

400 276B-750

500 276B-1000

Submersible Pump Controller

276B Series

50 - 500 600 - 1200

B = 0.87”

C = 1.56” C = 2.06”

Time Mark Model Number

Single-Phase 3-Phase

HP

1/4 276A-10

1/3 276A-15

1/2 276A-15 276A-10

3/4 276A-20 276A-10 * *

1 276A-25 276A-15 276A-10

2 276A-35 276A-20 276A-10 *

3 276B-50 276A-25 276A-15 276A-10

5 276B-80 276A-40 276A-25 276A-15

10 276B-150 276B-75 276A-40 276A-20

15 276B-60 276A-30

20 276B-80 276A-40

25 276B-100 276B-50

30 276B-150 276B-60

40 276B-150 276B-75

50 276B-200 276B-100

60 276B-250 276B-150

75 276B-300 276B-150

120VAC 240VAC 240VAC 480VAC

* *

* *

* Direct connection to Model 276C (see page 8)

* * Direct connection to Model 422

B = 0.87”

*

*

*

3-PHASE INSTALLATION

The basic Model 422 Controller is designed for use with

single-phase pump motors. However, it can easily be

used in 3-phase applications by installing the current

cancelling transformer, Model 276C. The Model 276C

(figure 6) monitors two of the three phases, and cancels

the effect of the current signal in the third phase, which

would otherwise cause a phase shift error in the Model

422.

Figure 6. MODEL 276C

IMPORTANT NOTE:

In 3-phase applications, the current inputs must

come from the same phases providing the voltage

input. The applications schematics shown on the

last page describe the interconnections.

INSTALLATION

Mount the Model 422 in the control panel or in a suitable

enclosure. Connect the voltage and current inputs to

the appropriate terminals on the Model 422 Monitor.

If the 4-20mA output is used, connect it across a 300

resistive load. Set the four MODE switches on the

Model 422 according to the chart below. During the

initial setup you may wish to disable all time delays.

DIP SW MODE ON OFF

After the system is completely installed, a simple test and

adjustment will insure that the polarity and threshold are

correct.

1

2

3

4

Overload Restart Disabled Enabled

Restart Delay Enabled Disabled

Reset Button Enabled Disabled

Trip Delay Enabled Disabled

Page 4 of 8 11/2011

© 2011 TIME MARK CORPORATION

Page 5

TIME MARK is a division of

MODEL 422

Submersible Pump Controller

READ ALL INSTRUCTIONS BEFORE INSTALLING, OPERATING OR SERVICING THIS DEVICE.

KEEP THIS DATA SHEET FOR FUTURE REFERENCE.

GENERAL SAFETY

POTENTIALLY HAZARDOUS VOLTAGES ARE PRESENT AT THE TERMINALS OF THE MODEL 422.

ALL ELECTRICAL POWER SHOULD BE REMOVED WHEN CONNECTING OR DISCONNECTING WIRING.

THIS DEVICE SHOULD BE INSTALLED AND SERVICED BY QUALIFIED PERSONNEL.

INSTALLATION INSTRUCTIONS

ADJUSTMENT

Connect a temporary jumper across the NO contacts on

the Model 422 (this keeps the motor running as the

Model 422 trips off and resets).

With the correct voltage applied to the system, the

motor should start and run continuously. Make sure the

motor is running under its normally loaded condition.

With a clamp-type ammeter, measure the current in one

of the wires connected to the CT terminals on the Model

422. A reading between 2 and 3.5 amps should be

measured for best results. This current level can be

changed by exchanging the CT with a different ratio.

Turn the UNDER adjustment through its entire range

and find the spot where the UNDERLOAD LED just

illuminates.

Turn the UNDER adjustment until the LED just goes

out. If the UNDERLOAD LED is lit all the time, reverse

the two wires connected to the CT terminals and readjust.

Repeat this procedure for the OVER adjustment. If the

OVERLOAD indicator LED stays on all the time, the

current input may be incorrect. Check the CTs for

proper sizing.

Set the SECONDS adjustment for the appropriate TRIP

delay, and HOURS adjustment for the appropriate

RESTART delay, as required for the application.

Remove the jumper from the NO contacts; the motor

should continue to run. The adjustment is now

complete.

TROUBLESHOOTING

Should the Model 422 Submersible Pump Controller fail

to operate, check all connections to the device and its

control circuits. Insure that the proper voltage and

currents have been applied.

Check all fuses. Should the Model 422 operate

improperly, check that the CT is properly sized. Check

all DIP switch settings. If problems persist, contact the

factory for technical assistance.

OPERATION

When AC voltage is first applied, the output transfers

for approximately two seconds, completing the motor

control circuit and allowing the motor to come up to

speed.

If the power being used is within acceptable limits the

contacts remain energized and the motor continues to

run. If the power drops or rises outside the limits, the

contacts will open.

WARRANTY

This product is warranted to be free from defects in

materials and workmanship for one year. Should this

device fail to operate, we will repair it for one year from

the date of manufacture. For complete warranty

details, see the Terms and Conditions of Sales page in

the front section of the Time Mark catalog or contact

Time Mark at 1-800-862-2875.

Page 5 of 8 11/2011

© 2011 TIME MARK CORPORATION

Page 6

MOTOR

4-20mA

OUTPUT

REVERSE WIRES TO CT

IF MOTOR FAILS TO RUN

FOR MORE THAN THE INITIAL

2 SECOND PERIOD.

MODEL 276A-xx

L1

L2

MANUAL

RESTART

120VAC

COIL

MOTOR

4-20mA OUTPUT

REVERSE WIRES TO CT

IF MOTOR FAILS TO RUN

FOR MORE THAN THE INITIAL

2 SECOND PERIOD.

MODEL 276B-xx

L1

L2

MANUAL

RESTART

240VAC

COIL

TIME MARK is a division of

MODEL 422

Submersible Pump Controller

TYPICAL APPLICATIONS

SINGLE-PHASE, 120V, <3 HP

SINGLE-PHASE, 240V, 7.5 HP

Shows No Power Applied

Shows No Power Applied

Page 6 of 8 11/2011

© 2011 TIME MARK CORPORATION

Page 7

4-20mA

OUTPUT

REVERSE WIRES

TO CT IF MOTOR

FAILS TO RUN

FOR MORE THAN

THE INITIAL

2 SECOND PERIOD.

M

O

D

E

L

2

7

6

C

L1

L2

MANUAL

RESTART

240VAC

COIL

OBSERVE POLARITY

AS SHOWN

USE MODEL 276A-xx

MOTOR

L3

TIME MARK is a division of

MOTOR

4-20mA OUTPUT

REVERSE WIRES TO CT

IF MOTOR FAILS TO RUN

FOR MORE THAN THE INITIAL

2 SECOND PERIOD.

L1

L2

MANUAL

RESTART

240VAC

COIL

MODEL 276A-xx

MODEL 422

Submersible Pump Controller

TYPICAL APPLICATIONS

SINGLE-PHASE, 240V, 1/2 TO 5 HP

3-PHASE, 240V, 1 TO 10 HP

Shows No Power Applied

Shows No Power Applied

Page 7 of 8 11/2011

© 2011 TIME MARK CORPORATION

Page 8

4-20mA

OUTPUT

REVERSE WIRES

TO CT IF MOTOR

FAILS TO RUN

FOR MORE THAN

THE INITIAL

2 SECOND PERIOD.

M

O

D

E

L

2

7

6

C

MANUAL

RESTART

120VAC

COIL

MOTOR

OBSERVE POLARITY

AS SHOWN

USE MODEL 276B-xx

120VAC

480VAC

T

I

M

E

M

A

R

K

3

-

P

H

A

S

E

M

O

N

I

T

O

R

L1

L3

L2

4-20mA

OUTPUT

REVERSE WIRES

TO CT IF MOTOR

FAILS TO RUN

FOR MORE THAN

THE INITIAL

2 SECOND PERIOD.

M

O

D

E

L

2

7

6

C

L1

L2

MANUAL

RESTART

240VAC

COIL

OBSERVE POLARITY

AS SHOWN

MOTOR

L3

TIME MARK is a division of

MODEL 422

Submersible Pump Controller

TYPICAL APPLICATIONS

Over/Under Load & Phase Loss Protection

3-PHASE, 240V, <1 HP

THE INFORMATION PRESENTED IN THIS GUIDE IS CORRECT TO THE BEST OF OUR KNOWLEDGE. HOWEVER, TIME MARK CORPORATION

DOES NOT WARRANT THE APPLICATIONS AS OUTLINED NOR MAKE ANY OFFERS THAT THE CIRCUITS ARE FREE FROM PATENT

INFRINGEMENT. TIME MARK CORPORATION RESERVES THE RIGHT TO CHANGE OR ALTER SPECIFICATIONS AT ANY TIME.

Shows No Power Applied

Shows No Power Applied

Page 8 of 8 11/2011

© 2011 TIME MARK CORPORATION

Loading...

Loading...